Cooked instant noodles and making method thereof

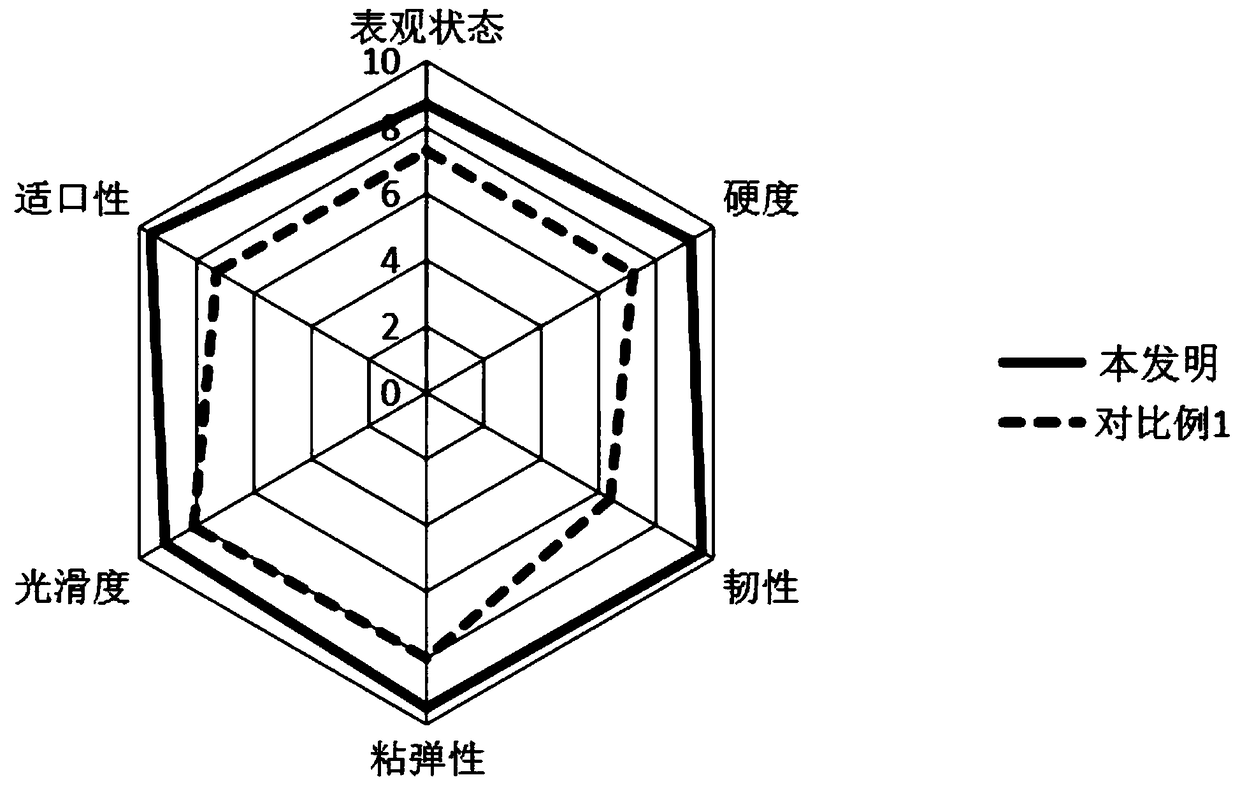

A technology for noodles and instant food, applied in the direction of food science, food ingredients as taste improvers, etc., can solve the problems of undiscovered patent publications, unable to form tiny holes, unable to fully gelatinize noodles, etc., and achieves good dispersibility, The effect of quick rehydration and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of cooking instant noodles, its composition and parts by weight are as follows:

[0027] 45-65 parts of wheat flour, 15-30 parts of acetate modified starch, 3-10 parts of gluten powder, 0.2-0.5 parts of sodium alginate, 1-2 parts of table salt, 0.1-0.25 parts of soda ash, 0.3-0.6 parts of compound phosphate 0.1-0.2 parts of propylene glycol alginate, 20-30 parts of water, and 0.0005-0.0015 parts of food coloring.

[0028] Preferably, the composite phosphate includes sodium tripolyphosphate, sodium hexametaphosphate, and sodium pyrophosphate, and the mass ratio of the three is 2-4:2-4:1.

[0029] Preferably, the food coloring is gardenia yellow.

[0030] A preparation method for cooking instant noodles as described above, the steps are as follows:

[0031] ⑴ Kneading noodles: Take table salt and dissolve it in water; mix the rest of the raw materials in the dough mixer and dry mix them for 2-5 minutes, then add salt water, first stir quickly for 5-8 minutes, and...

Embodiment 2

[0037] A kind of cooking instant noodles, its composition and parts by weight are as follows:

[0038] 50 parts of wheat flour, 20 parts of acetic acidified modified starch, 5 parts of gluten powder, 0.2 parts of sodium alginate, 2 parts of table salt, 0.2 parts of soda ash, 0.5 parts of compound phosphate, 0.2 parts of propylene glycol alginate, 30 parts of water, edible Pigment 0.0005 parts;

[0039] Wherein, the compound phosphate includes sodium tripolyphosphate, sodium hexametaphosphate, and sodium pyrophosphate in a ratio of 2:2:1;

[0040] Wherein, the food coloring is gardenia yellow.

[0041] A preparation method for cooking instant noodles as described above, the steps are as follows:

[0042] (1) Kneading dough: take the above-mentioned salt and dissolve it in water; put the rest of the raw materials into the kneading machine and dry mix for 3 minutes, then add salt water, stir quickly for 5 minutes, and then stir slowly for 15 minutes to make it evenly mixed int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com