Stirring-type tea fermentation machine

A tea fermentation machine and stirring technology, applied in the field of tea processing, can solve the problems of uneven stirring of tea leaves, poor control of temperature and humidity, etc., and achieve the effects of avoiding burning or even rot, better uniform stirring, and ensuring fermentation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

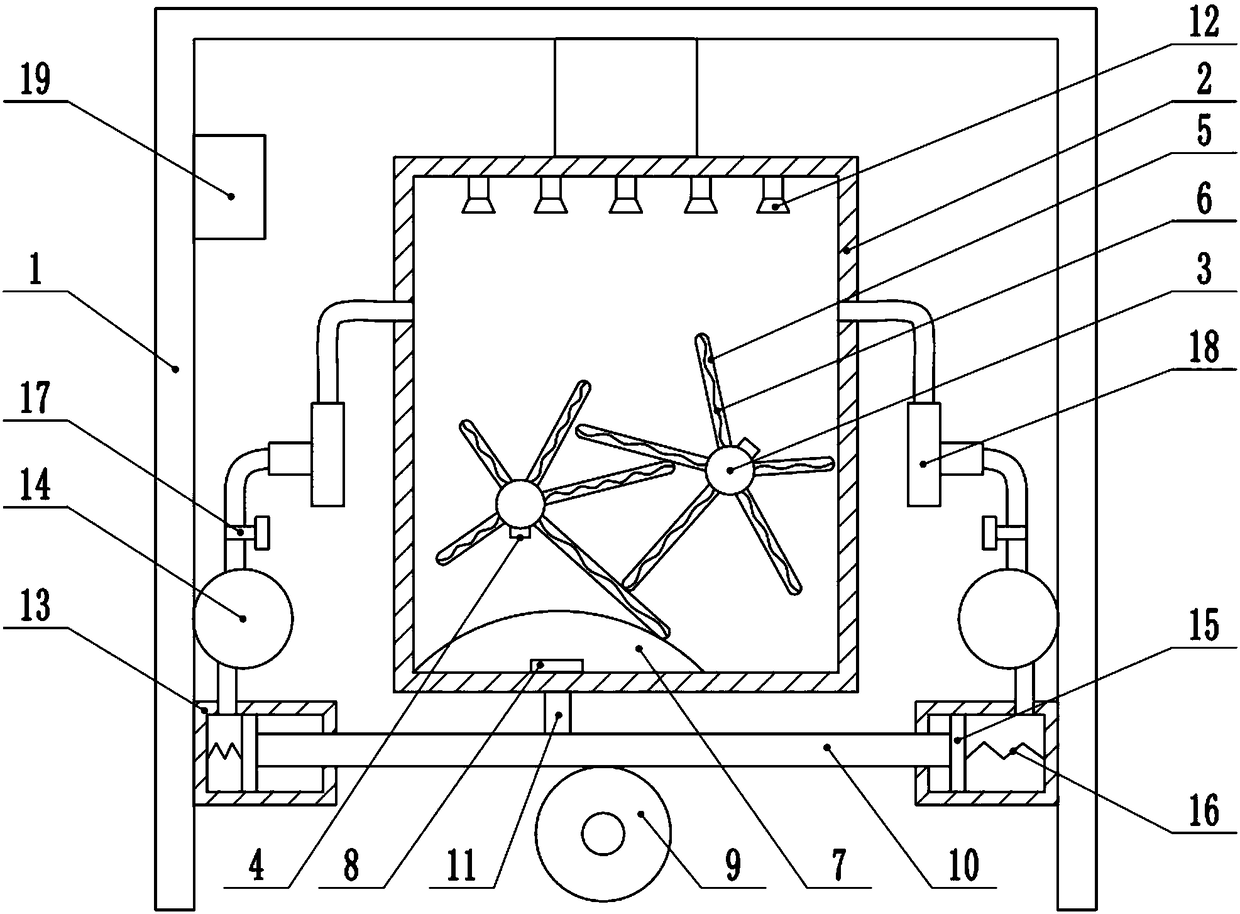

[0019] The reference signs in the drawings of the description include: frame 1, fermentation chamber 2, rotating shaft 3, temperature and humidity sensor 4, stirring plate 5, heating wire 6, slider 7, first magnet 8, gear 9, rack 10, Second magnet 11, nozzle 12, piston cylinder 13, air bag 14, piston 15, spring 16, valve 17, vortex tube 18, controller 19.

[0020] The embodiment is basically as attached figure 1 Shown:

[0021] Stirring tea fermentation machine, including a frame 1, a fermentation chamber 2 is fixedly connected to the frame 1, and two rotating shafts 3 are rotatably connected in the fermentation chamber 2, and a torsion spring is welded between each rotating shaft 3 and the inner wall of the fermentation chamber 2 , the effect of the torsion spring is mainly to use its elasticity to make the rotating shaft 3 reversely rotate when the rotating shaft 3 is separated f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com