Patents

Literature

32results about How to "Control fermentation temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

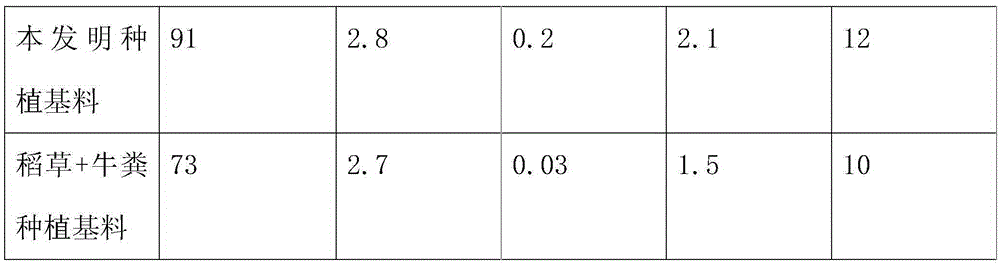

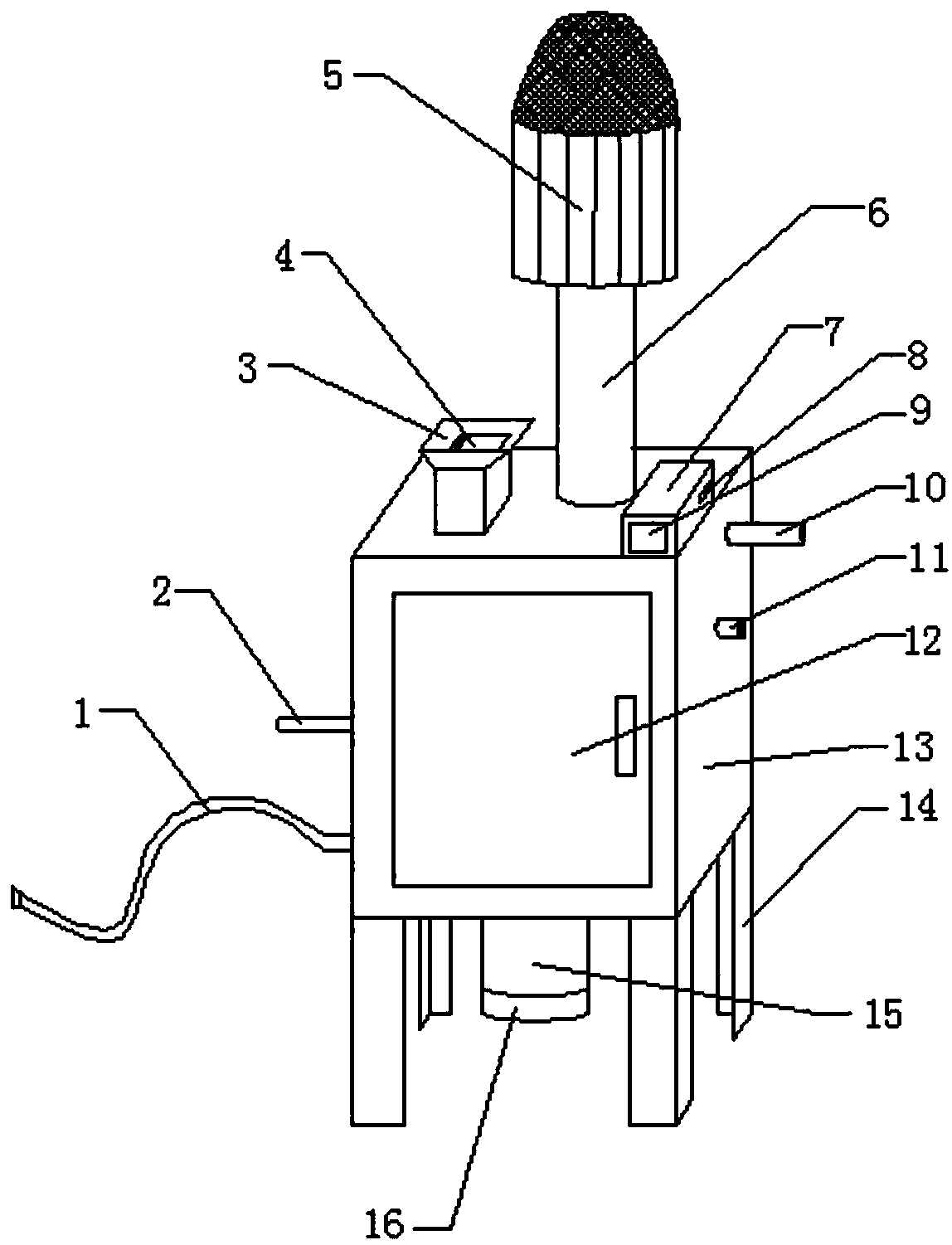

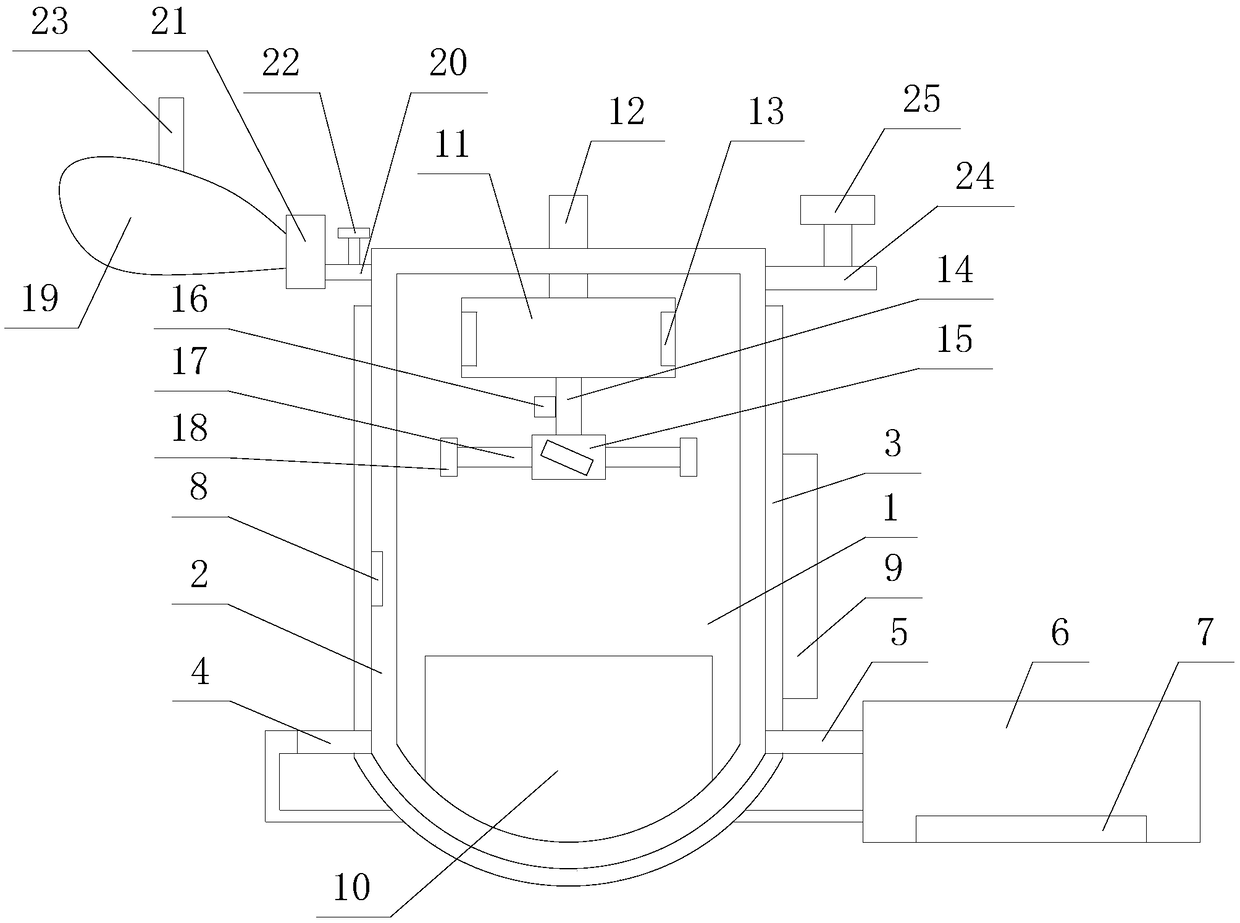

Home-brewed liquor manufacturing apparatus

ActiveCN101679928AEasy to manufactureEasy to operateFermented solutions distillation/rectificationTemperature control using plurality of sensorsComing outDistillation

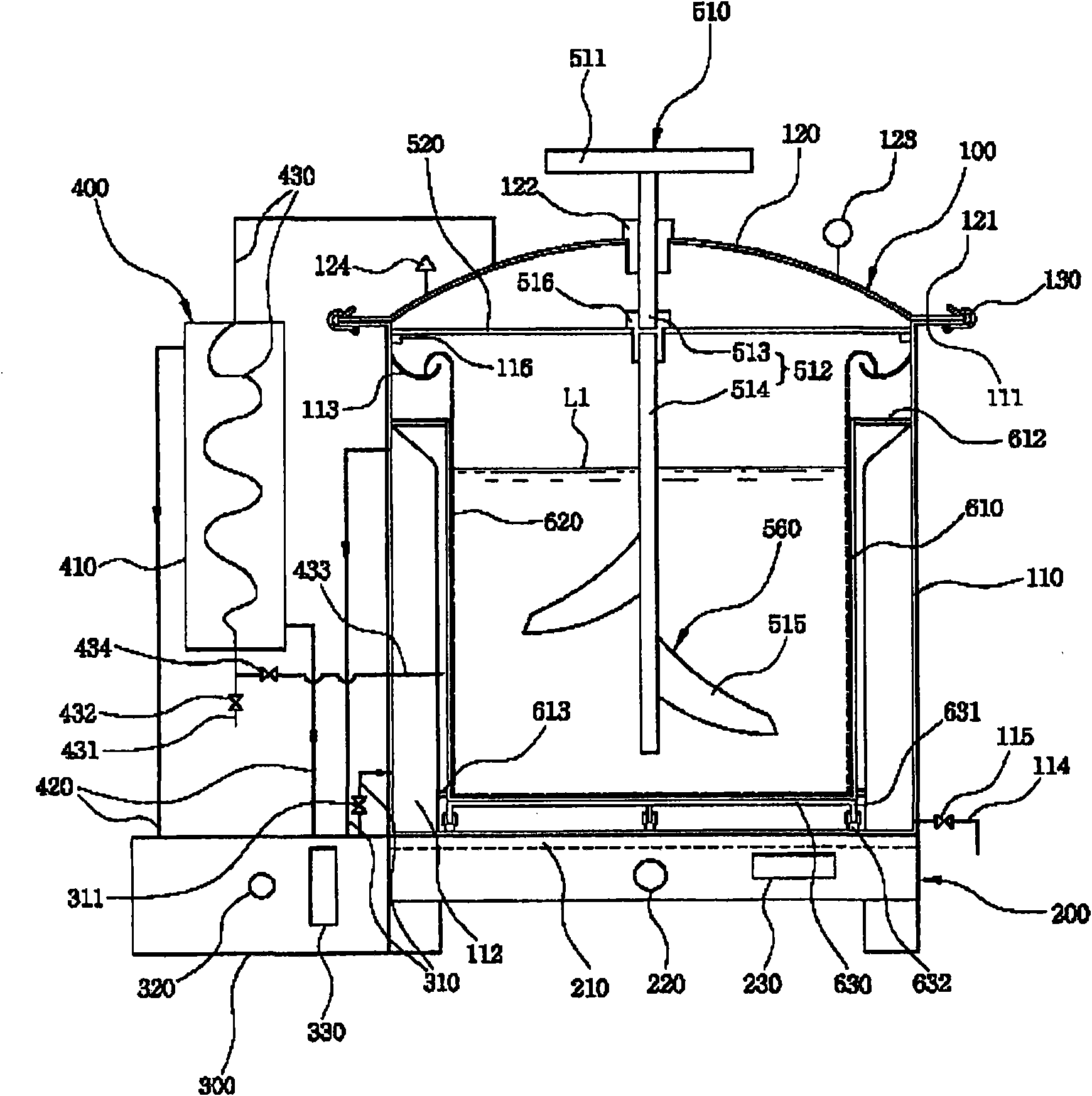

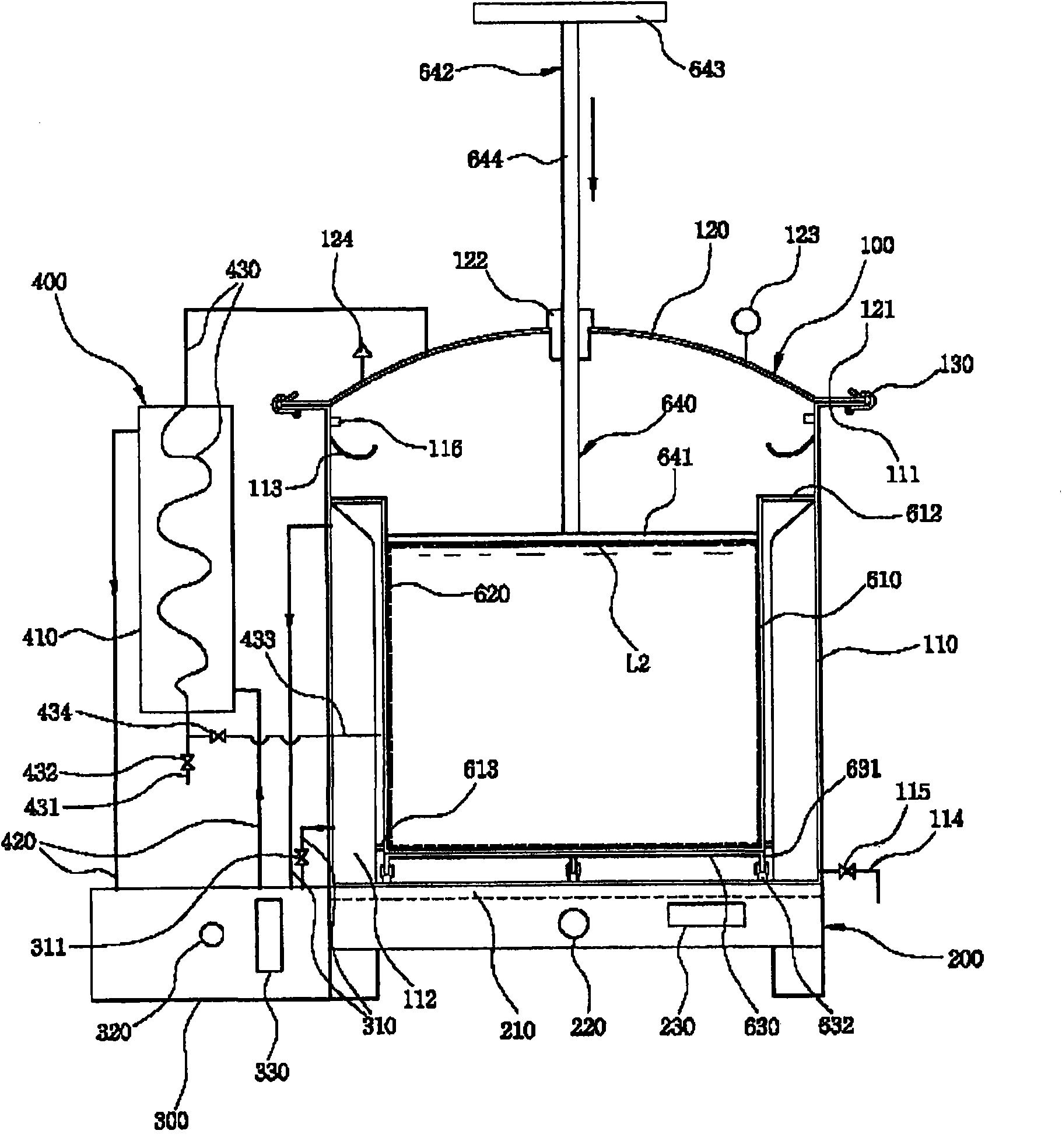

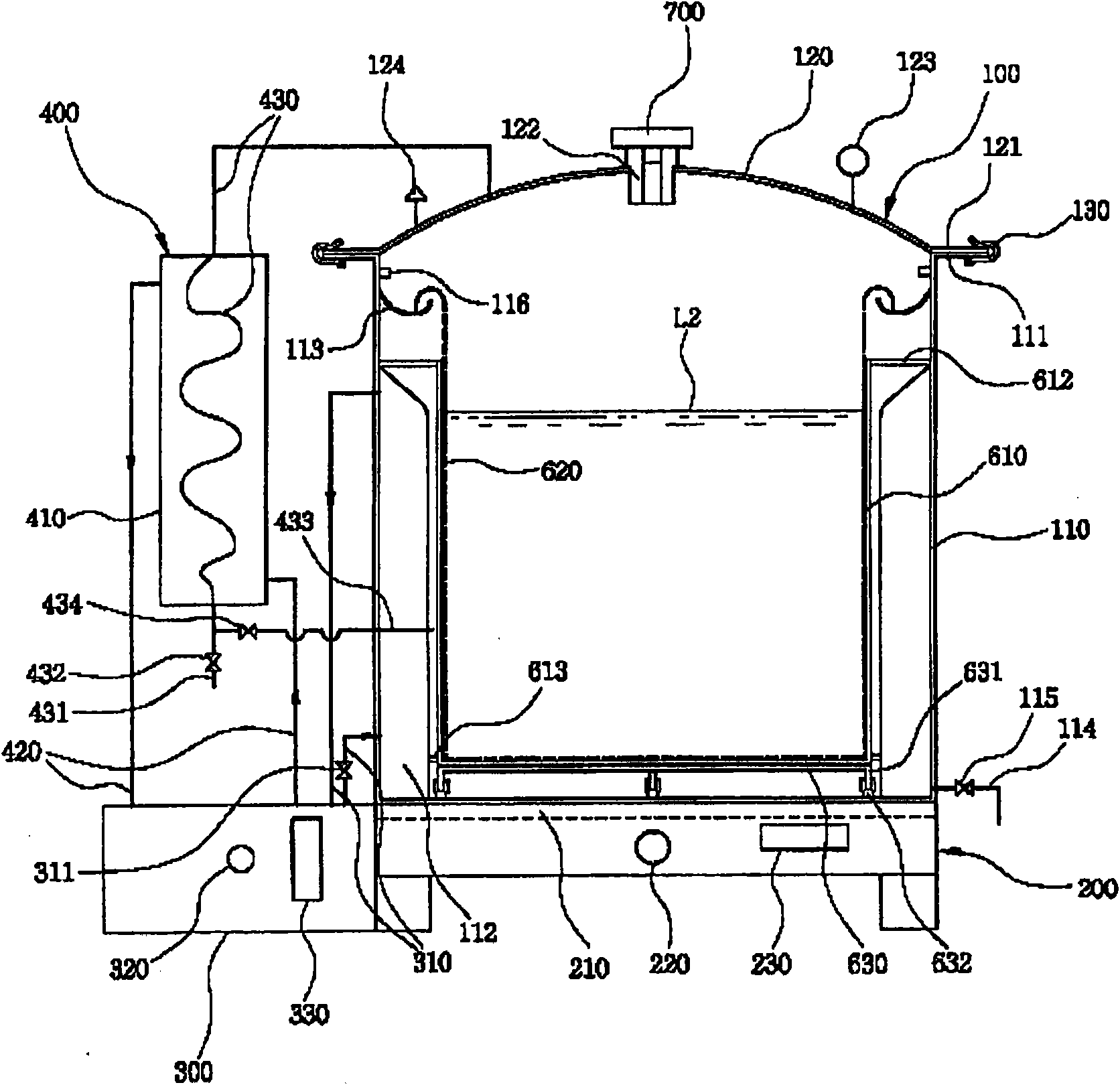

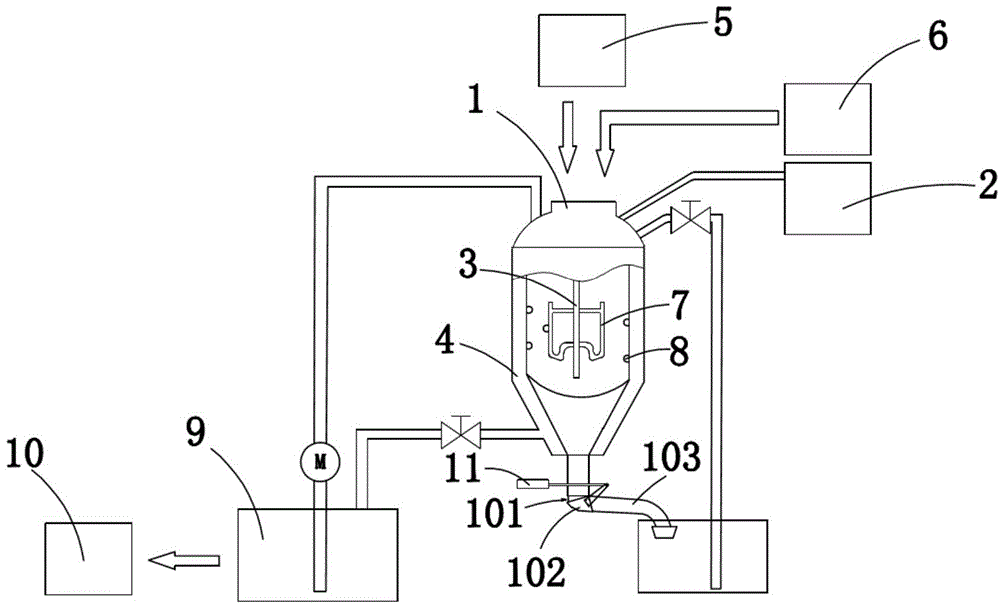

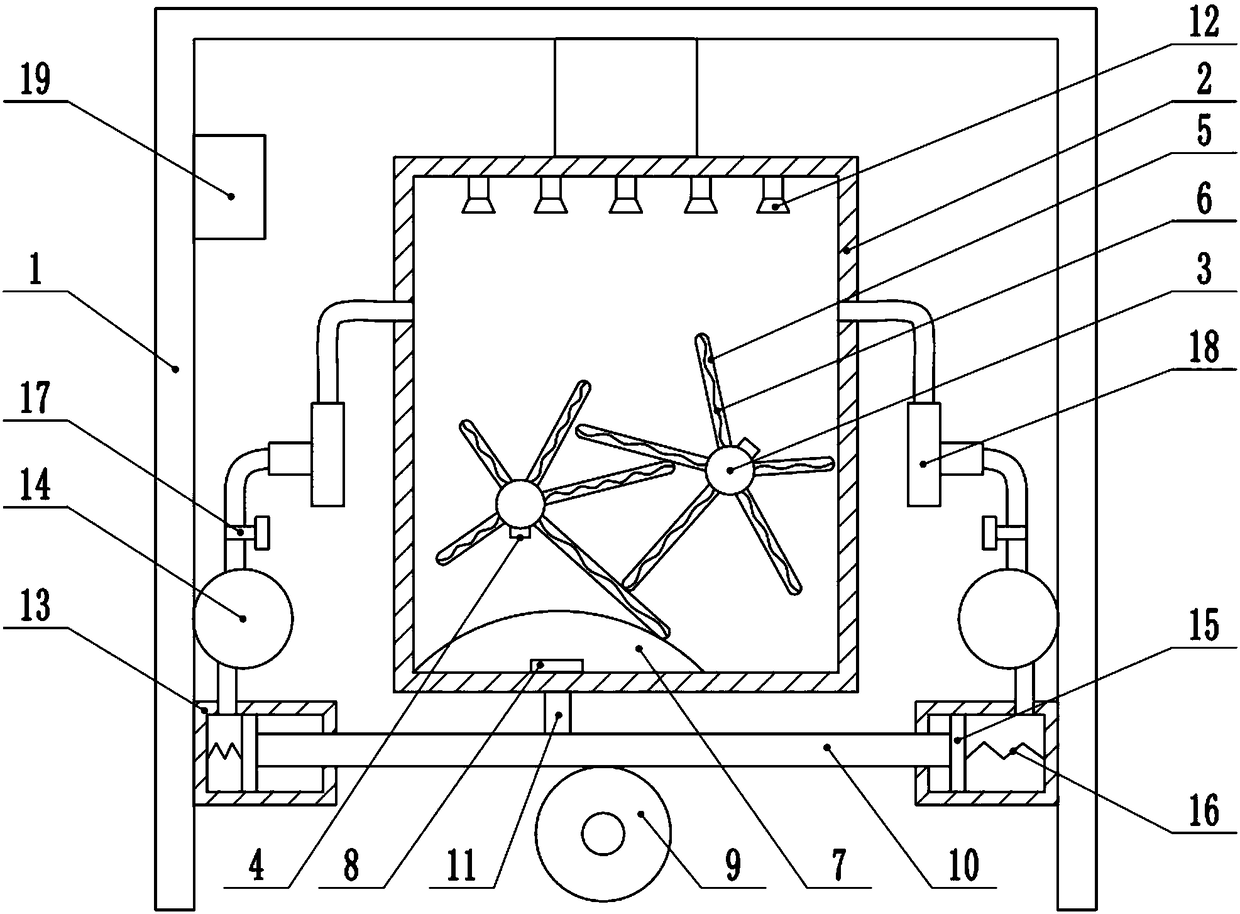

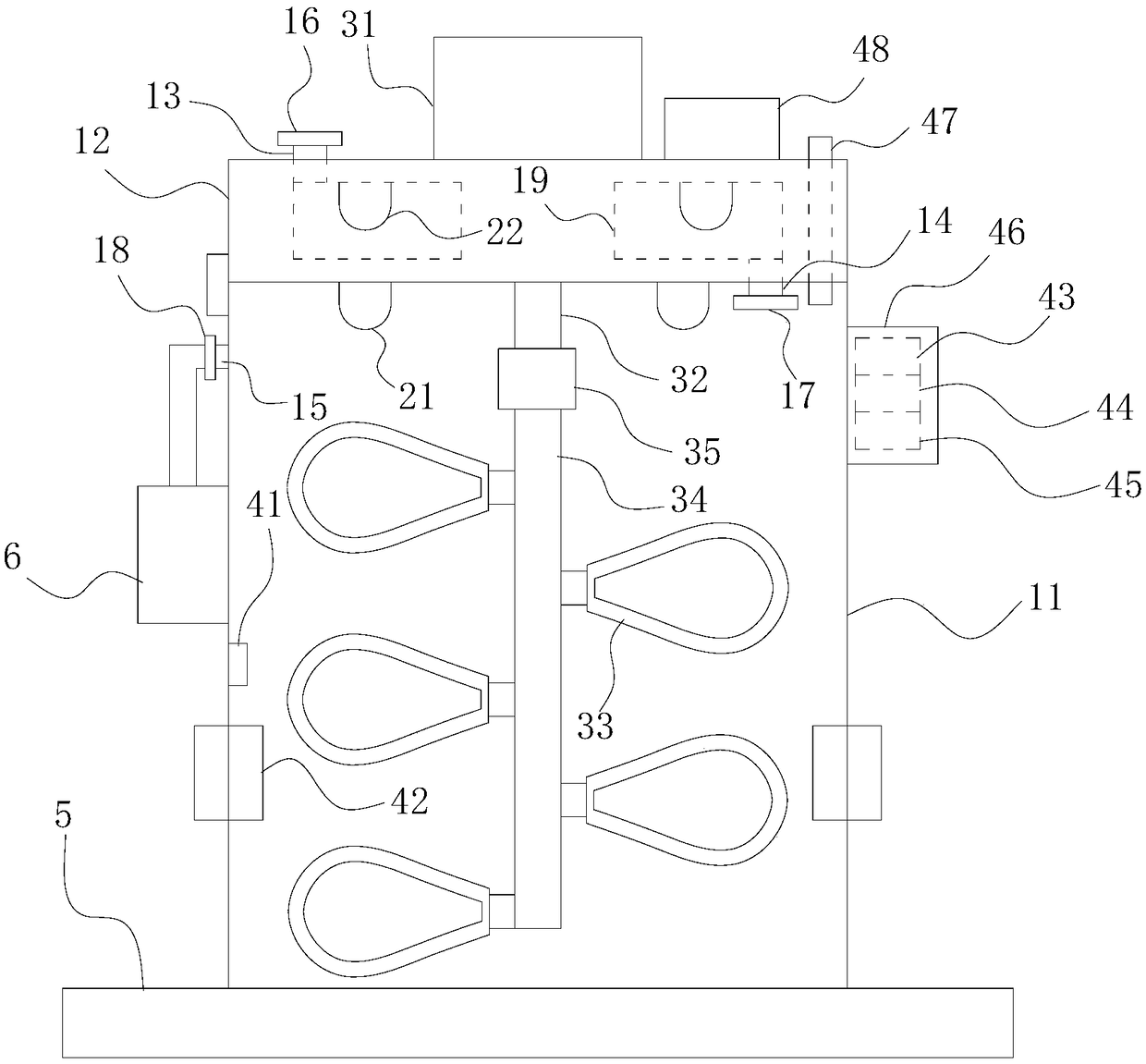

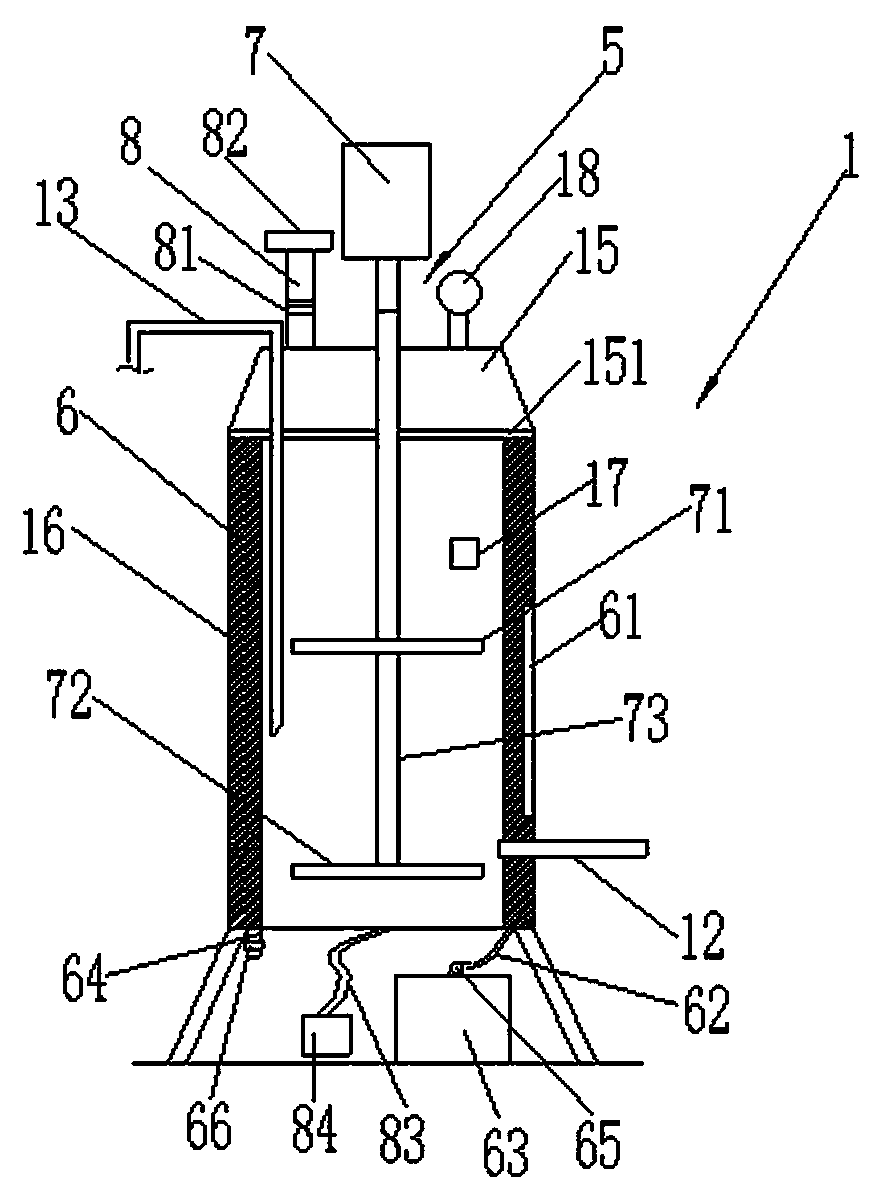

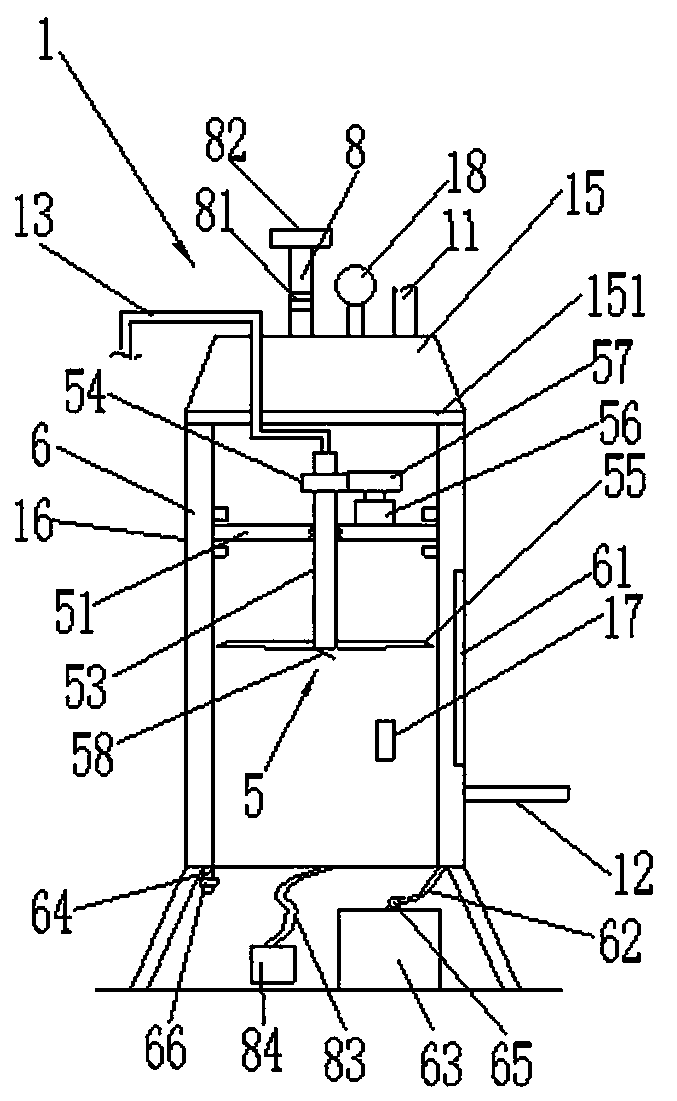

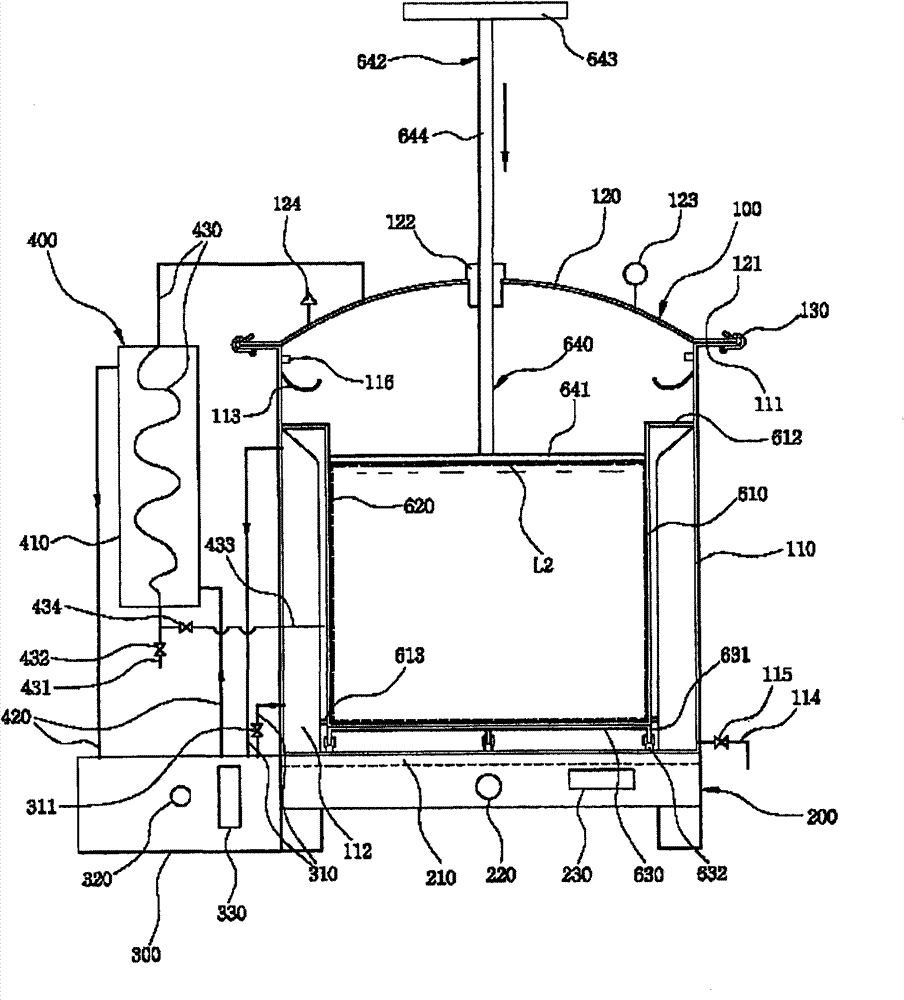

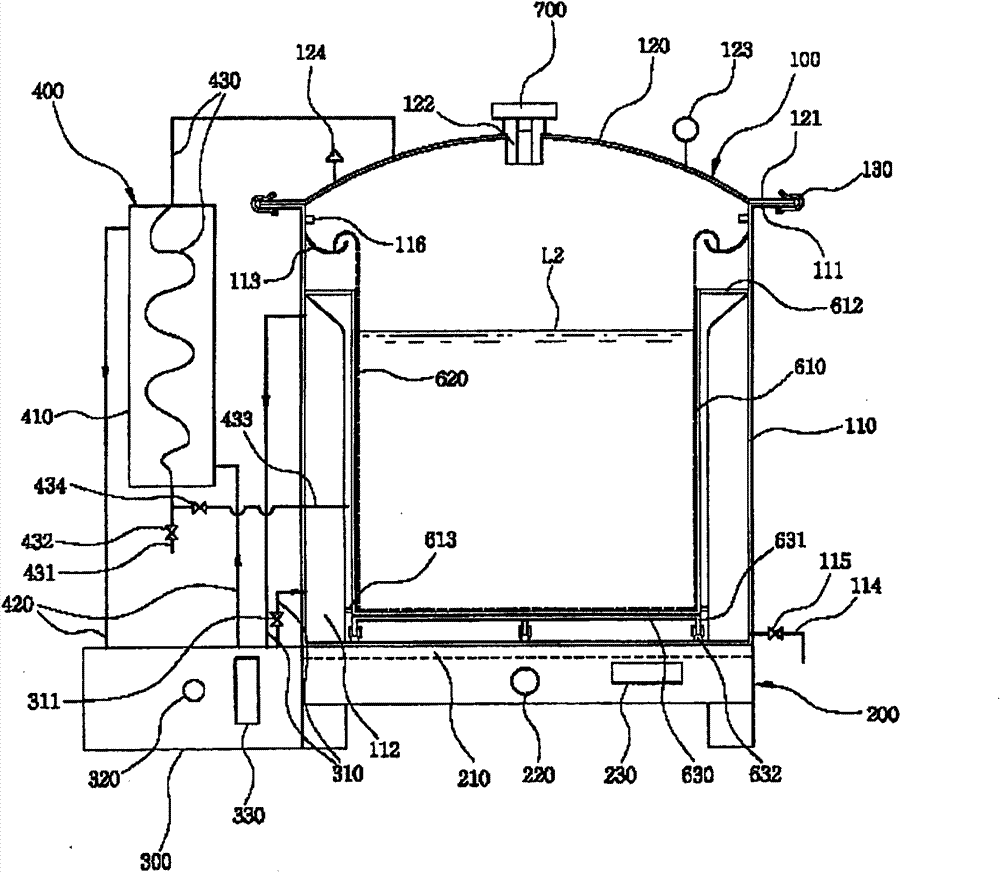

The present invention relates to a liquor manufacturing apparatus for home use. Particularly, the present invention relates to a liquor manufacturing apparatus for home use, which includes a single device consisting of a heater, the cooler, the condenser, the stirrer and the filter to enable to perform all processes required for liquor preparation and which enables anyone to easily make desired liquor even in general homes using grains, fruits or other plant materials. The liquor manufacturing apparatus for home use comprises: a combined fermentation and distillation tank including a tank body having a cooling jacket mounted at the inside wall surface thereof so as to allow cooling water to be filled therein and to pass therethrough and a lid being adapted to hermetically seal the top portion of the tank body; an electric heater adapted to heat the tank body; a cooler adapted to supply the cooling water to the cooling jacket so as to cool the tank body; a condenser adapted to cool steam and volatile substance coming out of the combined fermentation and distillation tank; a combined steaming and filtering container disposed inside the tank body; a fabric filter disposed inside the combined steaming and filtering container and adapted to contain contents produced in the liquor preparing process; and a stirrer adapted to stir the contents inside the fabric filter during fermentation.

Owner:DAEBONG LS CO LTD

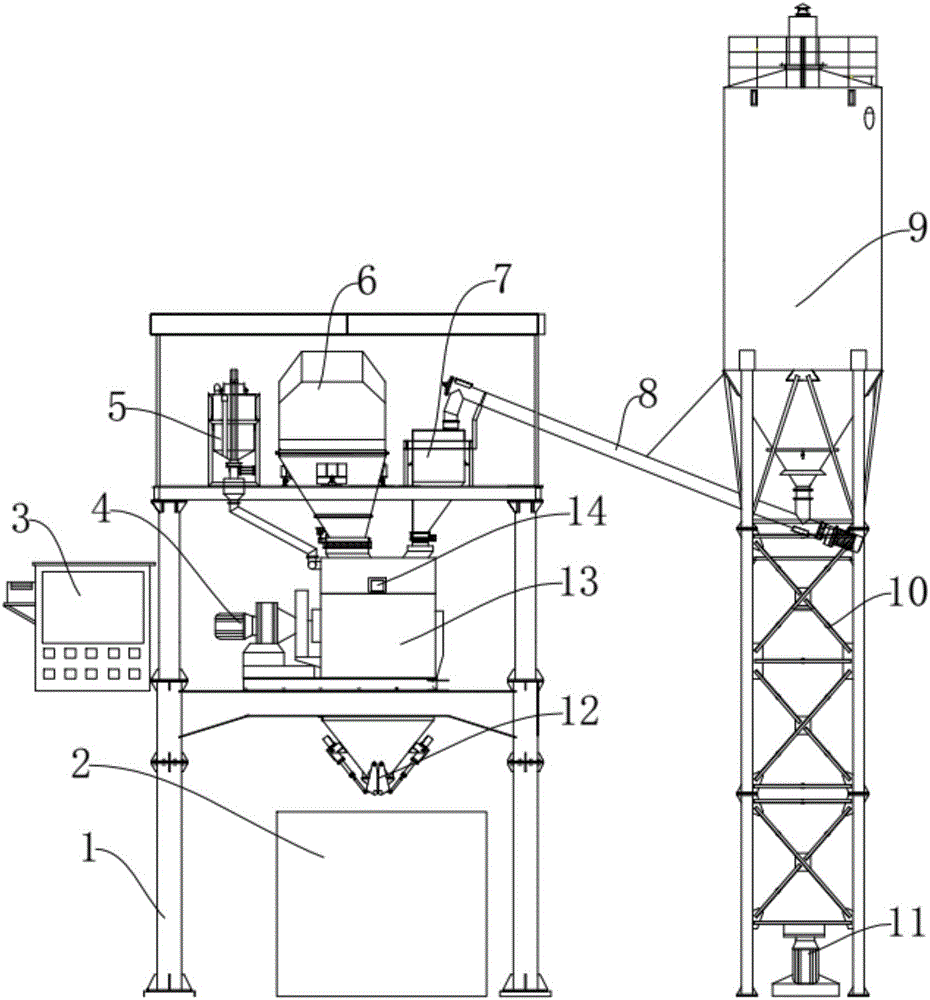

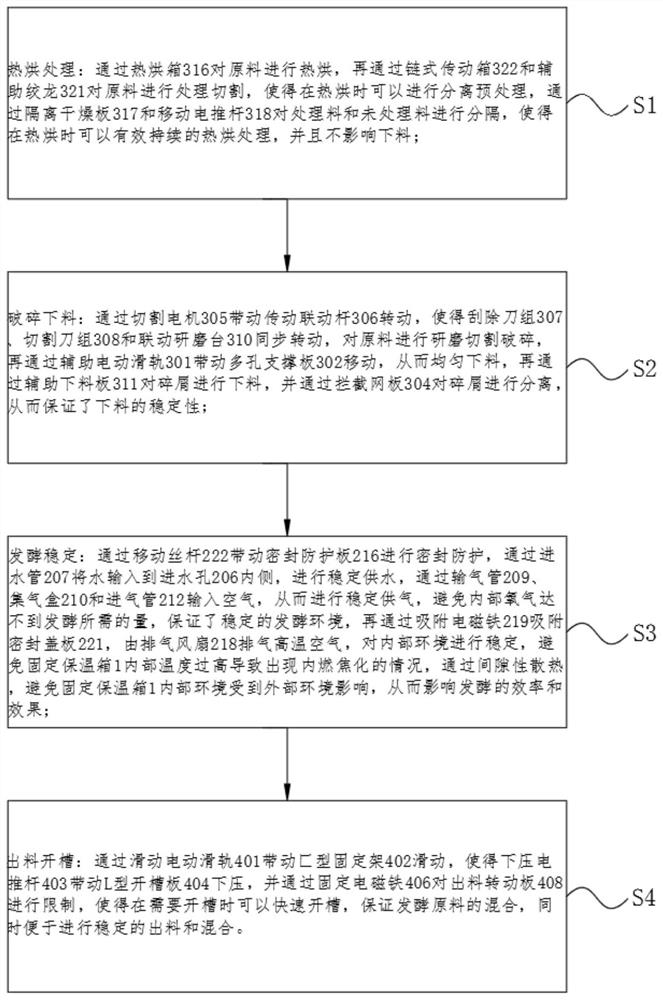

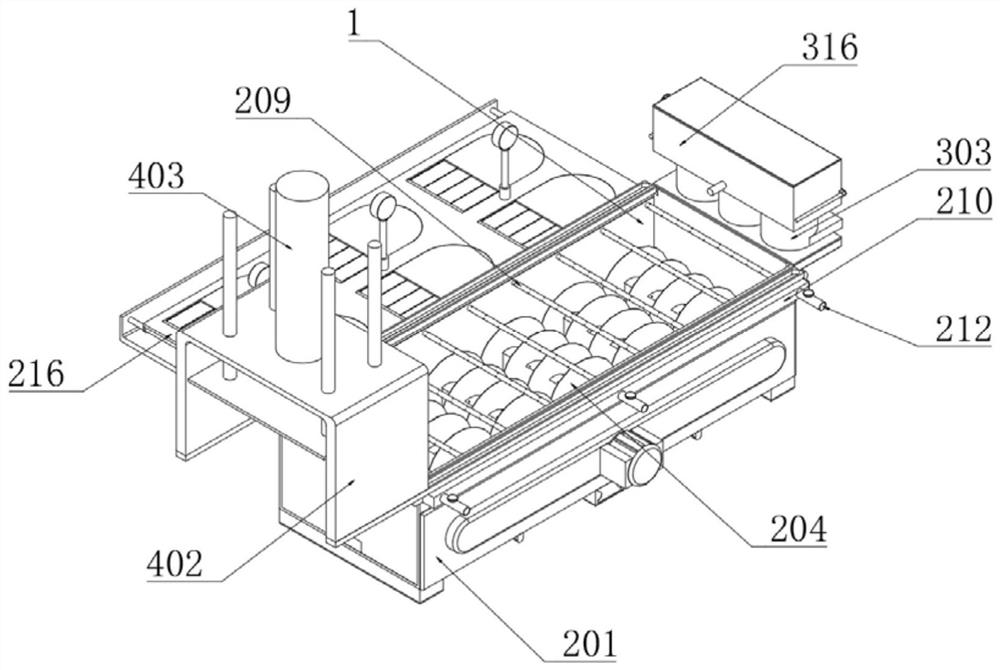

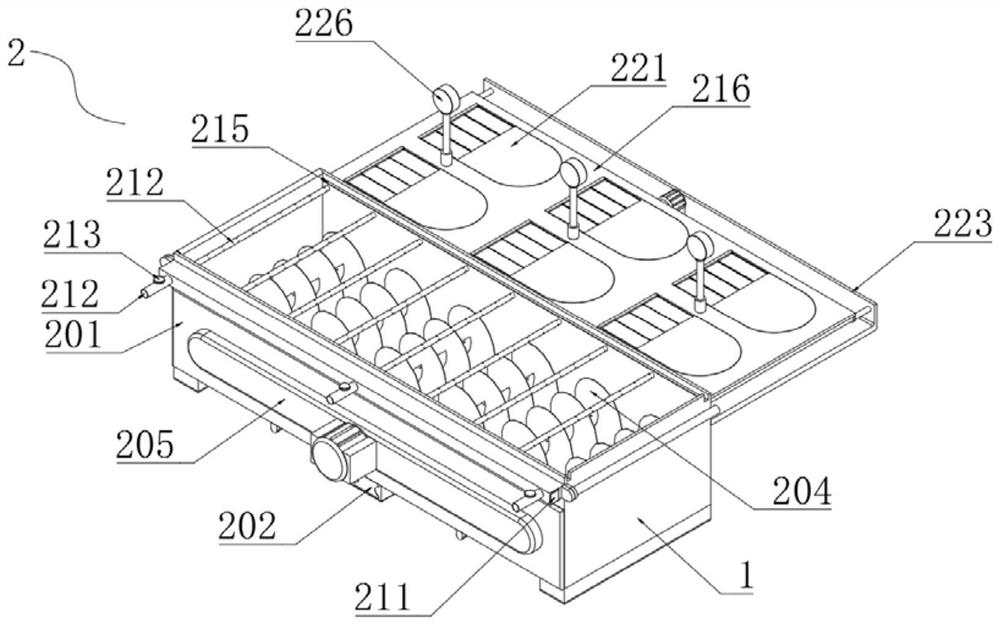

Intelligent preparation system and preparation method for synthesizing quick-acting and slow-release integrated efficient ecological compound fertilizer through straw microbial fermentation

ActiveCN104817399ARapid Corrosion DegradationAccelerated fermentation degradationBio-organic fraction processingEnergy inputCelluloseBiotechnology

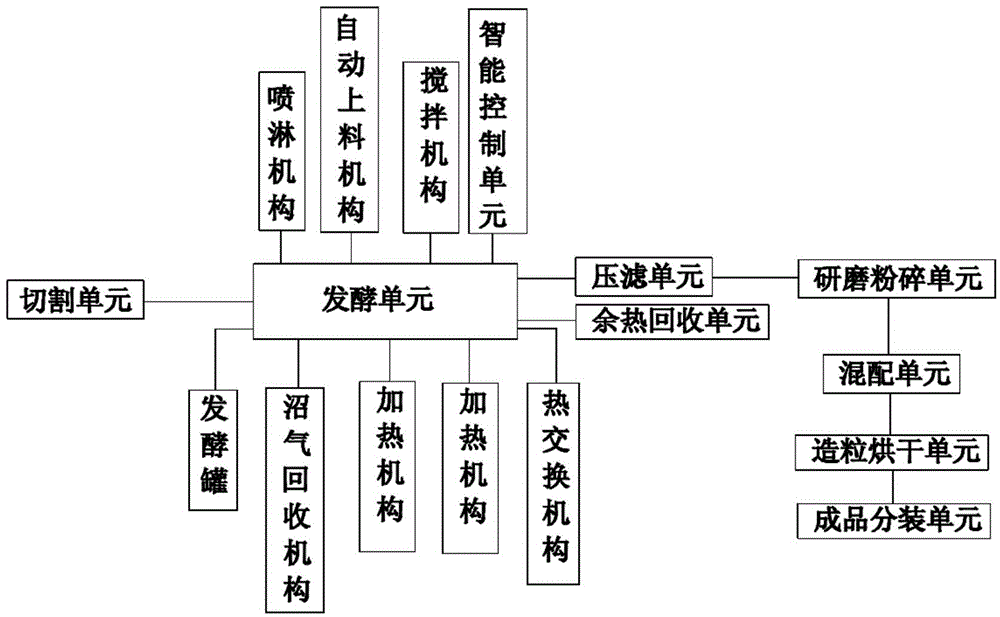

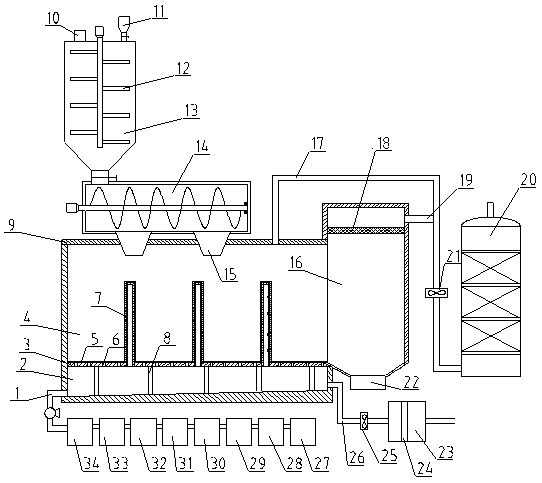

The invention discloses an intelligent preparation system and preparation method for synthesizing a quick-acting and slow-release integrated efficient ecological compound fertilizer through straw microbial fermentation. The system comprises a cutting unit, a fermentation unit, an intelligent control unit, a waste heat recovery unit, a press filtration unit, a grinding and crushing unit, a blending unit, a granulation and drying unit and a finished product sub-packaging unit, wherein the fermentation unit comprises a fermentation tank, a biogas recovery mechanism, a heating mechanism, a heat exchange mechanism, a sprinkling mechanism, an automatic feeding mechanism and a stirring mechanism. The method comprises the following steps: performing sealed fermentation on straws and animal feces; and performing water press filtration on a fermentation product, then performing high-temperature inactivation, adding an appropriate amount of inorganic quick-acting fertilizer and trace element fertilizer, rooting powder, a drought-resistant water retention agent and clay, mixing, and performing granulation and drying to obtain the compound fertilizer. By adopting the system and the method disclosed by the invention, fresh animal feces are used as a leaven which contains a lot of microorganism bacteria and digestive enzymes and can promote biological degradation and decomposition of the straws; and moreover, the animal feces are further fermented to be beneficial for opening unstable ester bonds in straw cellulose, accelerating the degradation of the straws and shortening the fermentation period.

Owner:ANHUI JULI MACHINERY MFG

Low-lactose long-shelf life yoghourt and preparation method thereof

ActiveCN103564045AImprove stabilityControl fermentation temperatureMilk preparationSodium lactateSucrose

The invention provides low-lactose long-shelf life yoghourt which comprises the following raw materials: 60-98.9 parts by weight of milk, 0.01-0.5 part by weight of emulsifiers, 3-14 parts by weight of thickening agents, and 7-12 parts by weight of sugar; the emulsifier is a combination of one or more than one of sucrose fatty acid ester, glyceryl monostearate fatty acid ester, stearoyl sodium lactate, and glycerol distearate; the thickening agent is a combination of one or more than one of pectin, sodium caseinate, agar, gelatin, modified starch, gellan gum, propylene glycol alginate, and xanthan gum. The low-lactose long-shelf life yoghourt has good stability. The invention also provides a preparation method of the low-lactose long-shelf life yoghourt; the method controls the fermentation temperature and carries out secondary sterilization; the low-lactose long-shelf life yoghourt prepared by the method has good stability.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Pseudo-ginseng yeast extraction method and application

InactiveCN104825383AAvoid smallControl fermentation temperatureCosmetic preparationsToilet preparationsBiotechnologyYeast

The invention discloses a pseudo-ginseng yeast extraction method and application. The pseudo-ginseng yeast extraction method includes the steps of (1), strain activation; (2), strain purification; (3), strain expanded cultivation; (4), pseudo-ginseng suspension preparation; (5), strain inoculation and (6), fermentation. The application includes pseudo-ginseng fermentation extract is directly used as a finished product of facial mask or essence or toner without adding any auxiliary materials. The pseudo-ginseng yeast extraction method has the advantages that production cost is saved, product quality is improved, production steps are simplified to greatest extent, massive production and industrialized production of fermentation technology can be realized, and stability in product stability can be guaranteed fully. Pseudo-ginseng yeast has the advantages that the pseudo-ginseng yeast is purely natural, is 100% of plant essence and does not contain any chemical ingredient, thereby being free of causing any side effect to skin; the pseudo-ginseng yeast is easy to absorb, and the extract is obtained through a fermentation process, so that molecules can obtain smaller ingredients when compared with common extraction methods, and the extract can be absorbed by skin fully.

Owner:YUNNAN BAIYAO GROUP

Tea leaf processing technology

InactiveCN107258956AIncrease contact areaUniform adhesionPre-extraction tea treatmentEngineeringRosin

The invention belongs to the field of tea leaf processing, and particularly relates to a tea leaf processing technology. The tea leaf processing technology comprises the following steps of fixation, twisting, fermentation and drying, a fermentation device is used for fermenting tea leaves, and the fermentation device is characterized in that rosin strips are used for splicing a charging box, and the charging device is heated by steam, so that the contact area of the tea leaves and spice is enlarged; and besides, the steam is used for driving a sector gear to rotate, a first gear rack, a second gear rack and a gear move to drive a rotating plate to rotate, and the rotating plate is used for turning over the tea leaves, so that the fragrance is uniformly adhered to the tea leaves, and the tea leaves are good in quality.

Owner:湄潭县一品缘茶业有限公司

Garbage fermenting system and method of garbage incineration power plant

InactiveCN109503232AAvoid settingSimple structureBio-organic fraction processingBiological combination treatmentPower stationLitter

The invention discloses a garbage fermenting system and a garbage fermenting method of a garbage incineration power plant. The garbage fermenting system comprises a fermenting tank, a feeding system and a discharging system, wherein a top cover is arranged on the top of the fermenting tank; a partition board is arranged above supporting columns inside the fermenting tank; the partition board partitions an inner cavity of the fermenting tank into a fermentation chamber and a filtrate storage chamber; a liquid draining pipe is arranged at one end of the filtrate storage chamber; a filtrate purifying system is connected to the end part of the liquid draining pipe; a gas inlet pipe is arranged at the other end of the filtrate storage chamber; a blast blower and a temperature adjusting chamberare mounted on the gas inlet pipe; the feeding system comprises a material mixing tank and a screw feeder; a garbage inlet and a fermenting agent storage tank are arranged on the top of the material mixing tank; the discharging system is a discharging bin; a gas exhausting main pipe is mounted on the top of the fermenting tank; a deodorizing tower is mounted on the end part of a gas exhausting pipe. By adopting the garbage fermenting system and the garbage fermenting method, the fermentation temperature in the fermenting tank and the fermentation time can be controlled, environmental odor canbe quickly and effectively eliminated, generation and escape of the odor can be reduced and leachate produced in the garbage fermenting process can also be effectively treated.

Owner:QUJING YUNDIAN TOUXIN ENERGY POWER GENERATION

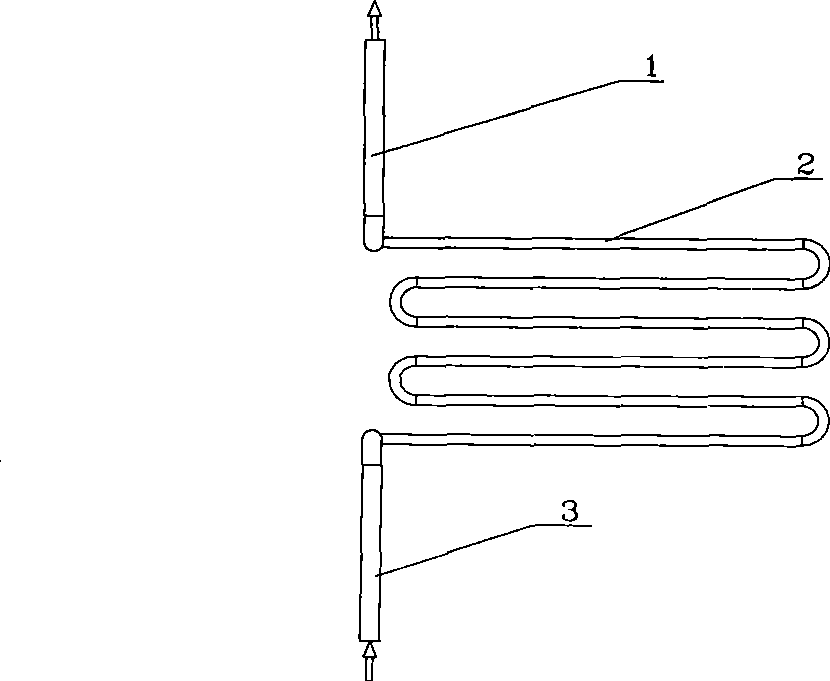

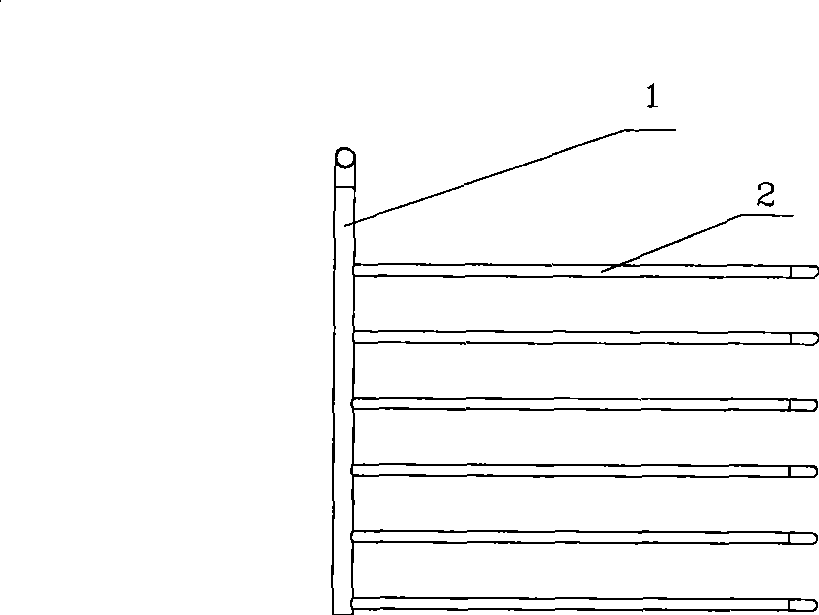

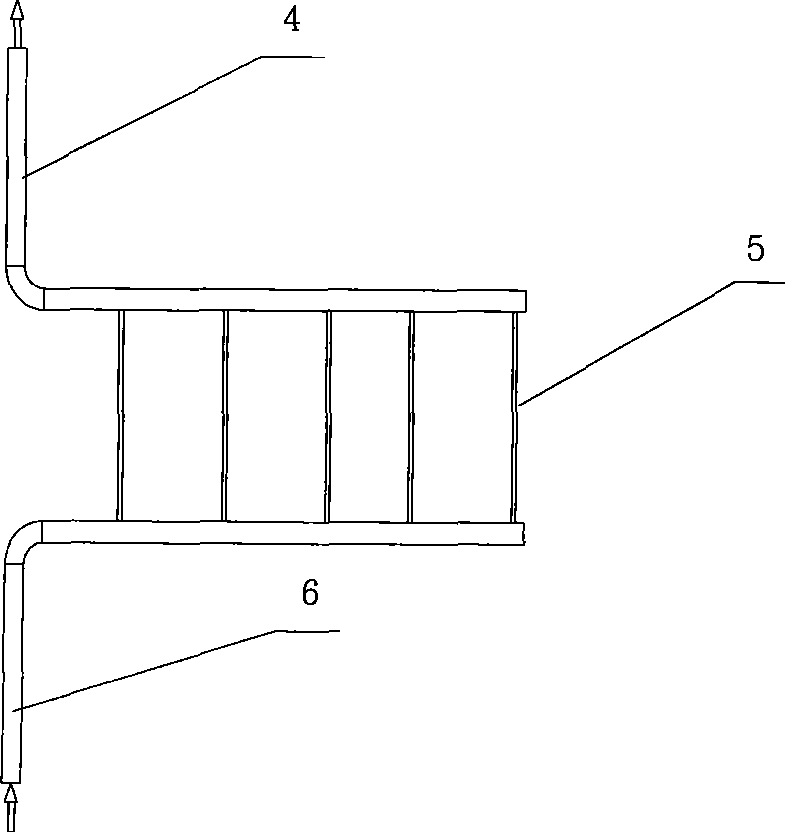

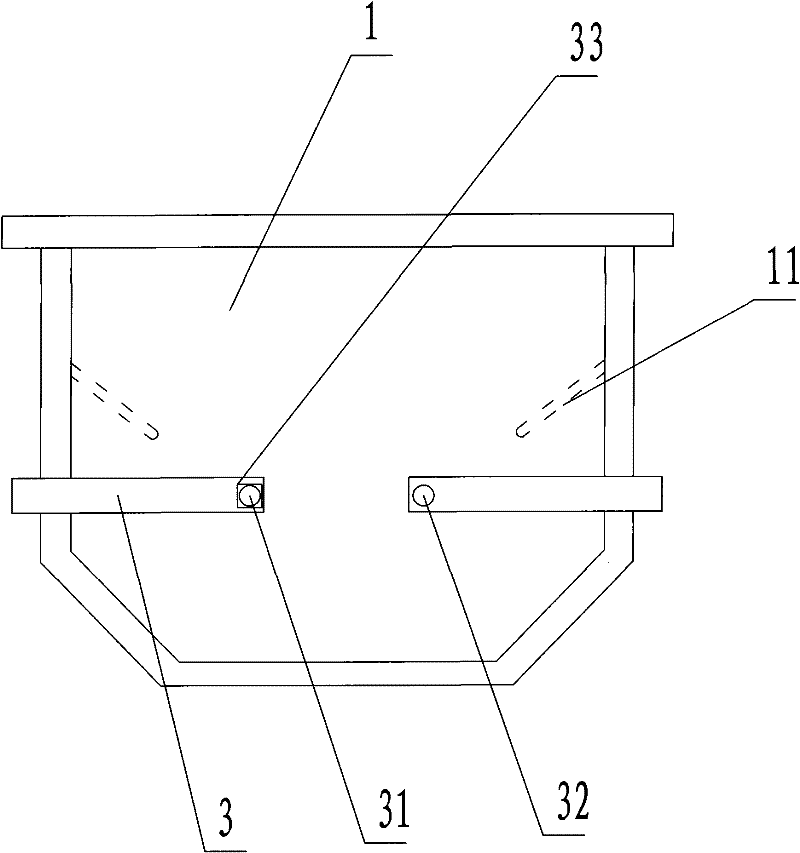

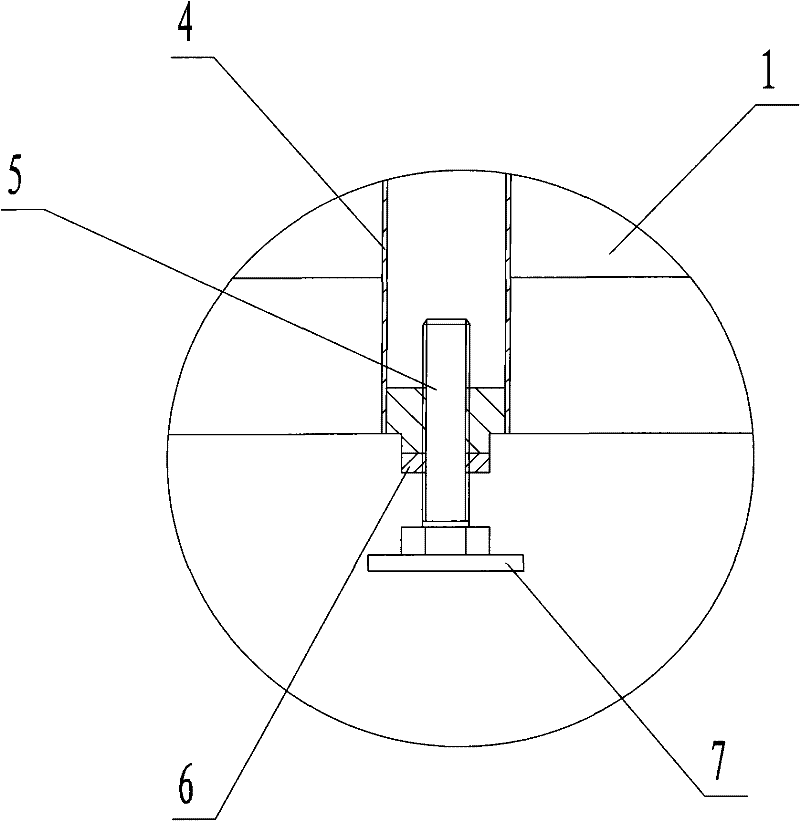

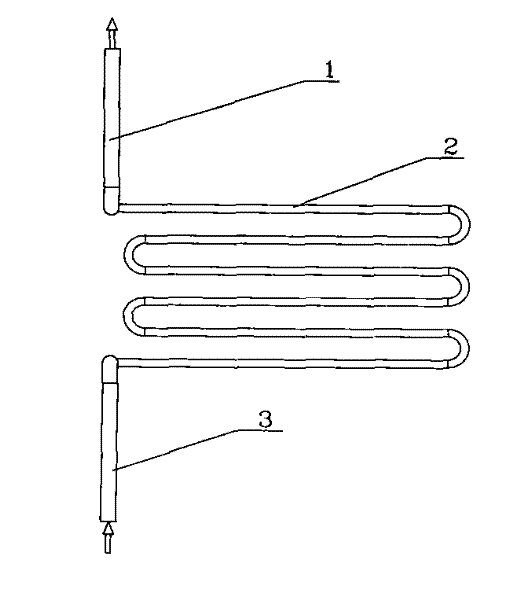

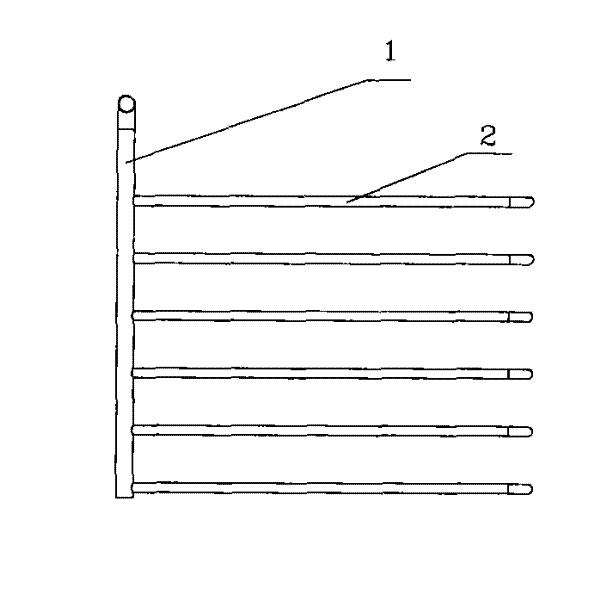

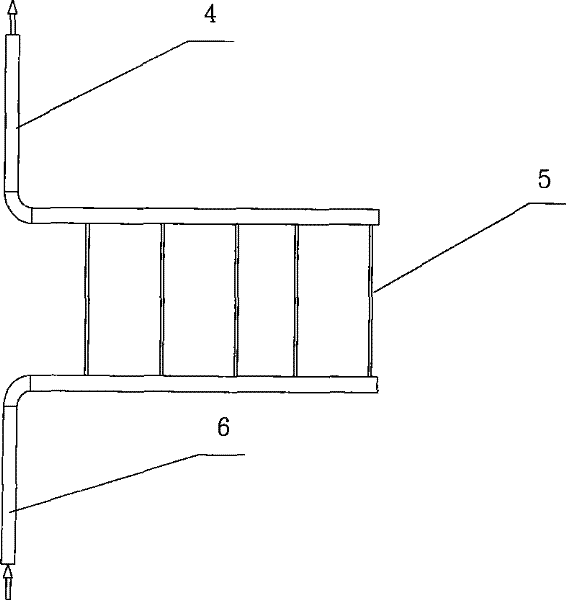

Control method for fermentation temperature in daqu liquor production cellar

ActiveCN101486961AControl fermentation temperatureQuality improvementAlcoholic beverage preparationBiologyToo slowly

The invention relates to a fermentation temperature control method in cellar pools for Daqu liquor production and belongs to the technical field of Daqu liquor production. The fermentation temperature control method realizes the fermentation temperature control inside the Daqu liquor producing cell pool in a heat exchanging way by arranging a heat exchanging device inside a Daqu liquor producing cell pool. When temperature of maternal fermented grains in the cell pool is too low or the temperature rises too slowly, hot water is charged, and heat is fed so as to heat the maternal fermented grains and shorten temperature rise time; when temperature of the maternal fermented grains in the cell pool is too high or the temperature rises too fast, cold water is charged, and heat-removing is carried out so as to cool the maternal fermented grains and reduce temperature rise speed; and in middle and late fermentation stage, waste hot water in workshop production is used for reserving temperature of the maternal fermented grains. The fermentation temperature control method of the cellar pools for Daqu liquor production can raise fermentation speed, shorten fermentation time and improve liquor quality.

Owner:LUZHOU LAOJIAO +1

Stirring-type tea fermentation machine

InactiveCN108497111AAchieve coolingControl fermentation temperaturePre-extraction tea treatmentCold airGear wheel

The invention relates to the technical field of tea processing, and discloses a stirring-type tea fermentation machine. The machine comprises a frame; a fermentation chamber is arranged on the frame;the fermentation chamber is internally and rotatably connected to rotating shafts; the rotating shafts are fixedly connected to stirring plates; the fermentation chamber is internally and slidably connected with a slide block which pushes against the stirring plates; the slide block is fixedly connected to a first magnet; the frame is rotatably connected to a gear; the gear engages with a rack; the rack is fixedly connected to a second magnet used for attracting the first magnet; spray heads are arranged in the fermentation chamber; the frame is fixedly connected to piston cylinders and air bags; a one-way air inlet valve is arranged on each piston cylinder; a piston is slidably connected into each piston cylinder; the ends of the rack are fixedly connected to the pistons; the air bags communicate with the piston cylinders and the fermentation chamber; a one-way valve is arranged between each air bag and each piston cylinder; a valve and a vortex tube are mounted between each air bag and the fermentation chamber; and the air inlet end of each vortex tube communicates with one of the air bags, and the cold air end of each vortex tube communicates with the fermentation chamber. The machine solves the problem of uneven stirring and poor temperature and humidity control din the tea fermentation process.

Owner:贵州省凤冈县翠巅香生态茶业有限公司

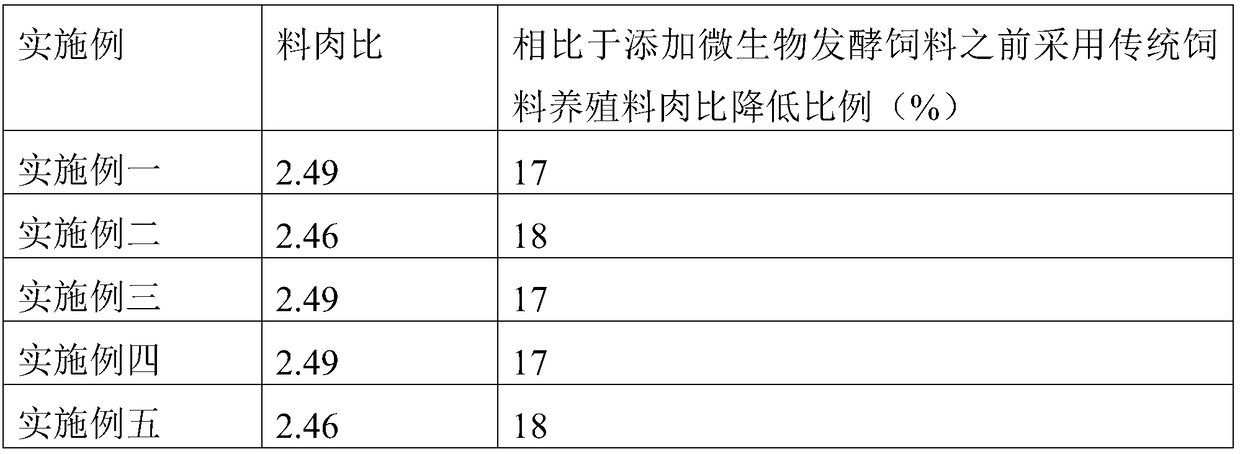

Preparation method of microorganism fermented feed

InactiveCN109170151AImprove digestion and absorptionImprove growthFood processingAnimal feeding stuffLaboratory cultureFermentation starter

The present invention discloses a preparation method of a microorganism fermented feed. The preparation method comprises the following steps: step one, a microorganism fermentation agent is prepared:the microorganism fermentation agent comprises the following microorganisms in parts by mass: 10-20 parts of yeasts, 10-20 parts of bacillus subtilis, 5-8 parts of lactic acid bacteria and 5-8 parts of aspergillus niger; step two: a medium is used to culture the microorganism fermentation agent; step three: a fermented product is prepared: the fermented product comprises the following substances in parts by mass: 40-50 parts of soybean meal, 40-50 parts of rice bran, 5-10 parts of bone meal and 0.1-0.2 part of brown sugar; step four, water and the brown sugar are added; when the brown sugar iscompletely dissolved, the microorganism culture solution is added; and fermentation is conducted for fermentation time of 25-30 days; and step five, drying is conducted. The prepared microorganism fermented feed contains fermentation metabolites beneficial to livestock, helps breeding of beneficial microorganisms in the intestines of the poultry and livestock and the health of the intestines, andimproves the growth of the poultry and livestock.

Owner:张项春

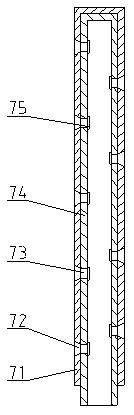

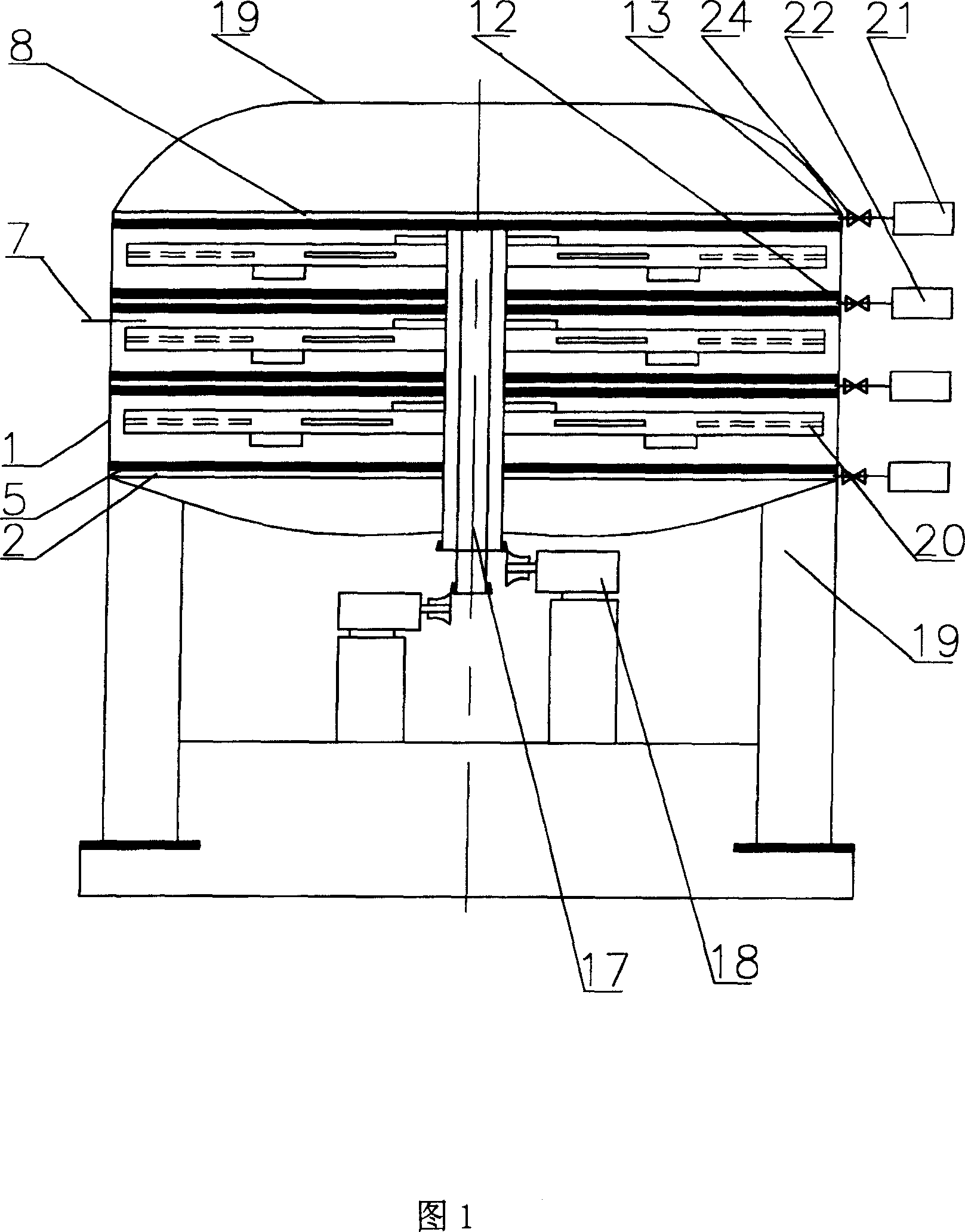

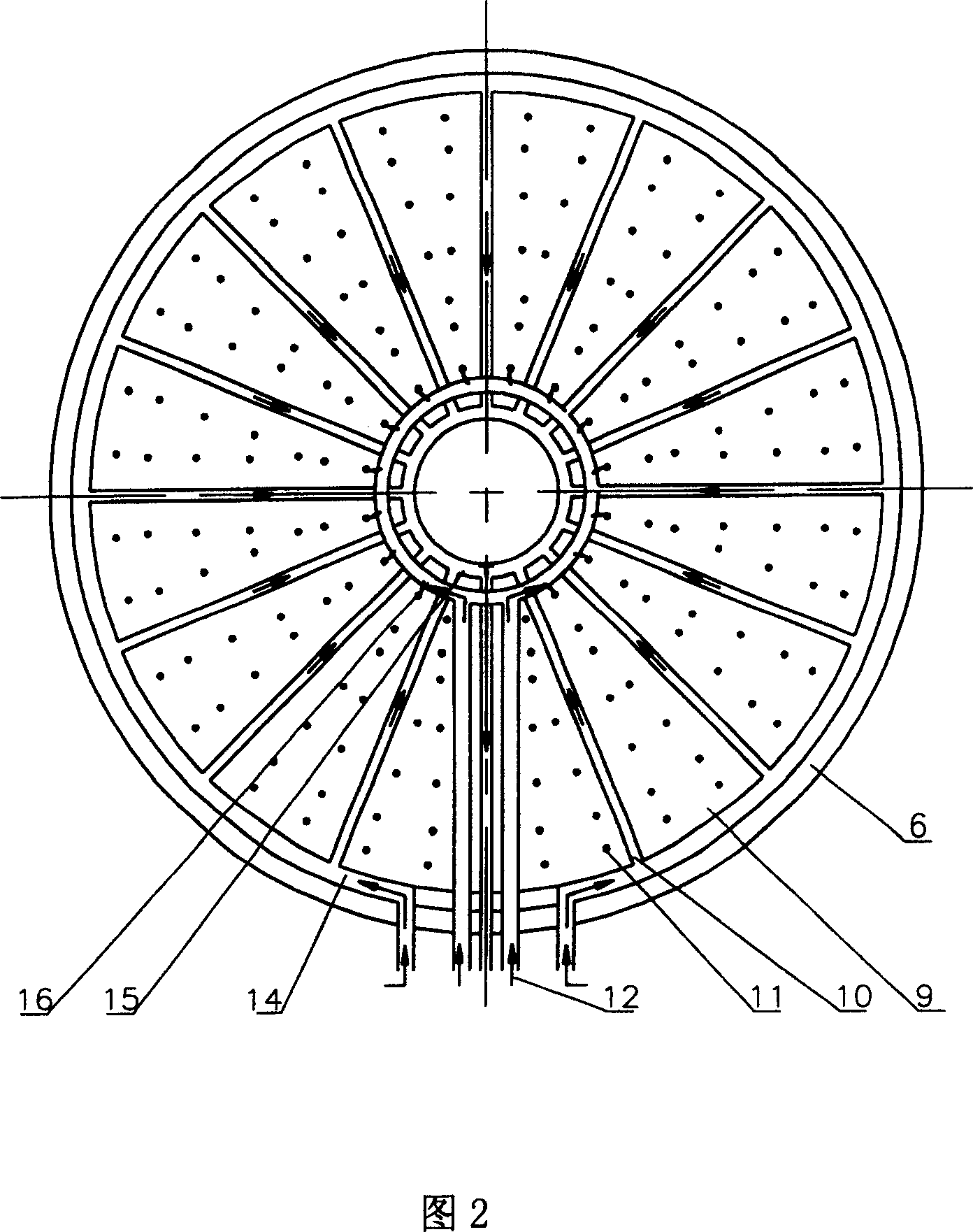

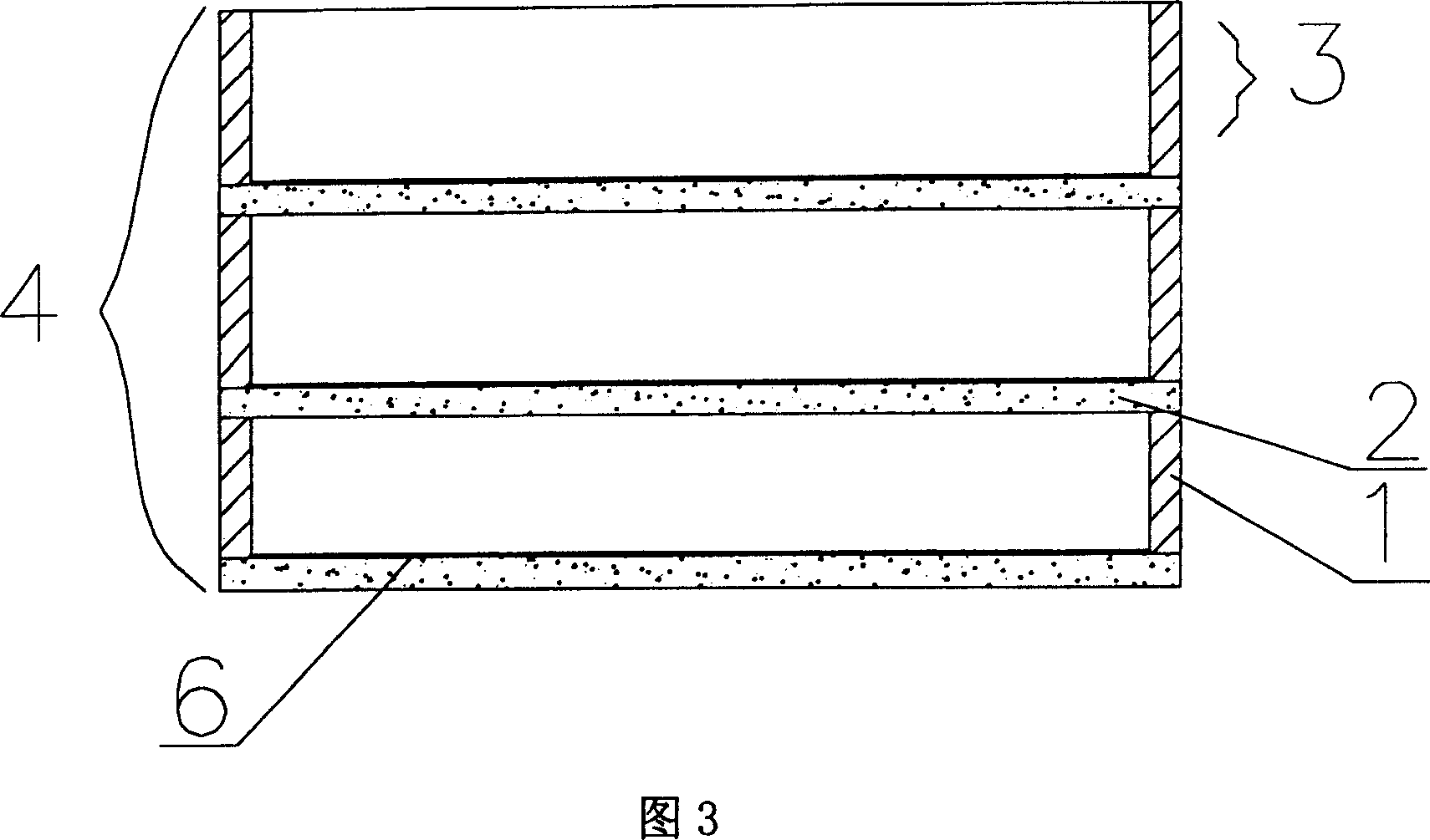

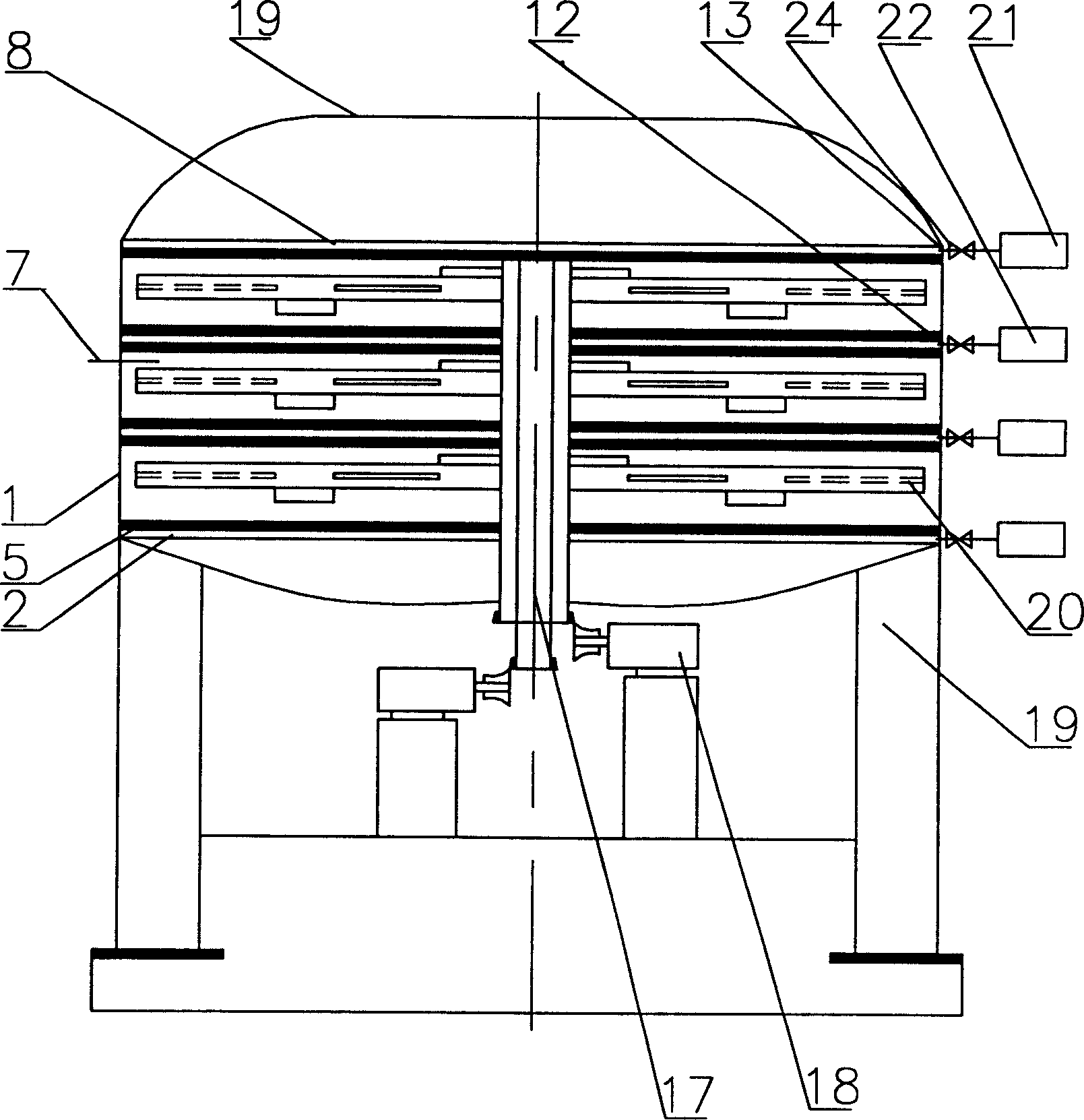

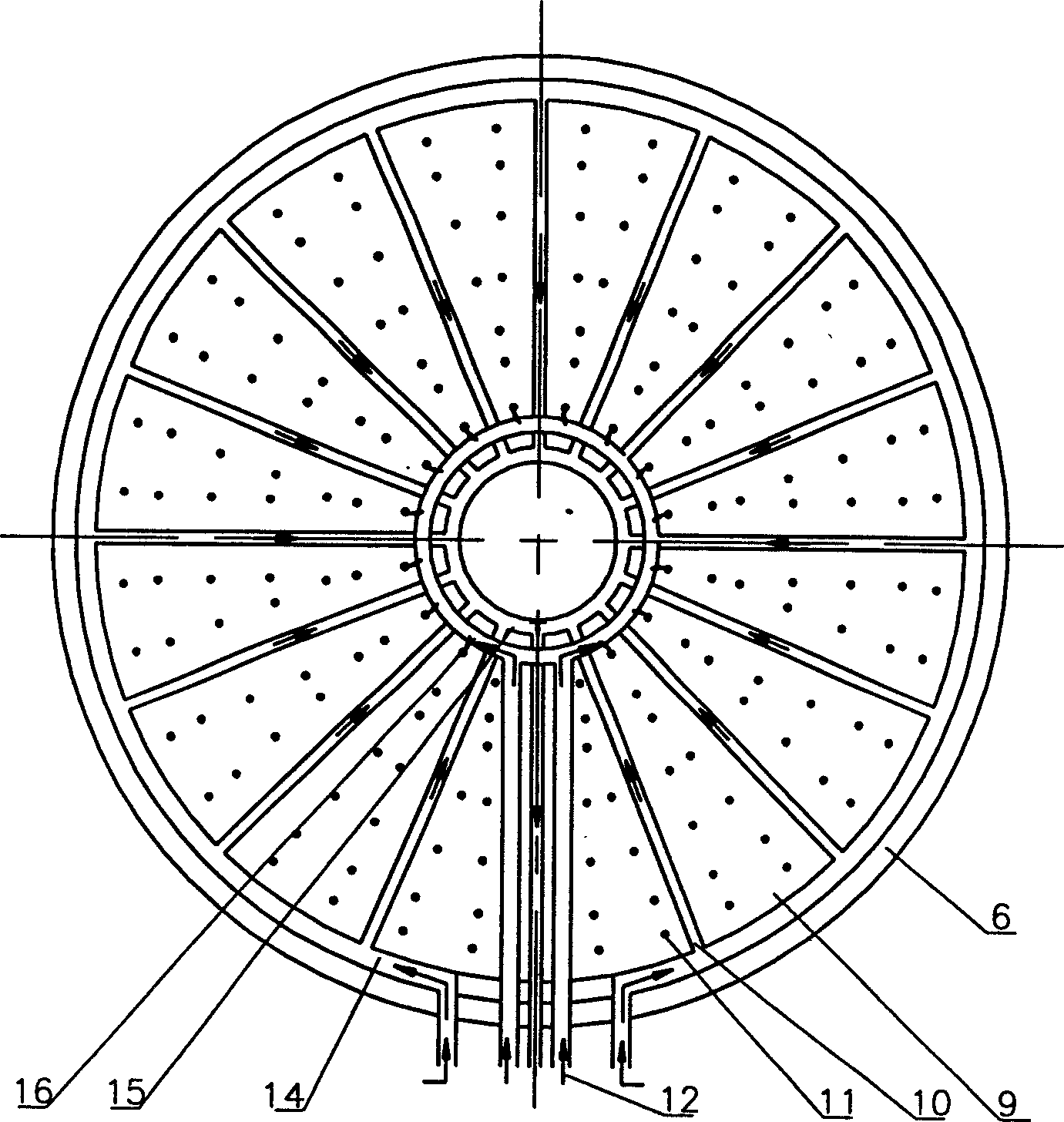

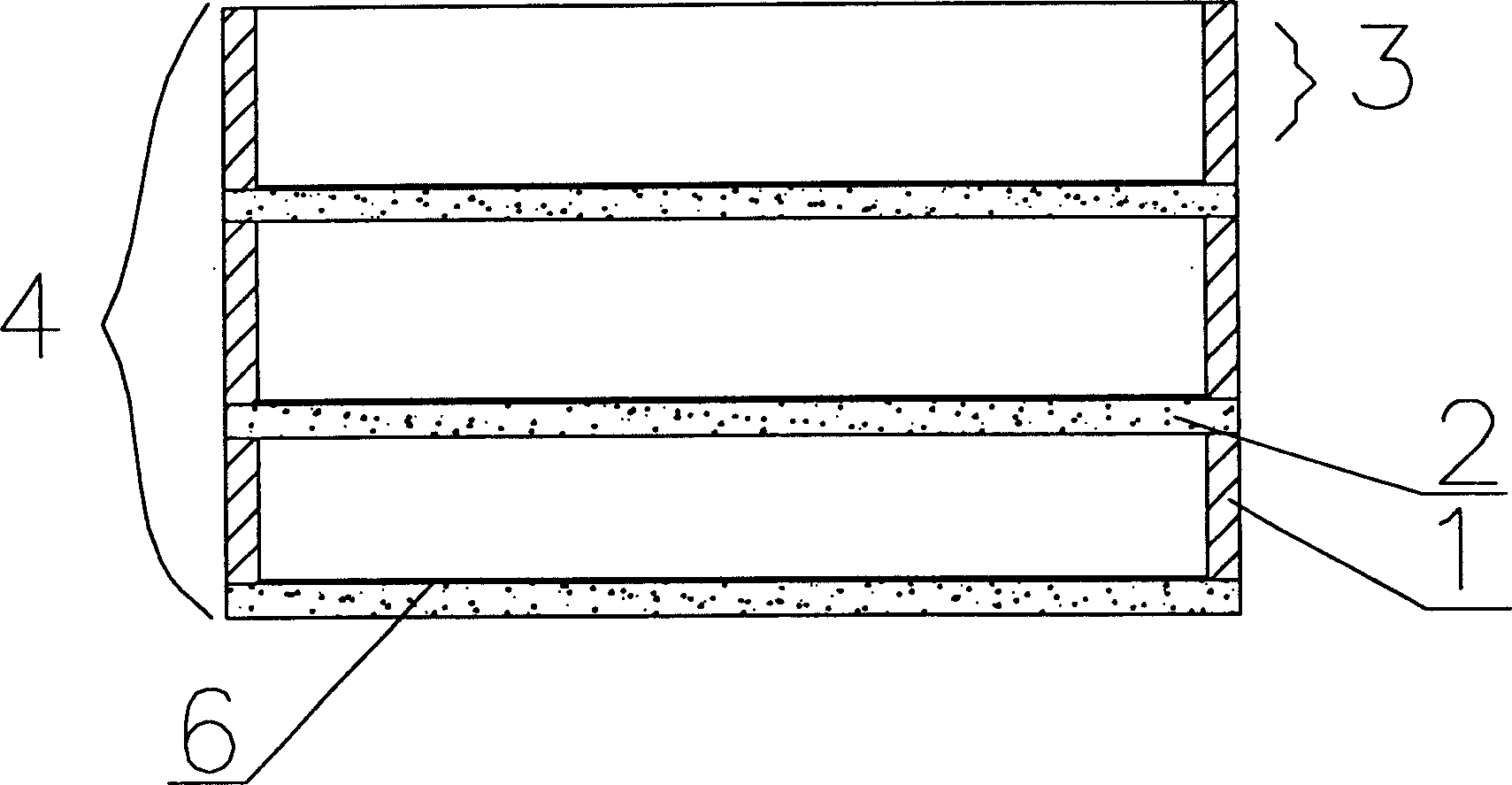

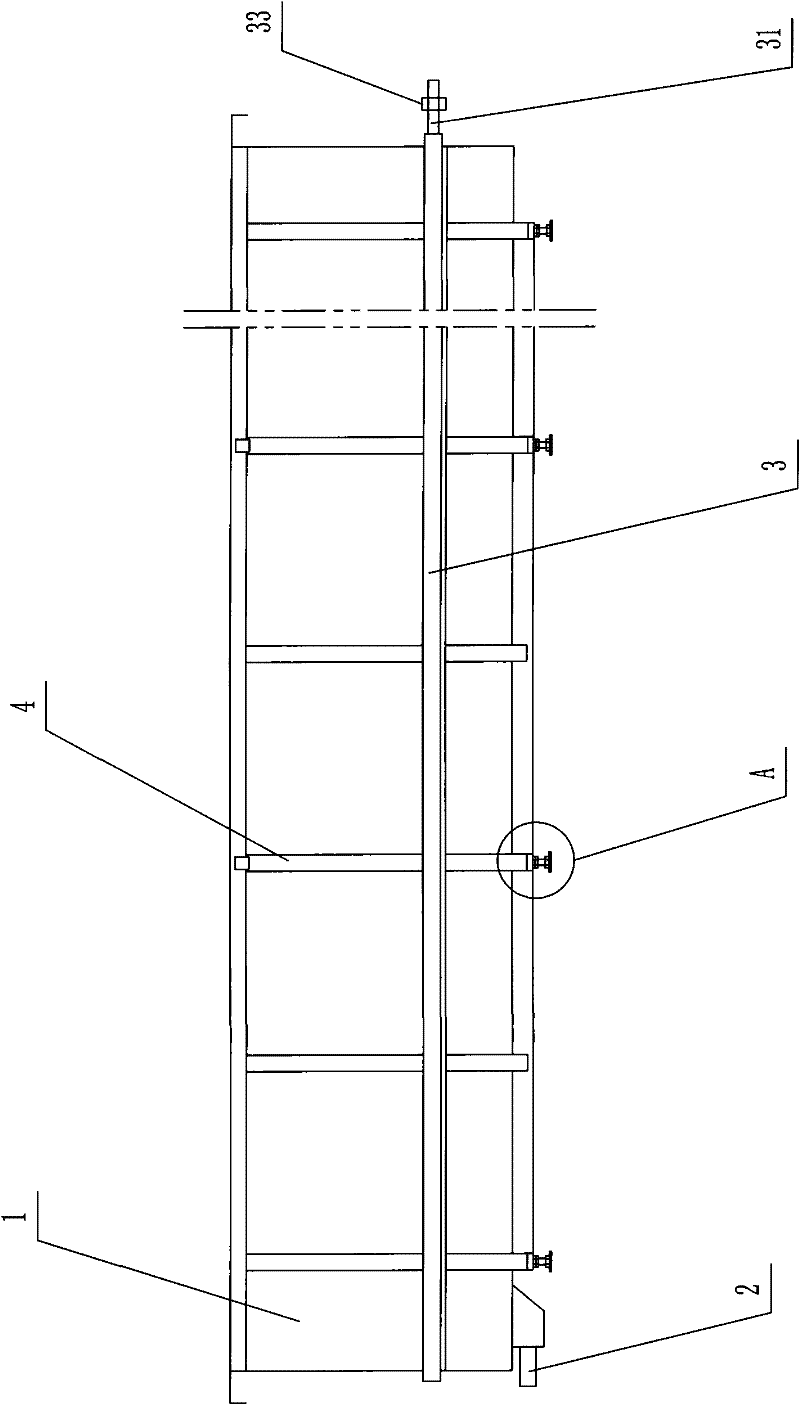

Modular solid state fermentation reactor

InactiveCN1304556CEasy to addFree from pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsTransmission channelComputer module

The invention relates to a modularized solid-state fermentation reactor, composed of one or many singly-operable modules, mixed arm and concentric shaft; the module is composed of annular transmission channel and a cylindrical outer wall, and a pipeline system with mutually-separated transmission channel and non-transmission channel is arranged on a basal disc, where the non-transmission channel carries heat conductivity fluid and the transmission channel feeds water, nutrient substance, oxygen gas, extract and so on to the modules; the concentric shaft is installed with the mixed arm, which keeps rotating around the mixed arm to blend the materials. It closely operates, the distribution of fed liquid material is uniform, the reaction conditions are accurately controlled according to the change of environmental parameters, and it provides a method of in-situ extracting the needed microbe product in a reactor.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

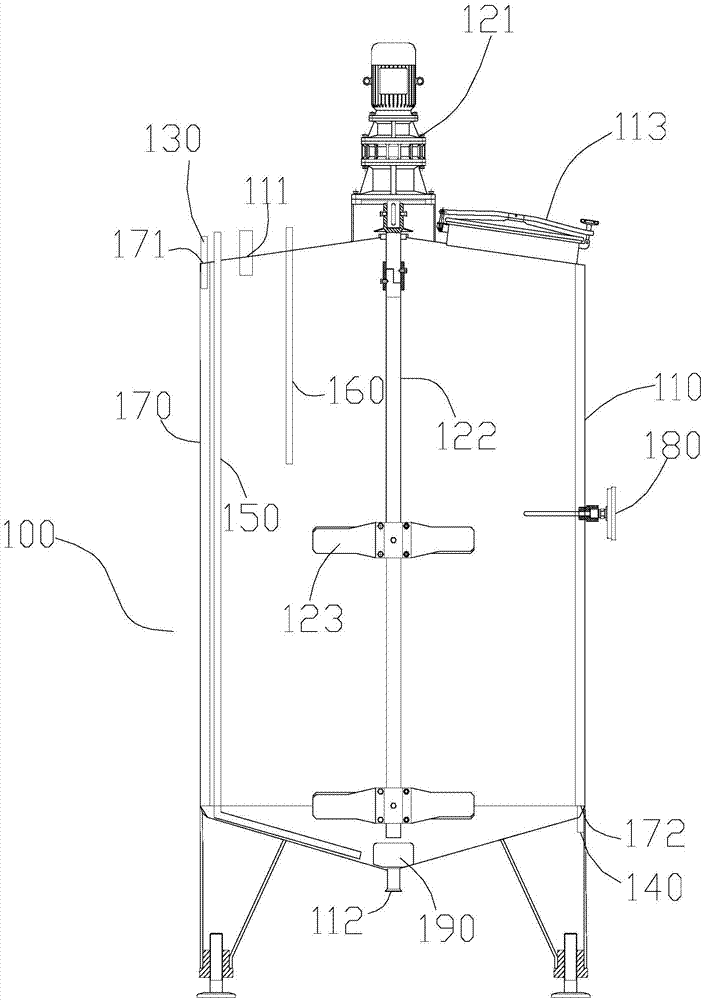

Fermentation tank

InactiveCN109136004AAvoid cakingAvoid wastingAlcoholic beverage preparationTemperature controlAgricultural engineering

The invention relates to a fermentation tank which comprises a tank body, a sterilizing device, a stirring device, a temperature control device, a weighing device and an air interchanger, wherein a turnable cover is arranged on the tank body; the cover is provided with a cavity; an air interchanging port is formed in the tank body; the sterilizing device comprises a tank sterilizer and an air sterilizer; the tank sterilizer is fixed on the lower surface of the cover; the air sterilizer is arranged in the cavity; the stirring device comprises a motor and a stirrer; the motor is in drive connection with the stirrer for rotating; the stirrer is arranged in the tank body; the temperature control device comprises a temperature sensor and a temperature regulator; the temperature sensor and the temperature regulator are respectively fixed in the tank body; the weighing device is arranged below the tank body; the air interchanger is connected with the air interchanging port. According to the fermentation tank disclosed by the invention, the initial starch concentration, air quantity in the fermentation process, the fermentation temperature and infectious microbes can be effectively controlled, so that fermentation is performed in an optimum environment, and the wine making efficiency and quality are improved.

Owner:德保县广鑫贸易有限公司

Bio-organic fertilizer produced by means of slaughter line organic waste and production method thereof

InactiveCN109111253APromote growthPromote growth and developmentBio-organic fraction processingAnimal corpse fertilisersIntestinal structureMicrobial agent

The invention discloses bio-organic fertilizer produced by means of slaughter line organic waste and a production method thereof, and belongs to the technical field of bio-organic fertilizer. On one hand, the technical purpose of applying the slaughter line organic waste to the bio-organic fertilizer is achieved, and on the other hand, the problems that the slaughter line organic waste is high inharmlessness cost and hard to recycle are solved. The bio-organic fertilizer produced by means of the slaughter line organic waste is prepared from the raw materials: 85%-90% of dried cattle and sheepmanure, 5%-15% of wet cattle and sheep manure, fresh cattle and sheep blood, beef and mutton or cattle and sheep intestines or a mixture of the beef, the mutton and the cattle and sheep intestines, adecomposition agent and a compound microbial agent; the production method of the bio-organic fertilizer produced by means of the slaughter line organic waste comprises the steps of beef and mutton orcattle and sheep intestine crushing, preparation, mixing, primary fermentation, secondary fermentation, crushing and screening. By means of the bio-organic fertilizer produced by means of the slaughter line organic waste and the production method thereof, a novel idea is provided for treating the waste produced by a slaughter production line, the cattle and sheep blood which flows to a sewage treatment link along with slaughter sewage is used directly, pressure of slaughter line sewage treatment is greatly reduced, the waste is used fully, and clean production is achieved.

Owner:玛曲曲源肥业科技有限公司

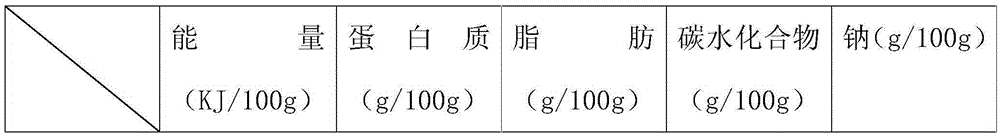

Rice-husk plantation base material for agaricus bisporus, preparation method thereof and method for planting agaricus bisporus by using rice husk

InactiveCN105347929AReduce ammonia removal timeShorten fermentation timeCalcareous fertilisersBio-organic fraction processingBiotechnologyAgaricus

A disclosed rice-husk plantation base material for agaricus bisporus comprises the following compositions in parts by weight: 15-25 parts of rice husk, 65-75 parts of cow dung, 2-4 parts of lime, 0.5-1.5 parts of a phosphate fertilizer, 0.5-1.5 parts of gypsum, 2-4 parts of a vegetable cake, and 0.5-1.5 parts of calcium carbonate. The preparation method for the plantation base material for agaricus bisporus comprises uniformly mixing rice husk, cow dung, lime, the phosphorus fertilizer, gypsum, vegetable cake and calcium carbonate, and piling in a room and fermenting to obtain the plantation base material, and performing turning during piling fermentation. The plantation base material can be momentarily prepared and stored and is not influenced by time and climate, also the raw materials are easy to obtain, price is low, and fermentation time is short, indoor fermentation is employed, fermentation temperature is easy to control, mechanical turning and industrialized production are easy to realize, and production labor cost is substantially reduced. The plantation base material is good in quality, nutrition ratio is scientific and reasonable, agaricus bisporus is fruited ahead of about 10 days compared with a traditional plantation base material, the yield of fresh agaricus bisporus in per one mu farmland is increased by 200 Kg, and the quality of fresh agaricus bisporus is relatively good.

Owner:CHONGQING XUNYE EDIBLE FUNGI PLANTATION DEV CO LTD

Low-lactose long-shelf life yoghourt and preparation method thereof

ActiveCN103564045BImprove stabilityControl fermentation temperatureMilk preparationBiotechnologySucrose

The invention provides a low-lactose yoghurt with a long shelf life. The raw materials for making it include: 60 to 98.9 parts by weight of milk, 0.01 to 0.5 parts by weight of an emulsifier, 3 to 14 parts by weight of a thickener and 7 to 12 parts by weight of sugar; And the emulsifier is one or more combinations of sucrose fatty acid ester, glyceryl monostearate, sodium stearoyl lactylate and glyceryl distearate; the thickener is pectin, sodium caseinate , agar, gelatin, modified starch, gellan gum, propylene glycol alginate, xanthan gum, or a combination of several. The low-lactose long-shelf-life yoghurt has good stability. The present invention also provides a method for preparing the above-mentioned low-lactose long-shelf-life yogurt, which controls the fermentation temperature and performs secondary sterilization, and the low-lactose long-shelf-life yogurt prepared by the method has better stability.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Fermentation device for functional zinc-rich feed additive

InactiveCN108065435ASimple structureImprove fermentation effectFeeding-stuffExhaust valveDrive shaft

The invention discloses a fermentation device for a functional zinc-rich feed additive. The fermentation device includes a casing, a water outlet pipe is fixedly installed on the right side of the casing, an exhaust valve is fixedly installed below the water outlet pipe, and an intake valve is fixedly installed on the left side of the casing. A distribution box is fixedly mounted on the upper surface of the casing, a transmission shaft is fixedly installed on the left side of the distribution box, a motor is fixedly installed at the top of the transmission shaft, and a feeding pipe is fixedlyinstalled on the left side of the transmission shaft. A sealing door is movably installed inside the feeding pipe, a water tank is fixedly installed inside the casing, a fermentation tank is fixedly installed inside the water tank, a rotating shaft is movably installed inside the fermentation tank, and a stirring knife is fixedly installed on the outer surface of the rotating shaft. A built-in battery is electrically connected with a control panel, the motor and a power supply socket through a wire. The fermentation device has a simple structure, is convenient and practical, has a good fermentation effect, and can well guarantee the fermentation environment and improve the fermentation efficiency.

Owner:安徽天昊中慧生物科技有限公司

Alcohol fermentation tank, alcohol fermentation system and alcohol fermentation process

PendingCN107988038AReduce the temperatureProcess parameter controlVinegar preparationAqueous alcoholEngineering

The invention discloses an alcohol fermentation tank. The alcohol fermentation tank comprises a tank body, a heat exchange medium input pipe, a heat exchange medium output pipe, a compressed air pipeand temperature sensing equipment; a stirring device is arranged in the tank body; a jacket structure is arranged on the outside wall of the tank body; a heat exchange medium input port is formed in one end of the jacket structure; a heat exchange medium output port is formed in the other end of the jacket structure; a material outlet of the heat exchange medium input pipe is connected with the heat exchange medium input port; a material inlet of the heat exchange medium output pipe is connected with the heat exchange medium output port; one end of the compressed air pipe extends into the tankbody; an air outlet of the compressed air pipe is positioned at the material outlet of the tank body; the temperature sensing equipment is mounted on the tank body; one end of the temperature sensingequipment extends into the tank body. The invention also discloses an alcohol fermentation system and an alcohol fermentation process. The alcohol fermentation tank disclosed by the invention can precisely control the fermenting temperature of alcohol, and further has the characteristics of small occupied floor area and high production efficiency.

Owner:TIANDI YIHAO BEVERAGE JIANGMEN CITY

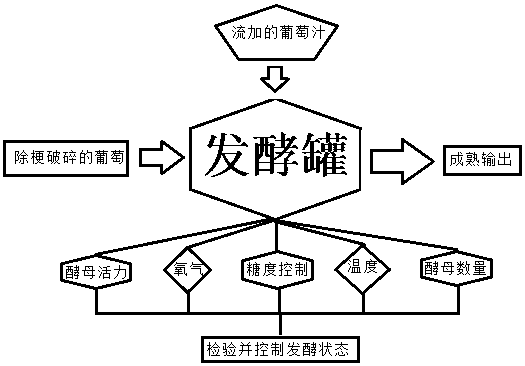

Production method of pure-juice grape white spirit

InactiveCN110804512AOptimal fermentation degreeOptimal vitalityWine preparationBiotechnologyForeign matter

The invention discloses a production method of pure-juice grape white spirit. The production method comprises the following steps: (1) metering and checking delivered fresh grapes; (2) pouring the grapes into a screening platform to further screen out and remove impurities to remove mildewed fruits; (3) crushing the grapes into pulp; (4) performing pre-fermenting; (5) adding activated yeast; (6) performing fermenting; (7) performing squeezing; (8) performing distilling; (9) performing ageing; (10) performing blending; and (11) performing filling: brushing a wine bottle, then performing qualitytesting to check whether foreign matter exists, and capping the wine bottle by using a capping machine. The production method has the advantages that the yeast reaches an optimal fermentation degree;the alcohol degree is between 15% and 18%; no saccharide is added in a fermentation process, and concentrated grape juice is fed in batches or multiple times; the fermentation temperature is controlled; activity and number of saccharomycetes in the fermentation materials are controlled; and the sugar degree of the raw materials is controlled, so that the yeast is kept in an optimal activity state, then the alcohol degree of 15-18%vol is achieved, and the grape white spirit with high yield and good quality is obtained.

Owner:杭州公望酒业有限公司

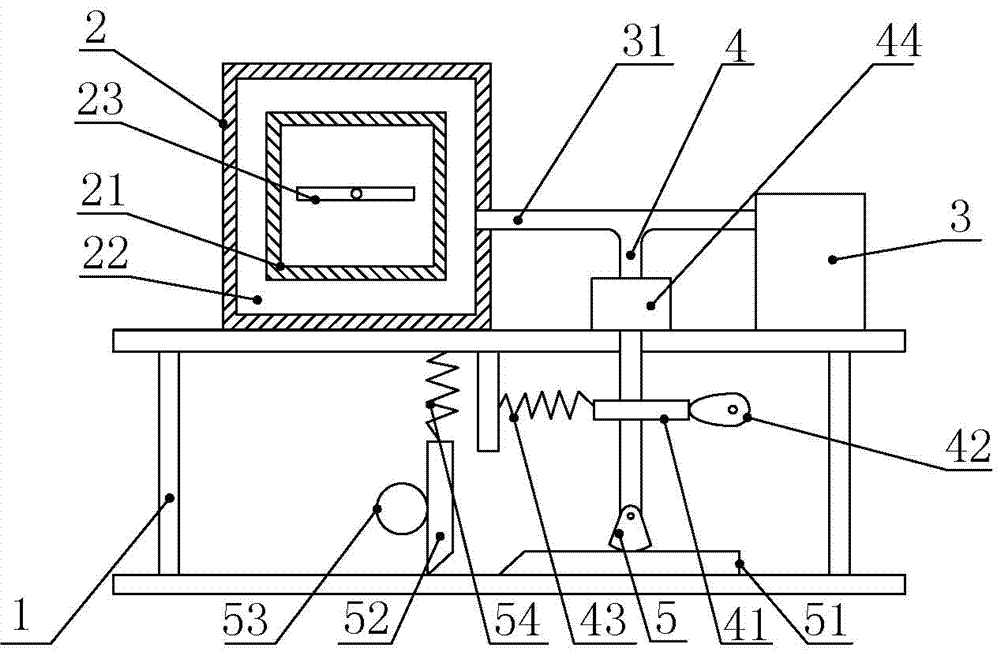

Agricultural flour deep processing equipment

InactiveCN105994463AGuaranteed tasteReduce labor burdenMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsAgricultural scienceAgricultural engineering

The invention discloses agricultural flour deep processing equipment which comprises a rack, a dough kneading box, an operation box and a lifting rack. The dough kneading box is mounted on the support, an automatic discharging door is arranged below the dough kneading box, a receiving hopper is arranged below the automatic discharging door, and a temperature display screen is arranged on the front portion of the dough kneading box. A stirring motor is mounted at one side of the dough kneading box, an operation box is arranged at one side of the stirring motor, an additive storage tank is arranged above the dough kneading box, and a clean water storage box is arranged at one side of the additive storage tank. A flour transfer box is arranged at one side of the clean water storage box, a flour conveying auger is mounted above the flour transfer box, a flour storage tank is mounted above the flour conveying auger, and the flour storage tank is mounted on the lifting rack. The agricultural flour deep processing equipment has the advantages that the automatic blending and stirring function can be completed by setting the matching ratio of a flour mixture, and the manpower burden is greatly relieved; meanwhile, fermentation flour can be fermented, the fermentation temperature and time can be effectively controlled, and the taste of made cooked wheaten food is guaranteed.

Owner:薛文超

Modular solid state fermentation reactor

InactiveCN1597915AEasy to addFree from pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsTransmission channelComputer module

The invention relates to a modularized solid-state fermentation reactor, composed of one or many singly-operable modules, mixed arm and concentric shaft; the module is composed of annular transmission channel and a cylindrical outer wall, and a pipeline system with mutually-separated transmission channel and non-transmission channel is arranged on a basal disc, where the non-transmission channel carries heat conductivity fluid and the transmission channel feeds water, nutrient substance, oxygen gas, extract and so on to the modules; the concentric shaft is installed with the mixed arm, which keeps rotating around the mixed arm to blend the materials. It closely operates, the distribution of fed liquid material is uniform, the reaction conditions are accurately controlled according to the change of environmental parameters, and it provides a method of in-situ extracting the needed microbe product in a reactor.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Wine-brewing fermenting device

InactiveCN108949461ASimple structureReasonable designAlcoholic beverage preparationTemperature controlWater storage tank

The invention discloses a wine-brewing fermenting device which comprises a fermenting tank, wherein a tank wall of the fermenting tank has an interlayer structure; a water jacket is arranged in the interlayer of the tank wall of the fermenting tank; a heat-insulating layer is coated on the outer wall of the fermenting tank; a water feeding pipe is arranged on one side of the water jacket while a water draining pipe is arranged on the other side; a temperature control tank is arranged on one side of the exterior of the fermenting tank; a temperature-adjusting device and a temperature-adjustingmedium are arranged in the temperature control tank; a fermenting pool is arranged on the bottom in the fermenting tank; a water storage tank is arranged on the top of the fermenting tank; a water adding pipe is arranged on the top of the water storage tank; an electric heating device is arranged in the water storage tank; a water pipe and a rotating rack are arranged on the bottom of the water storage tank; a plurality of spraying pipes are uniformly distributed on the rotating rack; one end of each spraying pipe is connected with the water pipe while the other end is connected with an atomizer; an air storage bag is arranged on one side of the upper part on the exterior of the fermenting tank; the air storage bag is connected with the fermenting tank through an air pipe. The wine-brewingfermenting device is capable of effectively controlling the fermentation speed and fermentation temperature, supplying a constant temperature condition for fermentation and greatly promoting the quality of products after fermentation.

Owner:广安市前锋区观阁镇小学校

Preparation method of barley tea drink

InactiveCN110973312AControl fermentation temperatureReduce humidityTea substituesBiotechnologyHydrolysate

The invention provides a preparation method of a barley tea drink. The method includes the steps of: 1) barley treatment: selecting full barley as the raw material, then performing soaking in a container holding fresh bamboo water, putting the container in an ultrasonic device, and putting the ultrasonic device in a germination box for germination treatment to obtain barley malt; 2) treatment of soybean meal; and 3) enzyme deactivating treatment: jetting the soybean meal enzymatic hydrolysate obtained in step 2) onto the barley malt, and then performing enzyme deactivating treatment in an enzyme deactivating machine so as to obtain the barley tea drink. The barley tea drink obtained by the method can effectively utilize nutrients, has mellow tea aroma, and can promote digestion.

Owner:潜山县下河有机茶厂

Baijiu brewing method

InactiveCN109837178AIncrease softnessGuaranteed thicknessAlcoholic beverage preparationBrewingChemistry

The invention discloses a Baijiu brewing method comprising the following steps: A, preparing high-temperature Daqu; B, preparing medium-temperature Daqu; and C, mixing the high-temperature Daqu and the medium-temperature Daqu in a certain proportion, to obtain a mixed yeast; and D, adding the mixed yeast into grains, and fermenting to obtain the product.

Owner:刘大兴

Pre-fermentation process of yellow rice wine

ActiveCN101798557BIncrease the amount of feedImprove site utilizationAlcoholic beverage preparationYeastBiology

The invention discloses a pre-fermentation process of yellow rice wine, which has the advantages of work place saving, reduction of the intensity of labour, and improvement of the production efficiency and the quality of yellow rice wine. The pre-fermentation process comprises the following steps of: soaking rice, steaming rice, adding Chinese yeast to the steamed rice and uniformly stirring the steamed rice and conveying the rice to a stainless steel fermentation tank by a conveyor belt; then, controlling the temperature of the steamed rice in the stainless steel fermentation tank by a temperature regulator arranged on the stainless steel fermentation tank to ensure that the temperature of the steamed rice in the stainless steel fermentation tank satisfies the fermentation requirements, adding the brewing water to the stainless steel fermentation tank via a water pipe, stirring the fermented mash in the stainless steel fermentation tank by a stirring device to make the fermented mashat the uniform temperature, adding the rice and the wheat starter to the stainless steel fermentation tank by the conveyor belt and further fermenting the material, and finally, transferring the material to a fermentation cylinder by a pipeline and a pump.

Owner:JIANGSU ZHANGJIAGANG BREWING

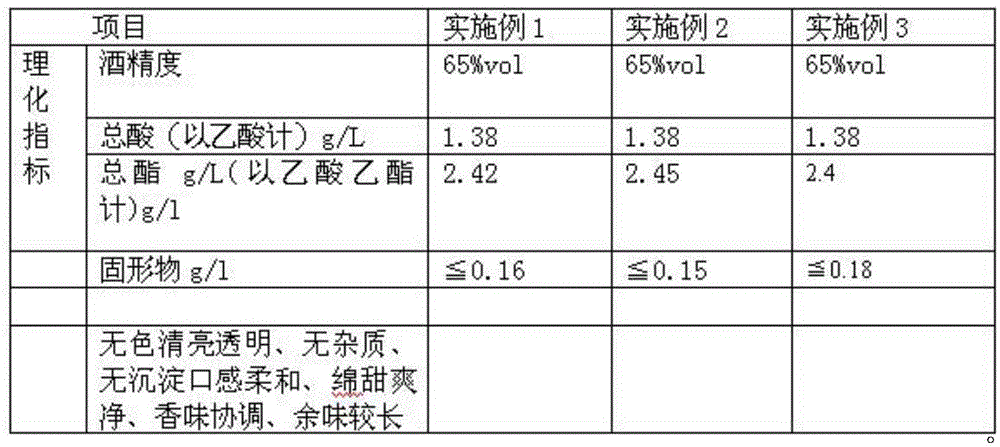

A kind of brewing method of fen-flavor liquor

ActiveCN104212693BHigh yieldPure wineAlcoholic beverage preparationMicroorganism based processesBiotechnologyWarm water

The invention discloses a brewing method of fen-flavor liquor. The brewing method comprises the steps of firstly, smashing sorghum to form sorghum powder, adding warm water, stacking, moisturizing, and then, filling the sorghum powder into a retort boiler to steam to obtain cooked sorghum powder; filling rice hulls into the opened retort boiler to steam; smashing the cooked sorghum powder, adding warm water to uniformly mix, cooling, adding the steamed rice hulls to uniformly mix, then, adding a yeast for making hard liquor and monascus, storing in a cellar, and fermenting for 45 days to obtain fermented grains; and distilling the fermented grains at a high temperature, and storing the fermented grains in a liquor storage tank for more than 1 year to obtain the fen-flavor liquor. The brewing method has the advantages that the process is simple, the quality of the liquor is stable, the yield of white spirit is increased, the style of the liquor is kept, and the produced fen-flavor liquor is softener in taste, sweet and refreshing, coordinated in fragrance and relatively long in aftertaste.

Owner:BEIPIAO HUAYI WINE

A kind of monascus culture medium and the preparation process of monascus using the medium

ActiveCN106987527BSuitable for growthSuitable for metabolismFungiMicroorganism based processesBiotechnologySucrose

The invention discloses a Monascus culture medium and a Monascus preparation process using the culture medium. The culture medium is made of the following raw materials in weight percentage: 7-14 parts of powder, 0.4-2.7 parts of nutrient solution and 100 parts of 1 part of distilled water; the powder is made of the following raw materials in percentage by weight: 4-12 parts of rice flour and 0.1-7 parts of dry corn steep powder; the nutrient solution is made of raw materials in the following percentages by weight: 0.1-1.5 parts of sucrose, 1-3 parts of plant peptone, 0.05-0.35 parts of sodium nitrate, 0.05-0.4 parts of magnesium sulfate, 0.05-0.3 parts of potassium dihydrogen sulfate and acidity regulator; the medium will not agglomerate during the preparation of Monascus using this medium , and the heat dissipation and air permeability of the medium are good, and the mass transfer and heat transfer are fast, which is beneficial to the growth of Monascus and the metabolism of Monascus pigment.

Owner:福建省古田县程久红粬有限公司

Control method for fermentation temperature in daqu liquor production cellar

ActiveCN101486961BControl fermentation temperatureQuality improvementAlcoholic beverage preparationTemperature controlBiology

The invention relates to a fermentation temperature control method in cellar pools for Daqu liquor production and belongs to the technical field of Daqu liquor production. The fermentation temperature control method realizes the fermentation temperature control inside the Daqu liquor producing cell pool in a heat exchanging way by arranging a heat exchanging device inside a Daqu liquor producing cell pool. When temperature of maternal fermented grains in the cell pool is too low or the temperature rises too slowly, hot water is charged, and heat is fed so as to heat the maternal fermented grains and shorten temperature rise time; when temperature of the maternal fermented grains in the cell pool is too high or the temperature rises too fast, cold water is charged, and heat-removing is carried out so as to cool the maternal fermented grains and reduce temperature rise speed; and in middle and late fermentation stage, waste hot water in workshop production is used for reserving temperature of the maternal fermented grains. The fermentation temperature control method of the cellar pools for Daqu liquor production can raise fermentation speed, shorten fermentation time and improve liquor quality.

Owner:LUZHOU LAOJIAO CO LTD +1

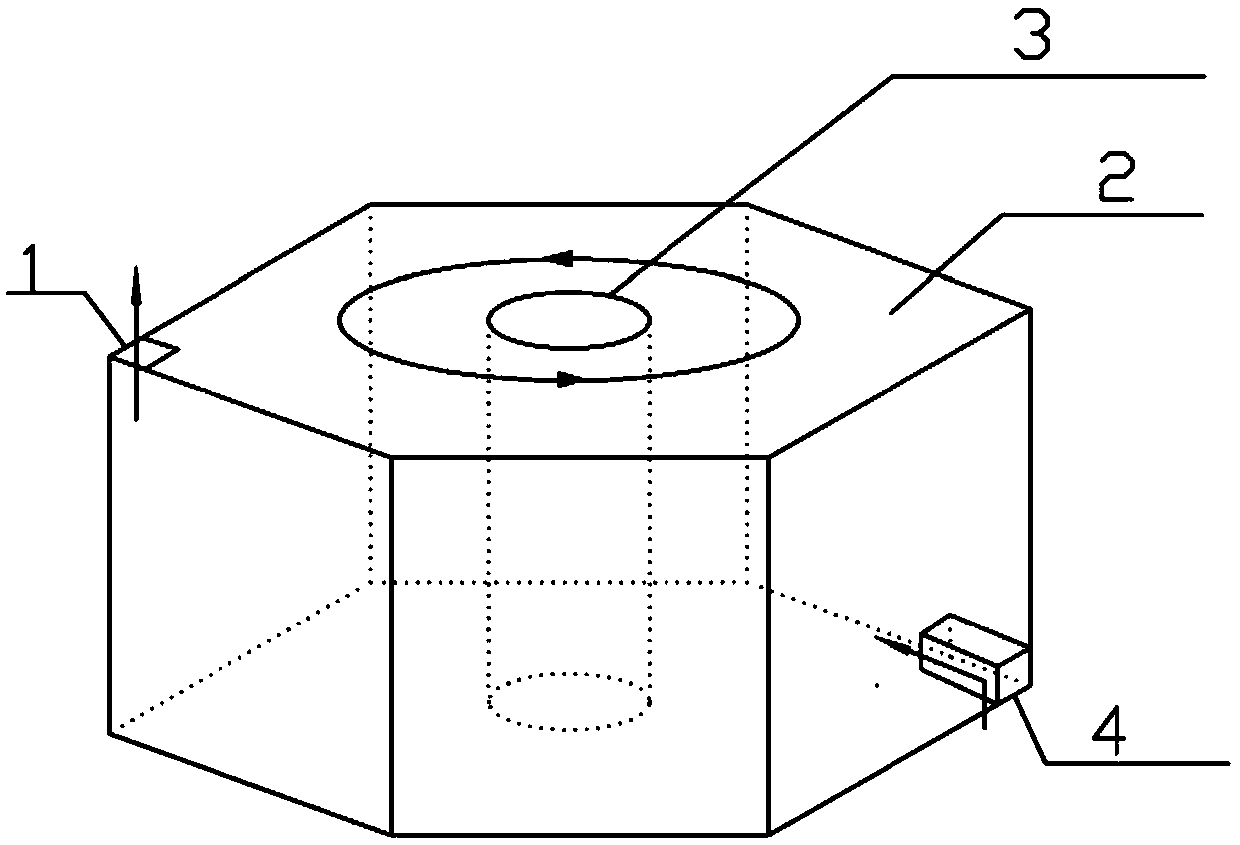

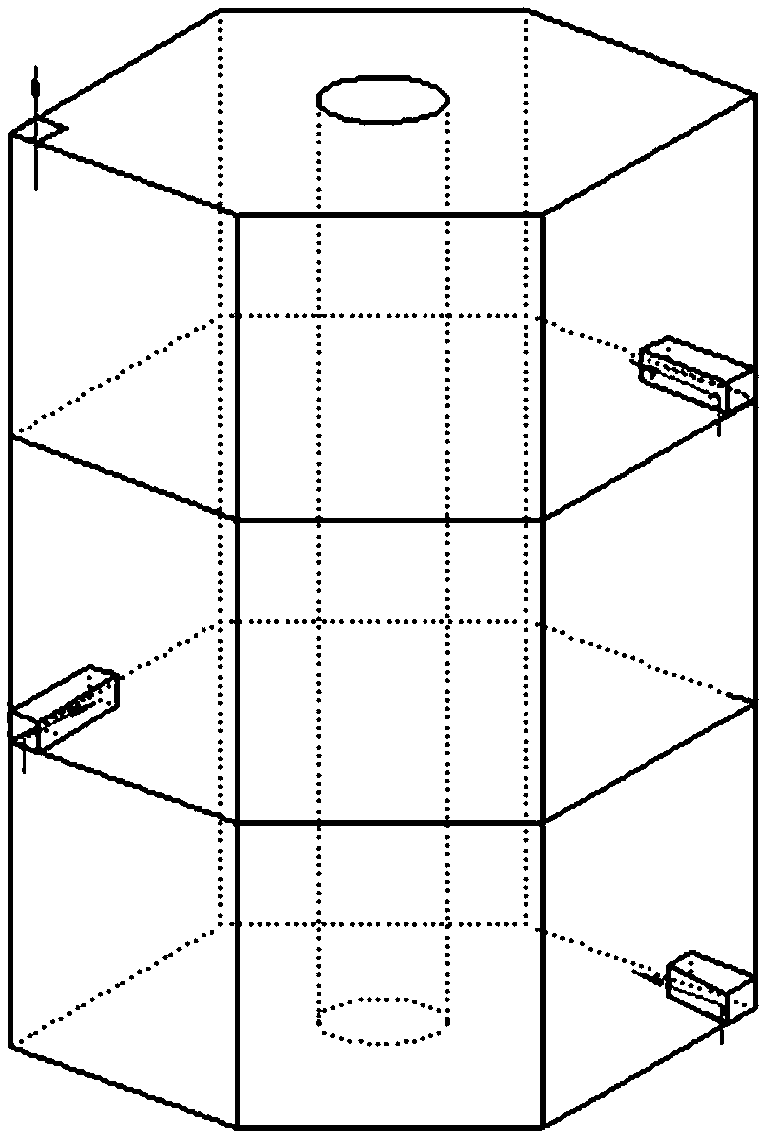

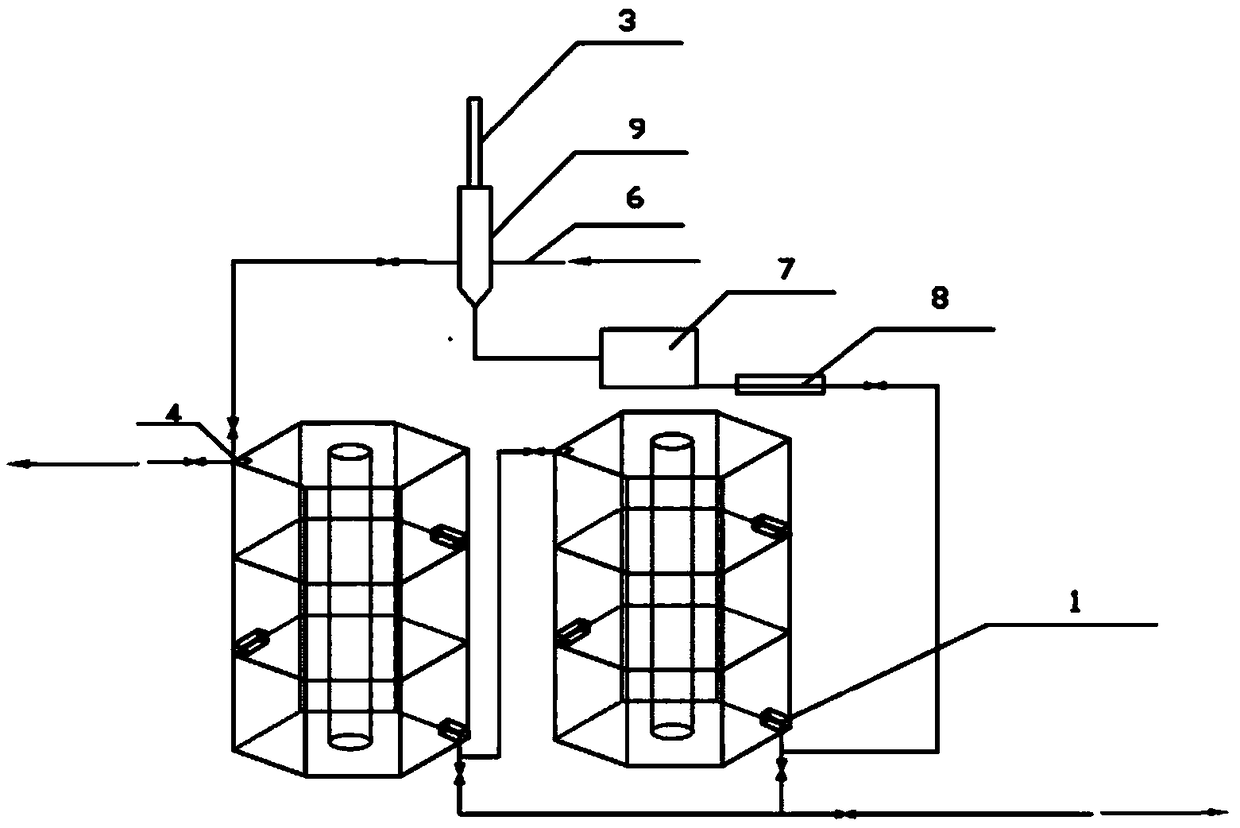

Cellular liquid fermenting device and method

InactiveCN109401915ARealize zone temperature controlControl fermentation temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlControl system

The invention discloses a cellular liquid fermenting device and method. The device comprises a fermenting assembly, a material supplying assembly and a control system, wherein the fermenting assemblyconsists of a single or a plurality of fermenting tanks connected to one another; each fermenting tank is in the shape of a hexagonal prism; a feeding opening is formed in one side of the bottom of each fermenting tank; a discharging opening is formed in one side of the top of each fermenting tank; a central hole is formed in each fermenting tank around the axis, and is used for mounting a heatingtube, each heating tube is used for heating liquid in the corresponding fermenting tank, and the tank body of each fermenting tank and the corresponding central hole form a fermenting cavity; a heating sensor is arranged in the tank body of each fermenting tank, and is used for measuring the temperature of the liquid in the tank body; and the material supplying assembly provides raw materials andstrains which are required for the fermenting assembly according to the command of the control system. For a liquid fermenting mode, the small hexagonal prism shaped fermenting tank bodies are randomly combined and connected according to the yield and the fermenting process, and a traditional single large fermenting tank is replaced; and further, partitioned temperature control and stepped heating can be realized, and the cellular liquid fermenting device and method are a brand-new fermenting device and process.

Owner:YANCHENG INST OF TECH

Organic fertilizer and preparation method thereof

ActiveCN113929507AEvenly mixed with each otherStabilizationBio-organic fraction processingOrganic fertiliser apparatusAgricultural engineeringOrganic manure

The invention discloses an organic fertilizer and a preparation method thereof. The side end of a transmission connecting rod is connected with a material turning auger in a welded mode, one end of the transmission connecting rod is provided with a water inlet hole, the inner side of the water inlet hole is connected with a water inlet pipe in a sleeved mode, and the air inlet end of an air conveying pipe is installed at one end of an air collecting box in a penetrating mode; a gear transmission box drives a material overturning auger to overturn fermented raw materials, the raw materials and zymophyte materials can be mixed more evenly through material overturning in the early stage of fermentation, the situation that internal combustion coking occurs in the bottom end due to the fact that the fermentation temperature is too high is avoided, air is conveyed to the inner side of a fixed heat preservation box after being dried through a drying net box through an air inlet pipe, and water is discharged into a water inlet hole in the inner side of the transmission connecting rod through the water inlet pipe; the temperature, humidity and oxygen degree of the internal environment can be effectively controlled through interstitial treatment in the fermentation process, so that the treatment can be stably carried out in the fermentation process;.

Owner:山东天择生物科技发展有限公司

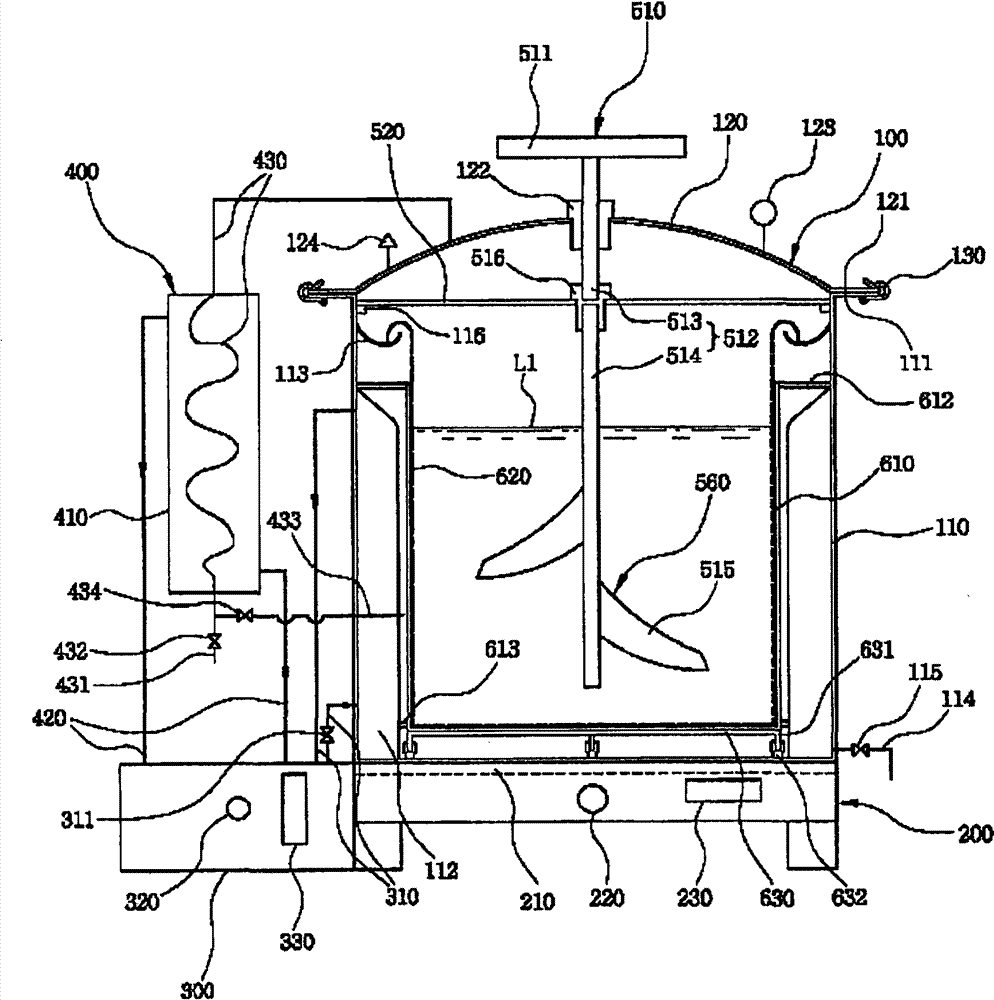

Home-brewed liquor manufacturing apparatus

ActiveCN101679928BEasy to operateAvoid pollutionFermented solutions distillation/rectificationTemperature control using plurality of sensorsComing outDistillation

The present invention relates to a liquor manufacturing apparatus for home use. Particularly, the present invention relates to a liquor manufacturing apparatus for home use, which includes a single device consisting of a heater, the cooler, the condenser, the stirrer and the filter to enable to perform all processes required for liquor preparation and which enables anyone to easily make desired liquor even in general homes using grains, fruits or other plant materials. The liquor manufacturing apparatus for home use comprises: a combined fermentation and distillation tank including a tank body having a cooling jacket mounted at the inside wall surface thereof so as to allow cooling water to be filled therein and to pass therethrough and a lid being adapted to hermetically seal the top portion of the tank body; an electric heater adapted to heat the tank body; a cooler adapted to supply the cooling water to the cooling jacket so as to cool the tank body; a condenser adapted to cool steam and volatile substance coming out of the combined fermentation and distillation tank; a combined steaming and filtering container disposed inside the tank body; a fabric filter disposed inside the combined steaming and filtering container and adapted to contain contents produced in the liquor preparing process; and a stirrer adapted to stir the contents inside the fabric filter during fermentation.

Owner:DAEBONG LS CO LTD

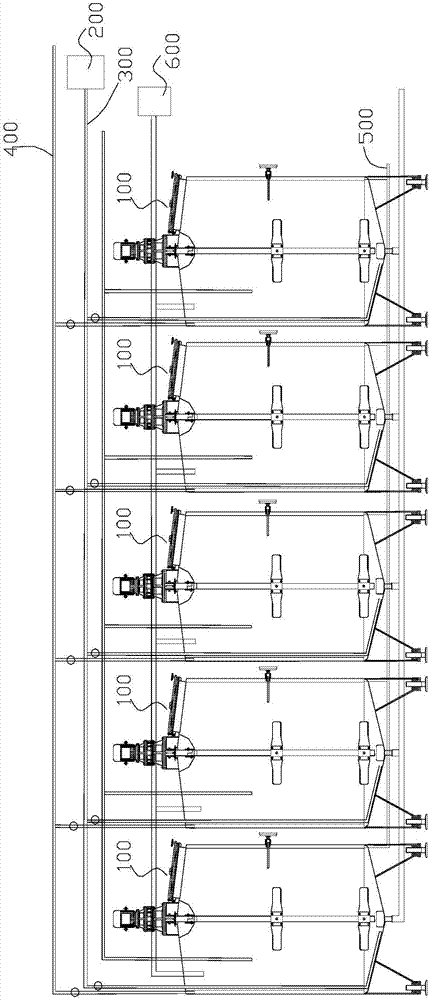

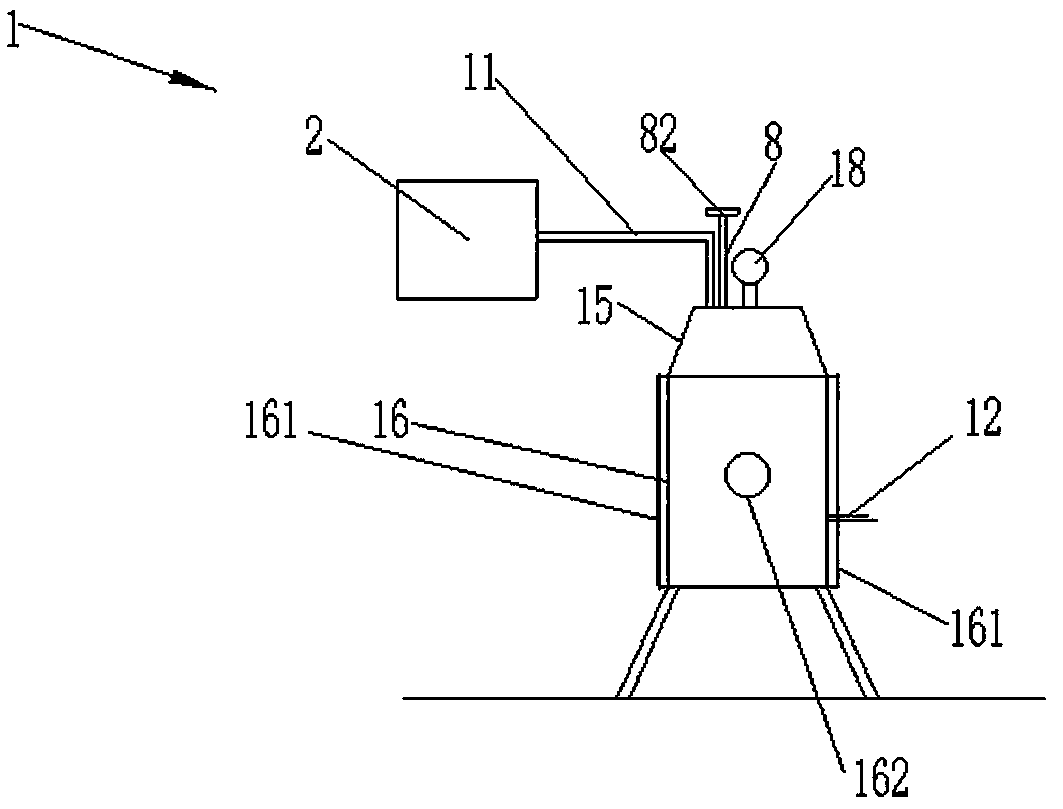

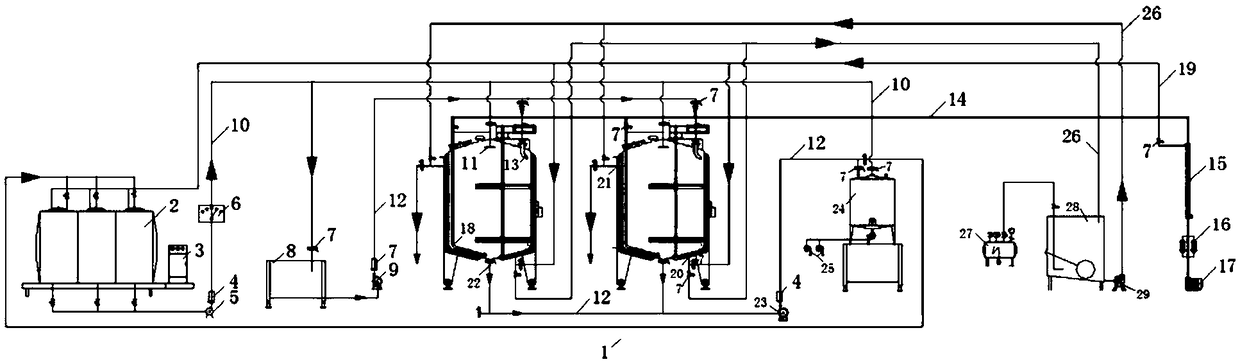

Koumiss production line

The invention discloses a koumiss production line. The production line is characterized in that the production line mainly comprises a plurality of fermenting tanks, an acidic water and alkaline waterCIP cleaning unit, a cooling system, a material system, a hot water system and an air system. Compared with traditional herder-operated manual cylinders, an industrial combined automatic koumiss fermentation system in the invention has the following advantages: the automatic degree is high, so labor is saved; the fermentation temperature, the fermentation time and aerobic fermentation are effectively controlled, so the koumiss produced in every batch has the same taste; the occupied area is small, the fermentation system is easy to operate, the sanitary requirements are high, and the fermentation is completed in a closed container, so the production efficiency is high; and the fermentation temperature is effectively controlled, so the fermentation time is greatly shortened, and the cost for the product is reduced.

Owner:维殊机械科技(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com