Fermentation tank

A fermenter and tank technology, applied in the fermenter field, can solve the problems that the fermenter cannot be well controlled and affects the alcohol fermentation, and achieve the effect of improving efficiency and quality, and uniform air distribution

Inactive Publication Date: 2019-01-04

德保县广鑫贸易有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current fermentation work is generally carried out in a fermenter, and the existing fermenter cannot well control various factors affecting alcoholic fermentation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

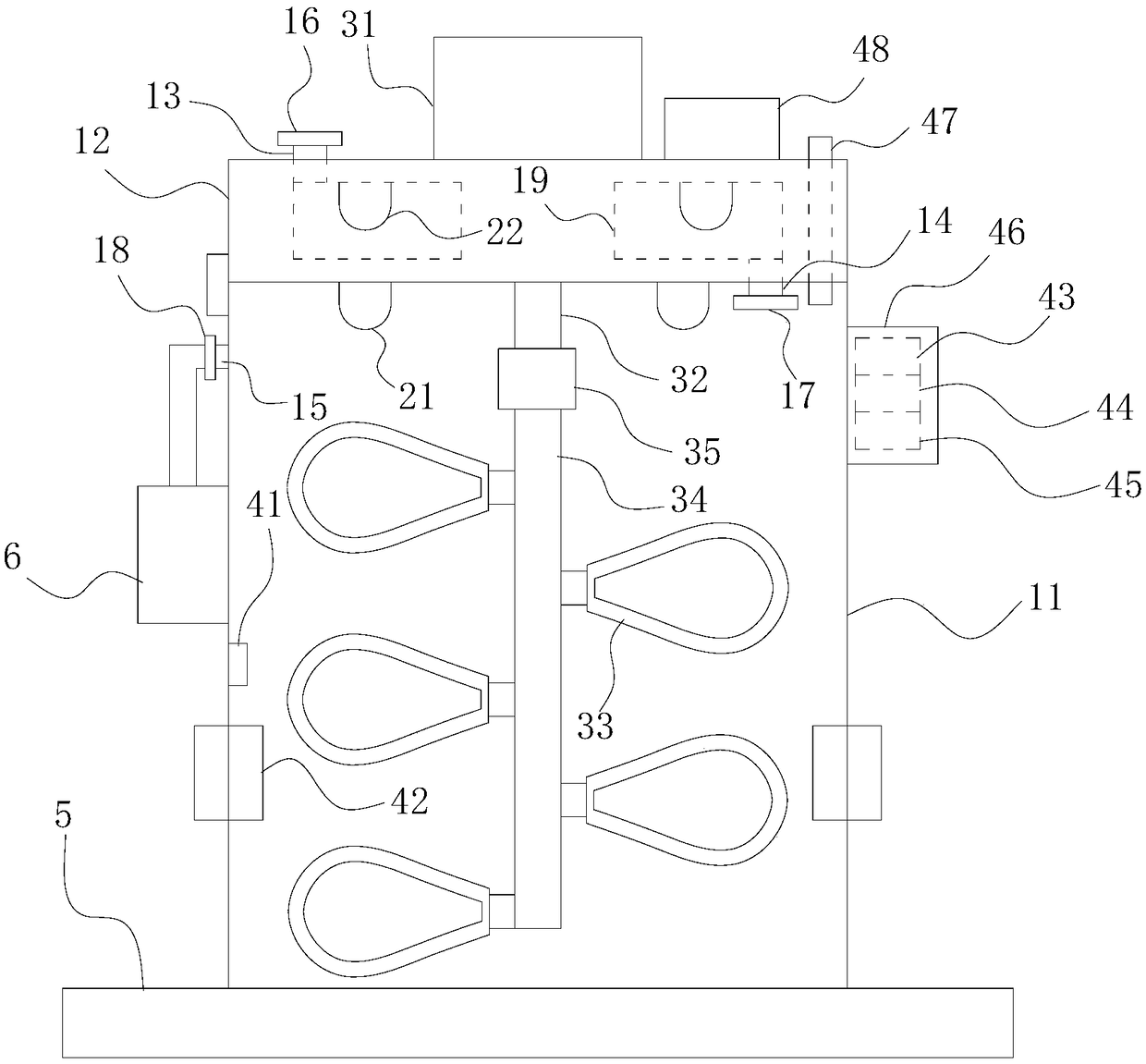

The invention relates to a fermentation tank which comprises a tank body, a sterilizing device, a stirring device, a temperature control device, a weighing device and an air interchanger, wherein a turnable cover is arranged on the tank body; the cover is provided with a cavity; an air interchanging port is formed in the tank body; the sterilizing device comprises a tank sterilizer and an air sterilizer; the tank sterilizer is fixed on the lower surface of the cover; the air sterilizer is arranged in the cavity; the stirring device comprises a motor and a stirrer; the motor is in drive connection with the stirrer for rotating; the stirrer is arranged in the tank body; the temperature control device comprises a temperature sensor and a temperature regulator; the temperature sensor and the temperature regulator are respectively fixed in the tank body; the weighing device is arranged below the tank body; the air interchanger is connected with the air interchanging port. According to the fermentation tank disclosed by the invention, the initial starch concentration, air quantity in the fermentation process, the fermentation temperature and infectious microbes can be effectively controlled, so that fermentation is performed in an optimum environment, and the wine making efficiency and quality are improved.

Description

technical field [0001] The invention relates to the technical field of brewing equipment, in particular to a fermenter. Background technique [0002] Chinese wine culture has a long history, and wine products are also extensive and profound. Drinking has become a part of Chinese people's life. The brewing process of liquor is divided into two parts: fermentation and distillation. It affects the efficiency and quality of wine making mainly in the fermentation process. The fermentation process requires sugar and enzymes. The sugar includes glucose and maltose. Fruit juice usually contains a lot of glucose and can be fermented directly. Grains contain a large amount of starch, which can be processed to produce maltose, and the sugar reacts with enzymes to produce ethanol and carbon dioxide at a certain temperature. This reaction process is called alcohol fermentation. The factors affecting alcohol fermentation mainly include the initial starch concentration, the air volume in ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C12G3/02

CPCC12G3/02

Inventor 罗丽策

Owner 德保县广鑫贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com