Patents

Literature

551 results about "Propylene glycol alginate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propylene glycol alginate (PGA) is an emulsifier, stabilizer, and thickener used in food products. It is a food additive with E number E405. Chemically, propylene glycol alginate is an ester of alginic acid, which is derived from kelp. Some of the carboxyl groups are esterified with propylene glycol, some are neutralized with an appropriate alkali, and some remain free.

Stabilized Glycosaminoglycan Preparations and Related Methods

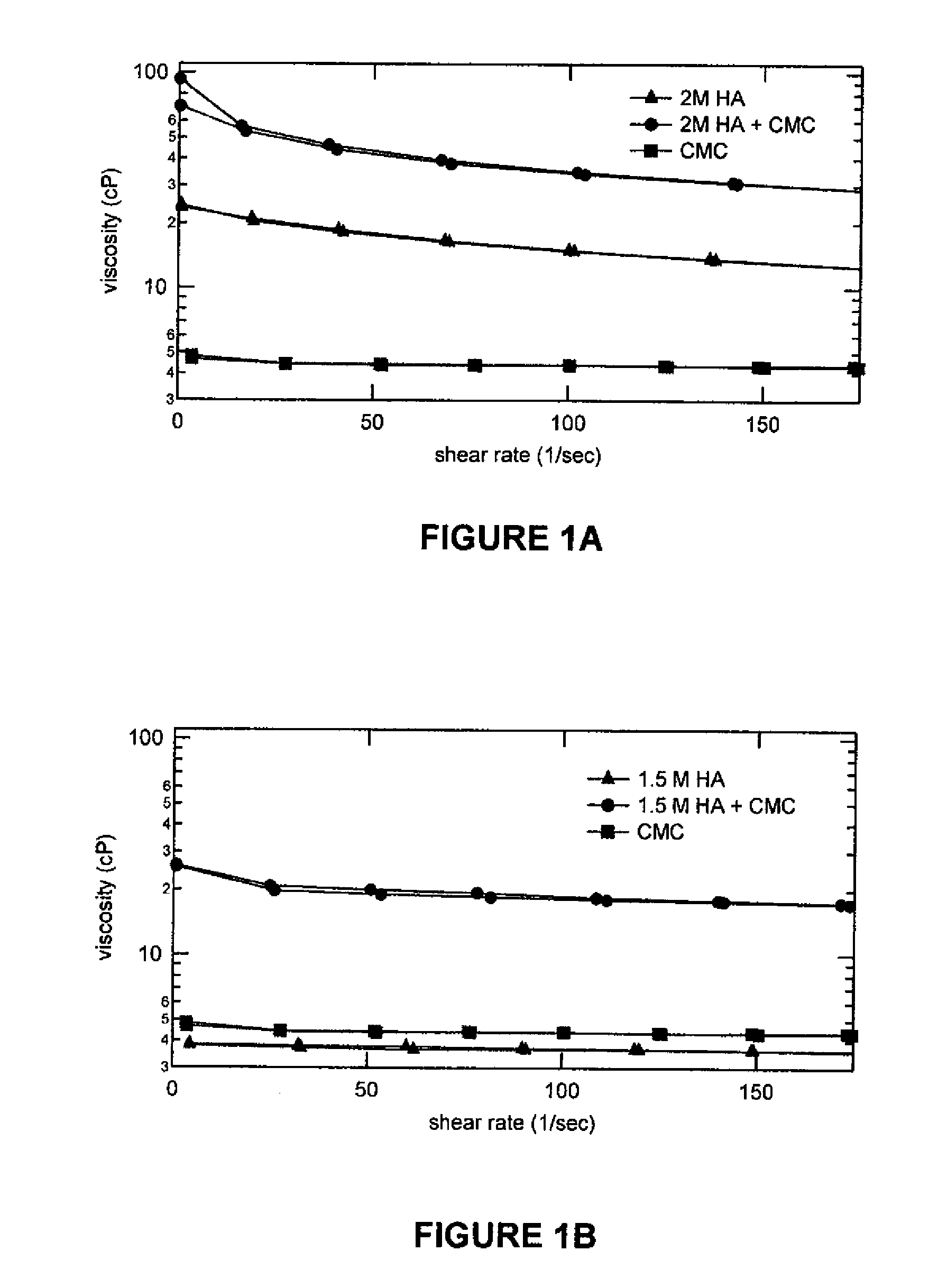

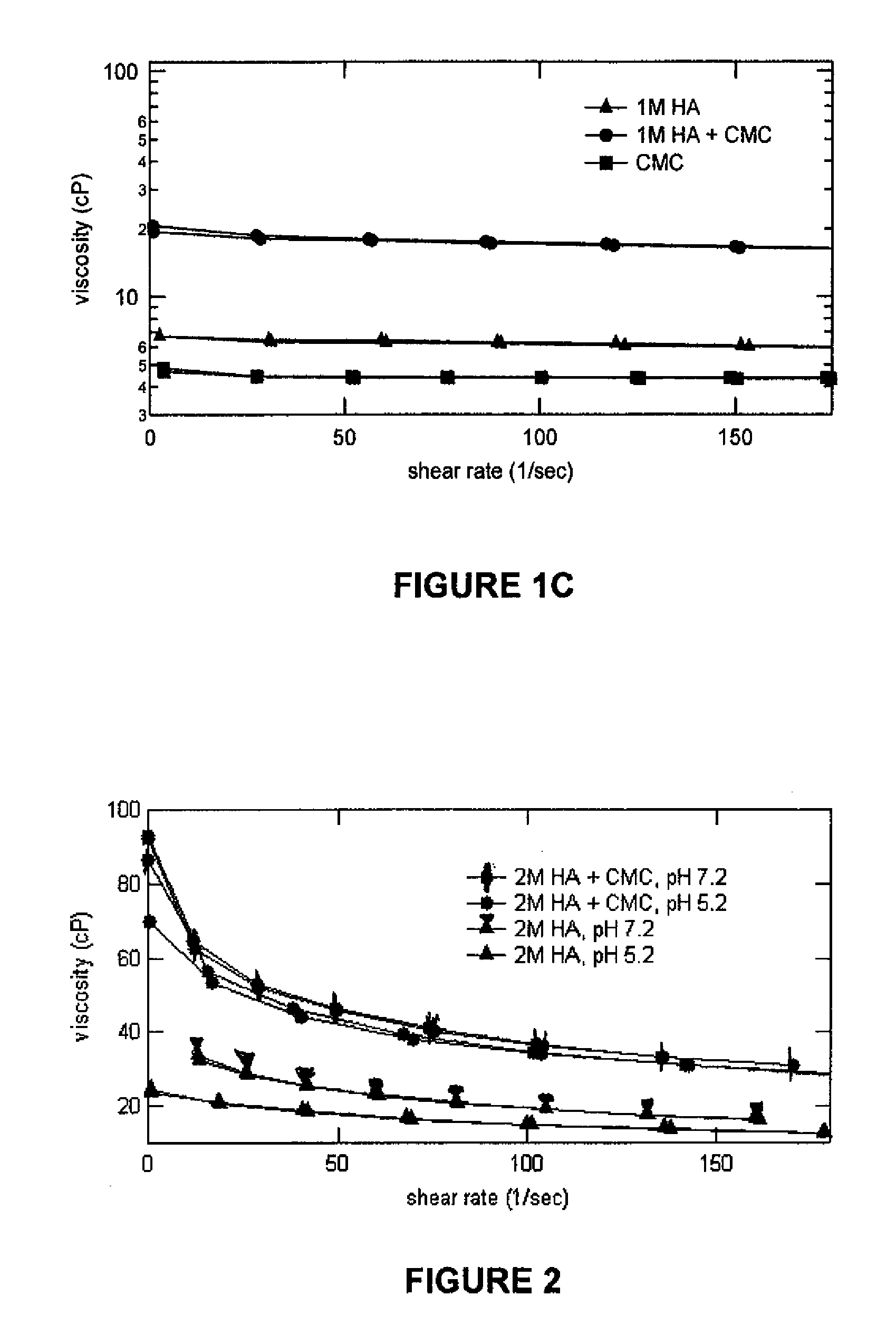

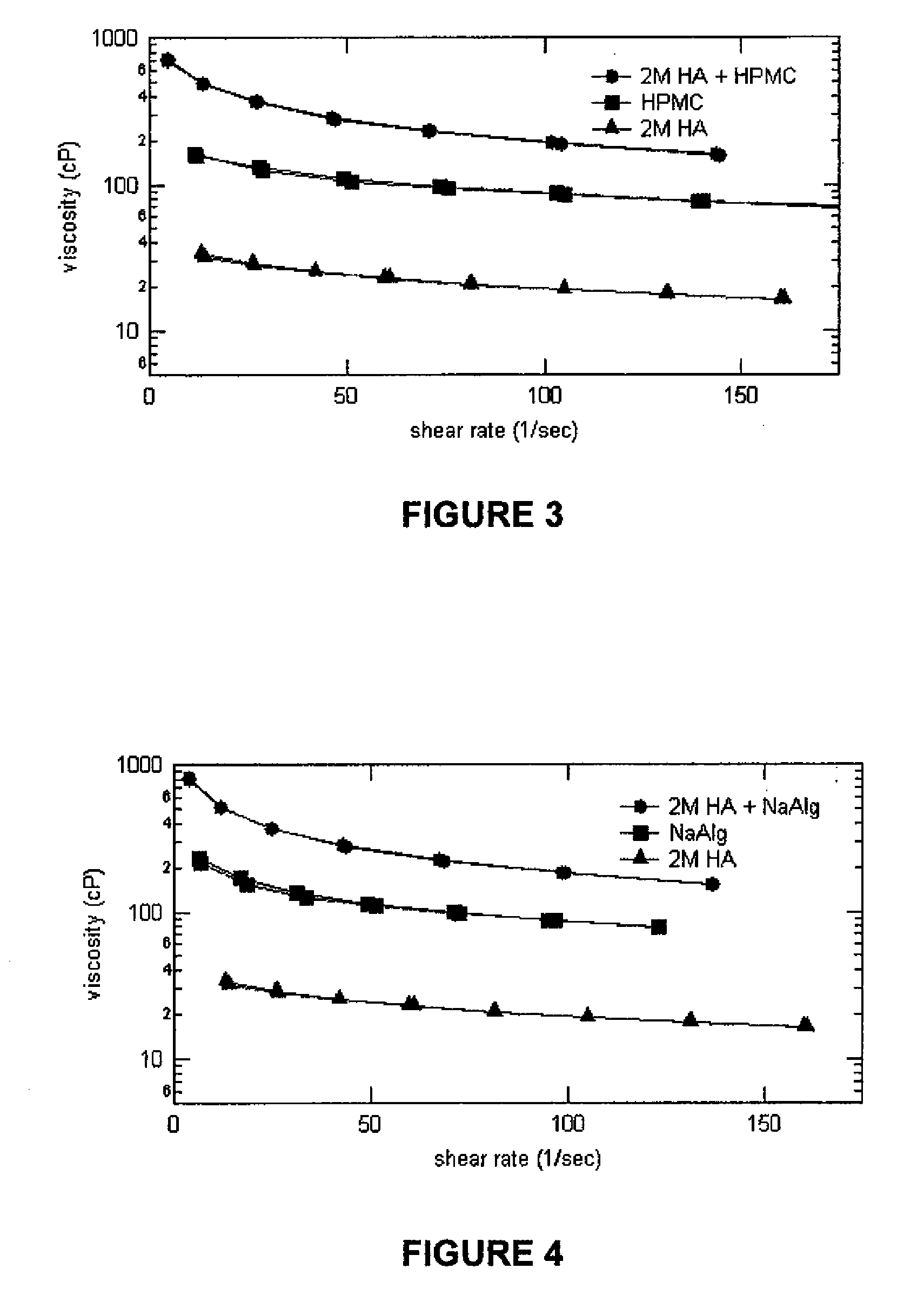

Compositions comprising a glycosaminoglycan (e.g., a hyaluronan, hyaluronic acid, hyaluronate, sodium hyaluronate, dermatan sulfate, karatan sulfate, chondroitin 6-sulfate, heparin, etc.) in combination with at least one component selected from; i) polyglycols (e.g., polyethylene glycol), ii) long chain hydroxy polyanionic polysaccharides (e.g., dextran, sodium alginate, alginic acid, propylene glycol alginate, carboxymethyl cellulose and carboxyethyl cellulose, hydroxyl ethyl starch, hydroxyl propyl methyl cellulose, hydroxy propyl ethyl cellulose, hydroxy propyl cellulose, methyl cellulose, polylysine, polyhistidine, polyhydroxy proline, poly ornithine, polyvinyl pyrolidone, polyvinyl alcohol, chitosan, etc.) and iii) long chain Nitrogen containing polymers (e.g., Polylysine, Polyvinylpyrrolidone, and polyvinyl alcohol). The invention also includes methods for using such compositions (e.g., as substance delivery materials, tissue fillers or bulking agents, as moistening or hydrating agents, etc.)

Owner:S K PHARMA INC

Capsule based drug delivery system

InactiveUS6352719B1Robust mechanical propertyGood oxygen barrierPowder deliveryOrganic non-active ingredientsMethyl celluloseBiomedical engineering

A soft capsule comprising a wall derived from a multilayer film that comprises three layers. The layers are an innermost sealing plasticized hydroxypropyl methyl cellulose, an adhesion promoting layer of propylene glycol alginate and a barrier layer of sodium alginate.

Owner:BIOPROGRESS TECH INT

Fermented milk beverage containing peanut, lotus root and pawpaw and production method thereof

The invention relates to the field of liquid milk, in particular relating to a fermented milk beverage containing peanut, lotus root and pawpaw and a production method thereof. On the basis of 100 parts of fermented milk beverage by weight, the fermented milk beverage containing peanut, lotus root and pawpaw comprises: 30-80 parts of liquid milk by weight, 0.004-0.007 part of leaven by weight, 3.5-8.0 parts of sweet substance by weight, 0.2-0.7 part of acidity regulator by weight, 0.1-1.5 parts of stabilizing agent by weight, 1-30 parts of peanut paste by weight, 1-10 parts of lotus root powder by weight, 1-5 parts of pawpaw primary paste by weight and the balance water, wherein the stabilizing agent is composed of thickening agent and / or emulsifier, and the thickening agent contains 0.1-0.25 part of high acyl pectin and propylene glycol alginate. The product of the invention has refreshing and smooth taste when being drunk and contains special fragrance of peanut, lotus root and pawpaw products. Tests prove that the product has no layering phenomenon or severe fat flotation in the storage and placement process within the 6-month quality guarantee period. Thus, the product of theinvention has favorable stability.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Set yoghurt and preparation method thereof

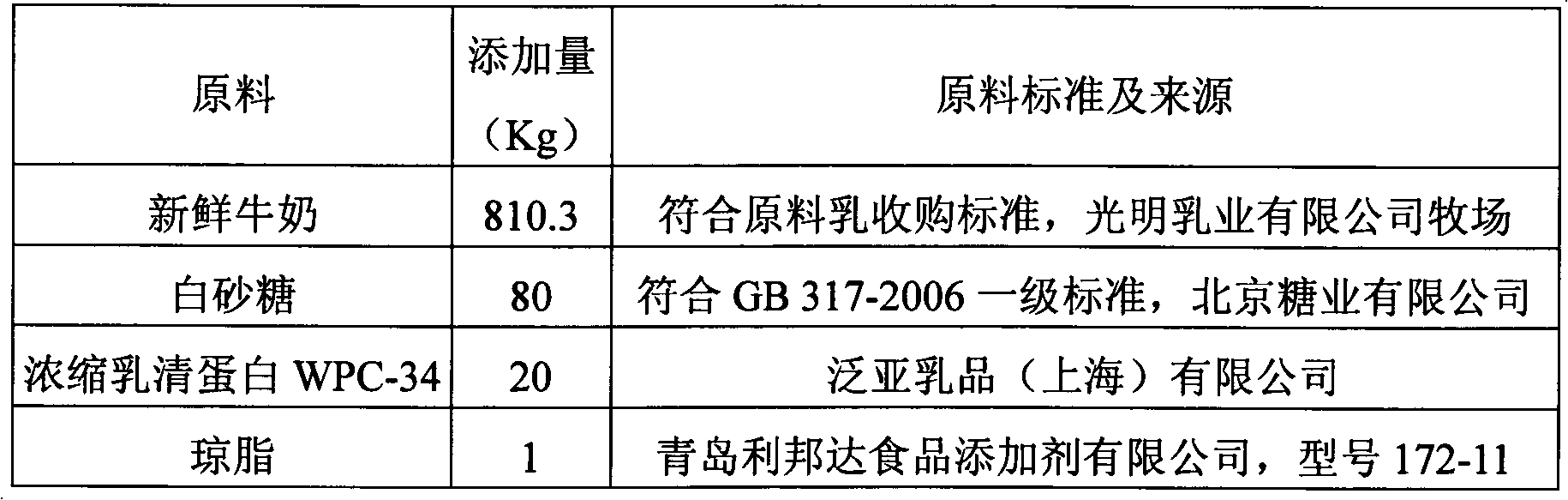

The invention discloses set yoghurt and a preparation method thereof. The set yoghurt comprises a fermentation agent and the following components in part by mass: 799.9 to 960 parts of milk, 0.3 to 90 parts of sweetening agent, 9 to 11 parts of food gum, 10 to 15 parts of modified starch and 5 to 25 parts of whey protein concentrate, wherein the food gum is one or more of gelatin, pectin, propylene glycol alginate and agar. The preparation method comprises the following steps of: 1) mixing the milk, the sweetening agent, the food gum, the modified starch and the whey protein concentrate, and uniformly stirring to form a feed liquid; 2) homogenizing, sterilizing, cooling, inoculating the fermentation agent, and fermenting; and 3) filling, cooling, and after-fermenting until yoghurt is solidified to obtain the set yoghurt. The set yoghurt is high in uniformity, and is in a more exquisite microstructure state and a solidified paste state. According to the preparation method, the industrialized and large-scale production can be performed by using the conventional stirred yoghurt production line, space is not required to be occupied additionally, and production cycle is short.

Owner:BRIGHT DAIRY & FOOD

Edible PGA coating composition

InactiveUS20050095272A1Low viscosityConfectioneryStarch adhesivesImmediate releaseBULK ACTIVE INGREDIENT

An edible, hardenable coating composition is disclosed which comprises high levels of low viscosity propylene glycol alginate and a surfactant, which may additionally contain a filler, a pigment, and optionally a small amount of a secondary film former and / or a strengthening polymer. The coating composition of the present invention may be applied to pharmaceutical and veterinary solid dosage forms, confectionery, seeds, animal feed, fertilizers, pesticide tablets, and foods and provides an elegant prompt release coating which does not retard the release of active ingredients from the coated substrate.

Owner:FMC CORP

Alum-free starch noodles and sheet jelly as well as a preparation method thereof

ActiveCN102669605ANo loss of edible performanceSafe edible performanceFood preparationHydrogenPhospholipid

The invention discloses alum-free starch noodles and sheet jelly as well as a preparation method thereof. The product is prepared from starch, modified phospholipid and certain ancillary materials, wherein the ancillary materials comprise propylene glycol alginate, sticky corn starch, hydrogen potassium sorbate, esterified modified starch, sodium glycerophosphate and octenyl succinic starch ester. Compared with the original starch noodles containing alum, the alum-free starch noodles have the benefits that the prepared product is free from alum and safer, and the edible performance does not decrease obviously.

Owner:HEILONGJIANG GANGJIN FOOD TECH DEV

Purple sweet potato dried noodles and production method of purple sweet potato dried noodles

InactiveCN104366271AStay nourishedImprove smoothnessFood ingredientsFood dryingCarrageenanDietary fiber

The invention provides purple sweet potato dried noodles and a production method of the purple sweet potato dried noodles, relating to the field of food processing. The purple sweet potato dried noodles comprise the following raw materials in parts by weight: 60-85 parts of high protein flour, 10-30 parts of whole purple sweet potato flour, 0.5-1.0 part of table salt, 2-10 parts of vital gluten, 0-0.2 part of konjac powder and 0.02-0.04 part of improvers (including carrageenan, acetate starch, propylene glycol alginate and propanediol). The purple sweet potato dried noodles, which are produced from the whole purple sweet potato flour and the flour, preserve the original nutrients and functional components of purple sweet potatoes, are good in taste and bright in color and are nutritional, and the smoothness of the dried noodles is improved; the purple sweet potato dried noodles are rich in anthocyanin, dietary fiber and microelements such as calcium, iron, zinc and selenium which are essential elements of human bodies for resisting fatigue and ageing and enriching blood; the purple sweet potato dried noodles have a good heath function as well as the efficacies of nourishing and protecting the stomach as well as strengthening the kidneys and tonifying the deficiency after being taken for a long time.

Owner:ANHUI YANHU FLOUR

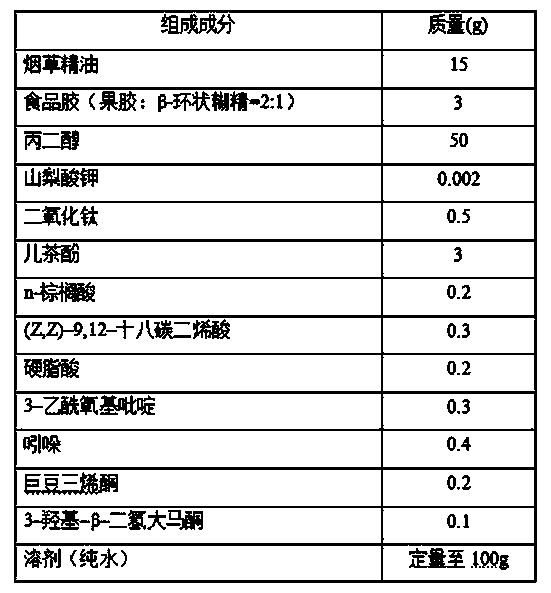

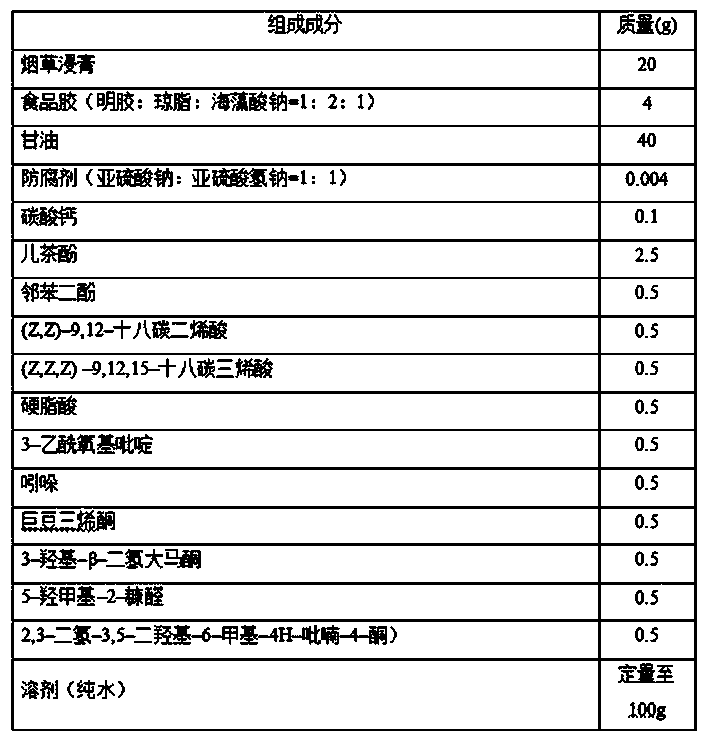

Solid state cartridge for electronic cigarettes and preparation method thereof

InactiveCN104382224ARich flue gas compositionPrevent volatilizationTobacco treatmentBiotechnologyCarrageenan

The invention relates to a solid state cartridge for electronic cigarettes. The solid state cartridge mainly includes the following ingredients according to percentage by weight: 0.1 to 20 percent of tobacco extract, 1 to 10 percent of food gum, 10 to 50 percent of humectant, 0.001 to 1 percent of preservative, 0.1 to 10 percent of heat-conducting filler, 0.1 to 10 percent of tobacco essence and flavor and 10 to 30 percent of water; the tobacco extract is one or combination of tobacco essential oil and tobacco extract; the food gum is one or combination of more than one of glutin, sodium caseinate, Arabic gum, sodium alginate, carrageenan, pectin, xanthan gum, Beta-cyclodextrine, sodium starch phosphate, sodium carboxymethyl starch, hydroxypropyl starch and propylene glycol alginate; the heat-conducting filler is one or combination of more than one of calcium carbonate, titanium dioxide, silicon carbide and carbon powder. The taste of the solid state cartridge is improved, the stability of the product is enhanced, and potential safety hazards caused by the leakage of electronic cigarette liquid are further prevented.

Owner:CHINA TOBACCO ZHEJIANG IND

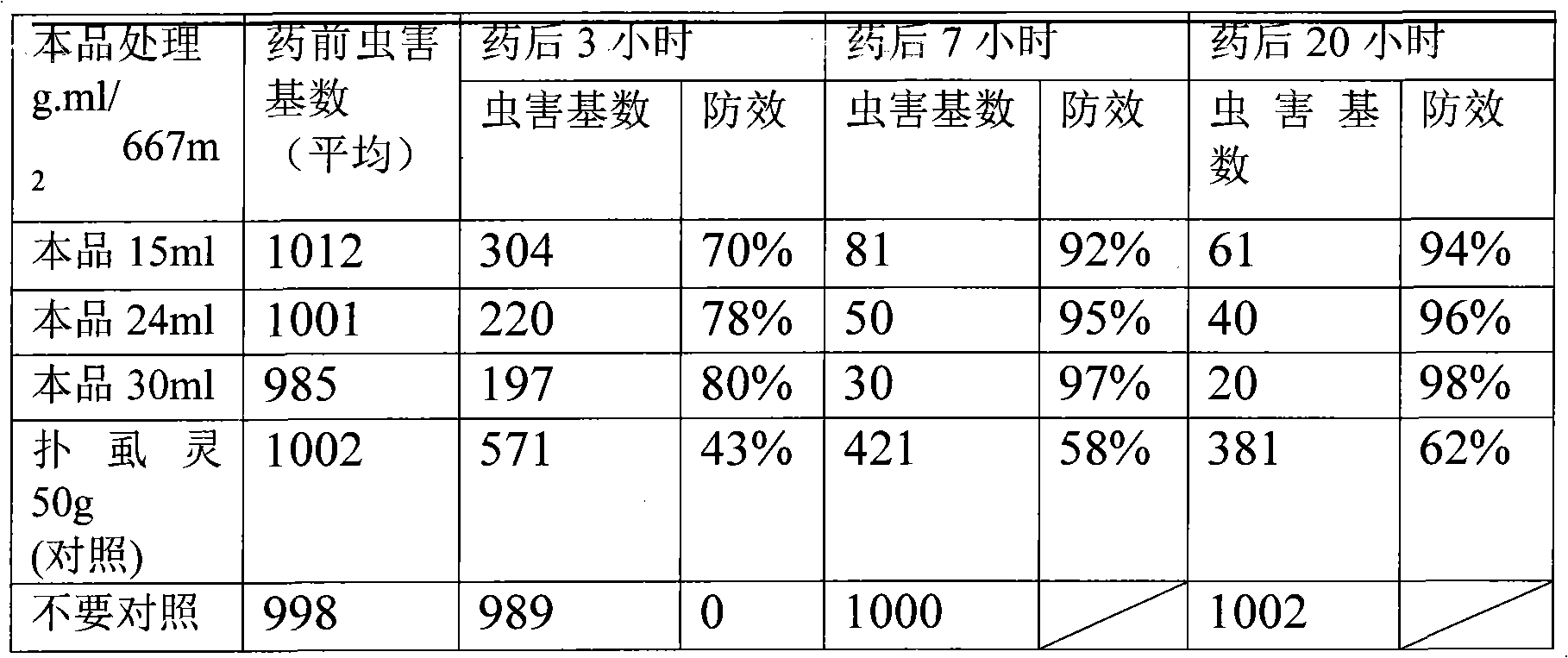

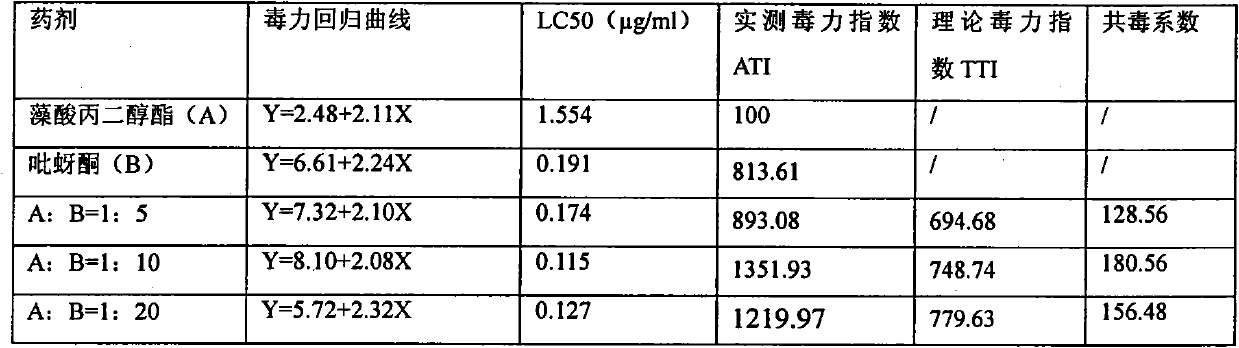

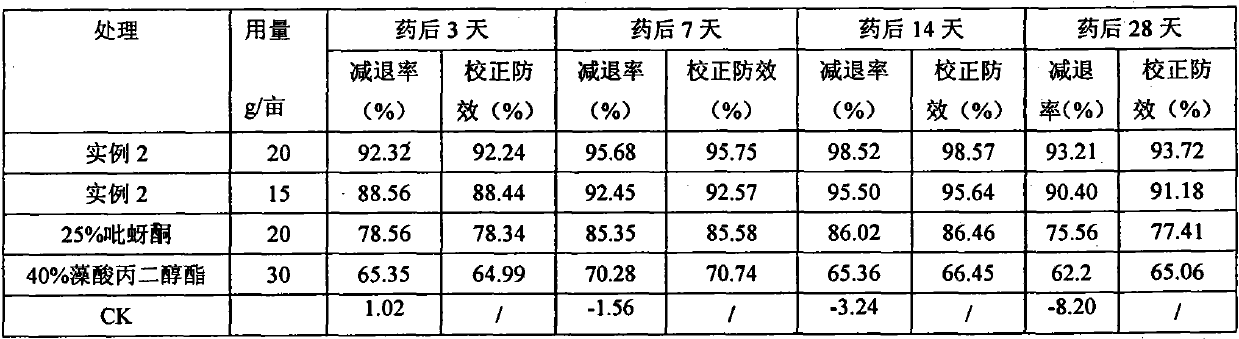

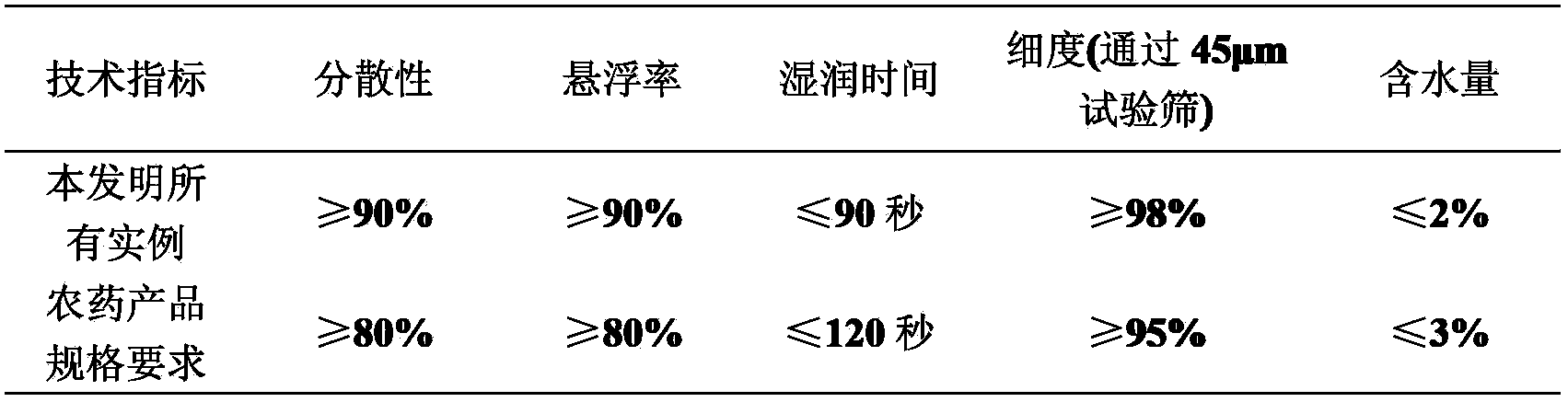

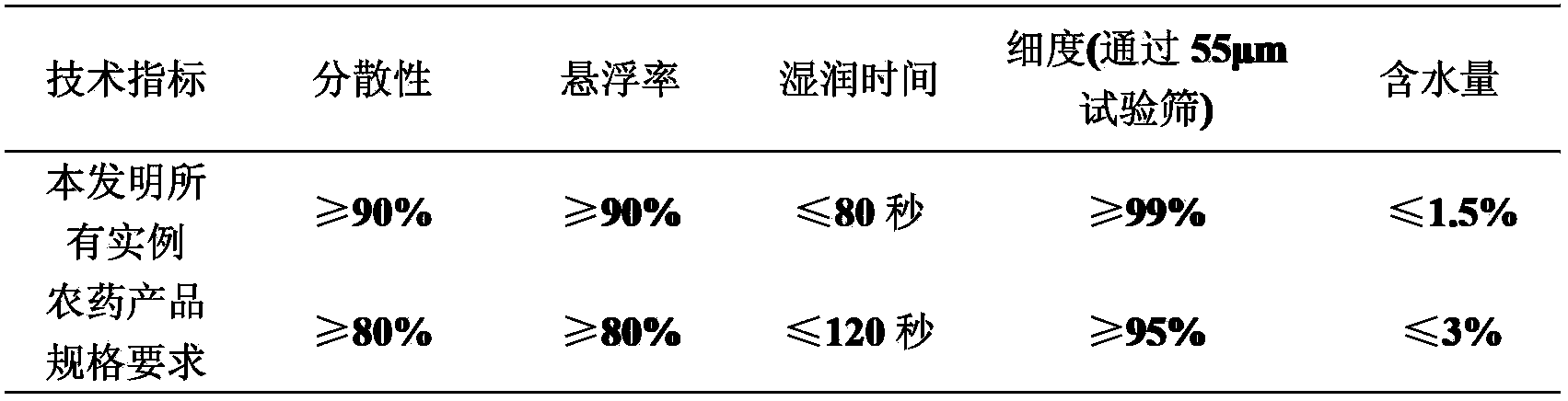

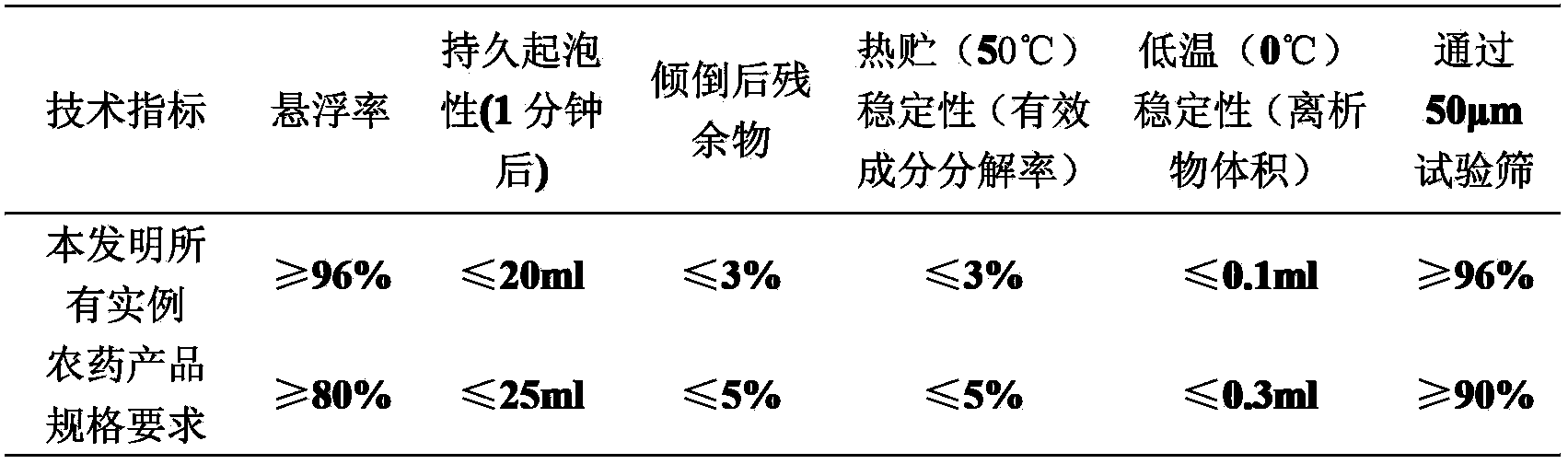

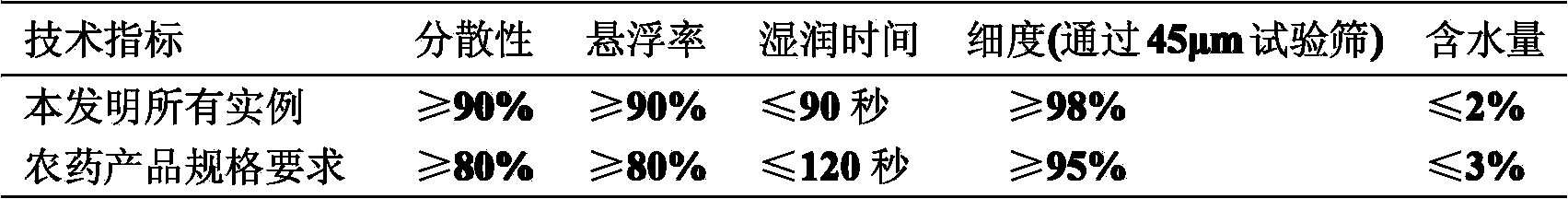

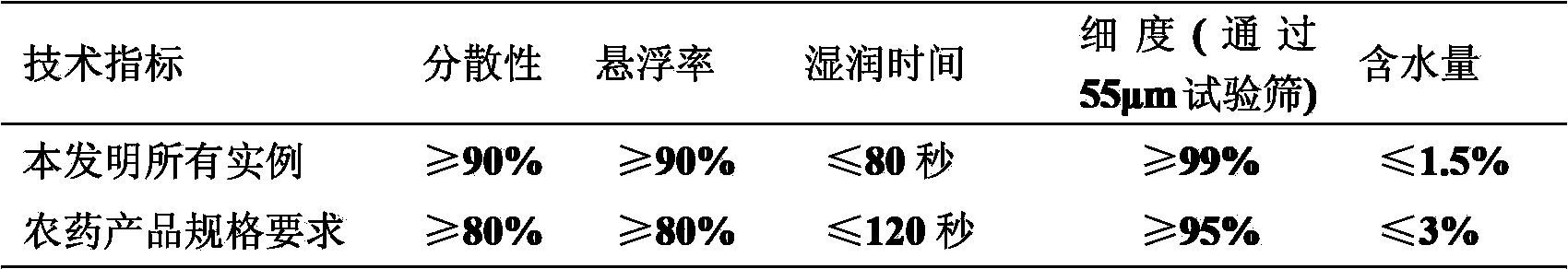

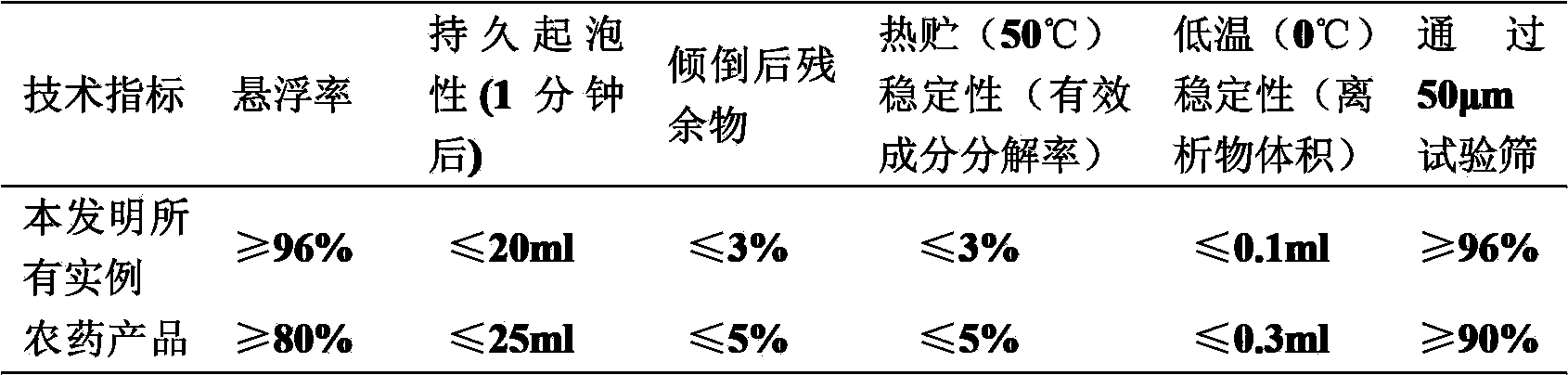

Insecticidal composition containing propylene glycol alginate

InactiveCN101926367AHigh surface tensionHigh viscosityBiocideArthropodicidesAvermectinActive component

The invention relates to an agricultural insecticidal composition, in particular to an insecticidal composition consisting of propylene glycol alginate and nitenpyram or avermectin or methylamine avermectins benzote. The insecticidal composition containing the propylene glycol alginate comprises an A active component and a B active component, wherein the A component comprises 0.1-30 percent of the propylene glycol alginate; the B component comprises the components in percentage by weight: 0.5-40 percent of the nitenpyram or the avermectin or the methylamine avermectins benzote, 10-50 percent of additive and 5-50 percent of excipient. The insecticidal composition containing the propylene glycol alginate has the advantages of low use cost, friendliness to a human body and the environment, long persistent period and different resistance generation and also enhances the utilization ratio of drug effective components.

Owner:ZHEJIANG SEGA SCI & TECH

Edible PGA coating composition

InactiveUS6881449B2Low viscosityStarch adhesivesPretreated surfacesAdditive ingredientBULK ACTIVE INGREDIENT

An edible, hardenable coating composition is disclosed which comprises high levels of low viscosity propylene glycol alginate and a surfactant, which may additionally contain a filler, a pigment, and optionally a small amount of a secondary film former and / or a strengthening polymer. The coating composition of the present invention may be applied to pharmaceutical and veterinary solid dosage forms, confectionery, seeds, animal feed, fertilizers, pesticide tablets, and foods and provides an elegant prompt release coating which does not retard the release of active ingredients from the coated substrate.

Owner:FMC CORP

Protein stabilizing agent

InactiveUS6887508B2Effective and stableStabilize the protein in the juicePeptide preparation methodsFood preparationProtein materialsOrganic chemistry

The present invention relates to a protein stabilizing agent for stabilizing a protein suspension in an aqueous acidic liquid such as a juice. The protein stabilizing agent is comprised of a high methoxyl pectin and a propylene glycol alginate. The present invention also includes compositions for suspension in an aqueous acidic liquid comprising a protein material and a protein stabilizing agent that contains a high methoxyl pectin and a propylene glycol alginate. The invention further includes aqueous acidic protein suspensions and methods of producing such suspensions, where the suspensions have a pH of from 3.0 to 5.5 and contain a stabilized suspension of a protein material and a protein stabilizing agent containing a high methoxyl pectin and a propylene glycol alginate therein.

Owner:PROTEIN TECH INT

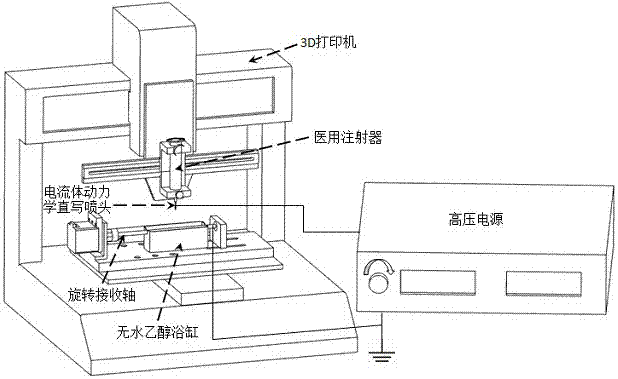

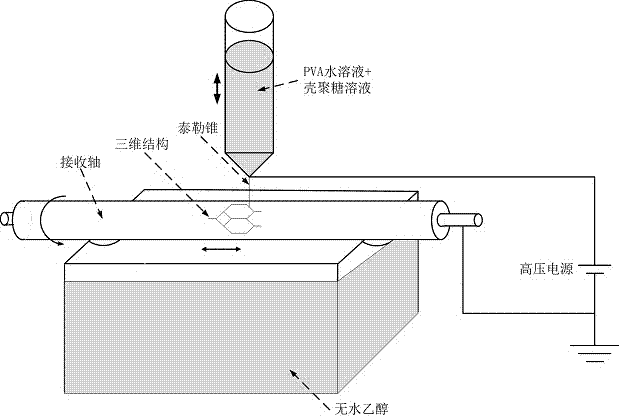

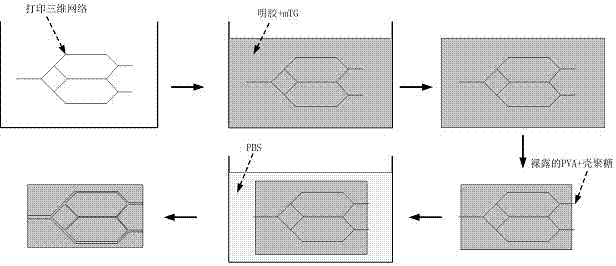

Construction system and method of 3D (three-dimensional) micro/nano-scale prefabricated vessel network of bone tissues

ActiveCN107296983AAchieve preparationEasy to getAdditive manufacturing apparatusPharmaceutical delivery mechanism3d shapesManufacturing technology

The invention discloses a construction system and method of a 3D (three-dimensional) micro / nano-scale prefabricated vessel network of bone tissues, which are used for the field of bio-manufacturing and used for manufacturing a micro / nano-scale prefabricated vessel access structure by combining an electrohydrodynamics direct-writing process and a subtractive manufacturing technology. A 3D shape of a required sacrificial material is prepared by promoting the sacrificial material to form sacrificial material solution with anhydrous ethanol, no harmful substance is generated in the whole process, and the material is easily available. The micro / nano-scale vessel structure is formed by virtue of printability of PVA (Polyvinyl Acetate), PGA (propylene glycol alginate) and chitosan, and the problem that the 3D micro / nano-scale vessel network cannot be obtained through biological 3D printing is solved, therefore, the system and the method have significance for solving the problem of the scale of a vessel in repair of human tissues in clinical medicine.

Owner:SHANGHAI UNIV

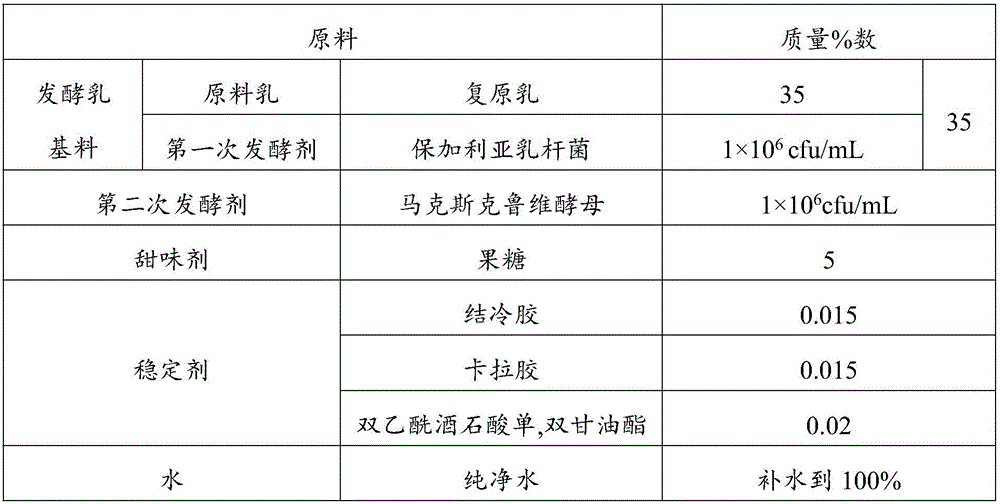

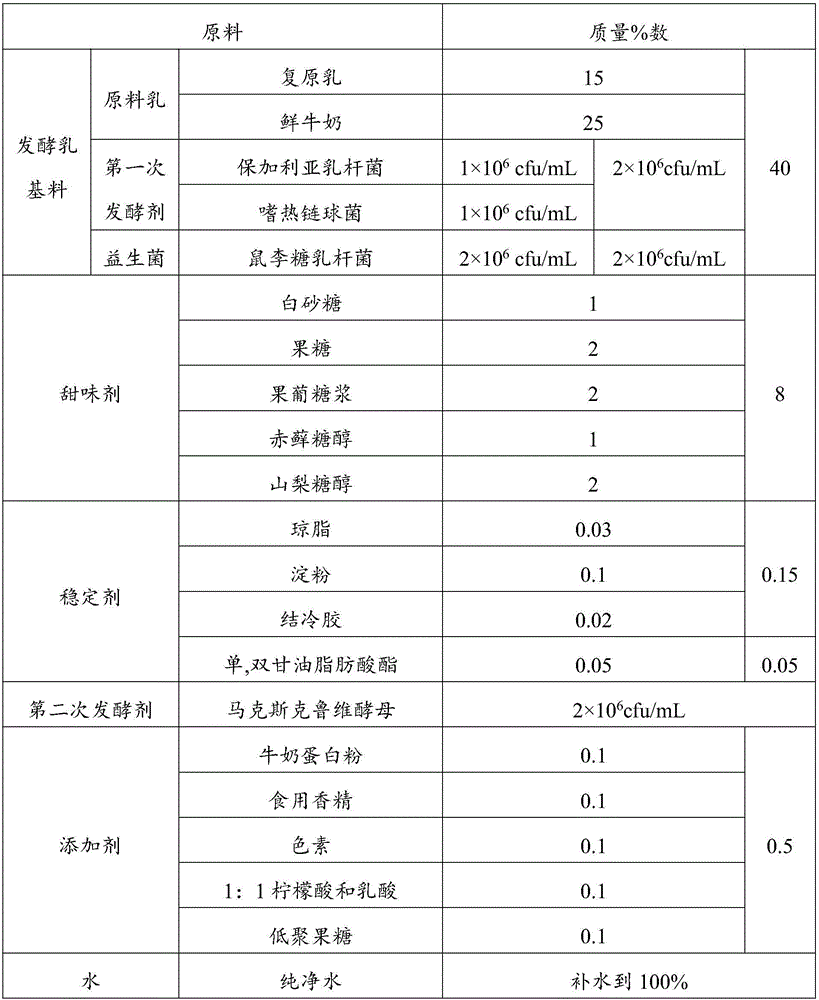

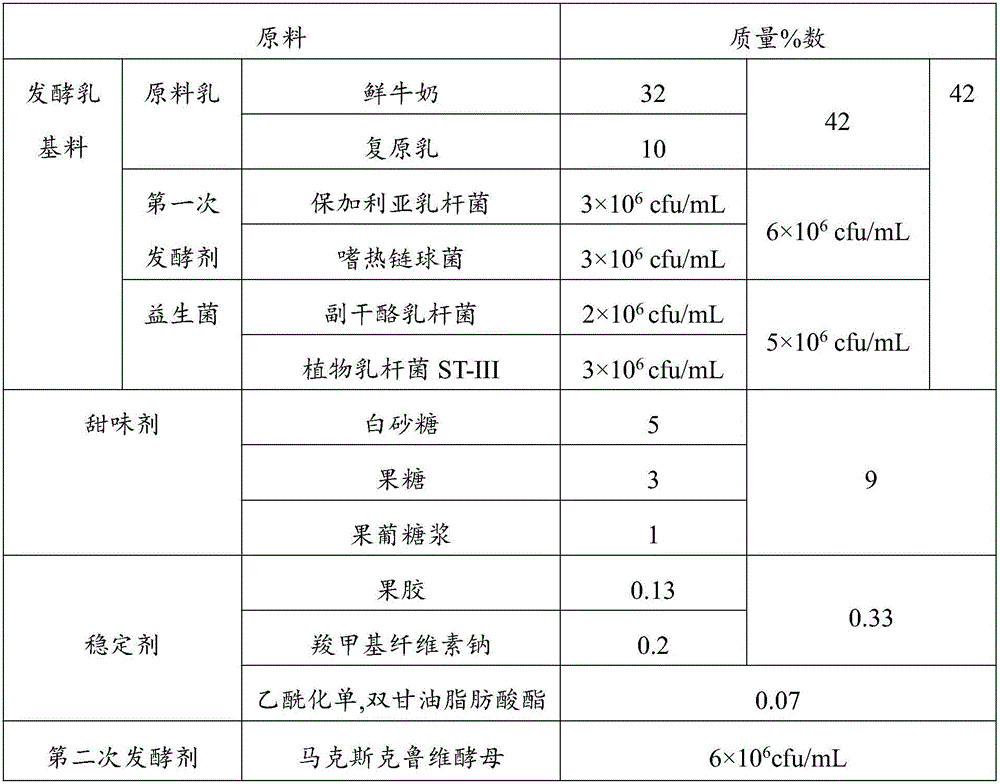

Raw material composition of fermented milk beverage, as well as fermented milk beverage and preparation method thereof

The invention discloses a raw material composition of a fermented milk beverage. The raw material composition comprises the following raw materials in percentage by mass: 35-60% of a fermented milk base material, 0.05-1% of a stabilizing agent, 5-15% of a sweetening agent and the balance of water, wherein the fermented milk base material is prepared through fermentation of raw material milk and lactic acid bacteria, and the stabilizing agent comprises the following components of (a) one, or two or more of sodium carboxymethyl cellulose, propylene glycol alginate, pectin, agar, starch, carrageenin and gellan gum; and (b) one, or two or more of mono(di)glycerin fatty acid ester, acetylated mono(di)glycerin fatty acid ester, and diacetyl tartaric acid ester of mono(di)glycerides. The raw material composition of the fermented milk beverage provided by the technical scheme of the invention is used as a raw material, and kluyveromyces lactis (kluyveromyces lactis) is added for fermentation, so that a gas-containing fermented milk beverage is made. The fermented milk beverage is subjected to secondary fermentation of lactic acid bacteria and microzymes, contains gas produced by natural fermentation, and is high in irritating mouth feel, unique in flavor, and good in stability.

Owner:BRIGHT DAIRY & FOOD

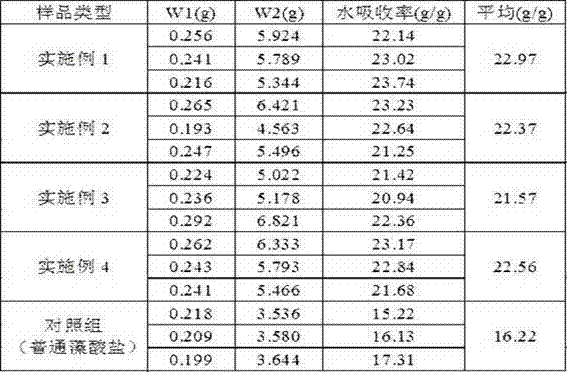

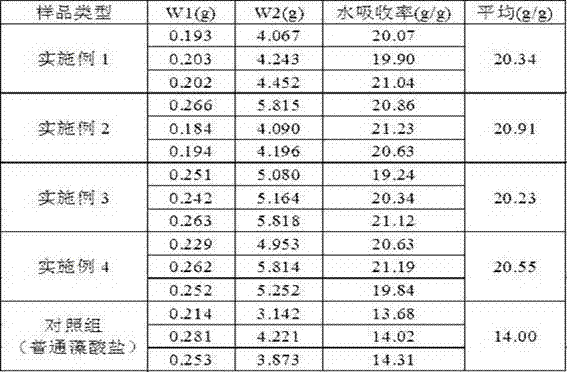

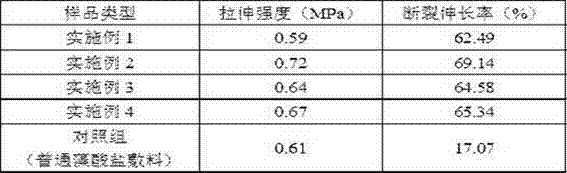

Preparation method of soft hygroscopic composite alginate dressing

InactiveCN106894111AGood flexibilityImprove antibacterial propertiesAbsorbent padsConjugated artificial filamentsBrown seaweedPolymer science

The invention discloses a preparation method of a soft hygroscopic composite alginate dressing. The preparation method includes: subjecting sodium alginate extracted from brown seaweed and carboxymethyl chitosan to cross-linking modification to form carboxymethyl chitosan / sodium alginate mixed liquid; adding propylene glycol alginate, stirring, and mixing well to form wet-process spinning dope; taking calcium chloride solution as solidification liquid for first solidification bath and one of zinc chloride solution, magnesium chloride solution and copper chloride solution as solidification liquid for second solidification bath for wet-spinning to obtain fiber; subjecting the fiber to needle-punched nonwoven cloth processing, slitting, packaging and sterilizing processes to obtain the soft hygroscopic composite alginate dressing. The alginate dressing prepared by the method has functions of absorbing liquid, maintaining moisture, resisting bacteria and stopping bleeding; due to spatial effect of carboxymethyl in the dressing, acting force among fiber macromolecules is weakened, so that flexibility of the fiber is enhanced, personalized needs of patients on the dressing are met better, and the alginate dressing has good application prospect.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

Stable Emulsion for Prevention of Skin Irritation and Items Using Same

An emulsion suitable for incorporation into wet wipes used to clean urine and fecal matter from the skin. The emulsion includes silicone oil and water-soluble zinc salt such as zinc chloride and zinc sulfate. Phase separation is prevented with an emulsification system that includes a gum blend and salt-tolerant emulsifier. The gum blend includes at least one gum and propylene glycol alginate.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Preparation method of amide alginate medical dressing

InactiveCN103627010AAvoid infectionImprove securityAbsorbent padsBandagesPolyamine CompoundWound surface

The invention discloses a preparation method of an amide alginate medical dressing, which comprises the following steps: mixing a propylene glycol alginate solution used as a component A and a polyamine compound solution or chitosan acetic acid solution used as a component B to react to generate an amide alginate aquogel, and forming the aquogel to obtain the medical dressing. The method overcomes the defects of high breaking tendency and inconvenience in use in the common alginate medical dressing; the prepared amide alginate medical dressing is more stable after swelling due to water absorption; and the aquogel formed after water absorption has a strong plugging effect on the wound surface, can not break up due to water absorption, and is convenient for medical personnel to operate.

Owner:戴建英

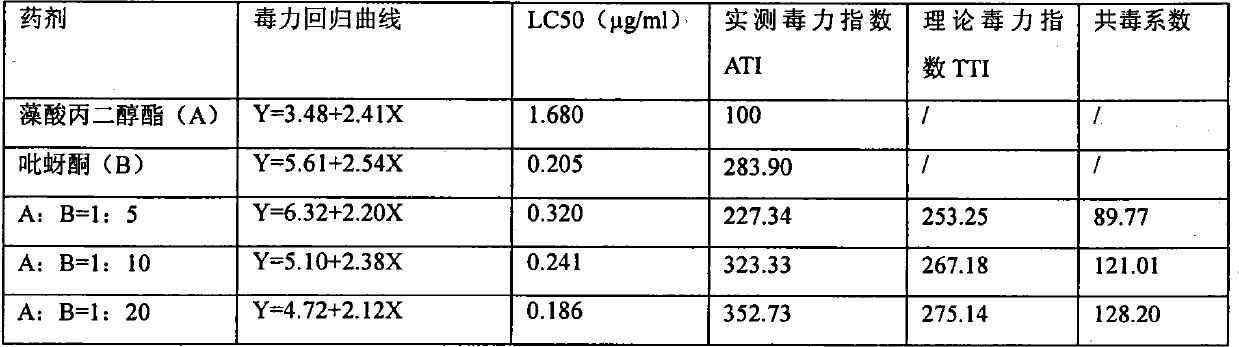

Composite insecticidal composition containing pymetrozine and propylene glycol alginate and application thereof

ActiveCN102017958AResidue reductionIncrease resistanceBiocideAnimal repellantsDrug resistanceActive ingredient

The invention discloses a composite insecticidal composition containing pymetrozine and propylene glycol alginate and the application thereof. The insecticidal composition uses pymetrozine and propylene glycol alginate as main active ingredients, wherein the weight ratio of the pymetrozine to the propylene glycol alginate is 0.1-80 to 0.1-60. The insecticidal composition can generate higher synergy, overcome and delay the drug resistance of pests, expand the prevention spectrum, have high desinsection speed, decrease the drug cost and lessen the toxicity. The insecticidal composition can prevent hemiptera pests on crops and particularly can be used for preventing paddy delphacidae and wheat aphids, and the effect of the insecticidal composition is significantly higher than that of single agent.

Owner:NANJING HUAZHOU PHARMA

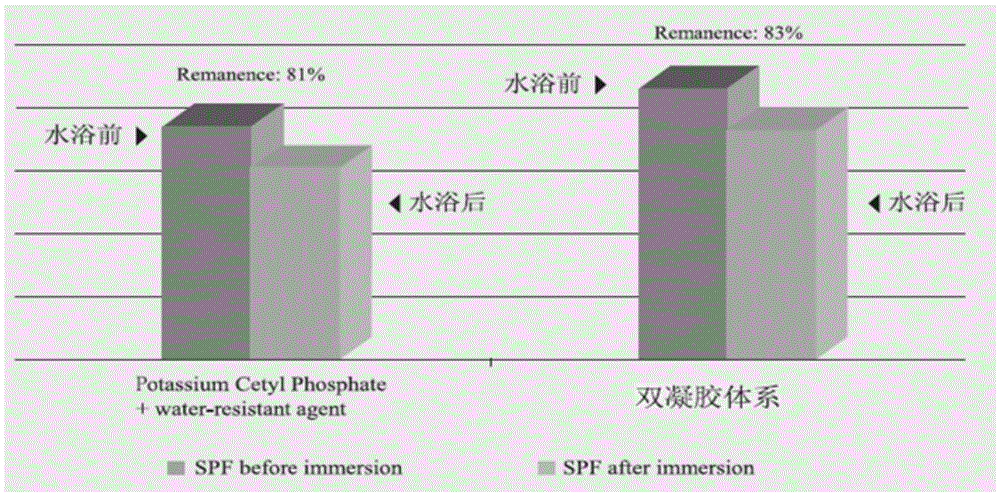

Sunscreen composition and preparation method and application thereof

ActiveCN105520850AHas absorptionWater and sweat resistantCosmetic preparationsToilet preparationsPropylene glycolPropylene glycol alginate

The invention relates to a sunscreen composition, which is prepared from the following components in parts by weight: 8-22 parts of sunscreen, 3-6.5 parts of skin-moisturizing oil, 1.2-5 parts of propylene glycol alginate, 0.15-0.45 parts of ethyl cellulose, 0.15-0.45 parts of propylene glycol isostearate, 58.2-82 parts of water, 1-5 parts of wetting agent and 0.5-4 parts of auxiliary material, wherein the auxiliary material comprises a thickening agent and a neutralizer. The invention further provides a preparation method and application of the sunscreen composition. The sunscreen composition disclosed by the invention has the advantages of being fresh and cool, easy to smear, waterproof, sweatproof and the like; the preparation method is suitable for industrial production, and can be used for preparation of cosmetics.

Owner:MENTHOLATUM (CHINA) PHARM CO LTD

Food composition and weight loss method for treating obesity

InactiveUS7053066B2Lowering indexImprove the level ofBiocideSugar derivativesEnzymatic hydrolysisMedicine

The invention relates to a method for treating overweight persons or patients with obesity using a food composition able to control the release of glucose into the patient's blood. This is achieved by the introduction into the food composition of a therapeutically effective amount of an additive, such as propylene glycol alginate (PGA) or other hydrophilic agent or pharmaceutically acceptable salts thereof, which reduces the cooking losses and enhances the starch cell wall membrane to thereby slow the enzymatic hydrolysis of the starch by insulin. The result is a steady state release of glucose and a net reduction in the release of blood glucose (glycemic index) relative to release of glucose observed in an overweight or obese patient having consumed a food composition without propylene glycol alginate, whereby the patient experiences a loss in body weight.

Owner:HEARTLAND HEALTH SOLUTINS

Alcohol-free fountain solution and preparation method thereof

The invention discloses an alcohol-free fountain solution. The alcohol-free fountain solution is characterized by consisting of following raw materials in parts by weight: 2-10 parts of alginic acid propylene glycol alginate, 1-5 parts of epoxy butyl stearate, 1-3 parts of glycine, 1-3 parts of arginine, 1-8 parts of sodium dodecyl sulfate, 1-5 parts of hydroxyethyl urea, 0.5-1 part of hydrogen peroxide, 1-3 parts of tannin, 1-2 parts of vanillin, 1-3 parts of EDTA (Ethylene Diamine Tetraacetic Acid), 0.2-1 part of organic silicon defoamer, 5-10 parts of additive and 30-50 parts of water. According to the alcohol-free fountain solution disclosed by the invention, IPA (Iso Propyle Alcohol) or other alcohol additives do not need to be added during a using process of the alcohol-free fountain solution, the cost is reduced, and the alcohol-free fountain solution is mild and harmless to a human body and environment and adapts to the requirements of energy conservation, environmental protection and safety.

Owner:宋睿

Low-lactose long-shelf life yoghourt and preparation method thereof

ActiveCN103564045AImprove stabilityControl fermentation temperatureMilk preparationSodium lactateSucrose

The invention provides low-lactose long-shelf life yoghourt which comprises the following raw materials: 60-98.9 parts by weight of milk, 0.01-0.5 part by weight of emulsifiers, 3-14 parts by weight of thickening agents, and 7-12 parts by weight of sugar; the emulsifier is a combination of one or more than one of sucrose fatty acid ester, glyceryl monostearate fatty acid ester, stearoyl sodium lactate, and glycerol distearate; the thickening agent is a combination of one or more than one of pectin, sodium caseinate, agar, gelatin, modified starch, gellan gum, propylene glycol alginate, and xanthan gum. The low-lactose long-shelf life yoghourt has good stability. The invention also provides a preparation method of the low-lactose long-shelf life yoghourt; the method controls the fermentation temperature and carries out secondary sterilization; the low-lactose long-shelf life yoghourt prepared by the method has good stability.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

High-efficient insecticide composition containing propylene glycol alginate

InactiveCN103563901AGood compatibilityReduce dosageBiocideAnimal repellantsActive componentFlubendiamide

The invention discloses a high-efficient insecticide composition containing propylene glycol alginate. The high-efficient insecticide composition comprises an active component A and an active component B. The active component A is propylene glycol alginate; the active component B is one compound optionally selected from flonicamid, cyantraniliprole, tolfenpyrad, sulfoxaflor, flubendiamide, and chlorantraniliprole; and the weight ratio of the active component A to the active component B is 1:80-60:1. The high-efficient insecticide composition possesses obvious synergistic effect on a plurality of insects which are capable of causing harm to agricultural production; is capable of reducing insecticide dosage, insecticide residue on crops, and environmental pollution; is safe for people and livestock; and possesses excellent environmental compatibility. In addition, drug resistance of insects is difficult to be caused by the high-efficient insecticide composition containing propylene glycol alginate.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

Milk beverage stabilizing agent, acid milk beverage using same and preparation method

The invention discloses a milk beverage stabilizing agent, an acid milk beverage using the same and a preparation method in the technical field of food. The milk beverage stabilizing agent comprises the following components in percentage by mass: 50%-70% of carboxymethyl curdlan, 10%-30% of Arabic gum, 10%-20% of propylene glycol alginate and 5%-10% of guar gum. The acid milk beverage comprises the following components in percentage by mass: 1%-8% of whole milk powder or defatted milk powder, 0.2%-1% of stabilizing agent, 10%-20% of white granulated sugar and the balance of water. The preparation method for the acid milk beverage comprises the following steps: taking 35 to 55 DEG C water, adding the white granulated sugar and the stabilizing agent into the water in turn, and stirring the mixture till the white granulated sugar and the stabilizing agent are dissolved to obtain solution A; taking the 35 to 55 DEG C water, adding the whole milk powder or the defatted milk powder into the water, and stirring the mixture till the whole milk powder or the defatted milk powder is dissolved to obtain solution B; and mixing the solution A and the solution B, cooling the solution to between 15 and 25 DEG C, adjusting pH to 4 by using citric acid solution, and heating, homogenizing and pasteurizing the solution to obtain the acid milk beverage. Because the carboxymethyl curdlan and the Arabic gum are introduced into the stabilizing agent, the stabilizing agent has good emulsifying effect and acid resistance, and can effectively improve the stability of a product.

Owner:SHANGHAI JIAO TONG UNIV

Preparation process of walnut yogurt

InactiveCN108935684APreserve the inherent flavorEasy to manufactureMilk preparationNutritive valuesFreeze-drying

The present invention relates to a preparation process of walnut yogurt. The yogurt is prepared from the following components in parts by weight: 20 parts of walnut pulp, 76.5 parts of fresh milk, 3 parts of inulin, 0.1 part of sucralose, 0.2 part of sodium carboxymethyl cellulose and 0.2 part of propylene glycol alginate, wherein the walnut pulp is prepared from walnut kernels as a raw material.The preparation process of the walnut yoghourt comprises the following steps: a, raw material treatment; b, pulping; c, proportioning; d, degassing and homogenization; e, heating for sterilization; f,inoculation; g, fermentation; and h, freezing and after-ripening, wherein the fermentation material is prepared by mixing lactobacillus bulgaricus freeze-dried powder and streptococcus thermophilus freeze-dried powder according to a weight ratio of 1:1.2 in the step g. The yogurt has the advantages of high nutritive value, good market prospect and simple production process.

Owner:HENAN FENGZHIYUAN BIOLOGICAL TECH

Ceramic for cutter and preparation method thereof

The invention provides ceramic for a cutter. The ceramic is prepared from the following raw materials in parts by weight: 20-23 parts of silica powder, 7-10 parts of boron nitride, 24-27 parts of silicon carbide, 30-35 parts of quartz, 0.7-0.9 part of triethyl citrate, 0.4-0.6 parts of magnesium stearate, 3-4 parts of alumina fiber, 7-9 parts of nanosilicon dioxide, 0.2-0.4 part of propylene glycol alginate, a proper amount of deionized water, 1.7-2 parts of polyethylene glycol and 3-4 parts of a wear-resisting additive. The ceramic has fine texture and good wear resistance without air holes; the alumina fiber and the nanosilicon dioxide are added to the ceramic, so that the wear resistance, the thermal conductivity and the smoothness of the ceramic are greatly improved; the ceramic is suitable for the cutter and low in cost; by using the wear-resisting additive, the surface smoothness, the wear resistance and the heat resistance of the ceramic can be improved.

Owner:山东润蒙应急救援装备有限公司

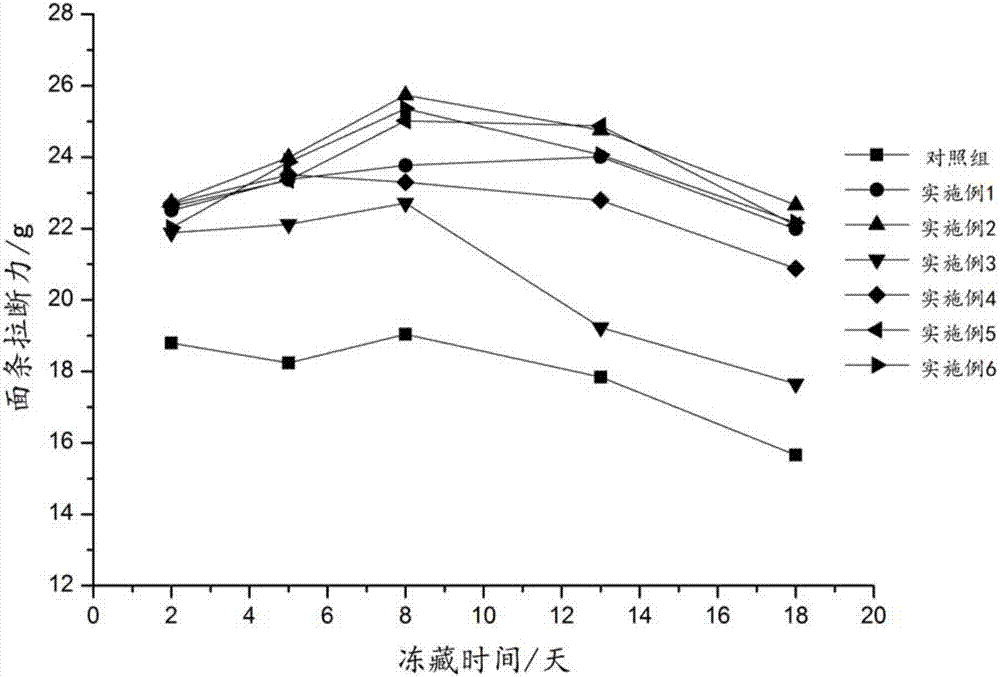

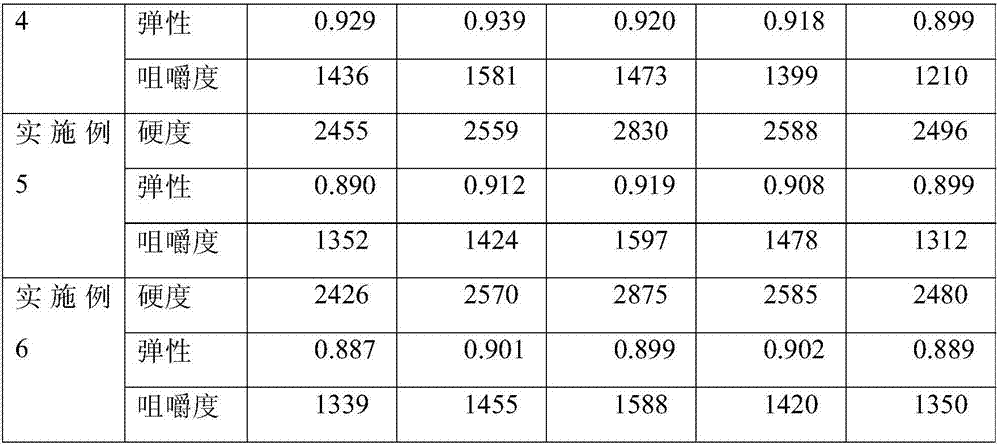

Quality-improved frozen cooked noodles and processing method thereof

ActiveCN107048188AImprove qualityEasy to eatFood preservationFood ingredient functionsPhosphateSlurry

The invention discloses quality-improved frozen cooked noodles and a processing method thereof. The frozen cooked noodles are prepared from wheat flour, mixed beans, egg white powder, propylene glycol alginate, diacetyl tartaric acid ester of mono(di)glycerides, compound phosphate, modified starch, salt and the like. The processing method comprises the steps: mixing and pulping the mixed beans and water; adding salt, egg white powder, propylene glycol alginate, diacetyl tartaric acid ester of mono(di)glycerides, compound phosphate and modified starch to obtain mixed slurry; adding the mixed slurry to the wheat flour and kneading dough in vacuum; and after the dough is prepared, carrying out aging, rolling, cutting, continuous steaming of noodles at high humidity, cyclic spraying of noodles, continuous boiling of noodles, washing for cooling, atomized oil spraying and quick freezing to obtain the frozen cooked noodles. The quality-improved frozen cooked noodles provided by present invention are smooth and compact in surface, tough, elastic and chewy in mouthfeel, rich in nutrients and stable in freezing storage quality, and the processing method is simple and convenient in operation and low in cost.

Owner:南阳麦香源食品有限公司 +1

Impurity removing process for ion-absorbed rare earth ore leaching mother liquor

The invention discloses an impurity removing process for an ion-absorbed rare earth ore leaching mother liquor. The impurity removing process comprises the following steps: performing solid-liquid separation on the leaching mother liquor containing impurities through a fine sieve; discharging the leaching liquid into an impurity removing tank and adjusting a pH value; adding a chemical impurity removing agent; stirring using a compressed air; adding methylcyclopentenolone, or maltol, or ethyl maltol, asparagine or glutamine; adding yellow mud and propylene glycol alginate as a settling assistant; fully stirring using the compressed air; stopping the air stirring, and leaving the impurity removing tank to stand for about 8 hours; discharging the clarified and purified upper mother liquor into a rare earth precipitation separation tank through a supernate discharging pipe having a soft connection; after depositions and impurity removing slags accumulated on the bottom layer of the impurity removing tank range from 0.5 m to 1.0 m, discharging the depositions and impurity removing slags into an impurity removing slag tank through a bottom slag discharging pipe; after further airing orpress-filtering dehydration of the impurity removing slags in the impurity removing slag tank, storing the aired and dehydrated impurity removing slags; and returning the supernate to the impurity removing tank. According to the impurity removing process for the ion-absorbed rare earth ore leaching mother liquor, the adopted reagent is safe and environmentally friendly, the environmental hazards are small, the impurity removing rate is high, rare earth ion loss is small, and the subsequent rare earth product quality is high.

Owner:王颖皓

Radix puerariae dried noodles and production method of radix puerariae dried noodles

The invention provides radix puerariae dried noodles and a production method of the radix puerariae dried noodles, relating to the field of food processing. The radix puerariae dried noodles comprise the following raw materials in parts by weight: 75-85 parts of flour, 5-20 parts of radix puerariae powder, 3-7 parts of vital gluten, 0.8-1.2 parts of table salt, 0.1-0.3 part of konjac powder and 0.02-0.04 part of improvers (including carrageenan, acetate starch, propylene glycol alginate and propanediol). By adding a proper amount of the radix puerariae powder, the radix puerariae dried noodles are rich in functional components such as physiological activators, namely flavonoid compounds and the like and are good in taste; by further adding the konjac powder and the vital gluten, the nutrient components of the radix puerariae dried noodles are further increased, and the finished radix puerariae dried noodles are relatively smooth in taste and are relatively elastic; furthermore, no any additive is added, so that the radix puerariae dried noodles can meet the social requirements on food safety.

Owner:ANHUI YANHU FLOUR

Pesticide composition

InactiveCN103563950AGood synergyGood lasting effectBiocideAnimal repellantsChlorfenapyrActive component

The present invention discloses a pesticide composition, which contains an active component A and an active component B, wherein the active component A is selected from propylene glycol alginate, the active component B is any one compound selected from spirotetramat, chlorfenapyr, lufenuron, pyriproxyfen, metaflumizone and pyridalyl, and a weight ratio of the active component A to the active component B is 1:80-40:1. The composition provides high activities for a plurality of pests of a plurality of crops, and has characteristics of significant synergistic effect, pest killing spectrum expanding, low use amount, rainfall erosion resistance, and significant synergy.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com