Device for rapidly detecting ferromagnetic grain in lubricating oil, detection method and signal processing circuit

A detection device and detection method technology, applied in the direction of measuring device, particle suspension analysis, suspension and porous material analysis, etc., to achieve the effect of low components, simple processing flow and high linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

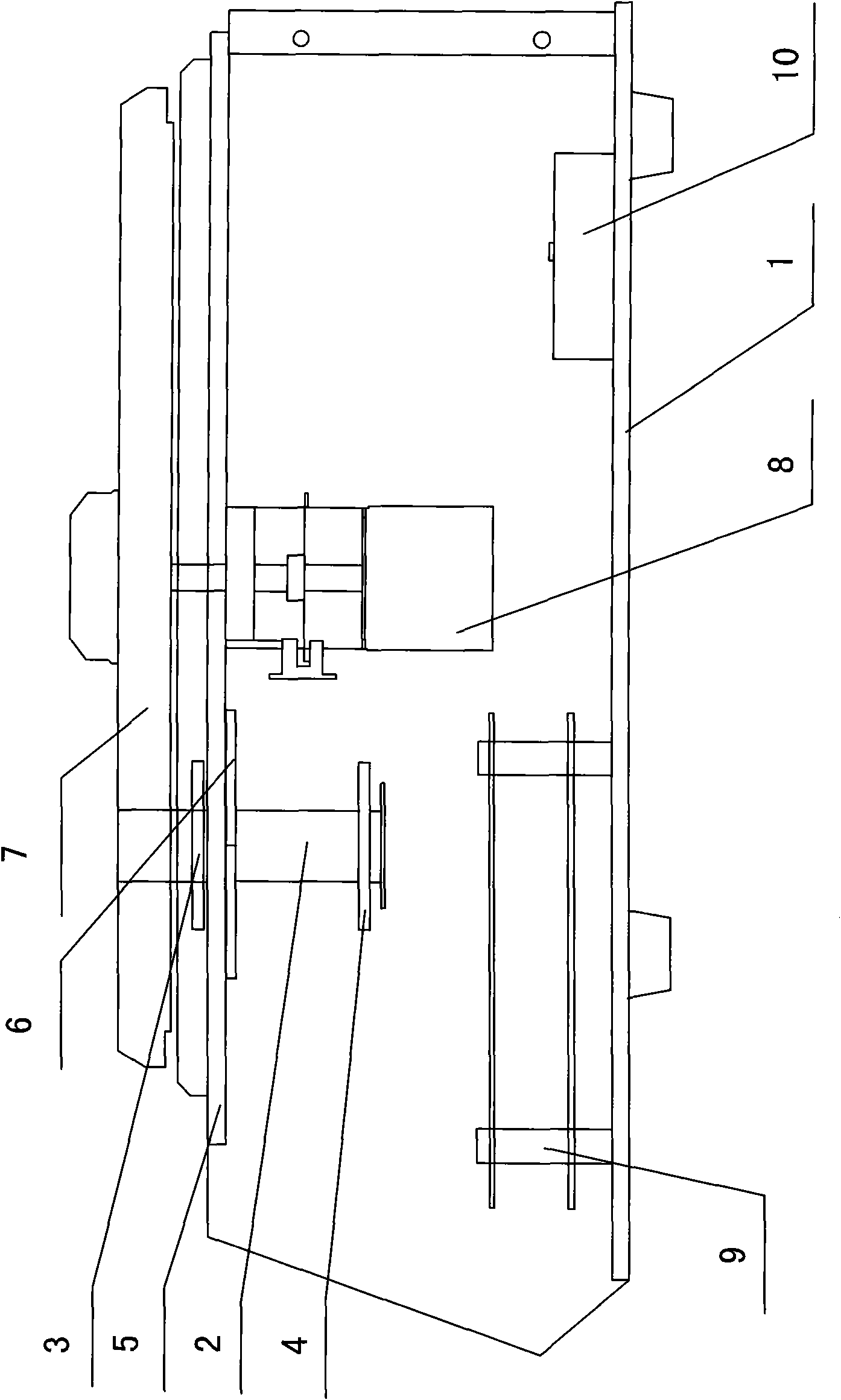

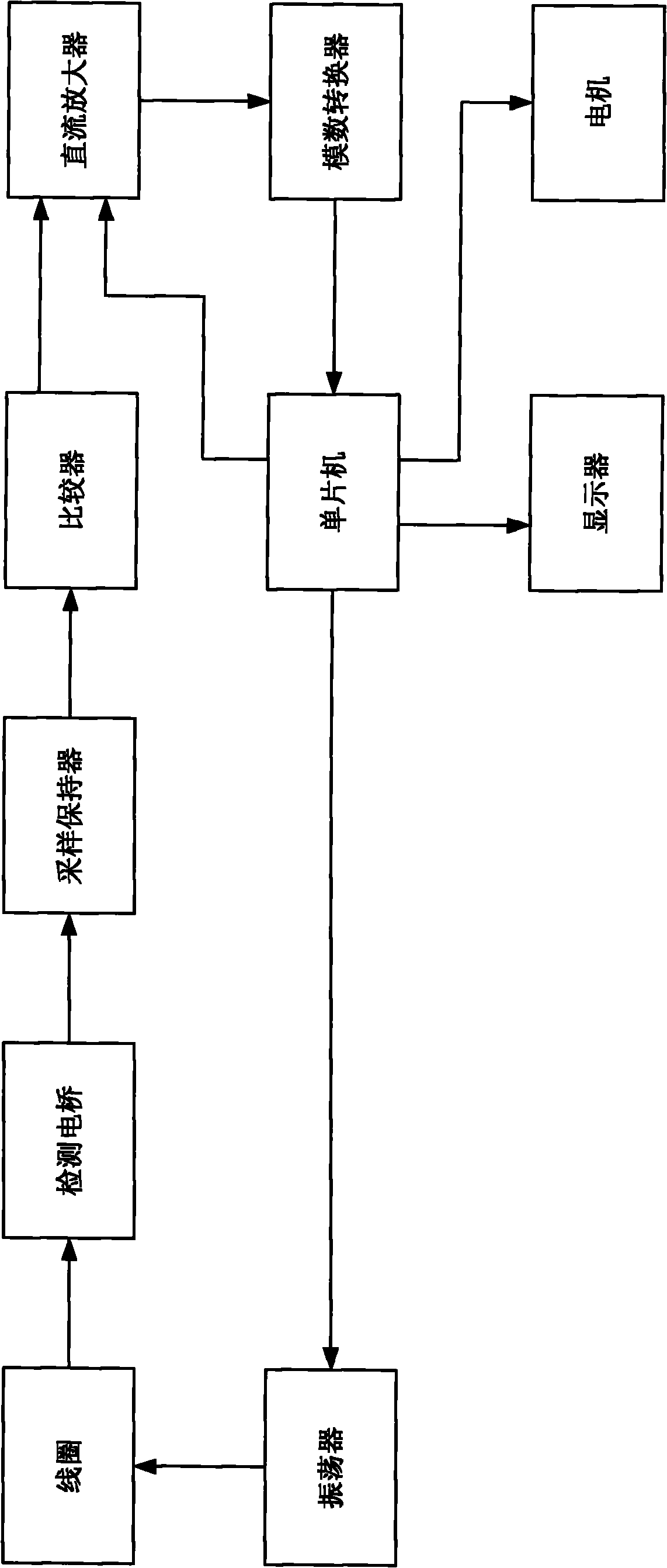

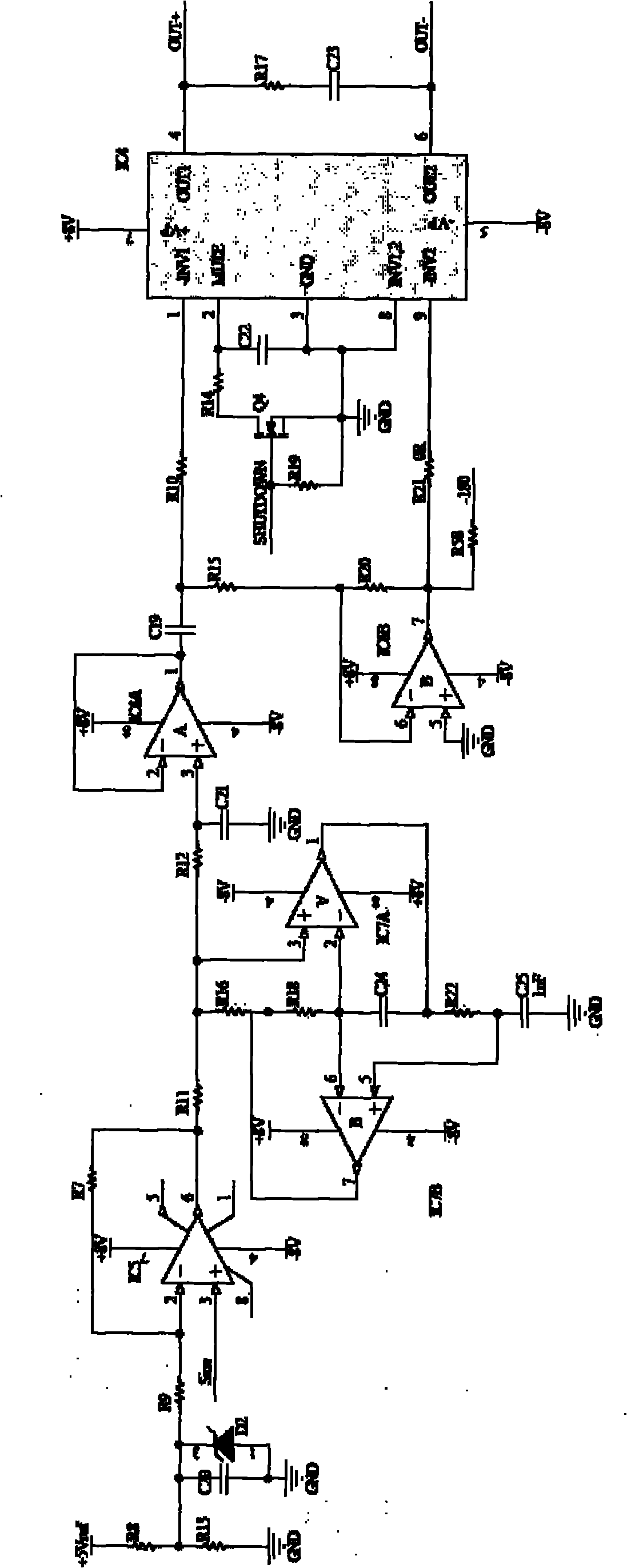

[0033] Please see attached figure 1 , main part of the present invention is an excitation coil 2, produces an alternating magnetic field by the excitation coil 2, and in the present embodiment, a magnetic core is in the middle of the excitation coil 2, and the magnetic core adopts a columnar iron core (the core material can be selected from plugged steel and other materials) coils are wound on the magnetic core to form the exciting coil 2. When the alternating current is passed into the exciting coil, the exciting coil 2 will generate an alternating magnetic field. As an alternating current, the exciting coil 2 generates an alternating magnetic field with a frequency of 1KHz-5KHz. At the equidistant place at both ends of the excitation coil 2, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com