Arc solar panel and processing technology

A technology of solar panels and solar energy, applied in sustainable manufacturing/processing, photovoltaic power generation, electrical components, etc., can solve the problems affecting the power generation of solar modules, the reduction of light energy of Tianyang solar chips, and unsuitable hot pressing molding methods, etc., to achieve Simple and reasonable process steps, good light transmission effect, and stable power generation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

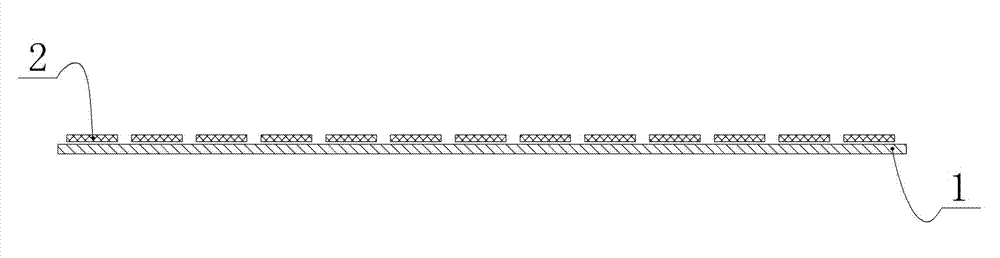

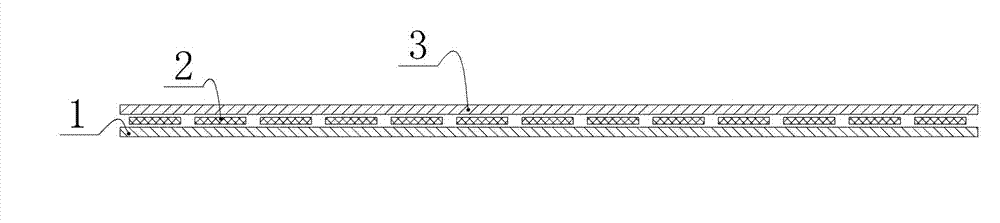

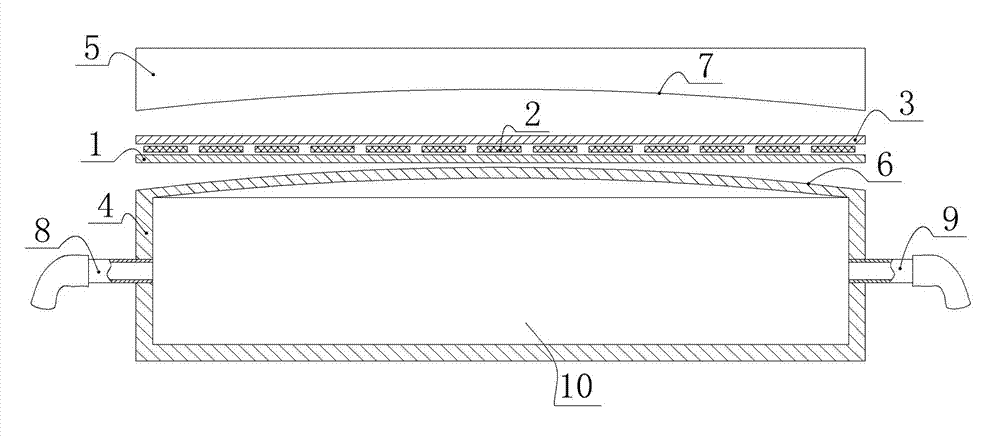

[0020] Such as Figure 5 As shown, a schematic structural view of an arc-shaped solar panel in the present invention is provided, which includes a plastic substrate 1, a solar crystalline silicon panel 2 and a crystal glue layer 3, and the shown solar crystalline silicon panel 2 is evenly arranged on the plastic substrate 1, The plastic substrate realizes the fixing and supporting functions. The crystal glue layer 3 adheres to the upper surface of the solar crystal silicon panel 2, and on the plastic substrate 1 between the solar crystal silicon panels 2, realizes the fixing and protection of the solar crystal silicon panel 2; because the crystal glue has a stable chemical properties and good light transmission effect, so that the entire curved solar panel has long-term good power generation performance.

[0021] The entire solar panel formed by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com