Patents

Literature

88results about How to "Stirring effect is even" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

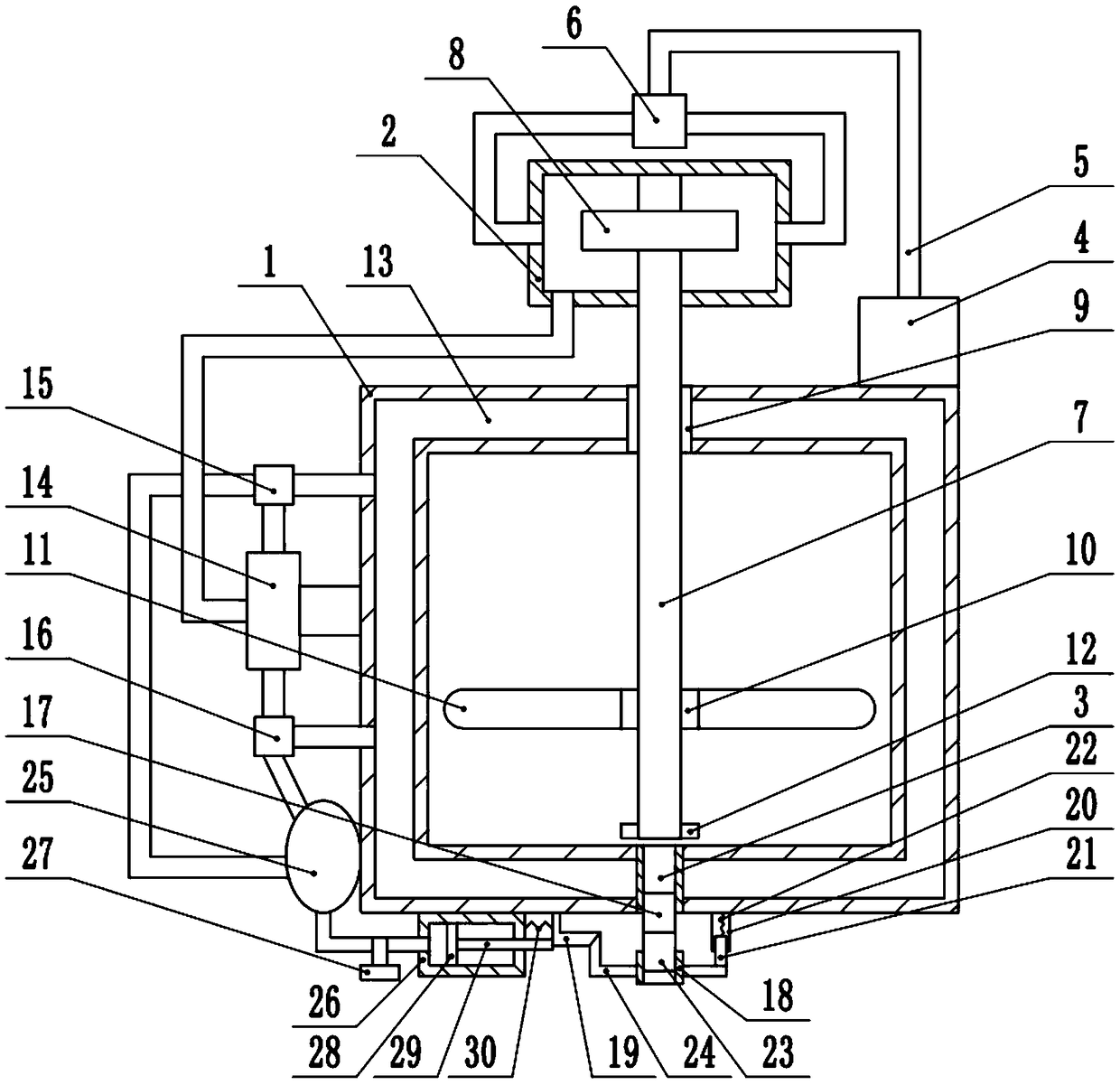

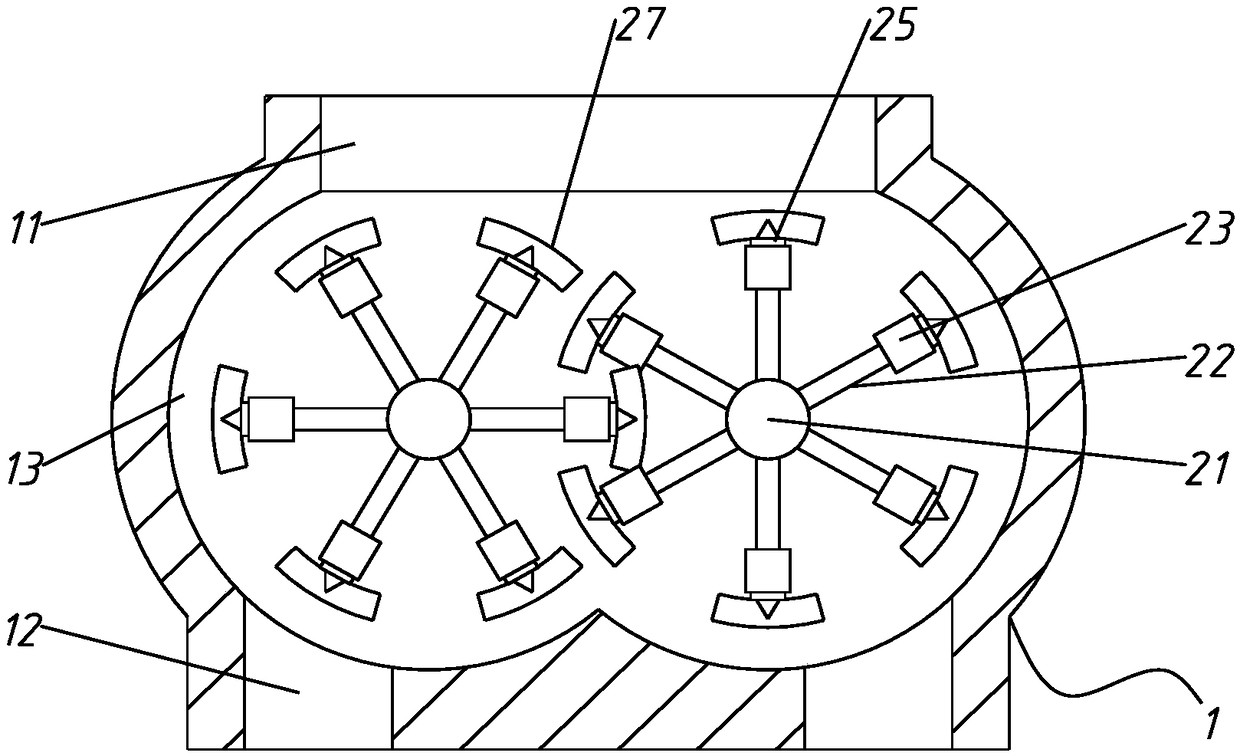

Rapid coating mixing device for medical treatment package, production, and printing

InactiveCN106890595AImprove the mixing effectStirring effect is evenTransportation and packagingMixer accessoriesEngineeringMedical treatment

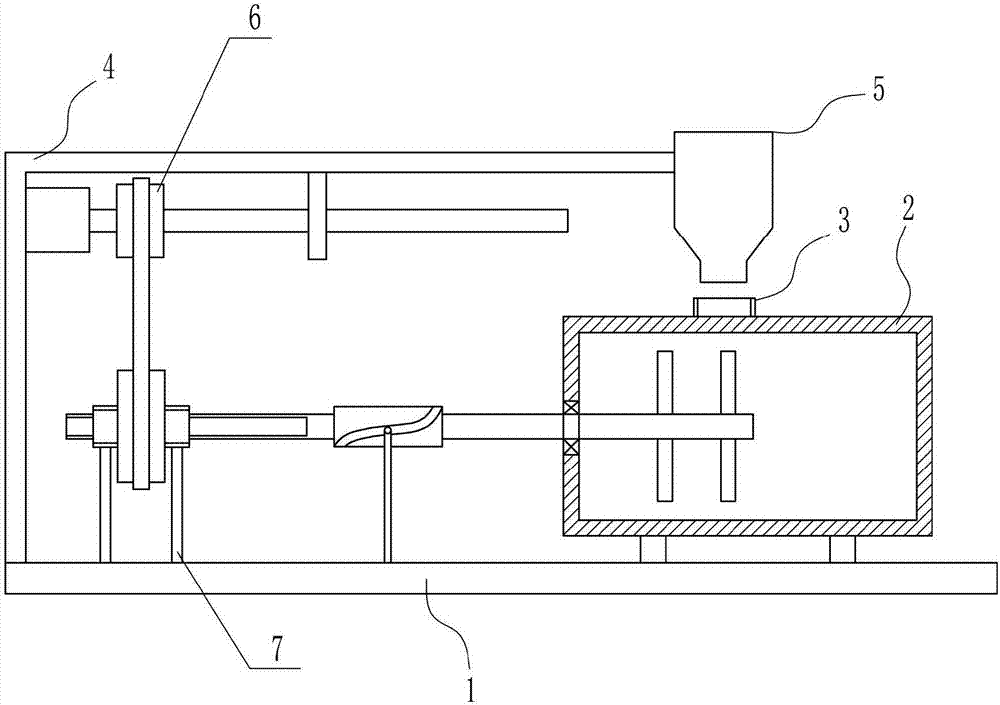

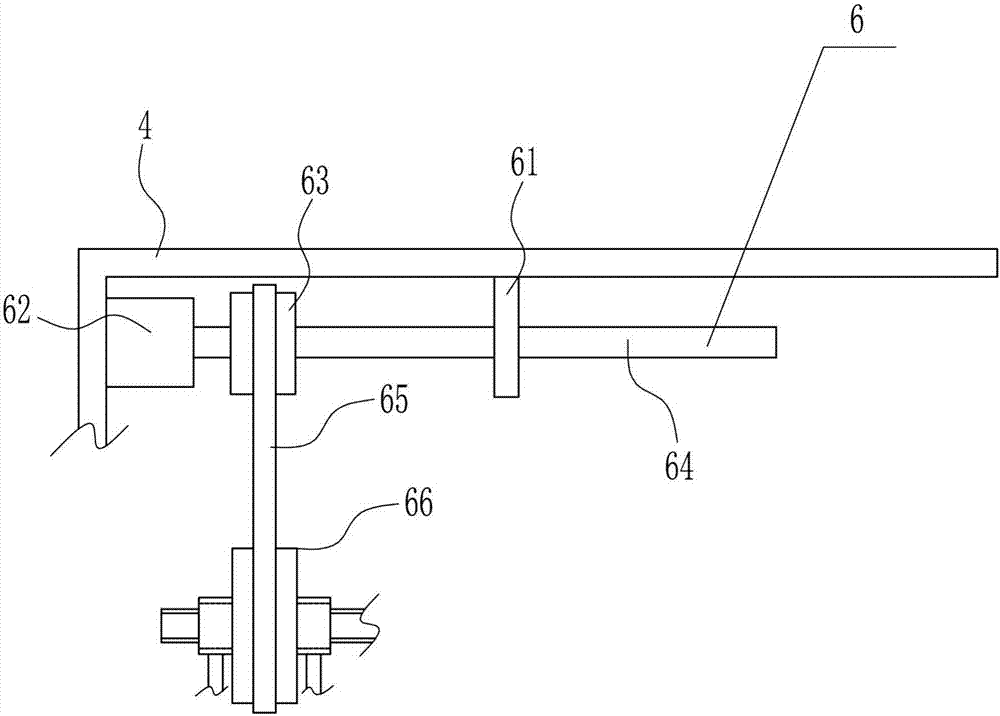

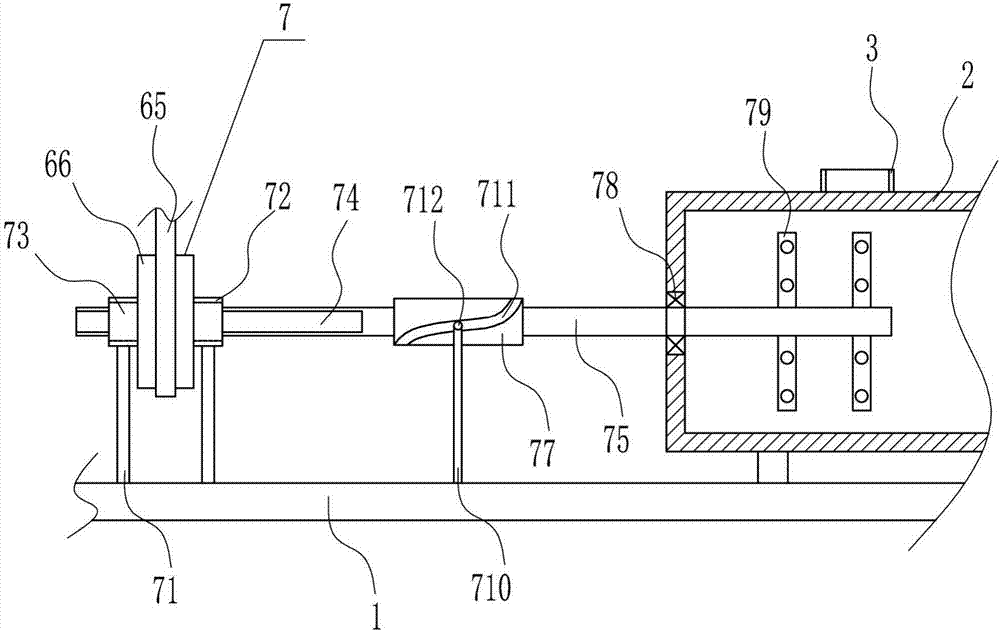

The invention relates to a coating mixer for medical treatment package, production, and printing, and particularly relates to a rapid coating mixing device for medical treatment package, production, and printing. The technical problem to be solved is to provide a rapid coating mixer with fast mixing speed and high working efficiency, capable of preventing coating from splashing and smudging people cloth and ground, and used for medical treatment package, production, and printing. In order to solve the technical problem, the invention provides the rapid coating mixing device for medical treatment package, production, and printing, comprising a bottom plate, a mixing frame, a feeding pipe, an L-type supporting plate, and a baiting hopper; the right side of the top part of the bottom plate is equipped with the mixing frame through bolt connection, and the left side of the top part of the mixing frame is connected with the feeding pipe. The mixing blade is rotated while crossly moved, so that the coating mixing is more uniform; an air outlet pipe sprays air, the coating is blown, and thus the coating mixing speed is accelerated.

Owner:滁州钰禾文具制品有限公司

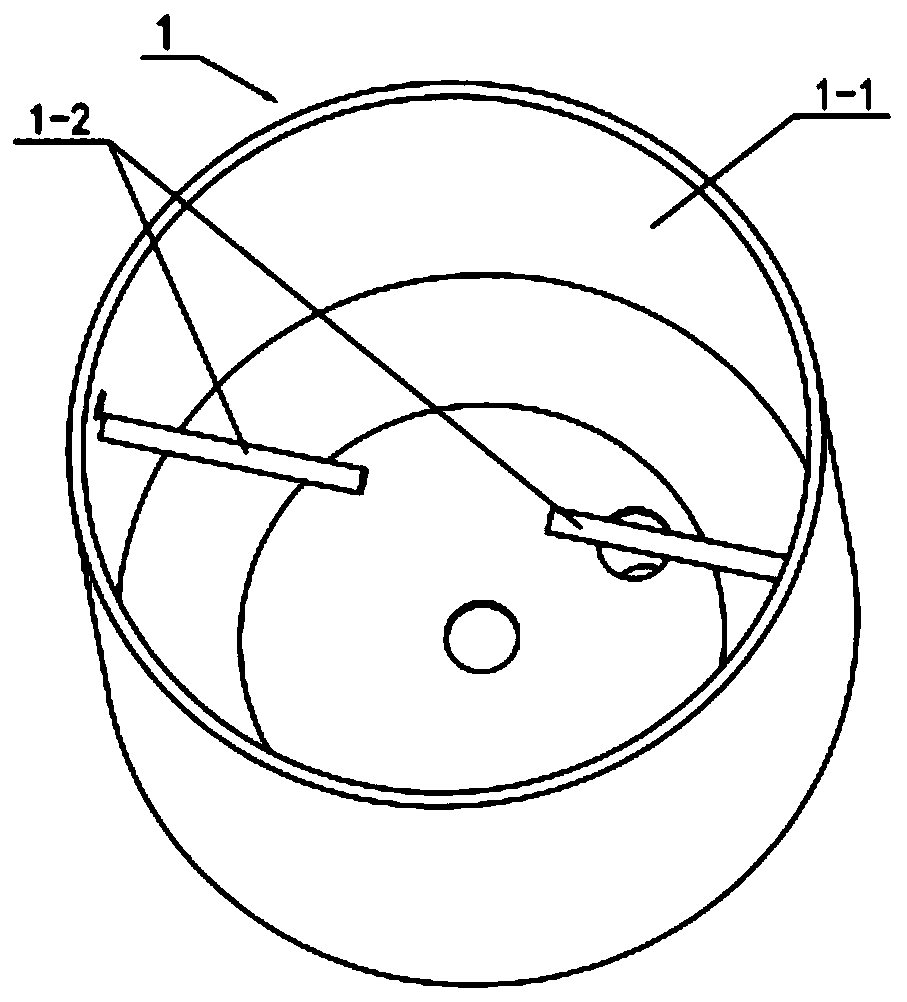

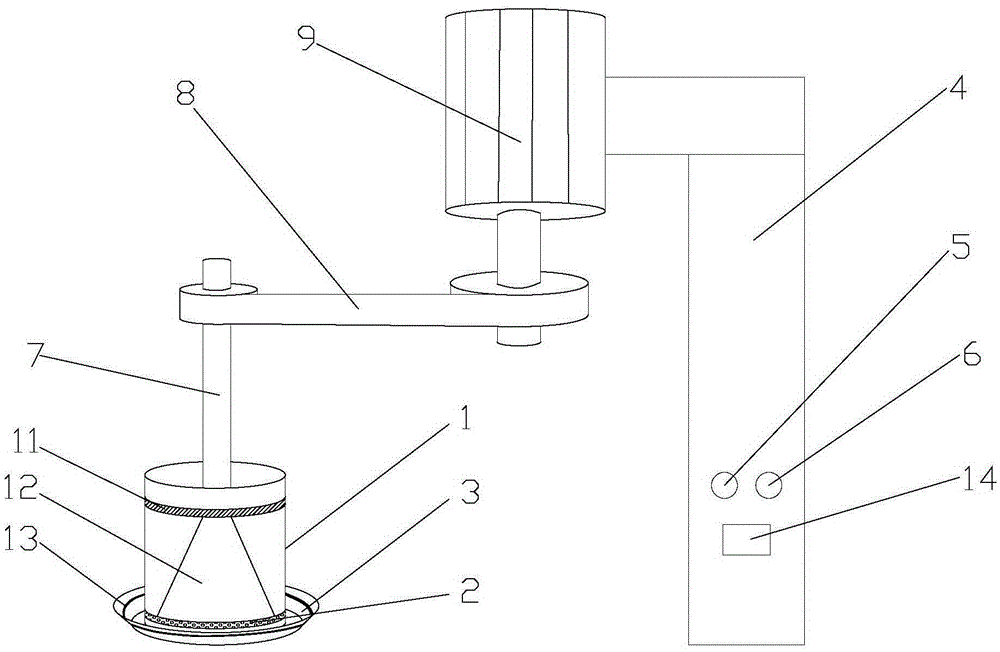

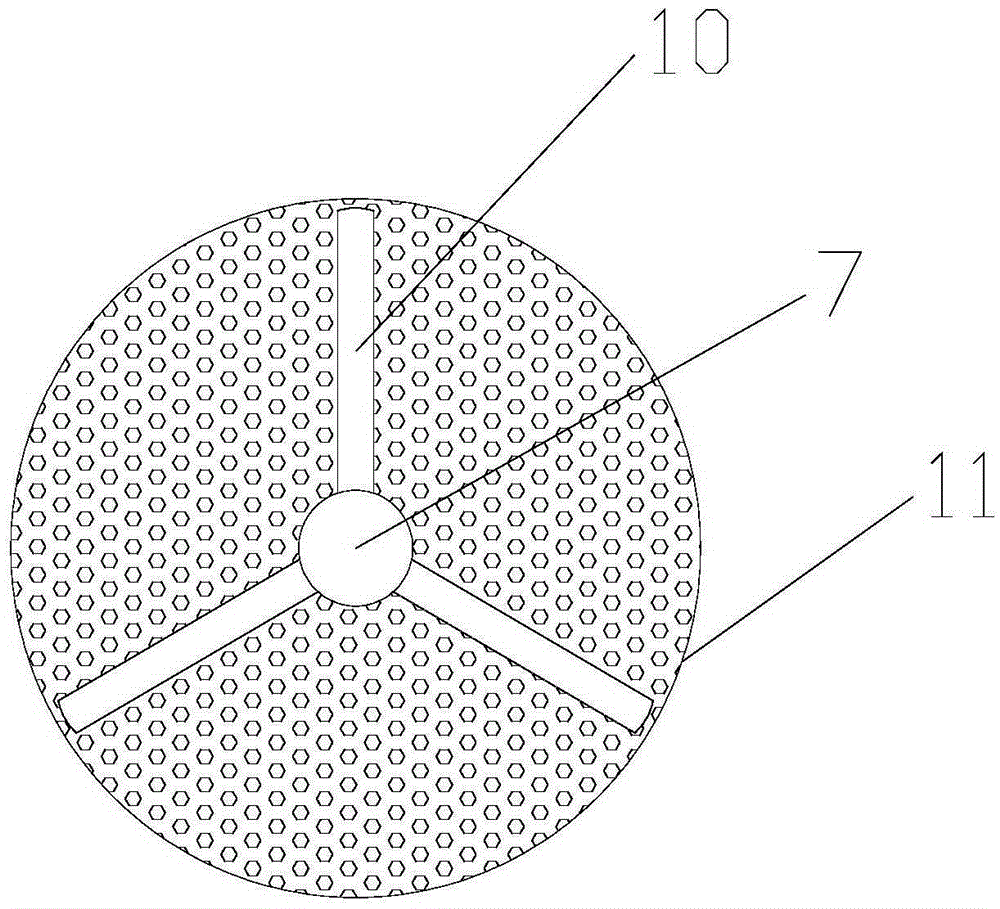

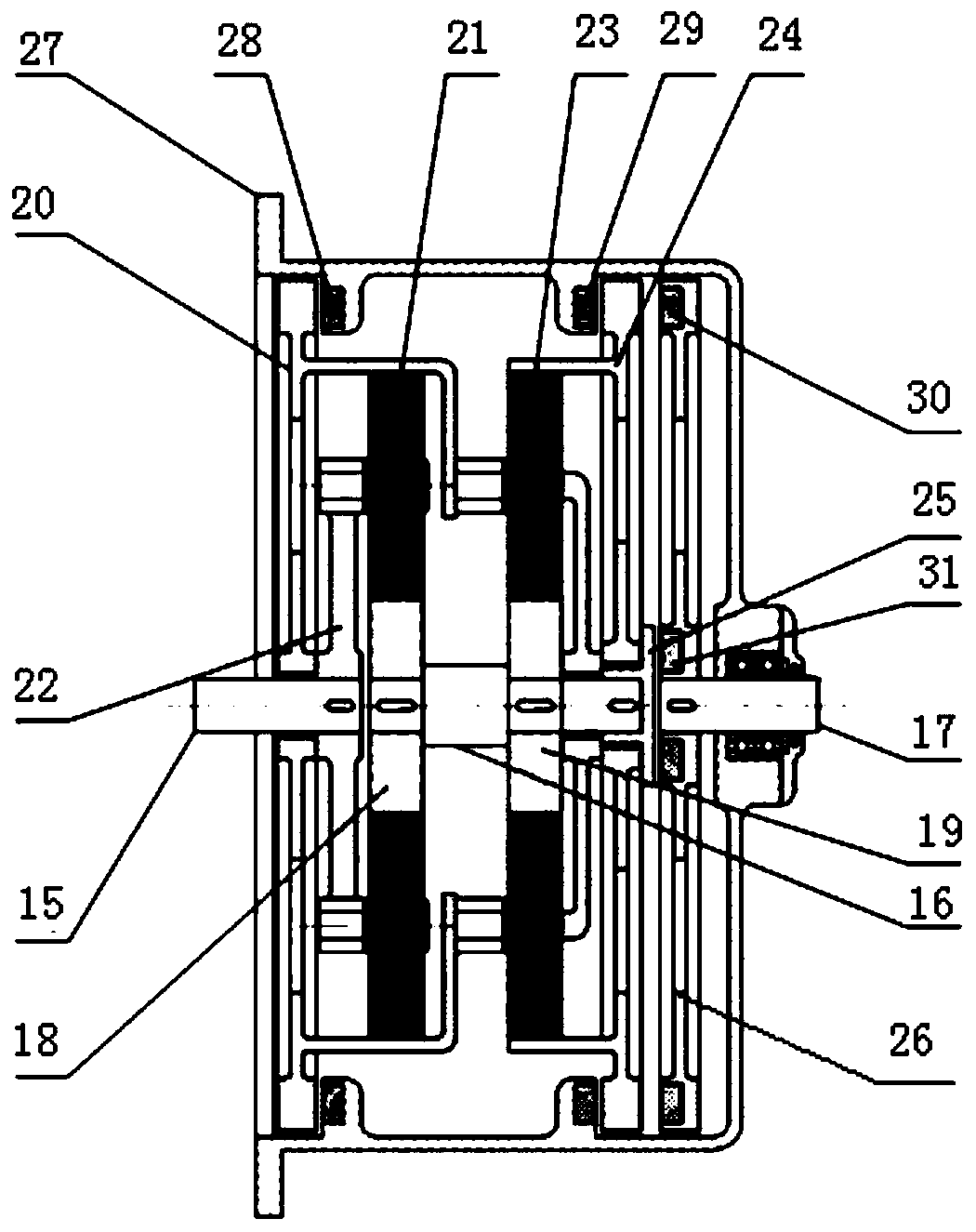

Pet food stirring device

InactiveCN108404760AAchieve circumferential stirringStir wellFeeding-stuffTransportation and packagingEngineeringMagnetic polarity

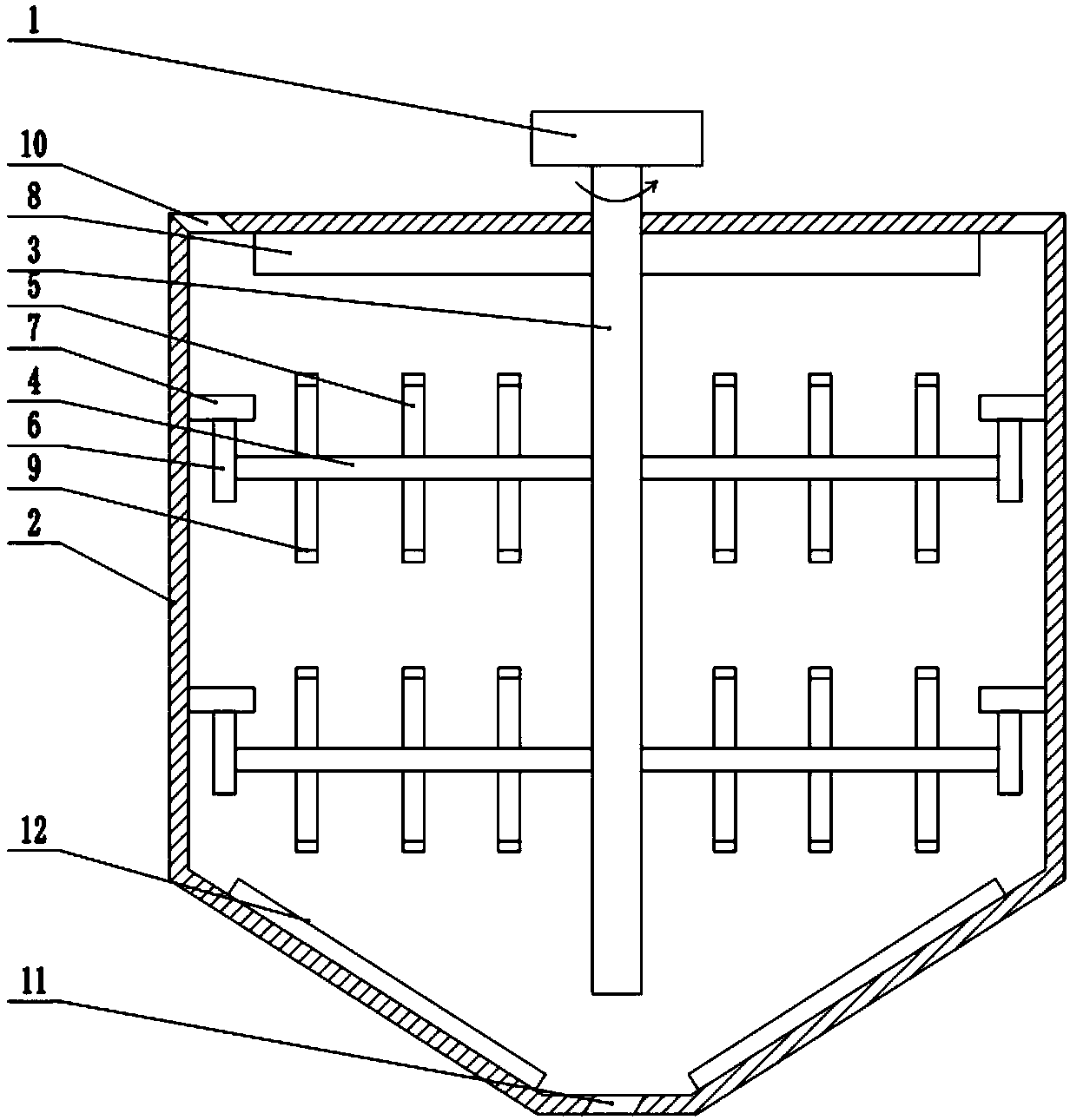

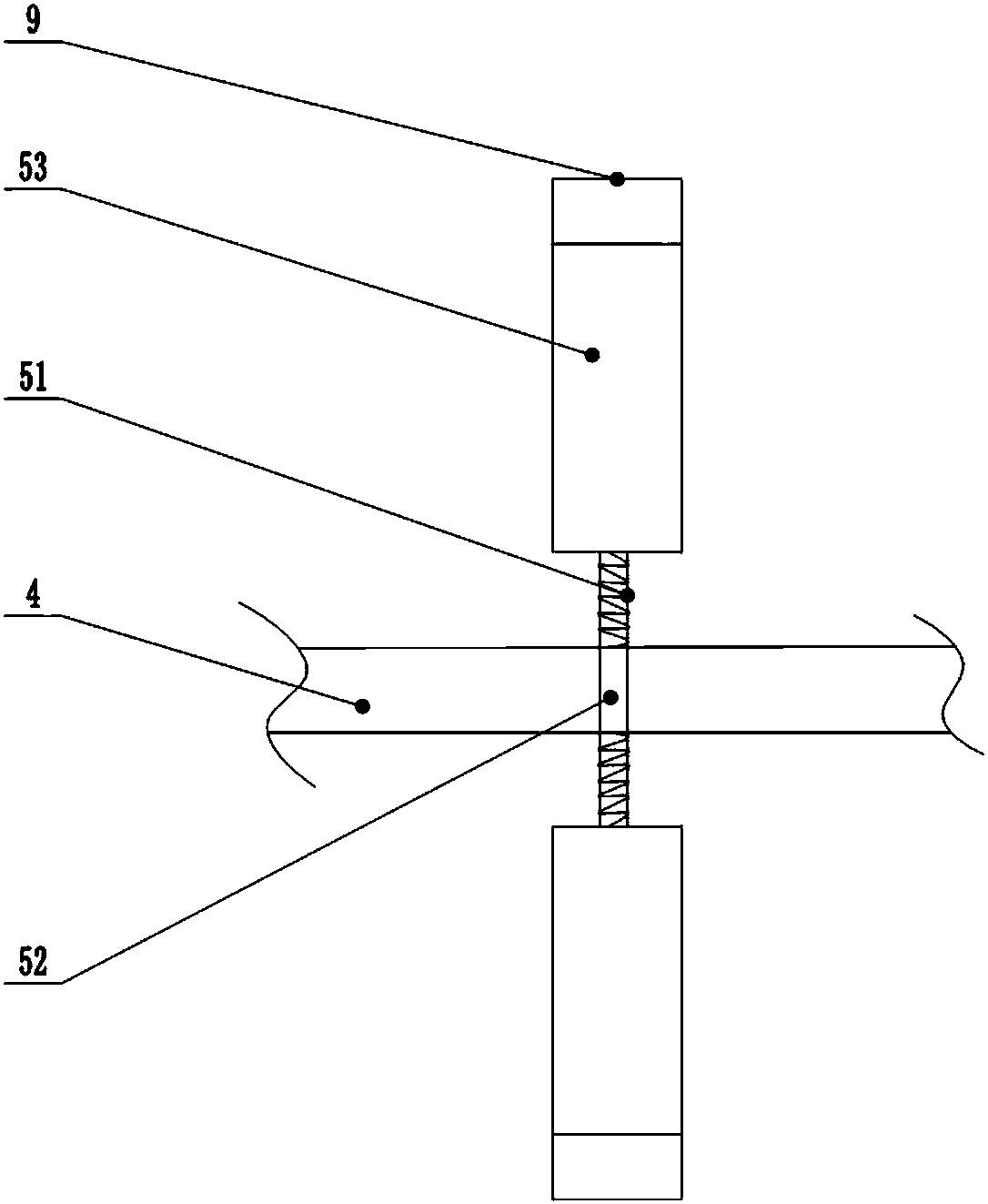

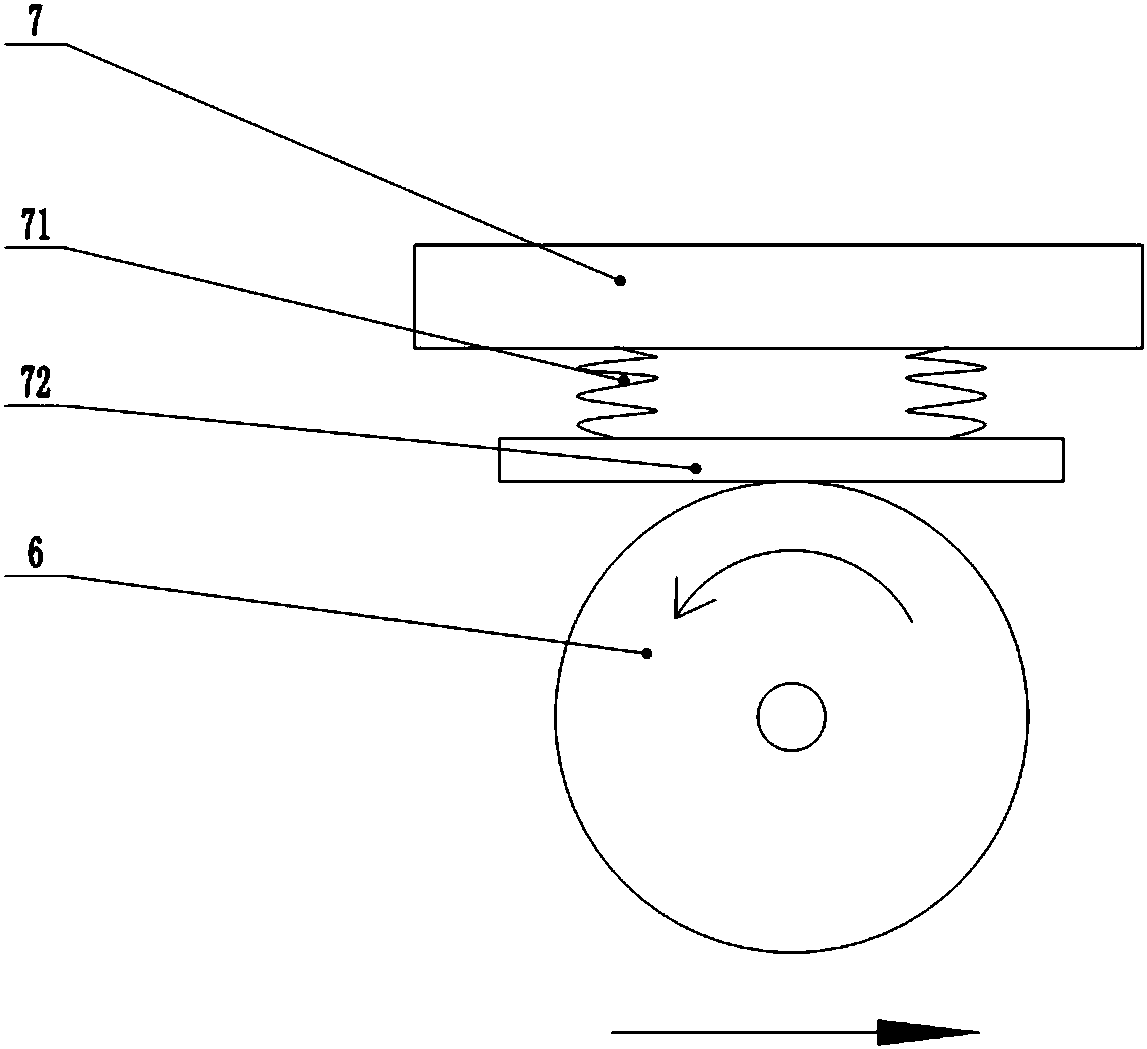

The invention discloses a pet food stirring device. The pet food stirring device comprises a motor, a housing and a vertical spindle; the top surface of the housing is provided with a feeding port, and the center of the top surface of the housing and the spindle are rotatingly sealed; the spindle is rotatingly matched with a horizontal first stirring rod which is perpendicularly provided with a second stirring rod, and the end portion of the first stirring rod is provided with a disc; the inner wall of the housing is fixedly provided with a ring-shaped baffle, and the circumference of the discabuts against the ring-shaped baffle; the second stirring rod is composed of a shaft rod and stirring blades, and the first stirring rod is provided with a sliding groove inside which the shaft rod can penetrate and slide; both extended ends of the shaft rod are connected with the stirring blades, and the shaft rod between the stirring blades and the first stirring rod is provided with a first spring in a sleeve mode; the inner wall of the top surface of the housing is provided with a first magnet, the stirring blades are provided with a second magnet, the closes ends of the first magnet andthe second magnet are identical in magnetic polarity, the lower portion of the housing is in an inverted cone shape, and the bottom of the housing is provided with a discharging port. The pet food stirring device can uniformly stir pet food.

Owner:CHONGQING SIWEITE PET SUPPLIES CO LTD

Material mixing and stirring equipment for chemical industry production

InactiveCN109925917AImprove the mixing effectWell mixedRotary stirring mixersTransportation and packagingChemical industryEngineering

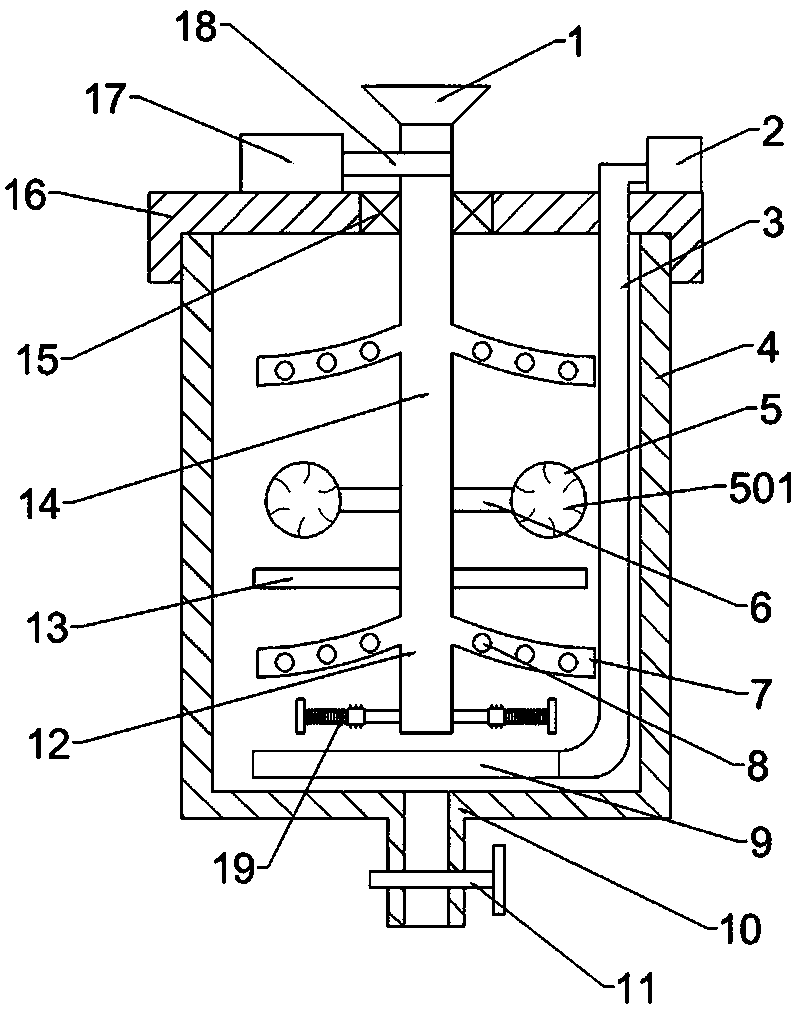

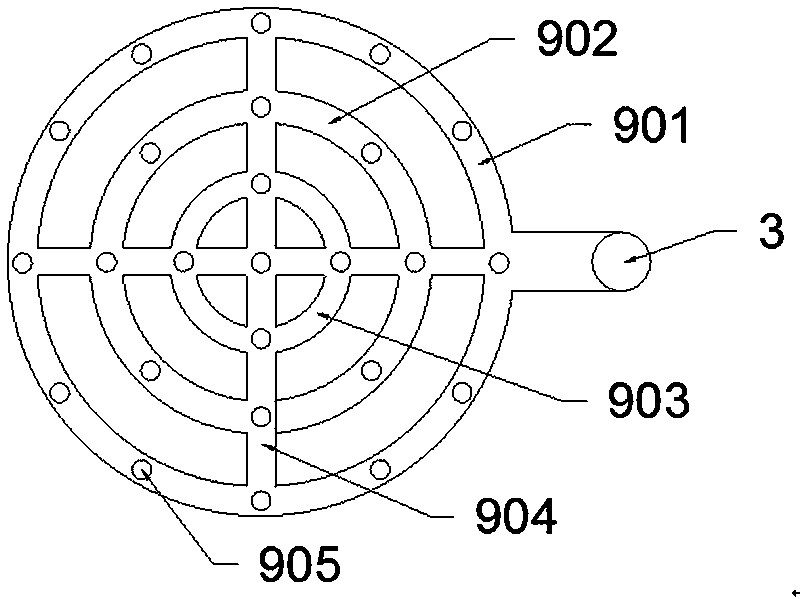

The invention relates to material mixing and stirring equipment for chemical industry production. The material mixing and stirring equipment comprises a barrel body, wherein a stirring shaft is arranged in the barrel body, a hollow inner cavity is arranged inside the stirring shaft, a material inlet hopper is arranged on the top end of the stirring shaft, the upper portion and the lower portion, positioned in the barrel body, of the stirring shaft are provided with material distribution pipes, the material distribution pipes are communicated to the hollow inner cavity in the stirring shaft, and are provided with a plurality of through holes, the middle portion of the stirring shaft are provided with connecting rods, the other end of the connecting rod is connected to a vortex generating member, and the bottom portion of the barrel body is provided with a gas distributing device. According to the present invention, the working principle is that the material can enter the hollow inner cavity of the stirring shaft through the material inlet hopper, the material distribution pipes can suck the material in the hollow inner cavity during the rotating due to the centrifugal force, the material enters the barrel body through the through holes on the material distribution pipes to be dispersed in different areas of the barrel body so as to improve the mixing effect of the material, andthe material distribution pipe has a certain stirring effect.

Owner:YUNXIAN LIANFA INDAL & TRADE

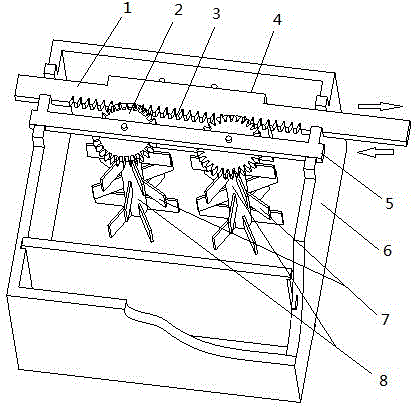

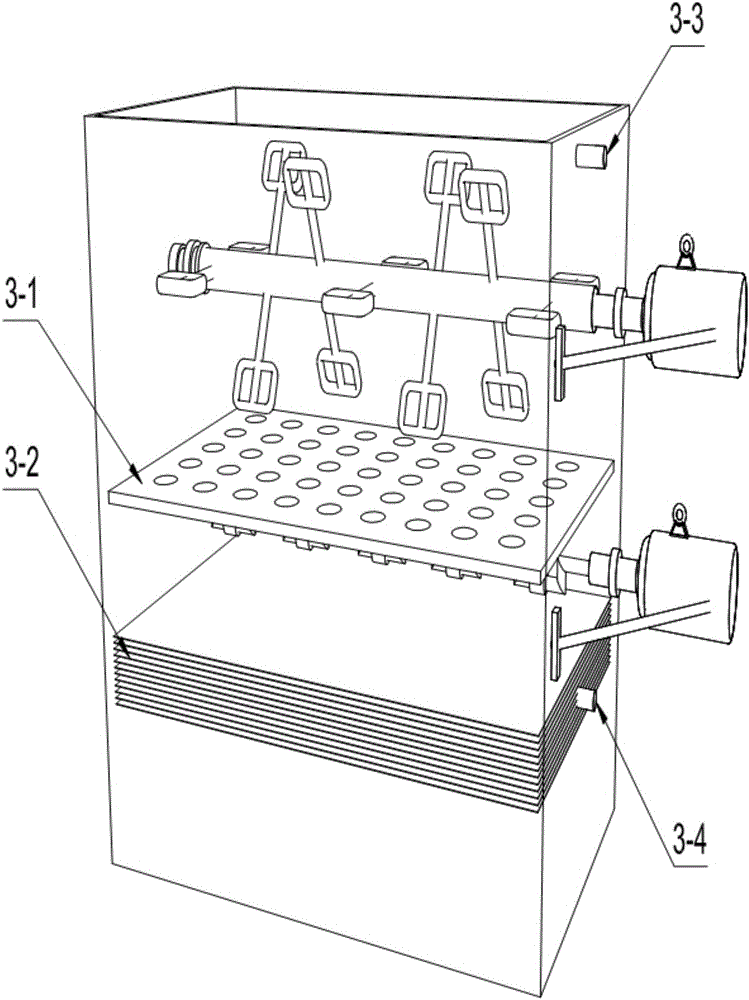

Stirring mechanism for electro-deposition

The invention discloses a stirring mechanism for electro-deposition which comprises an electro-deposition tank, a cathode, a cathode moving mechanism and a stirring mechanism body. The stirring mechanism body comprises near cathode stirring paddles, far cathode stirring paddles, a near cathode suspension beam, a far cathode suspension beam and limiting seats. When the stirring mechanism works, a horizontal reciprocating moving beam drives the near cathode stirring paddles connected with the near cathode suspension beam and the far cathode stirring paddles connected with the far cathode suspension beam to do horizontal synchronous reciprocating movement; under the dual actions of the near cathode stirring paddles and the far cathode stirring paddles in the mechanism, an electrolyte solution near cathode planes and in the whole electro-deposition tank can be stirred uniformly at high intensity. The stirring mechanism for electro-deposition greatly improves the uniformity of thickness distribution of a deposition layer and is simple in structure and low in cost.

Owner:HENAN POLYTECHNIC UNIV

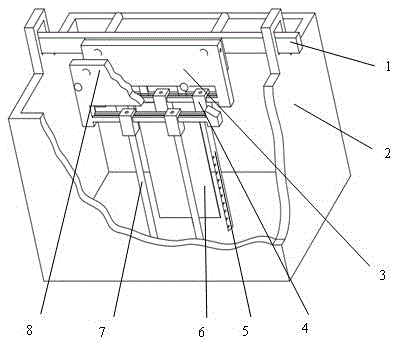

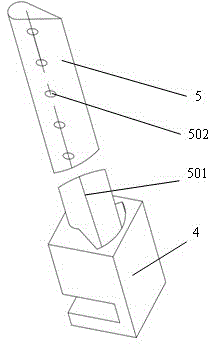

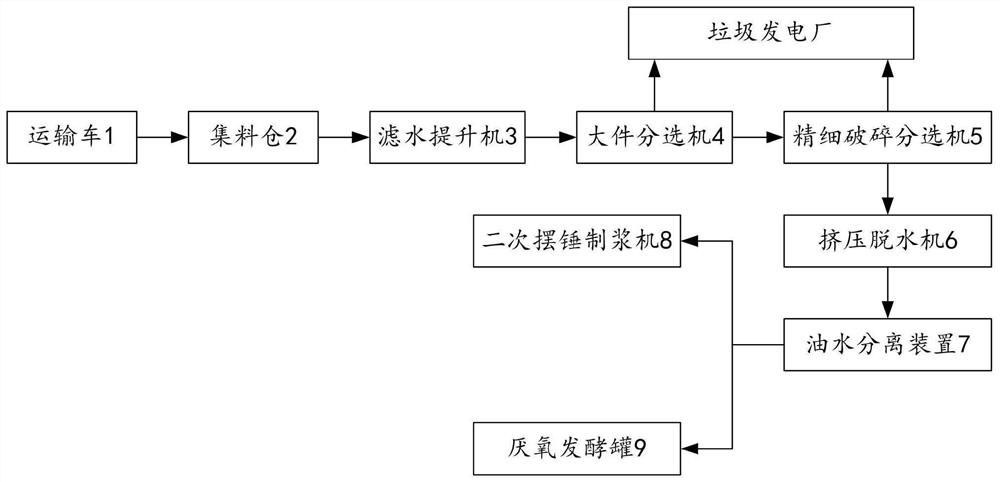

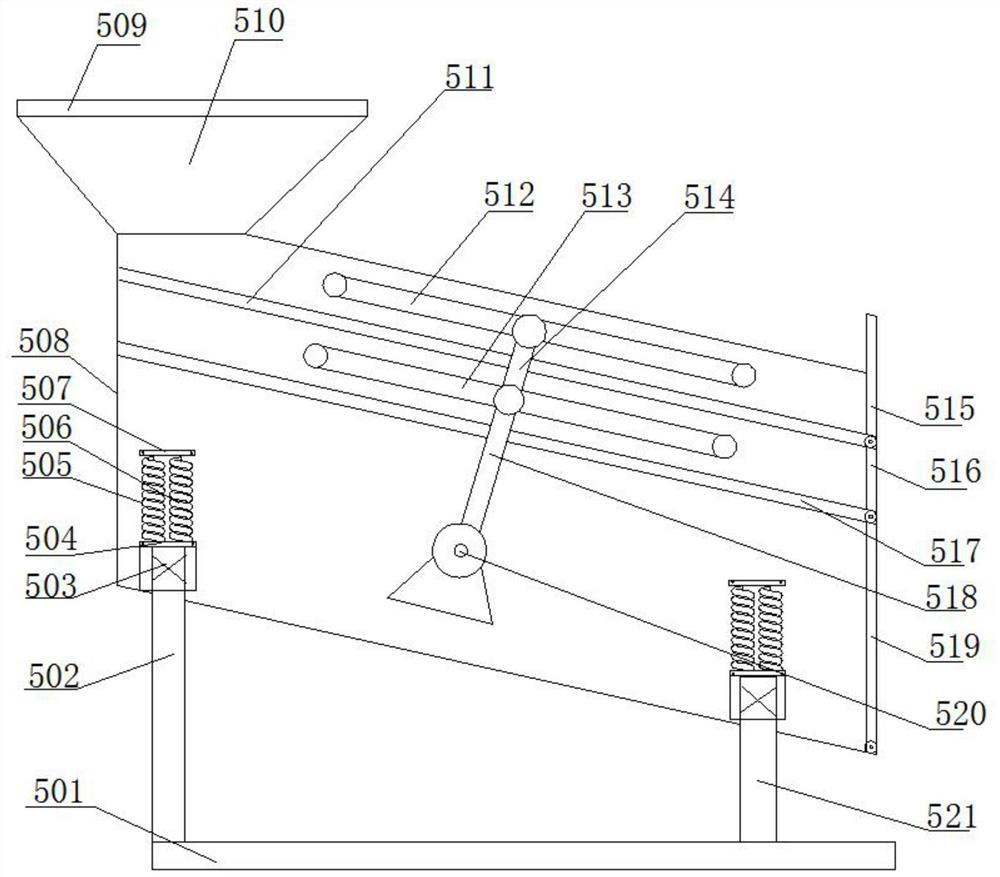

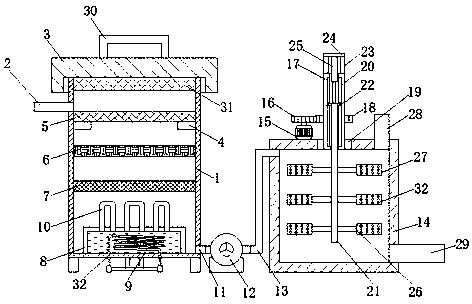

Automatic sorting treatment system for kitchen waste and treatment process

ActiveCN112139222ASolve the problem of uneven deliveryStirring effect is evenSolid waste disposalTransportation and packagingForeign matterWater filter

The invention discloses an automatic sorting treatment system for kitchen waste and a treatment process, relates to the field of domestic waste treatment, and solves the problems that existing kitchenwaste is large in reserve and threatens human health. The automatic sorting treatment system comprises a transport vehicle, a material collecting bin, a water filtering elevator, a large-foreign matter sorting machine, a fine crushing and sorting machine, an extrusion dehydrator, an oil-water separation device, a secondary pendulum bob pulping machine and an anaerobic fermentation tank, wherein the water filtering elevator is used for receiving the kitchen waste uniformly conveyed by the material collecting bin and carrying out water filtering treatment; the large-foreign matter sorting machine is used for sorting large foreign matters in the kitchen waste residues; the fine crushing and sorting machine is used for carrying out fine crushing on the large sorted kitchen waste residues andsorting out inorganic impurities; the extrusion dehydrator is used for carrying out extrusion dehydration treatment on the finely sorted kitchen waste residues; the oil-water separation device is usedfor mixing kitchen waste swill obtained after water filtration and kitchen waste slurry obtained after extrusion dehydration and then carrying out oil extraction and dehydration treatment; the secondary pendulum bob pulping machine is used for finely pulping the kitchen waste residues subjected to oil extraction and dehydration; and the anaerobic fermentation tank is used for carrying out anaerobic fermentation on kitchen waste liquid subjected to oil extraction and dehydration. The automatic sorting treatment system is high in treatment efficiency, good in treatment effect, energy-saving andenvironmentally-friendly.

Owner:吉林省佳园再生科技有限公司

Ink box for copying machine

ActiveCN108790415ASpeed up the flowFast fullRotary stirring mixersTransportation and packagingCold airEngineering

The invention relates to the technical field of copying machine equipment and discloses an ink box for a copying machine. The ink box comprises an ink box body and an air guiding box. The ink box bodyis provided with an ink outlet. The air guiding box is provided with air inlets and an air outlet. The ink box body is provided with an air supply box. A guide pipe communicates with the air supply box and is provided with a first three-way valve. The first three-way valve communicates with the air inlets. A rotating shaft is connected into the air guiding box in a rotary manner. A turbine is connected to the rotating shaft in a sleeving manner. One end of the rotating shaft penetrates the air guiding box and extends into the ink box body. A sliding sleeve is connected to the rotating shaft in a sleeving and threaded manner. A stirring plate is fixedly connected to the sliding sleeve. A cavity is formed in the inner wall of the ink box body. A vortex tube is fixedly connected to the ink box body, wherein the vortex tube communicates with the air outlet. The hot air end and the cold air end of the vortex tube each communicate with the cavity. A second three-way valve is connected between the hot air end of the vortex tube and the cavity. A third three-way valve is connected between the cold air end of the vortex tube and the cavity. By means of the ink box, the problem that in theprior art, due to the fact that ink in an ink box is frozen, normal coping cannot be conducted is solved.

Owner:贵州省仁怀市西科电脑科技有限公司

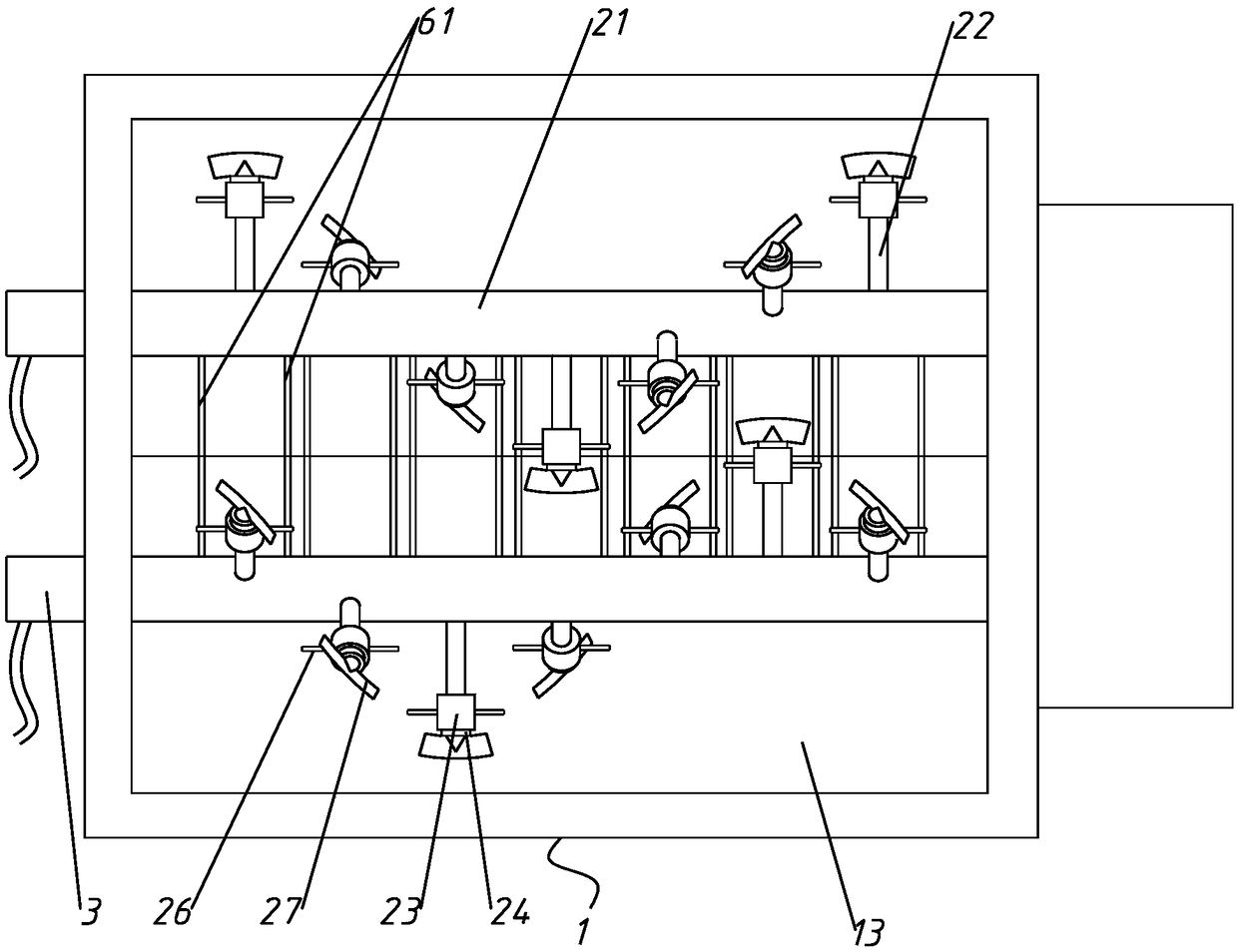

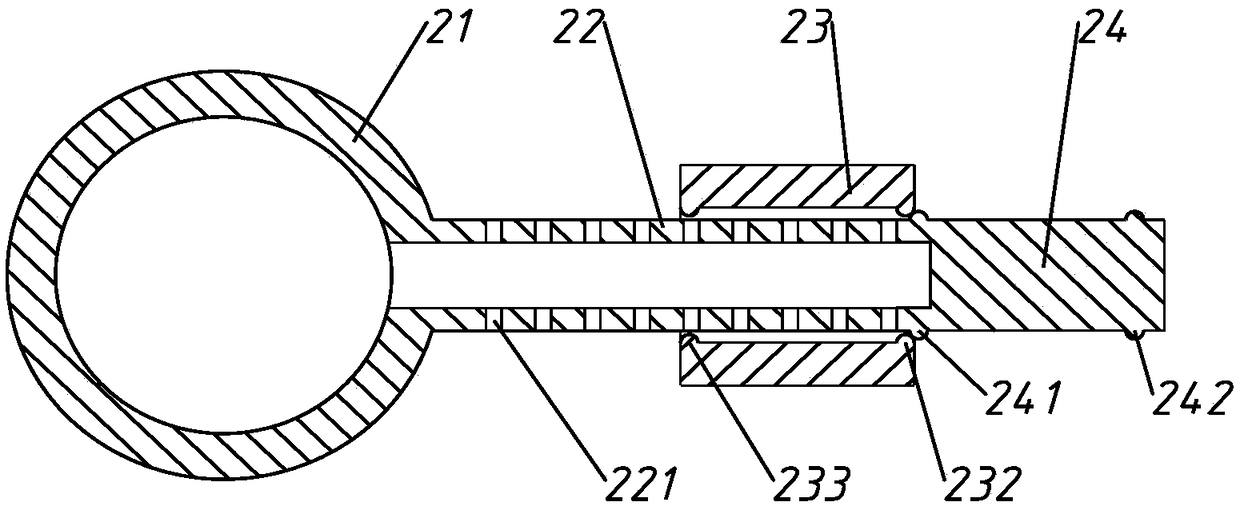

Double-shaft horizontal type mixer for mixing concrete

InactiveCN108789826AIncrease freedomLow failure rateCement mixing apparatusLiquid ingredients supply apparatusMixing effectHollow core

The invention belongs to the technical field of mixers, and provides a double-shaft horizontal type mixer for mixing concrete. The double-shaft horizontal mixer comprises a machine shell, a stock binis arranged inside the machine shell, a feeding inlet is formed in the upper part of the machine shell, and a discharge port is formed in the lower part of the machine shell. The feeding inlet and thedischarge port both communicate with the stock bin, and mixing main shafts are rotatably arranged in the stock bin. The mixing main shafts are each provided with a plurality of mixing rods in the radial direction of the mixing main shafts, the mixing main shafts are of hollow core structures, and first cavities are formed in the inner portions of the mixing main shafts. One ends of the first cavities are sealed, and liquid supply pumps are connected to the other ends of the first cavities through rotary joints. The mixing rods are of hollow core structures, and second cavities are formed in the inner portions of the mixing rods. The first cavities communicate with the second cavities. The mixing rods are each provided with a plurality of first through holes, and the first through holes communicate with the second cavities. Mixing blocks are slidably arranged on the mixing rods. Through the double-shaft horizontal mixer, the technical problem that the mixing effect is affected due to the fact that the structure of a mixing mechanism of a mixer in the prior art is limited due to the poor internal environment of a stock bin is solved.

Owner:高碑店市天筑新型建材有限公司

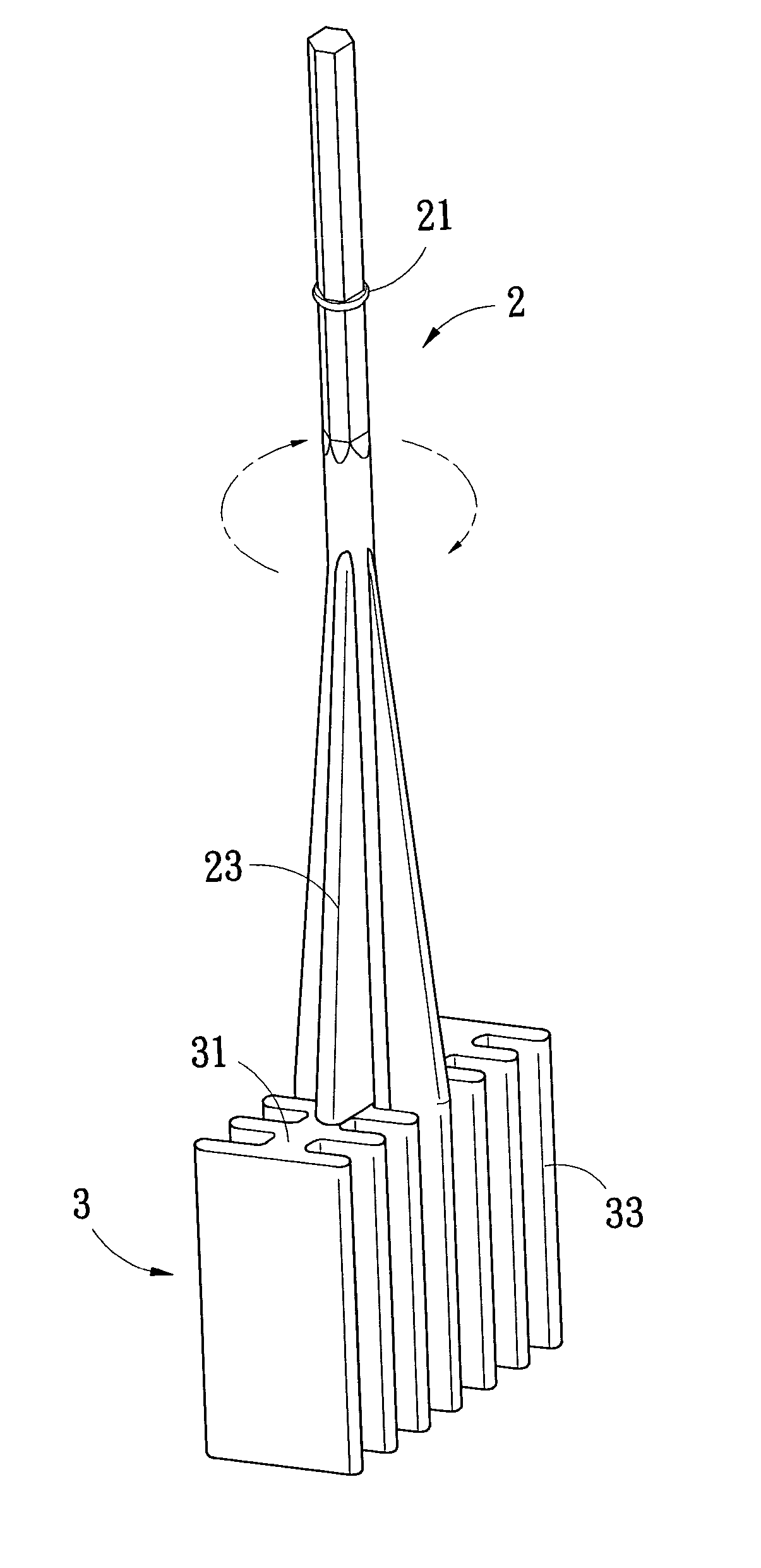

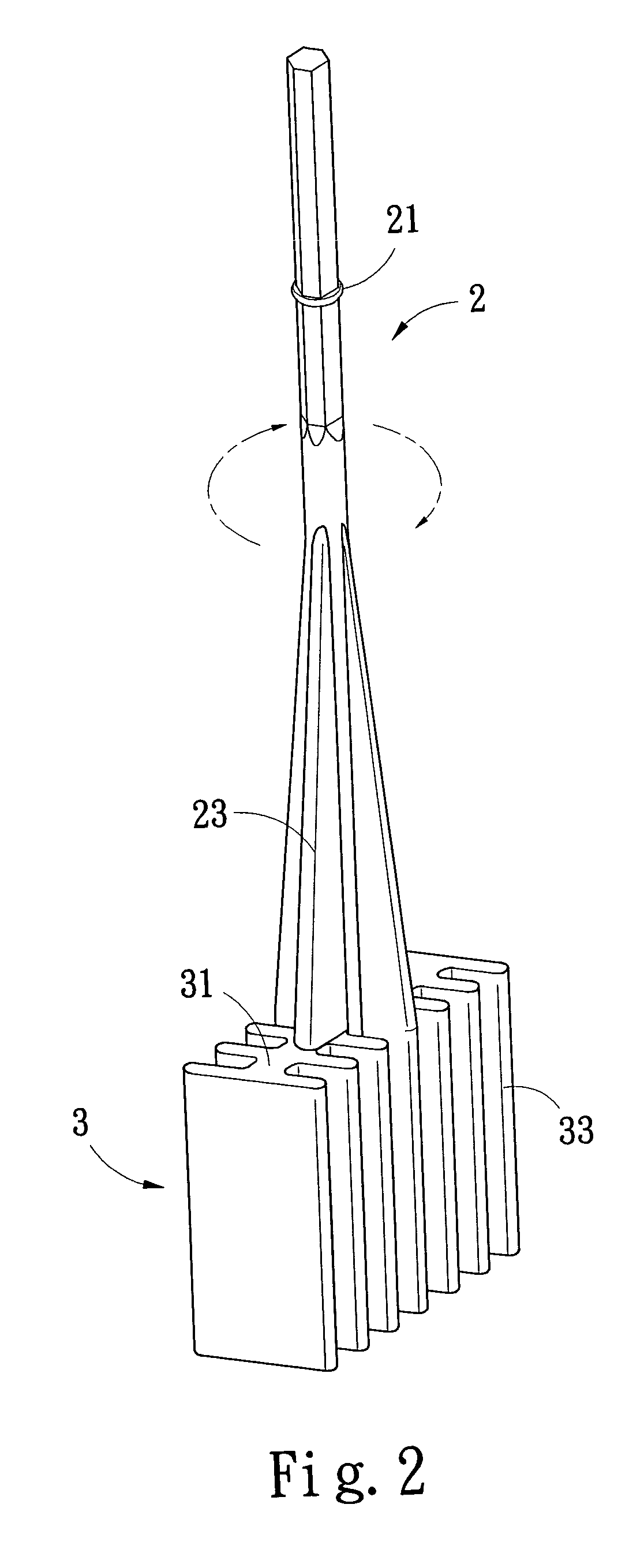

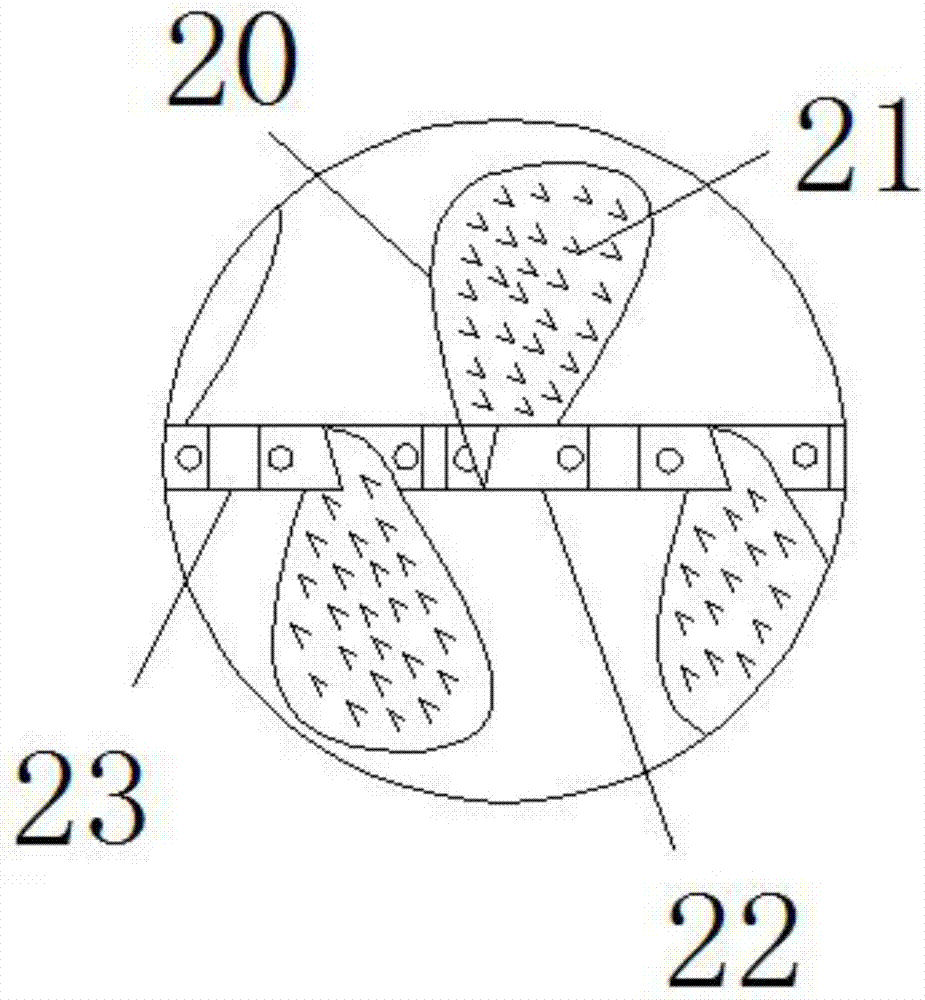

Stirrer

InactiveUS20050047269A1Stirring speed is fastStirring effect is evenRotary stirring mixersTransportation and packagingPulp and paper industry

A stirrer comprises a stirring shank and a flow-disturbing member; the flow-disturbing member is provided on the stirring shank and composed of two elongated strip members respectively provided on the upper and lower edges thereof as well as spacedly provided with a plurality of flow-disturbing blades. Each flow-disturbing blade is allocated between the two elongate strip members in a predetermined inclined angle, so that when the stirring shank is rotated, higher stirring speed and more uniform stirring effect can be obtained. The present invention suits stirring devices for paints (such as oil paint) used on a building.

Owner:NJEH CHUANG IND

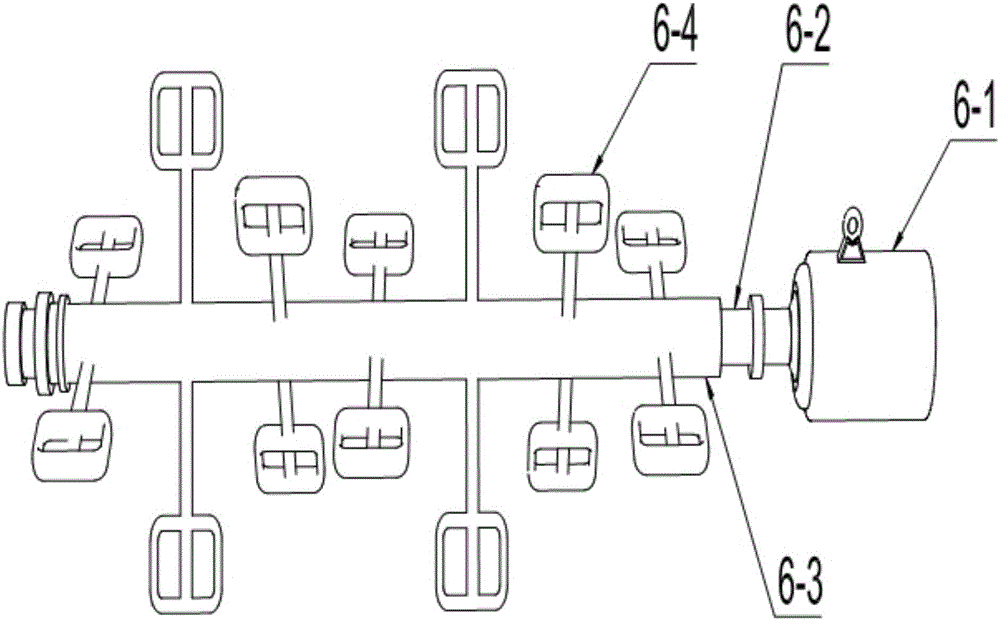

Electrodeposition device

The invention discloses an electrodeposition device which comprises an electrodeposition tank, a cathode, a cathode moving rod, a gear, a gear mounting rod and a stirring paddle.When the electrodeposition device works, the anode moving rod is in horizontal reciprocating motion under action of external force, a rack on the cathode moving rod drives the gear to be in forward and backward circular motion, and in this way, an electrolyte quickly flows under stirring action of the stirring paddle; the outer edge of the stirring paddle is close to the surface of the cathode, so that a flow field, on the surface of the cathode, of the electrolyte is relatively uniform, and uniformity of thickness of a cathode electrodeposition layer in the electrodeposition process is improved.

Owner:HENAN POLYTECHNIC UNIV

Plastic stirring machine facilitating slurry movement

The invention discloses a plastic stirring machine facilitating slurry movement. The plastic stirring machine comprises a machine body. A discharging opening is formed in one side of the machine body. The position, located above the discharging opening, of one side of the machine body is fixedly connected with a controller. A feeding opening is formed in the top of the machine body. The top of the machine body is fixedly connected with a first motor. The output end of the first motor penetrates the machine body and extends into a stirring box arranged in the machine body. The two sides of the output end, located in the stirring box, of the first motor are fixedly connected with first connecting rods. The side, far away from the output end of the first motor, of each first connecting rod is fixedly connected with a stirring plate. Material passing holes are formed in the surface of each stirring plate. According to the plastic stirring machine facilitating slurry movement, by means of cooperation of the first motor, the stirring plates, the material passing holes and material passing grooves, slurry movement is faster; the effect of even stirring of plastic raw materials during stirring is achieved; and the problem that uneven stirring is prone to happening to an original plastic stirring machine is solved.

Owner:山东森庆新材料科技有限公司

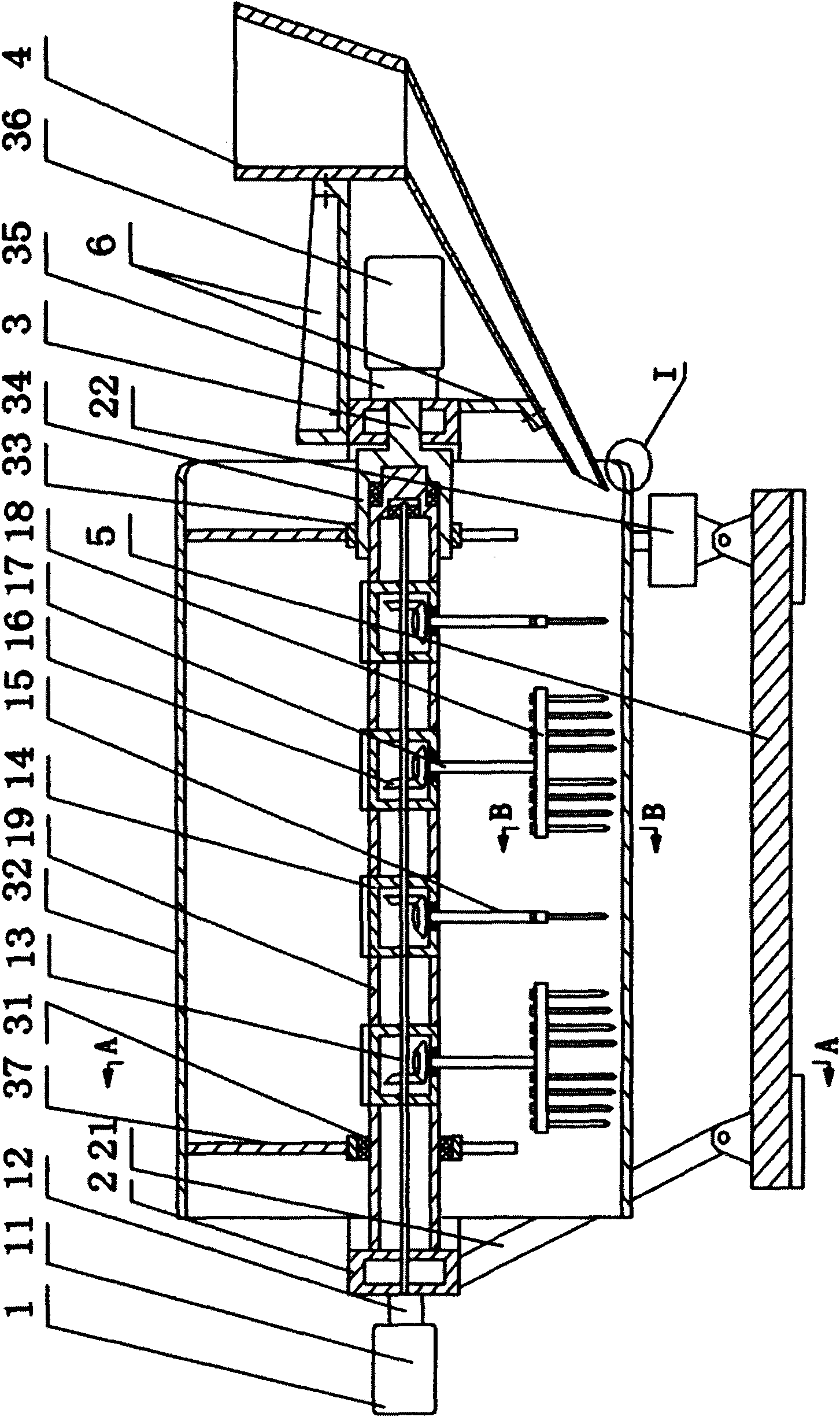

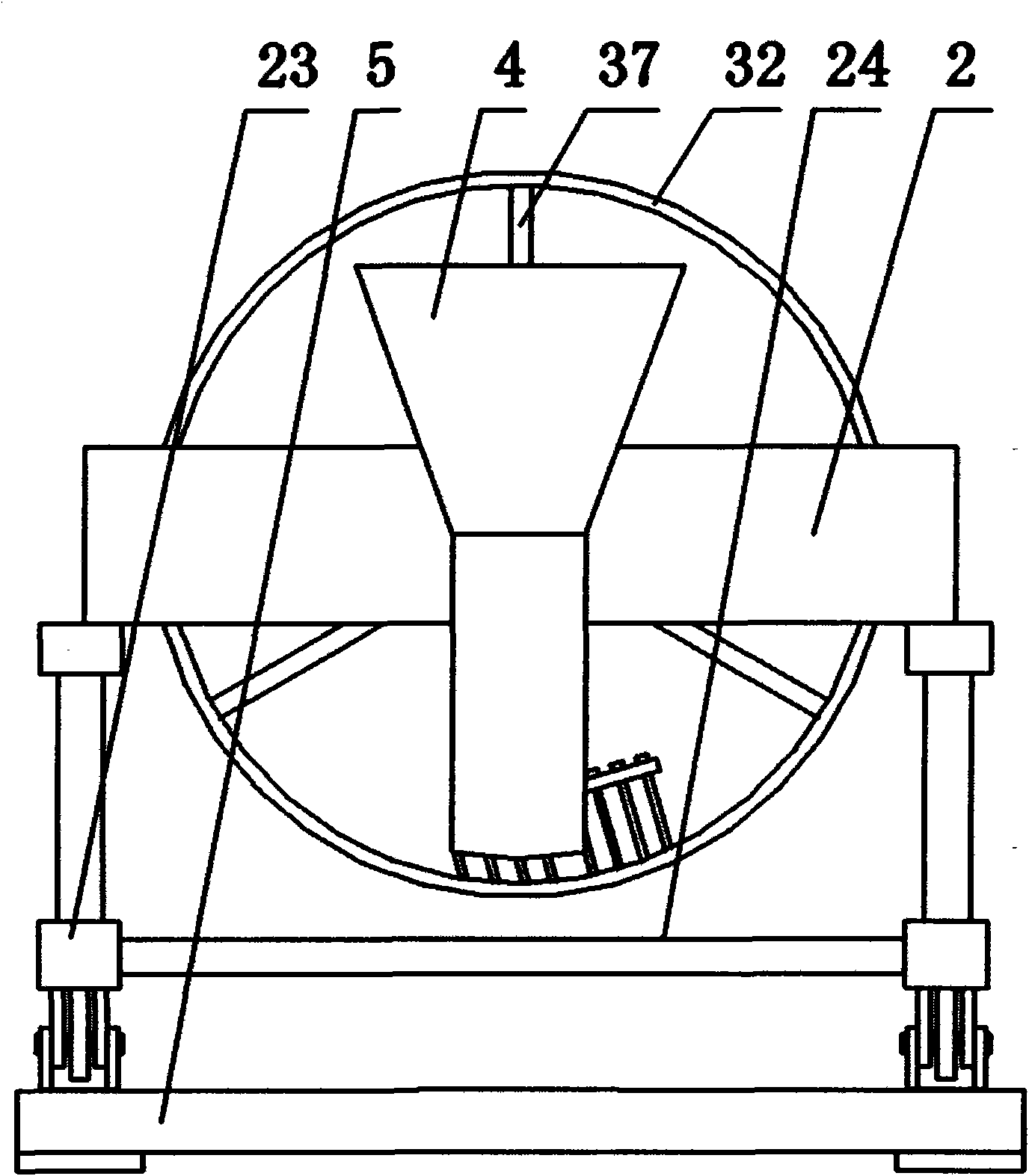

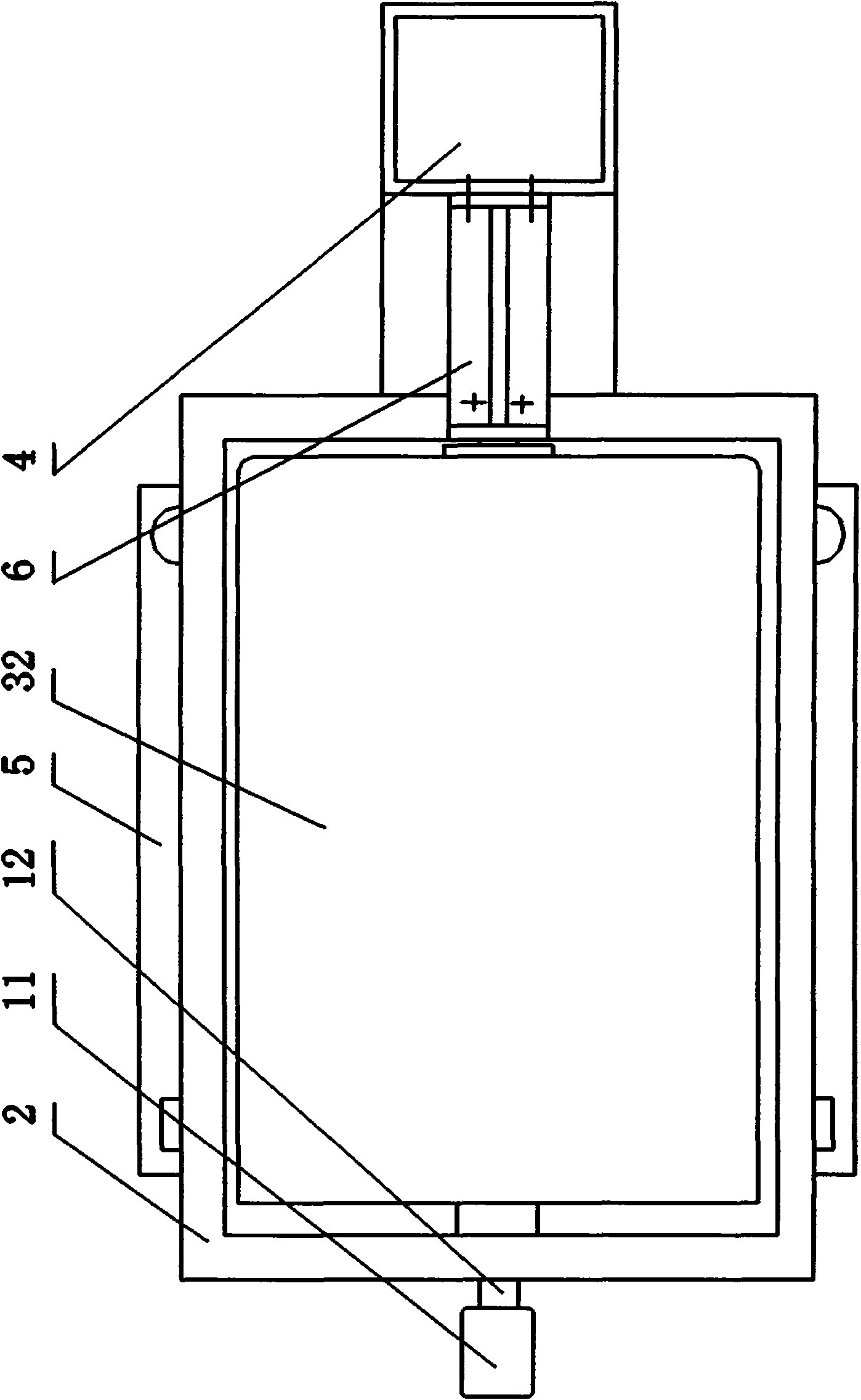

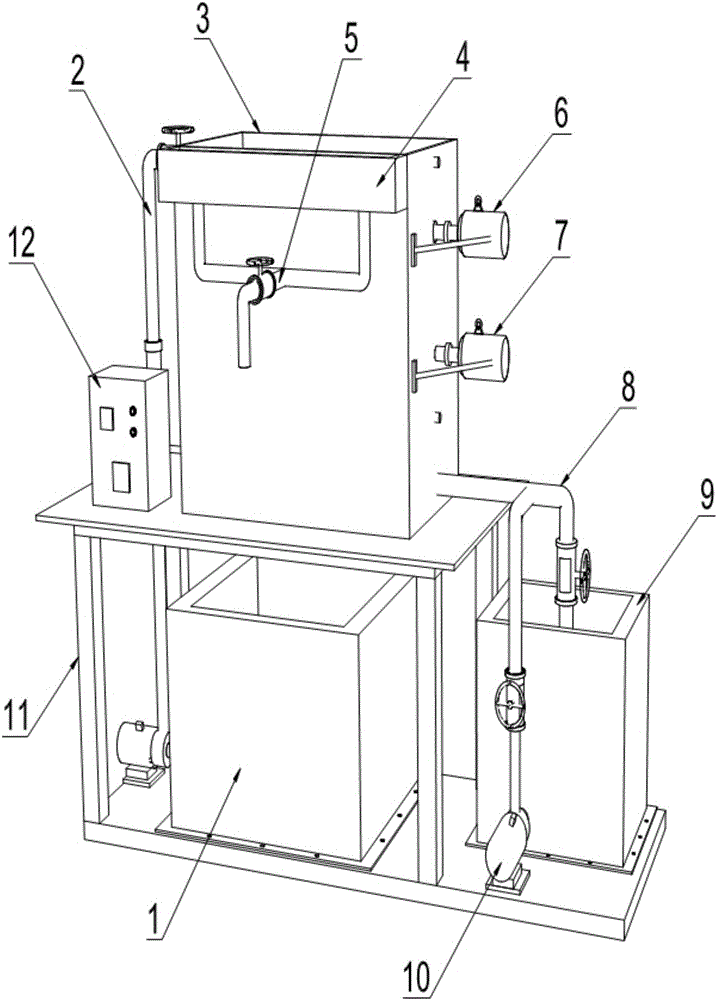

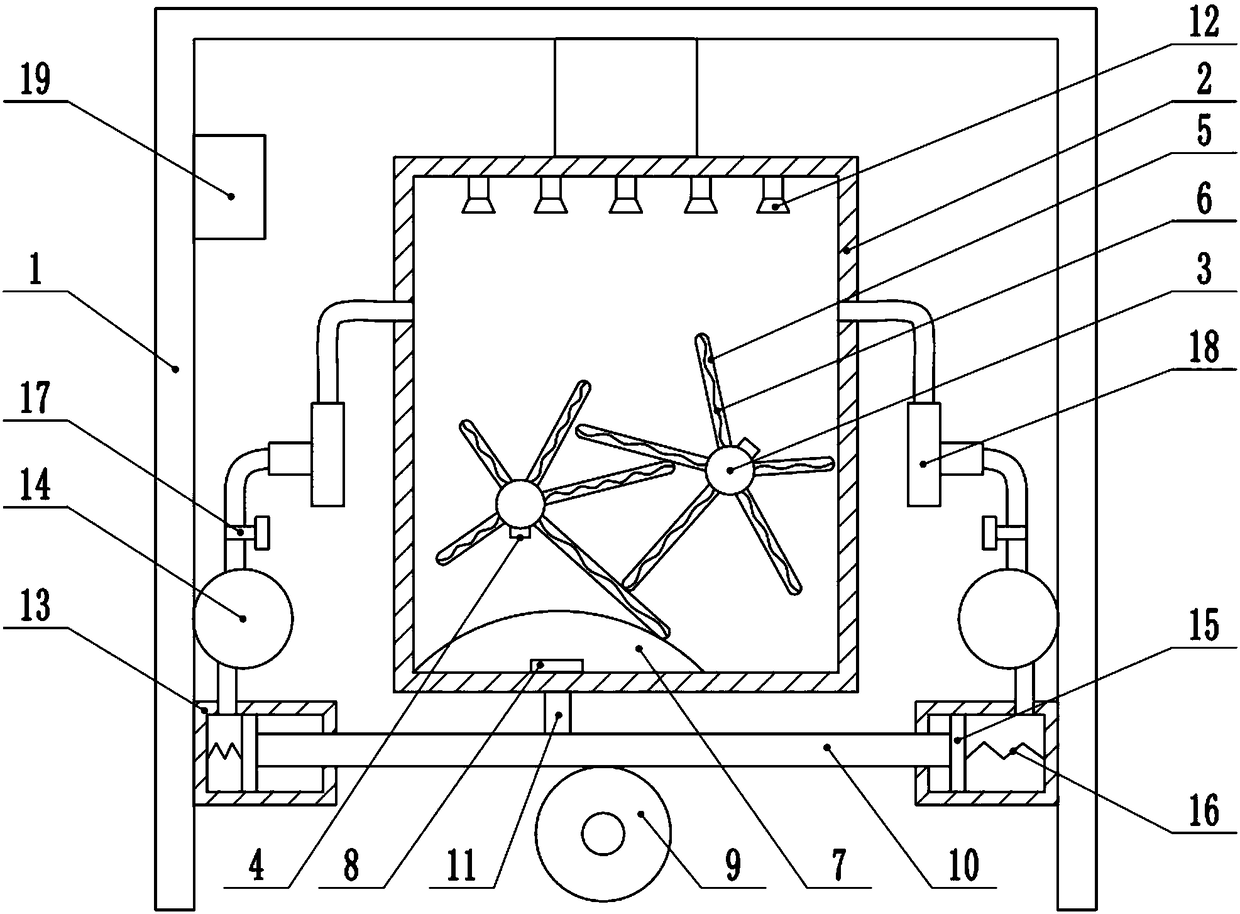

High-speed and high-efficiency blender with mighty rotating flow

InactiveCN101837611AWell mixedRealize uninterrupted operationCement mixing apparatusGear wheelEngineering

The invention relates to a high-speed and high-efficiency blender with mighty rotating flow, which has high efficiency, good stirring effect, large work flow and high stirring speed and can realize continuous operation. The blender comprises a stand, a framework, a roller arranged on the framework and a feed hopper, the roller is internally provided with a stirring mechanism, two sides of the framework are respectively provided with a roller driving device and a stirring driving device, and the stand is provided with a framework supporting mechanism. The blender is structurally characterized in that the stirring mechanism comprises a fixing shaft sleeve, a main shaft, a stirring shaft and a stirring wing arranged at the lower end of a stirring shaft, the fixing shaft sleeve and the main shaft are axially arranged along the roller, one end of the fixing shaft sleeve is connected with the framework, and the other end is in rotation connection with the roller driving device; the fixing shaft sleeve is provided with at least two gear boxes, and each gear box is respectively provided with a set of transmission gear; one end of the main shaft is connected with the stirring driving device and the other end is in rotation connection with the fixing shaft sleeve; and the upper end of the stirring shaft is connected with the main shaft through a gear.

Owner:台德恩

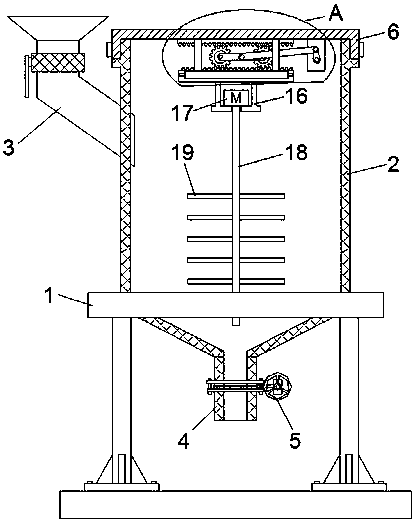

Stirring and vibrating water purifying device and working method thereof

ActiveCN105668838AInnovative designStirring effect is evenWater treatment parameter controlSpecific water treatment objectivesEngineeringSewage

The invention discloses a stirring and vibrating water purifying device and a working method thereof.The stirring and vibrating water purifying device is composed of a wastewater pool, a water drawing device, a purifying pool, a backwashing water collecting pool, a backwashing water discharging pipe, a stirring device, a vibrating device, a clean-water discharging pipe, a clean water pool, a backwashing device, a purifying pool support and a control system.The working method includes the steps that wastewater enters the purifying pool through the water drawing device, the stirring device is started to stir and mix the wastewater, meanwhile the vibrating device is started to continually vibrate large particles in the wastewater up and down, and treated clean water is discharged to the clean water pool through the clean-water discharging pipe; after the device runs for 15-25 hours, the backwashing device is started to backwash the device, and the backwashing water is collected through the backwashing water collecting pool to be discharged through the backwashing water discharging pipe.The stirring and vibrating water purifying device is simple in structure, high in wastewater purifying rate and wide in application range.

Owner:XUZHOU UNIV OF TECH

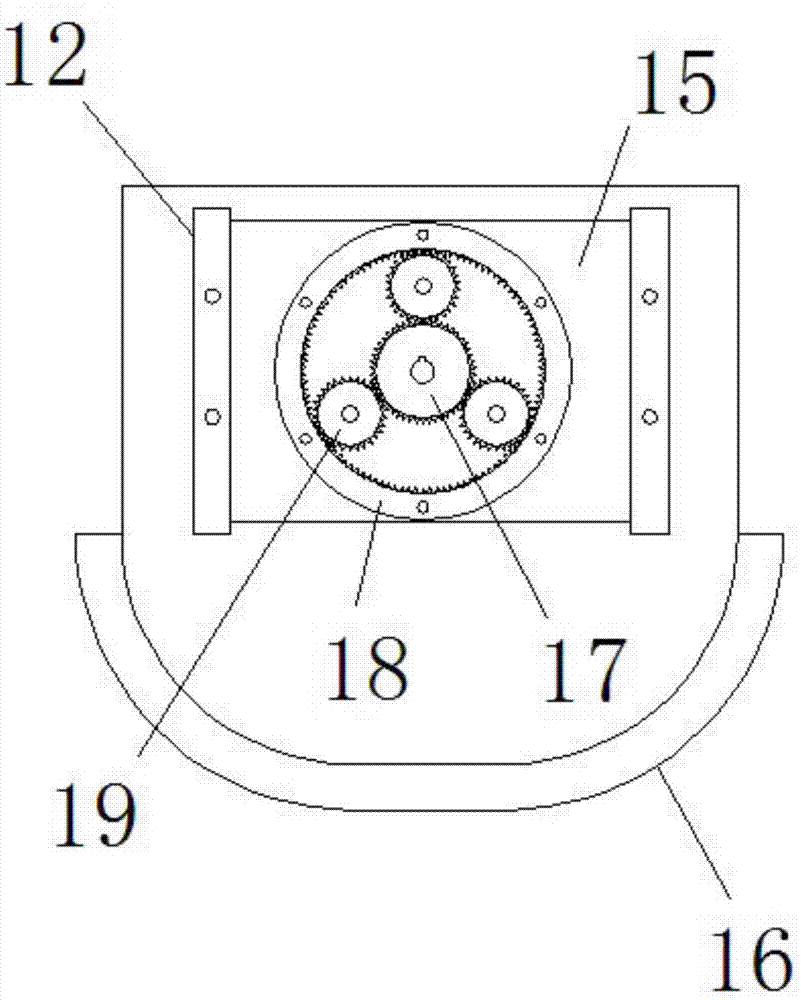

Lime drying sludge mixer

InactiveCN107973516AEasy to operateThe principle is simpleSludge treatment by de-watering/drying/thickeningHydraulic cylinderSludge

The invention discloses a lime drying sludge mixer. The lime drying sludge mixer comprises a stirring box and three agitators. The three agitators are arranged inside the stirring box. The bottom of the stirring box is fixedly connected with a bottom plate, and the top sides of the two ends of the bottom plate are fixedly connected with a hydraulic cylinder, a first motor is fixedly connected to one end, away from the bottom plate, of the hydraulic cylinder, a central gear is connected with an output shaft of the first motor in a sleeving manner, and three planetary gears are meshed with the central gear. The outer rings of the planetary gears are meshed with ring gears, a mounting plate is fixed on one, away from the first motor, of the ring gear through a bolt, slide rails are arranged on both sides of the mounting plate, and the slide rails are fixed on the side face of the stirring box. The other end of the hydraulic cylinder is hinged with the corresponding central gear, and the planetary gears on both sides of the stirring box are in one-to-one correspondence. The lime drying sludge mixer has a novel structure, and the three agitators are simultaneously linked by using a starwheel transmission mechanism to ensure a good stirring effect.

Owner:合肥挺泰环保科技有限公司

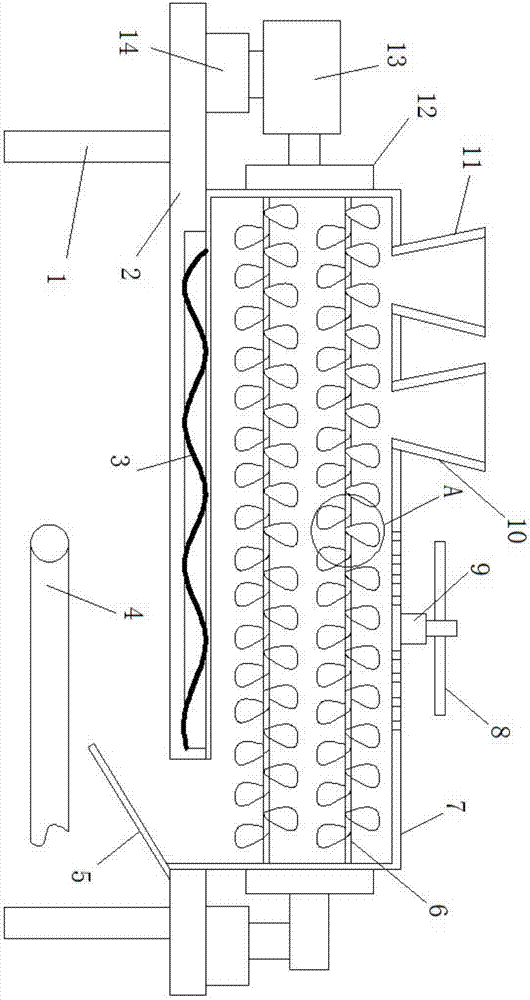

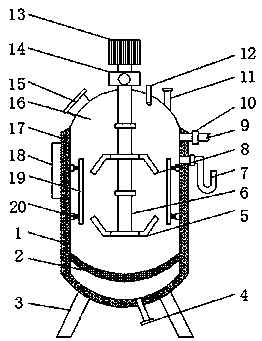

Stirring-type tea fermentation machine

InactiveCN108497111AAchieve coolingControl fermentation temperaturePre-extraction tea treatmentCold airGear wheel

The invention relates to the technical field of tea processing, and discloses a stirring-type tea fermentation machine. The machine comprises a frame; a fermentation chamber is arranged on the frame;the fermentation chamber is internally and rotatably connected to rotating shafts; the rotating shafts are fixedly connected to stirring plates; the fermentation chamber is internally and slidably connected with a slide block which pushes against the stirring plates; the slide block is fixedly connected to a first magnet; the frame is rotatably connected to a gear; the gear engages with a rack; the rack is fixedly connected to a second magnet used for attracting the first magnet; spray heads are arranged in the fermentation chamber; the frame is fixedly connected to piston cylinders and air bags; a one-way air inlet valve is arranged on each piston cylinder; a piston is slidably connected into each piston cylinder; the ends of the rack are fixedly connected to the pistons; the air bags communicate with the piston cylinders and the fermentation chamber; a one-way valve is arranged between each air bag and each piston cylinder; a valve and a vortex tube are mounted between each air bag and the fermentation chamber; and the air inlet end of each vortex tube communicates with one of the air bags, and the cold air end of each vortex tube communicates with the fermentation chamber. The machine solves the problem of uneven stirring and poor temperature and humidity control din the tea fermentation process.

Owner:贵州省凤冈县翠巅香生态茶业有限公司

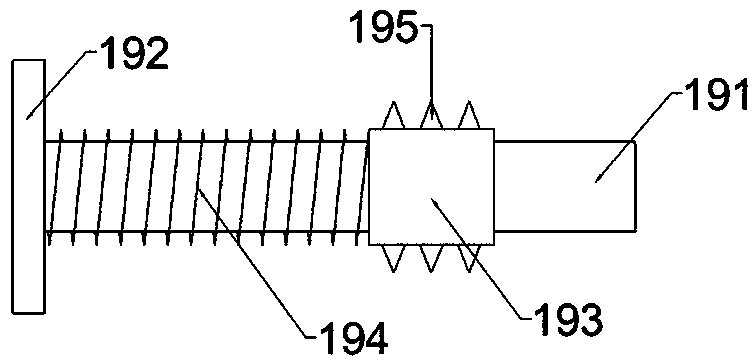

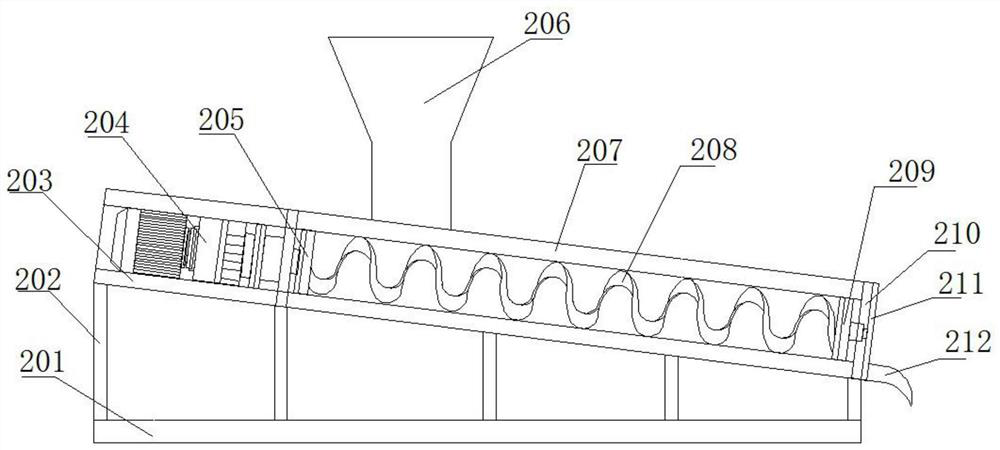

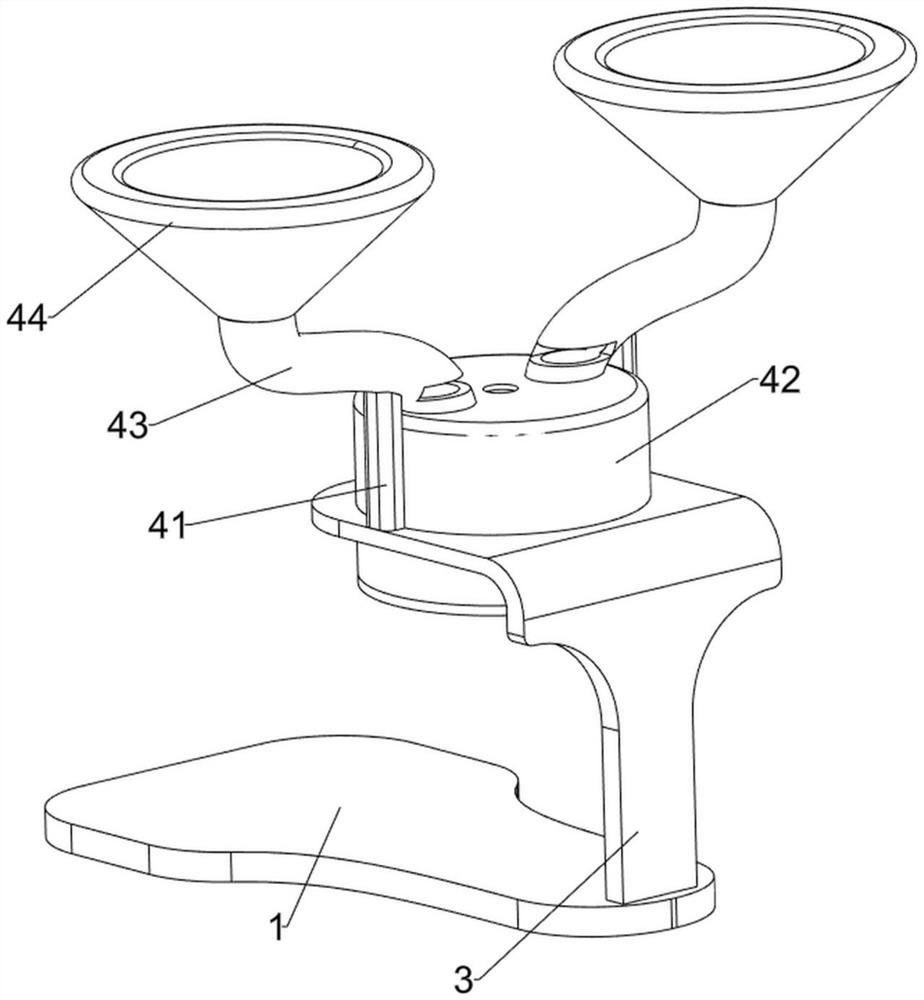

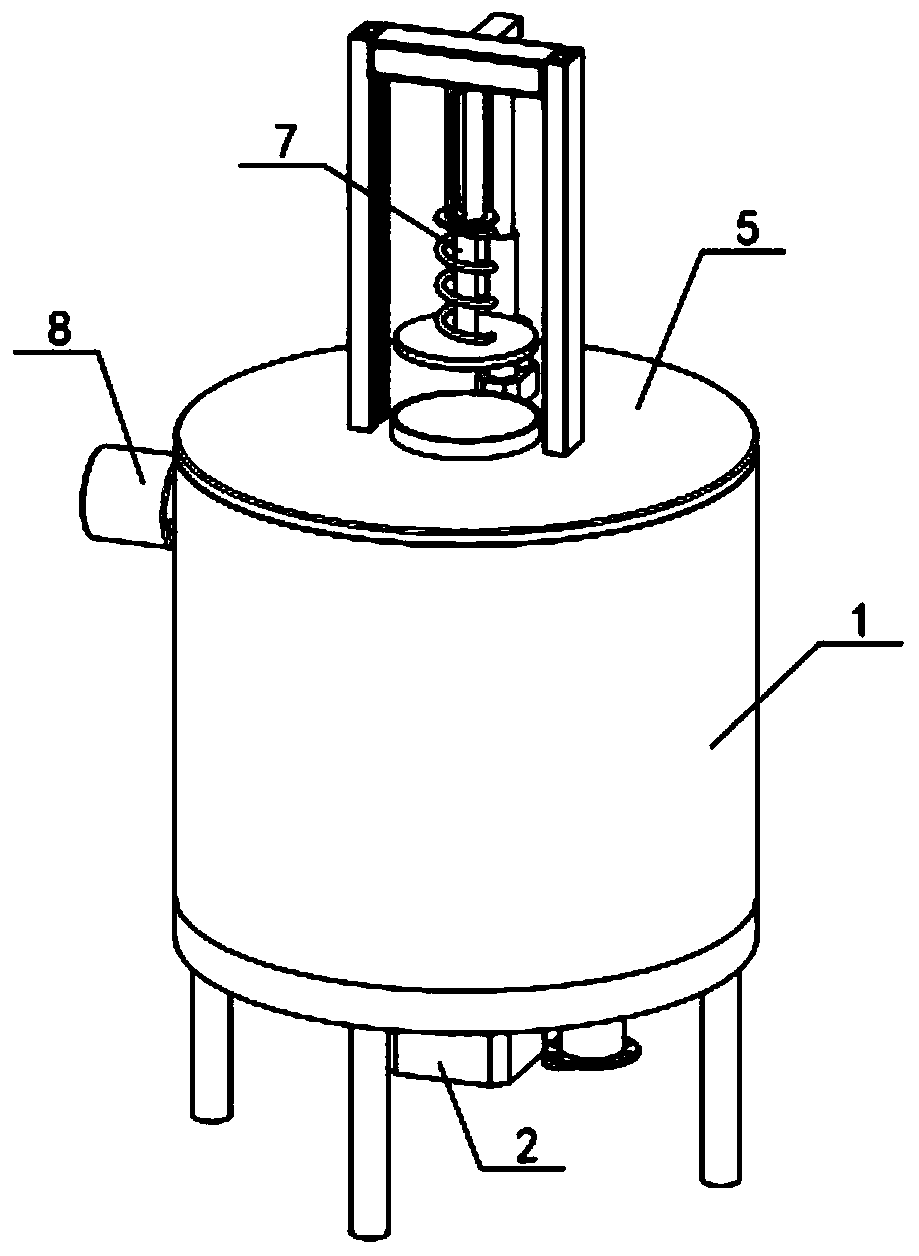

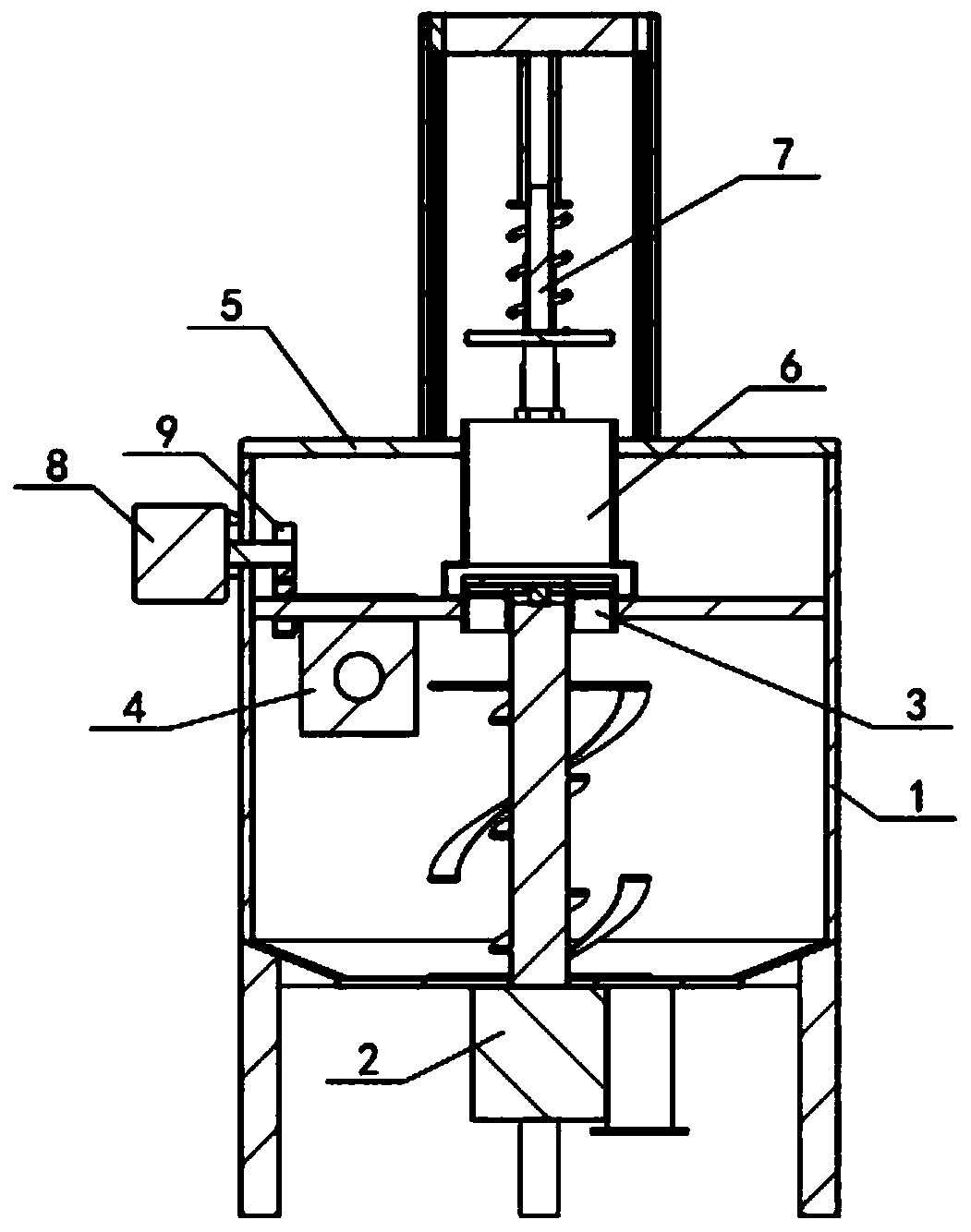

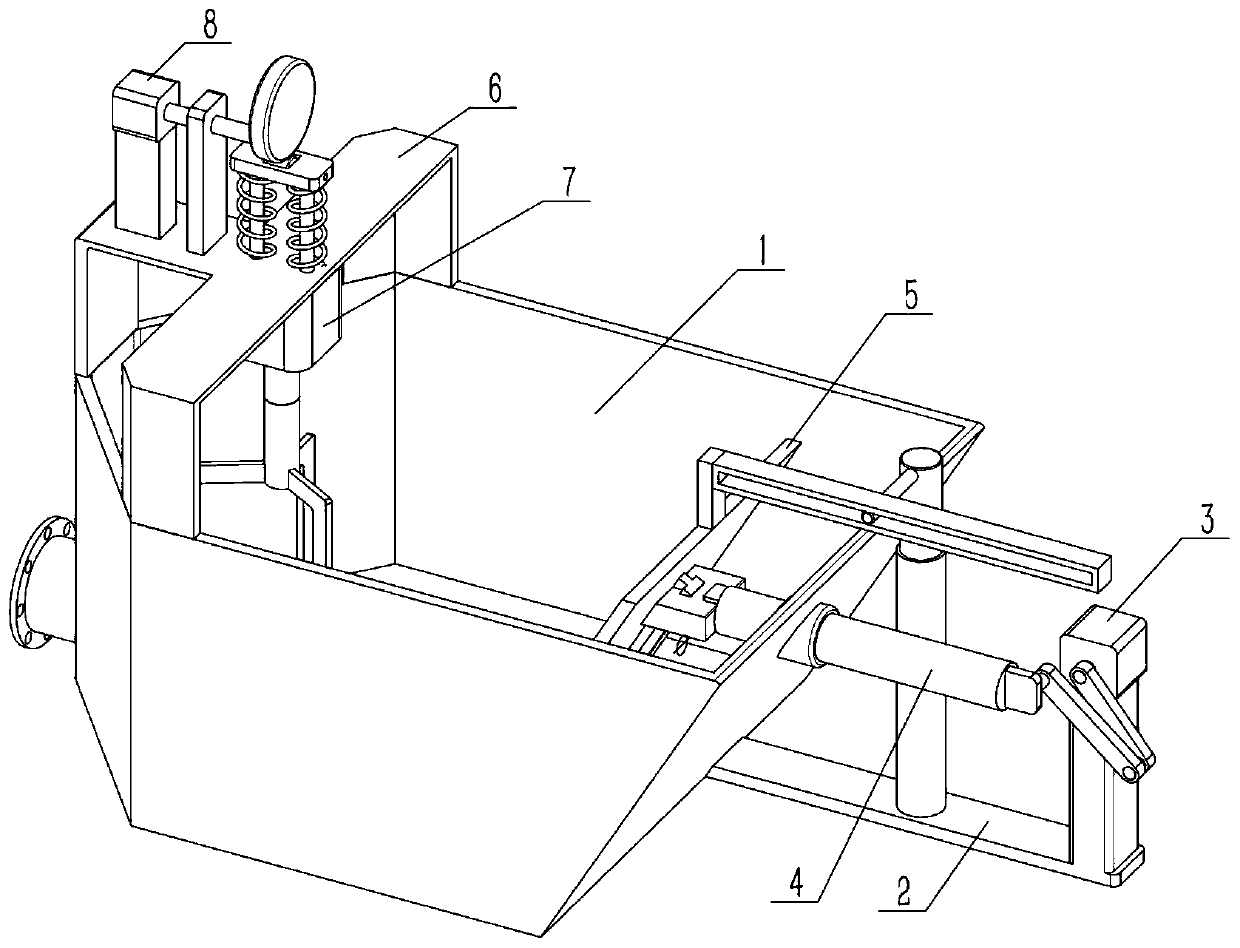

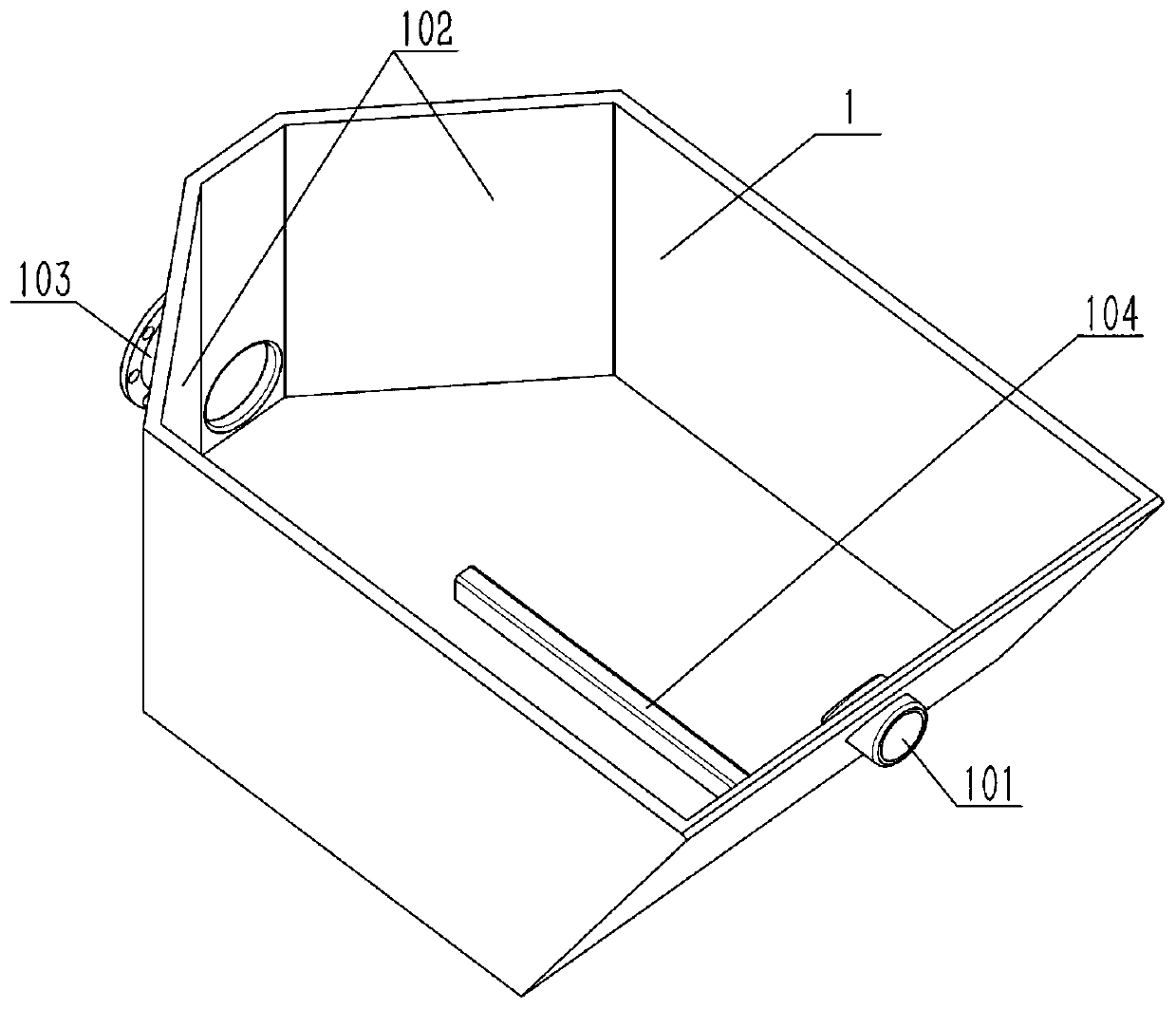

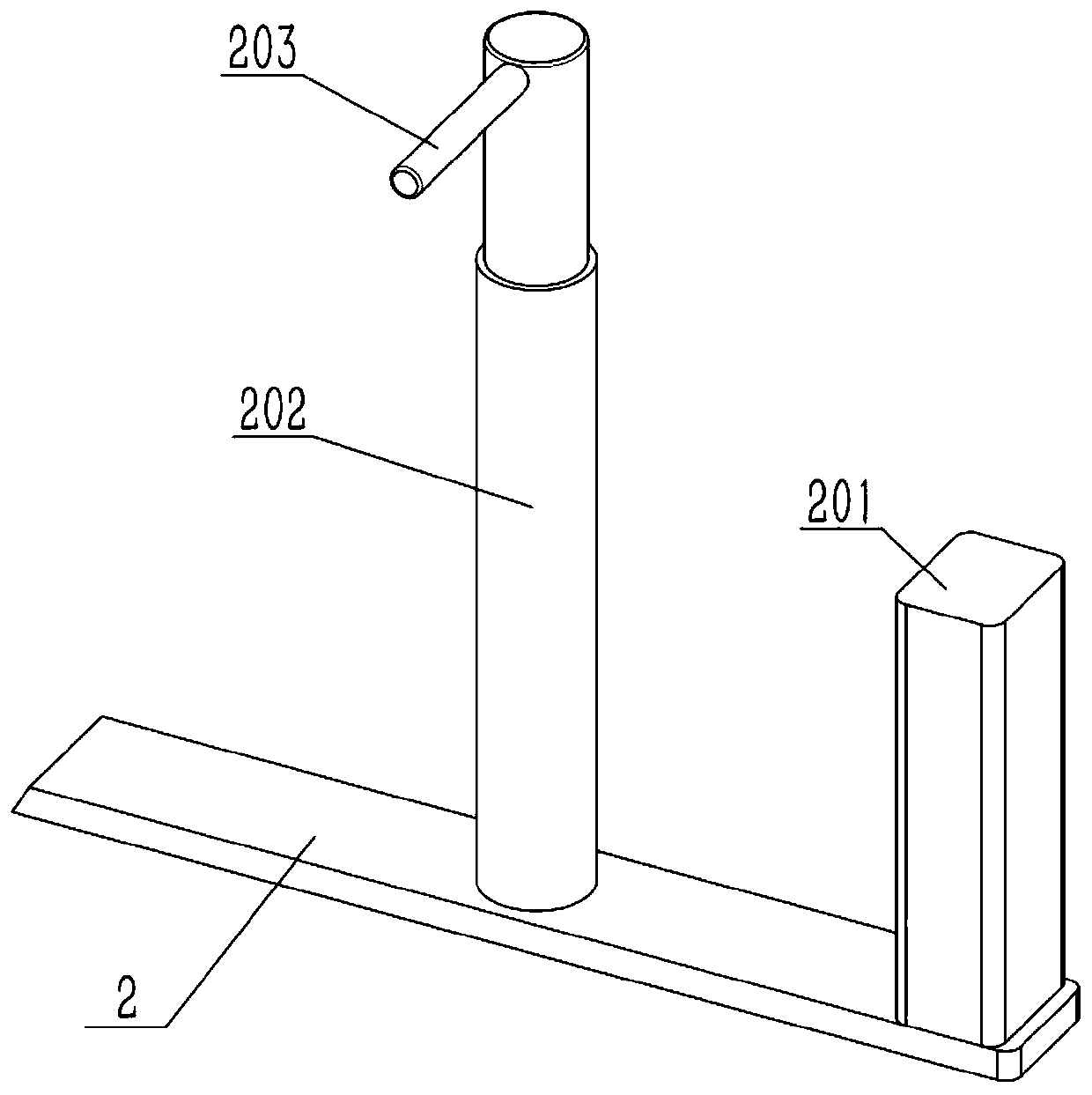

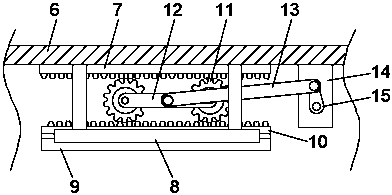

Particle extrusion device for modified starch processing

ActiveCN112497551ARealize the blanking effectStirring effect is evenSievingScreeningEngineeringMechanical engineering

The invention relates to a particle extrusion device, in particular to a particle extrusion device for modified starch processing . The particle extrusion device for modified starch processing provided by the invention is uniform in mixing and good in extrusion effect. The particle extrusion device for modified starch processing comprises a base, a supporting seat, a feeding mechanism, a rotatingmechanism and a reciprocating mechanism. A first supporting column is arranged on the base; the supporting seat is arranged on the base; the feeding mechanism is arranged at the upper part of the supporting seat; the rotating mechanism is arranged on the feeding mechanism; and the reciprocating mechanism is arranged at the lower part of the feeding mechanism, and is connected with the rotating mechanism in a sliding manner. According to the particle extrusion device for modified starch processing provided by the invention, modified starch is discharged through a discharging frame and slides into a stirring box through a discharging pipe, so that the discharging effect is achieved; and by arranging a collecting mechanism, the purified modified starch is collected by the collecting mechanismand is convenient for people to take and use.

Owner:DONGXIANG HEDA IND CO LTD

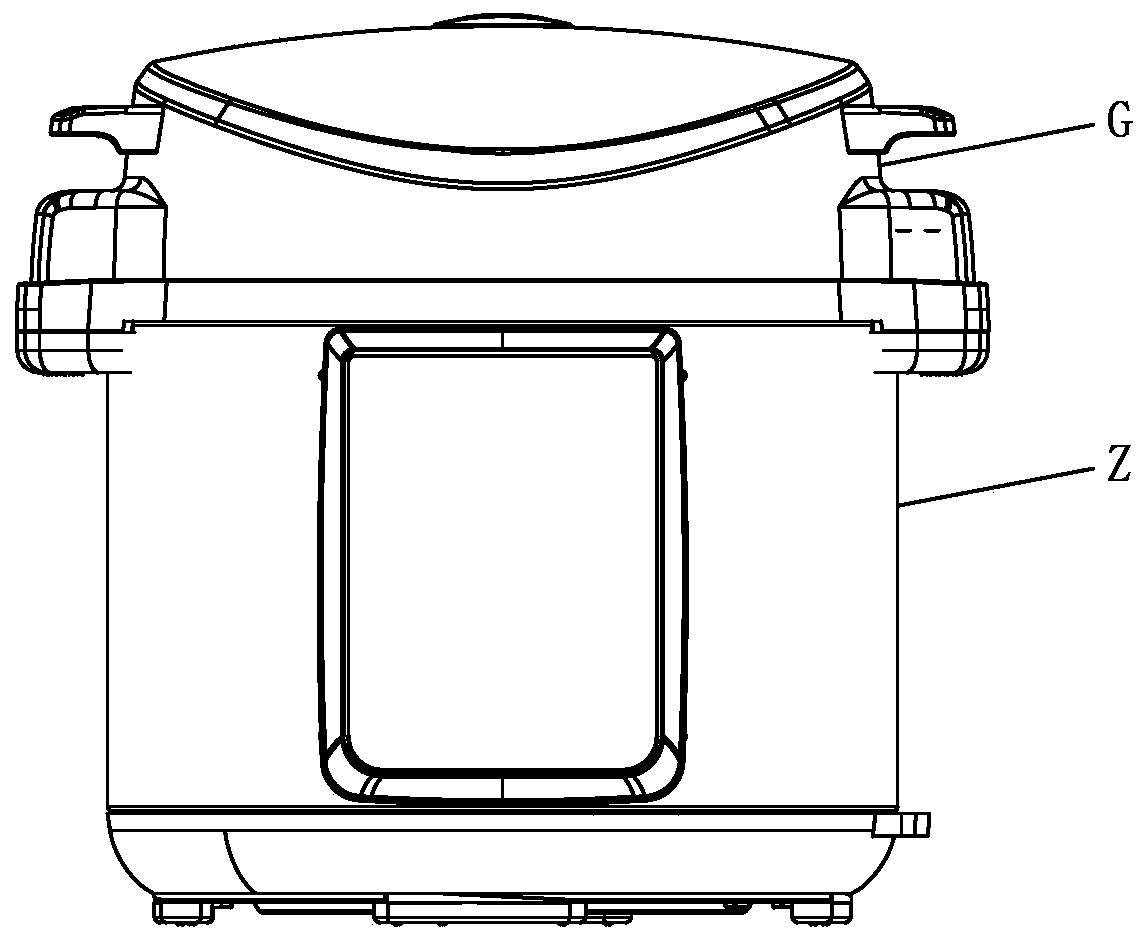

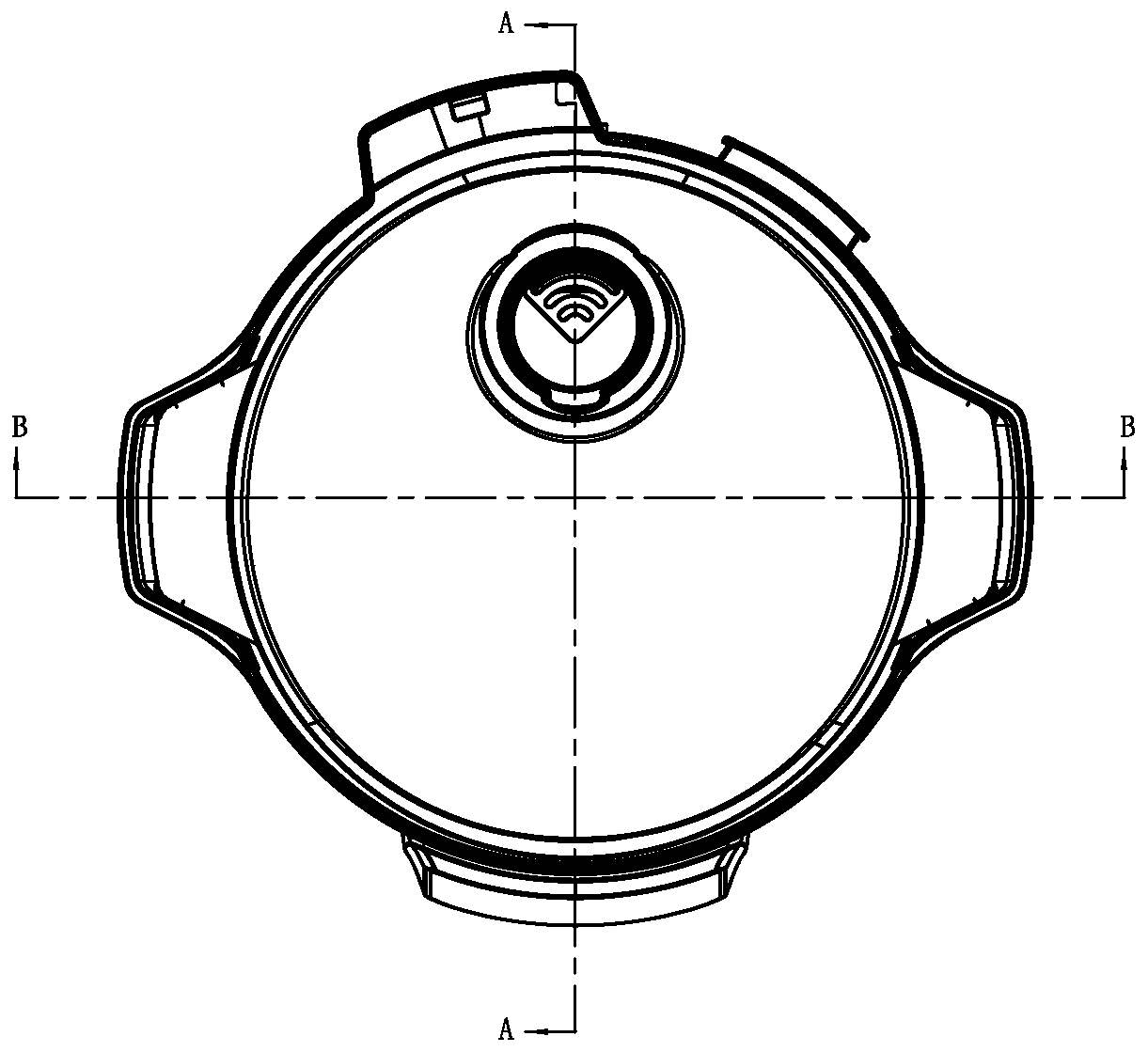

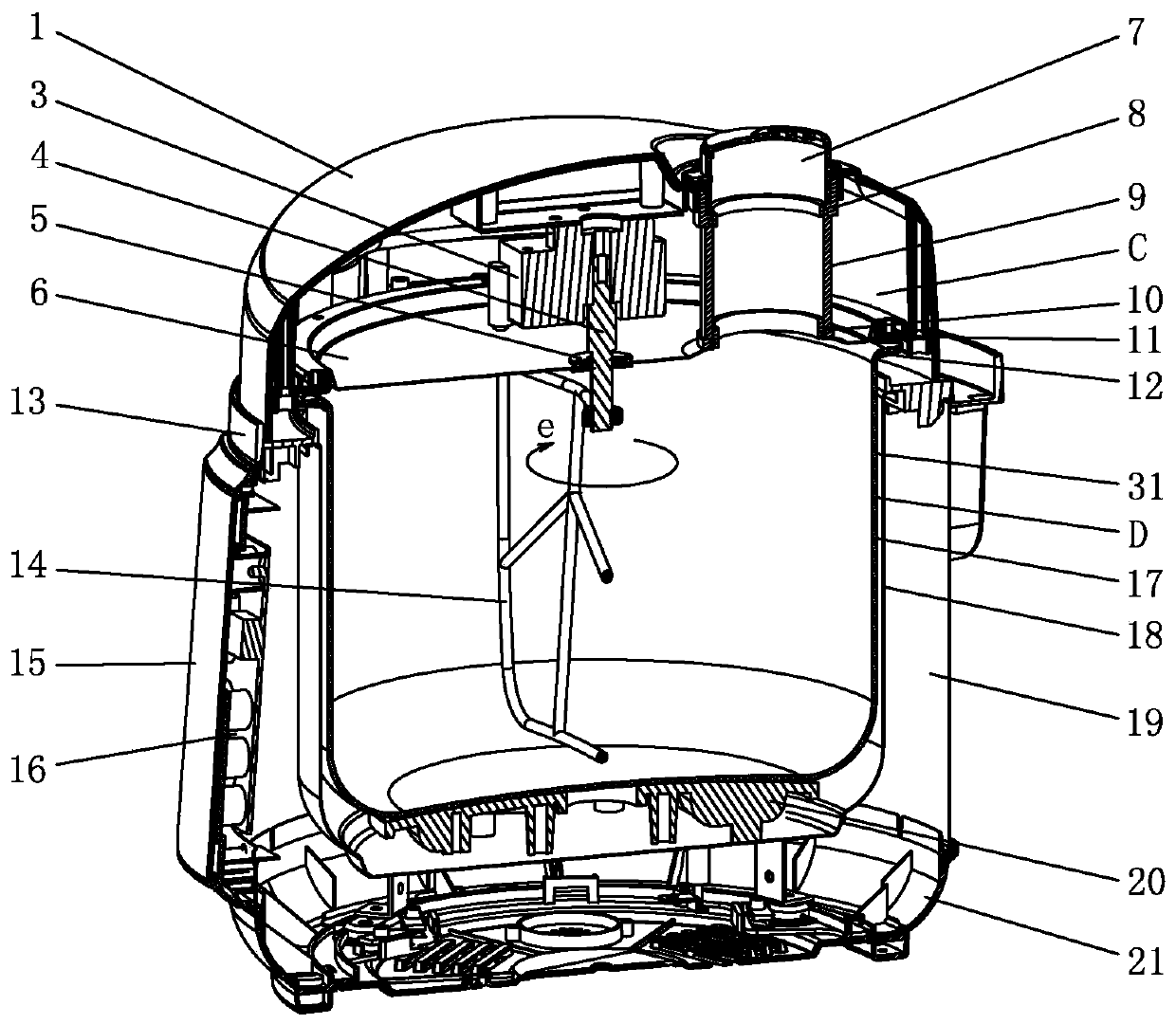

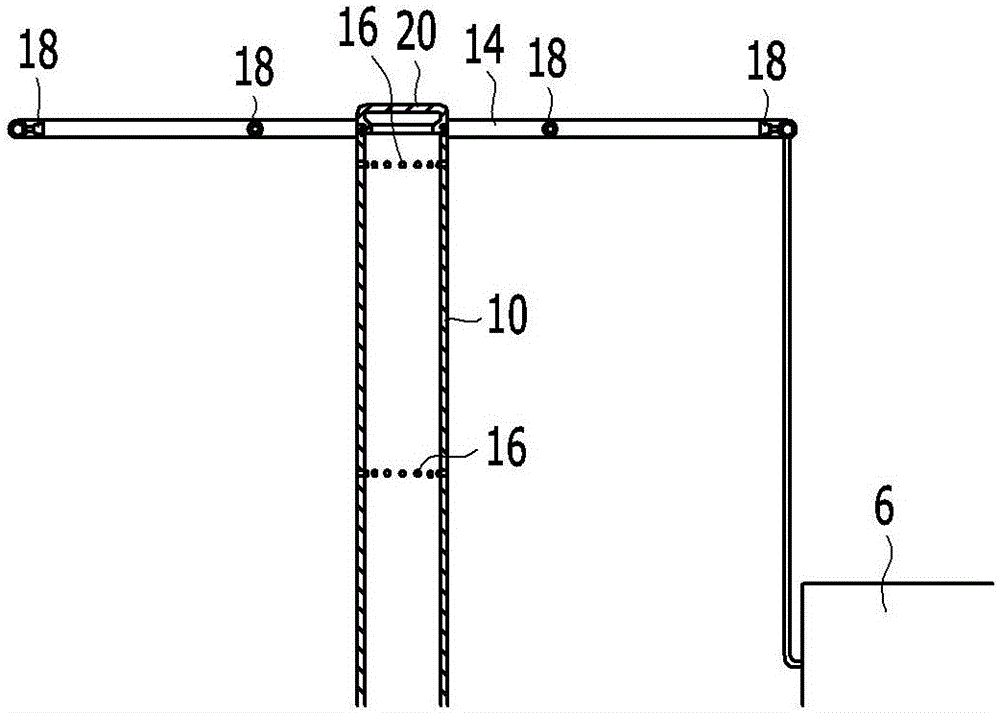

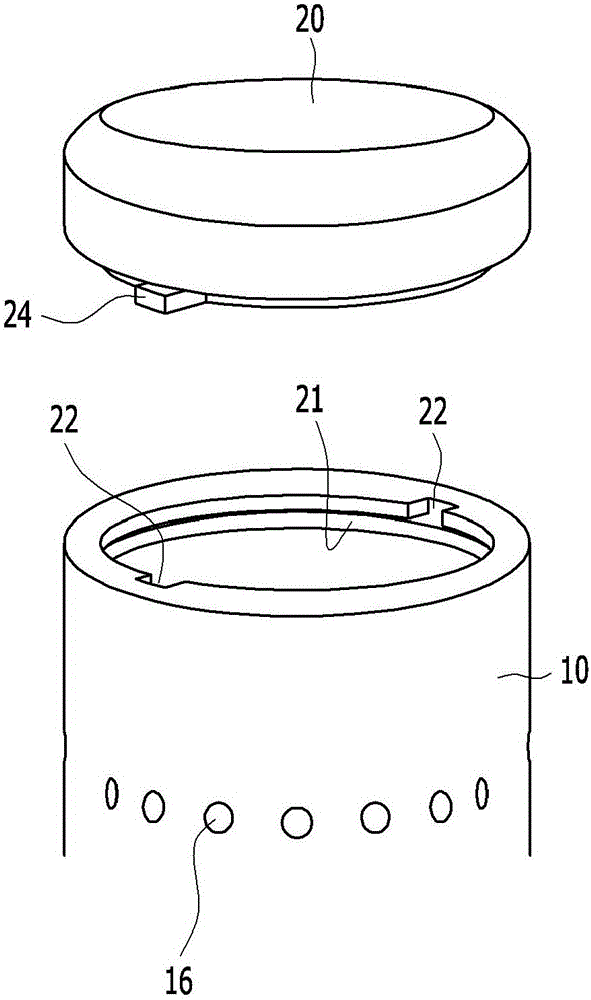

Cooking machine with heating and stirring functions

PendingCN111184430AReduce loadMeet the requirements of mixing strengthCooking-vessel lids/coversVessels with intergral heatingEngineeringAgitator

The invention relates to a cooking machine with heating and stirring functions. The cooking machine comprises a main machine assembly and a top cover assembly. A cooking cavity is formed in the main machine assembly. The cooking cavity is closed or opened by the top cover assembly. The main machine assembly and the top cover assembly are arranged in a split manner. A stirring mechanism is arrangedon the top cover assembly. The stirring mechanism comprises a power output assembly and a stirrer, and the output end of the power output assembly is in transmission connection with the stirrer to drive the stirrer to rotate in the cooking cavity. An electric coupling assembly is arranged between the main machine assembly and the top cover assembly, and the power output assembly is electrically connected with a power supply circuit on the main machine assembly through the electric coupling assembly in a closed state. The stirrer comprises a stirring frame and stirring strips arranged on the stirring frame. Bent parts protruding in the stirring direction e are arranged on the stirring frame and / or the stirring strips. The stirring strips divide the inner side of the stirring frame into a plurality of stirring areas. The cooking machine is large in stirring force and reliable in stirring performance, so that foods such as cakes can be made.

Owner:GUANGDONG CHANGHONG RIDIAN TECH

Cattle breeding feed stirring device

InactiveCN112058138AAvoid accumulationStirring effect is evenRotary stirring mixersTransportation and packagingAnimal scienceGear drive

The invention relates to the technical field of livestock breeding, and discloses a cattle breeding feed stirring device which comprises a support, a first rack is fixedly connected to the right sideof the inner wall of the support, a third gear is meshed with the front face of the first rack, and a first gear disc is fixedly connected to the bottom of the third gear;the bottom of the first geardisc is engaged with a columnar gear, and the bottom of the columnar gear is engaged with a second gear disc. stirring blades are fixedly connected to the outer side of the second gear disc, sliding pieces are fixedly connected to the inner walls of the stirring blades, a spiral stirring column is fixedly connected to the middle of the third gear, and a first gear is fixedly connected to the top of the spiral stirring column. According to the cattle breeding feed stirring device, the first rack drives the third gear to rotate, the third gear drives the first gear disc and a spiral stirring column to rotate; the columnar gear, the third gear disc and the stirring blades are matched for use, so that a uniform stirring effect is achieved, the spiral stirring column rotates clockwise, and thestirring blades rotate anticlockwise; the accumulation of the raw materials is avoided in the stirring process, so that the stirring is more sufficient.

Owner:湖南振鑫农业科技有限公司

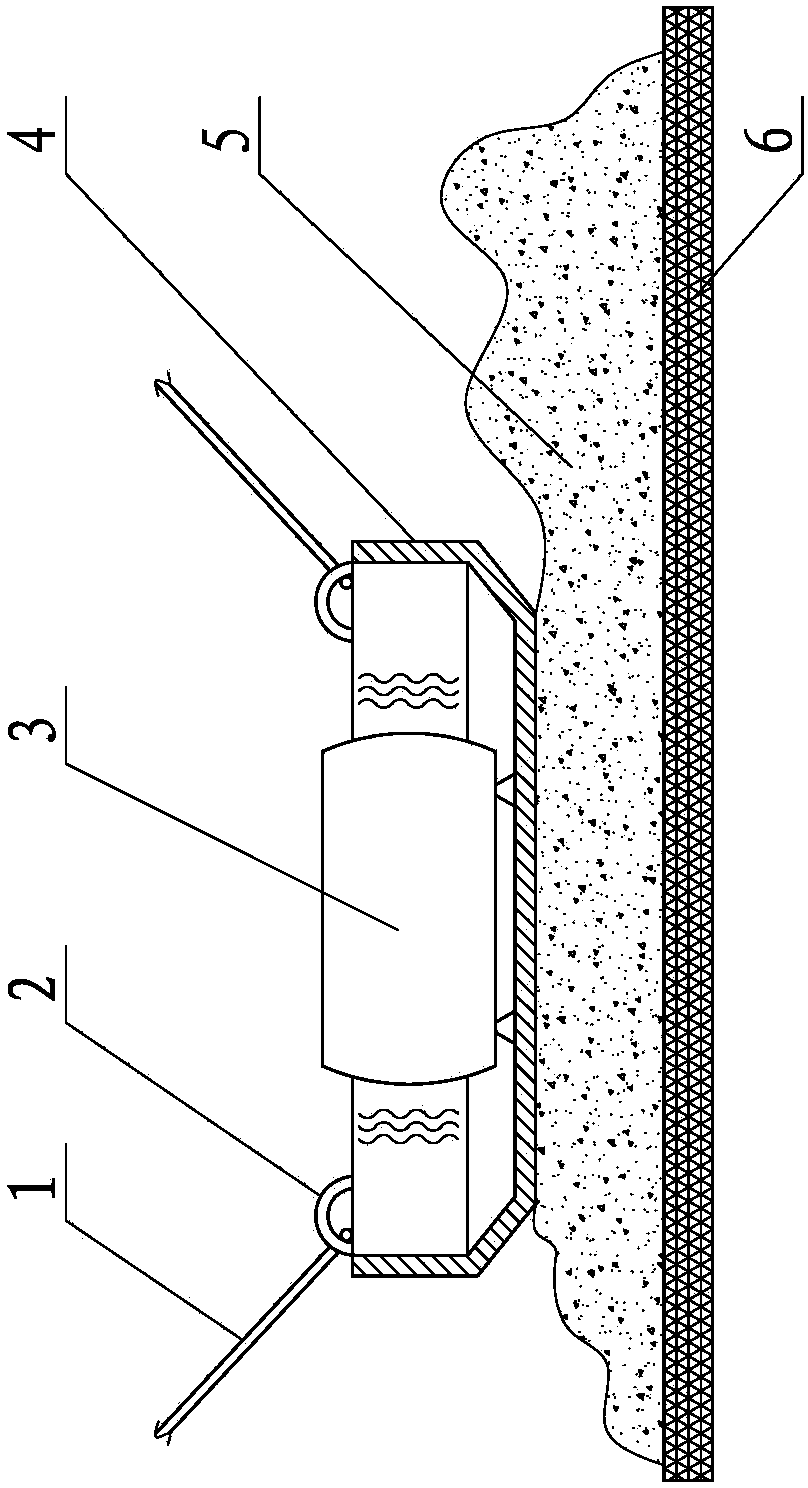

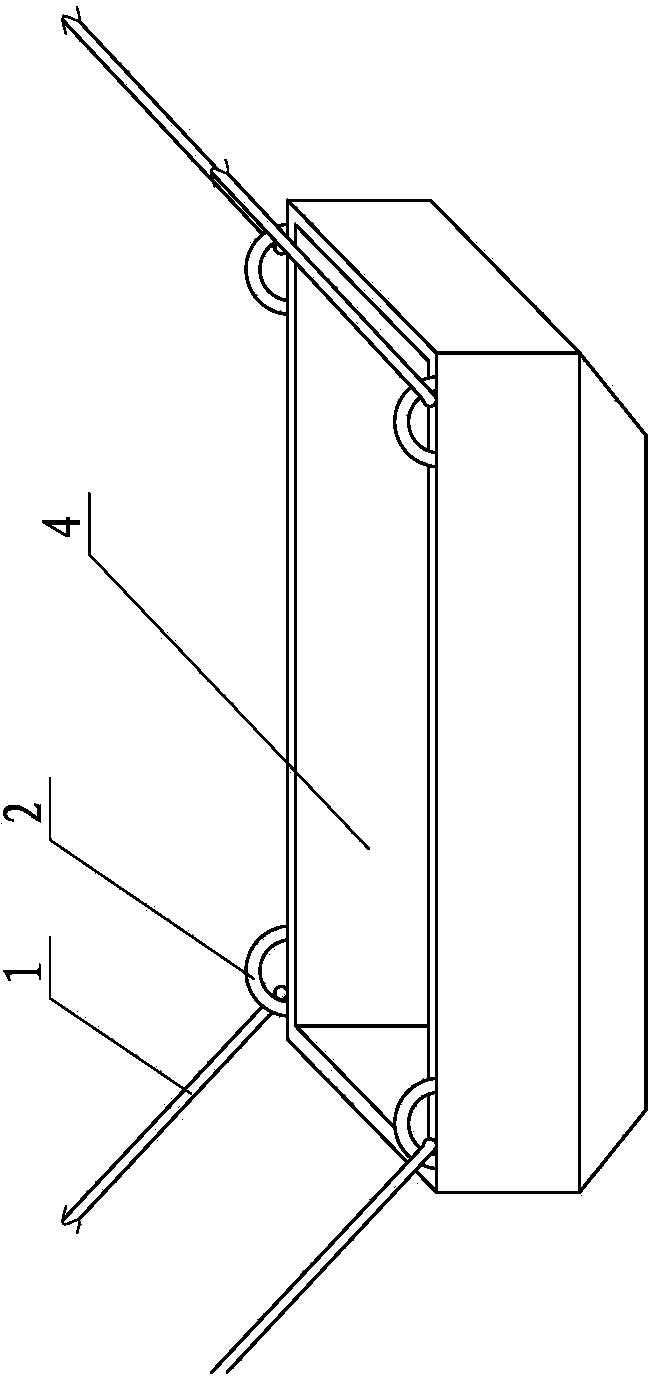

Emergency efficient fireproof concrete pug agitating equipment and application method thereof

InactiveCN103862576APrevent splashPlay a protective effectCement mixing apparatusRefractoryMaterials science

The invention provides emergency efficient fireproof concrete pug agitating equipment and an application method thereof, belonging to the field of application of unshaped fireproof materials, and particularly relates to an emergency efficient fireproof concrete pug agitating method. The emergency efficient fireproof concrete pug agitating equipment is characterized by comprising a stainless steel boat, a pulling rope and an attaching type high-frequency vibrator, wherein the stainless steel boat is in a box shape with an opened upper end; the stainless steel boat is provided with a hanging ring; the hanging ring is connected with the pulling rope; the stainless steel boat is internally provided with the attaching type high-frequency vibrator. The agitating equipment provided by the invention is portable and practical; the equipment is combined with manual agitation so as to obtain high-quality mixed agitated fireproof concrete pug.

Owner:SHANDONG YAOHUA REFRACTORY MATERIAL SCI & TECH CO LTD

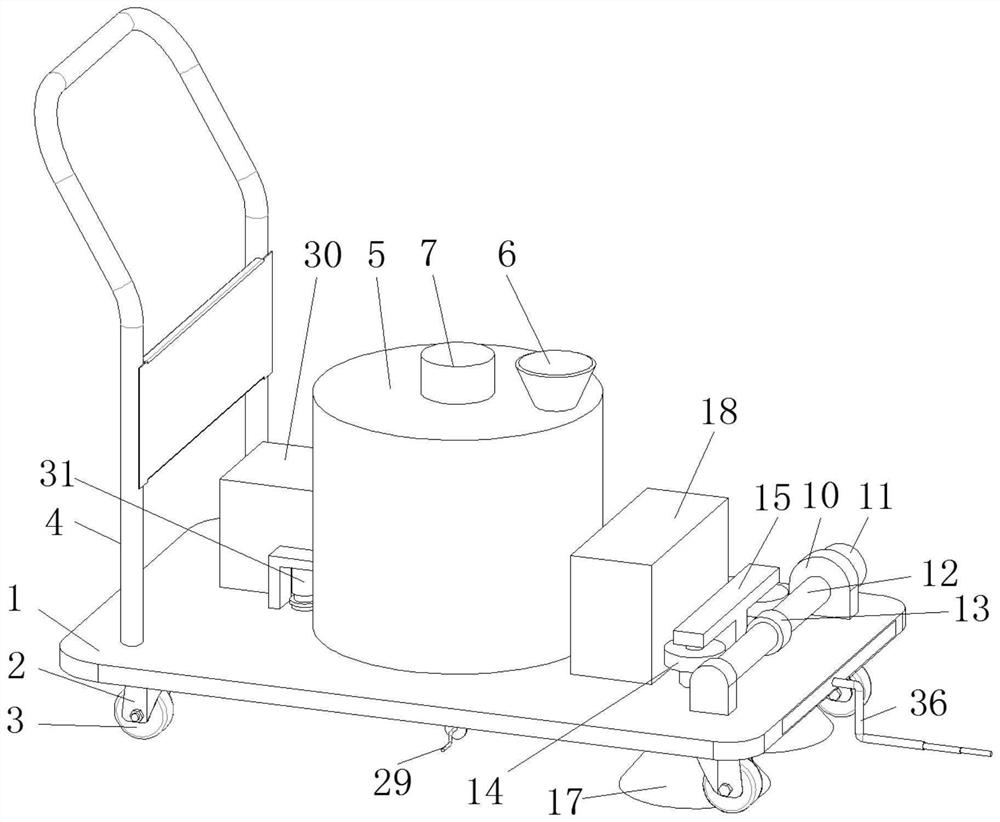

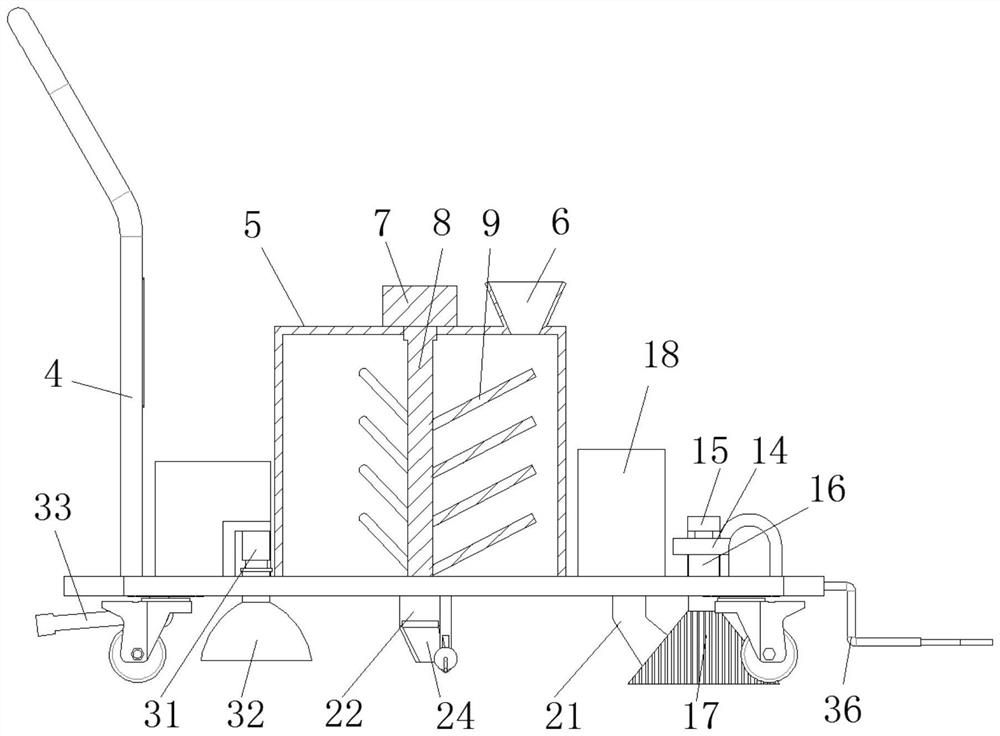

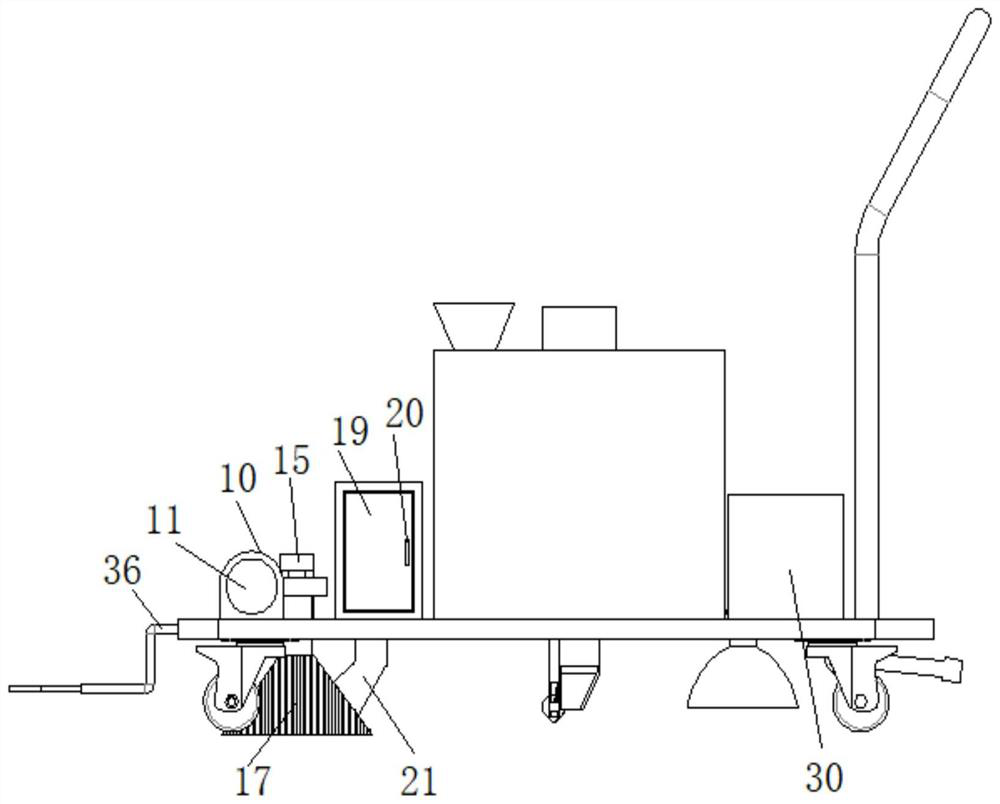

Road marking device for municipal construction

InactiveCN112482182AStirring effect is evenQuality improvementRoad cleaningRoads maintainenceArchitectural engineeringElectric machinery

The invention discloses a road marking device for municipal construction, and relates to the technical field of municipal construction, the road marking device comprises a vehicle plate, a mounting frame is fixedly connected to the bottom of the vehicle plate, wheels are rotatably connected to the interior of the mounting frame, a push handle is fixedly connected to the upper surface of the vehicle plate, and a storage box is fixedly connected to the upper surface of the vehicle plate; and a feeding hole is formed in the upper surface of the storage box. According to the road marking device for municipal construction, through arrangement of a motor, a stirring shaft and a stirring rod, the road marking device for municipal construction has a uniform stirring effect, and the road marking quality is improved; through arrangement of a supporting rod and a spring, the device achieves the convenient and stable fixing effect when not used; and through arrangement of a nozzle, a flow guide plate, a control plate and a screw rod, in the using process, the size of the nozzle can be conveniently adjusted, the width range of pavement marking is adjusted through the screw rod, the device is suitable for different occasions, the labor intensity of workers is reduced, and the purposes of wide application range and flexible use are achieved.

Owner:曹雪丽

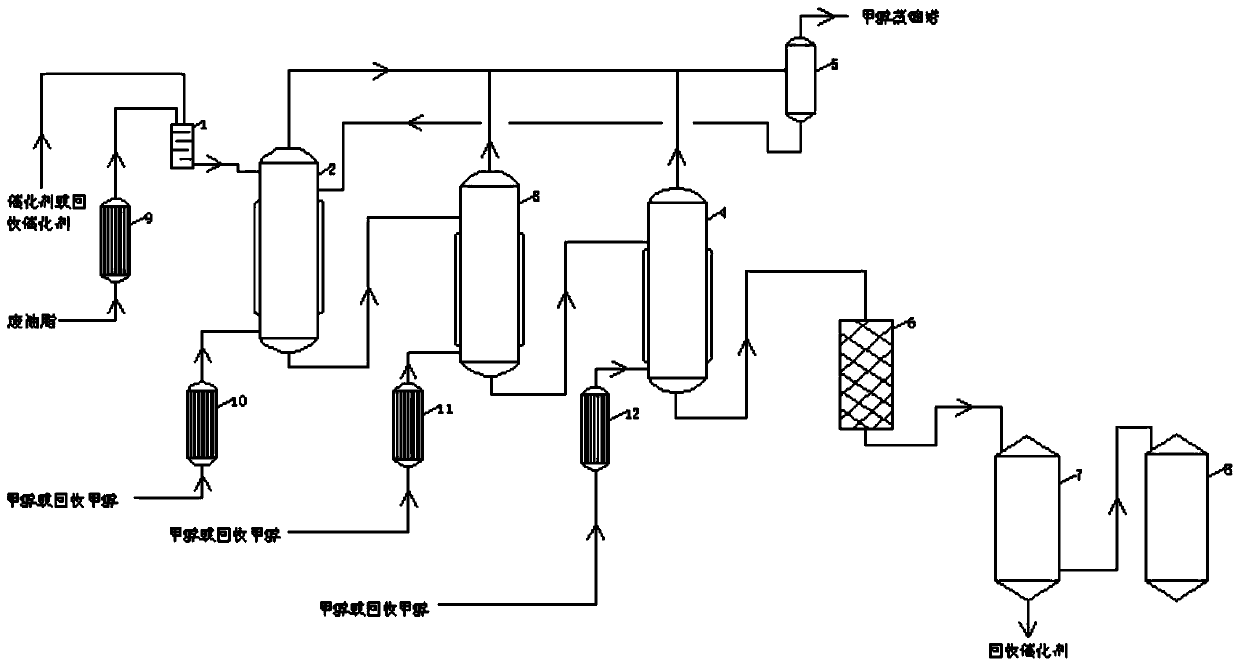

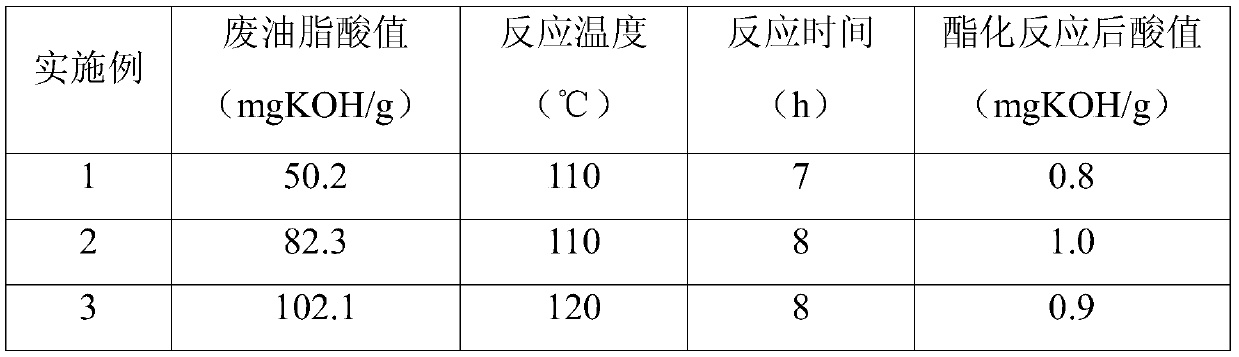

Method for continuous esterification of waste oil and fat

InactiveCN110093212AEvenly distributedStirring effect is evenFatty acid esterificationLiquid carbonaceous fuelsOil and greaseMethanol water

The invention discloses a method for continuous esterification of waste oil and fat. Purified waste oil and fat mixes with a prepared catalyst after being heated; tertiary esterification is performed,each level of materials enters a tower from the side surface at the upper part of the reaction tower, methanol enters the tower from the side surface at the bottom of the reaction tower after heatinggasification, and a reaction temperature is kept at 110-130 DEG C; water generated by each stage of esterification is led out from the top of the reaction tower with excess methanol to enter a gas-liquid separation device, the separated waste oil and fat returns back to a primary reaction tower through liquid dropping, and the separated methanol water vapor enters a methanol distillation column to perform distillation and recycling; and a reacted esterification product enters a transition groove to perform standing after cooling, so that the catalyst can be separated to perform recycling, andthe esterification product enters a storage groove. The method has characteristics of being high in degree of automation, simple and efficient in operation, low in production cost and stable in product quality.

Owner:LONGYAN ZHUOYUE NEW ENERGY CO LTD

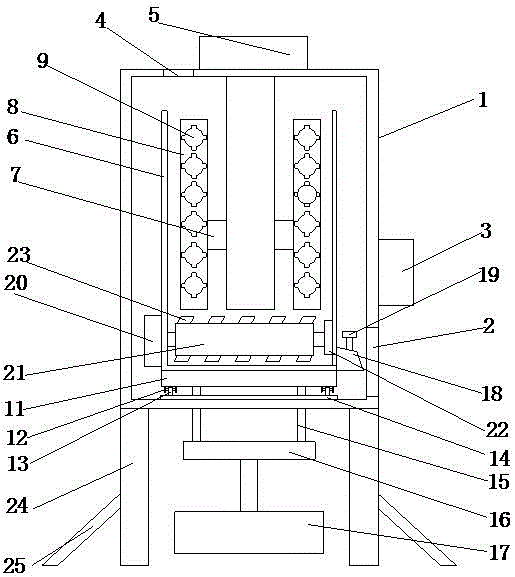

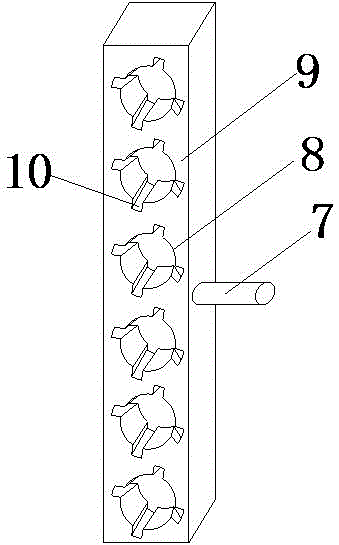

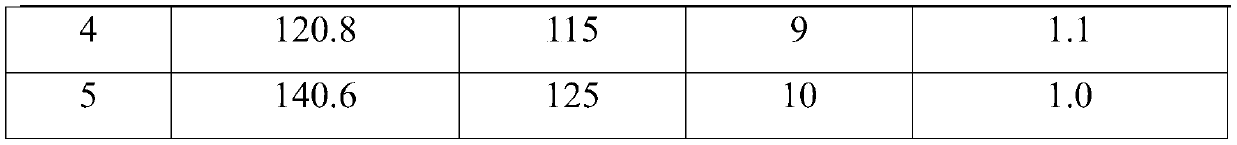

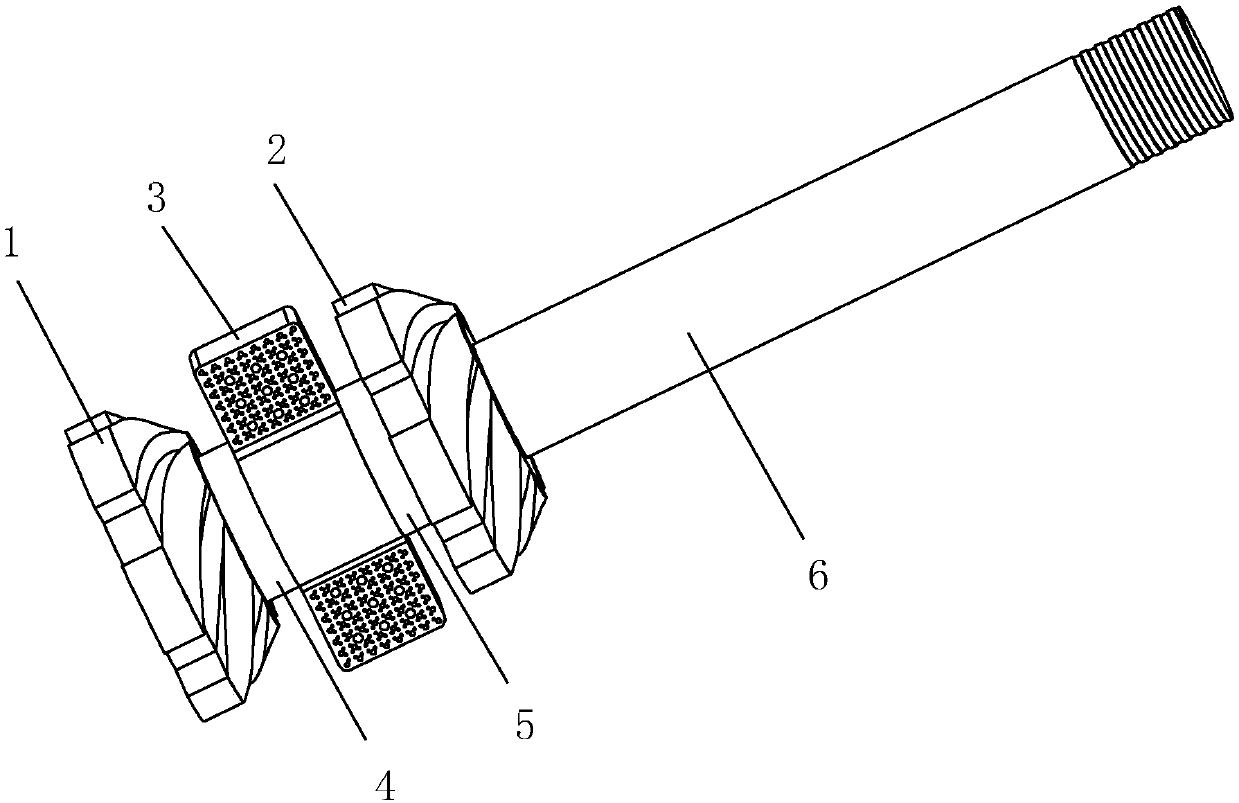

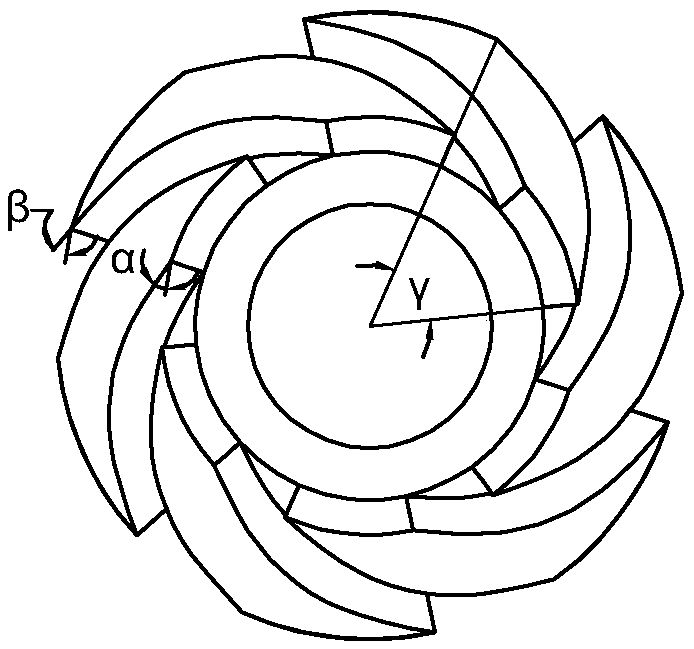

Long-acting composite type graphite stirring device for aluminum alloy refining and preparation method

ActiveCN110607461AStirring effect is evenSuitable for component homogenizationRotary stirring mixersTransportation and packagingImpellerMixed flow

The invention relates to a long-acting composite type graphite stirring device for aluminum alloy refining and a preparation method. The long-acting composite type graphite stirring device comprises ahollow shaft, a lower layer straight blade spiral mixed-flow impeller, a lower sleeve, a multi-aperture blade, an upper sleeve and an upper layer straight blade spiral mixed-flow impeller, and the lower layer straight blade spiral mixed-flow impeller, the lower sleeve, the multi-aperture blade, the upper sleeve and the upper layer straight blade spiral mixed-flow impeller are installed on the hollow shaft. The straight blade spiral mixed-flow impellers are mainly composed of straight blade radial flow type blades and spiral face axial water guide blades with log spirals as molded lines. The stirring impeller structure is improved, advantages of axial flow type and radial flow type stirring impellers are combined, the multi-aperture blade is added, thus aluminum alloy melt can be dispersedinto small-size fluid masses effectively, and the stirring and mixing uniformity of aluminum alloy components is improved. In addition, metallization modified treatment is conducted on the surface ofthe graphite stirring device, a novel TiC coating material is adopted for replacing a traditional coating material, oxidation resistance and corrosion resistance of the graphite stirring device are enhanced, and the inherent defects of an existing graphite stirring device are overcome radically.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

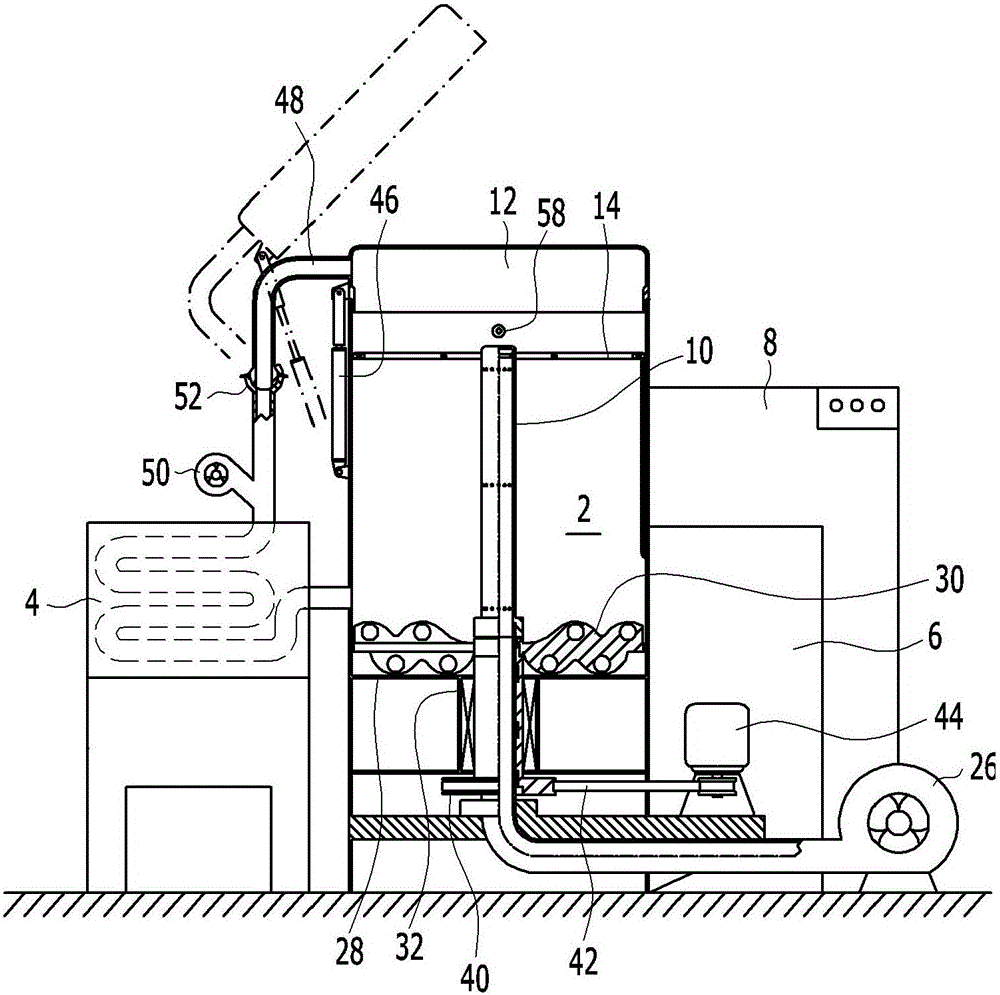

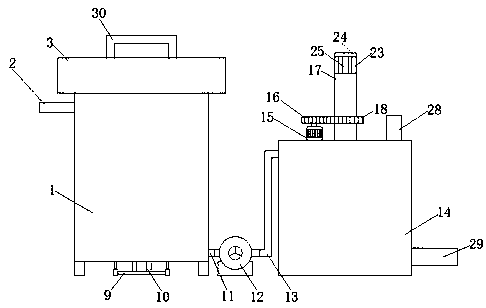

High-temperature thermal decomposition incinerator

ActiveCN106352349AReduce internal temperatureEasy to handleFuel supply regulationIncinerator apparatusCombustion chamberEngineering

The invention provides a high-temperature thermal decomposition incinerator that comprises: a combustion chamber that charges a material to be incinerated into a space that is separated from the outside and causes combustion to occur at a high temperature while forcibly supplying outside air; an air supply pipe (10) that is disposed in the center of the combustion chamber (2) and forcibly supplies outside air; a fuel supply pipe (14) that is provided at an internal upper peripheral edge of the combustion chamber (2) and injects fuel; a stirring rod (30) that is provided so as to extend from the center of a perforated plate (28) serving as a base of the combustion chamber (2) so as to able to rotate about an axis of the air supply pipe (10) and that mixes incinerated material; a heat recovery device (4) that is disposed at one side outside the combustion chamber (2) and recovers hot air from the combustion chamber (2); and a circulation pipe 48 that is routed from a lid (12) of the combustion chamber (2) so as to pass through the heat exchange device (4) and return to the combustion chamber (2) and then return to a position above the stirring rod (30), thereby causing the hot air of the combustion chamber (2) to flow through the heat recovery device (4).

Owner:UNKNOWN +1

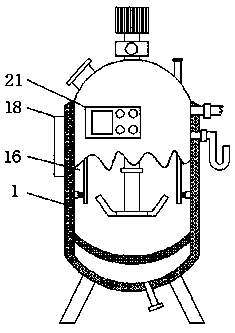

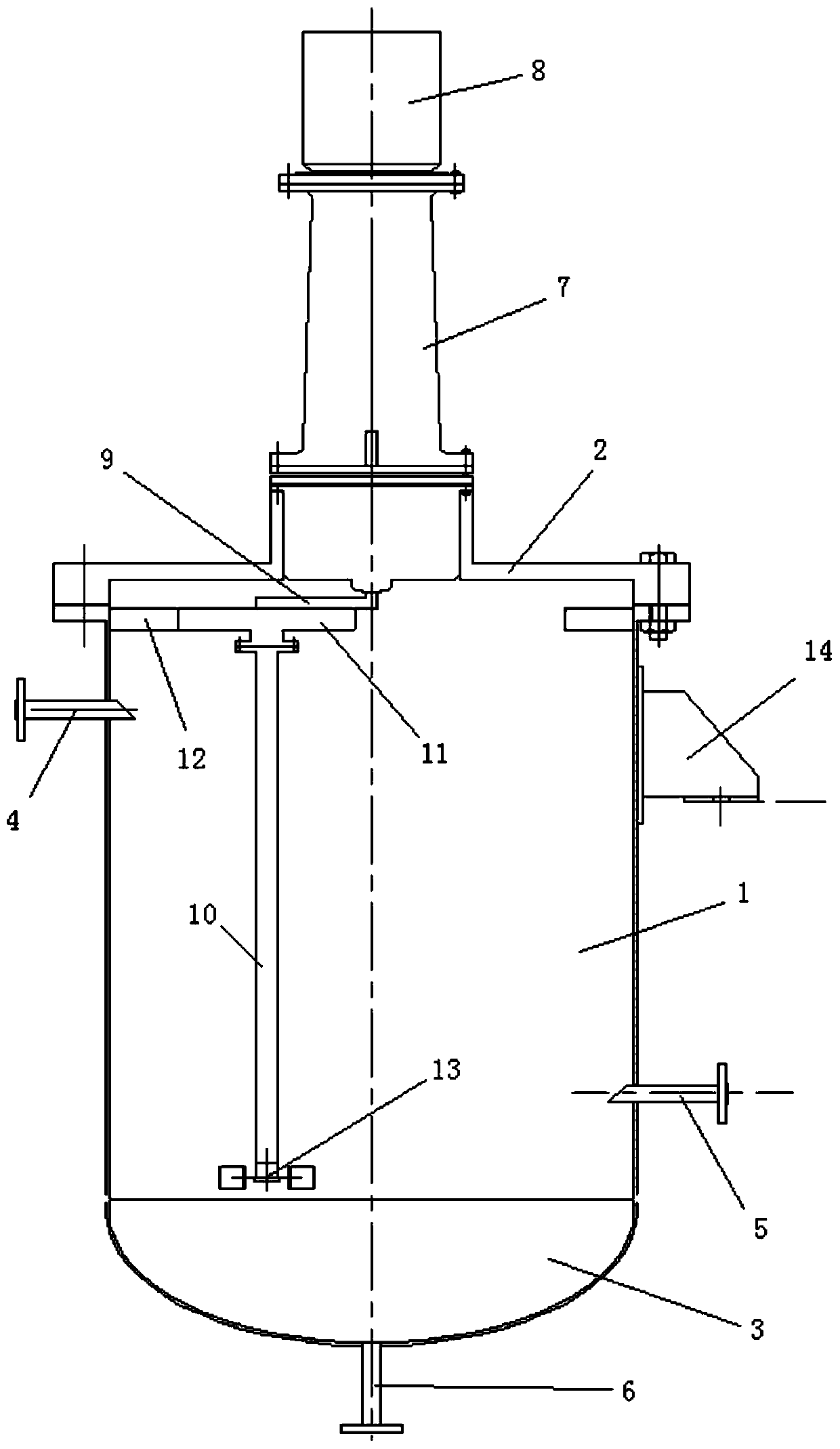

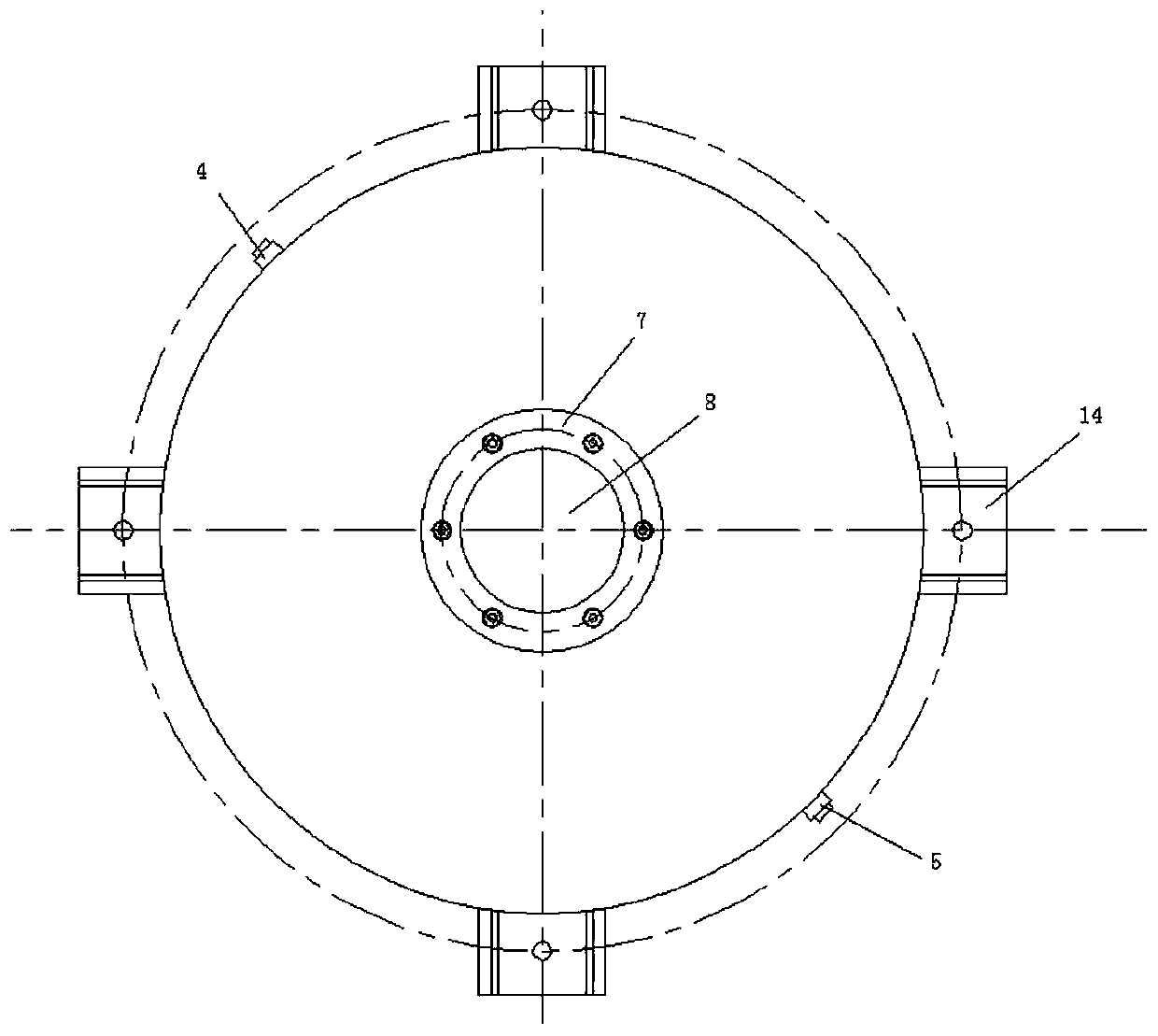

Modified starch reaction kettle

PendingCN107670627AEasy to collectChange directionChemical/physical/physico-chemical stationary reactorsEngineeringThermal water

The invention discloses a modified starch reaction kettle. The reaction kettle comprises a reaction kettle body and a reaction kettle inner cavity, wherein the bottom of the reaction kettle body is fixedly connected with support legs, the reaction kettle inner cavity is formed in the reaction kettle body, a discharging port is formed in the bottom of the reaction kettle body, a filter plate is arranged in a position, close to the bottom end, in the reaction kettle inner cavity, a spring rod is arranged on the inner side wall of the reaction kettle inner cavity, one end of the spring rod is connected with a baffle plate, a heating device is mounted on one side of the reaction kettle body, the other side of the reaction kettle body is connected with a sampling pipe and a hot water inlet pipe, and a cold water inlet pipe and a temperature measuring probe are arranged on one side of the top of the reaction kettle body. The sampling pipe is designed in a U-shaped pipe shape, sampled liquidscan be stored in the sampling pipe, sampling of the sampled liquids is facilitated, and the reaction kettle is more convenient to use; the filter plate is arranged in the reaction kettle inner cavityand can filter out some impurities, solid precipitates cannot be discharged from the discharging port, and the practical effect can be improved.

Owner:JIANGXI HONGDA CHEM IND

Printing ink, and preparation system and preparation method thereof

InactiveCN110227382AImprove efficiencyStirring effect is evenTransportation and packagingInksEpoxyEngineering

The invention relates to the field of preparation of inks, and concretely relates to a printing ink, and a preparation system and a preparation method thereof. The printing ink comprises, by weight, 20 parts of toluene, 15 parts of butanone, 10 parts of isopropyl alcohol, 5 parts of ethyl ester, 15 parts of polyurethane resin, 10 parts of epoxy resin, 10 parts of carbon black and 1 part of sodiumpolyacrylate. The preparation system comprises a stirring container, a grinding stirrer, a center frame, a filter spoiler pocket, a top cover, a processing cylinder wall, a pressure applicator, a second motor and a second gear. The raw materials are pre-ground by a grinding disc, and the fine raw materials are conveyed into a container body automatically and uniformly while grinding; and the fineraw materials are uniformly mixed with the fluid raw materials, and liquid ink is filtered by the filtering spoiling pocket while stirred. The method allows the printing ink to be prepared without scattering the raw materials with other devices and grinding the ink after stirring. The device has the advantages of effectiveness in elimination of dusts generated during grinding, uniform stirring effect, and high preparation efficiency of the printing ink.

Owner:唐雅君

Chemical sewage filter device

InactiveCN110194541AFilter thoroughlyEasy to handleTreatment involving filtrationMultistage water/sewage treatmentActivated carbonFiltration

The invention discloses a chemical sewage filter device. The device comprises a filter box body, the top on the left side of the filter box body is communicated with a water inlet pipe, and the top ofthe filter box body is movably connected to a box cover, placement blocks are fixedly connected to two sides of the inner cavity of the filter box body, and the tops of the placement blocks are in flexible connection with a coarse grain filter screen. According to the invention, through the cooperative use of the filter box body, the water inlet pipe, the box cover, the placement blocks, the coarse grain filter screen, a fiber filter layer, an activated carbon plate, a condensation box, a circulating pipe, a condensation pipe, a water pumping pipe, a water pump, a water delivery pipe, a mixing box body, a motor, a pinion, a casing pipe, a large gear, a bearing, a sliding chute, a vertical rod, pulleys, vertical plates, a roof plate, an electric telescopic rod, connecting rods, stirring blades, a dosing pipe and a water outlet pipe, and blending with disinfectant liquid medicine, the sewage treatment effect can be better, the device can prevent secondary pollution caused by sewage, also prevents scald of high temperature sewage to operators, and makes sewage filtration more thorough.

Owner:陈思宇

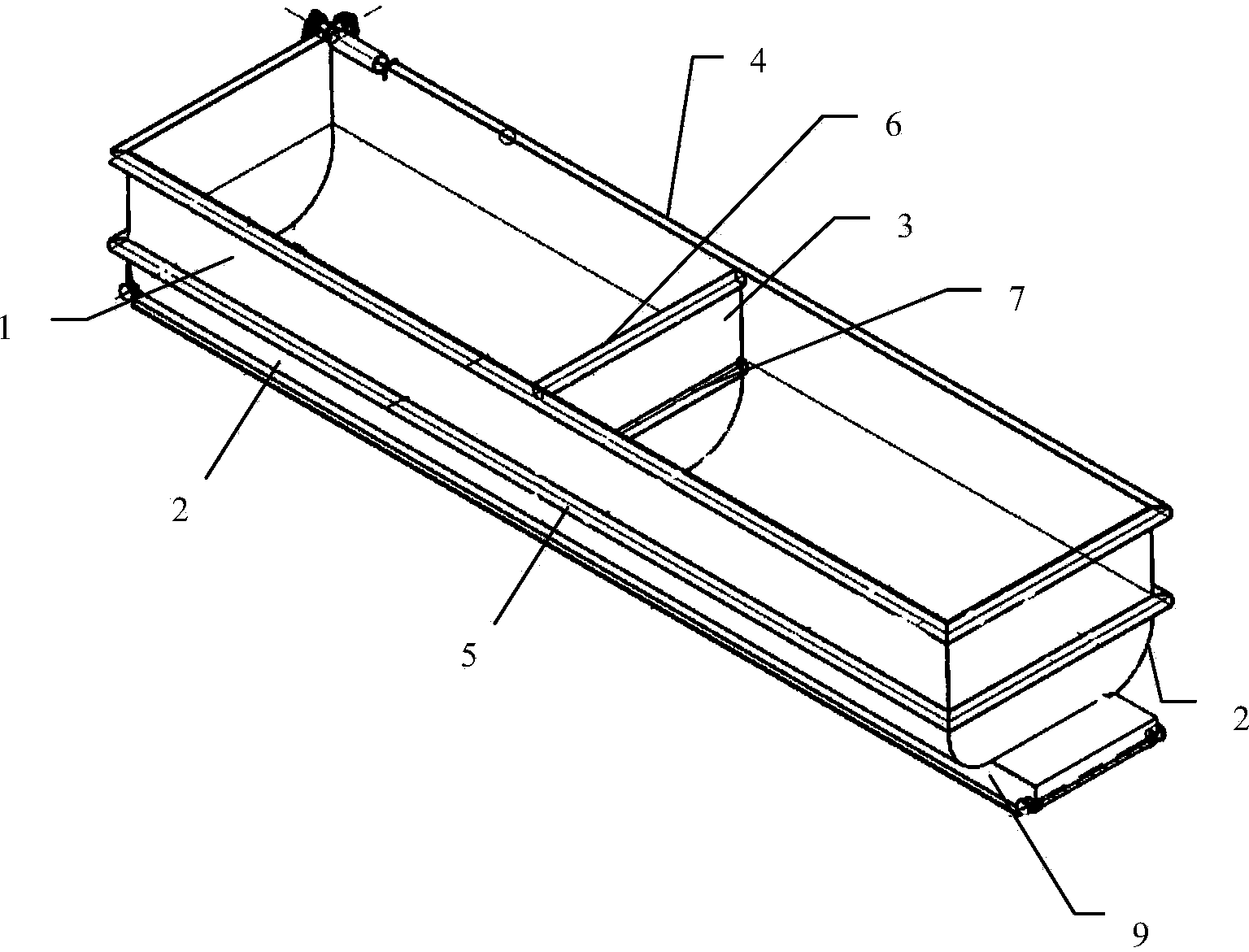

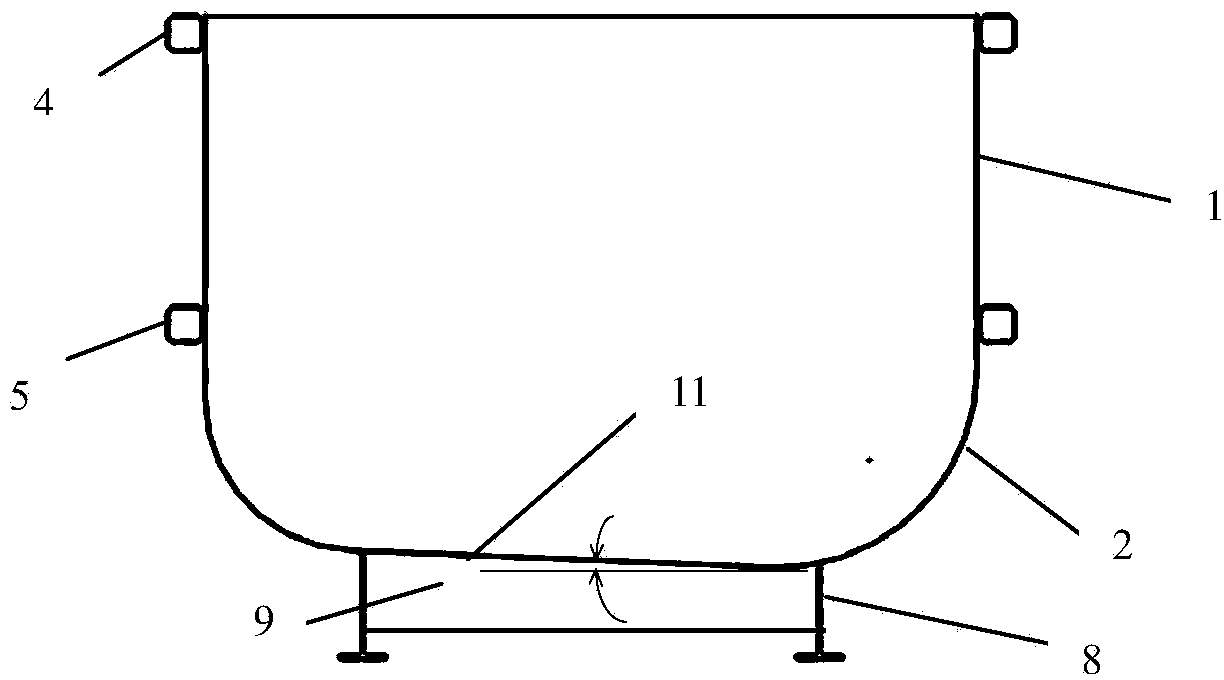

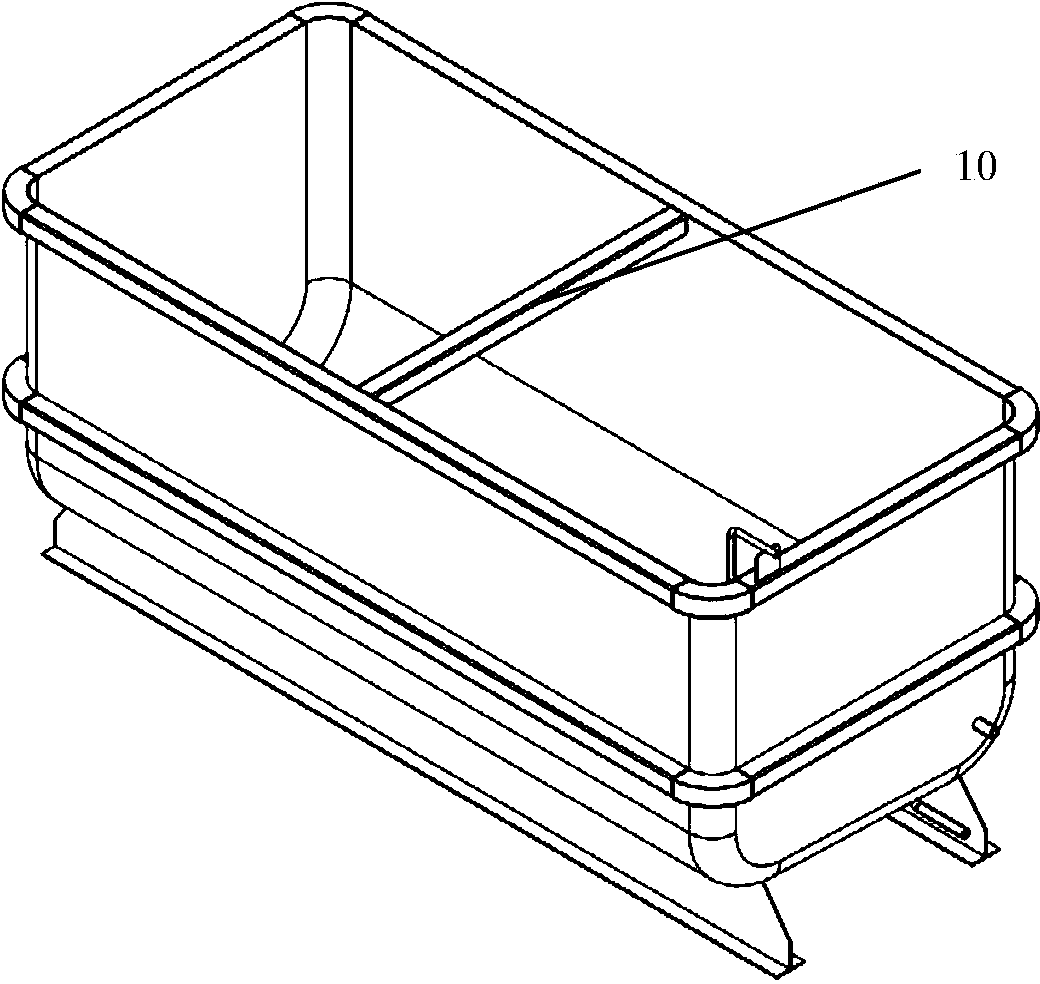

Mud tank for well drilling

InactiveCN104373066AIngenious structureReasonable structureFlushingBiochemical engineeringWell drilling

The invention discloses a mud tank for well drilling. A main body is of a cuboid tank shape and comprises a tank body side plate and a tank body bottom plate, a bottom plate supporting structure is arranged below the tank body bottom plate, the tank body side plate is divided into an upper tank body side plate portion and a lower tank body side plate portion, each short side of the lower tank body side plate portion is a vertical side plate, and each long side of the lower tank body side plate portion is a one-quarter arc plate bent inwards. An upper side plate reinforcing rib plate is fixedly arranged on the periphery of the position, at an upper opening of the tank body, of the tank body side plate, and a middle side plate reinforcing rib plate is fixedly arranged on the periphery of the position, at the joint of the upper tank body side plate portion and the lower tank body side plate portion, of the tank body side plate. The mud tank for well drilling is superior and more reasonable in structure, can meet strength requirements, can also be used for completing mud stirring more uniformly and thoroughly, and reduces the production and use cost.

Owner:NAT OILWELL VARCO PETROLEUM EQUIP SHANGHAI

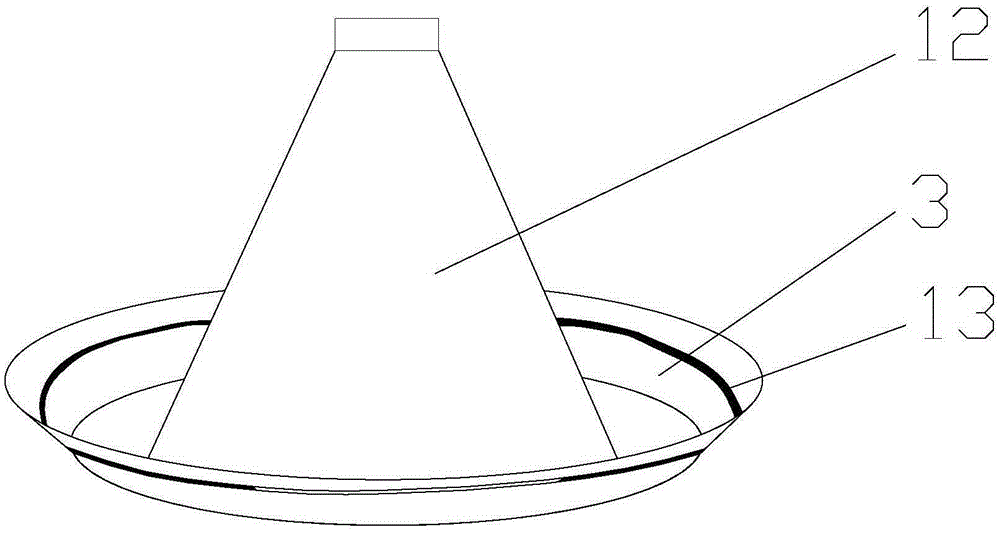

Feeding trough for raising chickens

The invention relates to the field of chicken raising equipment, in particular to a feeding trough for raising chickens. The feeding trough is mainly composed of a feeding mechanism, a feed cylinder, a discharge port and a trough, wherein the feeding mechanism is arranged above the feed cylinder, the trough is sleeved with the feed cylinder, and the discharge port surrounds the lower side wall of the feed cylinder by a cycle; the feeding mechanism is mainly composed of a support, a start button, a shutoff button, a main shaft, a belt wheel, a driving motor, a scraper and screen cloth arranged above the feed cylinder. By adopting the structure, automatic feeding and stirring during feeding of feed can be achieved by means of the feeding mechanism, and automatic feeding and feeding stop are achieved through an inductive switch and a feed level line. The feeding trough is safe and convenient to operate, saves a great number of manpower and material resources and reduces raising cost of raising households.

Owner:JIANGSU CHANGSHUN AGRI & ANIMAL HUSBANDRY

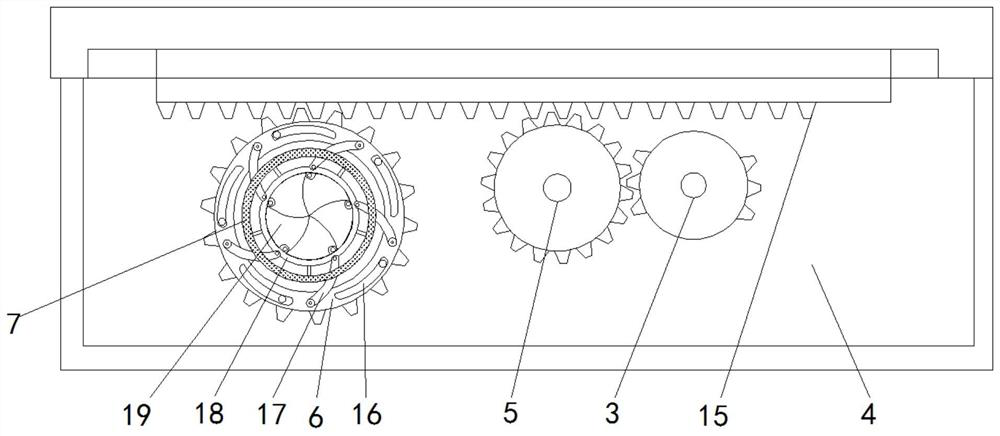

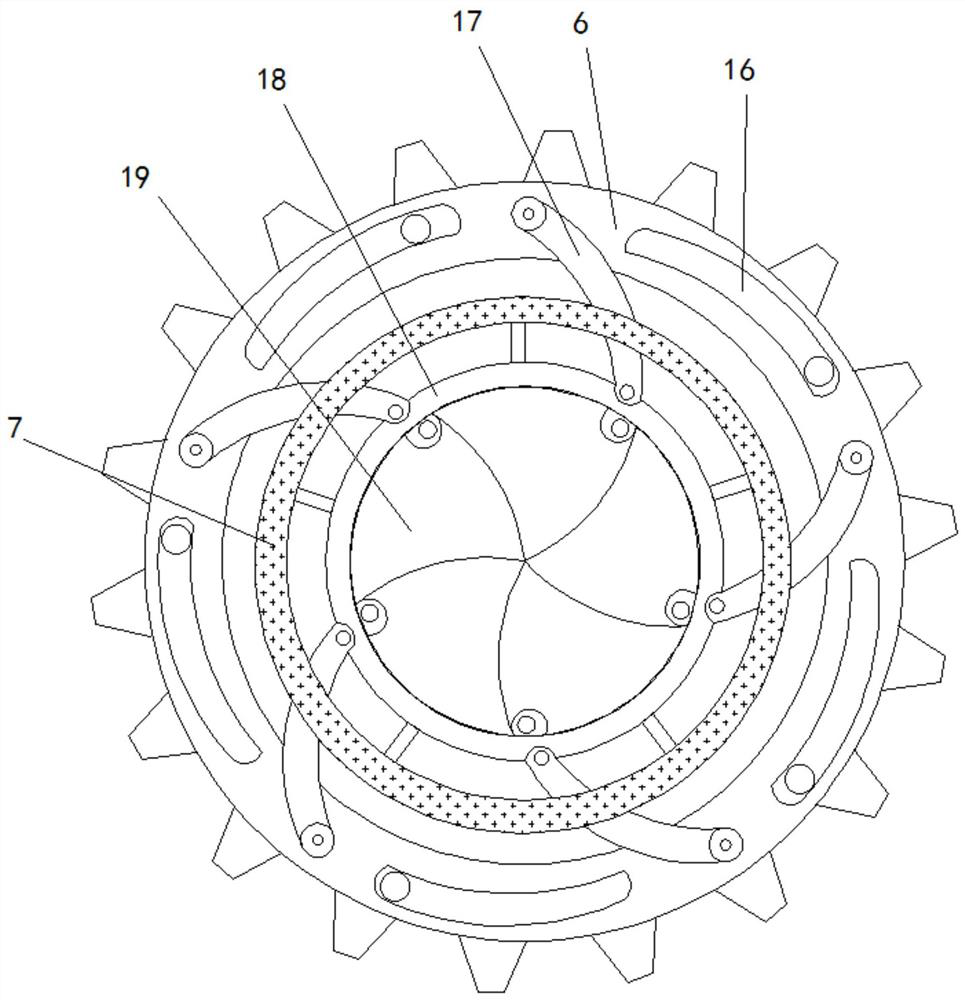

Circular stirring concrete stirrer

ActiveCN111231115AStirring effect is fastStirring effect is evenCement mixing apparatusStructural engineeringMechanical engineering

The invention relates to the field of concrete preparation, in particular to a circular stirring concrete stirrer. The circular stirring concrete stirrer comprises a motor II, a spindle, stirring blades and ramming blades. According to different concrete mixing degrees, different stirring modes are employed, so that the stirring efficiency and the stirring effect are improved and the service lifeof rotary stirring equipment is prolonged. In an early stirring operation, a push-stirring plate moves left and right to a great extent for large-scaled initial stirring, and meanwhile, a rotary stirring mechanism composed of the stirring blades and the ramming blades stir concrete at fixed points, so that the work strength of the rotary stirring mechanism in the early stage is reduced. In the middle and later periods of stirring operation, the push-stirring plate moves leftward to push the initially stirred concrete to the rotary stirring mechanism to be stirred more finely, and then the push-stirring plate is elevated to move rightward, so that the finely stirred concrete flows back to the right side naturally to be circulated. So repeatedly, it is convenient to stir the concrete quicklyin a large volume container and the stirring effect is uniform.

Owner:ZHEJIANG GUANGSHA COLLEGE OF APPLIED CONSTRTECH

Concrete wet material stirring machine

InactiveCN110576514AExpand the mixing rangeStirring effect is evenCement mixing apparatusPulp and paper industry

The invention discloses a concrete wet material stirring machine. The stirring machine comprises a machine frame, wherein a machine body is fixedly arranged at the upper end of the machine frame, a feeding hopper is arranged on the side wall of the machine body in a penetrating mode, a discharging opening is formed in the bottom of the machine body, a valve is arranged on the discharging opening,a cover body is fixedly arranged at the upper end of the machine body, a first toothed plate which is transversely arranged is welded to the bottom of the cover body, two rails are symmetrically and fixedly connected to the bottoms, located at the front end and the rear end of the first toothed plate, of the cover body, a sliding seat is transversely and slidably connected between the two rails, adriving mechanism is arranged between the upper end of the sliding seat and the first toothed plate, a frame body is welded to the bottom of the sliding seat, a first motor is arranged on the frame body, and the output end of the first motor is vertically downward and welded with a stirring shaft. According to the stirring machine, the first motor, the stirring shaft and stirring blades can be driven to integrally move back and forth in the machine body to stir materials, so that the stirring range is larger, the stirring effect is more uniform, and the product quality is guaranteed.

Owner:江苏广昊建筑科技有限公司

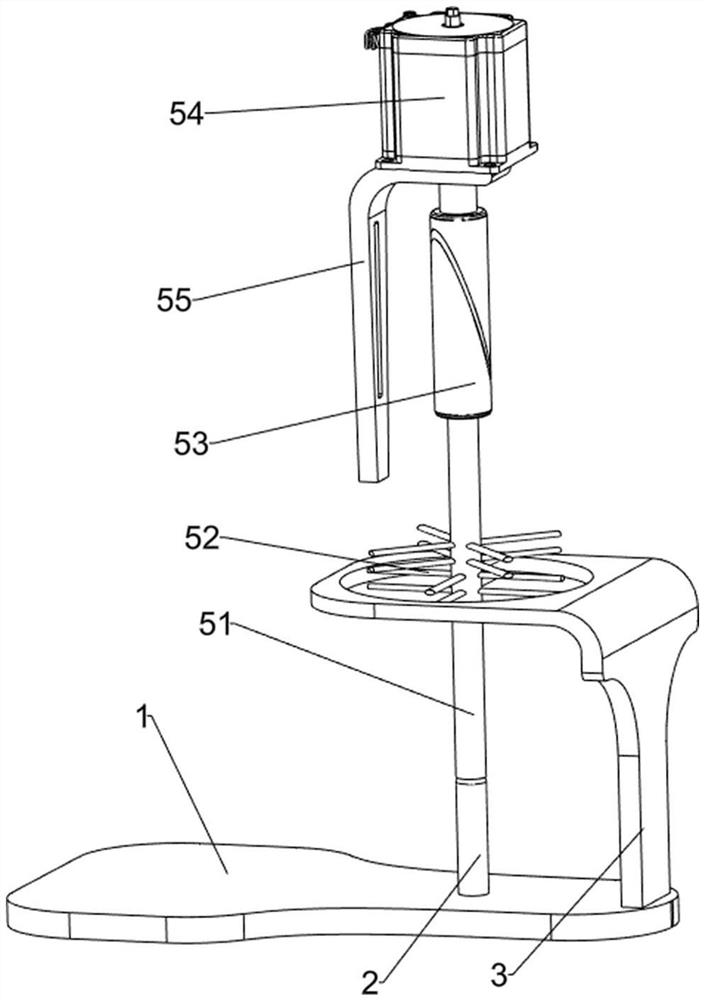

Composite rotary stirring device and working method thereof

ActiveCN110449074ANo stirring dead angleImplement chaotic mixingTransportation and packagingRotary stirring mixersMechanical engineering

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com