Koumiss production line

A production line, yogurt milk technology, applied in milk preparations, dairy products, applications, etc., can solve the problem that the fermentation temperature and time and aerobic fermentation cannot be accurately controlled, the taste of yogurt is different, and the cost of mass production Advanced problems, to achieve the effect of shortening fermentation time, consistent taste, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

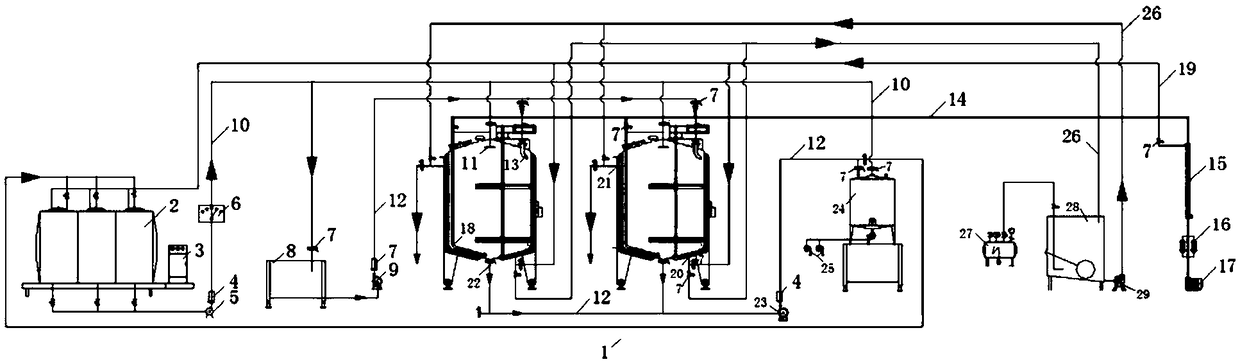

[0019] Such as figure 1 As shown, the present invention provides a kind of sour kumiss production line, it is characterized in that, production line 1 mainly comprises several fermentation tanks 30, acid-base water CIP cleaning unit 2, cooling system, material system, hot water system, air system; The outlet of the alkaline water CIP cleaning unit 2 is connected to the milk collection tank 8, the fermentation tank 30, and the finished product tank 24 through the cleaning pipeline 10, and the milk collection tank 8, the fermentation tank 30, and the finished product tank 24 pass through the cleaning pipeline 10 Connect the acid-base water CIP cleaning unit 2 to form a circulation; the water cooling pipeline 19 of the cooling system is connected to the bottom of the fermentation tank 30, and the top of the fermentation tank 30 is provided with a cooling water outlet 21; the material system includes the Milk collection tank 8, the milk collection tank 8 is connected to the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com