A kind of brewing method of fen-flavor liquor

A technology for fragrance-type liquor and fermented grains, which is applied in microorganism-based methods, preparation of alcoholic beverages, biochemical equipment and methods, etc. problems, to achieve the effect of ensuring the style of the wine body, the quality of the wine body is better and more stable, and the quality of the wine is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

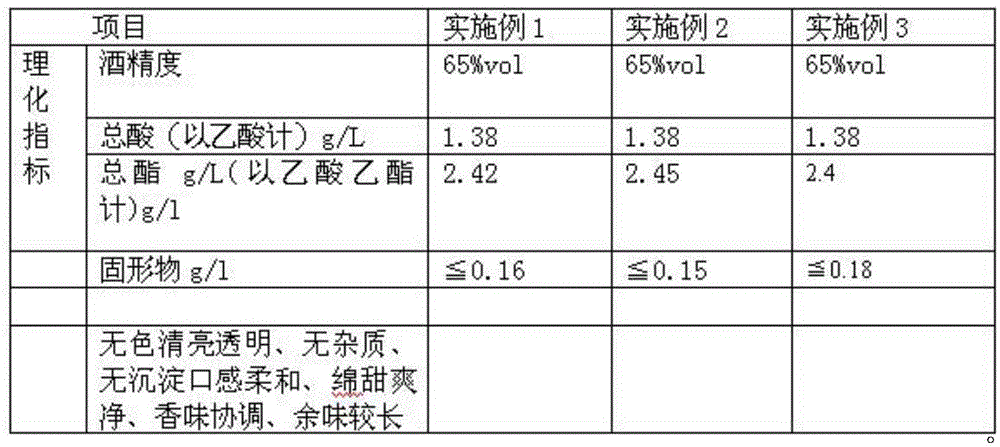

Examples

Embodiment 1

[0020] 1.1, run material

[0021] The sorghum is crushed into sorghum flour, and 100kg of sorghum flour is added to 30kg of warm water at 25°C for accumulation and moistening for 5 hours;

[0022] 1.2 Steamed ingredients

[0023] After filling the moistened sorghum flour into the retort, steam the material at 100°C for 40 minutes to obtain cooked sorghum flour; put the rice husk into the retort, and steam the material in the open at 100°C for 20 minutes;

[0024] 1.3 Ingredients

[0025] Break the cooked sorghum flour, add 35kg of warm water at 25°C and mix evenly, cool to 15°C, add 52kg of steamed rice husk and mix evenly, then add 23kg of Daqu and 2kg of Monascus to obtain the mixture;

[0026] 1.4. Fermentation

[0027] The mixture is fermented in the cellar for 45 days. The conditions of the mixture in the cellar are as follows: moisture mass percentage 40%, temperature 18°C, acidity 0.8g / L, starch content ≥25%, temperature changes during the fermentation process according to Table 1....

Embodiment 2

[0033] 1.1, run material

[0034] The sorghum is crushed into sorghum flour, and 100kg of sorghum flour is added to 35kg of 30℃ warm water for accumulation and moistening for 7h;

[0035] 1.2 Steamed ingredients

[0036] After filling the moistened sorghum flour in the retort, steam the material at 120°C for 25 minutes to obtain cooked sorghum flour; put the rice husk into the retort, and steam the material at 120°C for 22 minutes;

[0037] 1.3 Ingredients

[0038] Crush the cooked sorghum flour, add 40kg of warm water at 30°C and mix well, cool to 17°C, add 55kg of steamed rice husk and mix evenly, then add 23kg of Daqu and 2kg of Monascus to obtain the mixture;

[0039] 1.4. Fermentation

[0040] The mixture is fermented in the cellar for 45 days. The conditions of the mixture in the cellar are: 42% moisture mass percentage, temperature 20℃, acidity 0.9g / L, starch content ≥25%, temperature change during fermentation process according to Table 1. , Get the glutinous rice, the physical a...

Embodiment 3

[0046] 1.1 Moisturizing

[0047] The sorghum is crushed into sorghum flour, and 100kg of sorghum flour is added to 32kg of 28℃ warm water for accumulation and moistening for 8h;

[0048] 1.2 Steamed ingredients

[0049] After filling the moistened sorghum flour into the retort, steam the material at 110°C for 30 minutes to obtain the cooked sorghum flour; put the rice husk into the retort, and steam the material at 110°C for 25 minutes;

[0050] 1.3 Ingredients

[0051] Break the cooked sorghum flour, add 38kg of warm water at 28°C and mix well, cool to 16°C, add 53kg of steamed rice husk and mix evenly, then add 23kg of Daqu and 2kg of Monascus to obtain the mixture;

[0052] 1.4. Fermentation in the cellar

[0053] The mixture was fermented in the cellar for 45 days, and the conditions of the mixture in the cellar were 41% by mass, temperature 19℃, acidity of 0.8g / L, starch content ≥25%, and temperature changes during the fermentation process according to Table 4. , To obtain mash, moi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com