Patents

Literature

152results about How to "Solve easy adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

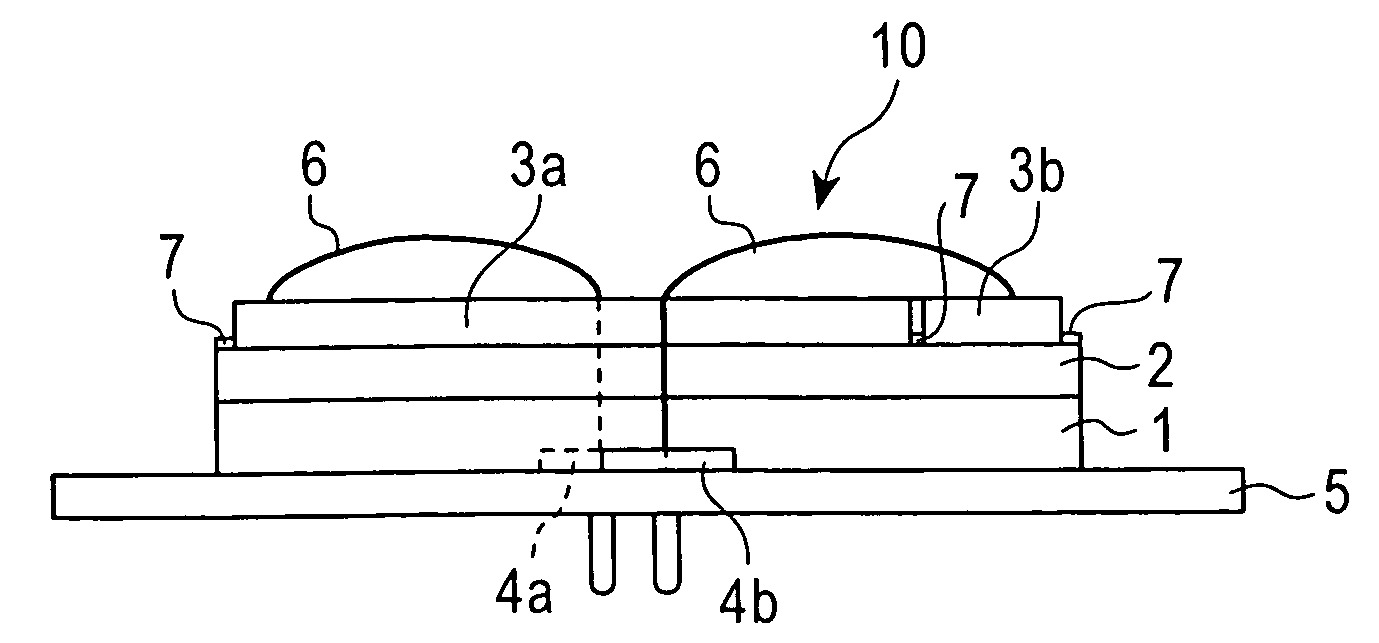

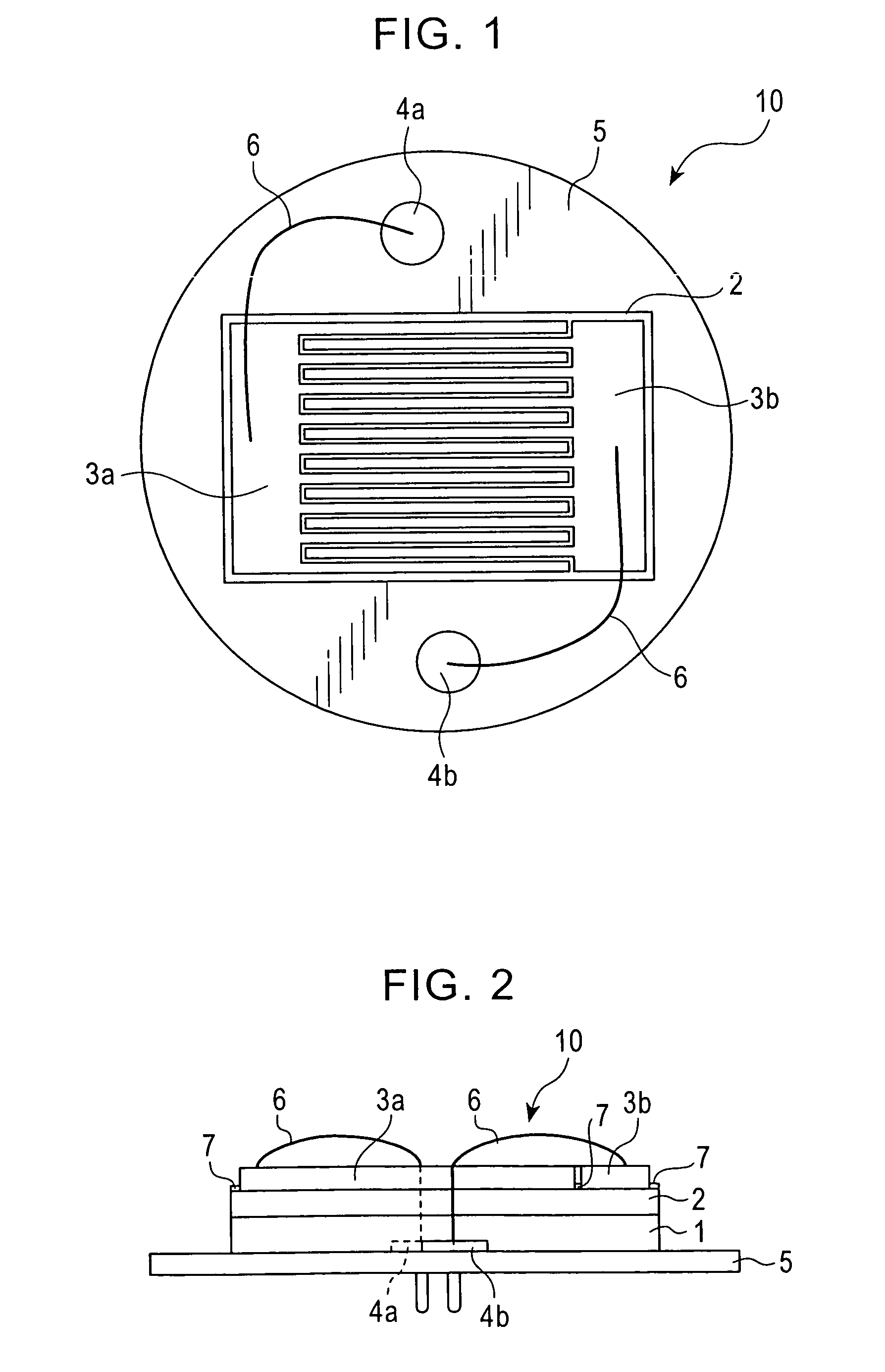

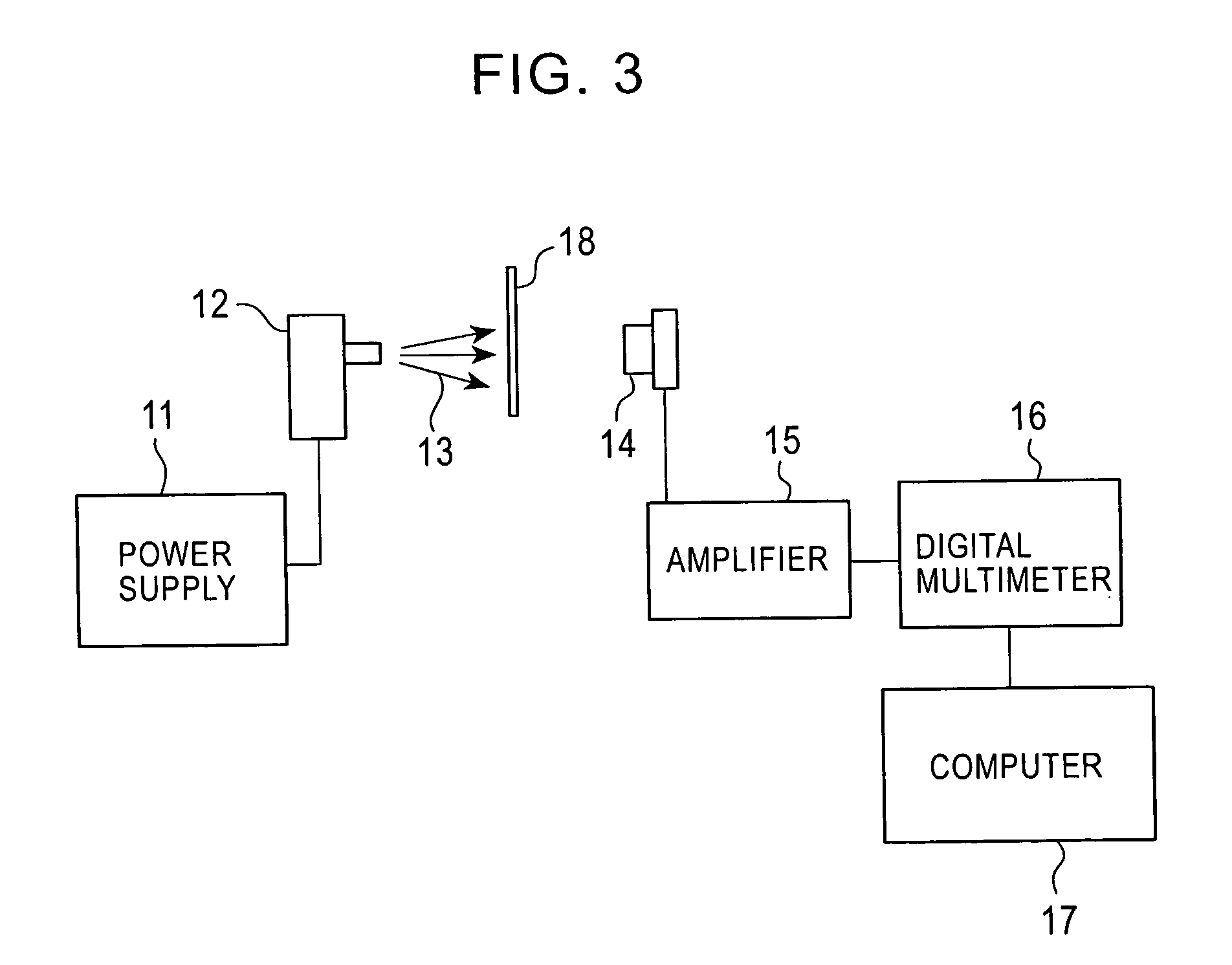

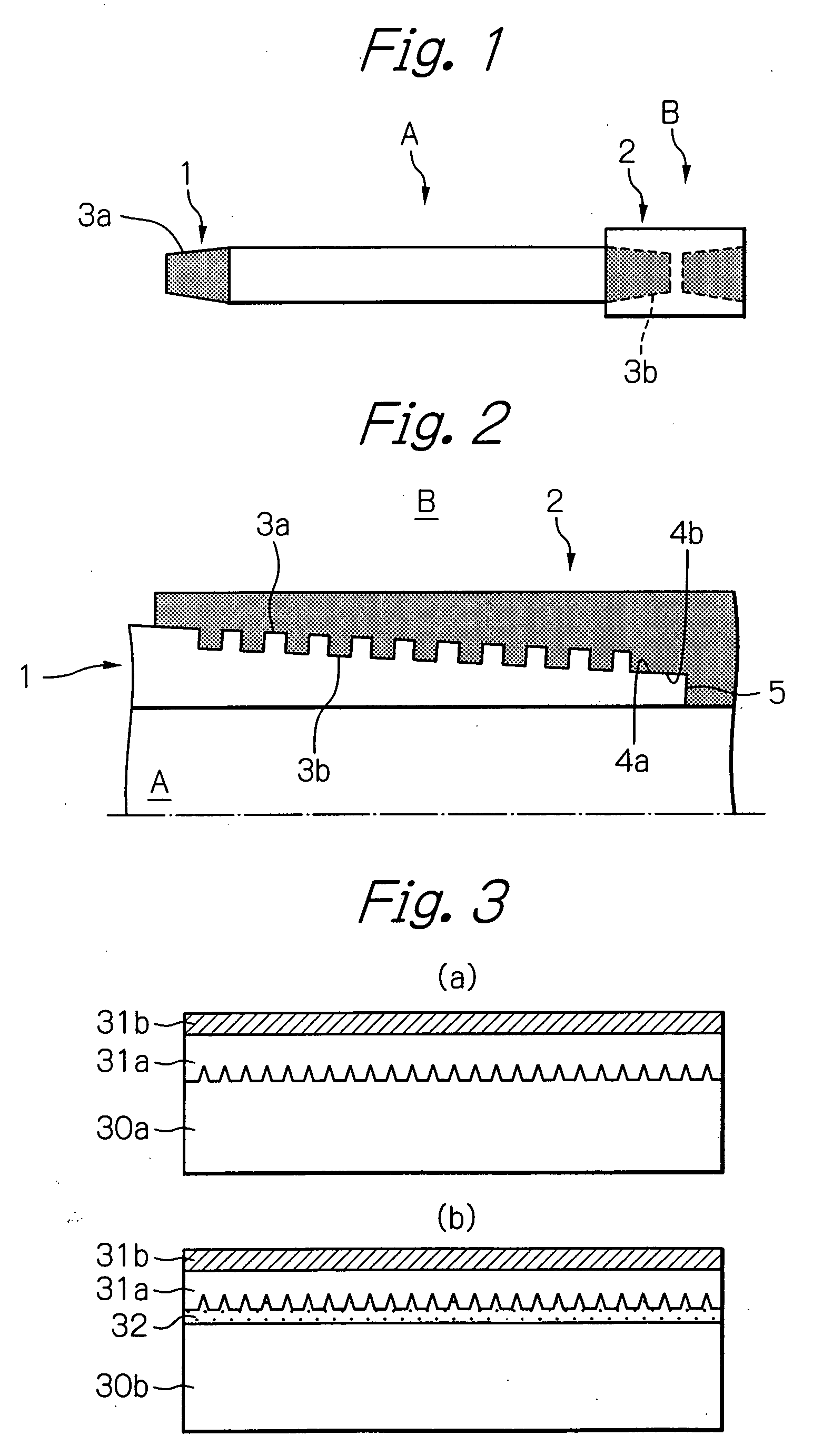

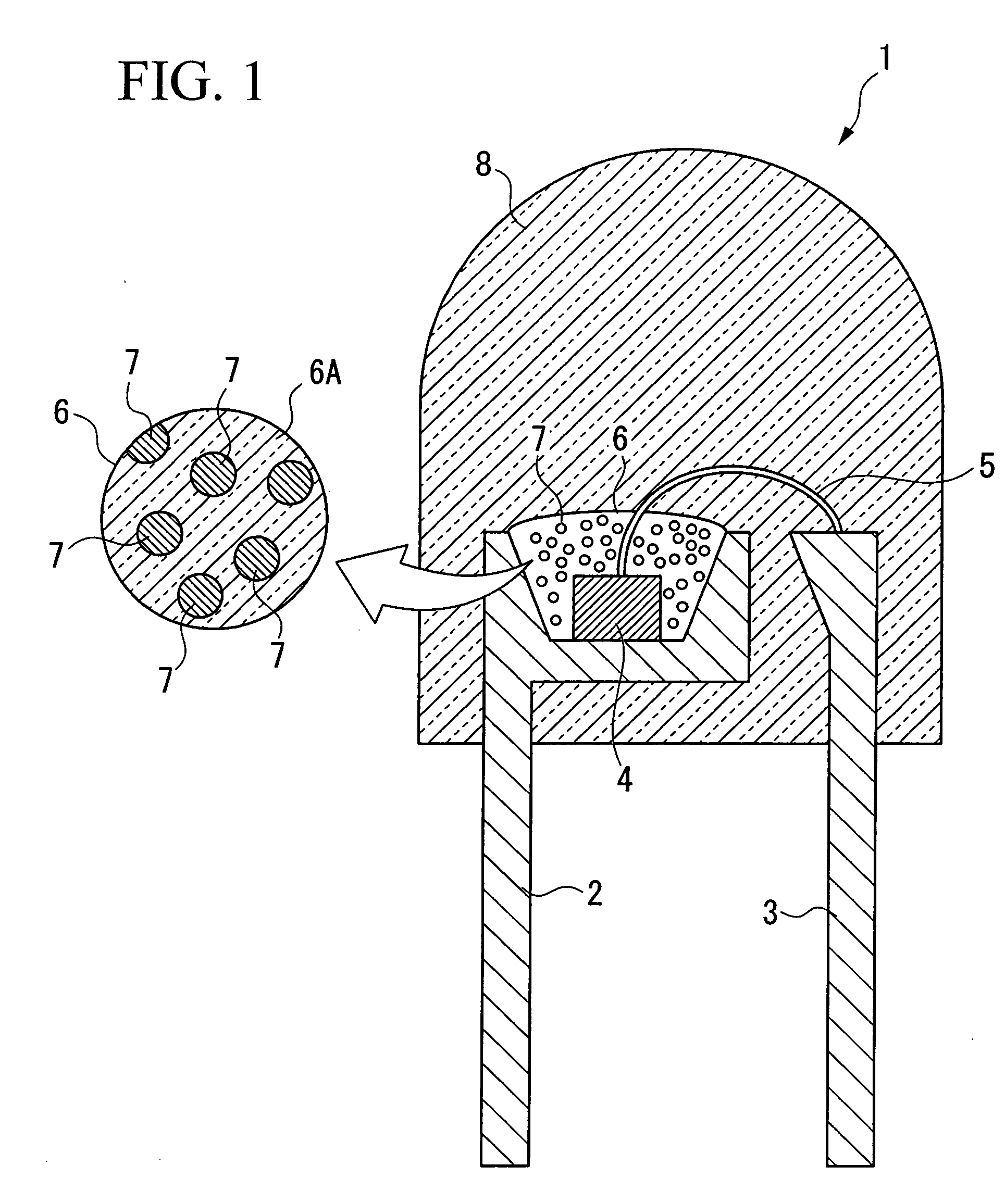

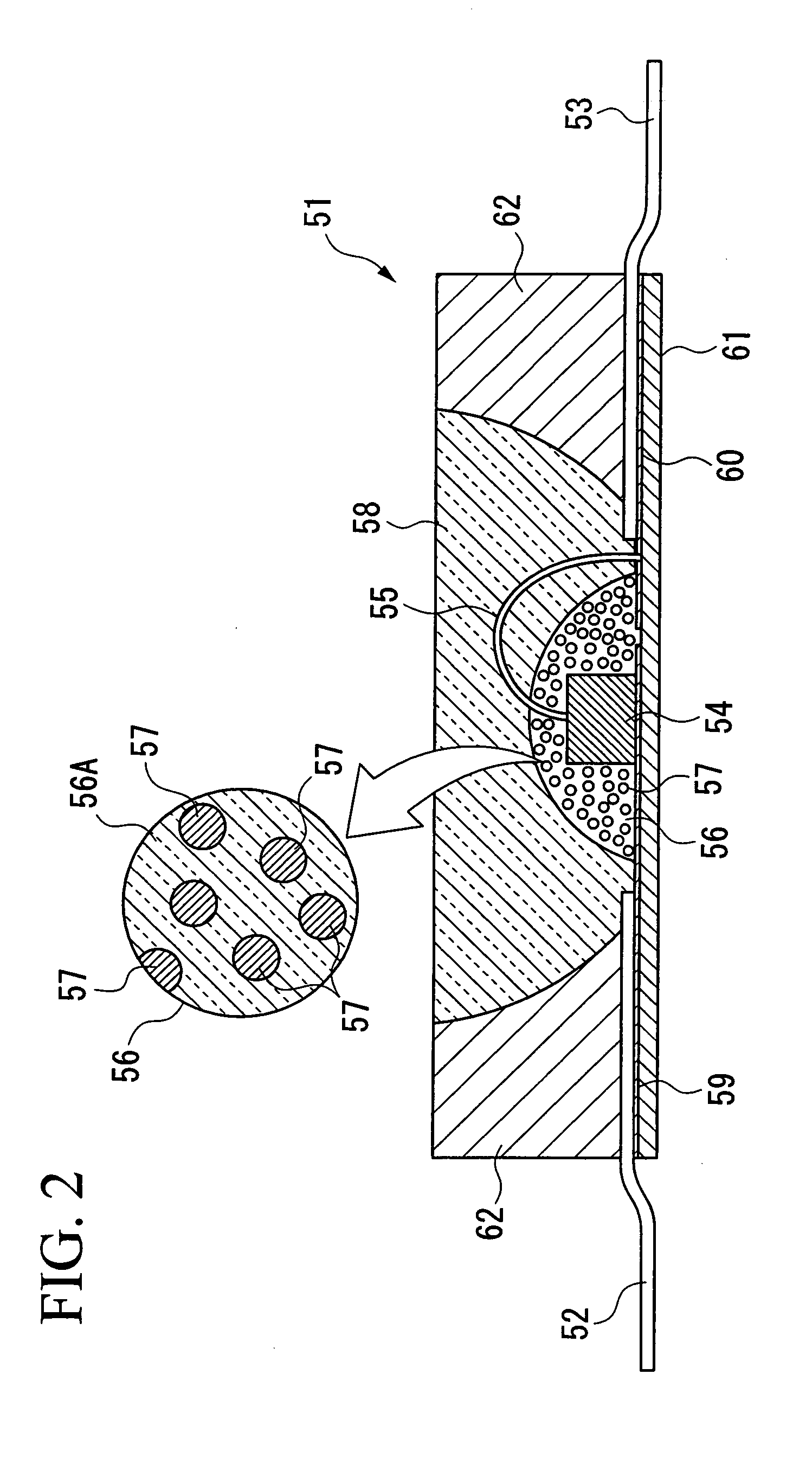

Ultraviolet sensor and method for manufacturing the same

InactiveUS7193241B2Low costConstant responsivitySolid-state devicesPhotometry for measuring UV lightUltravioletFluoride

An ultraviolet sensor includes a substrate; a diamond layer, placed on the substrate, functioning as a detector; and at least one pair of surface electrodes arranged on the diamond layer. The diamond layer has a detecting region present at the surface thereof, the detecting region has at least one sub-region exposed from the surface electrodes, and the sub-region has a covering layer, made of oxide or fluoride, lying thereon. A method for manufacturing the ultraviolet sensor includes a step of forming a diamond layer, functioning as a detector, on a substrate; a step of forming at least one pair of surface electrodes on the diamond layer; and a step of forming a covering layer, made of oxide or fluoride, on at least one sub-region of a detecting region present at the surface of the diamond layer, the sub-region being exposed from the surface electrodes.

Owner:KOBE STEEL LTD

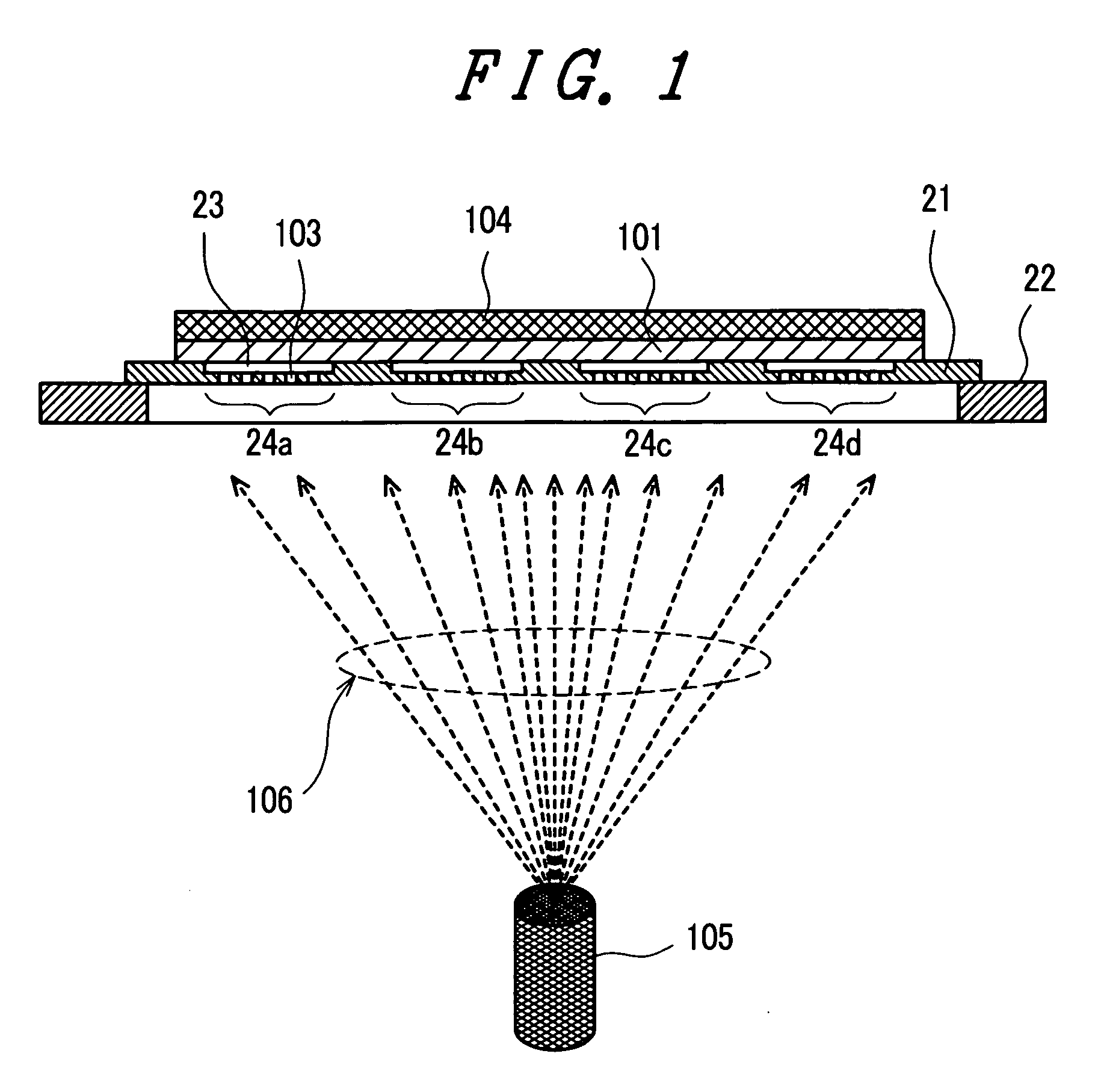

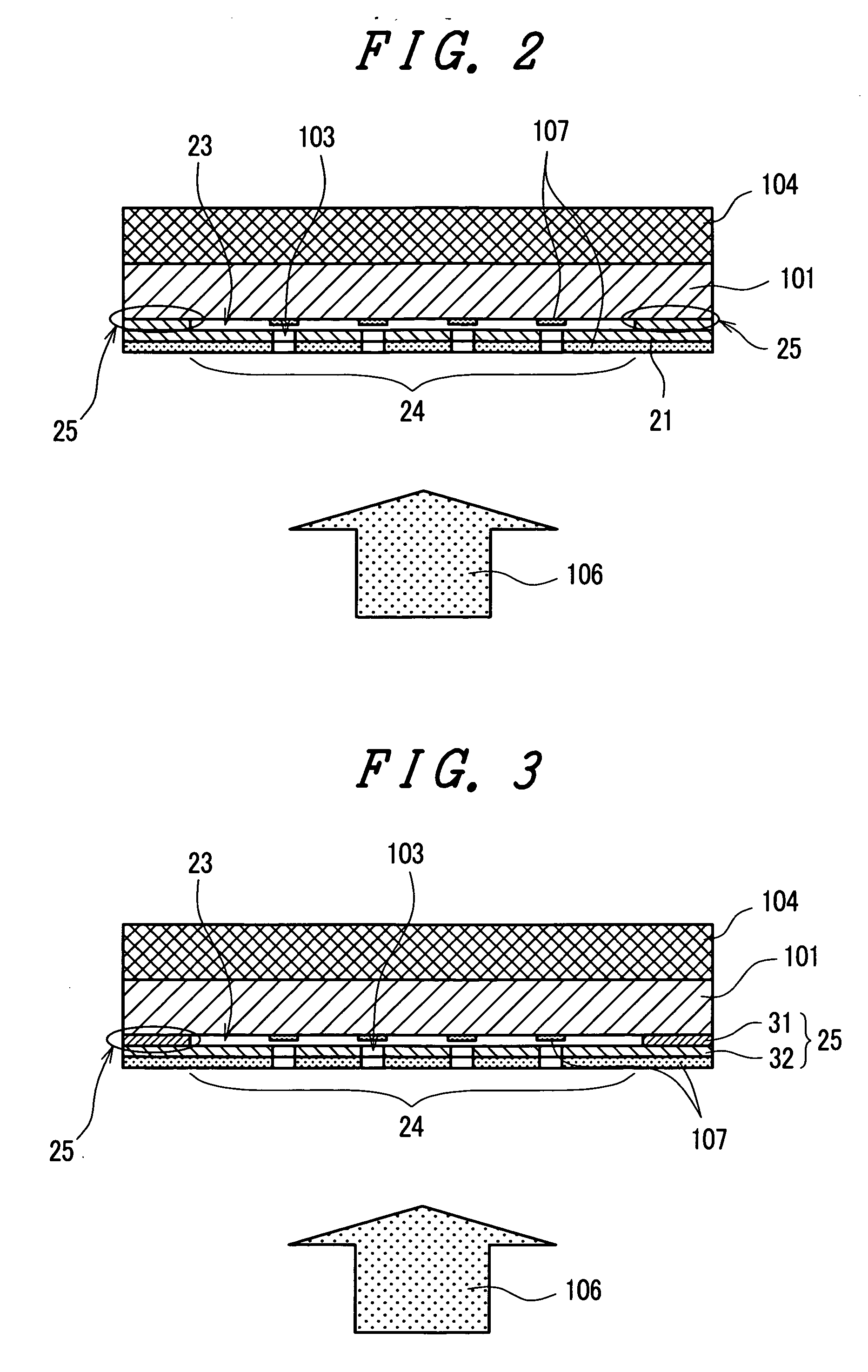

Method of manufacturing the organic electroluminescent display and organic electroluminescent display manufactured by the method

ActiveUS20070072337A1Suppress deterioration of propertyNot to damageSolid-state devicesVacuum evaporation coatingOrganic filmEngineering

The present invention provides an organic EL display panel manufacturing method which is capable of forming a desired organic film or the like with high accuracy without imparting damages to a substrate and an organic film and an organic EL display panel which is manufactured by the method. An opening portion which corresponds to a panel pattern region of a display panel is formed in a vapor deposition mask. The opening portion has a bottom surface in the inside of a recessed surface which is retracted from a surface on which the vapor deposition mask is brought into contact with the substrate. The opening portion of the vapor deposition mask is spaced apart from the substrate with a predetermined gap space and evaporated particles from an evaporating source are vapor-deposited to the substrate through the opening portion.

Owner:SAMSUNG DISPLAY CO LTD +1

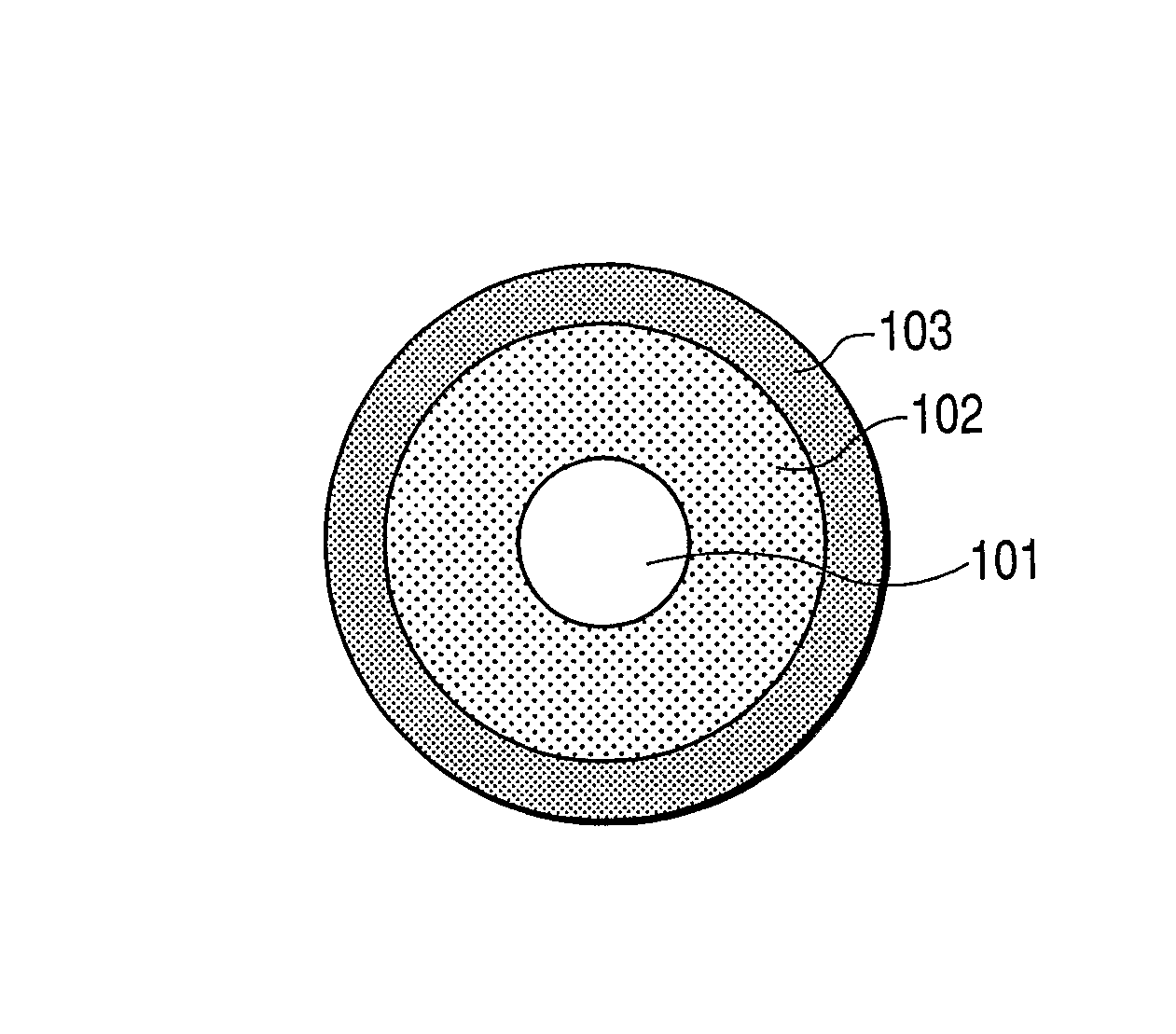

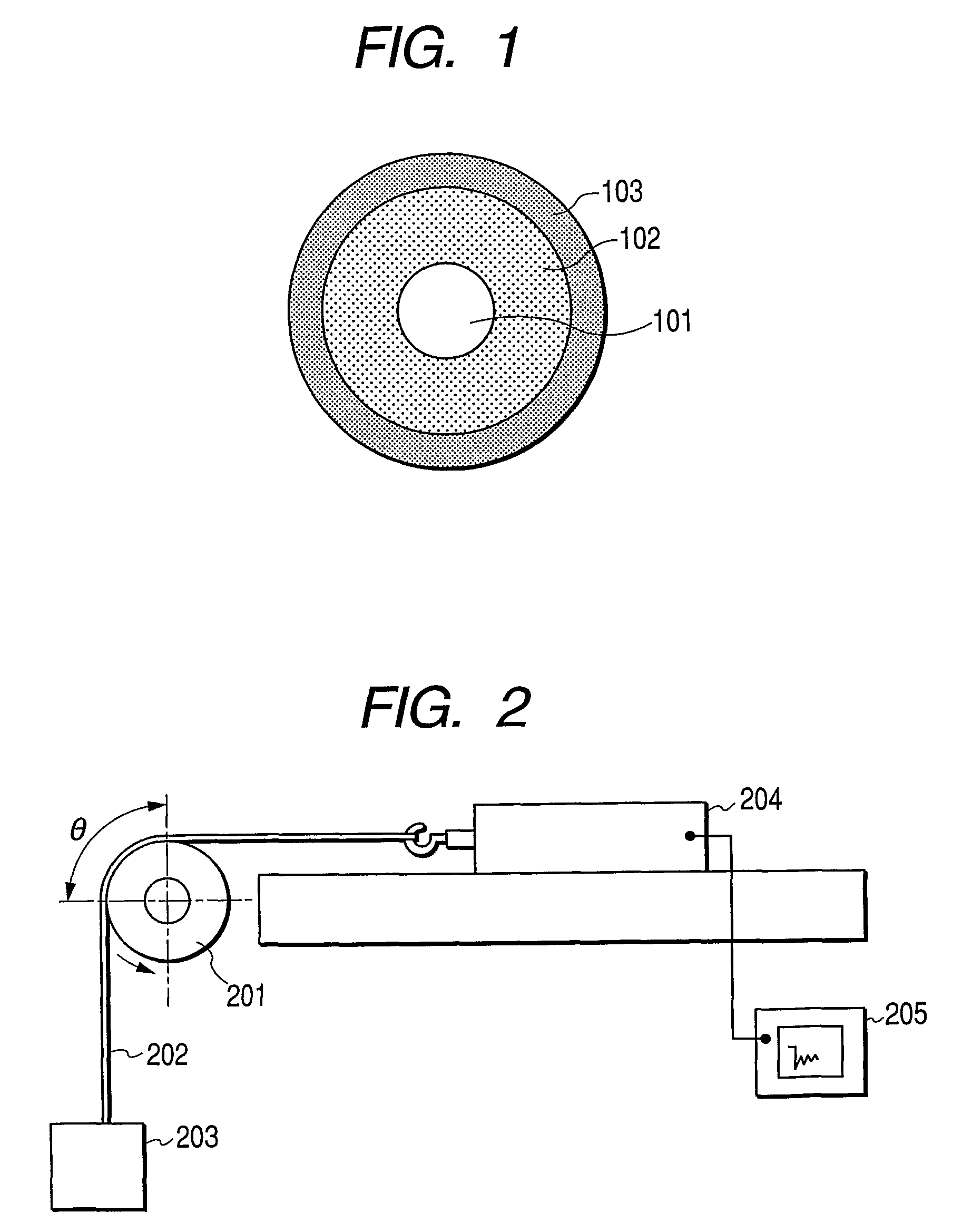

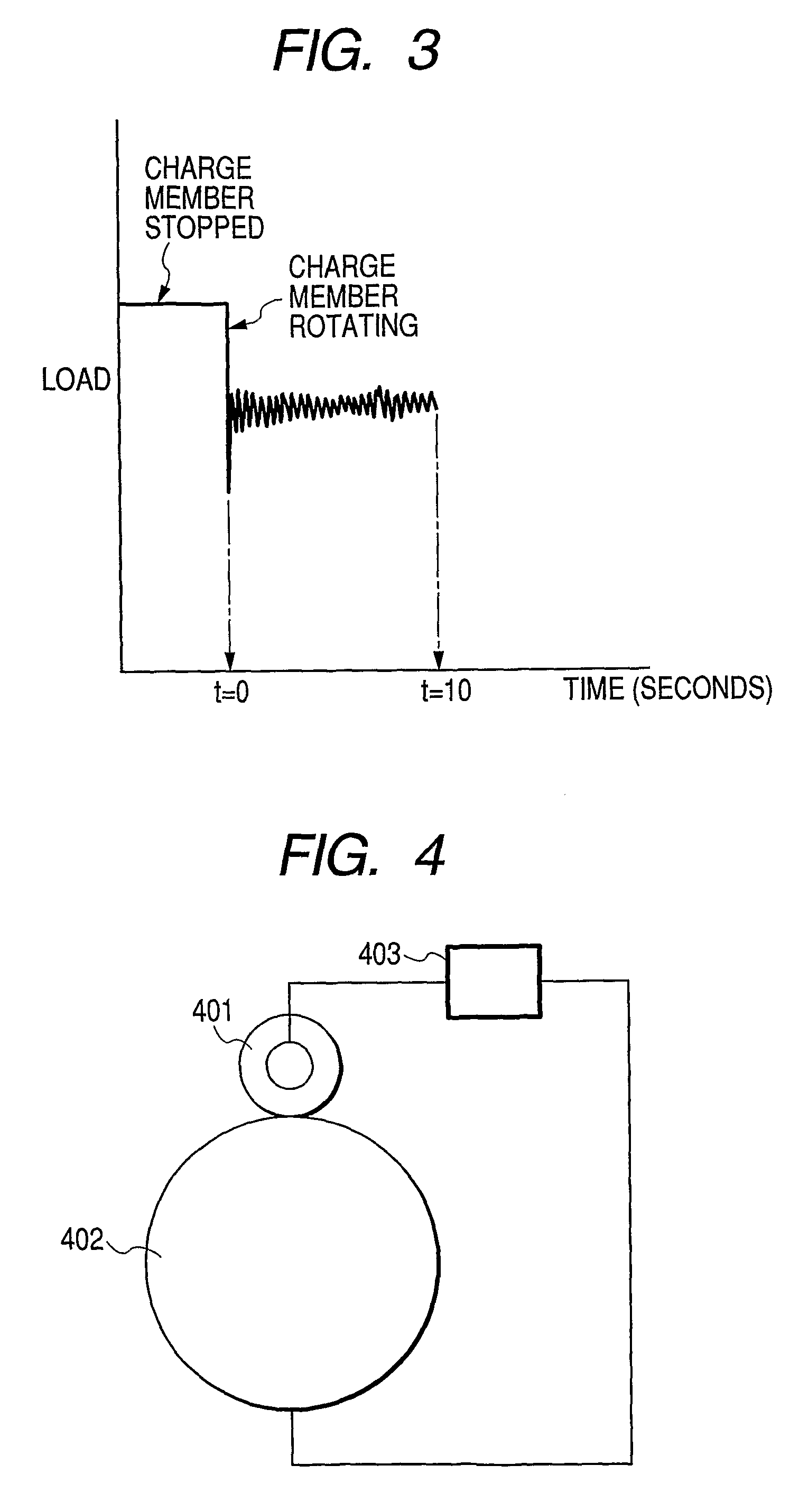

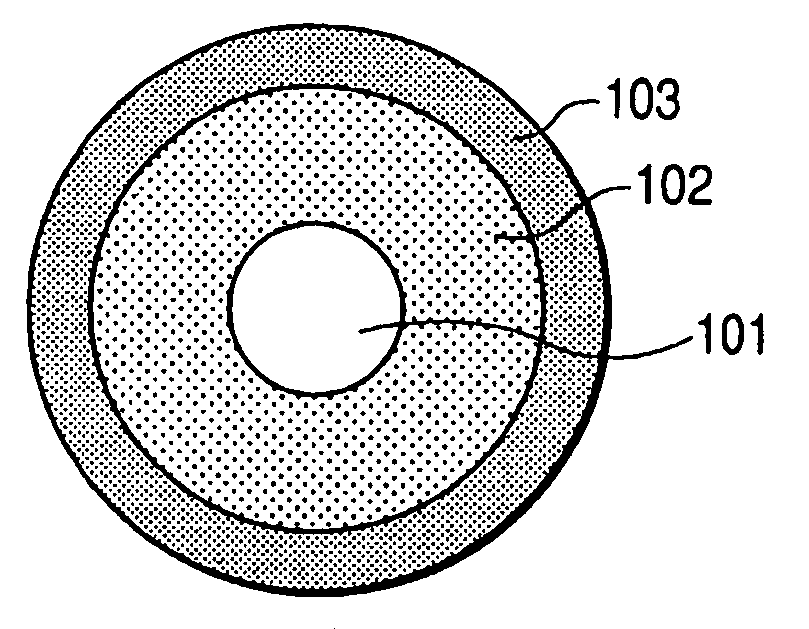

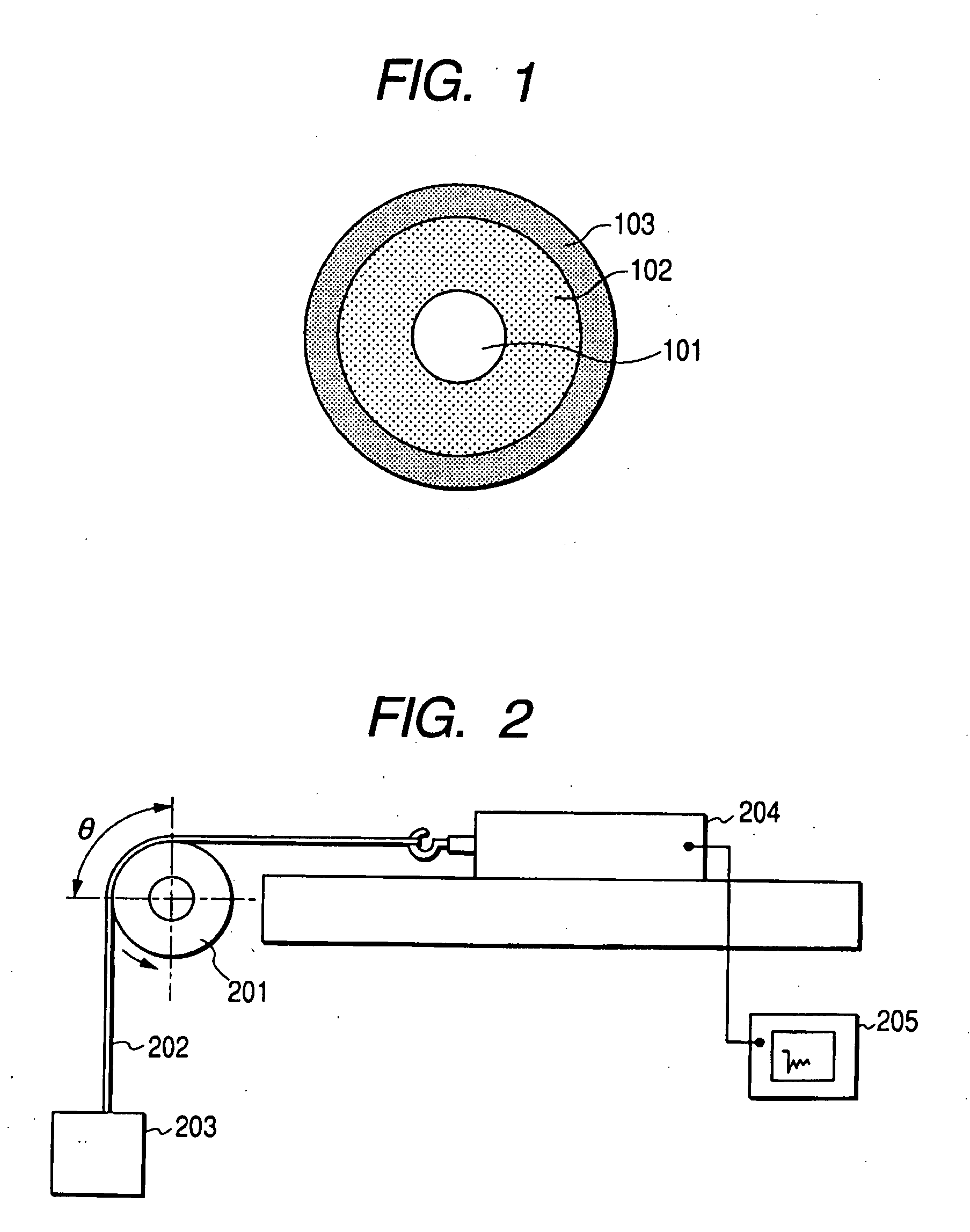

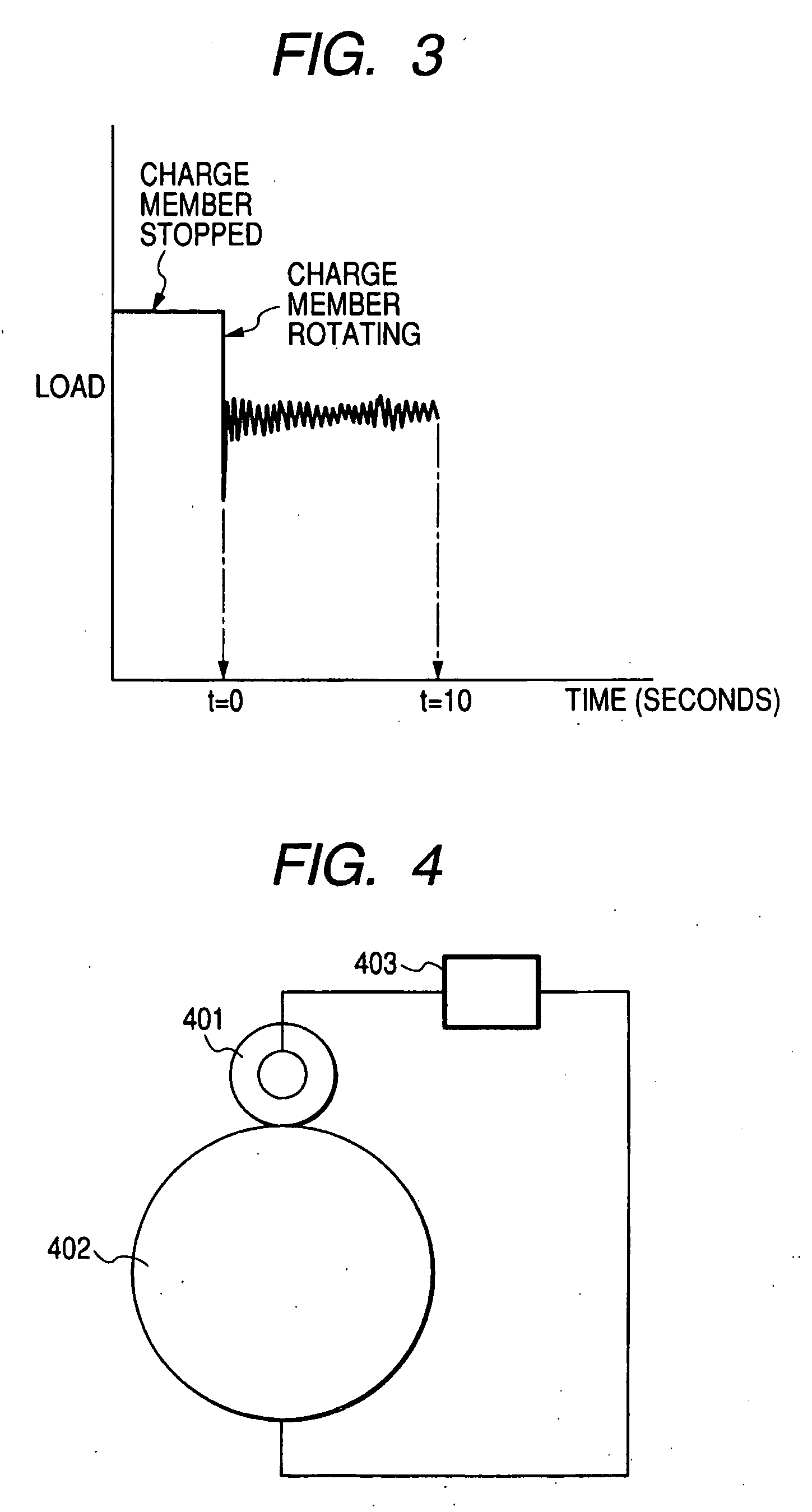

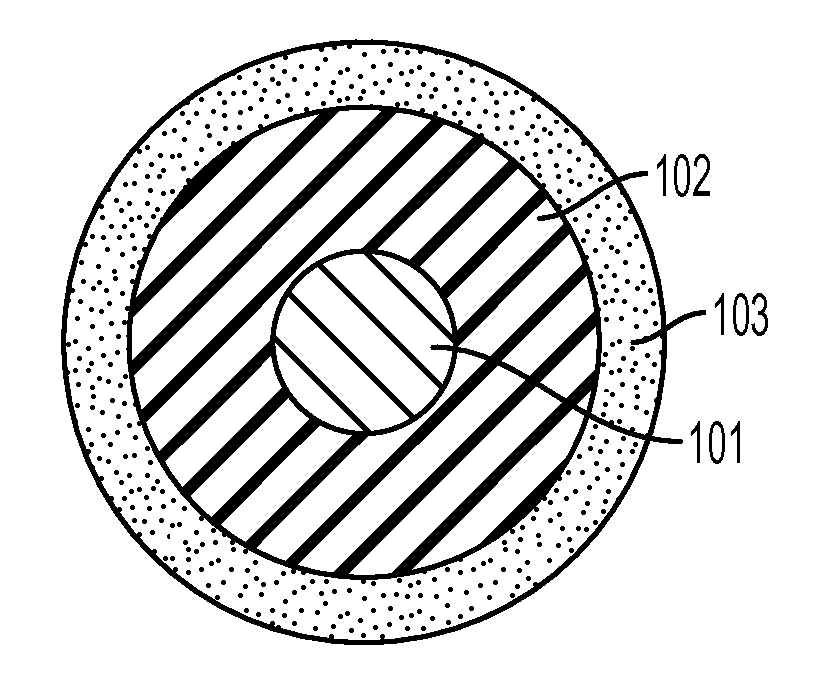

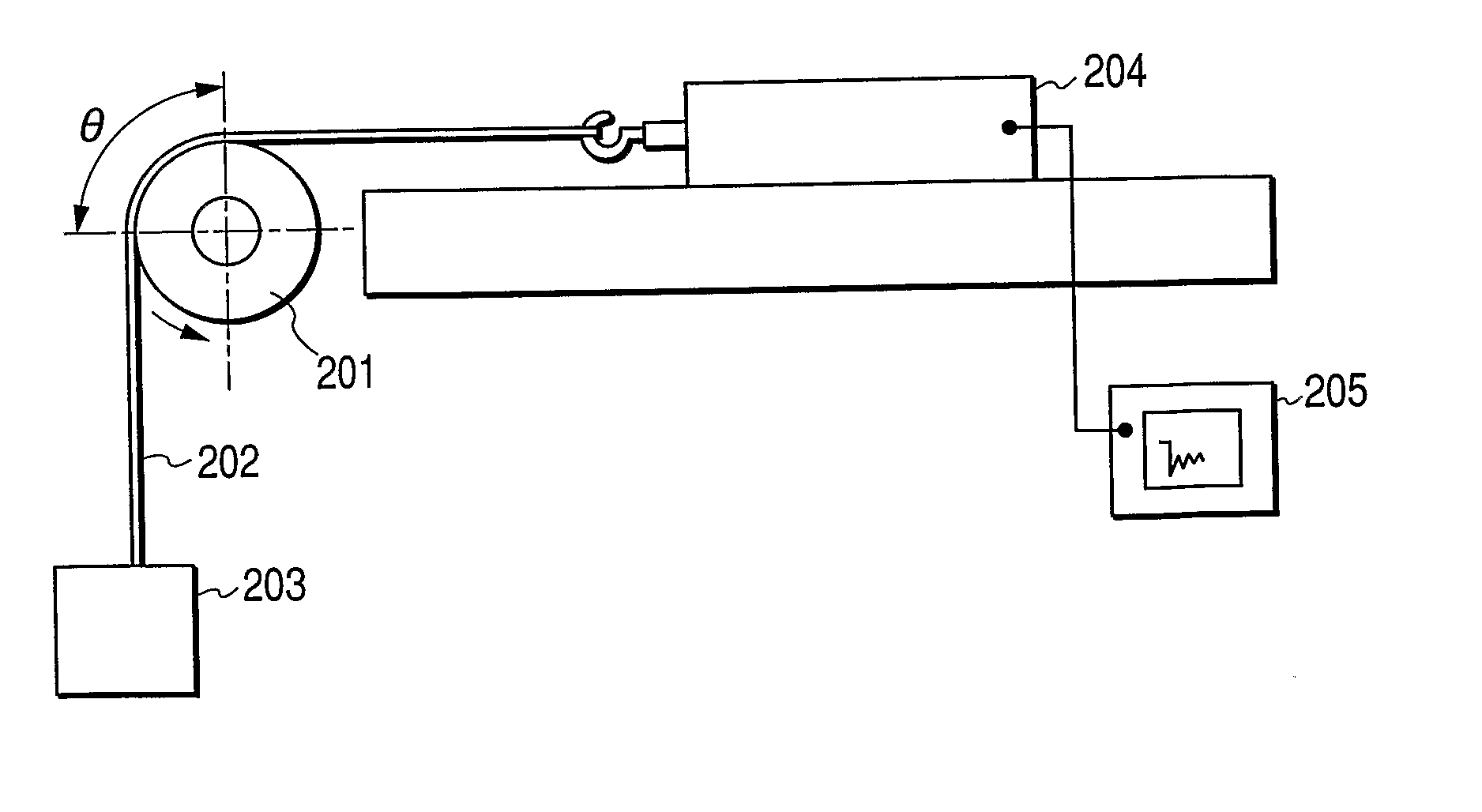

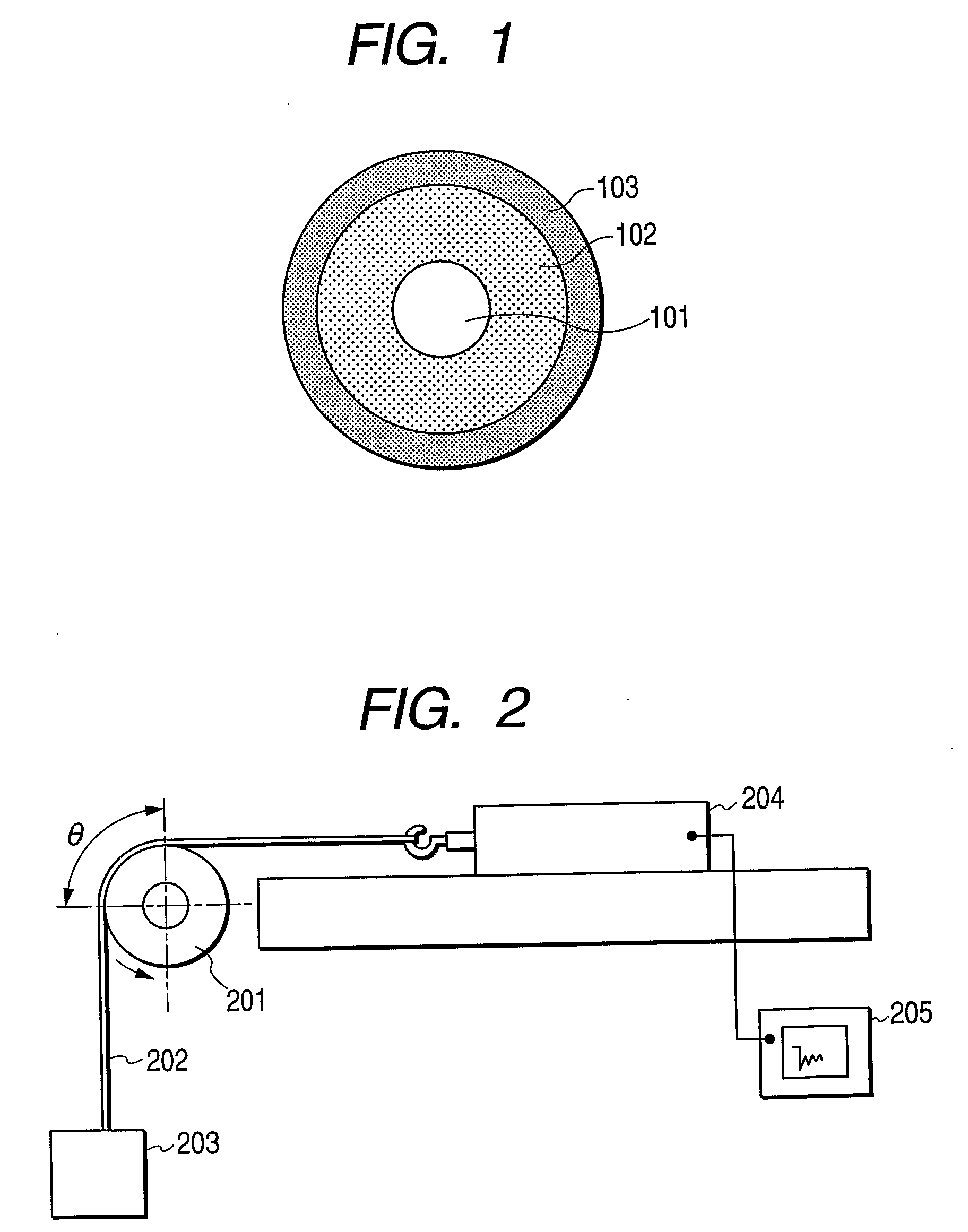

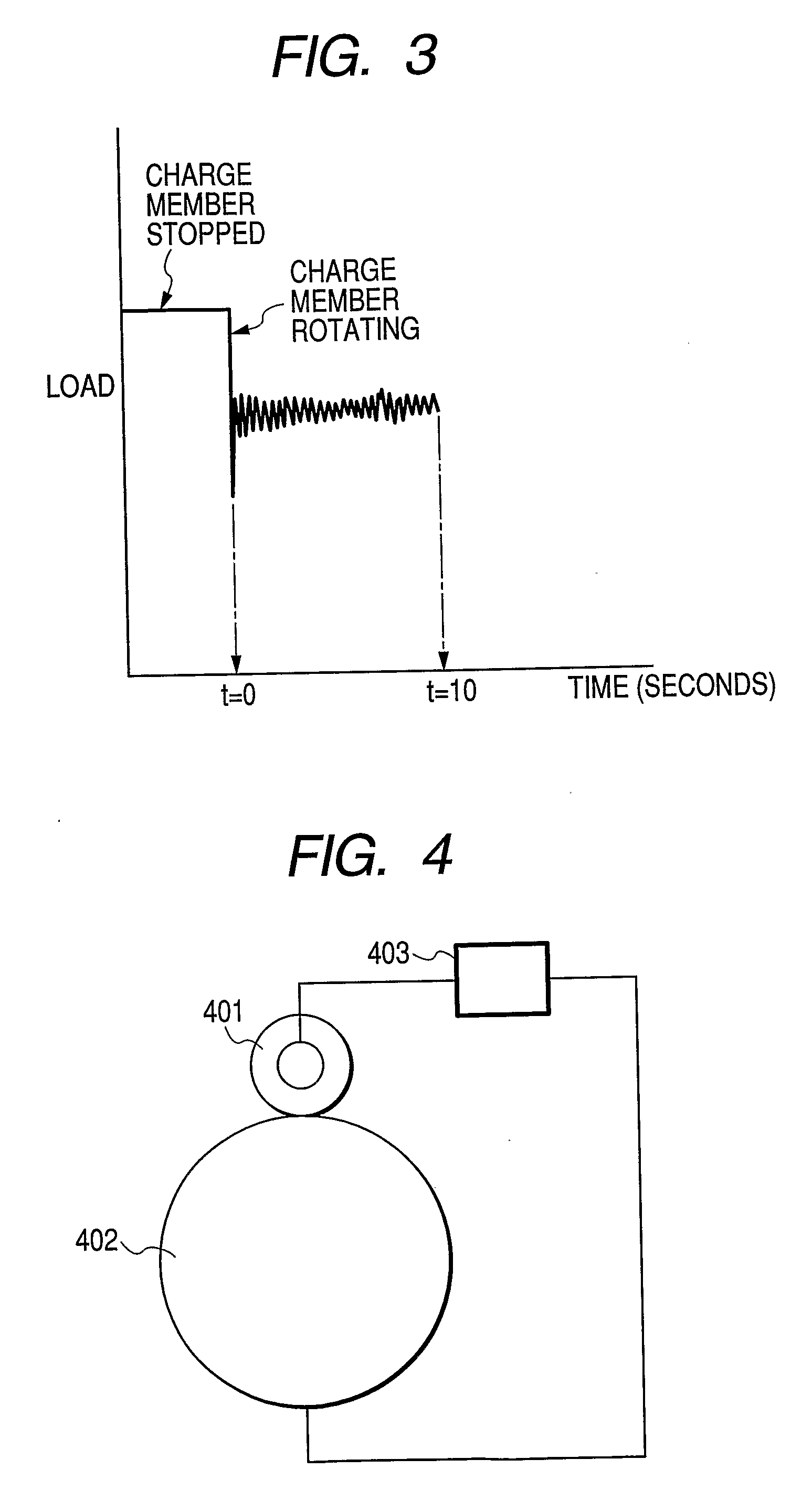

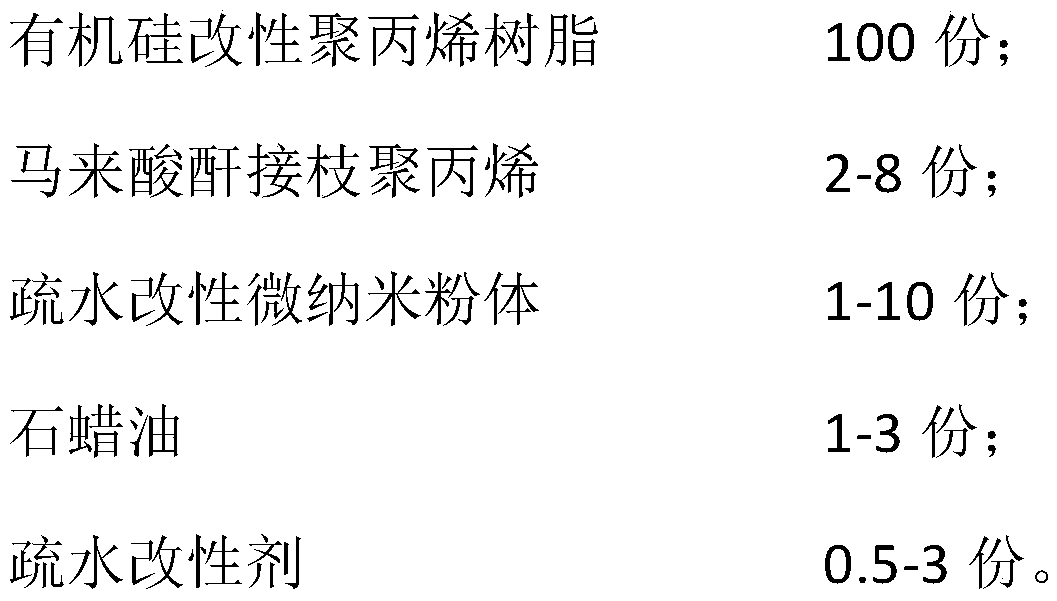

Charging member, process cartridge and electrophotographic apparatus

ActiveUS7962068B2Charging and image output are made stable for a longSolve easy adhesionShaft and bearingsPortable power-driven toolsSurface layerEngineering

An object of the present invention is to provide a charging member in which a toner, an additive for use in the toner, or the like is hard to adhere to the surface even under repeated use for a long time, and hence the charging and image output are made stable for a long time even if the charging member is used in the DC contact charging method, and a process cartridge and an electrophotographic apparatus having the charging member. The present invention provides a charging member comprising a support, a conductive elastic layer formed on the support, and a surface layer formed on the conductive elastic layer, characterized in that the surface layer contains a polysiloxane having a fluoroalkyl group and an oxyalkylene group, and a process cartridge and an electrophotographic apparatus having the charging member.

Owner:CANON KK

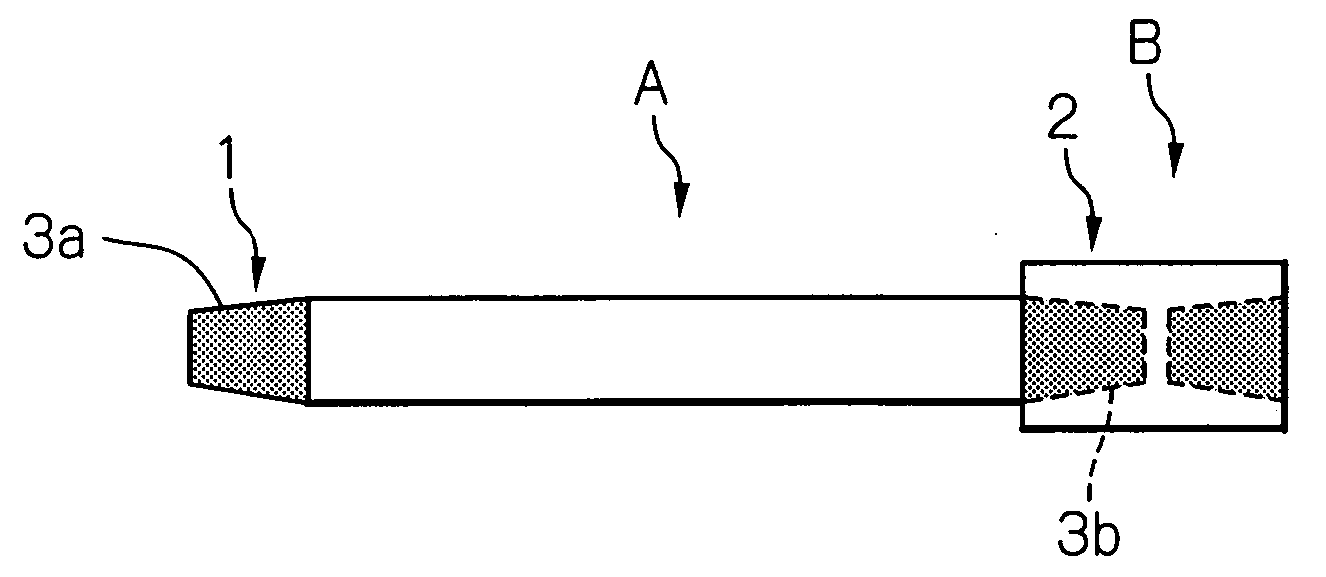

Threaded joint for steel pipes

InactiveUS20060228505A1Improve the lubrication effectLubricating property worsenEarth drilling toolsDrilling rodsViscous liquidAlkaline earth metal

A threaded joint for steel pipes for use in an oil well which has improved galling resistance and which is protected from rusting comprises a pin and a box each having a contact surface including a threaded portion and an unthreaded metal contact portion. The contact surface of at least one of the pin and the box has a lower layer of a viscous liquid or semisolid lubricating coating comprising at least wax and a fatty acid alkaline earth metal salt and not containing a harmful heavy metal such as lead and an upper layer of a dry solid coating formed from an aqueous resin coating composition, an organic solvent type coating composition, or an ultraviolet curing coating composition.

Owner:NIPPON STEEL CORP +1

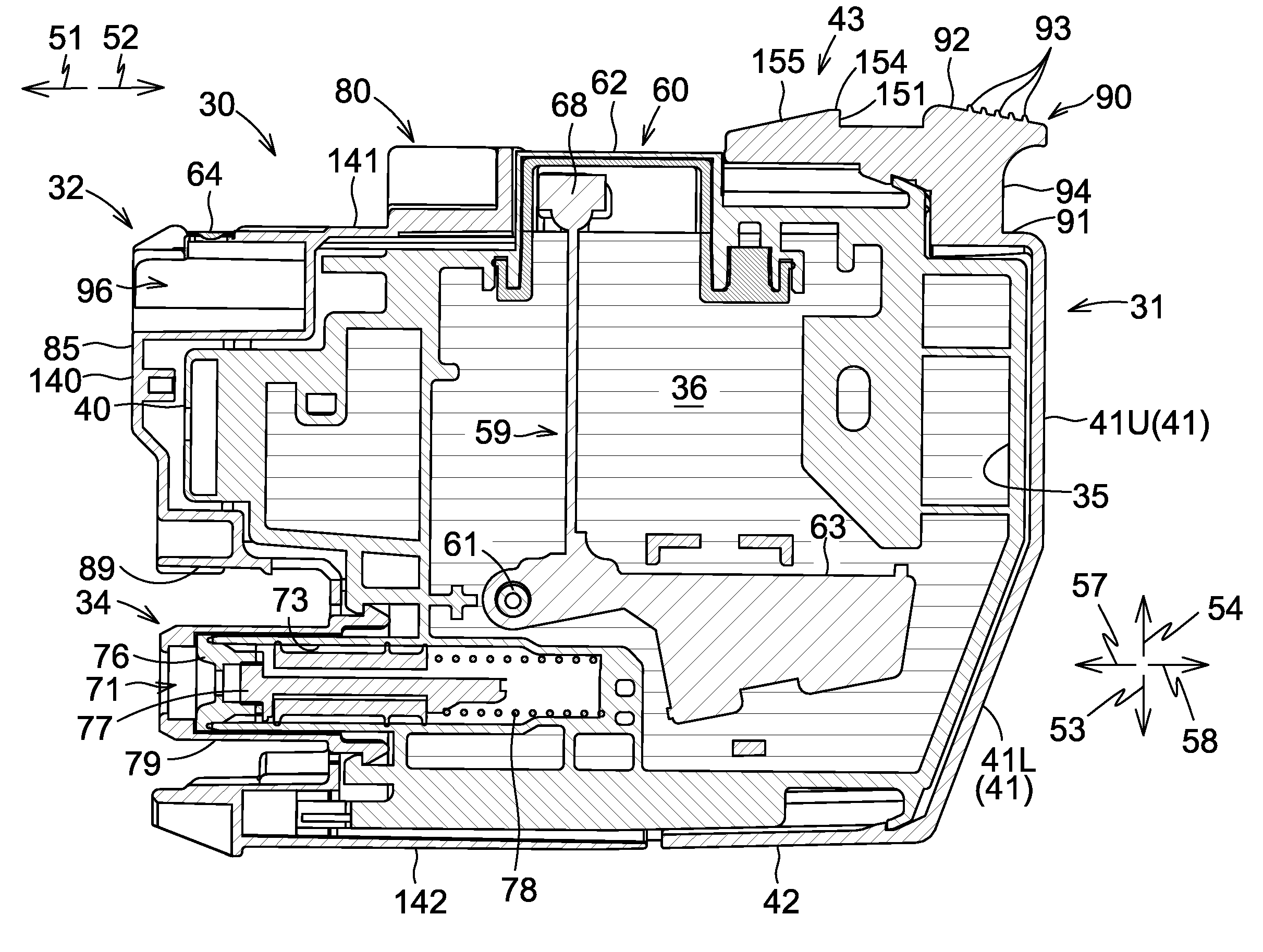

Liquid cartridge

A liquid cartridge includes a first surface and a second surface facing a particular direction, with a liquid outlet through the first surface. A circuit board is mounted on the second surface, and a liquid detection mechanism including a light access portion extends above the second surface further than the circuit board in the particular direction.

Owner:BROTHER KOGYO KK

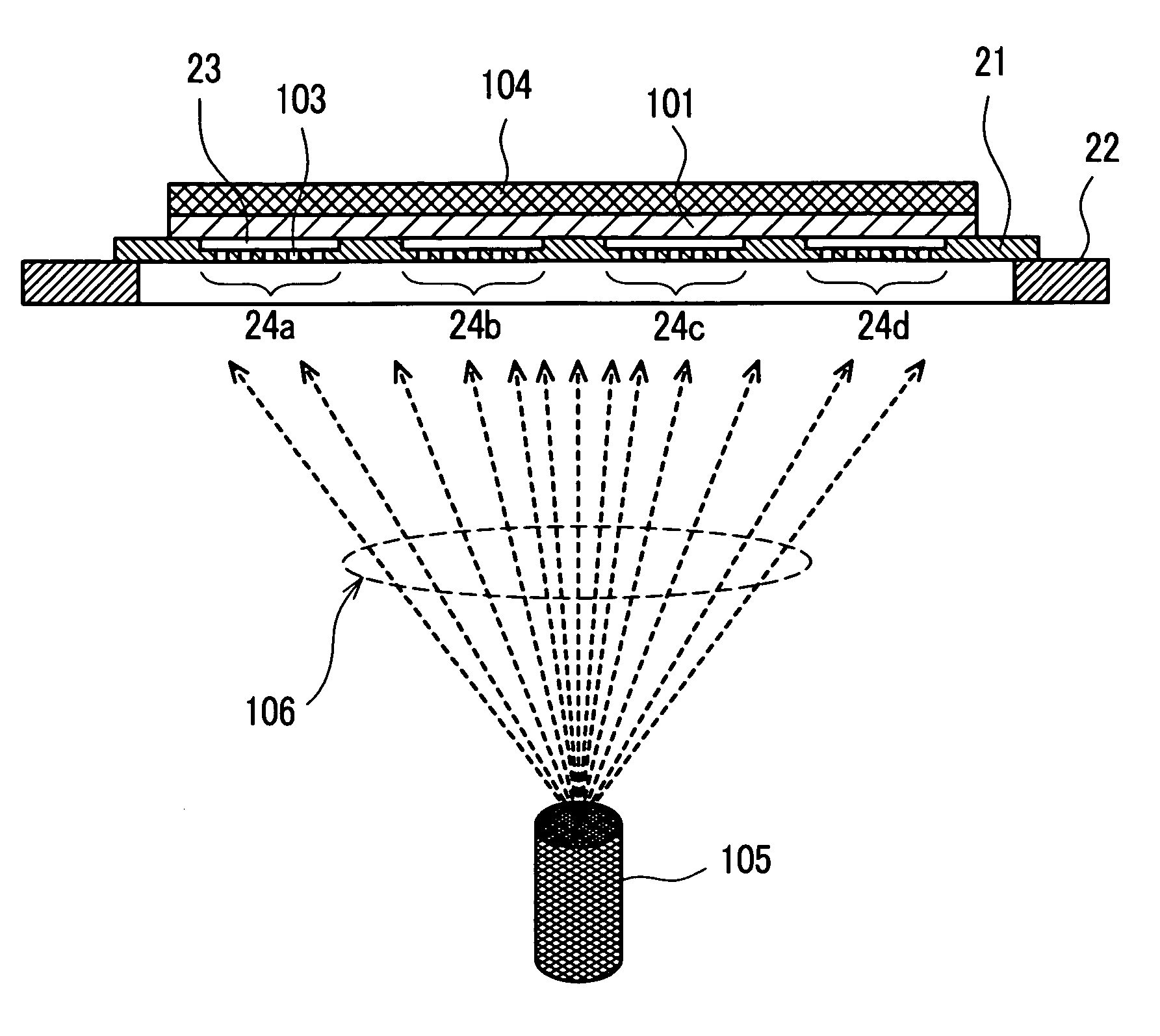

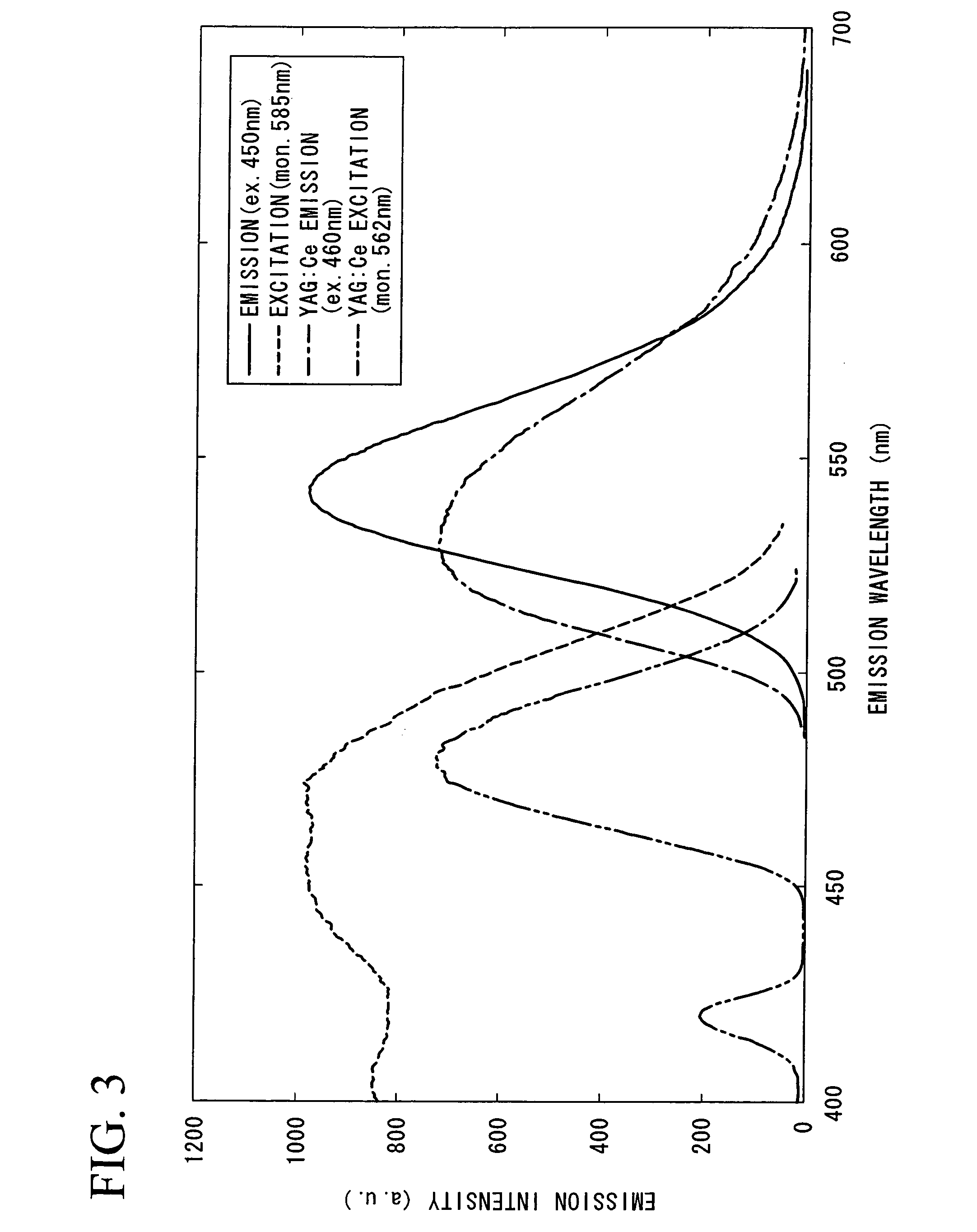

Powdered fluorescent material and method for manufacturing the same, light-emitting device, and illumination apparatus

InactiveUS20060208260A1High visible light transmittanceImprove luminous efficiencyOptical filtersSolid-state devicesLight emitting deviceMaterials science

Powdered fluorescent material excited by visible light that emits visible light has particles with particle sizes of 20 μm or less in the content of below 2% by mass. The method for manufacturing a powdered fluorescent material comprises the steps of: sintering raw material powder of the fluorescent material; and chemically processing the sintered powder after said sintering with acid solution.

Owner:THE FUJIKURA CABLE WORKS LTD +1

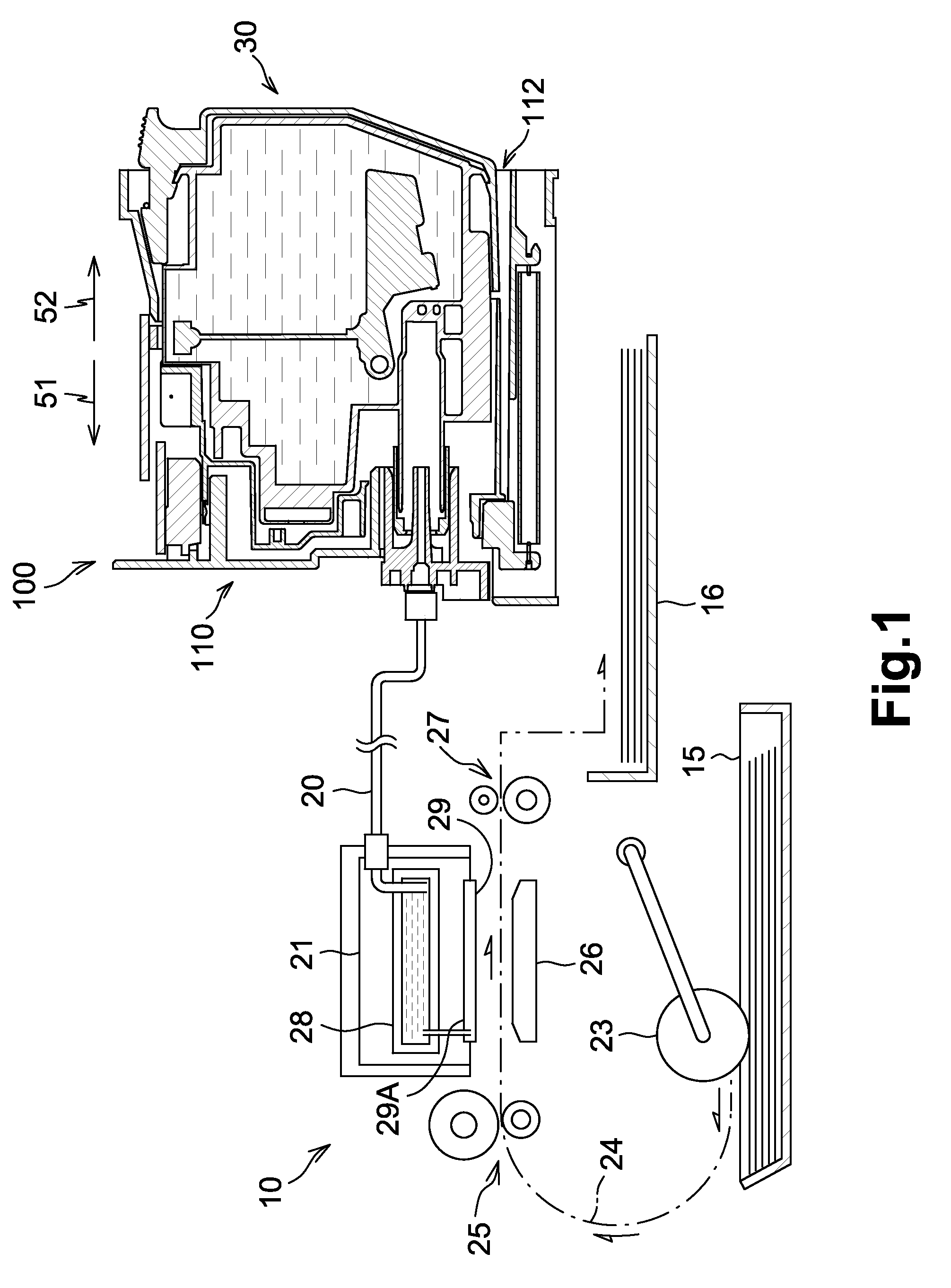

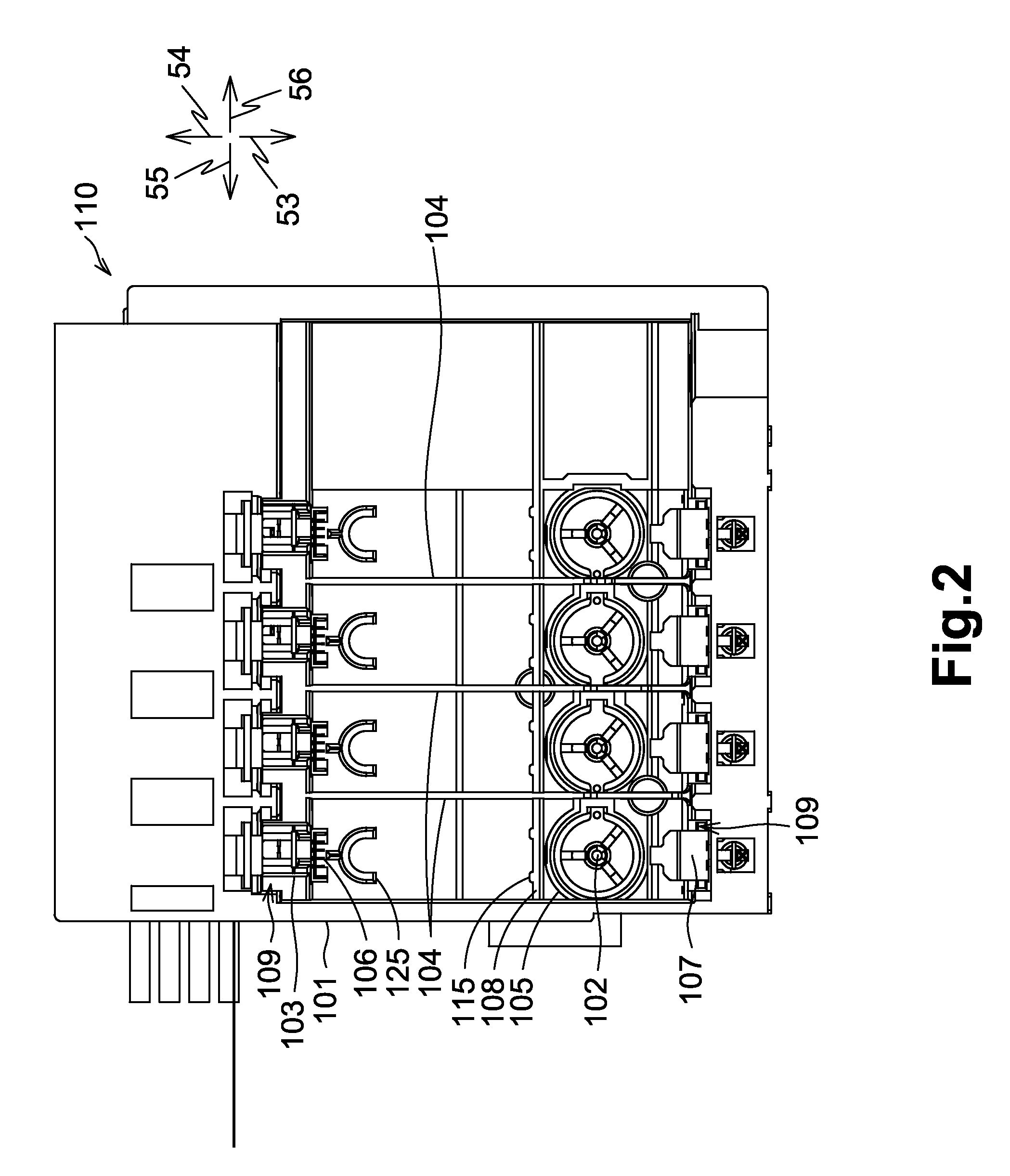

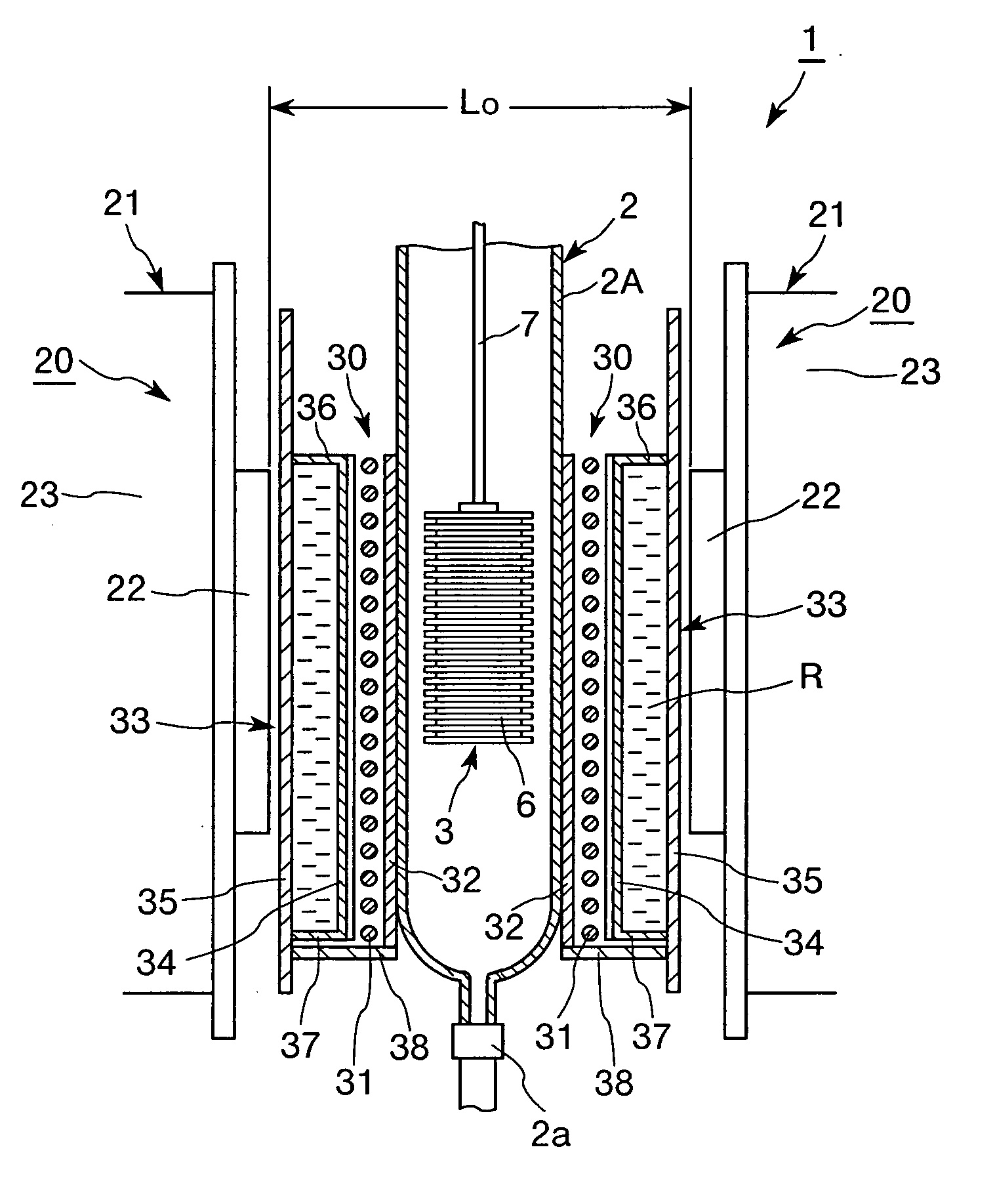

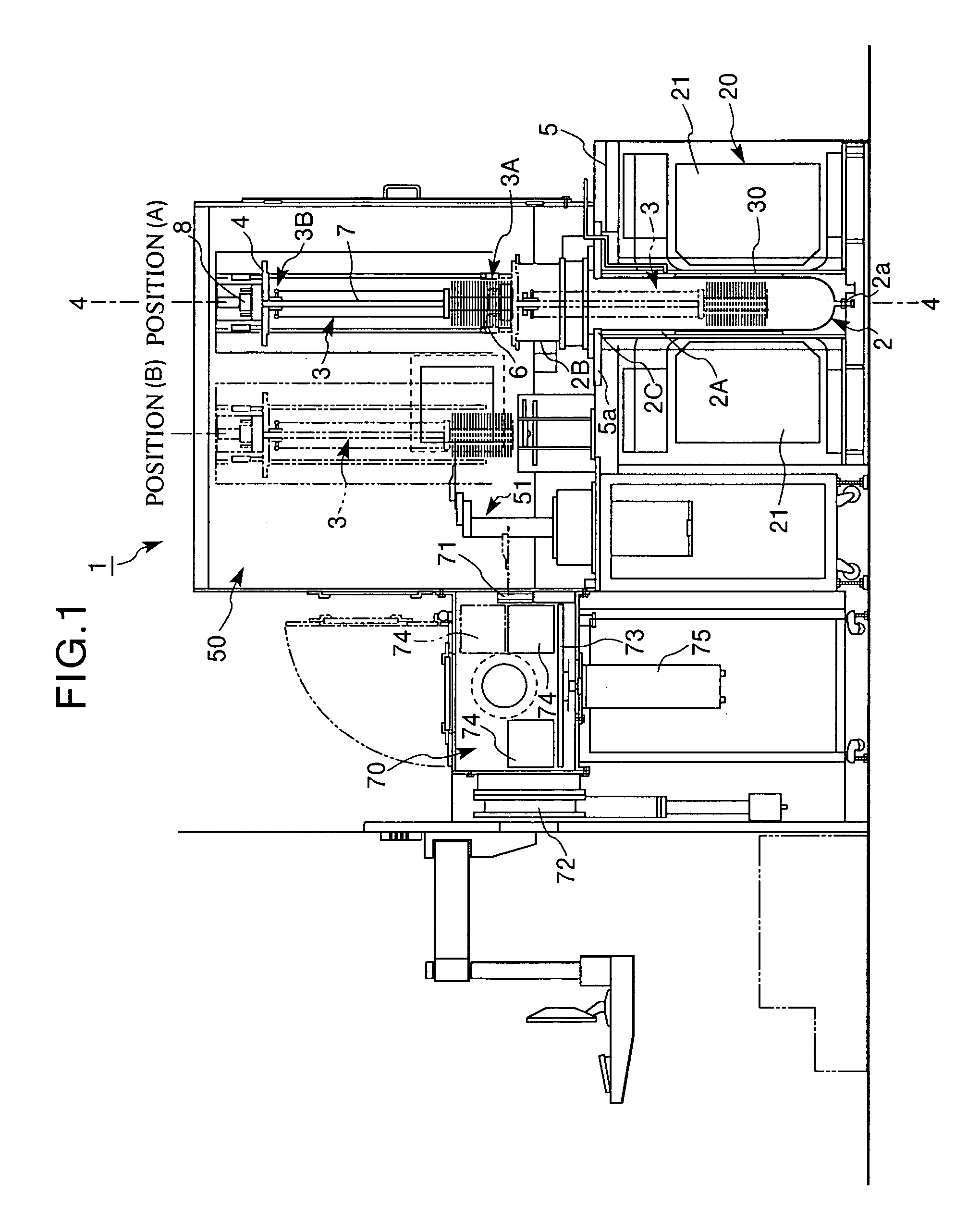

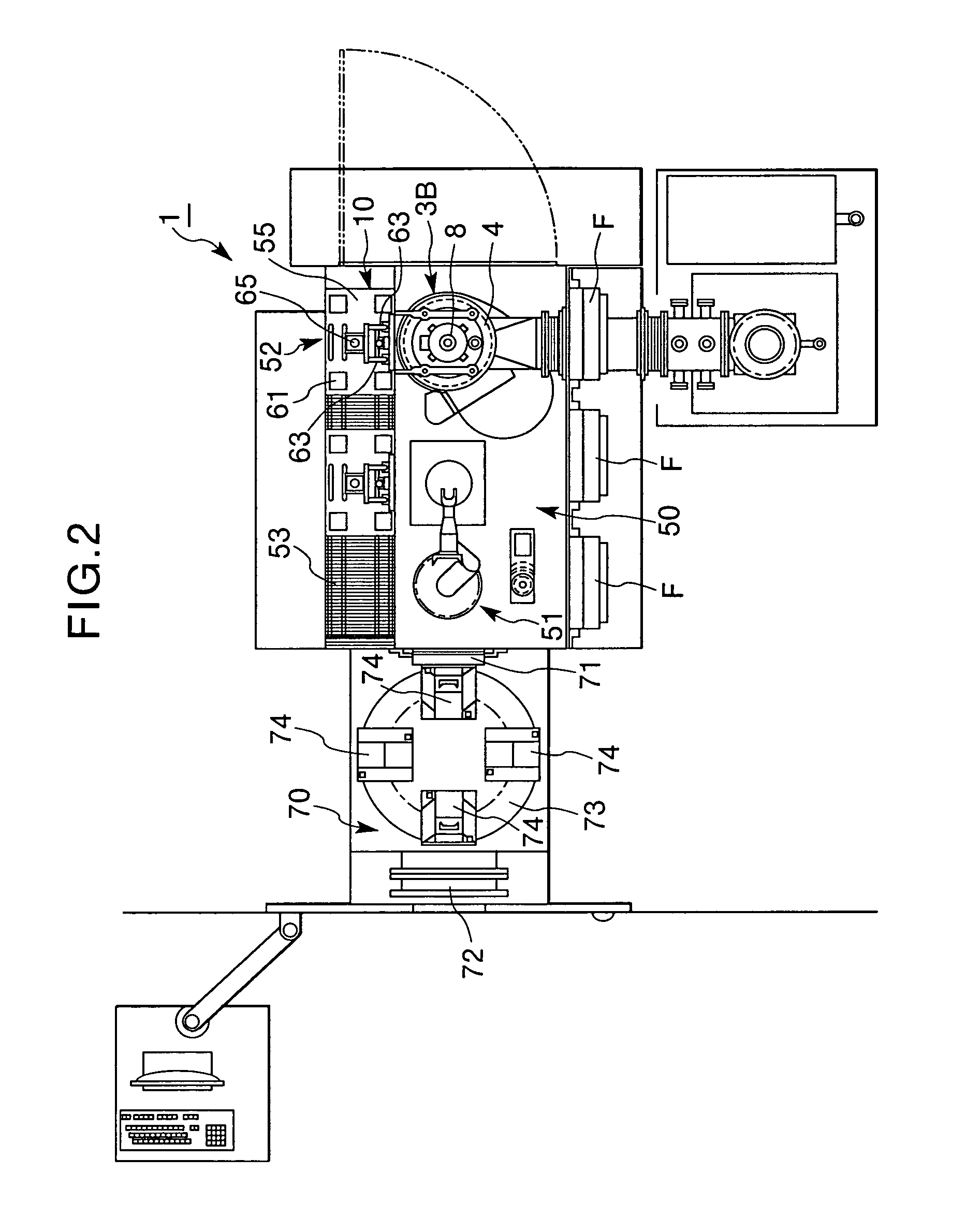

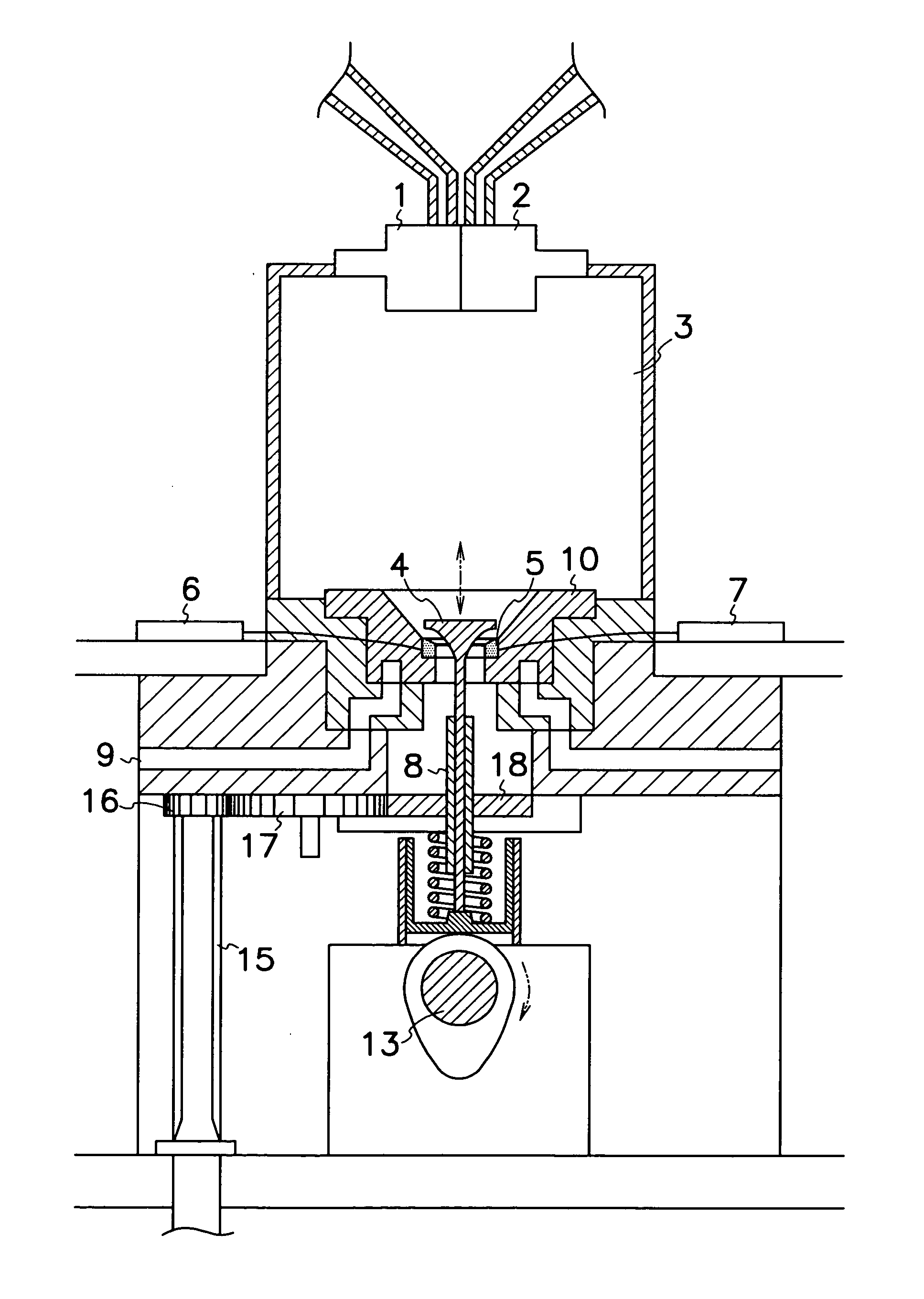

Heat treatment apparatus and method

InactiveUS20050023266A1Reduction in treatment periodImprove throughputMuffle furnacesSemiconductor/solid-state device manufacturingEngineeringHeat treated

A heat treatment apparatus (1) has a treatment chamber 50, arranged adjacent to a heat treatment vessel (2), in which an internal space can be set to contain a prescribed atmosphere, and a conveyor (10) which acts on a holding unit (3), which holds the object of treatment, to cause the object of treatment to move between the heat treatment vessel (2) and the treatment chamber (50).

Owner:FUTEK FURNACE

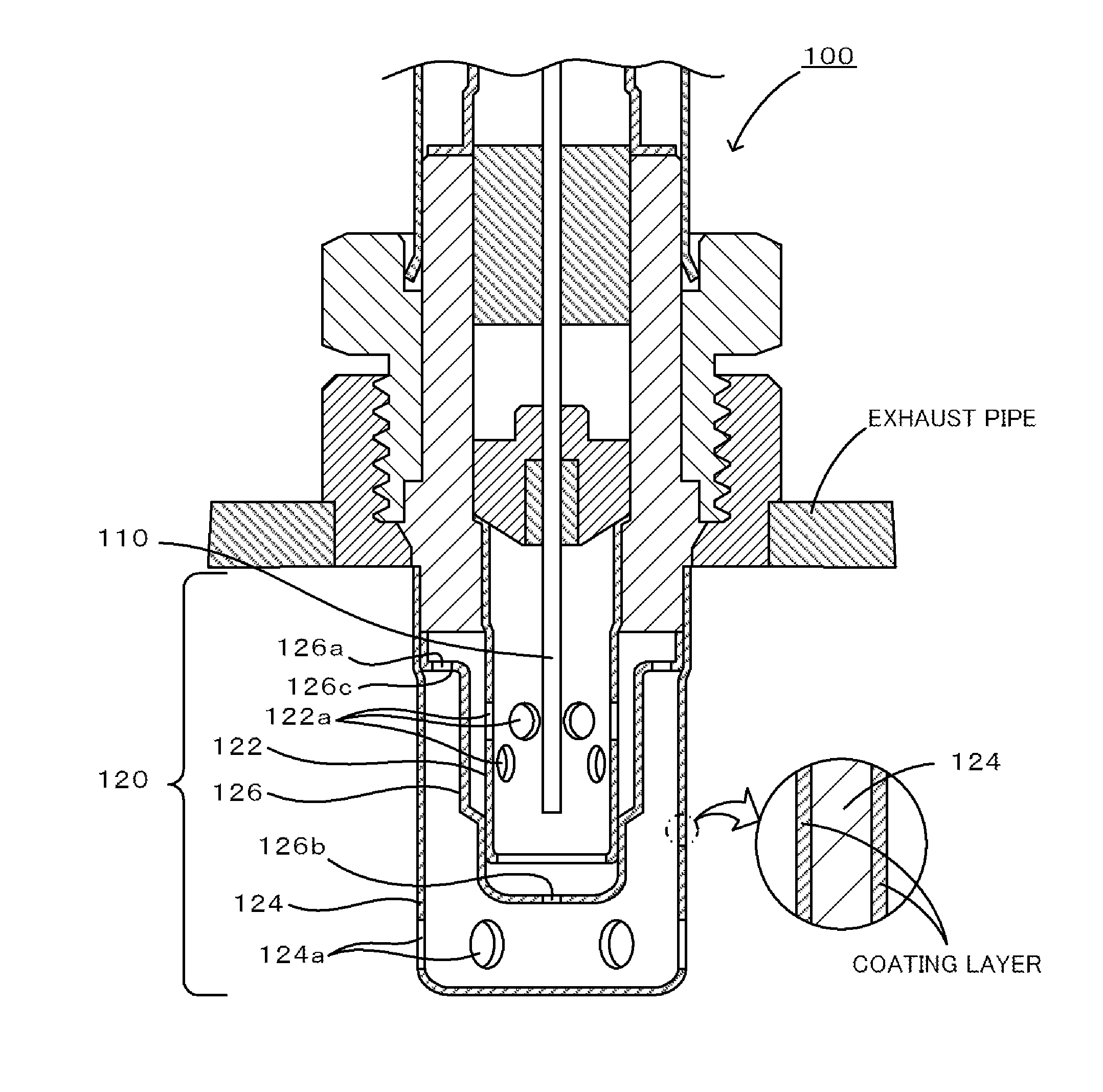

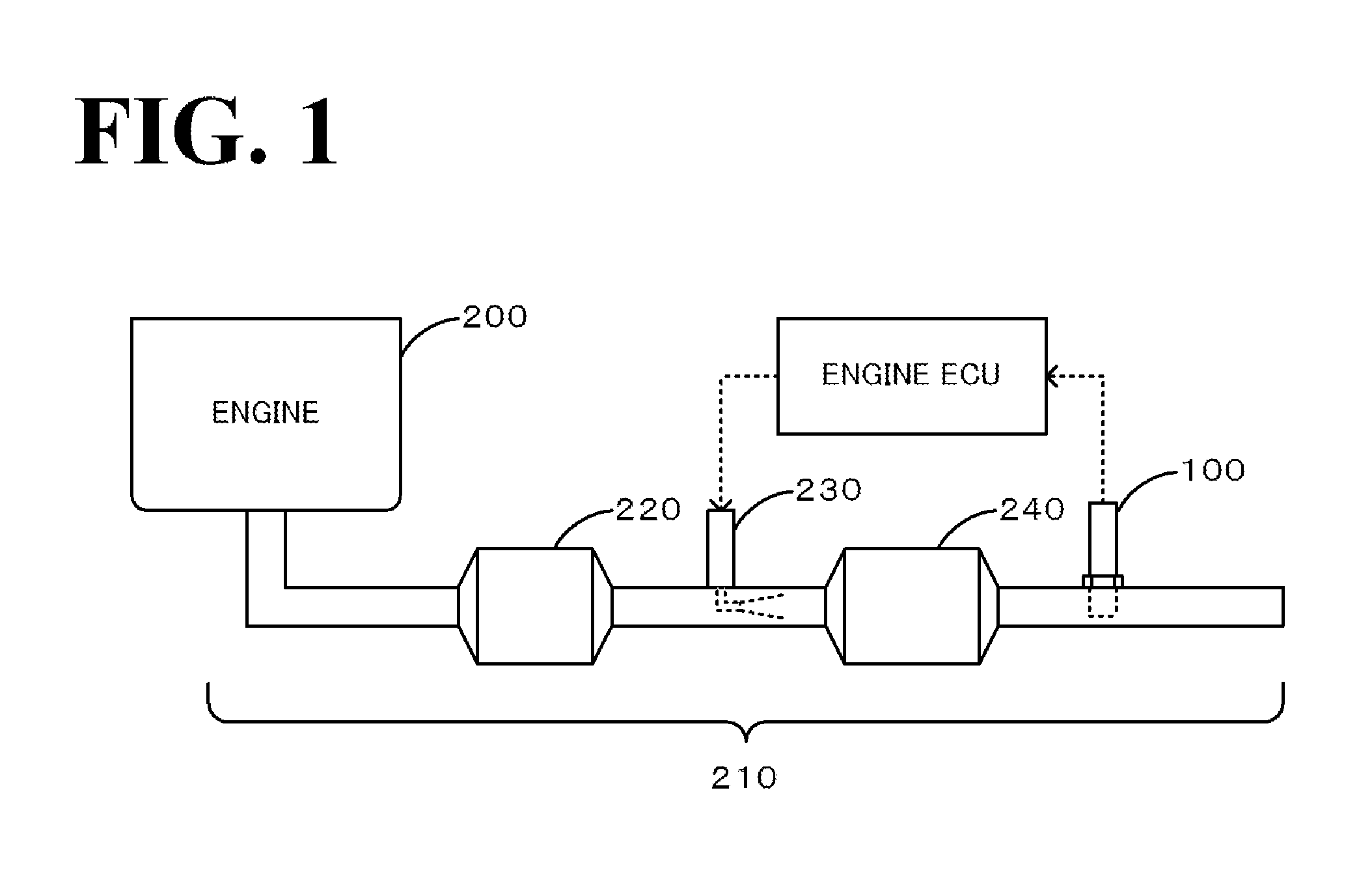

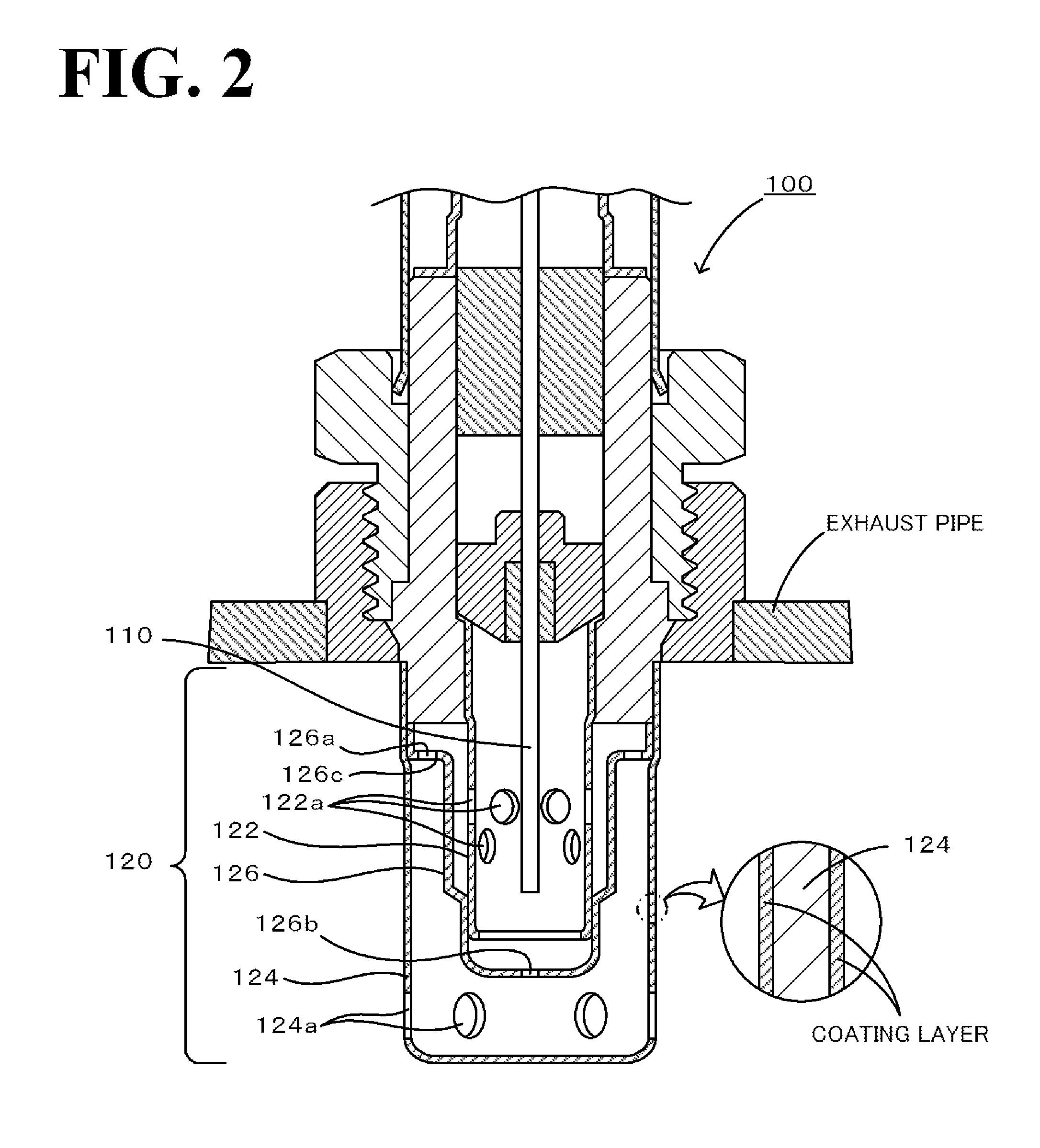

Ammonia concentration detection sensor

ActiveUS20110011152A1Low detection sensitivityFormation of crackAnalysing fluids using sonic/ultrasonic/infrasonic wavesInternal-combustion engine testingAmmoniaNH3 compound

Owner:NGK INSULATORS LTD

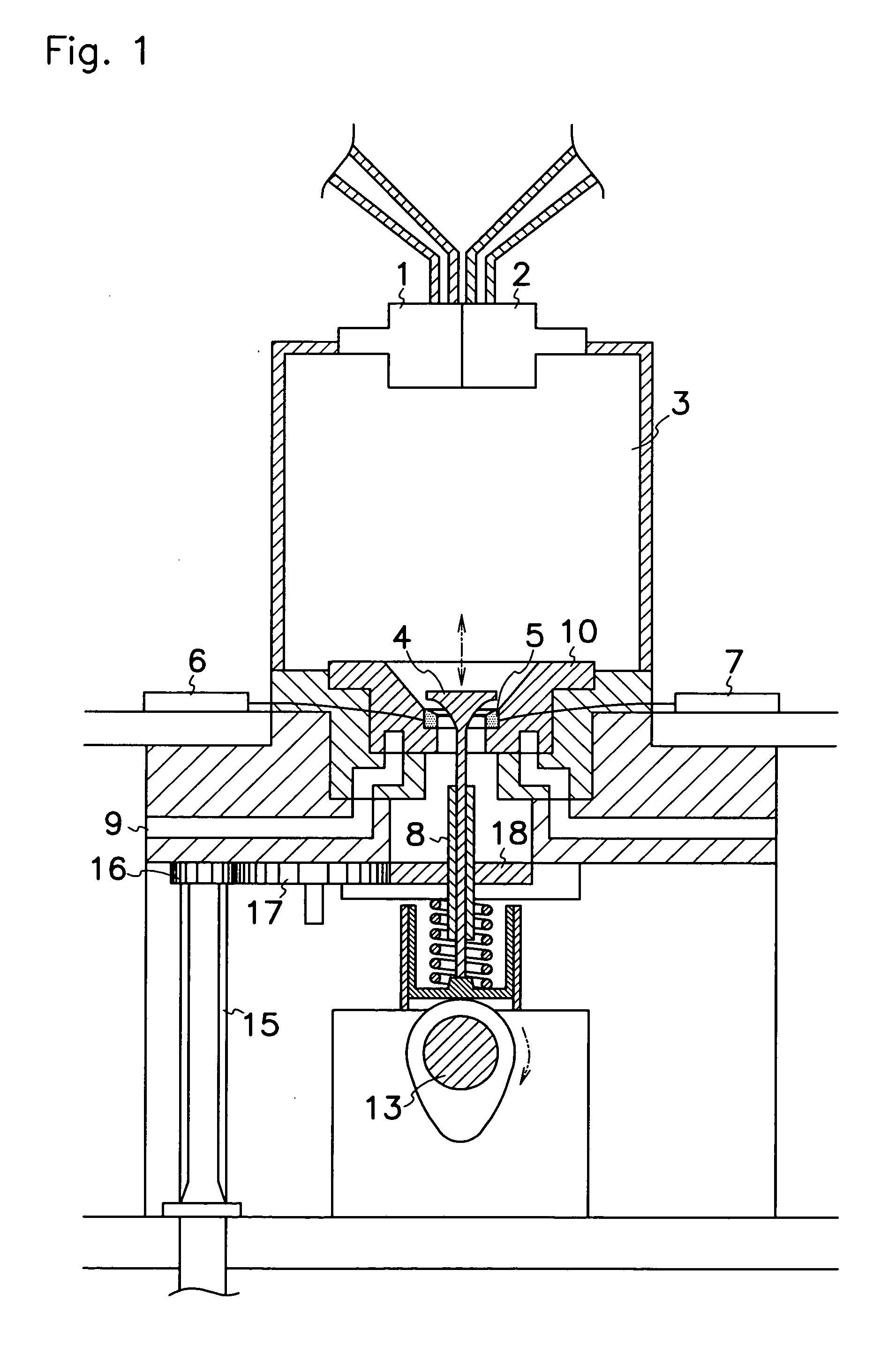

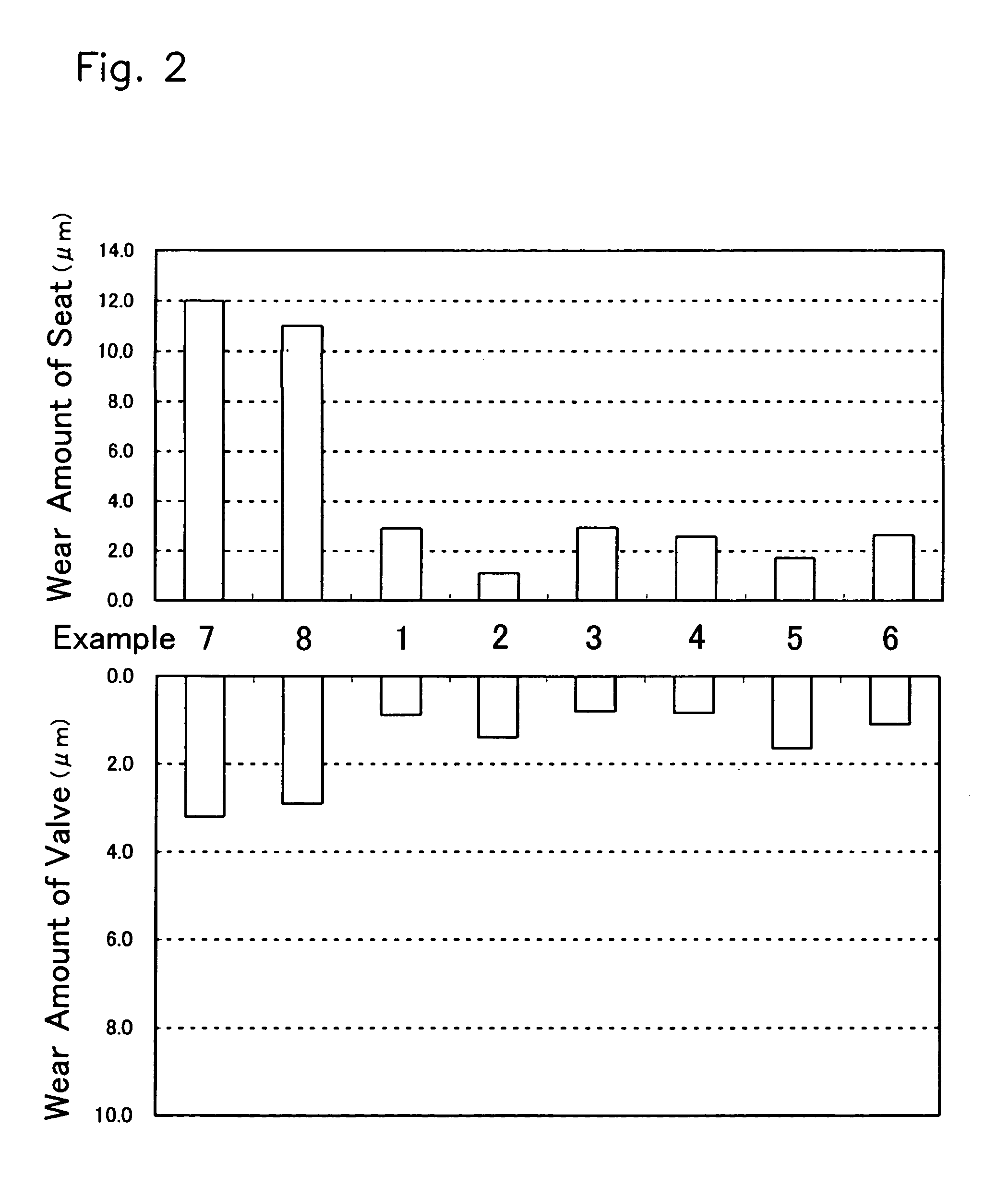

Iron-based sintered alloy with dispersed hard particles

An iron-based sintered alloy having improved thermal and mechanical strength is provided. The iron-based sintered alloy with dispersed hard particles comprises: a matrix comprising, by weight, 0.4 to 2% silicon (Si), 2 to 12% nickel (Ni), 3 to 12% molybdenum (Mo), 0.5 to 5% chromium (Cr), 0.6 to 4% vanadium (V), 0.1 to 3% niobium (Nb), 0.5 to 2% carbon (C), and the reminder of iron (Fe); and hard particles comprising 60 to 70% molybdenum (Mo), 0.3 to 1% boron (B), 0.1% or less carbon (C), and the reminder of iron (Fe). The hard particles are dispersed in the matrix in an amount in the range of 3 to 20% based on the entire alloy. They are sintered to produce the iron-based sintered alloy. Addition of boron into the ferromolybdenum hard particles enhances the wettability of the ferromolybdenum hard particles to prevent the hard particles from falling off the matrix. Thus, the adhesive property between the matrix and the hard particles is improved, thereby enhancing the thermal and mechanical strength of the iron-based sintered alloy.

Owner:RIKEN CO LTD

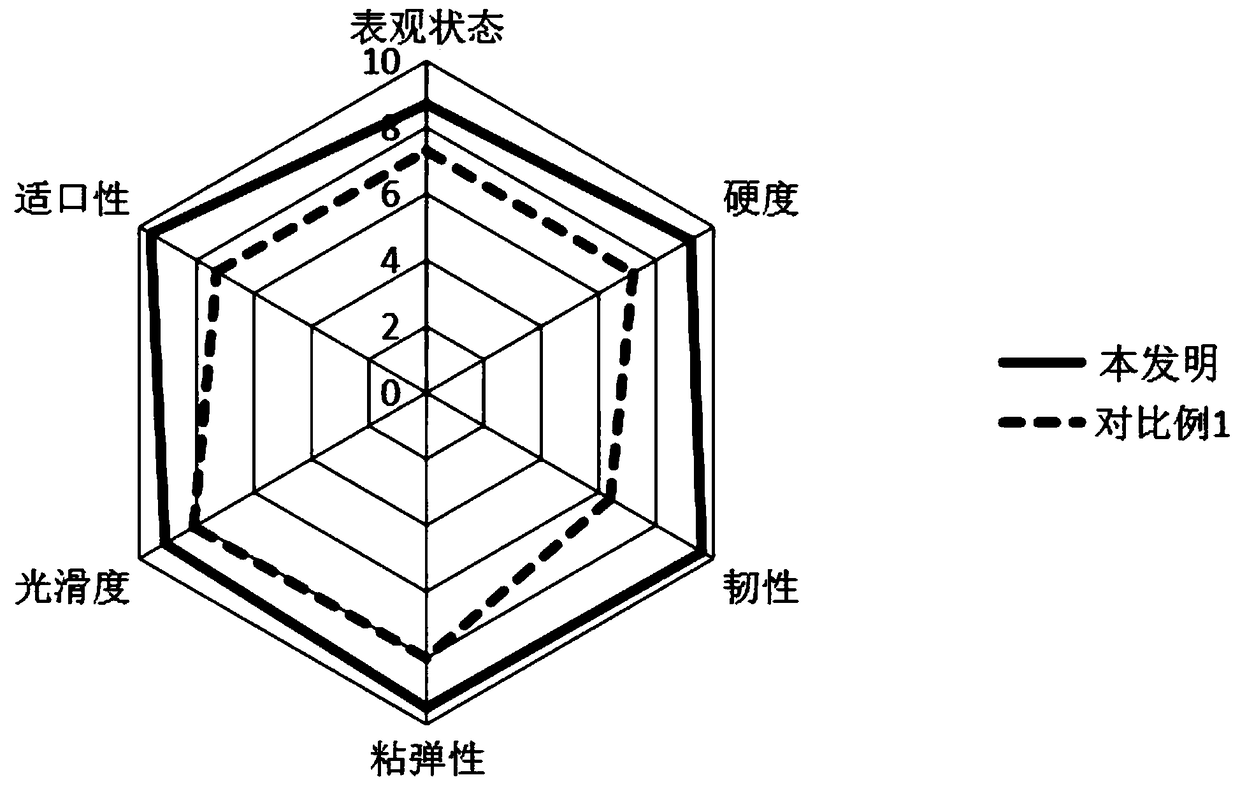

High-quality fresh-keeping convenient rice flour and processing method thereof

InactiveCN102805293AControl agingRapid coolingClimate change adaptationFood preservationChemistryEconomic shortage

The invention relates to high-quality fresh-keeping convenient rice flour and a processing method thereof. The processing method for the high-quality fresh-keeping convenient rice flour comprises the following steps of: cleaning out sand from machine-made rice, burdening, grinding powder, humidifying, extruding, gelatinizing, discharging filaments, cooling, ageing, slitting, cooking, dipping, rinsing, packaging once, sterilizing, cooling, testing and packaging. The processing method disclosed by the invention has the advantages of simple technology, small equipment investment and short processing period. The obtained product is convenient to eat and is durable in storage. On the basis of keeping the original taste of wet rice flour, auxiliary materials are added in the raw material rice so as to delay ageing, improve the taste and shorten rehydration time. According to the processing method disclosed by the invention, the shortages of long period and the like of the traditional production technology are broken through, the food eating convenience is realized, and the rice flour which is the traditional food gradually tends to industrial large-scale production.

Owner:江西华达昌食品有限公司

Charging member, process cartridge and electrophotographic apparatus

ActiveUS20090238601A1Image output is made stableCharging and image output are made stable for a longShaft and bearingsLayered productsSurface layerElectrical and Electronics engineering

A charging member is provided in which a toner, an additive for use in the toner, or the like is hard to adhere to the surface even under repeated use for a long time, and hence the charging and image output are made stable for a long time even if the charging member is used in the DC contact charging method. Also provided are a process cartridge and an electrophotographic apparatus having the charging member. The charging member includes a support, a conductive elastic layer formed on the support, and a surface layer formed on the conductive elastic layer, characterized in that the surface layer contains a polysiloxane having a fluoroalkyl group and an oxyalkylene group, and a process cartridge and an electrophotographic apparatus having the charging member.

Owner:CANON KK

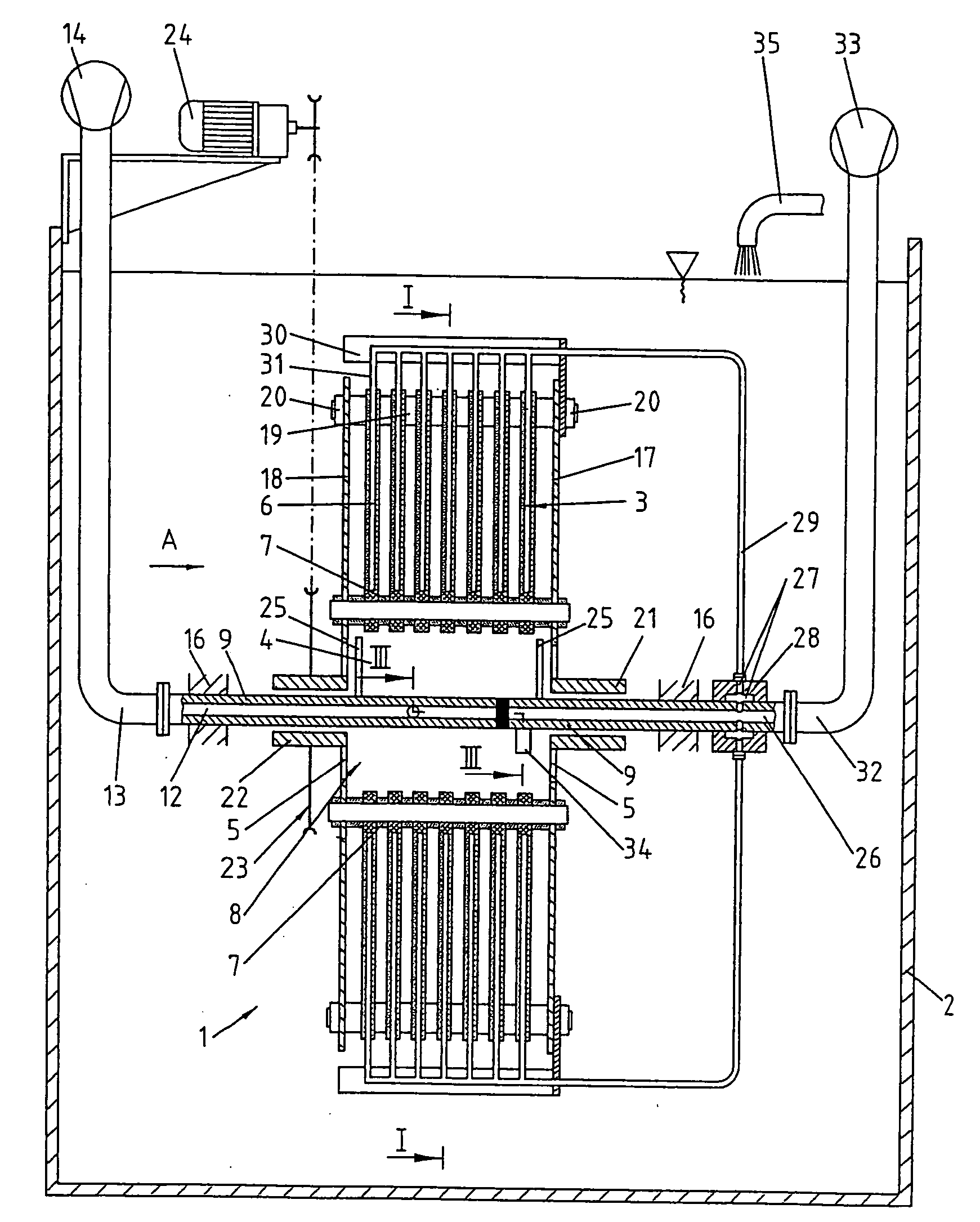

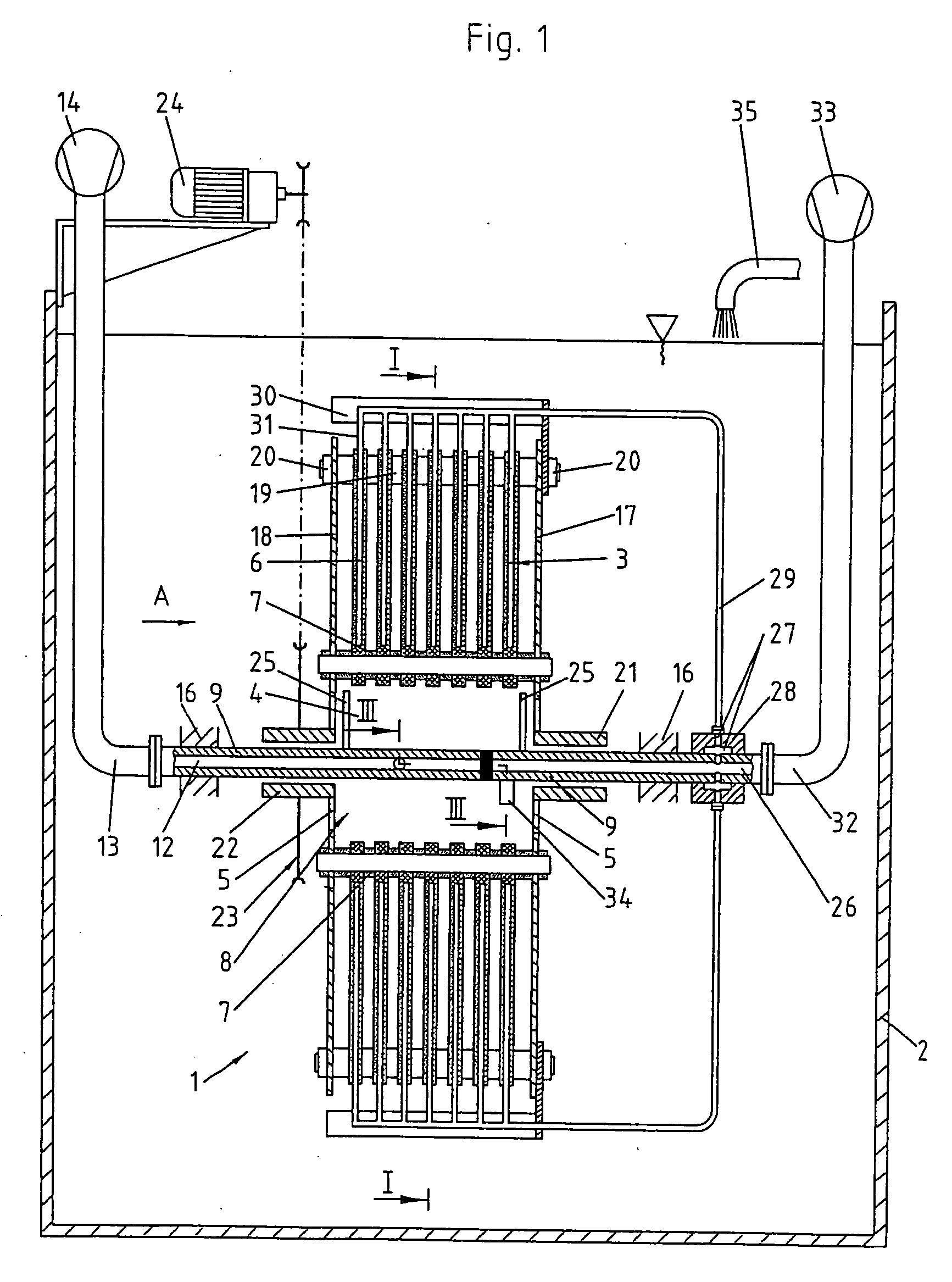

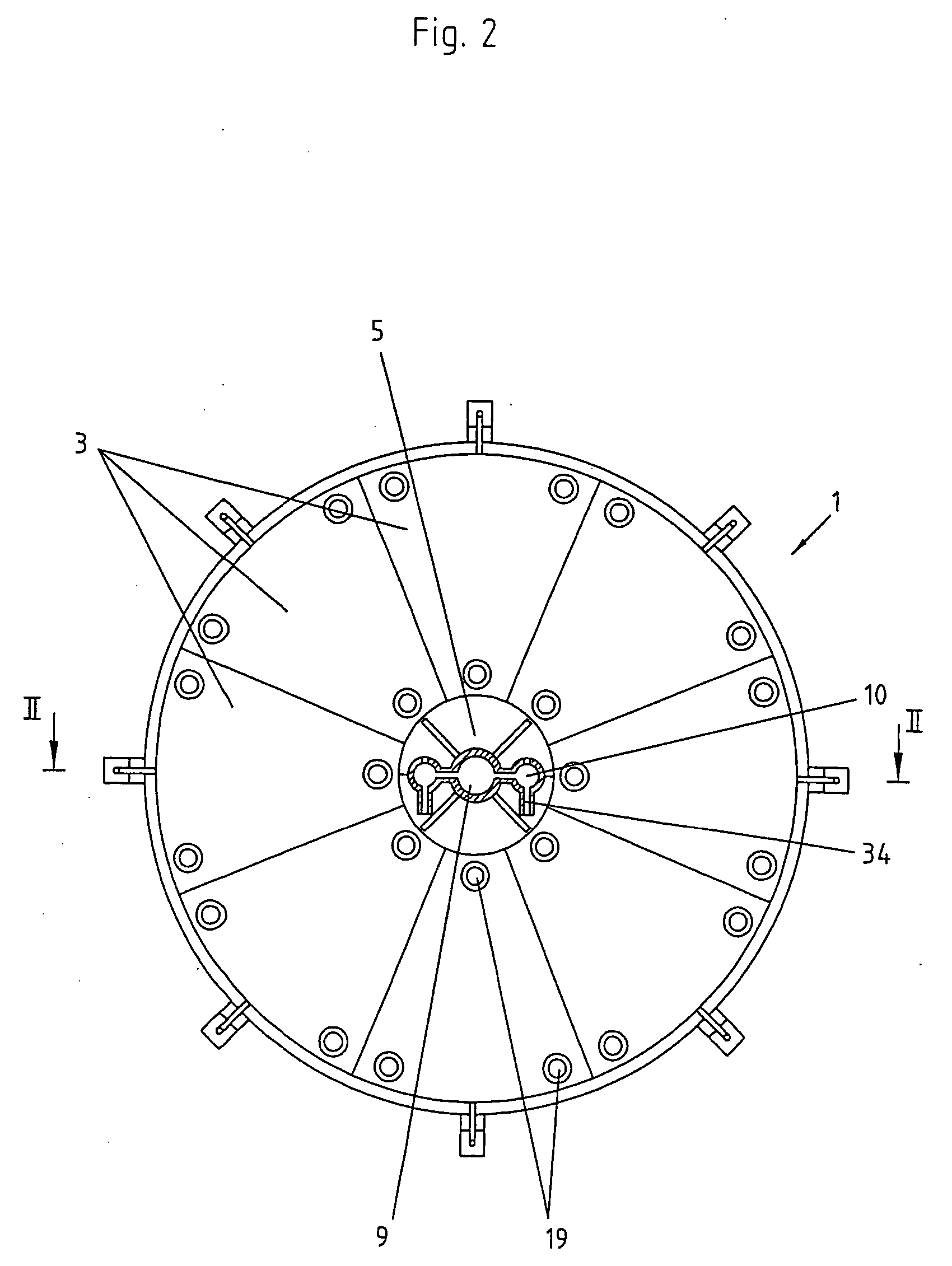

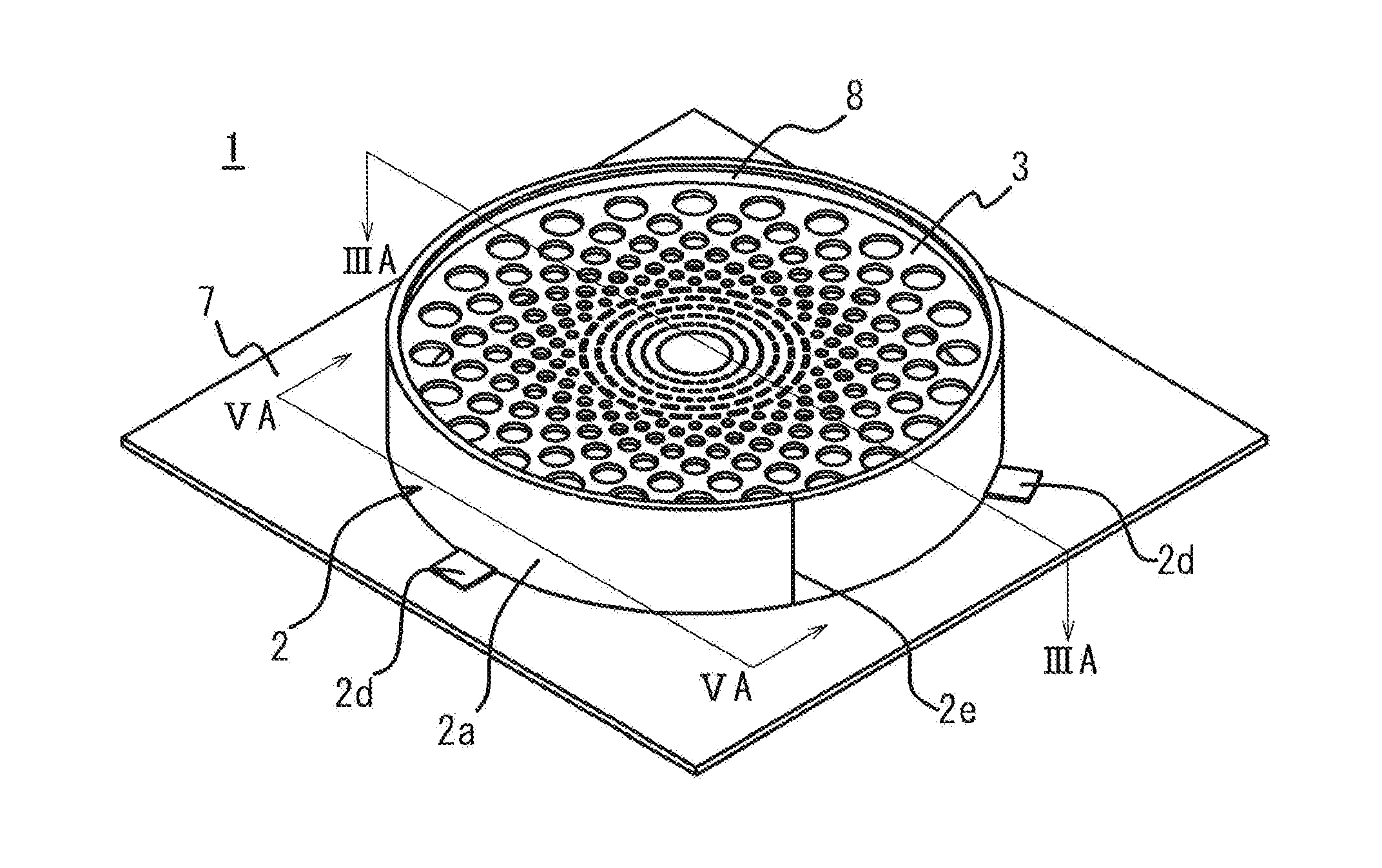

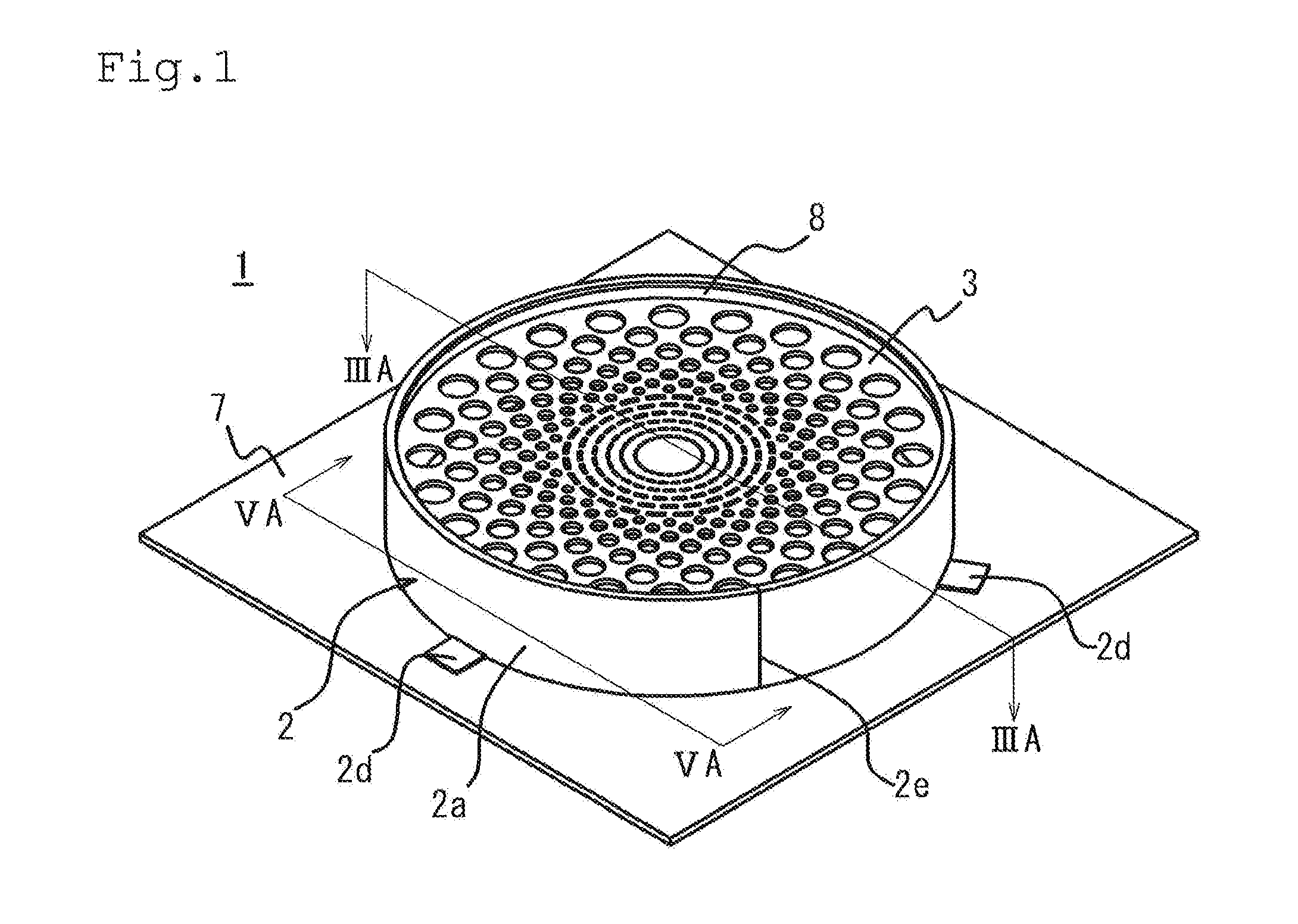

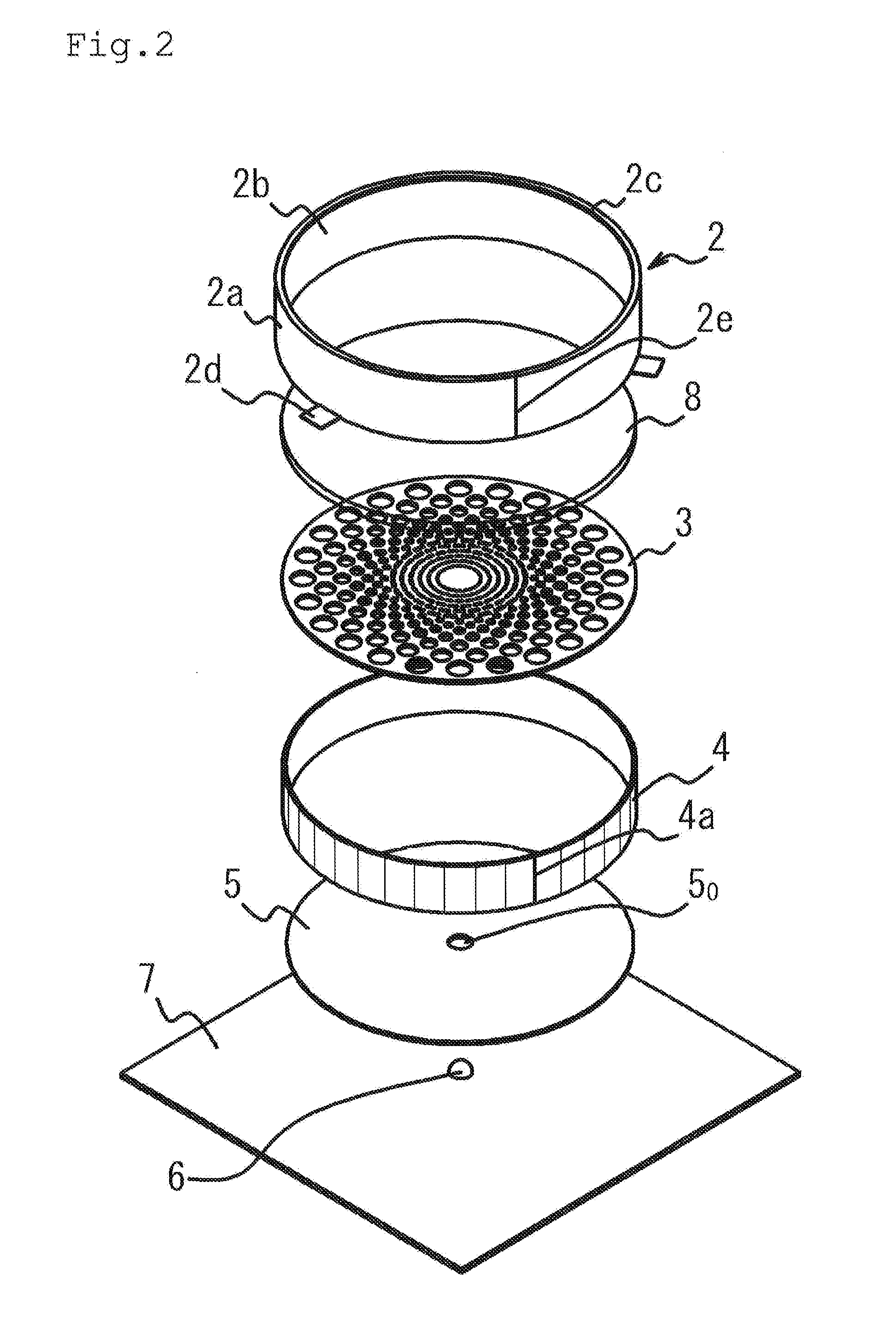

Filter device

InactiveUS20060060521A1Minimizing overall energy requiredGood effectMembrane filtersMoving filtering element filtersWastewaterSpin filter

The filter device is utilized for the separation of undissolved solid substances from liquids, in particular in the fields of waste water purification and water treatment. The filter device is arranged in a container as capable of rotation (2) and surrounded by the liquid to be filtered. The filter device (1) consists of several filter elements (6) with a space between one another, which are combined to form a rotating filter. The filtrate is drained away at the periphery of the filter elements (6). Solid substances are prevented from adhering to the filter elements (6) during the filtering process. The rotating filter comprises a hollow space in the center and an aeration device (8) is arranged in the hollow space, around which the filter device rotates. The filters are continuously cleaned by the mixture of air and liquid flowing through during the filtering process.

Owner:UTISOL TECH AG

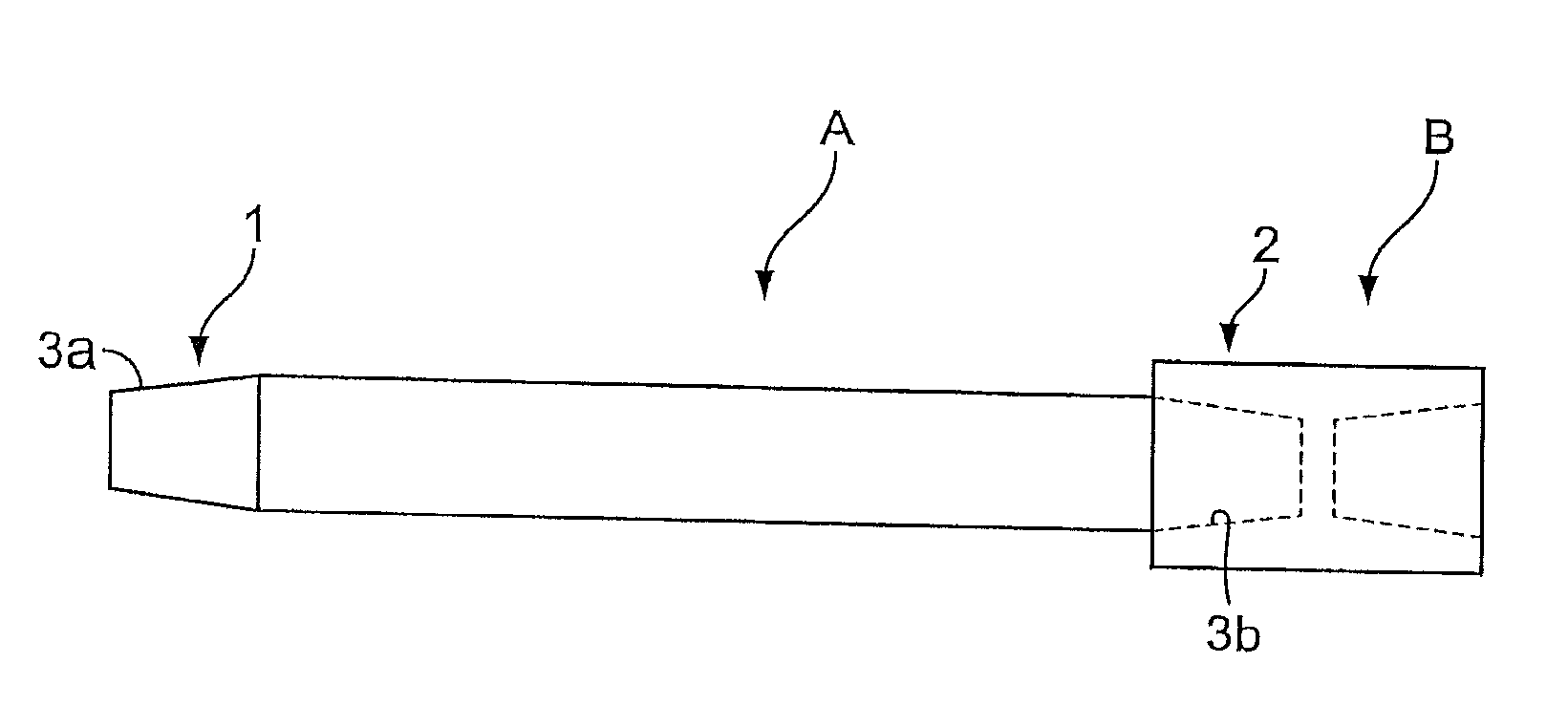

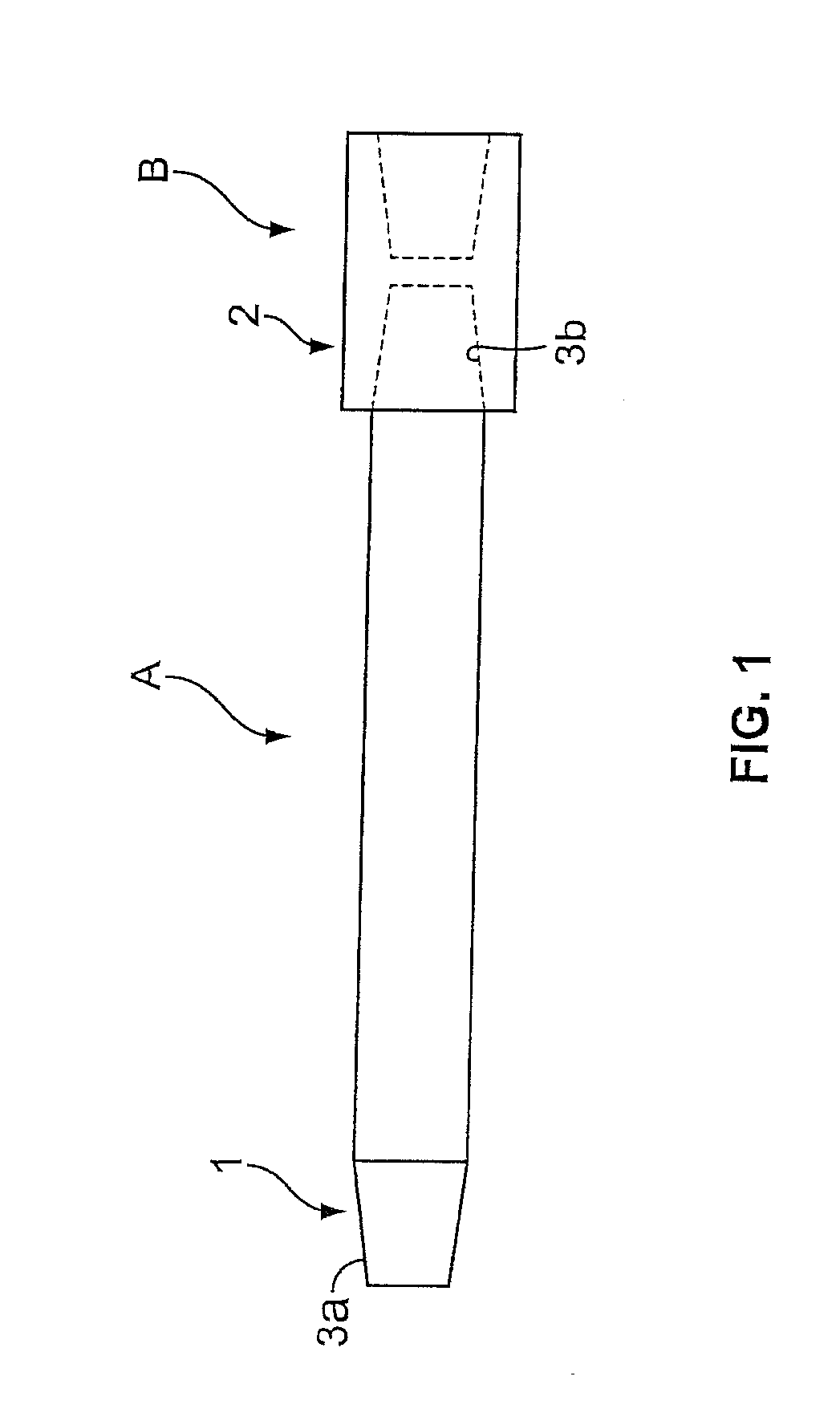

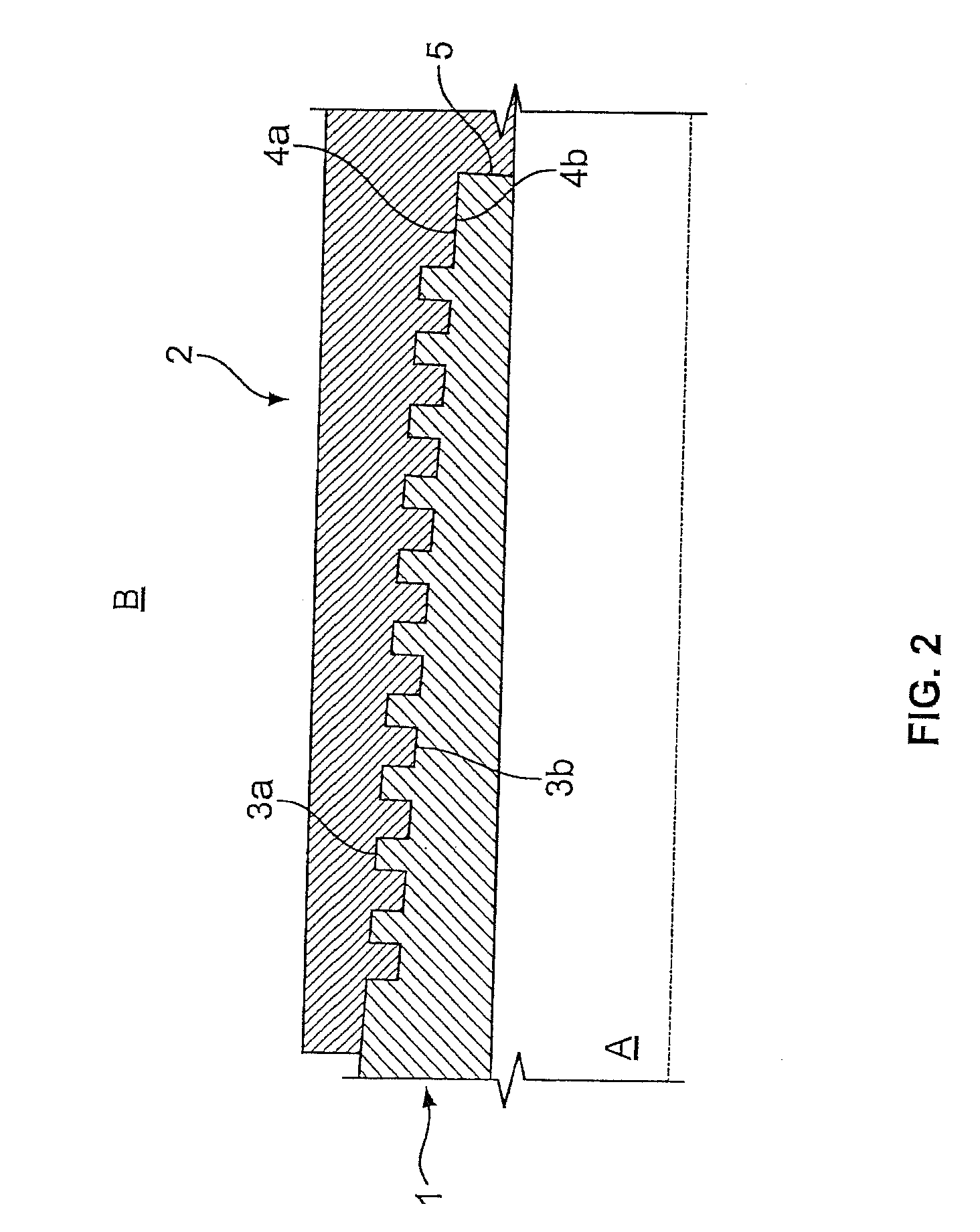

Charging member, process cartridge and electrophotographic apparatus

ActiveUS7664434B2Charging and image output are made stable for a longSolve easy adhesionShaft and bearingsLayered productsSurface layerEngineering

A charging member is provided in which a toner, an additive for use in the toner, or the like is hard to adhere to the surface even under repeated use for a long time, and hence the charging and image output are made stable for a long time even if the charging member is used in the DC contact charging method. Also provided are a process cartridge and an electrophotographic apparatus having the charging member. The charging member includes a support, a conductive elastic layer formed on the support, and a surface layer formed on the conductive elastic layer, characterized in that the surface layer contains a polysiloxane having a fluoroalkyl group and an oxyalkylene group, and a process cartridge and an electrophotographic apparatus having the charging member.

Owner:CANON KK

Charging member, process cartridge and electrophotographic apparatus

ActiveUS20070217823A1Image output is made stableCharging and image output are made stable for a longShaft and bearingsPortable power-driven toolsEngineeringPolysiloxene

An object of the present invention is to provide a charging member in which a toner, an additive for use in the toner, or the like is hard to adhere to the surface even under repeated use for a long time, and hence the charging and image output are made stable for a long time even if the charging member is used in the DC contact charging method, and a process cartridge and an electrophotographic apparatus having the charging member. The present invention provides a charging member comprising a support, a conductive elastic layer formed on the support, and a surface layer formed on the conductive elastic layer, characterized in that the surface layer contains a polysiloxane having a fluoroalkyl group and an oxyalkylene group, and a process cartridge and an electrophotographic apparatus having the charging member.

Owner:CANON KK

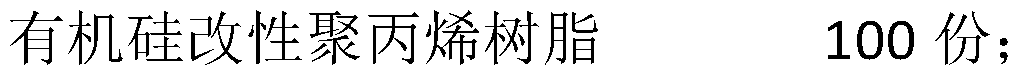

Self-cleaning polypropylene plastic barrel and preparation method thereof

The invention belongs to the technical field of plastic packaging barrels, in particular to a self-cleaning polypropylene plastic barrel and a preparation method thereof. The polypropylene plastic barrel comprises 100 parts of organic silicon modified polypropylene resin, 2-8 parts of maleic anhydride grafted polypropylene, 1-10 parts of hydrophobic modified micro-nano power, 1-3 parts of paraffinoil and 0.5-3 parts of hydrophobic modifier. The invention also provides a preparation method of the self-cleaning polypropylene plastic barrel. The self-cleaning polypropylene plastic barrel prepared by the invention has the surface self-cleaning property and difficult adhesion property that the prior polypropylene packaging barrel does not have, and also has higher mechanical properties, excellent impact performance and high and low temperature resistance performance.

Owner:TIANJIN RUIJIE PLASTIC PROD

Threaded Joint for Steel Pipes

ActiveUS20110025052A1Prevent rustExcellent galling resistance and air tightnessEarth drilling toolsLiquid surface applicatorsViscous liquidAlkaline earth metal

A threaded joint for steel pipes for use in an oil well which has improved galling resistance and which is protected from rusting comprises a pin and a box each having a contact surface including a threaded portion and an unthreaded metal contact portion. The contact surface of at least one of the pin and the box has a lower layer of a viscous liquid or semisolid lubricating coating comprising at least wax and a fatty acid alkaline earth metal salt and not containing a harmful heavy metal such as lead and an upper layer of a dry solid coating formed from an aqueous resin coating composition, an organic solvent type coating composition, or an ultraviolet curing coating composition.

Owner:NIPPON STEEL CORP +1

Anaerobic bacterium immobilization method

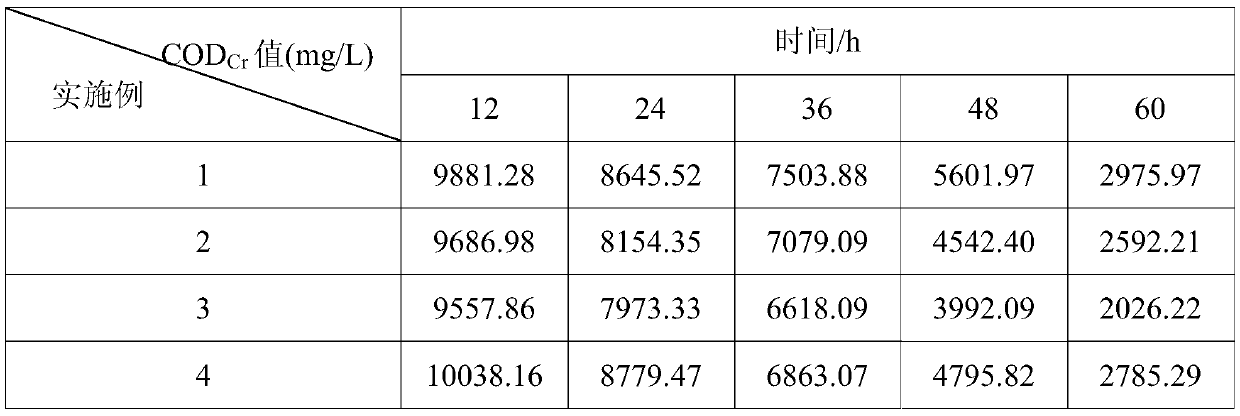

ActiveCN105505913ADoes not interfere with featuresSolve easy adhesionOn/in organic carrierBiological water/sewage treatmentPolyvinyl alcoholAnaerobic bacteria

The embodiment of the invention discloses an anaerobic bacterium immobilization method. The method includes the following steps of firstly, adding an embedding material to a growth factor solution, heating the solution to 50-120 DEG C, and evenly stirring the solution to prepare mixed size, wherein the embedding material is at least one of sodium alginate and polyvinyl alcohol; secondly, adding anaerobic bacteria to the mixed size after the temperature of the mixed size is cooled to 30-45 DEG C, and stirring the size to prepare mixed size containing anaerobic bacteria; thirdly, dropwise adding the mixed size containing anaerobic bacteria to a curing agent, and standing for 2-24 h at the temperature of 0-10 DEG C to obtain anaerobic bacterium embedding particles, wherein the curing agent is prepared from calcium chloride, talcum powder and a saturated boric acid solution; fourthly, flushing the anaerobic bacterium embedding particles with water or an NaCl aqueous solution to obtain cured anaerobic bacterium particles, wherein the mass percentage of NaCl in the NaCl aqueous solution is smaller than or equal to 0.9%. According to the method, talcum powder is added to the curing agent, and the problem that adhesion is likely to be caused in the anaerobic bacterium immobilization process is solved.

Owner:POTEN ENVIRONMENT GRP +1

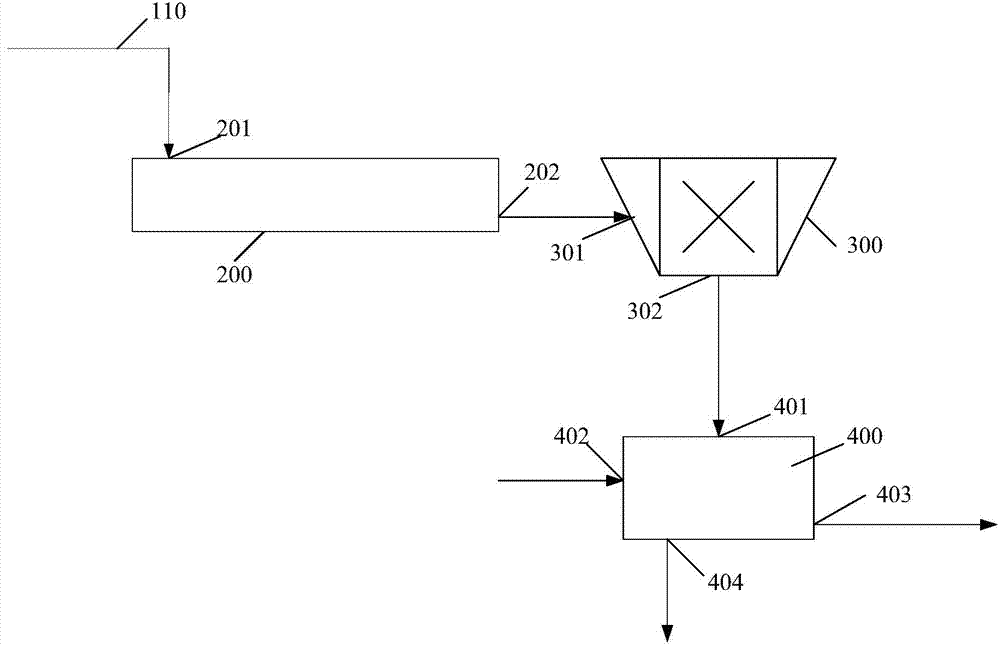

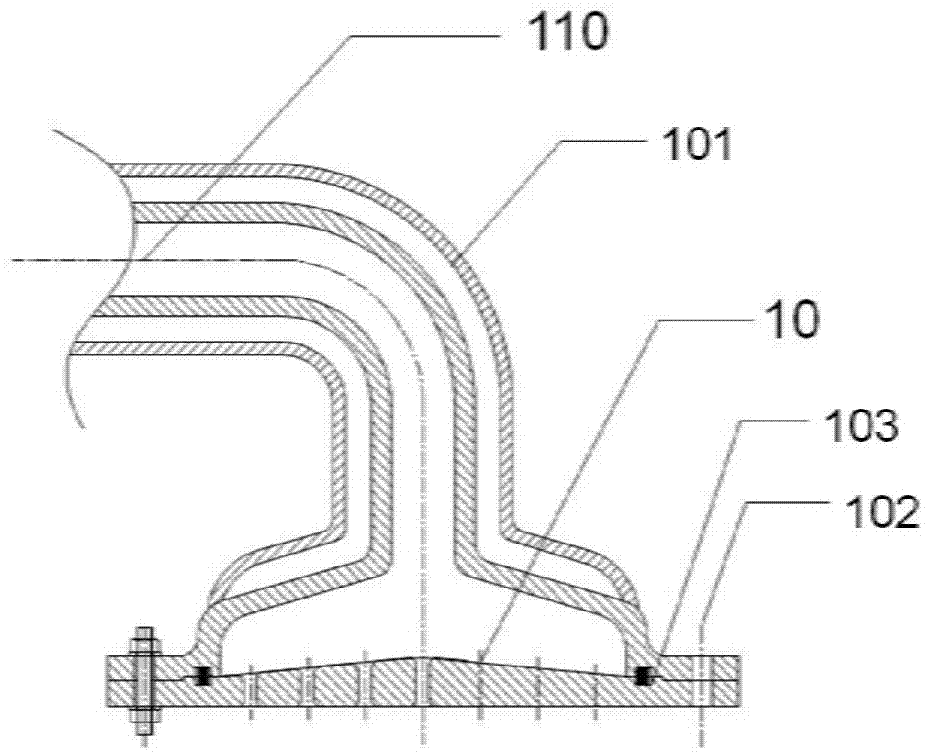

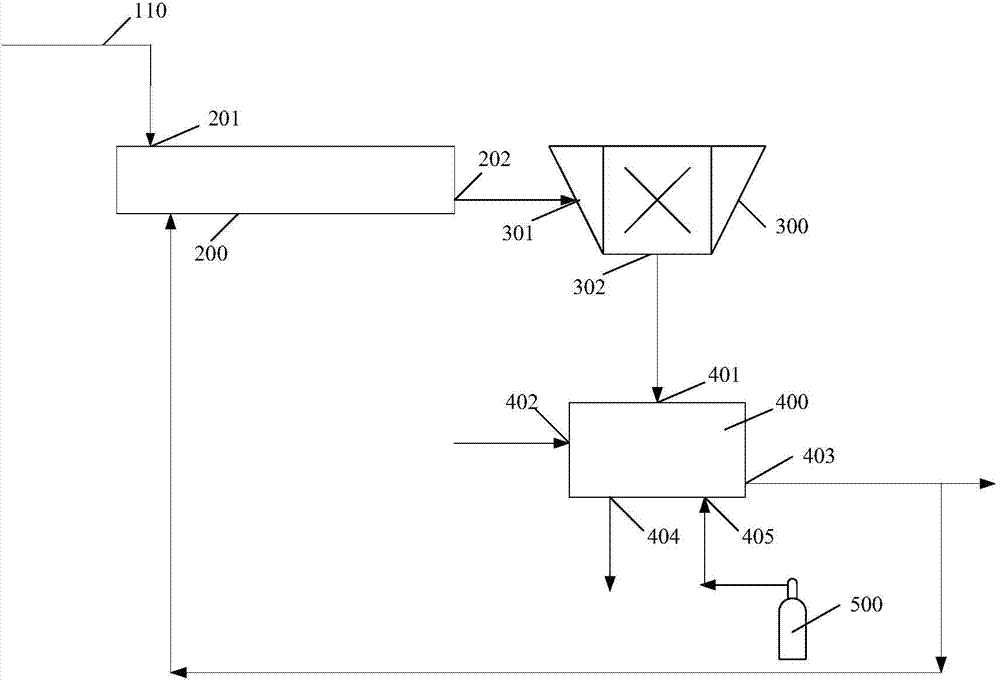

Lyocell fiber spinning solution waste recycling device and recycling method thereof

ActiveCN104711706ASmall sizeLarge specific surface areaArtificial filament recoveryTextile/flexible product manufactureManufacturing cost reductionSlag

The invention provides a lyocell fiber spinning solution waste recycling device and a recycling method thereof. The recycling device comprises a waste pipeline, a cooling device, a breaking device and a leaching device, wherein the waste pipeline is provided with a spinning solution waste inlet and a spinning solution waste outlet; the spinning solution waste inlet is connected to a spinning solution waste output device; the cooling device is provided with a cooling material inlet and a cooling material outlet; the cooling material inlet is communicated with the spinning solution waste outlet; the breaking device is provided with a breaking material inlet and a breaking material outlet; the breaking material inlet is communicated with the cooling material outlet; the leaching device is provided with a leaching material inlet, an NMMO leaching solvent inlet, a leaching liquid outlet and a leaching slag outlet; the leaching material inlet is communicated with the breaking material outlet; a plurality of extrusion holes are formed in the spinning solution waste outlet of the waste pipeline. By virtue of the application of the recycling device, the NMMO solvent in the lyocell fiber spinning solution waste is effectively recycled, so that the manufacturing cost is reduced.

Owner:CHINESE TEXTILE ACAD

General grade pitch-based carbon fiber spinning oil

InactiveCN103757899AAvoid stickingTensile strength has no effectCarbon fibresIsolation effectAntistatic agent

The invention discloses general grade pitch-based carbon fiber spinning oil. The oil is prepared by mixing deionized water, a lubricating agent, an antistatic agent, an emulsifying agent and a balance regulator in a stirring state. The general grade pitch-based carbon fiber spinning oil has the beneficial effects that the viscosity of the oil is 2-20mPa.s and the light transmittance is 80-98%; the oil has an antistatic effect when sprayed onto fiber surfaces, ensures cohesive forces between fiber monofilaments, achieves a fiber packing effect and prevents fiber adhesion; oil films formed on the fiber surfaces not only protect the monofilament surfaces from being damaged in spinning but also have the same adhesion prevention and isolation effects in the non-melting and carbonizing processes, so that the problems of easiness in adhesion, static electricity, wear and the like in the general grade pitch-based carbon fiber preparation process can be solved; test results indicate that the contact angles between the general grade pitch-based carbon fiber spinning oil and the fiber surfaces are 0-5 degrees, the oil can be well coated on the fiber surfaces, and the fiber strength retention rate is 95-100%, so that the oil basically has no impact on the tensile strength of fibers.

Owner:SHAANXI NORMAL UNIV

Illumination device

InactiveUS20130094216A1Easy to processDifficult to thermally weldPoint-like light sourceCoatingsOptical transmittanceOptoelectronics

An illumination device includes: a point light source; a substrate; a hollow frame having an engaging bent section at one of its edges; and a bottom surface reflection section, a side surface reflection section, and a light conducting reflection plate that are disposed inside the frame. The light conducting reflection plate is held between the bent section and the side surface reflection section that is held by the other edge of the frame and the bottom surface reflection section fixed to the substrate. The surface of the bottom surface reflection section facing the light conducting reflection plate, the inner surface of the side surface reflection section, and the surface of the light conducting reflection plate facing the bottom surface reflection section have high light reflectivity and low light transmissivity.

Owner:OPTO DESIGN INC

Process for preparing a sheet of plastic, this sheet and glazing containing it

InactiveUS6054189ASolve easy adhesionHard resistanceLayered productsPretreated surfacesMobile vehicleEngineering

The present invention relates to a process for preparing a sheet of plastic coated with a hard varnish on at least part of at least one of its sides, including: 1) preparing a sheet of plastic by injection molding, 2) applying the varnish to the said sheet, and 3) heating the combination at a temperature at least equal to the softening point of the plastic of which the sheet is made, the varnish of at least a central part of the said combination being free of any mechanical contact other than that with the said sheet; the flat or curved transparent sheet thus obtained; its application as a motor-vehicle component containing a transparent part forming glazing and as motor-vehicle glazing.

Owner:SAINT-GOBAIN GLASS FRANCE

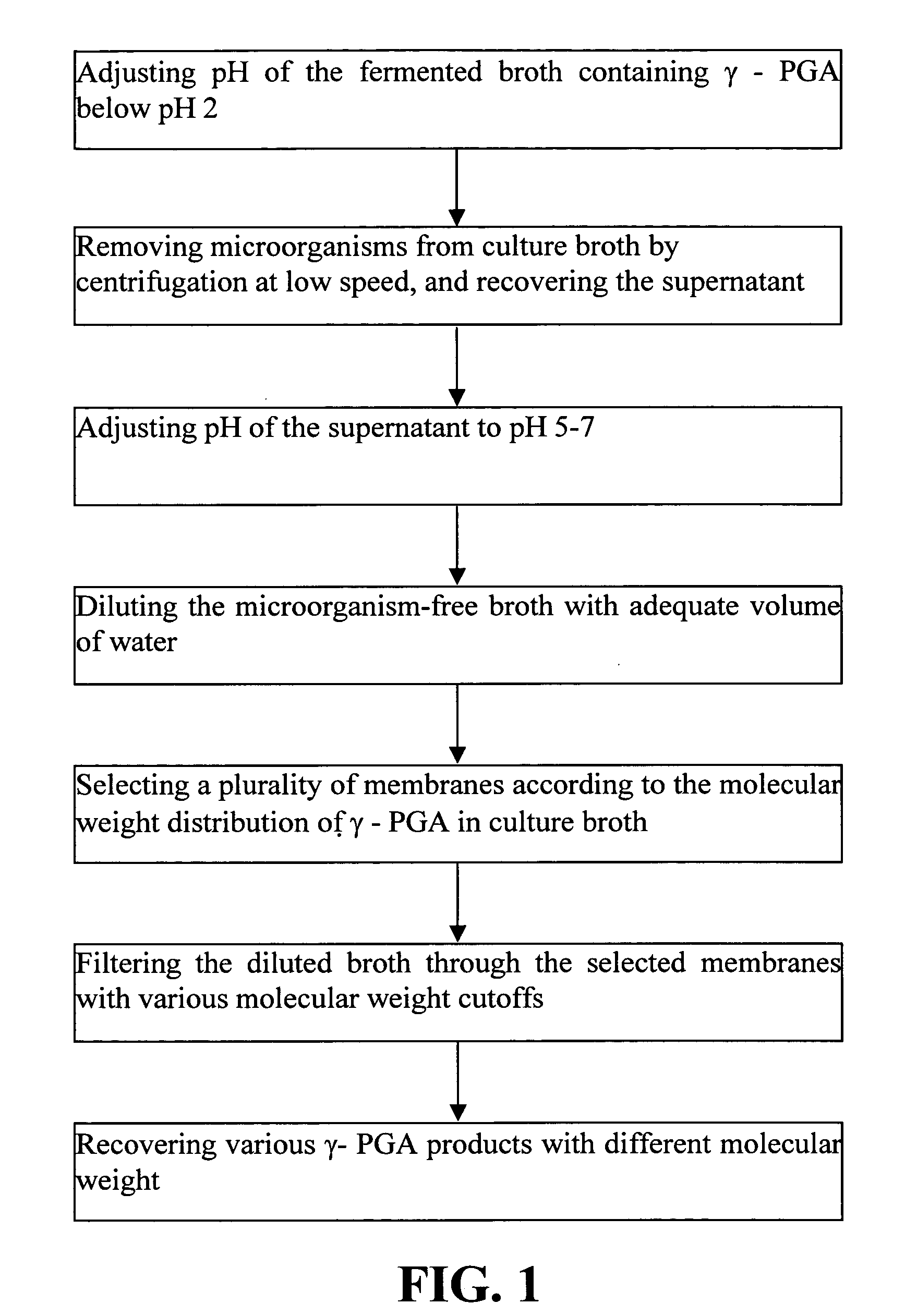

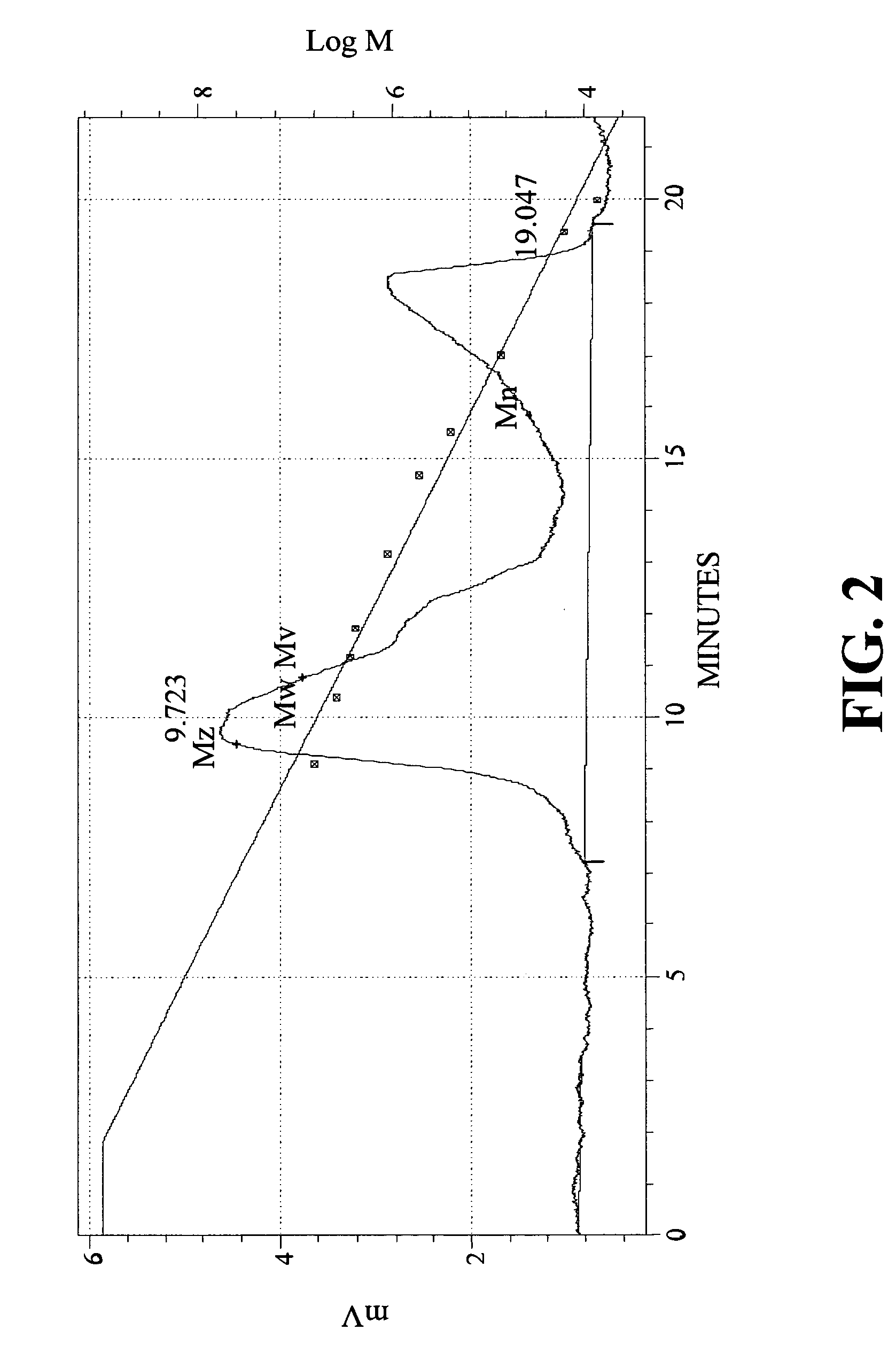

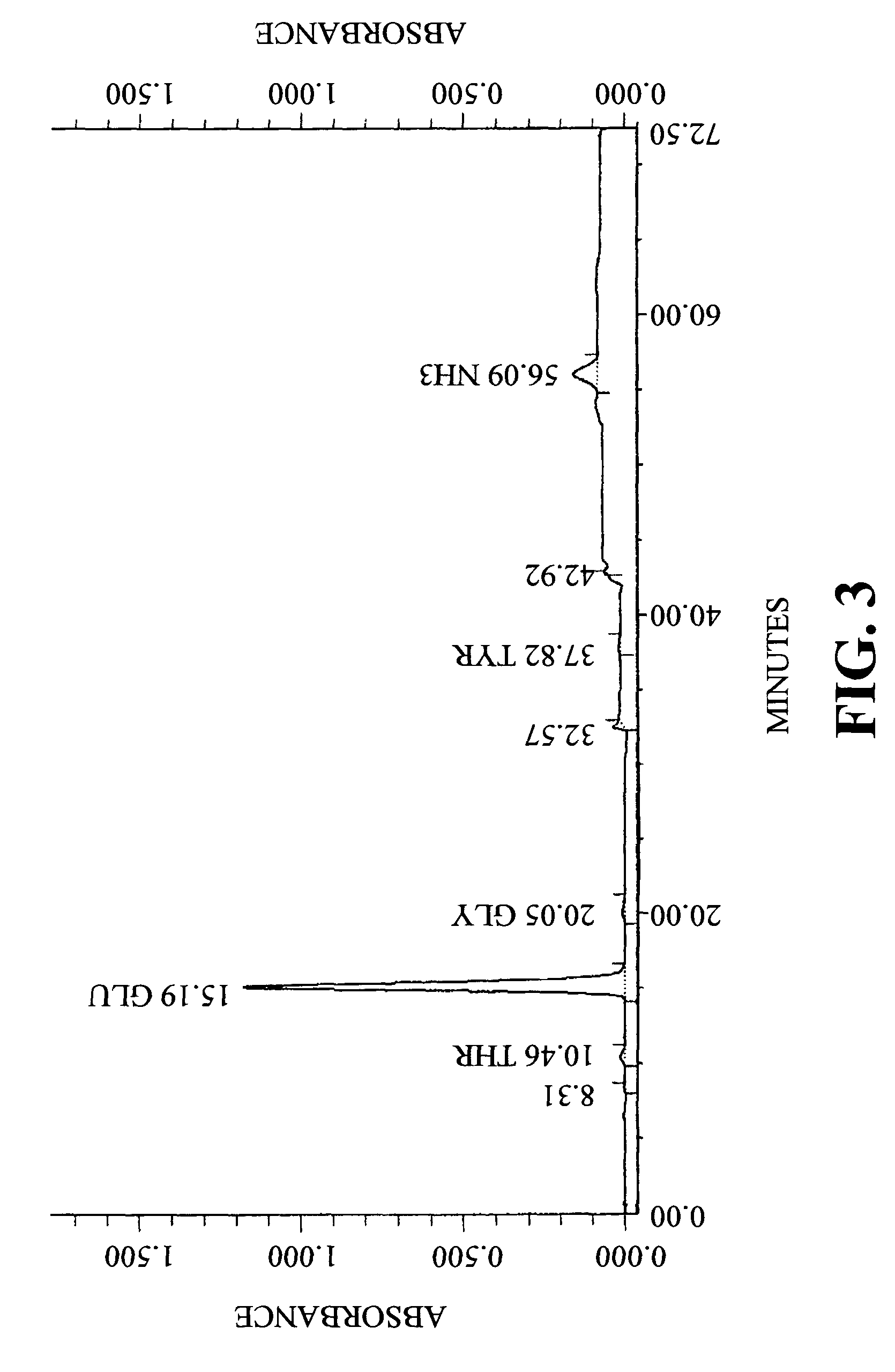

Method for recovering and purifying polyglutamic acid

InactiveUS20050037472A1Reduce consumptionReduce the amount of waterBacteriaFermentationProduction rateFiltration membrane

A method for recovering and purifying polyglutamic acid efficiently is disclosed, which method includes the steps of adjusting pH of a solution containing γ-PGA to neutral or slightly acidic range and filtering the solution through a plurality of filtration membranes with various molecular weight cutoffs to recover γ-PGA. Advantages of the method includes using none or minimum of organic solvent, reducing consumption of filtration membranes, reducing water volume for dilution, shortening operation time, high productivity, and obtaining various γ-PGA products with different range of molecular weight.

Owner:BIO INVIGOR CORP

Quasi-crystal abrasive paste applicable to surface mechanical finishing of soft metals

InactiveCN103242803AImprove smoothnessReduce wearOther chemical processesPolishing compositions with abrasivesSurface finishGranularity

The invention discloses a quasi-crystal abrasive paste applicable to the surface mechanical finishing of soft metals, and the adopted abrasive material thereof is a quasi-crystal alloy powder material. The quasi-crystal abrasive paste comprises a quasi-crystal alloy and related phase materials; the granularity of a powdered abrasive material is less than or equal to 50mu m; the mass percentage of the quasi-crystal powdered abrasive material in the abrasive paste is 1-90%, and the balance of the abrasive paste refers to abradant auxiliary materials such as oil-soluble or water-soluble pastes and the like. According to the invention, based on the unique grinding behavior and mechanism, the abrasive paste has an efficient mechanical finishing and defect repair capacity to the surfaces of soft metals / alloy specimens or workpieces; and compared with traditional abrasive materials, a surface finishing effect required by workpieces can be achieved efficiently, and the erosion amount is low, therefore, the abrasive paste is applicable to the surface finishing of high-precision workpieces, namely, the dimensional accuracy of workpieces can be kept while the surface quality of workpieces is satisfied. The abrasive paste disclosed by the invention has the characteristics of high stability, high liquidity, no adhesiveness and easiness for cleaning, therefore, the abrasive paste is an ideal grinding material for the mechanical finishing of soft materials.

Owner:DALIAN UNIV OF TECH

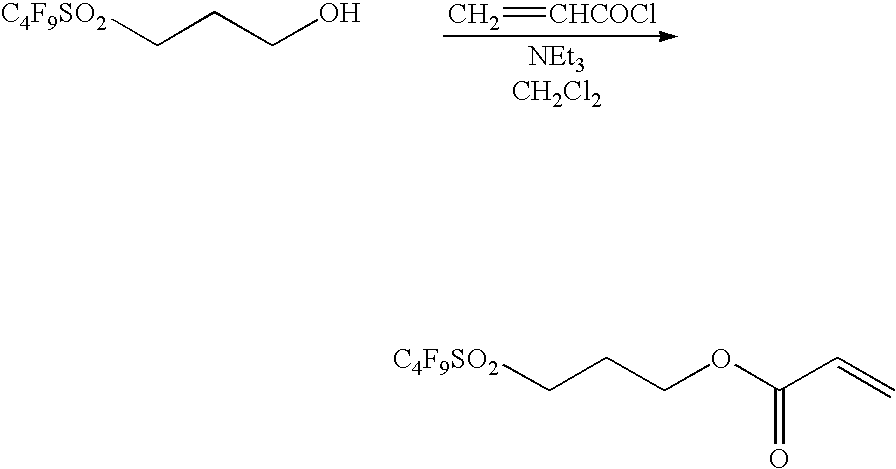

Method for manufacturing fluorine-containing polymer

ActiveUS20150191869A1Increase resistanceLower free energySynthetic resin layered productsLiquid repellent fibresPolymer scienceFluorine containing

Provided is a water and oil repellent composition that provides water and oil repellency that is excellent for base materials such as textile products, and is excellent for preventing adhesion of polymers on rolls during processing. The present invention involves a method for manufacturing a fluorine-containing polymer comprising a first polymer formed from a first monomer, and a second polymer formed from a second monomer. The manufacturing method includes: (I) a step for obtaining the first polymer by polymerizing the first monomer; and (II) a step for obtaining the second polymer by preparing and polymerizing the second monomer in the presence of the first polymer. The first monomer and / or the second monomer includes a fluorine-containing monomer (a), and both the first monomer and the second monomer include a halogenated olefin (b).

Owner:DAIKIN IND LTD +1

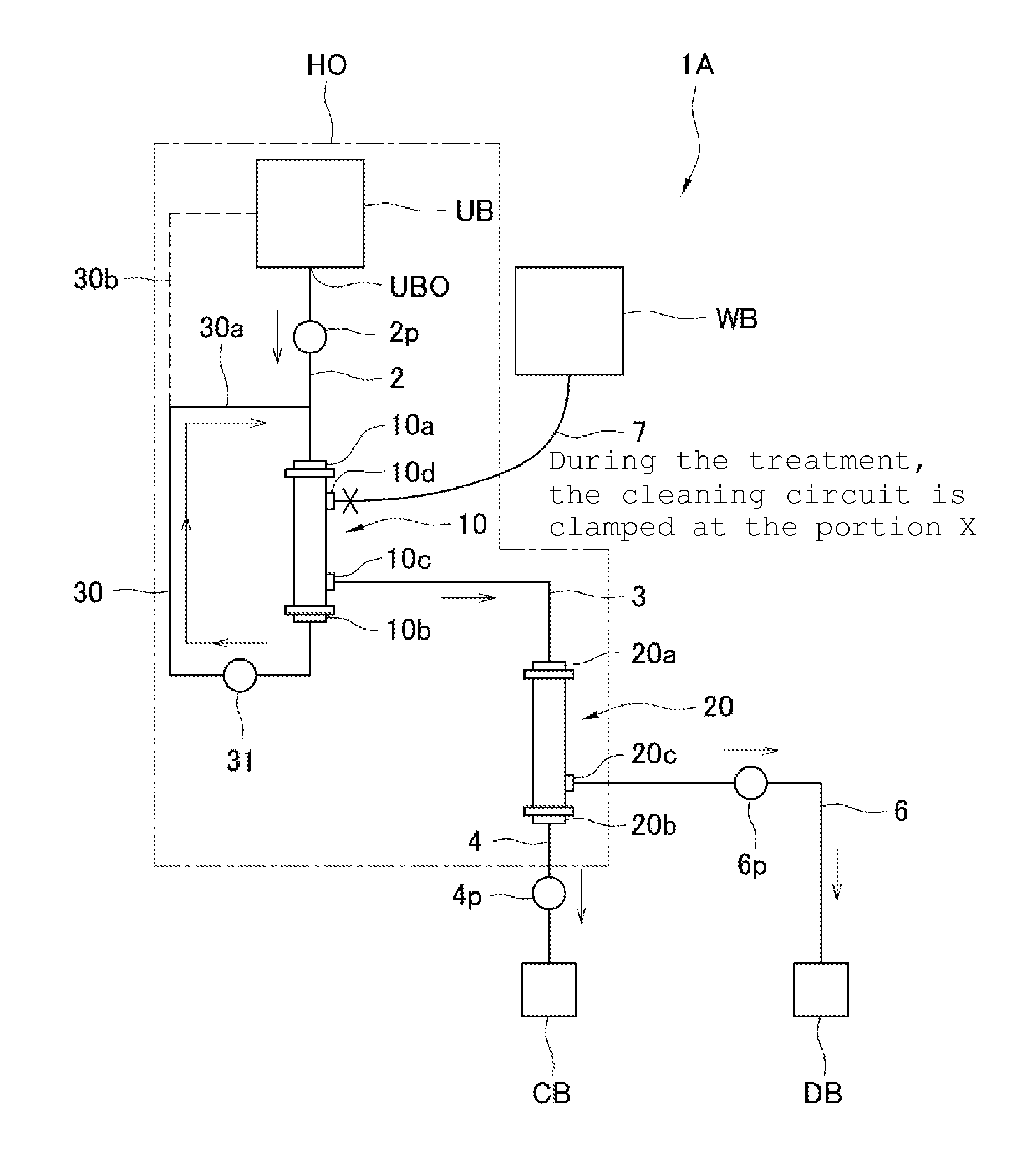

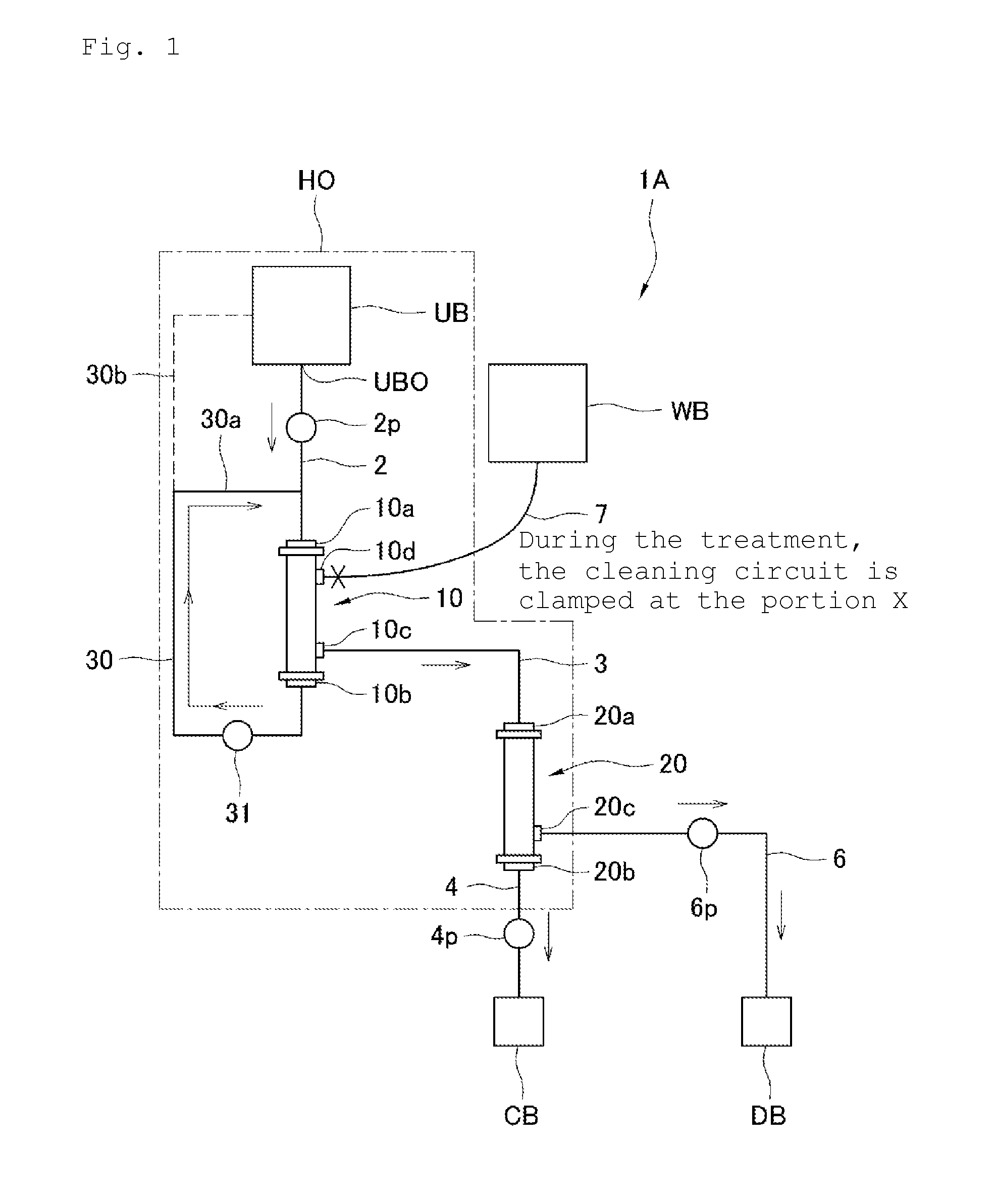

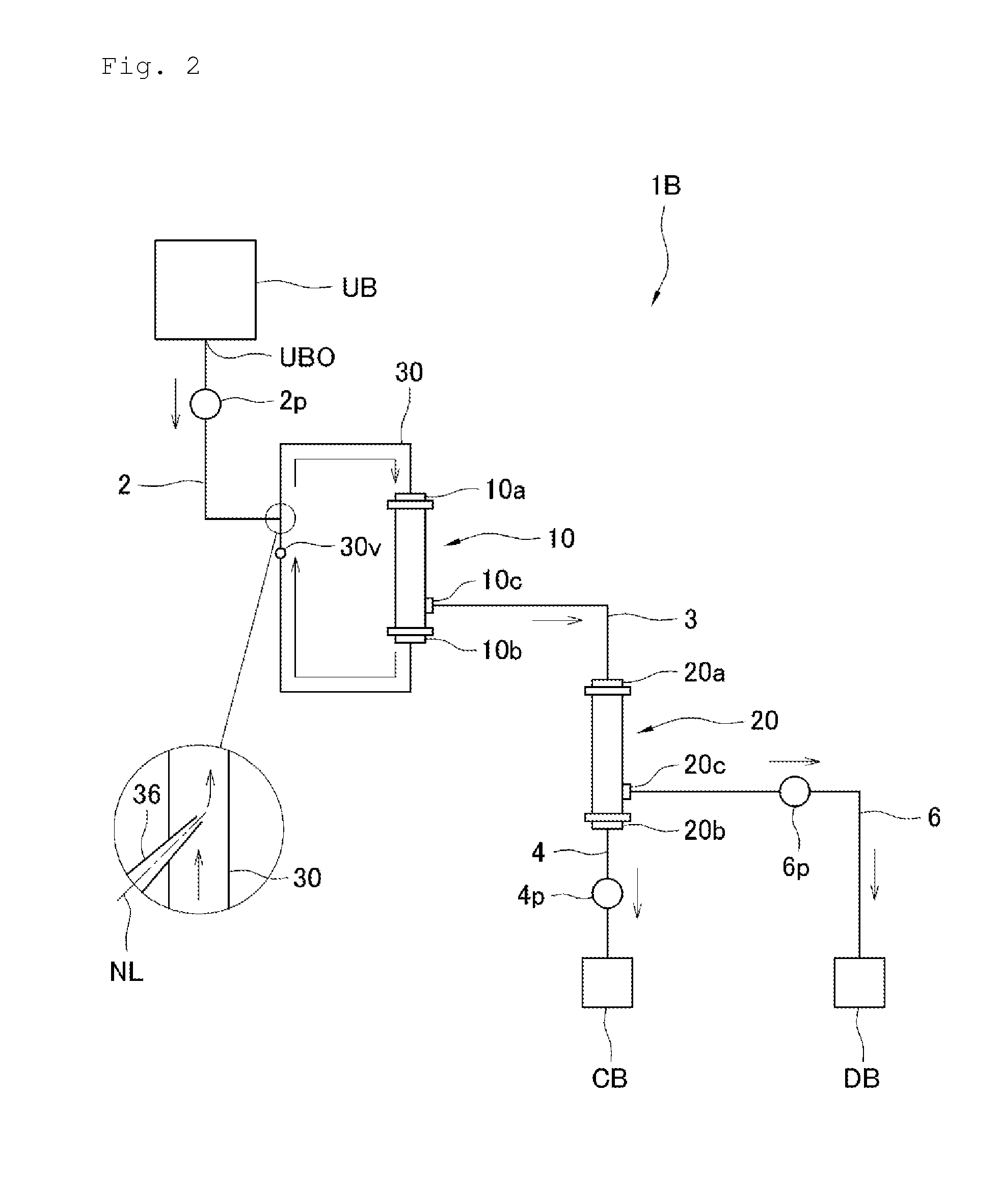

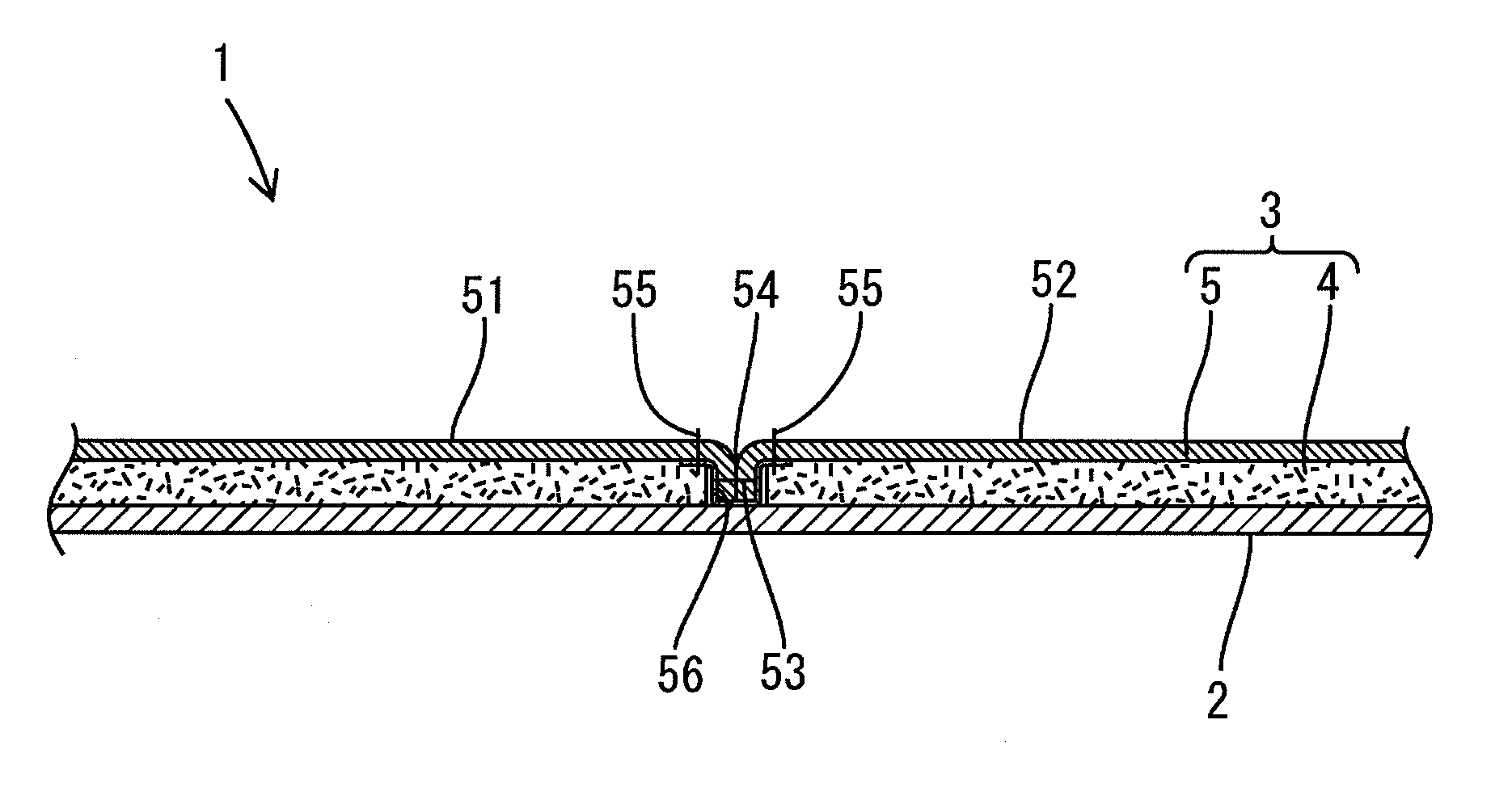

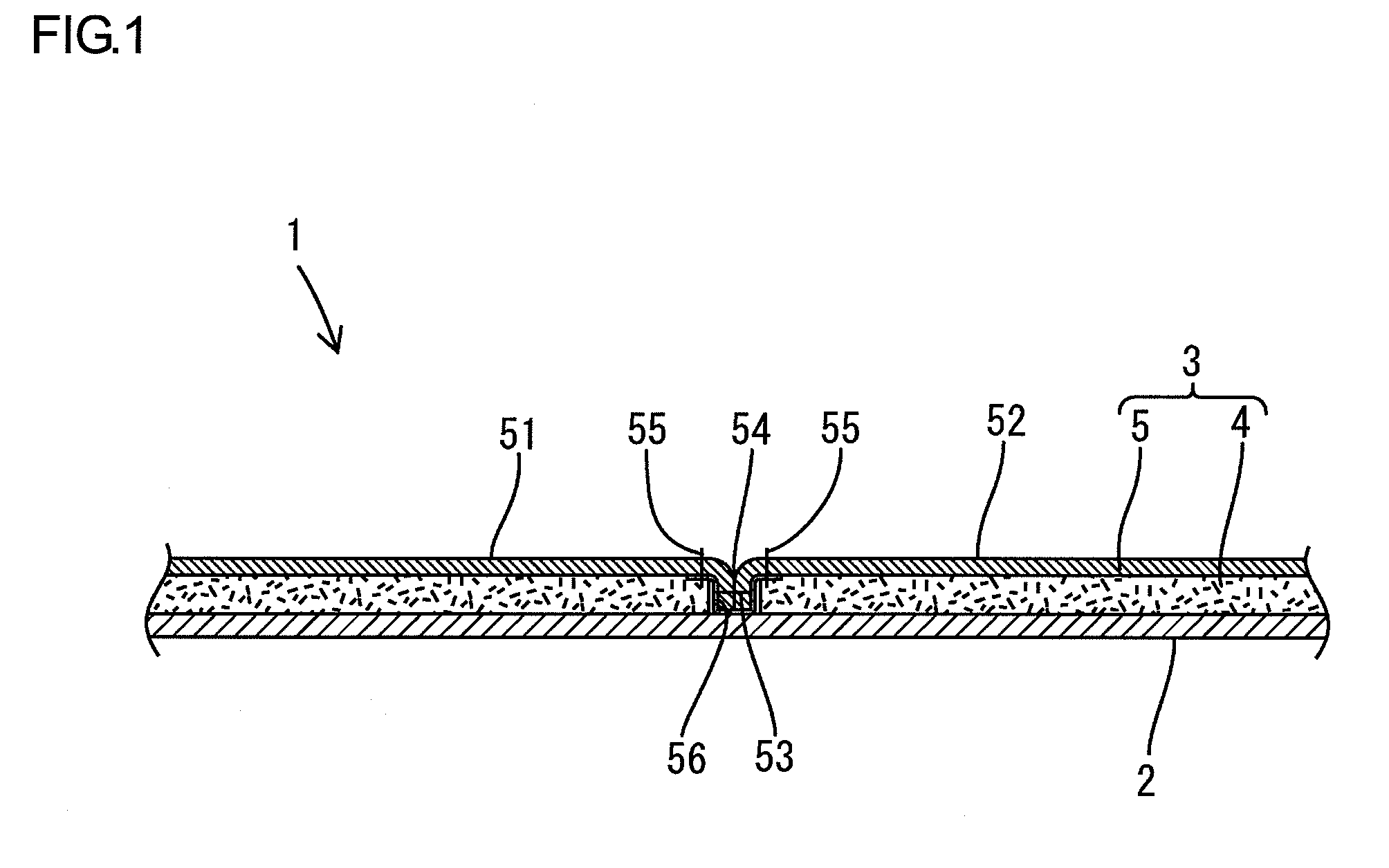

Stock solution concentrating device, stock solution treatment device, and circulation-type treatment device

InactiveUS20160022895A1Avoid treatmentImprove efficiencySemi-permeable membranesHaemofiltrationAscitic fluidPleural fluid

Provided are a stock solution concentrating device, a stock solution treatment device and a circulation-type treatment device that can prevent the deposition of cells and the like on a filtration member and that can continuously filter and concentrate a stock solution such as pleural and ascitic fluid or blood plasma. The stock solution concentrating device concentrates a stock solution such as pleural and ascitic fluid or blood plasma to form a concentrated solution, and is equipped with: a filter (10) having a filtration member that filters the stock solution; a concentrator (20) to which the filtrate which has been filtered is supplied, and which concentrates the filtrate to form a concentrated solution; and a stock solution supply unit that supplies the stock solution to the filter (10). The stock solution supply unit has a supply amount adjustment function for adjusting the amount of the stock solution supplied to the filter.

Owner:UNIVERSITY OF TOKUSHIMA +1

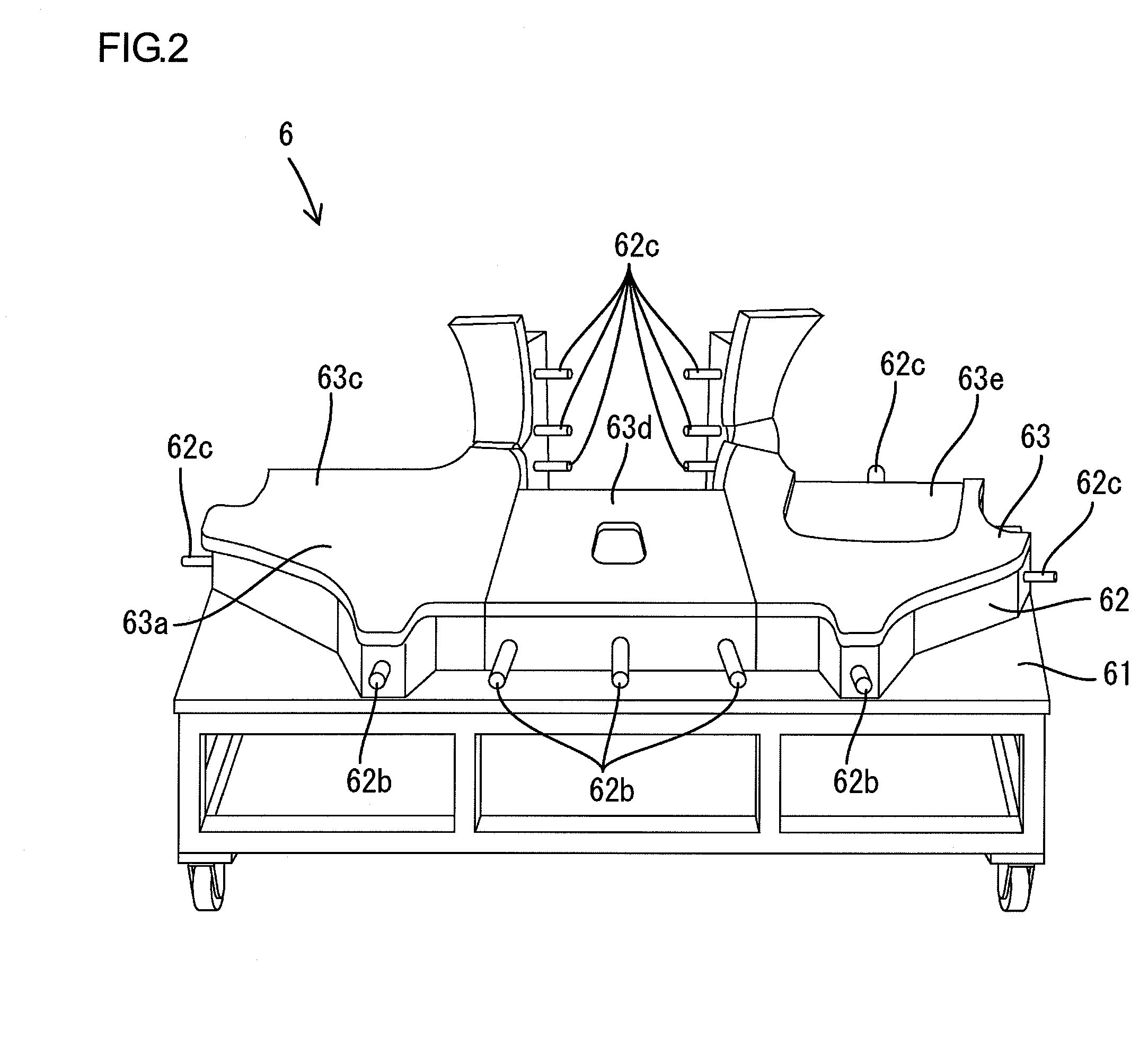

Manufacturing method of a vehicular interior part

ActiveUS20100193108A1Good appearanceDecrease dimensionSynthetic resin layered productsVehicle componentsBiomedical engineeringSurface shape

A manufacturing method of a vehicular interior part in which a cover member is attached to a base material, comprising the steps of forming a skin material, comprising a plurality of skin pieces sewn together, in accordance with a surface shape of said base material; and forming said cover member by attaching a soft material to a backside of said skin material after forming said skin material in accordance with said surface shape of said base material; and attaching said cover member to said base material.

Owner:TOYOTA BOSHOKU KK

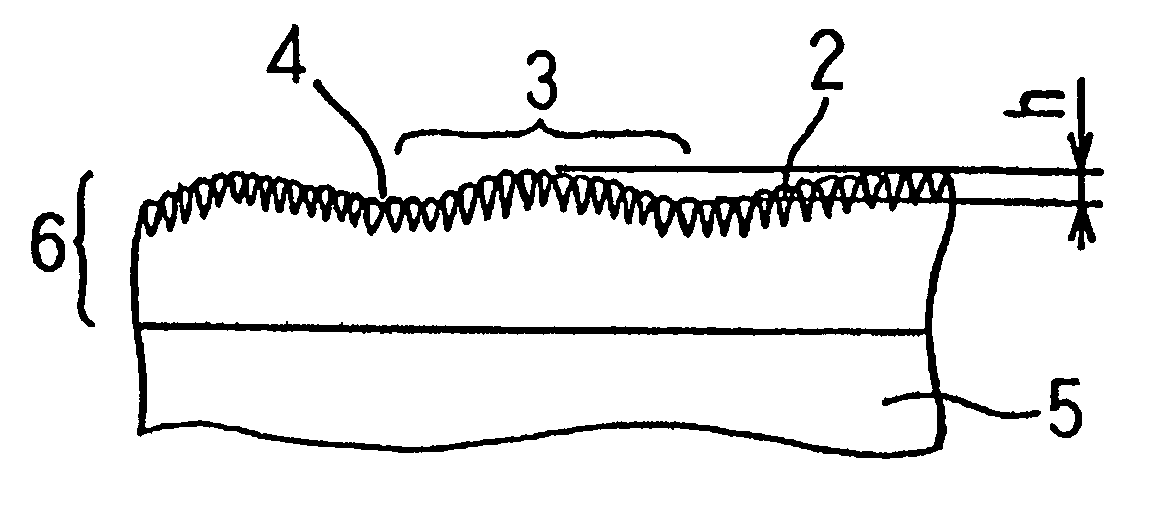

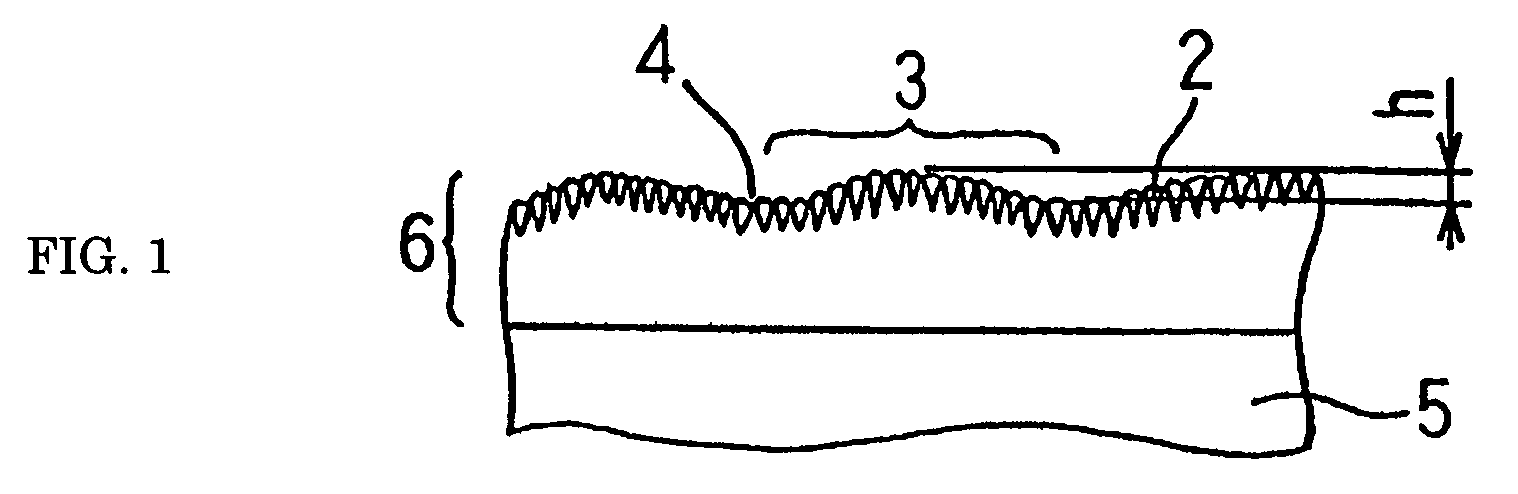

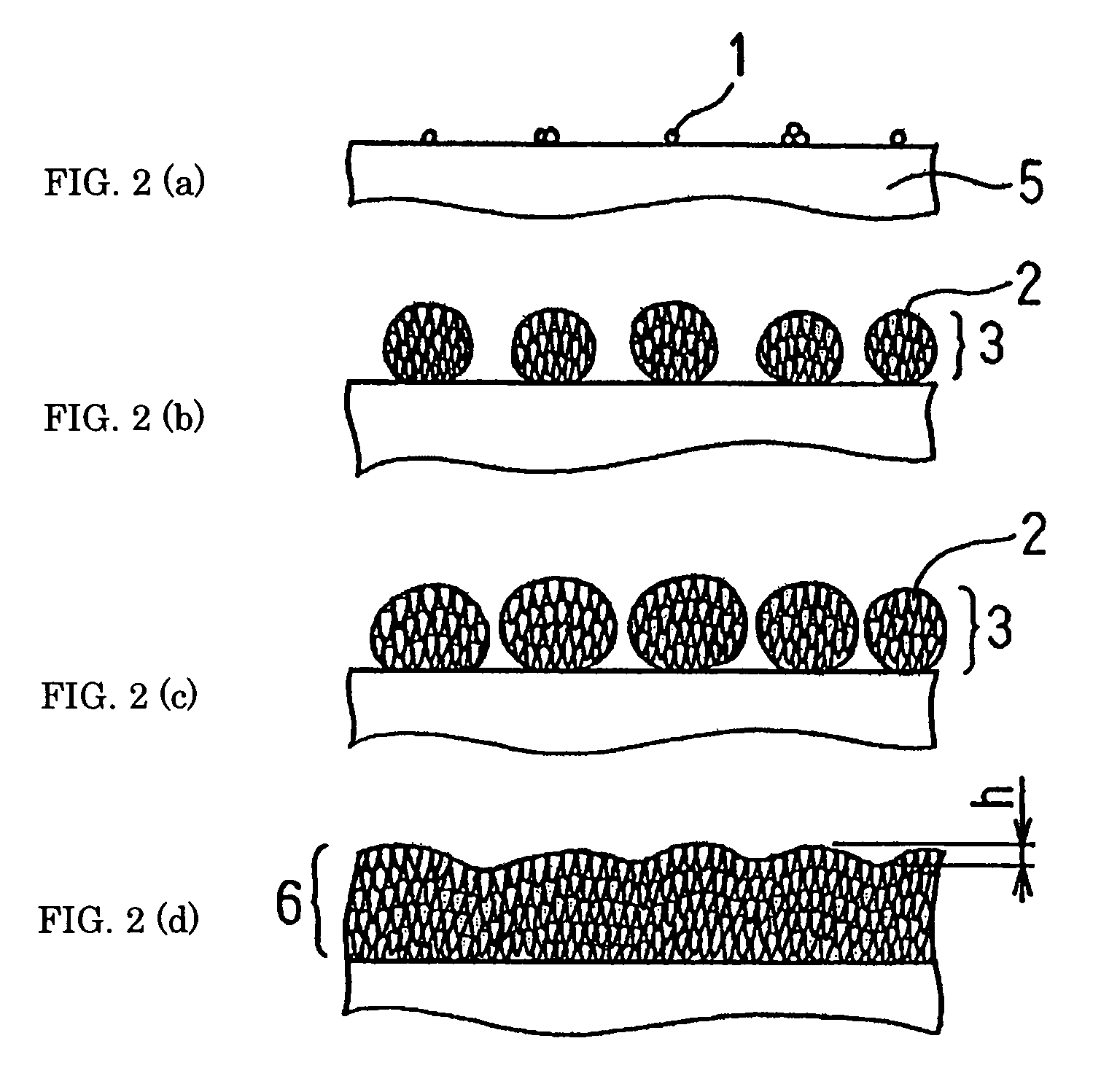

Diamond film coated tool and process for producing the same

ActiveUS7883775B2Improved in working precision and tool lifeEasy to participateThread cutting toolsPretreated surfacesMicrometerSurface roughness

The invention provides a diamond coated tool having an excellent cutting performance, wear resistance, adhesion resistance and work surface roughness in combination and a method of producing such a tool.A diamond coated tool comprising a substrate and a diamond coating formed on the surface of the substrate, wherein said substrate is made of a cemented carbide or a cermet, diamond grains constituting a growth surface of said diamond coating has an average grain size of about 1.5 micrometers or below, said diamond coating has a thickness ranging from about 0.1 micrometer to 20 micrometers, and said diamond coating has an average surface roughness Ra ranging from about 0.01 micrometer to 0.2 micrometer. Such a diamond coated tool can be obtained by carburizing the substrate consisting of a cemented carbide or a cermet, and growing up a diamond coating thereon.

Owner:SUMITOMO ELECTRIC IND LTD

Treatment for paper and method for treatment of paper

InactiveUS20090155600A1Increase resistanceLower free energyOther chemical processesWater-repelling agents additionRepeat unitCarbon atom

A treatment for paper, containing (A) a fluorine-containing polymer comprising repeating units derived from a fluorine-containing monomer (a) represented by the general formula (I): CH2═C(—X)—C(═O)—Y—(CH2)m-Z-(CH2)n—Rf (I) wherein X is hydrogen, methyl, fluoro, chloro, CFX1X2 (wherein X1 and X2 are each hydrogen, fluoro, or chloro), or the like; Y is —O— or —NH—; Z is —S—, —SO—, or —SO2—; Rf is fluoroalkyl having 1 to 6 carbon atoms; m is 1 to 10; and n is 0 to 10.

Owner:DAIKIN IND LTD

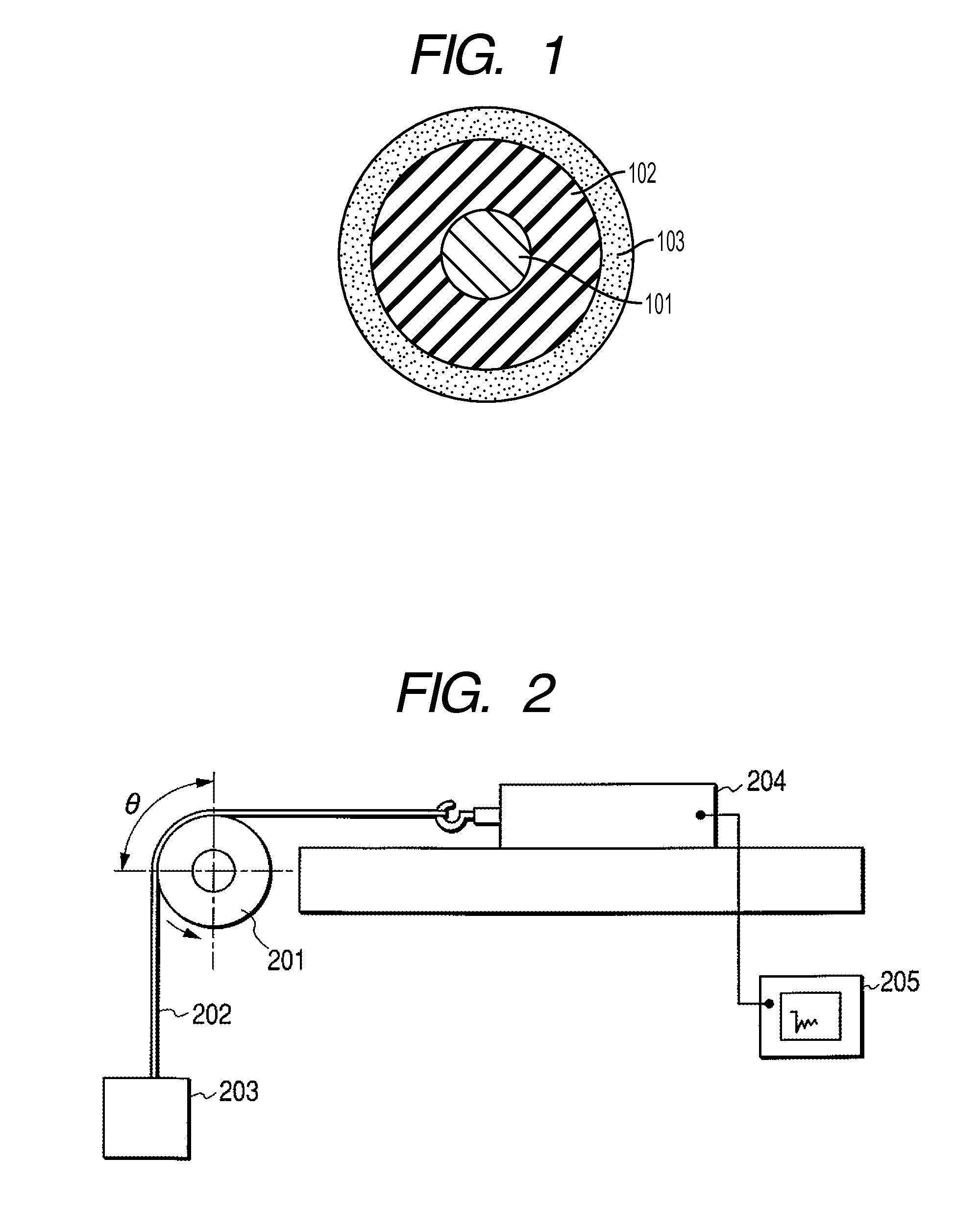

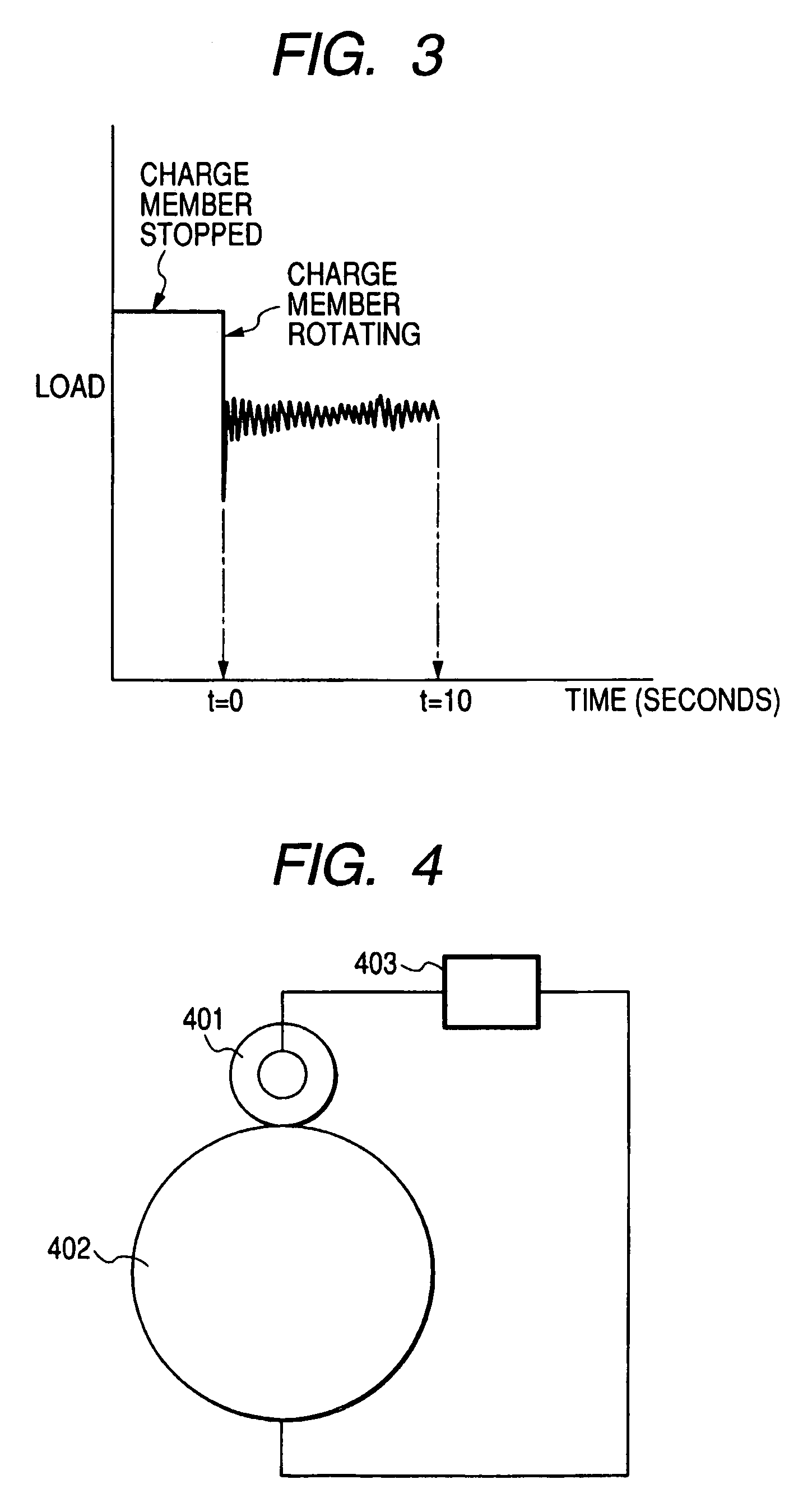

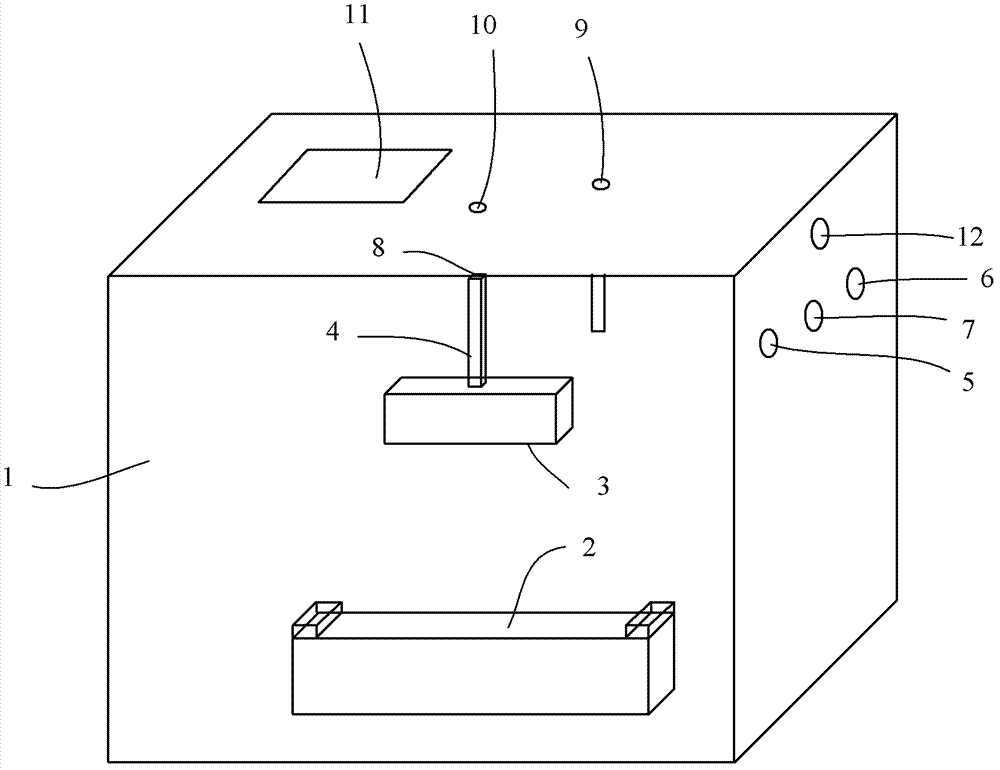

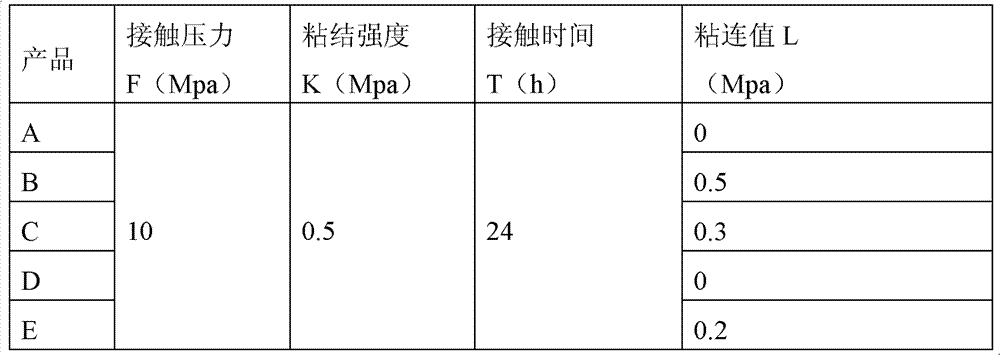

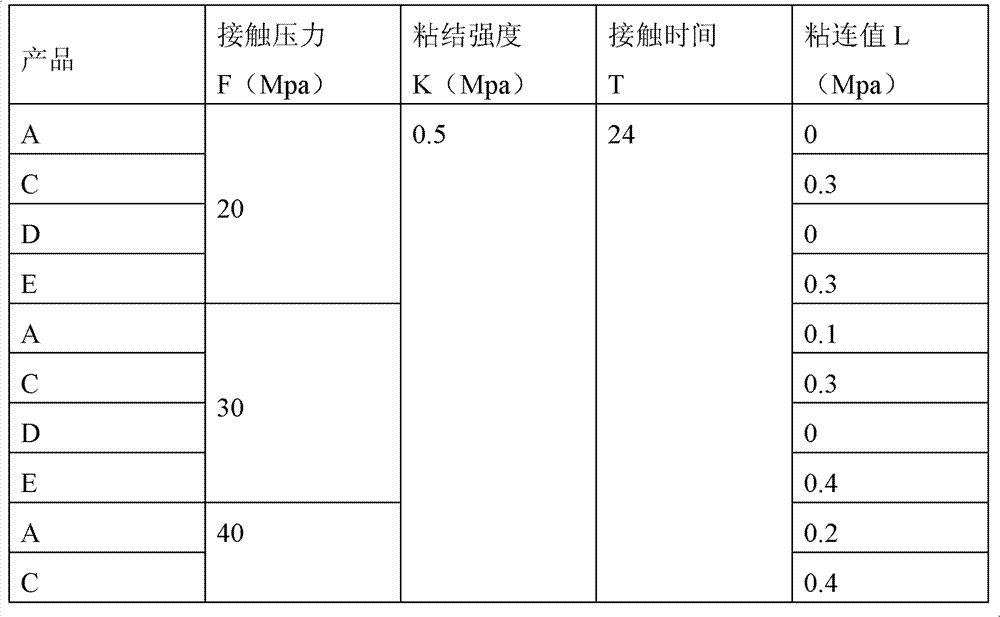

Device and method for determining surface tenacity of material

ActiveCN103364337ACompensate and improve anti-adhesionReduce easy adhesionUsing mechanical meansMaterial analysisTest sampleControl theory

The invention relates to a device and a method for determining the surface tenacity of a material. The device comprises a test environment, a first sample fixing bed, a second sample fixing bed, a temperature controller, a humidity regulator, a pressurization controller and a pressurization regulator, wherein the first sample fixing bed is arranged in the test environment and used for fixing a first test workpiece; the second sample fixing bed is arranged in the test environment, used for fixing a second test workpiece and opposite to the first sample fixing bed; the temperature controller is coupled with the test environment and is a device for controlling the temperature setting of the test environment; the humidity regulator is coupled with the test environment and is a device for controlling the humidity setting of the test environment; the pressurization controller is arranged in the test environment, and the pressure output end of the pressurization controller is coupled with the first sample fixing bed; the pressurization regulator is coupled with the pressurization controller so as to regulate the output pressure of the pressurization controller. By separating tensile forces (namely, tenacity L) of two test samples, the tenacity between two adjacent materials can be judged.

Owner:NIPPON PAINT CHINA

Cooked instant noodles and making method thereof

InactiveCN109363082ATaste is smooth and strongGreat tasteFood ingredient as mouthfeel improving agentPhosphateDeep frying

The invention relates to cooked instant noodles. The cooked instant noodles comprise the components in parts by weight of 45-65 parts of wheat flour, 15-30 parts of acetate modified starch, 3-10 partsof vital wheat gluten, 0.2-0.5 part of sodium alginate, 1-2 parts of table salt, 0.1-0.25 part of sodium carbonate, 0.3-0.6 part of composite phosphate, 0.1-0.2 part of propylene glycol alginate, 20-30 parts of water, and 0.0005-0.0015 part of edible pigment. The noodles disclosed by the invention are nutritive, healthy, free from deep frying, and smooth and chewy in mouth feel, and have the mouth feel of cooked noodles, after being soaked. Common instant noodles are large in differences in the eating manner of soaking and cooking due to secondary gelatinizing in the cooking process. A steaming manner and a cooking manner are combined for use, and the cooking process is favorable for absorption of moisture by wrappers, so that the gelatinizing degree is increased. The technique breaks through and reduces the mouth feel differences between different eating methods. The instant noodles disclosed by the invention have the advantages of being convenient, quick, and good in mouth feel.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com