Modular solid state fermentation reactor

A solid-state fermentation and reactor technology, applied in the field of modular solid-state fermentation reactors with variable volume, can solve the problems of product yield, quality decline, cumbersome multi-step operation, and the inability to realize precise control of growth conditions, so as to prevent bacterial contamination, extract handy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

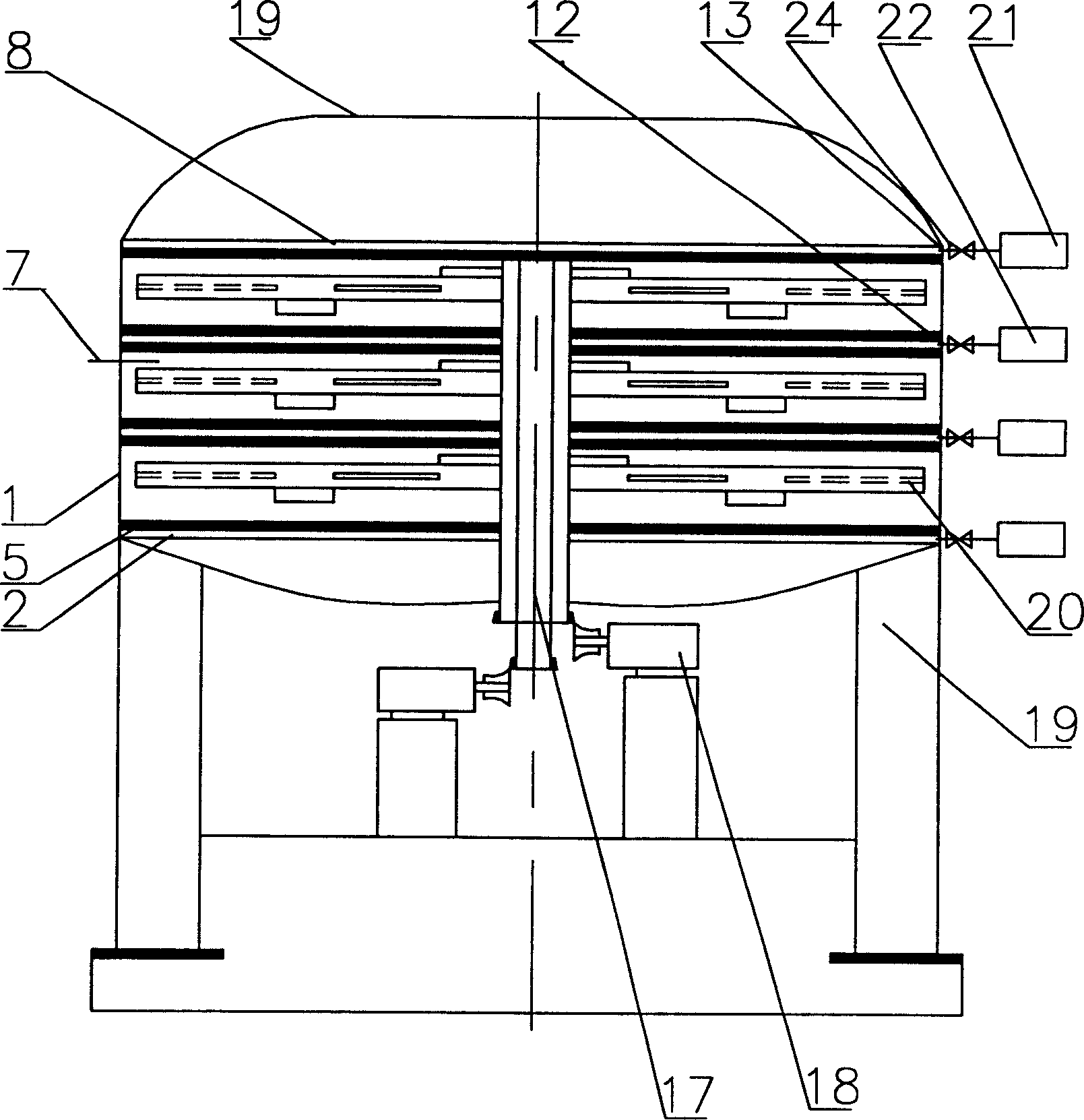

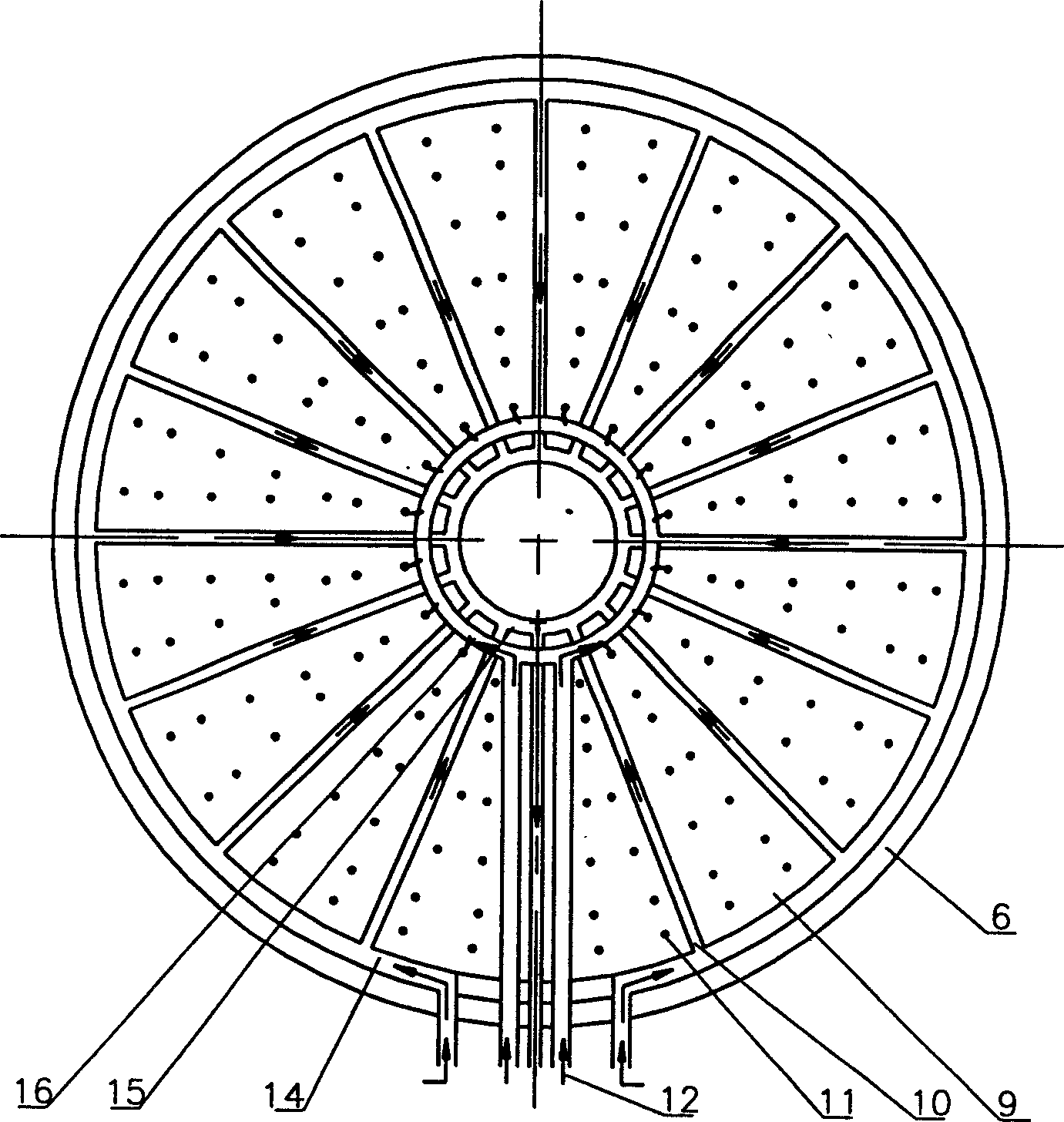

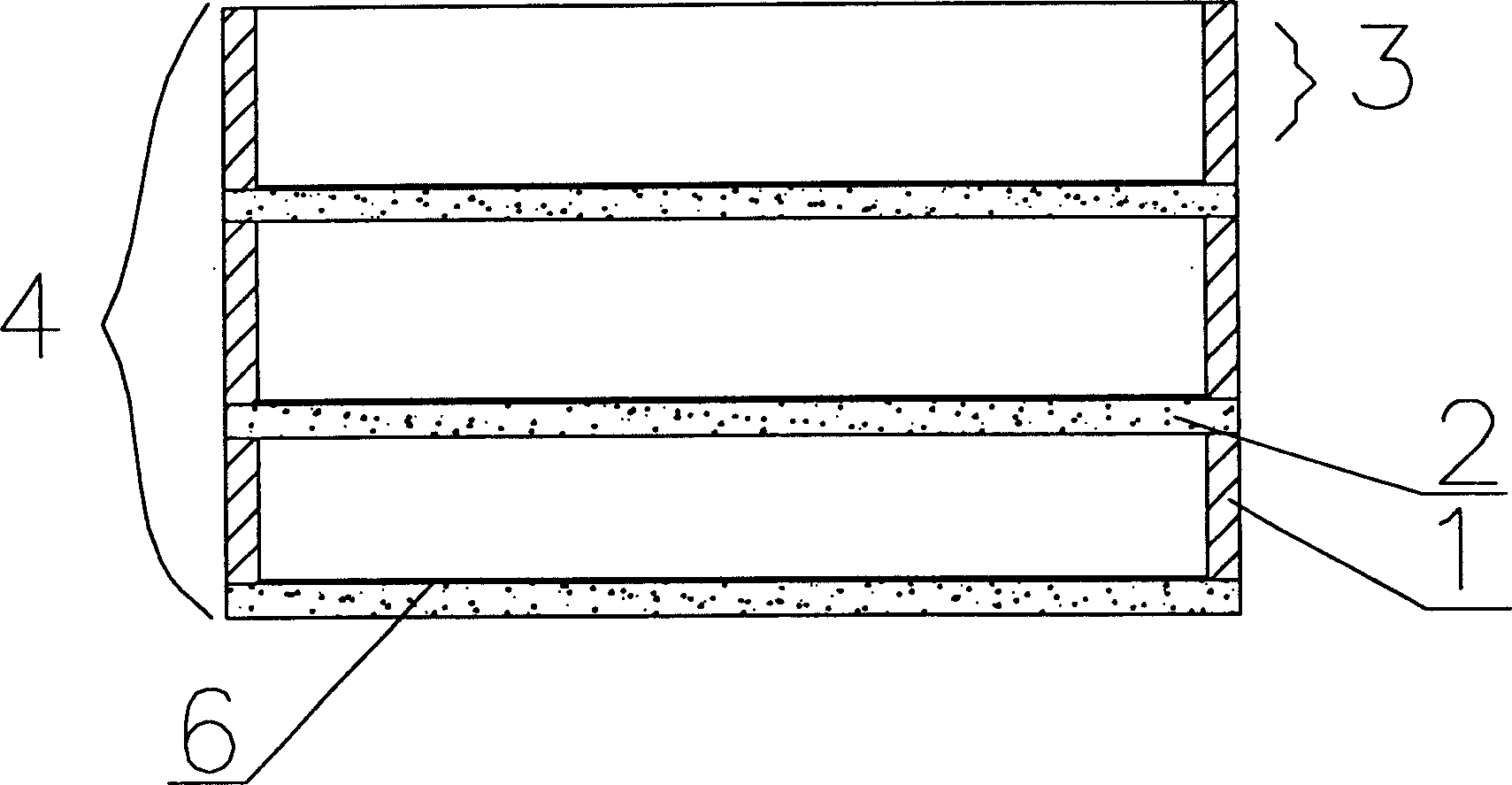

[0039] See figure 1 -5. Three-layer solid-state fermentation reactor, diameter 100cm, module height 8cm, microorganism: red yeast rice, raw material: indica rice. This example does not include the extraction of the active substance.

[0040] At first need to add 14.6kg (dry weight) soaked indica rice in each clean module 3, then install all modules 3 together to form stack 4, at this moment the inside of the reactor is isolated from the external environment. Sterilization fluid such as steam or ozone flows into the distribution ring from the distribution port, enters the transmission channel 9, and releases the fluid into the module through the hole 11 on the transmission channel. At the same time, steam is passed into the non-transport channel 10 to heat the reactor to an appropriate sterilization temperature (121°C for steam, 50°C for ethylene oxide). After sterilization, cooling water flows into the non-transmission channel 10 to cool the matrix, and the matrix enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com