Garbage fermenting system and method of garbage incineration power plant

A waste incineration and fermentation system technology, applied in the preparation and application of organic fertilizers, organic fertilizers, etc., can solve problems that affect the health of workers and air quality, unsatisfactory garbage fermentation effects, uneven heat transfer media, etc., to achieve structural Reasonable design and layout, shortened time, and the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

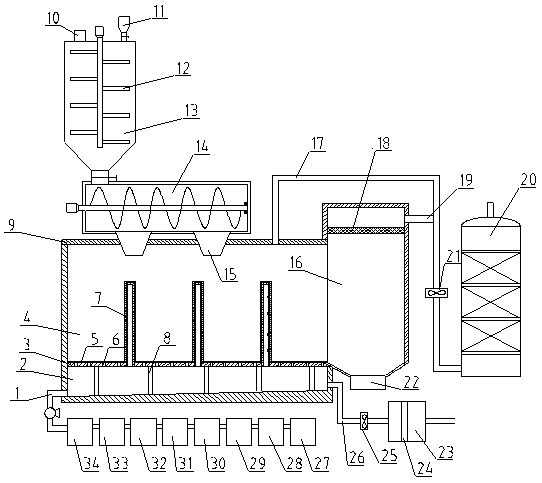

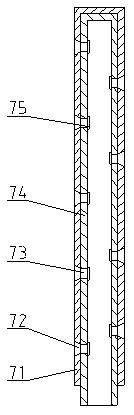

[0030] The garbage fermentation system of the garbage incineration power plant described in the present embodiment 1 comprises a fermentation tank, a feeding system and a discharging system,

[0031]The top of the fermenter is provided with a top cover 9, and the bottom surface in the fermenter is vertically provided with a plurality of support columns 8, and a dividing plate 3 is placed above the support column 8, and the dividing plate 3 divides the fermenter. The inner cavity of the partition is divided into a fermentation chamber 4 and a filtrate storage chamber 2, several percolation holes 6 are processed on the partition 3, a filter screen 5 is laid on the top surface of the partition 3, and a A plurality of thermostats 7, the fermentation chamber 4 is provided with a temperature sensor, the bottom surface of the filtrate storage chamber 2 is arranged as a slope structure, and a drain pipe 1 is arranged at the lower end of the filtrate storage chamber 2, and the drain pip...

Embodiment 2

[0049] The garbage fermentation system of the garbage incineration power plant described in the present embodiment 2 comprises a fermentation tank, a feeding system and a discharging system,

[0050] The top of the fermenter is provided with a top cover 9, and the bottom surface in the fermenter is vertically provided with a plurality of support columns 8, and a dividing plate 3 is placed above the support column 8, and the dividing plate 3 divides the fermenter. The inner cavity of the partition is divided into a fermentation chamber 4 and a filtrate storage chamber 2, several percolation holes 6 are processed on the partition 3, a filter screen 5 is laid on the top surface of the partition 3, and a A plurality of thermostats 7, the fermentation chamber 4 is provided with a temperature sensor, the bottom surface of the filtrate storage chamber 2 is arranged as a slope structure, and a drain pipe 1 is arranged at the lower end of the filtrate storage chamber 2, and the drain pi...

Embodiment 3

[0068] The garbage fermentation system of the garbage incineration power plant described in the present embodiment 3 comprises a fermentation tank, a feeding system and a discharging system,

[0069] The top of the fermenter is provided with a top cover 9, and the bottom surface in the fermenter is vertically provided with a plurality of support columns 8, and a dividing plate 3 is placed above the support column 8, and the dividing plate 3 divides the fermenter. The inner cavity of the partition is divided into a fermentation chamber 4 and a filtrate storage chamber 2, several percolation holes 6 are processed on the partition 3, a filter screen 5 is laid on the top surface of the partition 3, and a A plurality of thermostats 7, the fermentation chamber 4 is provided with a temperature sensor, the bottom surface of the filtrate storage chamber 2 is arranged as a slope structure, and a drain pipe 1 is arranged at the lower end of the filtrate storage chamber 2, and the drain pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com