Production method of pure-juice grape white spirit

A production method and grape technology, applied in the preparation of wine, biochemical equipment and methods, preparation of alcoholic beverages, etc., can solve the problems of high temperature, excessive yeast nutrition, high concentration of fermentation raw materials, etc., to achieve high yield and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

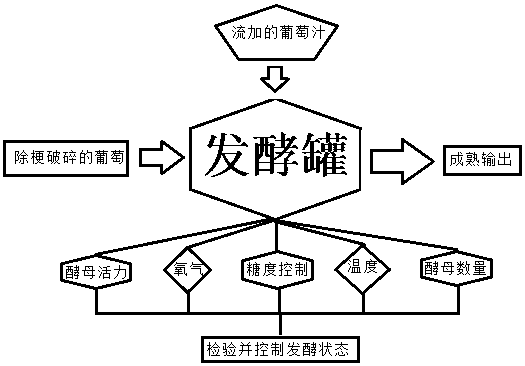

[0016] Such as figure 1 As shown, specific embodiment 1: the production method of pure juice grape liquor, comprising the following steps: (1) measuring and checking the fresh table grapes arriving, and selecting fresh grapes that meet the quality requirements as raw materials;

[0017] (2) Pour the grapes into the screening platform, and further screen and remove impurities to remove moldy and rotten fruits; (3) Broken into pulp: remove the grape stems and crush, collect and transport the crushed pulp to the fermenter; (4) Pre-fermentation : The grapes will be pre-fermented in the fermentation tank first, and the temperature will be controlled at 25-30°C; (5) Activate yeast and add: add yeast at 0.015% by weight, and stir with air after adding yeast; (6) Fermentation: Monitor the fermentation temperature, control the fermentation temperature at 28°C, control the total sugar at 10g / l, control the growth rate of s yeast spores at 20%, and inject sterile air every 5 hours. When ...

Embodiment 2

[0022] Embodiment 2: the production method of pure juice grape liquor, comprising the following steps: (1) measuring and checking the fresh grapes that arrive, and selecting fresh grapes that meet the quality requirements as raw materials;

[0023] (2) Pour the grapes into the screening platform, and further screen and remove impurities to remove moldy and rotten fruits; (3) Broken into pulp: remove the grape stems and crush, collect and transport the crushed pulp to the fermenter; (4) Pre-fermentation : The grapes will be pre-fermented in the fermentation tank first, and the temperature is controlled at 30°C; (5) Activation of yeast and addition: the yeast is put in at a weight ratio of 0.05%, and the air is stirred after adding the yeast; (6) Fermentation: For fermentation The temperature is monitored, the fermentation temperature is controlled at 35°C, the total sugar is controlled at 25g / l, the growth rate of s yeast spores is controlled at 50%, and sterile air is introduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com