Pre-fermentation process of yellow rice wine

A kind of pre-fermentation and process technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of small ceramic tank volume, difficult quality control of rice wine, low control ability, etc., to reduce labor and labor intensity, and improve site utilization. , the effect of improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific content of the present invention will be described in detail below through specific embodiments.

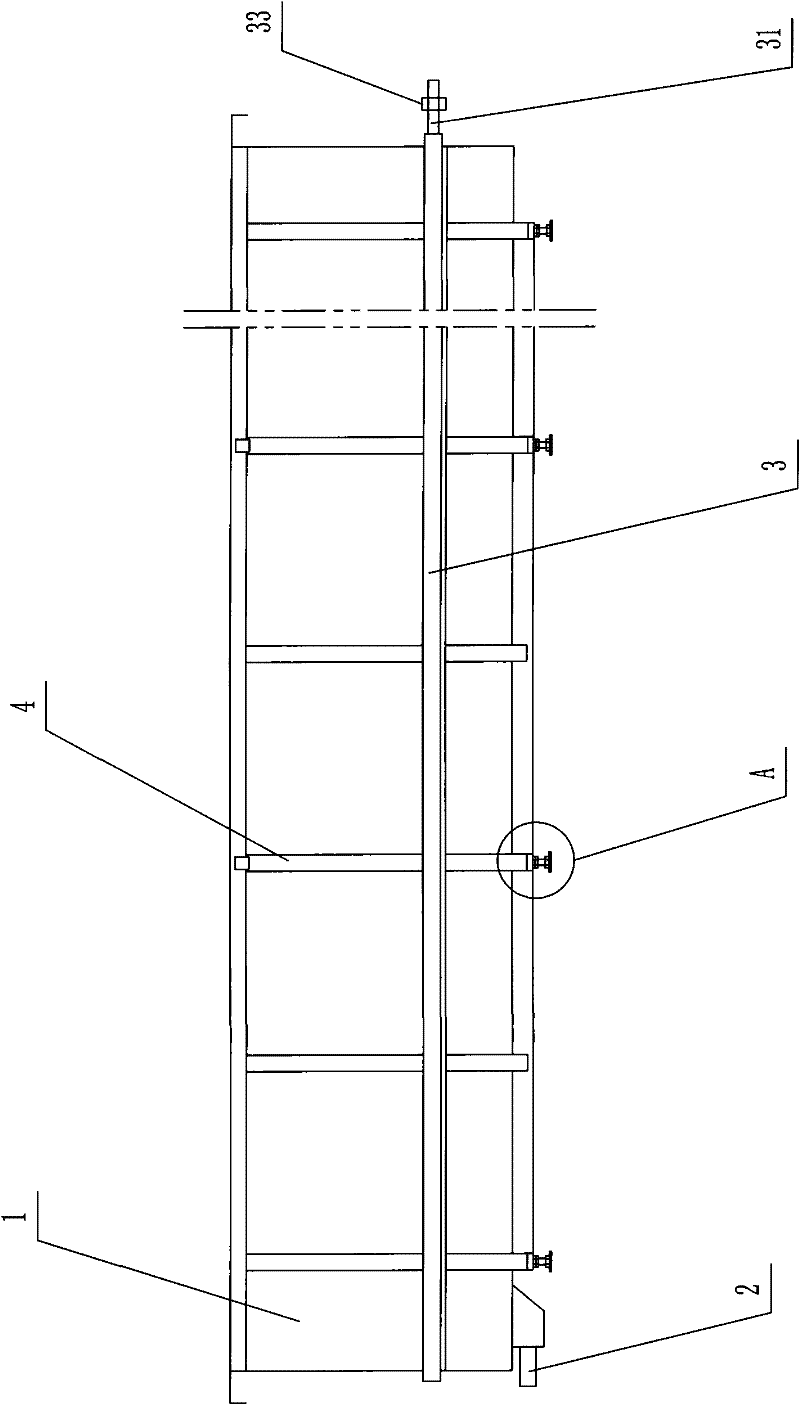

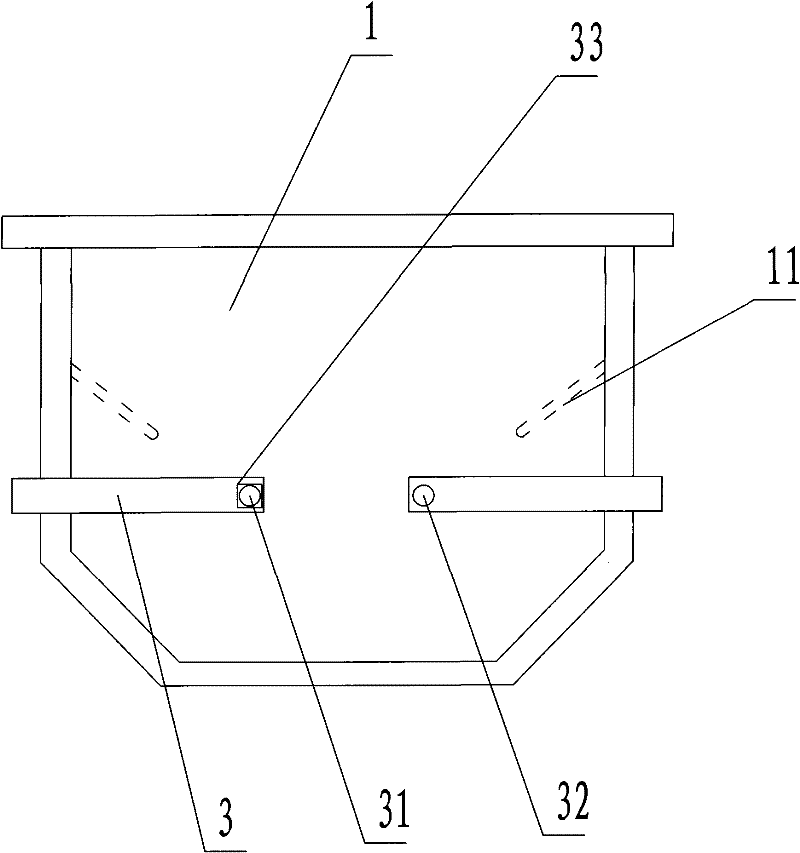

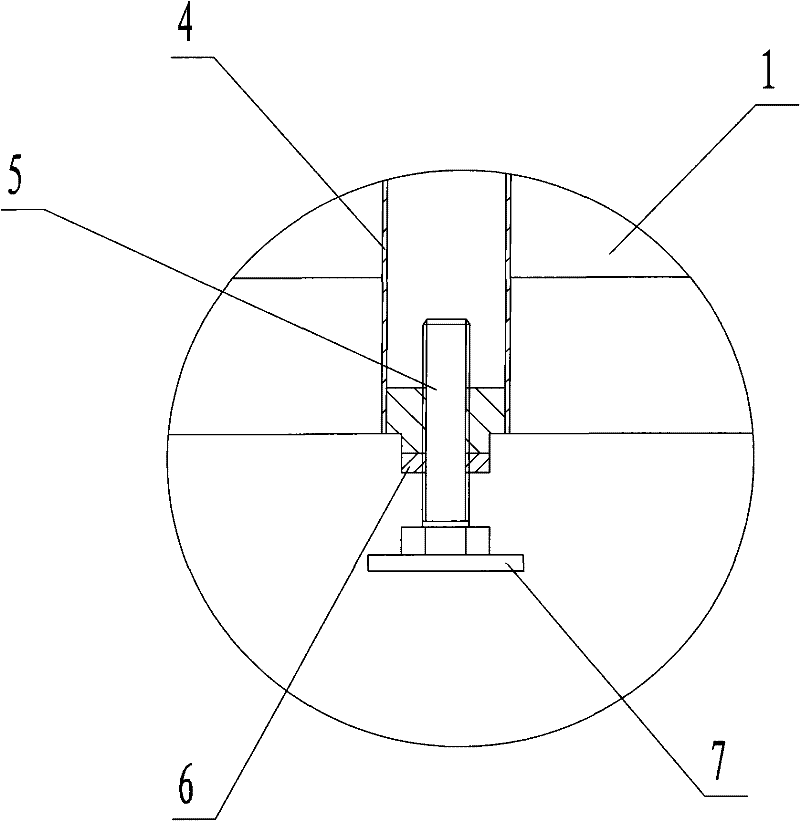

[0025] The pre-fermentation process of rice wine includes: soaking rice → steaming rice → adding wine medicine and mixing well → transporting the rice to the stainless steel fermentation tank by the conveyor belt. The conveyor belt is a conventional technology, and a chain conveyor belt or a roller conveyor belt can be used. Then, the temperature of the rice in the stainless steel fermentation tank is controlled by the temperature adjustment device installed on the stainless steel fermentation tank, so that the temperature of the rice in the stainless steel fermentation tank meets the fermentation requirements → the rice is fermented to produce saccharified liquid, when the content of saccharified liquid in the fermented liquid is high , add brewing water into the stainless steel fermentation tank through the water pipe → use the stirring device to stir the fer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com