Alcohol fermentation tank, alcohol fermentation system and alcohol fermentation process

An alcoholic fermentation and tank technology, which is applied in the preparation of vinegar and other directions, can solve the problems of uncontrollable alcoholic fermentation temperature, unfavorable old mature vinegar, incomplete fermentation, etc., so as to improve the quality of vinegar, occupy a small area, and control the alcoholic fermentation. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

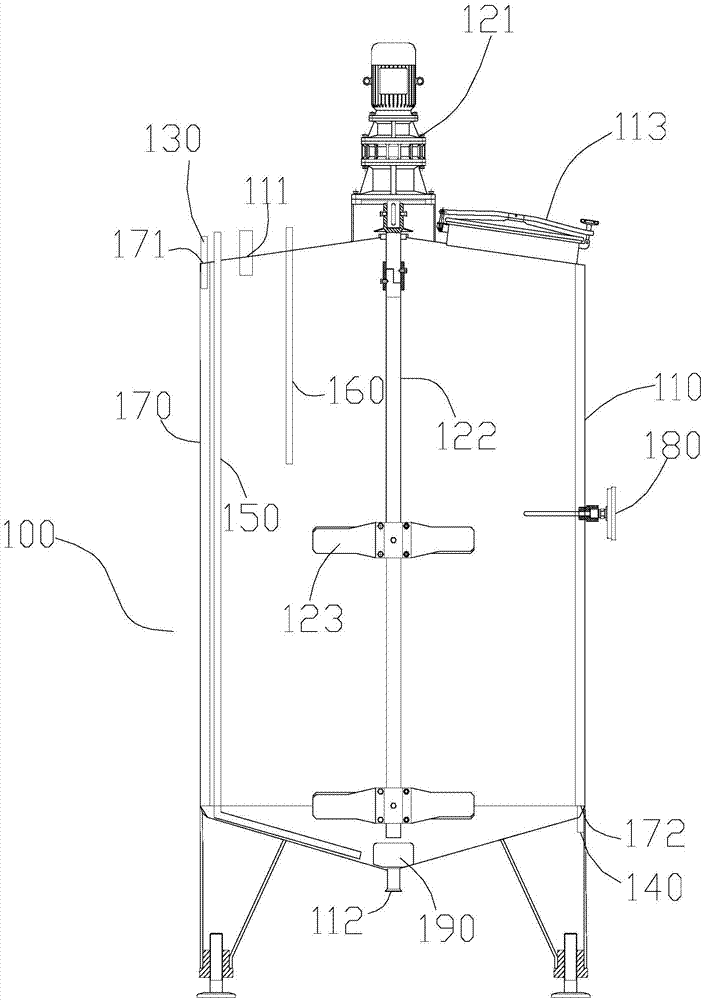

[0041] refer to figure 1 , an alcohol fermentation tank 100, comprising a tank body 110, the top of the tank body 110 is provided with a material input port 111, the bottom of the tank body 110 is provided with a material output port 112; the tank body 110 is provided with a stirring device; medium input pipe 130, heat exchange medium output pipe 140, compressed air pipe 150 and temperature sensing device 160;

[0042] The outer side wall of the tank body 110 is provided with a jacket structure 170, one end of the jacket structure 170 is provided with a heat exchange medium input port 171, and the other end is provided with a heat exchange medium output port 172; The port is connected with the heat exchange medium input port 171, and the feed port of the heat exchange medium output pipe 140 is connected with the heat exchange medium output port 172;

[0043] One end of the compressed air pipe 150 extends into the tank body 110, and the air outlet of the compressed air pipe 15...

Embodiment 2

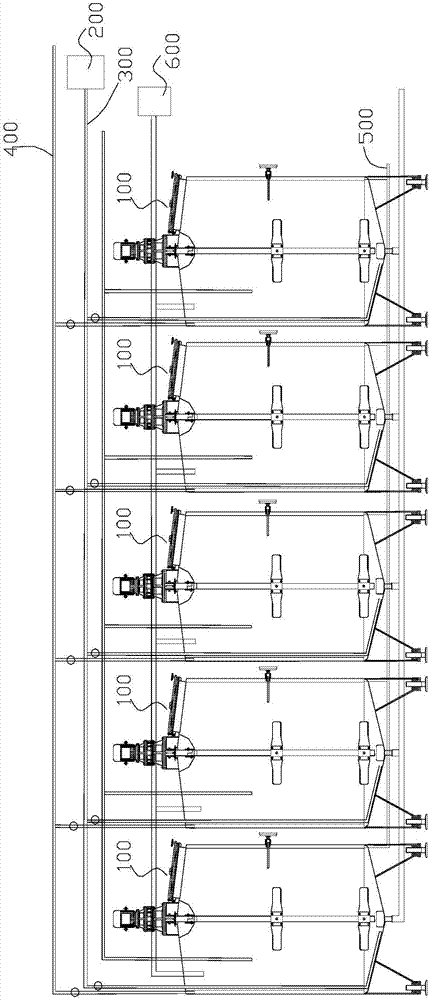

[0052] refer to figure 2 , an alcohol fermentation system, comprising the alcohol fermentation tank 100 of Embodiment 1, an air compressor 200, a compressed air main pipe 300, a heat exchange medium input main pipe 400, a heat exchange medium output main pipe 500 and a control cabinet with a central processing unit;

[0053] The air outlet of the air compressor 200 is connected with the air inlet of the compressed air main pipe 300, and the air outlet of the compressed air main pipe 300 is respectively connected with the air inlet of the compressed air pipe 150 of each alcohol fermentation tank 100; each compressed air pipe 150 are equipped with solenoid valves;

[0054] The discharge port of the heat exchange medium input main pipe 400 is respectively connected with the heat exchange medium input pipe 130 of each alcohol fermentation tank 100, and the feed port of the heat exchange medium output main pipe 500 is respectively connected with the heat exchange medium output of ...

Embodiment 3

[0059] An alcohol fermentation process, comprising the following steps:

[0060] Preparation step: provide a kind of alcohol fermentation system such as embodiment 2;

[0061] Fermentation step: The mash is sent to the alcohol fermentation tank of the alcohol fermentation system for alcohol fermentation. In the early stage of fermentation, the temperature in the tank is kept at 25-33°C for 12 hours; in the main fermentation period, the temperature in the tank is kept at 32-34°C. ℃, the time is 12 hours; in the middle and late fermentation, the temperature in the tank is kept below 35 ℃ for 8-10 days; the total fermentation time is 10-12 days, when the alcohol content reaches 9%-11% (V / V) When the fermentation is stopped, alcohol is obtained, and the free acidity of the alcohol is below 1.5°.

[0062] As a preferred embodiment, in the fermentation step, when the temperature detected by the temperature sensing device exceeds the preset value, the temperature in the tank is adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com