Cellular liquid fermenting device and method

A technology for liquid fermentation and fermentation method, which is applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc. Problems such as mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

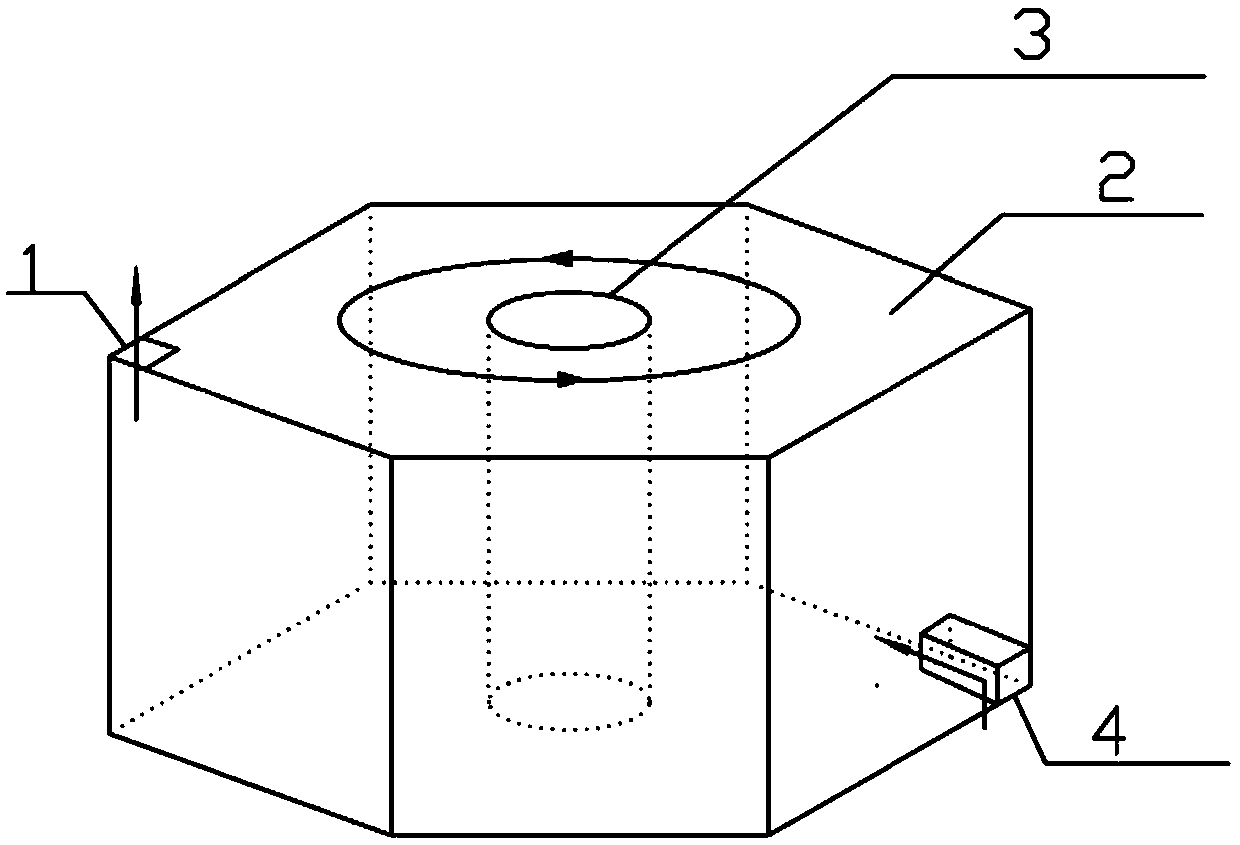

[0044] figure 1 Shows the schematic diagram of the structure of a single hexagonal column fermenter of the present invention, see figure 1 , the bottom side of the fermenter is provided with a feed inlet 1, the feed inlet has a built-in feed pipe, the top side is provided with a discharge port 4, and the fermenter is provided with a central hole 3 around the axis, which is used for installing a heating tube and heating The tube is used to heat the material liquid in the fermenter. The fermenter body and the center hole form a fermentation chamber. Because of the shape of the hexagonal prism and the flow direction of the material liquid at the bottom feed port, the fermentation liquid in the hexagonal prism fermenter is formed by the central hole. The column rotates on the axis, and a single hexagonal column fermenter is used for mixing and fermenting the feed liquid.

Embodiment 2

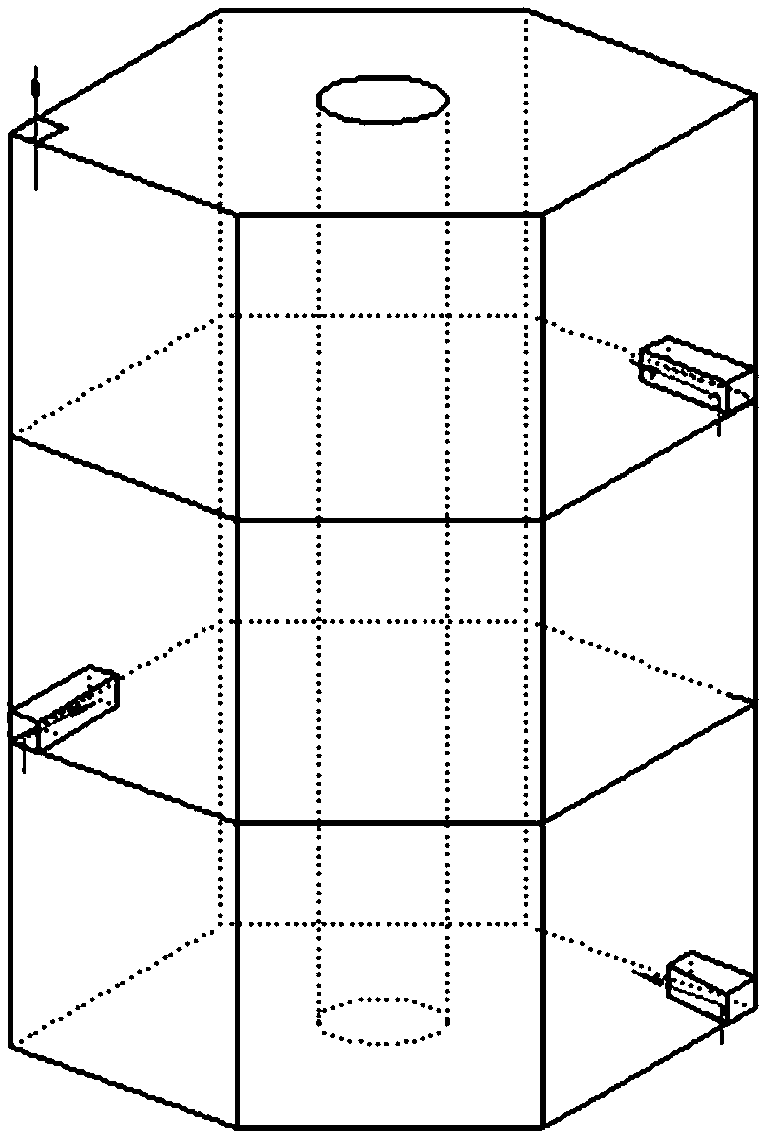

[0046] figure 2 Disclosed are the series schematic diagrams of three hexagonal column fermentation tanks of the present invention; as figure 2 As shown, the discharge port of the bottom fermentation tank is connected with the feed port of the middle fermentation tank, the discharge port of the middle fermentation tank is connected with the feed port of the top fermentation tank, and three hexagonal columns are connected in series. It can be seen that the fermentation tank of the present invention Tanks can be combined and spliced at will according to the yield and fermentation process.

Embodiment 3

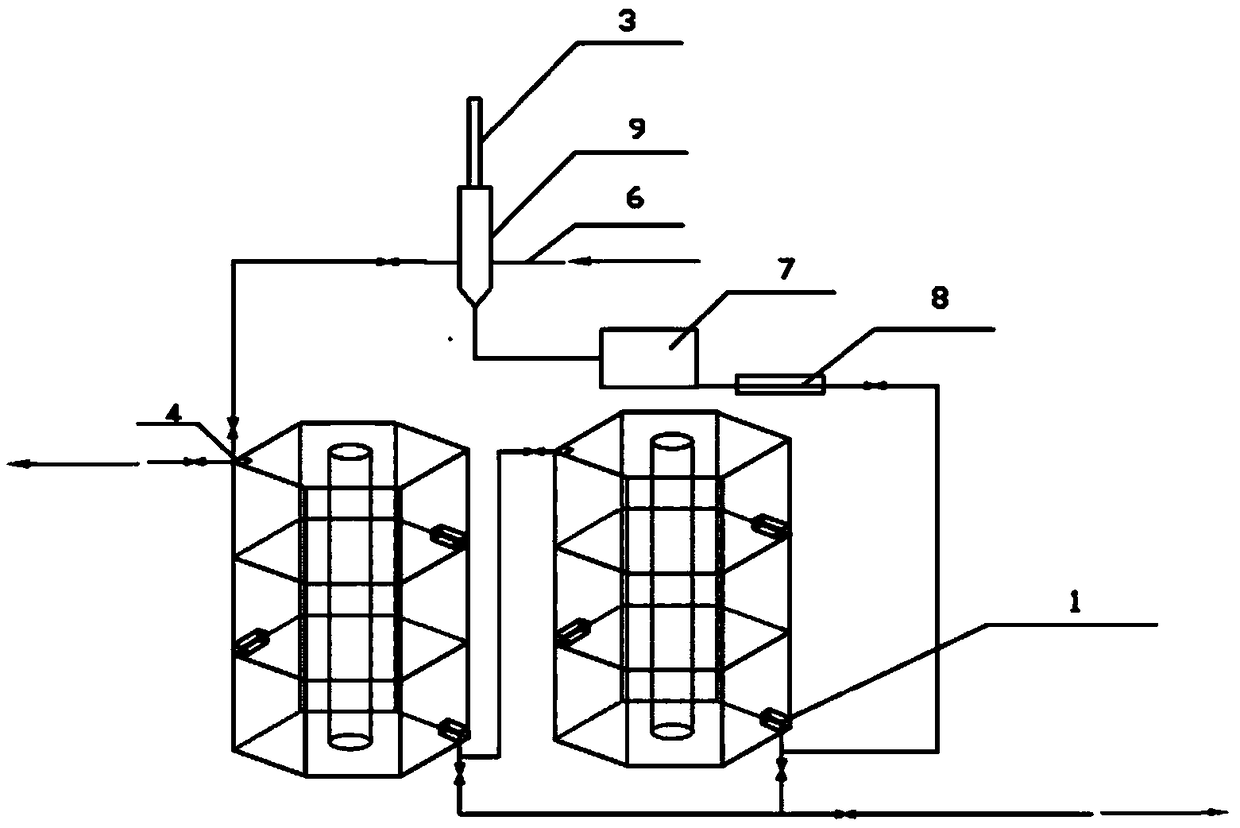

[0048] image 3 A honeycomb liquid fermentation device is disclosed, which includes a fermentation component, a feeding component and a control system. The fermentation component is composed of six hexagonal column fermentation tanks connected in series, 3 as a group, and the bottom side of the fermentation tank is equipped with a Feed port 1, a discharge port 4 is provided on the top side; a central hole 3 is provided around the axis of the fermenter for installing a heating tube, which is used for heating the feed liquid in the fermenter, and the fermenter body and the central hole form a Fermentation chamber 2; a heating sensor is installed in the fermenter tank to measure the temperature of the feed liquid in the tank; the feeding component provides the raw materials and strains required by the fermentation component according to the command of the control system.

[0049] In this embodiment, the feed assembly includes a batching and strain adding pipe 5, a water supply pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com