Patents

Literature

32results about How to "With stirring effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

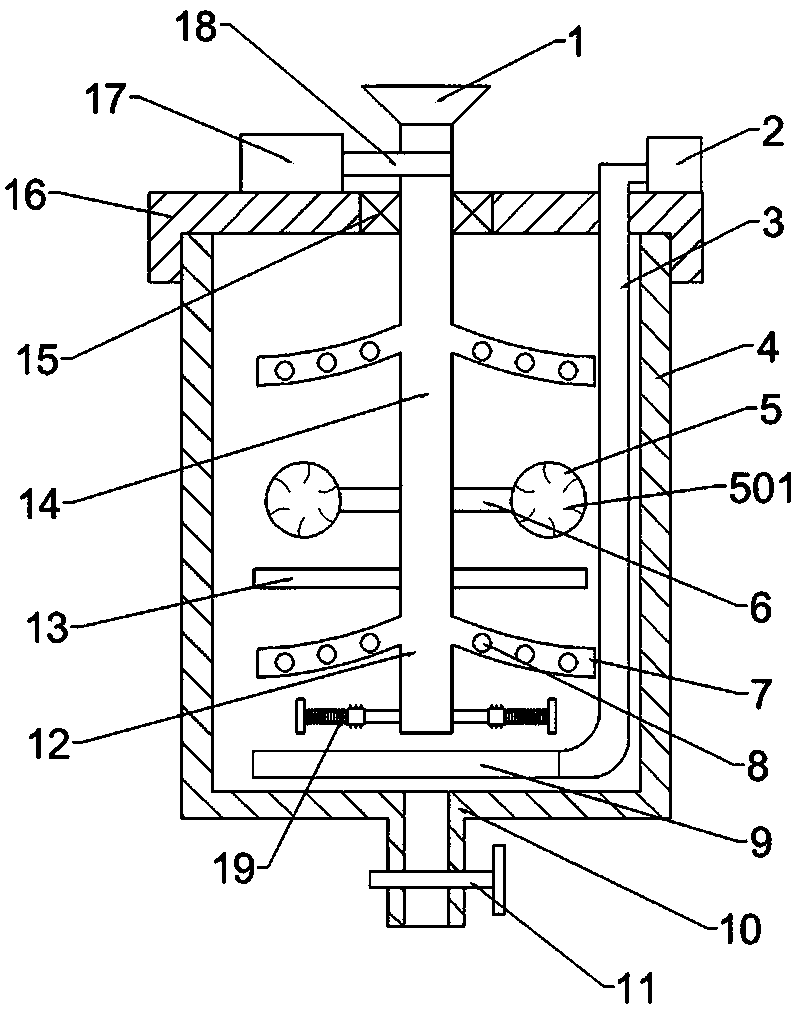

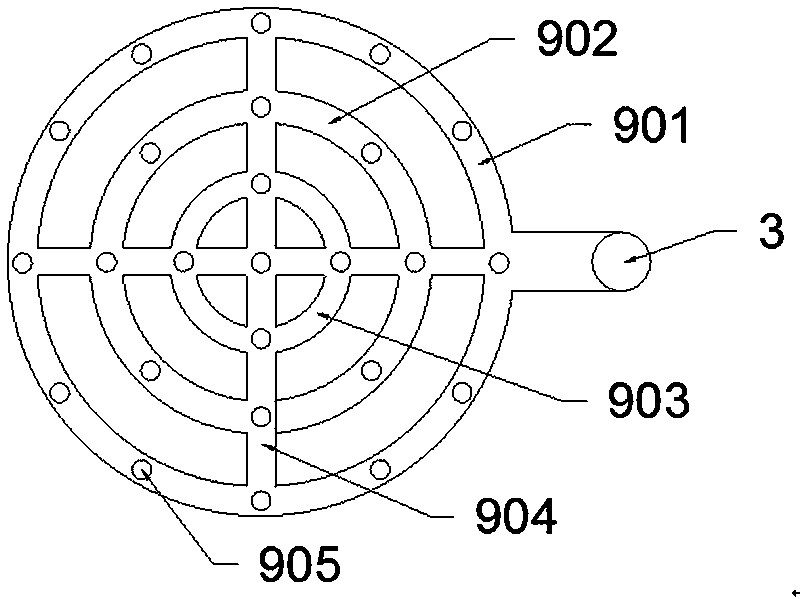

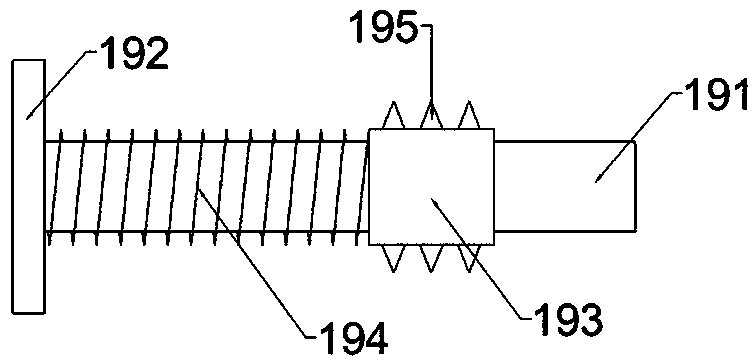

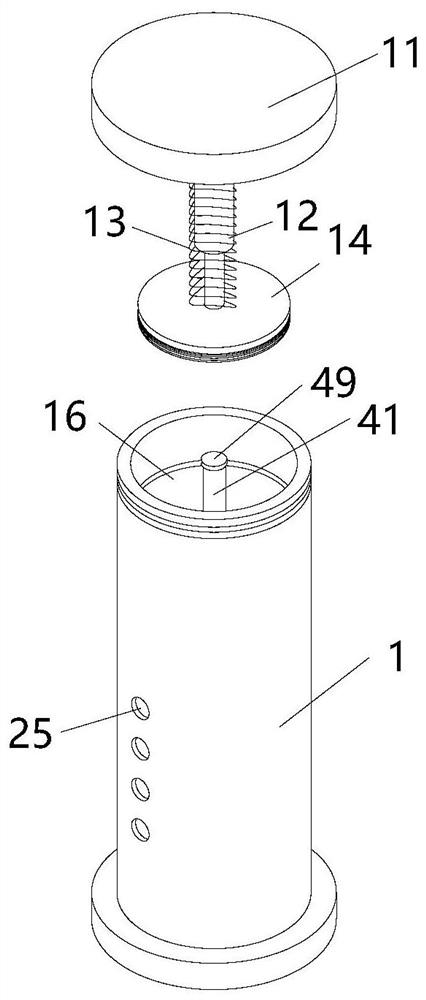

Material mixing and stirring equipment for chemical industry production

InactiveCN109925917AImprove the mixing effectWell mixedRotary stirring mixersTransportation and packagingChemical industryEngineering

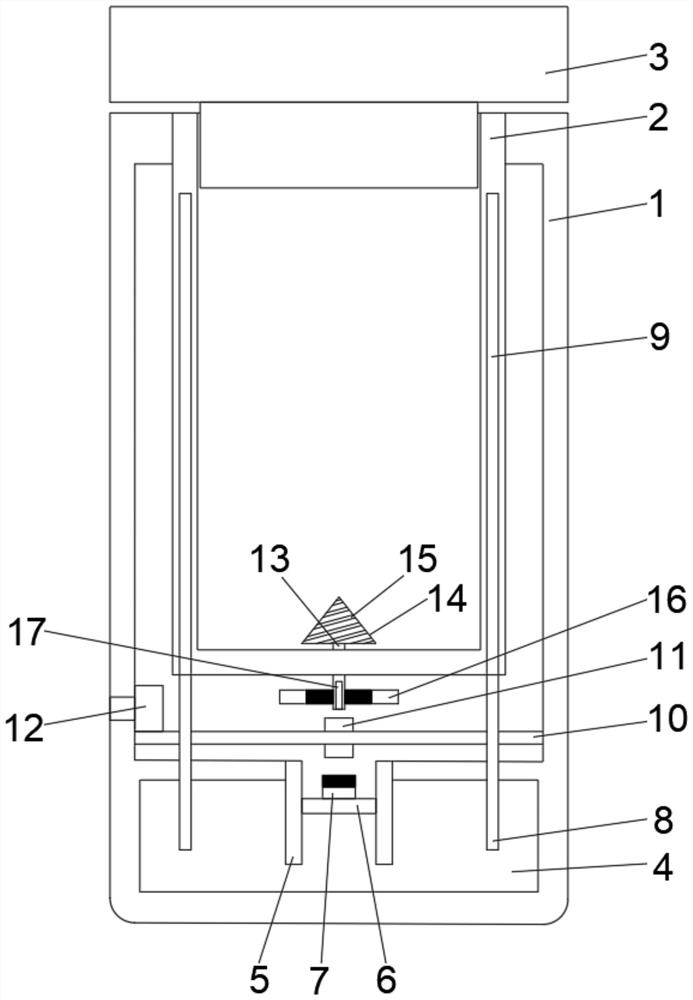

The invention relates to material mixing and stirring equipment for chemical industry production. The material mixing and stirring equipment comprises a barrel body, wherein a stirring shaft is arranged in the barrel body, a hollow inner cavity is arranged inside the stirring shaft, a material inlet hopper is arranged on the top end of the stirring shaft, the upper portion and the lower portion, positioned in the barrel body, of the stirring shaft are provided with material distribution pipes, the material distribution pipes are communicated to the hollow inner cavity in the stirring shaft, and are provided with a plurality of through holes, the middle portion of the stirring shaft are provided with connecting rods, the other end of the connecting rod is connected to a vortex generating member, and the bottom portion of the barrel body is provided with a gas distributing device. According to the present invention, the working principle is that the material can enter the hollow inner cavity of the stirring shaft through the material inlet hopper, the material distribution pipes can suck the material in the hollow inner cavity during the rotating due to the centrifugal force, the material enters the barrel body through the through holes on the material distribution pipes to be dispersed in different areas of the barrel body so as to improve the mixing effect of the material, andthe material distribution pipe has a certain stirring effect.

Owner:YUNXIAN LIANFA INDAL & TRADE

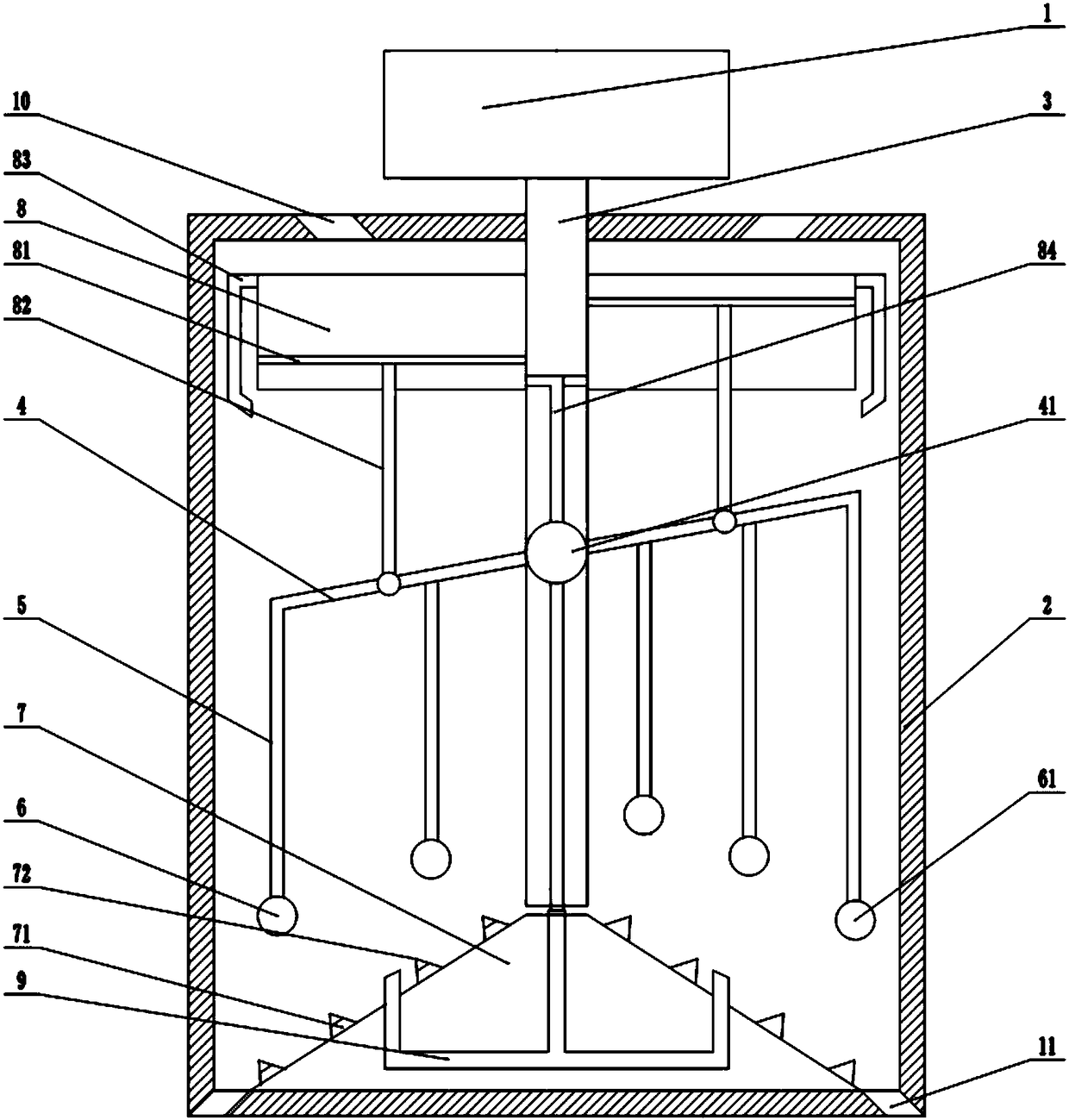

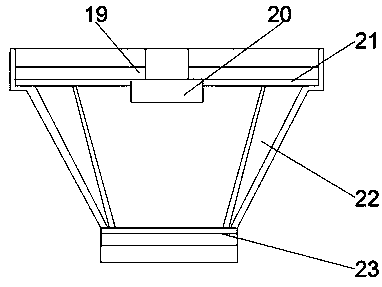

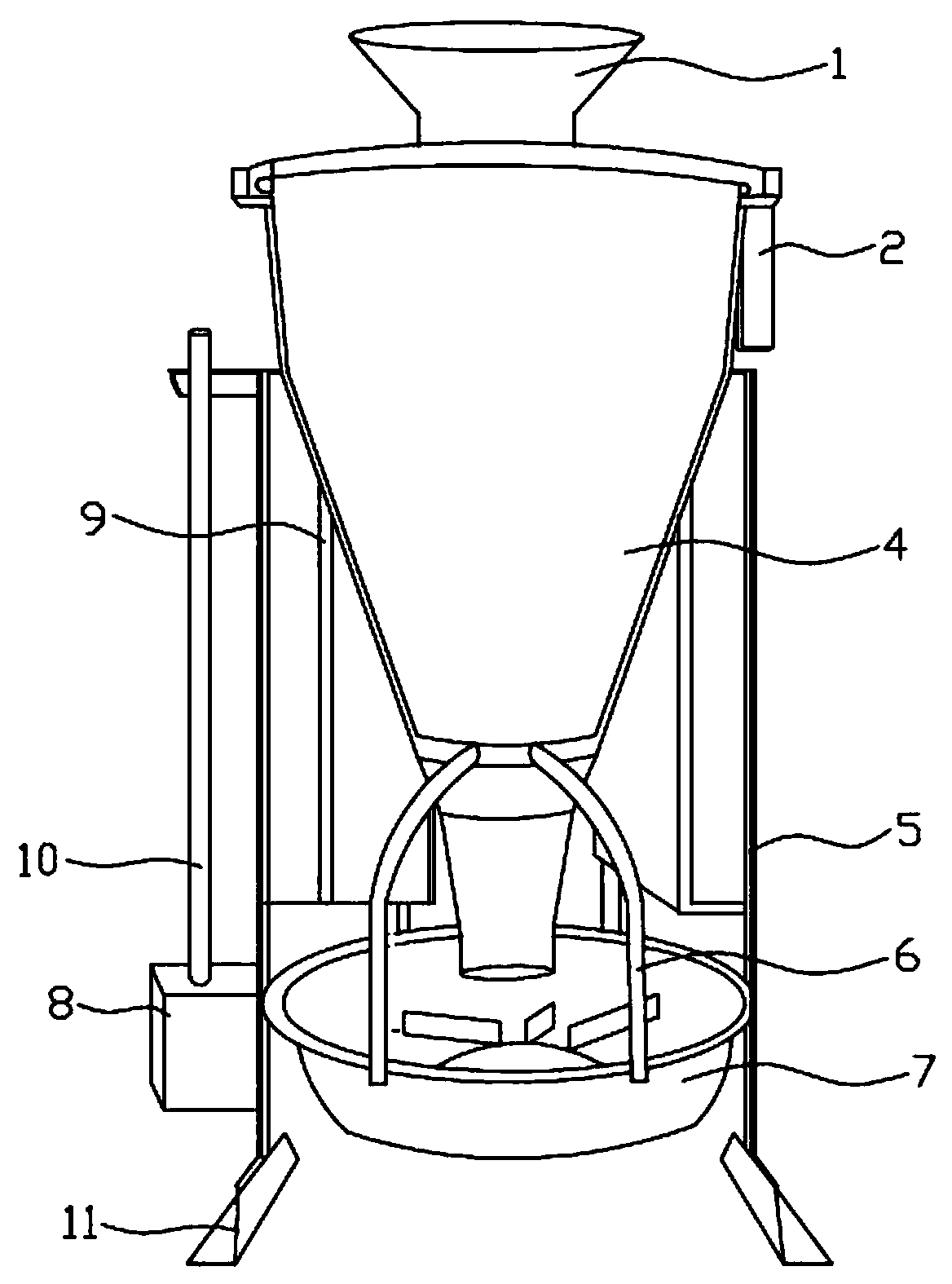

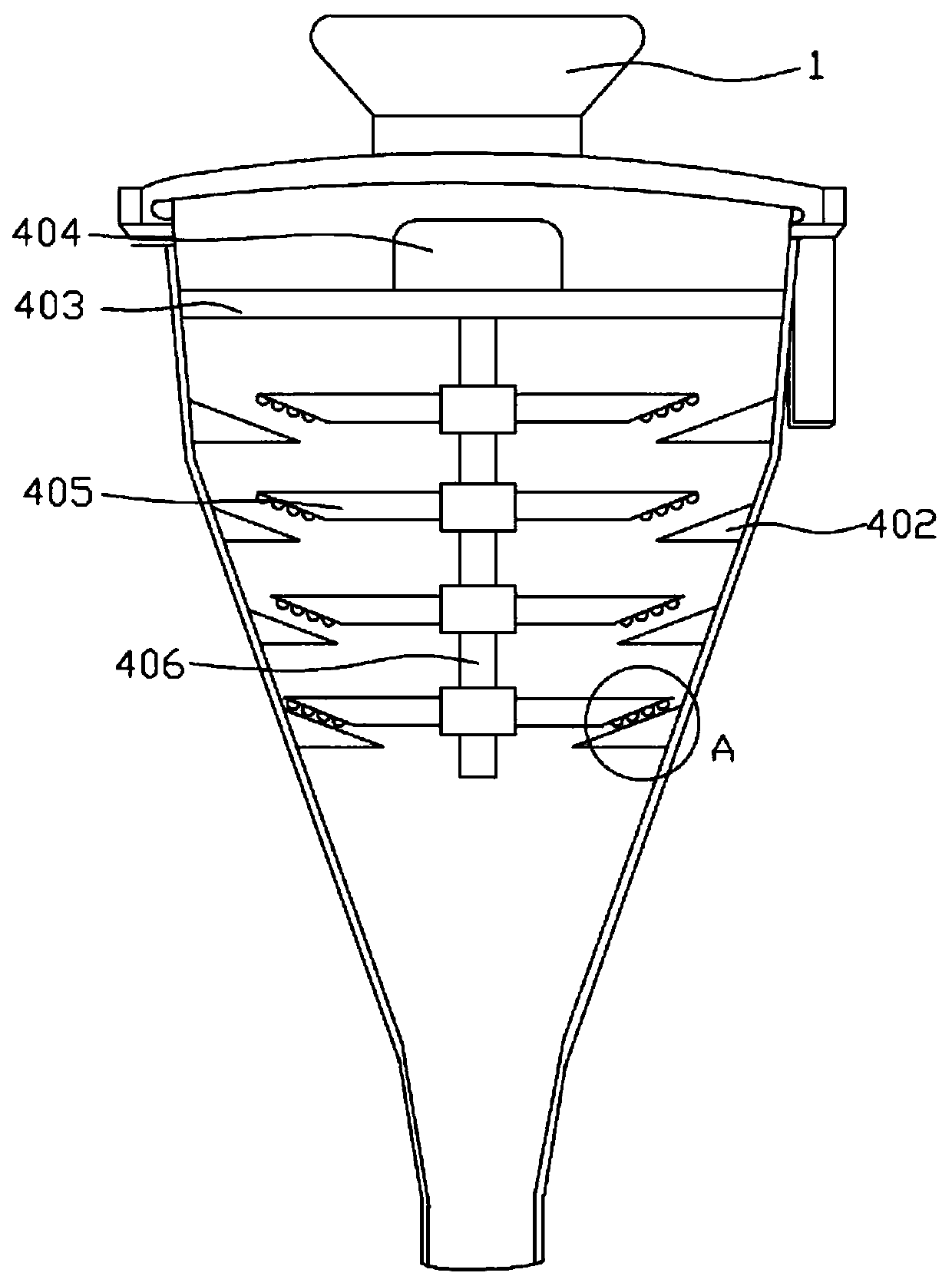

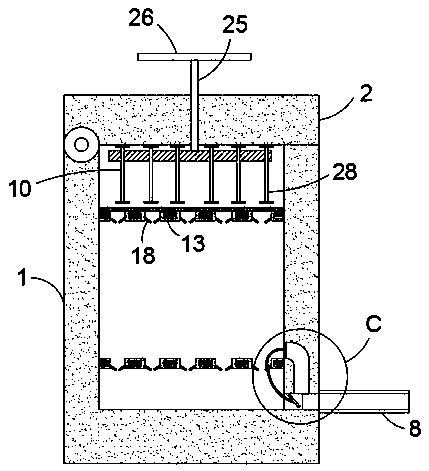

Pet feed mixing device

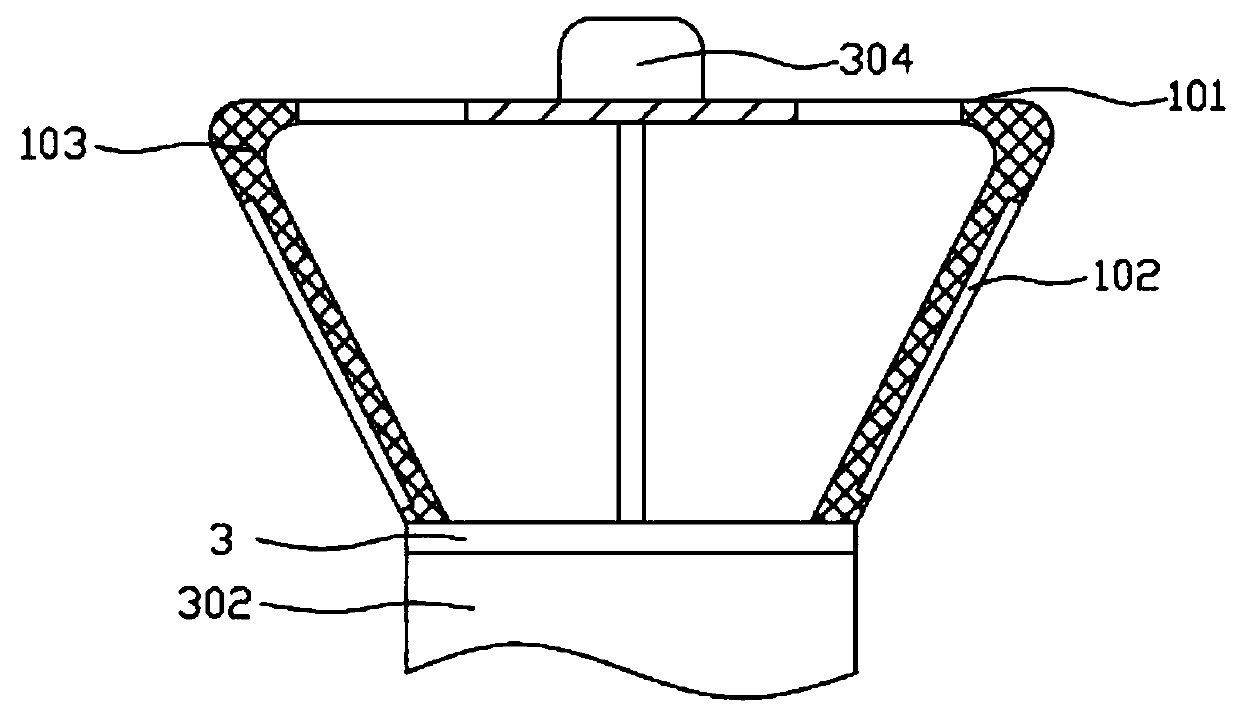

ActiveCN108211957AAchieve circumferential stirring and mixingRealize up and down stirring and mixingFeeding-stuffTransportation and packagingMagnetic polesCircular cone

The invention discloses a pet feed mixing device. The pet feed mixing device comprises a motor, a material mixing barrel, a circular cone table and a spindle, wherein a feeding inlet is formed in thetop surface of the material mixing barrel and the center of the top surface of the material mixing barrel is rotationally sealed with the spindle, the spindle is hollow and cylinders are arranged at the upper side part of the spindle, and a cross rod is in ball joint with the middle part of the spindle; a plurality of stirring rods are connected onto the cross rod on both sides of the spindle, a first magnet and a gravity block are respectively arranged at the end parts of the stirring rods on both sides, piston rods are hinged to the cross rod and connected with pistons in the cylinders, first guide pipes are arranged at the upper ends of the cylinders, and second guide pipes which extend into a cavity inside the spindle are arranged at the lower ends of the cylinders; the circular cone table is fixed at the bottom of the material mixing barrel, a plurality of protrusions are arranged on the circular cone table, second magnets are mounted on the protrusions on one side, the magnetic poles of the second magnets are the same as those of adjacent ends of first magnets, the second guide pipes extend out of the bottom of the spindle, and tee pipes are arranged inside the circular conetable, and rotationally connected with the second guide pipes, wherein two bifurcated pipes of the tee pipes respectively protrude from an inclined surface of the circular cone table. By adopting thedevice disclosed by the invention, granules and powdered pet feed can be uniformly mixed.

Owner:CHONGQING SIWEITE PET SUPPLIES CO LTD

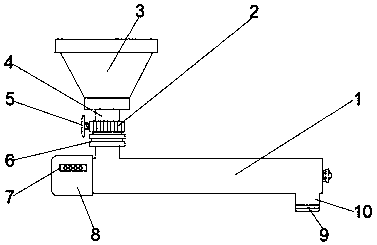

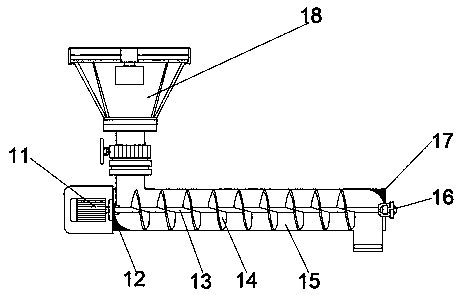

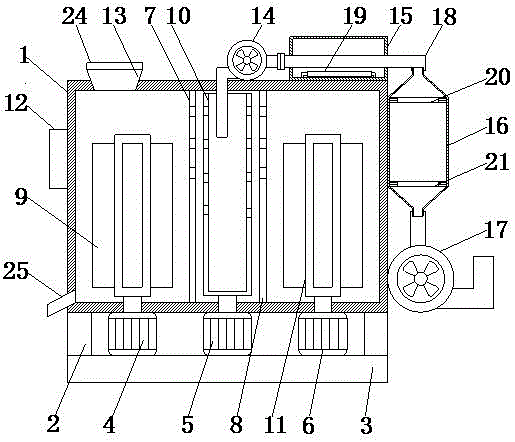

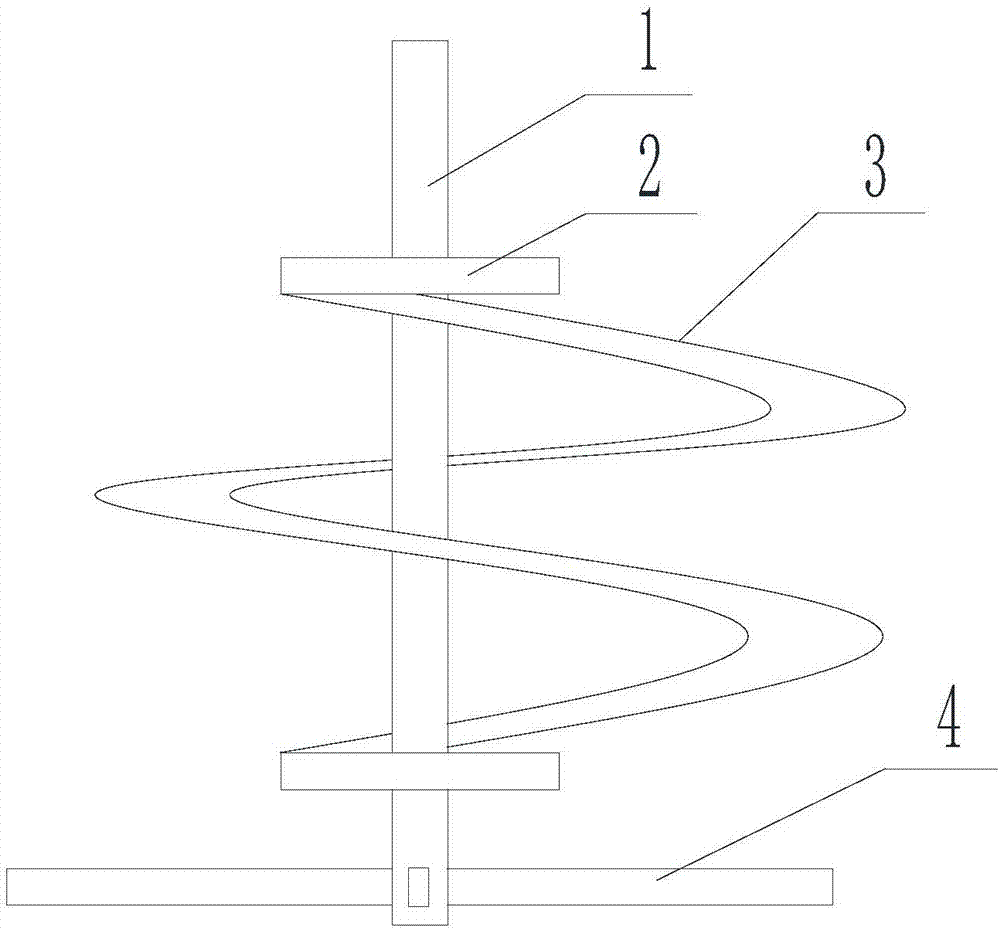

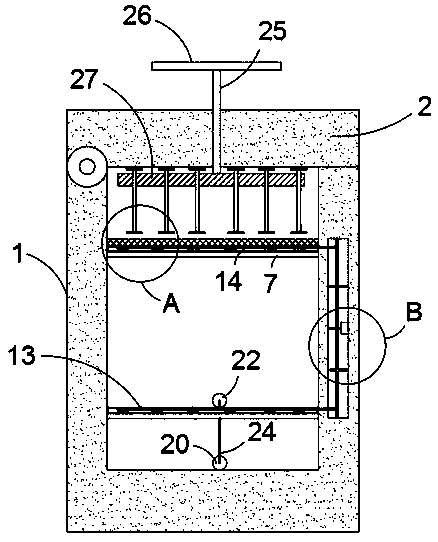

Dry-mixed mortar mixing and conveying machine

InactiveCN109129925AWon't raiseEfficient deliveryCement mixing apparatusEngineeringMechanical engineering

The invention relates to the technical field of conveying equipment and in particular discloses a dry-mixed mortar mixing and conveying machine which comprises a mixing conveying machine main body, afeeding hopper and a tank, wherein the feeding hopper is fixedly mounted at the top of a connecting tube; a stirring chamber is fixedly mounted inside the feeding hopper; a conveying pipeline is fixedly mounted inside the mixing conveying machine main body; a lower filling corner is fixedly mounted on one side close to the tank, of the conveying pipeline; an upper filling corner is fixedly mountedon the other side of the lower filling corner; the conveying pipeline is internally provided with a rotating shaft; spiral stirring blades are fixedly mounted on the rotating shaft; a fixing shaft rack is fixedly mounted on one side far away from the tank, of the rotating shaft. Due to adoption of the rotating shaft and the spiral stirring blades, the rotating shaft is driven by the motor, then the spiral stirring blades are rotated forwards, dry-mixed mortar is driven to move forwards, a special stirring effect is achieved, and the equipment is capable of conveying effectively, has an additional stirring effect and is applicable to mortar conveying.

Owner:潍坊正兴自动化设备科技有限公司

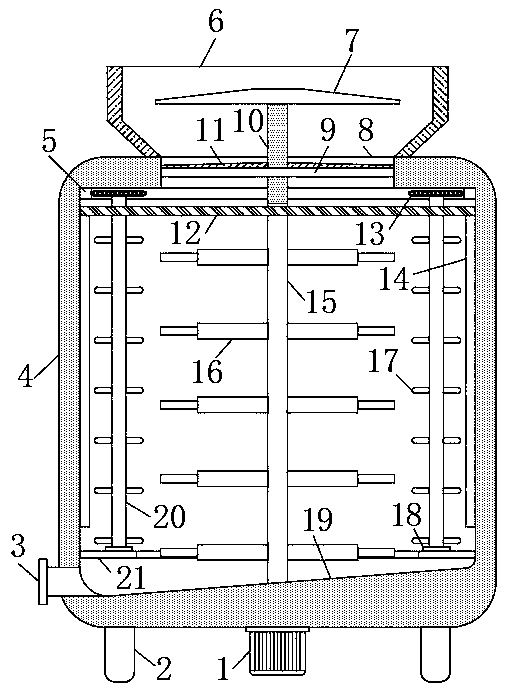

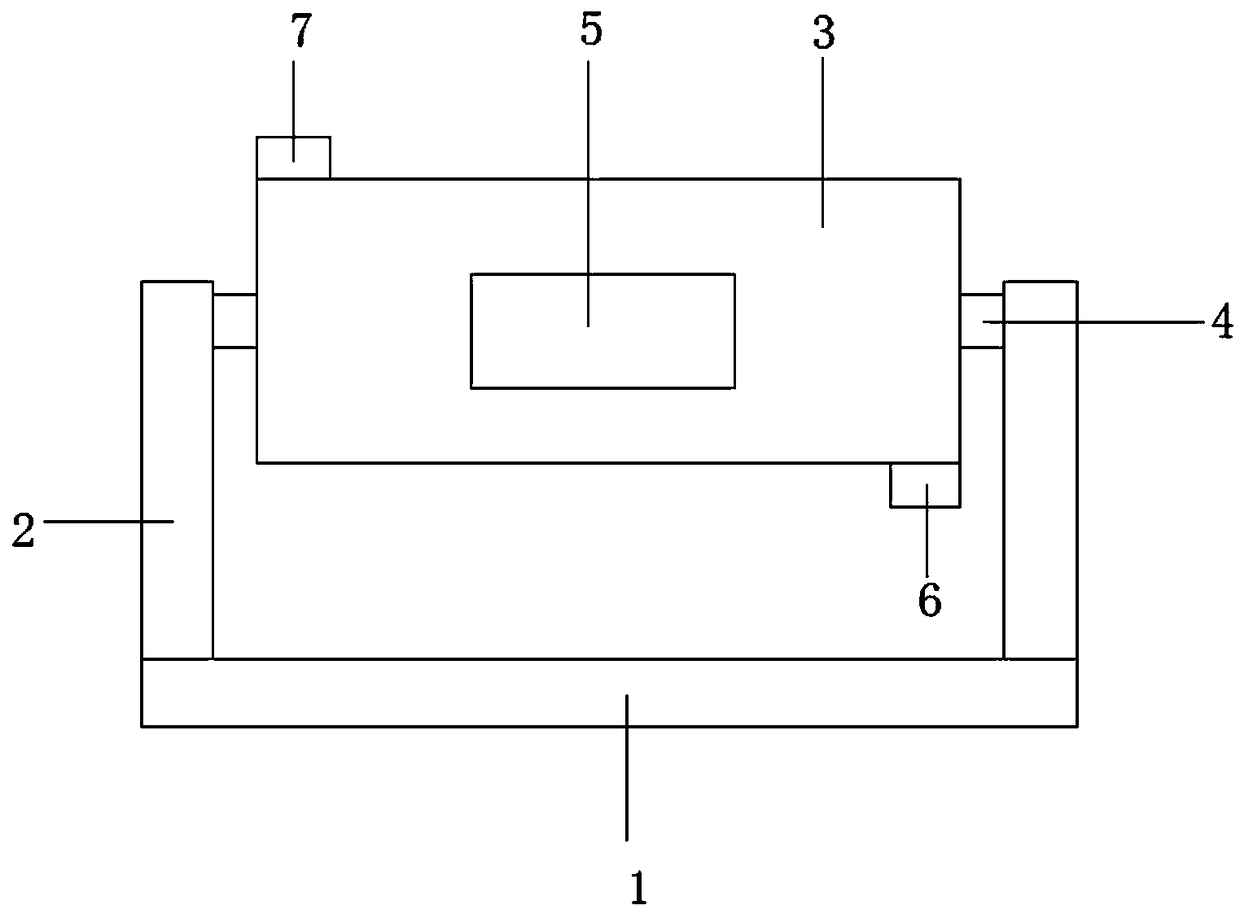

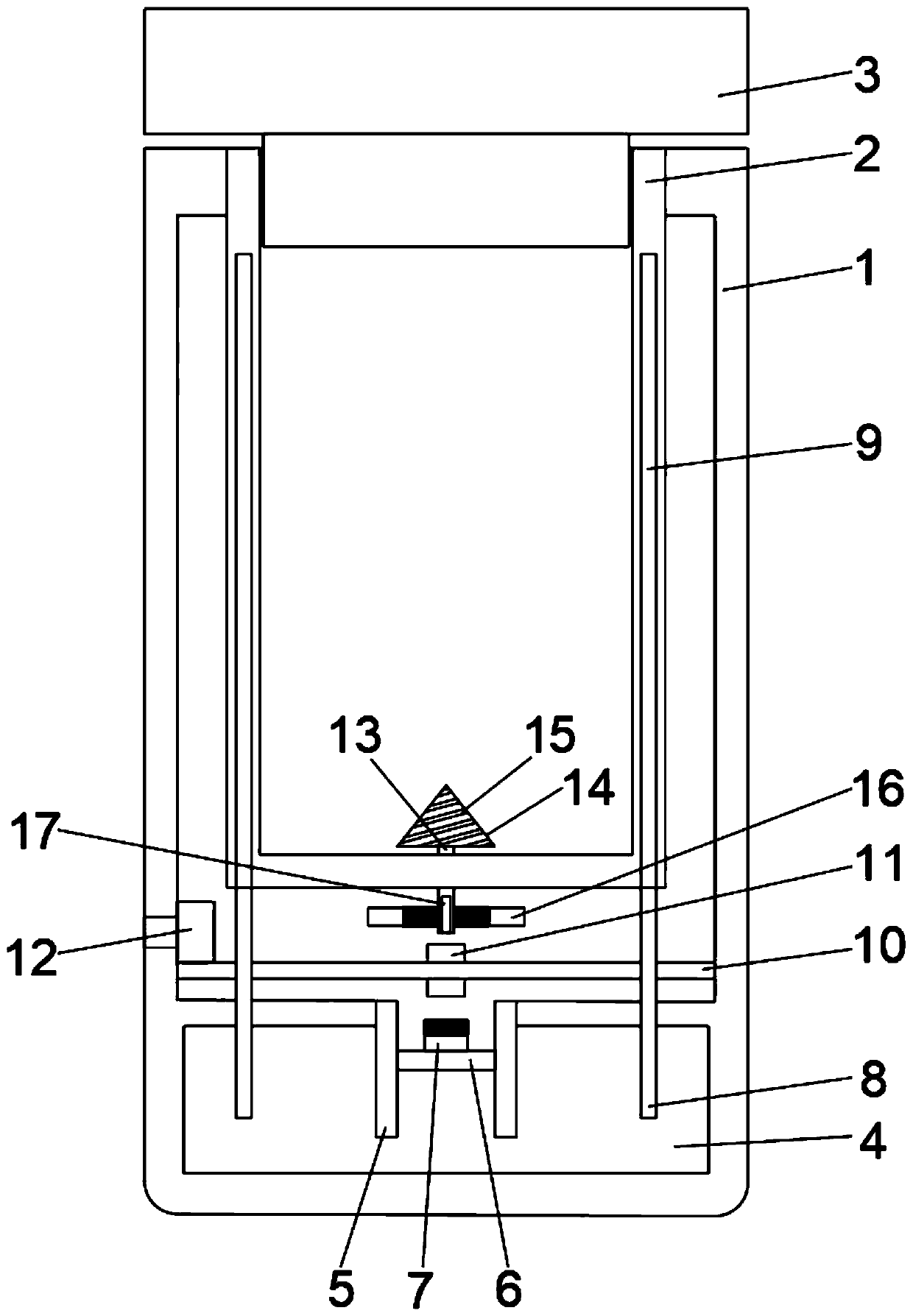

Energy-saving and environment-friendly pulping device for papermaking and printing

ActiveCN110552222AAffect the blending effectEasy to cleanRaw material divisionPapermakingElectric machinery

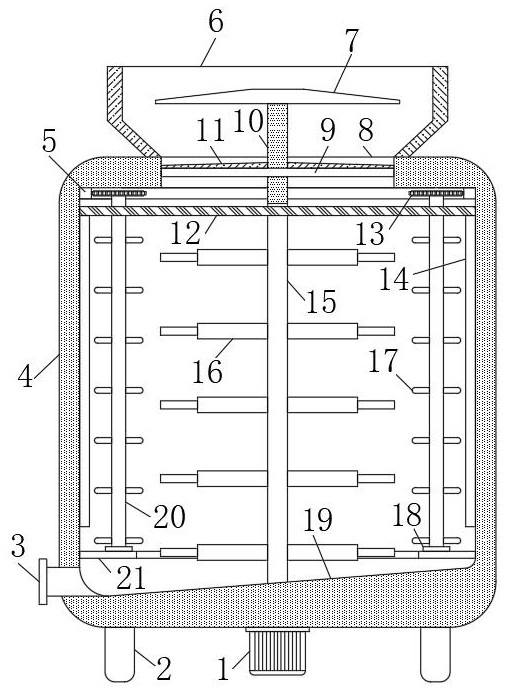

The invention discloses an energy-saving and environment-friendly pulping device for papermaking and printing. The pulping device comprises a box body, the lower end of the box body is fixedly connected with a plurality of supporting feet, a discharge port is arranged at the middle and lower position of the side wall of the box body, the middle part of the upper end of the box body is provided with a feed inlet, the upper end of the box body is fixedly connected with a feed hopper at a position corresponding to the feed port, the lower end of the box body is fixedly connected with a motor, theend of the output shaft of the motor penetrates through the lower end of the box body and is fixedly connected with a rotating rod, the output shaft of the motor is rotatably connected with the box body, a plurality of crushing knives are arranged at equal intervals along the axial direction on the outer side of the rotating rod, a rotating plate is sleeved on the rotating rod, and the two are fixedly connected. The invention has reasonable structural design, can disperse materials into the inside of the box body, is beneficial to improving the pulping effect, can fully mix the materials, andcan also prevent the materials from adhering to the inner wall of the box body.

Owner:温州市金龙纸业有限公司

Novel juice beverage stirring and mixing equipment and working method thereof

InactiveCN107362743AImprove the mixing effectGreat tasteTransportation and packagingMixersDrive wheelEngineering

The invention discloses novel juice beverage stirring and mixing equipment. The novel juice beverage stirring and mixing equipment comprises a driving wheel, an outer wheel ring and two stirring barrels, wherein the two stirring barrels comprise a first stirring barrel and a second stirring barrel; the first stirring barrel and the second stirring barrel are fixedly welded to a driving wheel; pistons are separately arranged in the first stirring barrel and the second stirring barrel and are separately connected with ejector pins fixedly; and a roller is mounted at an end of the ejector pin at the bottom end and is exactly inlaid in a slide way which is positioned on the inner wall of the outer wheel ring. The invention provides a novel stirring device and method for production of juice beverage. By the two rotating stirring barrels and an eccentric wheel structure, in a rotating process of the stirring barrels, the juice beverage in the stirring barrels continuously flows in a reciprocating manner, the stirring effect due to rotation is achieved, furthermore, the juice beverage is fully mixed in a material flowing process, the beverage mixing effect is improved, local uneven mixing is avoided, and the taste of the beverage is improved.

Owner:合肥图森工业设计有限公司

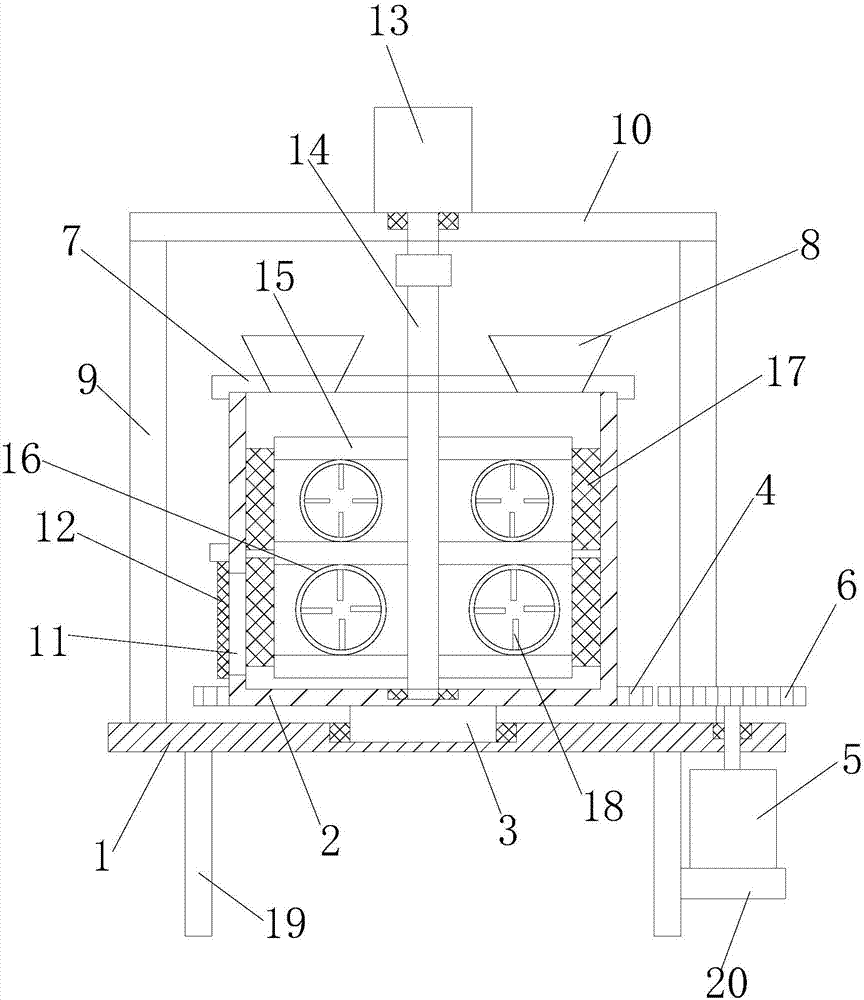

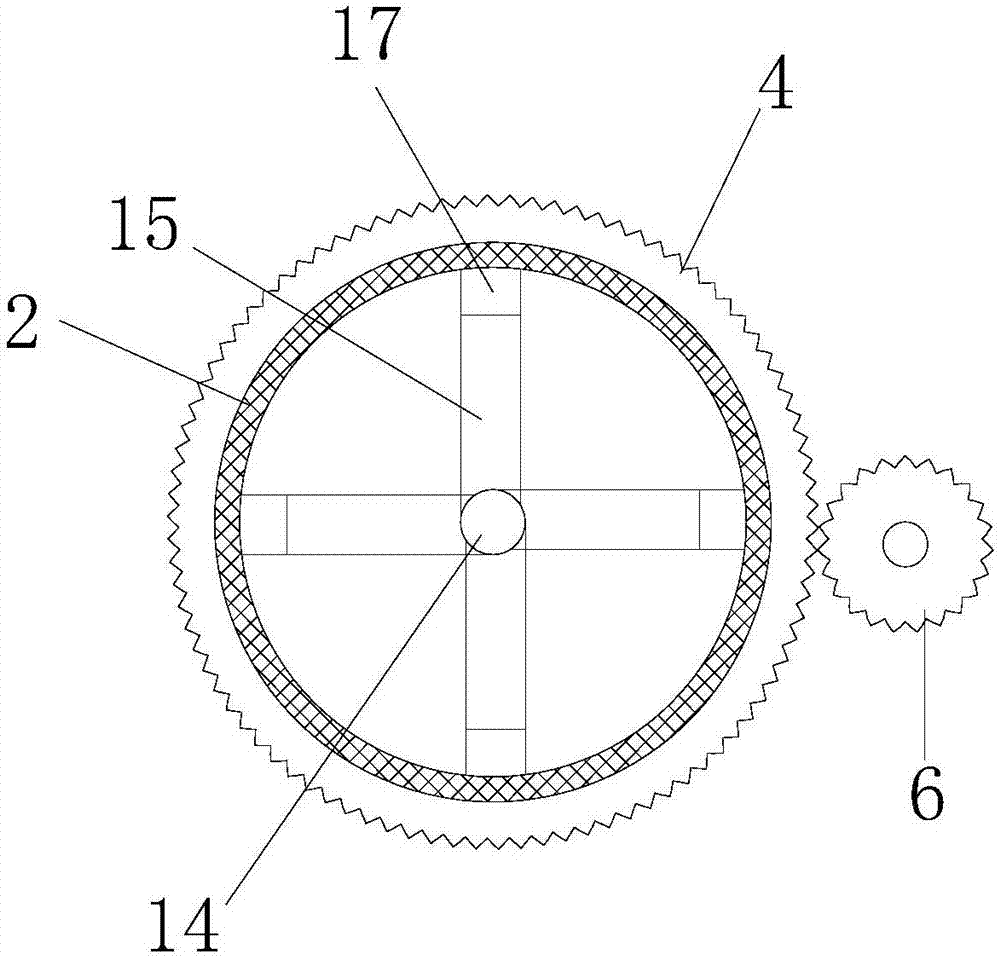

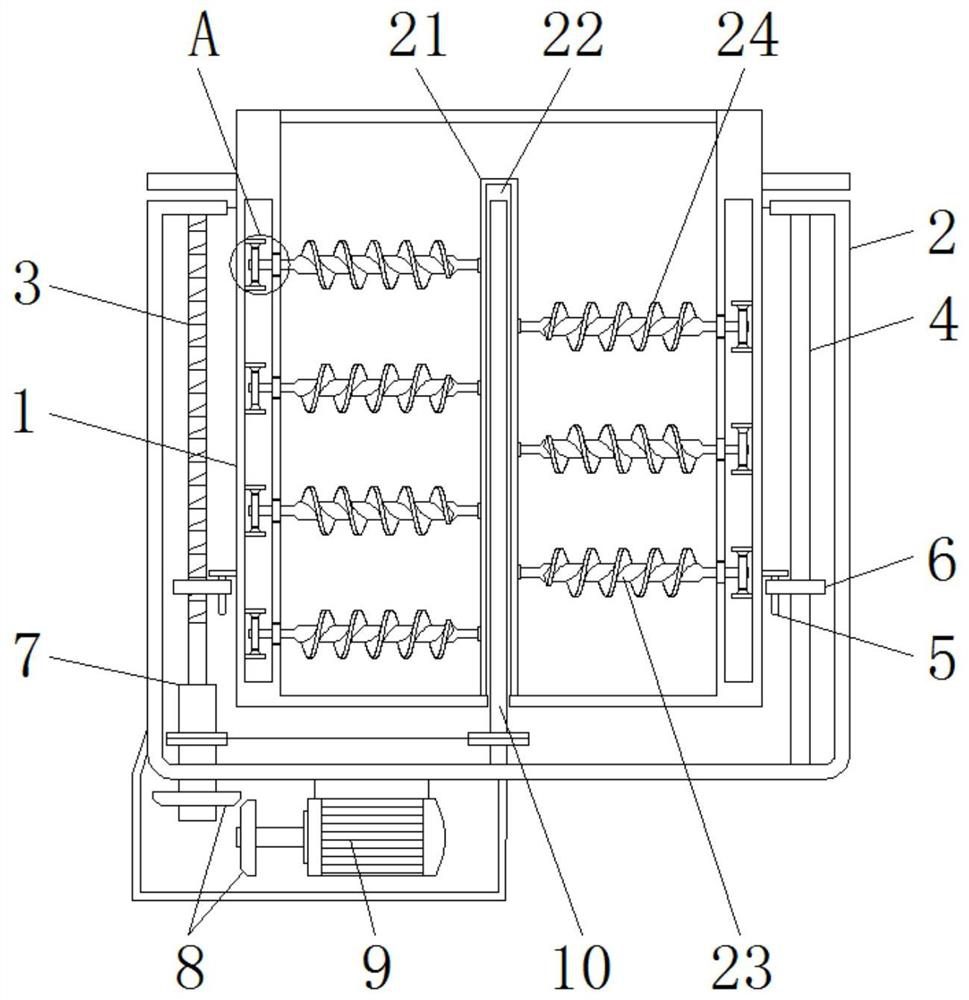

Efficient sand mixer

InactiveCN107126884APrevent sand from stickingImprove mixing effectRotating receptacle mixersTransportation and packagingEngineeringClamp connection

The invention discloses an efficient sand mixer. The efficient sand mixer comprises a workbench, a mixing drum, supports, a supporting plate, a speed reducing motor A, a rotating shaft A, stirring shafts, stirring rings, wall brushes and a speed reducing motor B. The bottom of the mixing drum is in rotational connection with the upper end face of the workbench through the rotating shaft A, a sawtooth rotating plate is arranged at the bottom outer periphery of the mixing drum, the speed reducing motor A is mounted on one side of the workbench, and an output end of the speed reducing motor A is fixedly connected with a sawtooth wheel which is meshed with the sawtooth rotating plate. A cover is in clamped connection with the top end of the mixing drum, feeding hoppers are arranged on two sides of the cover respectively, one side of the bottom of the mixing drum is provided with a discharging port, a seal cover for opening or closing the discharging port is hinged to the outer wall of the mixing drum, the supports are fixedly connected to the workbench on two sides of the mixing drum, and bottoms of two ends of the supporting plate are fixedly connected with the corresponding supports. The efficient sand mixer is high in mixing efficiency and uniform in mixing, and the drum wall is free of sand adhesion.

Owner:LIANGXI XUZHONG GENERAL MACHINERY DESIGN STUDIO

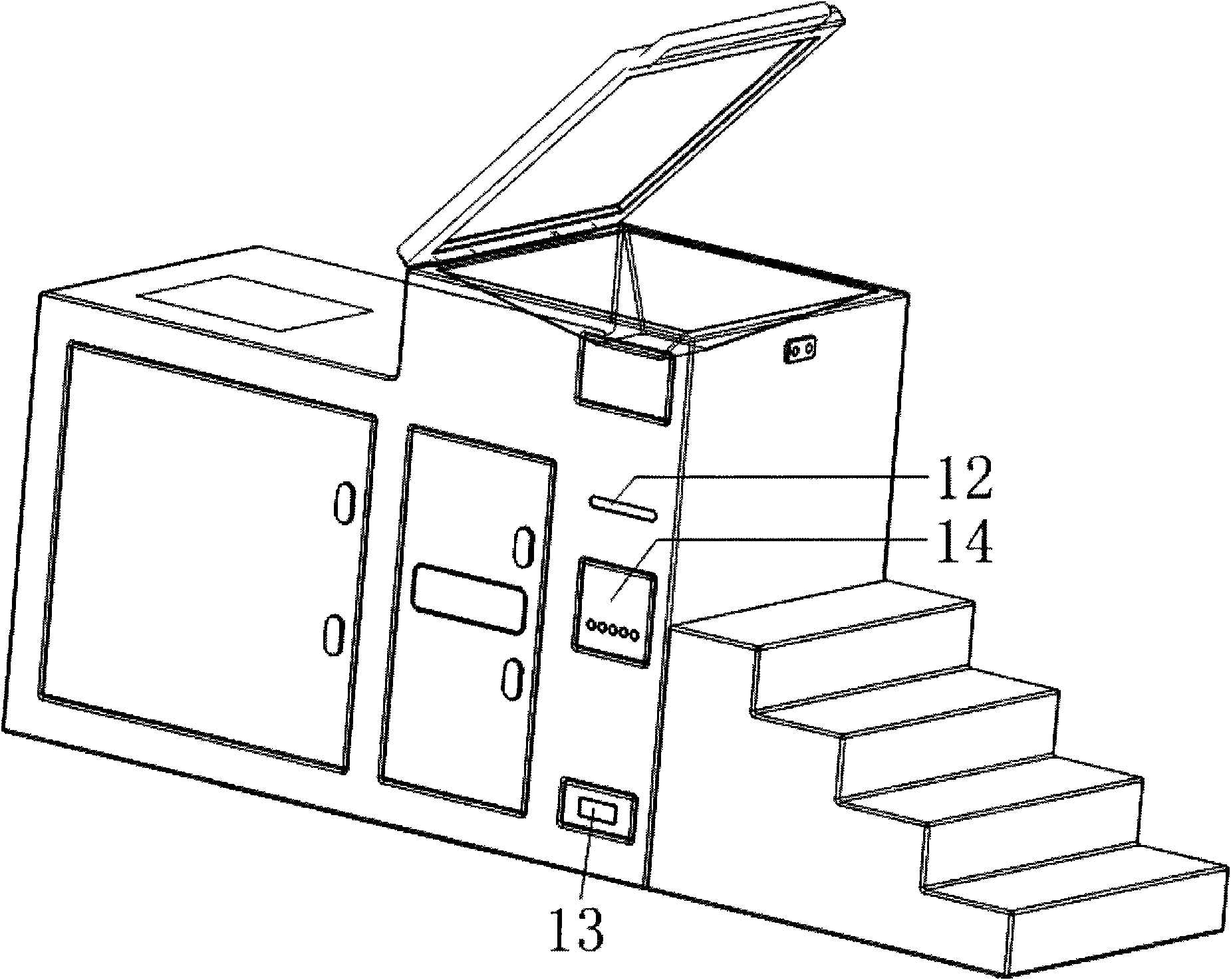

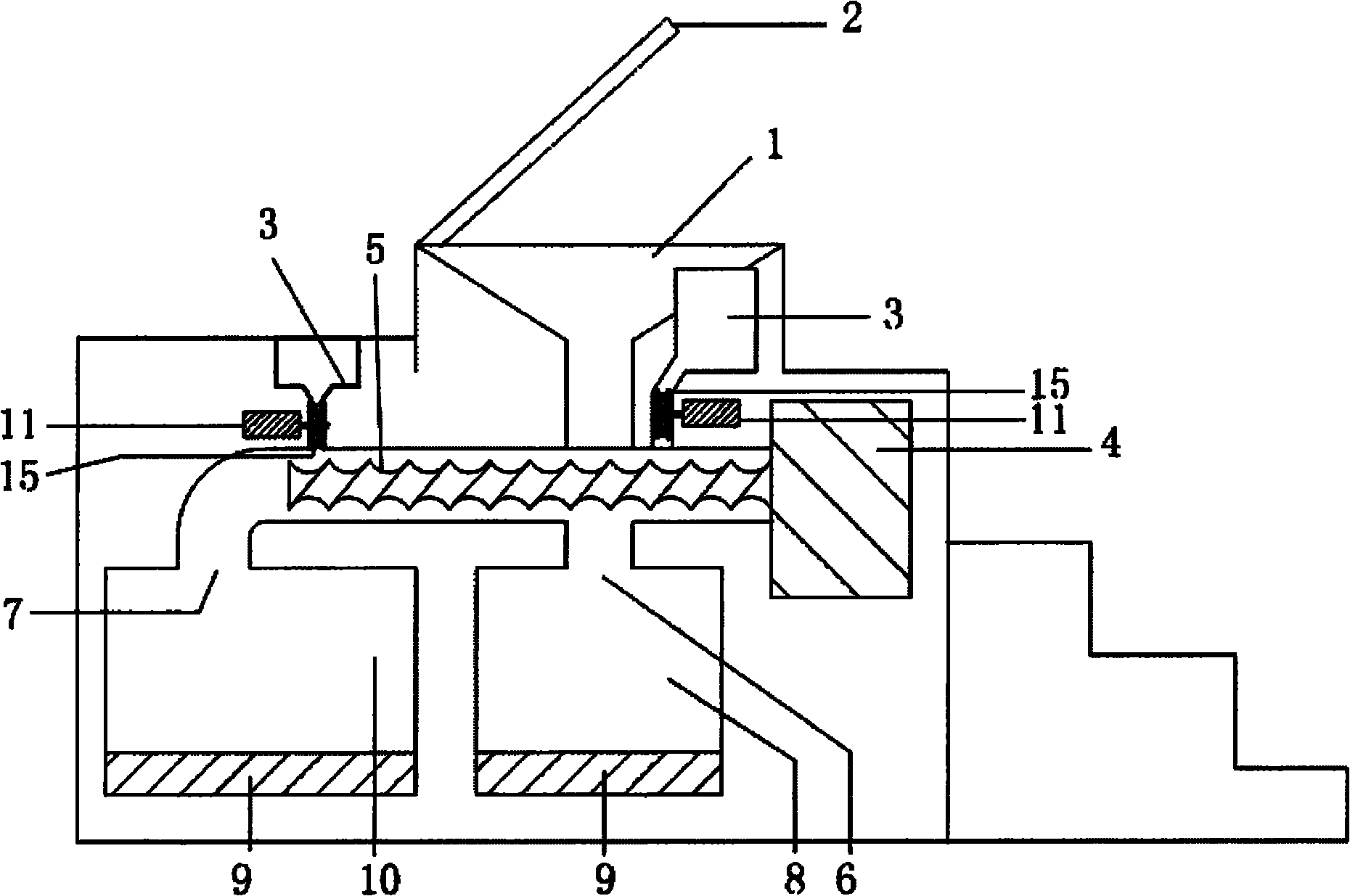

Automatic feeding device for pigs

InactiveCN110150169AWith stirring effectInhibition of antinutritional effectsAnimal feeding devicesHollow article cleaningEngineeringDigestion

The invention discloses an automatic feeding device for pigs. The automatic feeding device comprises a feed hopper, a barrel and supporting legs, the supporting legs are symmetrically arranged at thebottom of the barrel, the middle upper portions of the supporting legs are connected with supports, longitudinal stop rods are arranged between the supports, the barrel is mounted between the supports, the feed hopper is arranged on the upper portion of the barrel and comprises a feed cavity, a separation layer is arranged in the feed cavity, and a heating plate is obliquely arranged in the separation layer. By the aid of the device, feed use ratio is increased while the pigs are automatically fed, the digestion characteristic and the palatability of feed are improved, the digestive absorptioncapacity, the growth performance and the immunity of the pigs can be improved, and the meat quality and the breeding yield of the pigs are further improved.

Owner:ZHEJIANG OCEAN UNIV

Chemical material drying machine with stirring effect

InactiveCN106568307AShorten drying timeImprove efficiencyDrying gas arrangementsDrying solid materialsEngineeringWater tanks

The invention discloses a chemical material drying machine with a stirring effect. The chemical material drying machine with the stirring effect comprises a box body. Support legs are symmetrically and fixedly connected to the bottom part of the box body; a support seat is fixedly connected to the bottom parts of the support legs; a first motor, a second motor and a third motor are sequentially and fixedly connected onto the top part of the support seat and between the support legs from left to right; a first baffle plate and a second baffle plate are sequentially and fixedly connected into the box body from left to right; and an output shaft of the first motor penetrates through the box body and extends into the box body so as to be fixedly connected with the bottom part of a first stirring blade. According to the chemical material drying machine, through the arrangement of a controller, a first air blower, a second air blower, a first heating plate, a second heating plate, a water tank, a gas collection tank and a heating rod, raw materials can be quickly dried, so that the drying time of the raw materials is reduced, the work efficiency is improved, and the chemical material drying machine with the stirring effect is simple in structure, convenient to operate by employees, convenient to maintain, and low in machine manufacturing cost.

Owner:WUXI RISHENG CHEM CO LTD

Kitchen garbage crushing and fermenting device

InactiveCN102329719AAchieve separationWell mixedBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid wasteSolid waste collection

The invention provides a kitchen garbage crushing and fermenting device which comprises a shell, wherein the shell is provided with a feeding hole, the shell is internally provided with a pushing screw and a screw motor, one end of the pushing screw is connected with the screw motor and is arranged in a screw cavity, the lower part of the shell is provided with a solid waste collection box and a liquid waste collection box along the pushing direction of the pushing screw, the liquid waste collection box is communicated with the bottom of the screw cavity, the solid waste collection box is arranged at the bottom of the pushing screw in the pushing direction and is communicated with the screw cavity, the screw cavity is provided with a fermenting powder box with an opening towards the pushing screw, and the outlet of the fermenting powder box is provided with a fermenting powder box switch. Because the pushing screw rod is used, and the solid waste collection box and the liquid waste collection box are arranged along the pushing direction of the pushing screw, thus solid wastes can be separated from liquid wastes in a pushing process; and meanwhile, the pushing screw has a certain mixing effect, therefore, fermenting powder is fully mixed with the wastes.

Owner:李文庆

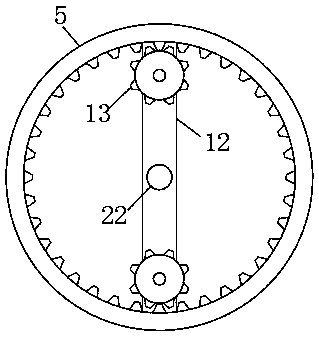

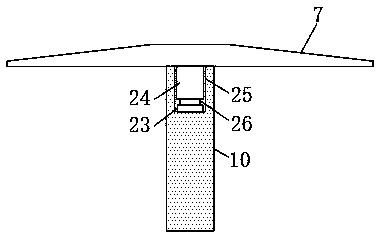

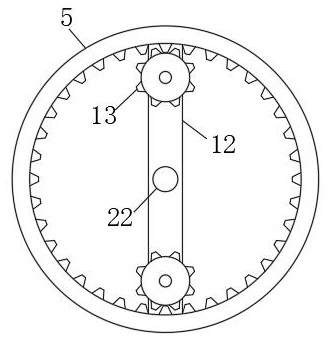

Powder coating blending device for paint spraying

InactiveCN112516875AHas the effect of stirring up and downWith stirring effectRotating receptacle mixersTransportation and packagingElectric machineGear wheel

The invention relates to the technical field of preparation devices, and discloses a powder coating blending device for paint spraying. The device comprises a fixed box, supporting legs are fixedly connected to four corners of the outer box bottom of the fixed box, a rotating mechanism is connected into the fixed box, the top of the fixed box fixedly communicates with a feeding pipe, the rotatingmechanism comprises a driving motor, a rotating shaft, a rotating box, a driving gear, a supporting rod, a driven gear, an inner gear ring and a plurality of rotating rods, the driving motor is fixedly connected to the inner box bottom of the fixed box, the rotating shaft is connected to the output end of the driving motor through a coupler, the rotating box is rotationally connected to the driving motor through a first bearing, and the rotating box is connected to the fixed box through a rolling mechanism. According to the blending device for the powder coating for paint spraying, the rotating directions of the rotating box and the rotating shaft are opposite, meanwhile, the rotating rod drives the stirring rod to rotate when rotating around the rotating shaft, the vertical stirring effect is achieved, the stirring effect is good, raw materials are stirred more uniformly, and the efficiency is high.

Owner:WUHU CHUANGYUAN NEW MATERIALS CO LTD

Leather liming device

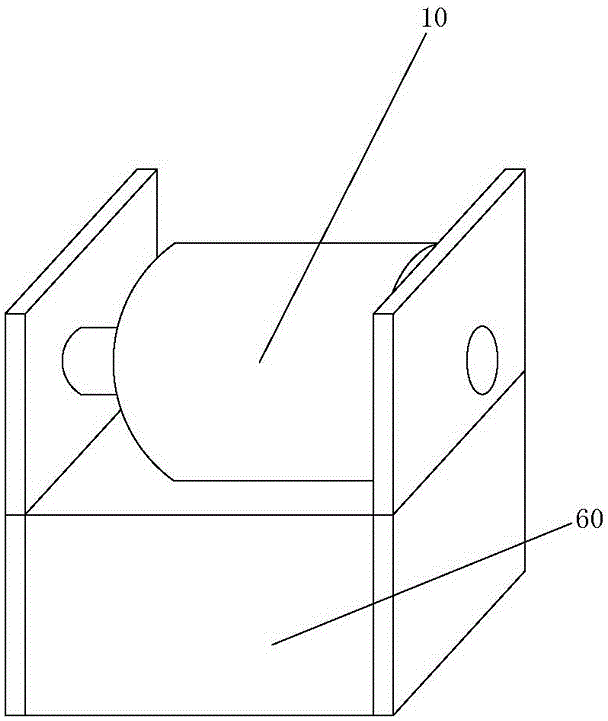

InactiveCN108913822AEasy to put inEasy to take outPre-tanning chemical treatmentLeather/skins/hides/pelt chemical treatment apparatusDrive motorSewage

The invention discloses a leather liming device. The device is characterized in that supporting frames are arranged at the two ends of a base, shaft holes are formed in the supporting frames, a limingbarrel is a cylindrical barrel, a rotating shaft is arranged at the two end faces of the liming barrel, the axis of the rotating shaft coincides with the axis of the liming barrel, the liming barrelis arranged on the supporting frames through cooperation of the rotating shaft and a shaft hole, the axis of the liming barrel is parallel to the base, a feeding gate, a liming barrel and a drug inletare formed in the side face of the liming barrel, a drive motor is connected to the rotating shaft, a water removal clamp is arranged on the feeding gate of the liming barrel, and comprises a lower supporting plate and an upper clamping plate, one side of the lower supporting plate is connected with the edge of a feeding opening, baffles are arranged on the other sides of the lower supporting plate, and the upper clamping plate can be arranged on the lower supporting plate in a lifting manner. The leather liming device can automatically rotate and stir, putting in and taking out of raw material leather can be facilitated, drug can be conveniently added, sewage can be conveniently drained, the consumed time of the liming procedure can be shortened, manpower is saved, and environment sanitation is ensured.

Owner:芜湖兴远新材料有限公司

Efficient stirring device for food production

ActiveCN112169651AImprove scraping effectAvoid echoingRotating receptacle mixersTransportation and packagingDrive shaftGear wheel

The invention discloses an efficient stirring device for food production, and belongs to the technical field of mixing devices. The efficient stirring device for food production comprises a supportingpiece and a mixing barrel, wherein the mixing barrel is located in the supporting piece and rotationally connected with the supporting piece, a containing groove is formed in the bottom end of the supporting piece, a driving motor is connected into the containing groove, and the output end of the driving motor is fixedly connected with a driving gear; the bottom end of the mixing cylinder is fixedly connected with a transmission shaft, the transmission shaft is fixedly connected with a driven gear, the driven gear is meshed with the driving gear, the upper end of the mixing cylinder is fixedly connected with a transmission ring, and the transmission ring is rotatably connected with the supporting piece. According to the wall scraping device, through the mixing cylinder, the first rotatingshaft, the driving motor, the driving gear, the driven gear and the stirring rod, the purpose of mixing the mixing cylinder with a large size is achieved, meanwhile, the stirring effect is improved,and through the supporting rod and the scraping rod, wall scraping is conducted on the inner wall of the mixing cylinder.

Owner:湖南童记三利和食品有限公司

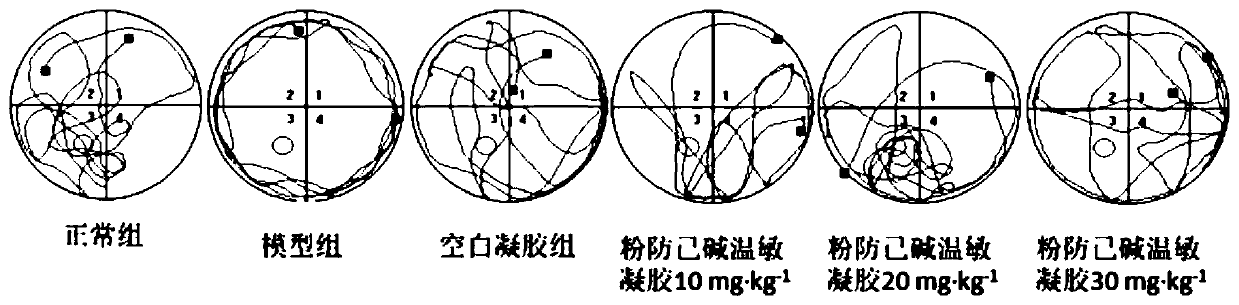

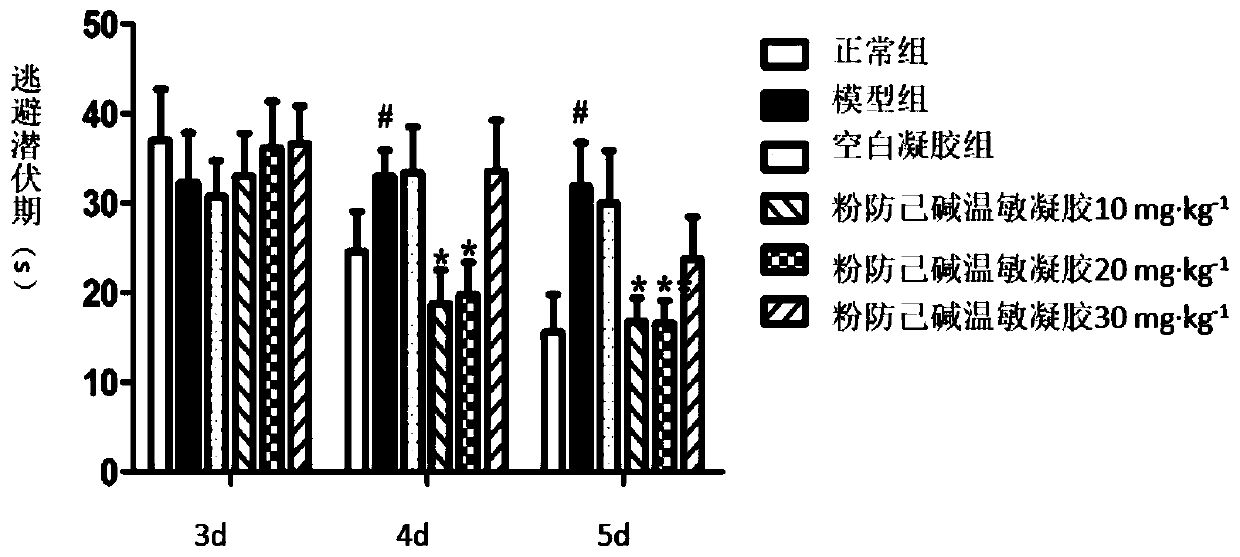

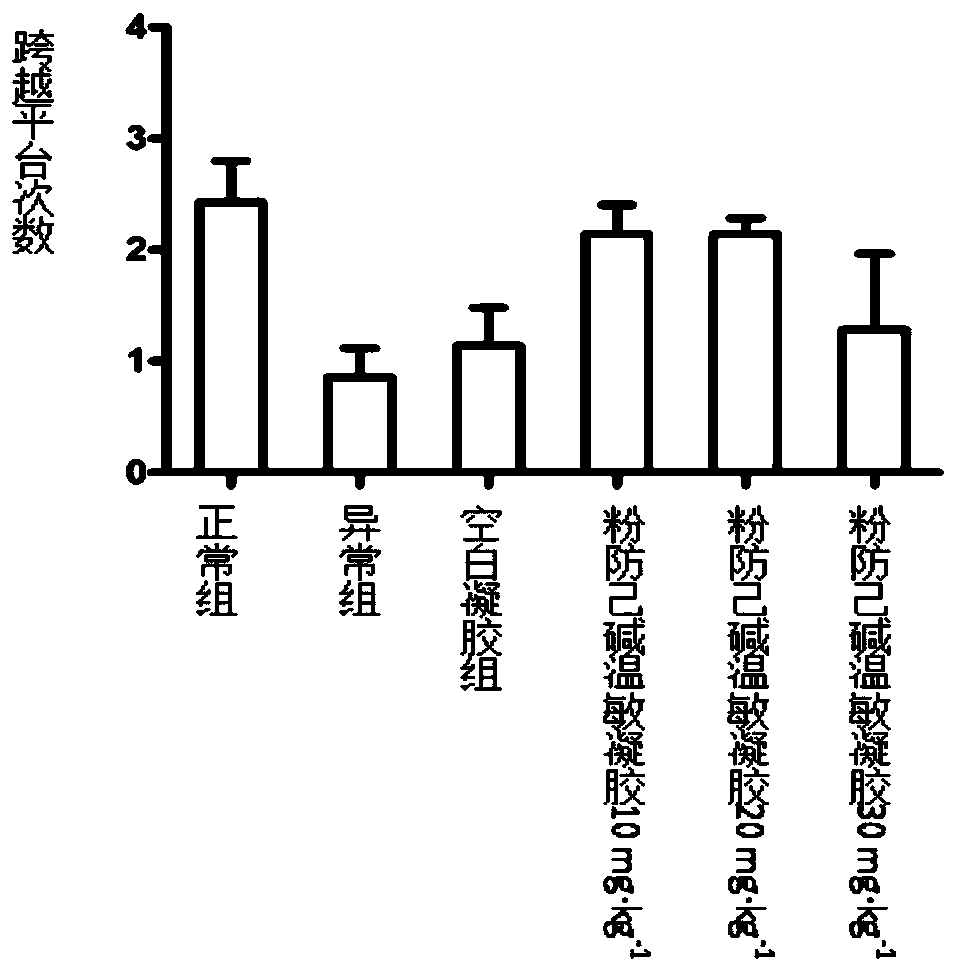

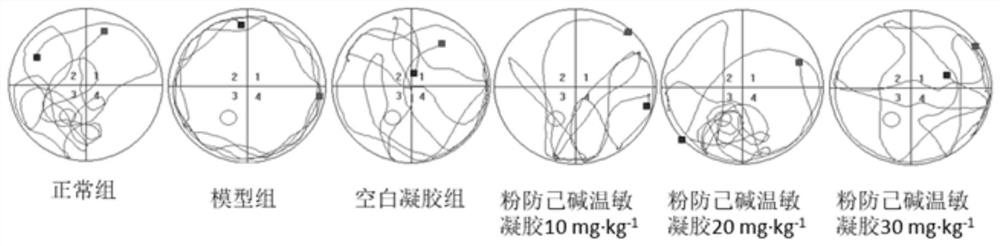

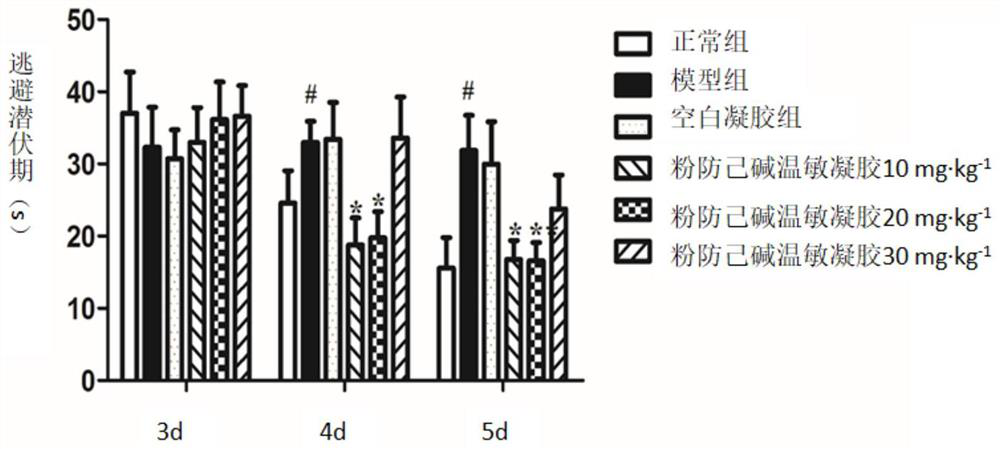

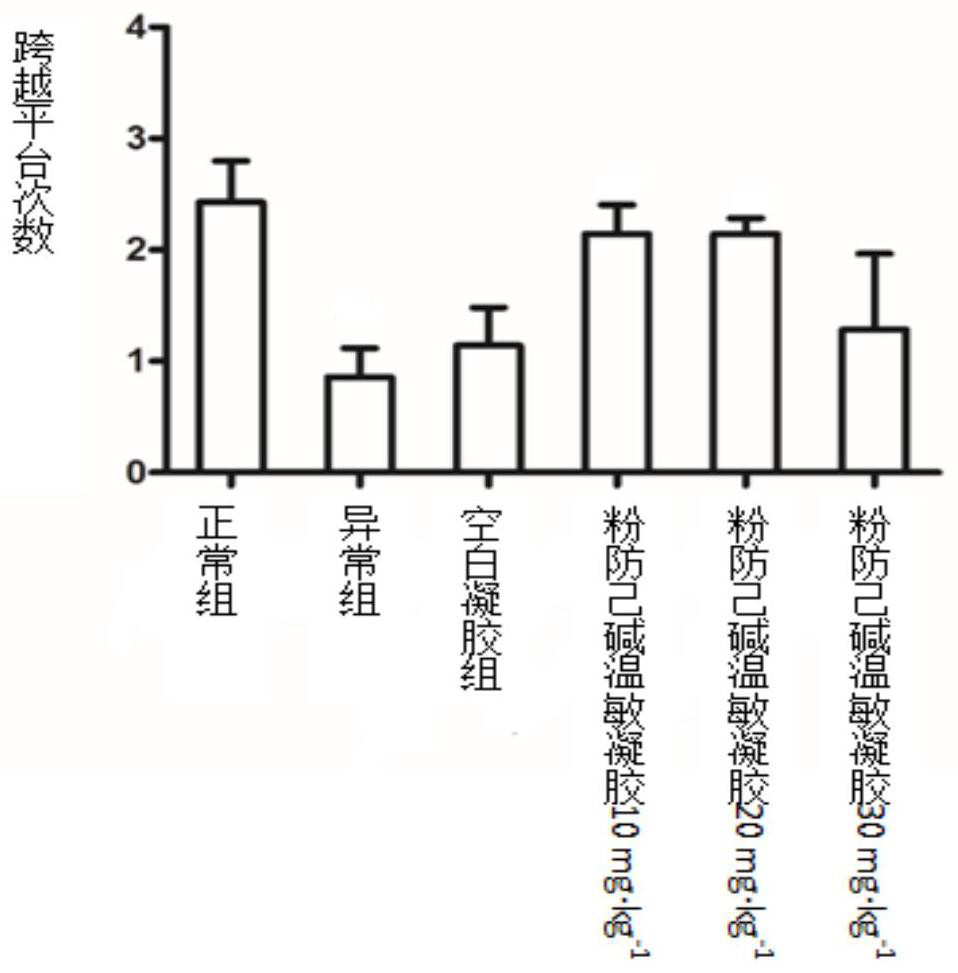

Application of tetrandrine and extraction method of tetrandrine

ActiveCN110179799AReduced average escape latencyEnhance the spirit of explorationOrganic active ingredientsNervous disorderMicrowaveMedicine

The invention discloses an application of tetrandrine, and an extraction method of the tetrandrine, in particular to an application of the tetrandrine to treatment of microwave radiation brain damageof mice, and the extraction method of the tetrandrine. The tetrandrine can notably reduce the escape latency period of the mice, improve the spatial learning memory capacity of the mice and reinforcethe exploration spirit and the autonomic activity behavior of the mice.

Owner:ACADEMY OF MILITARY MEDICAL SCI

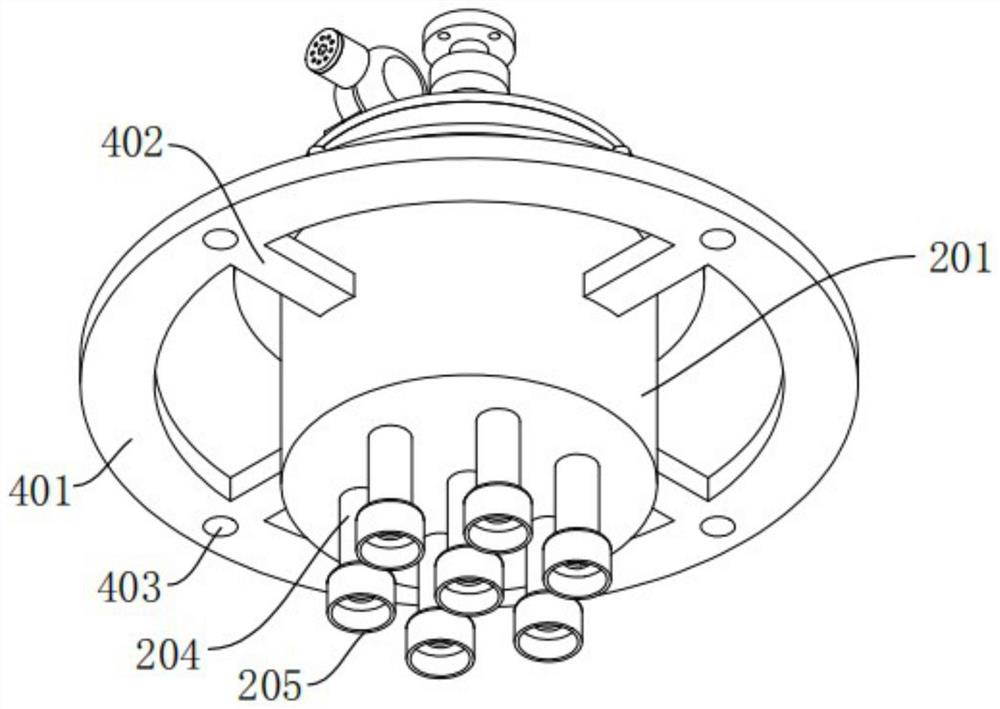

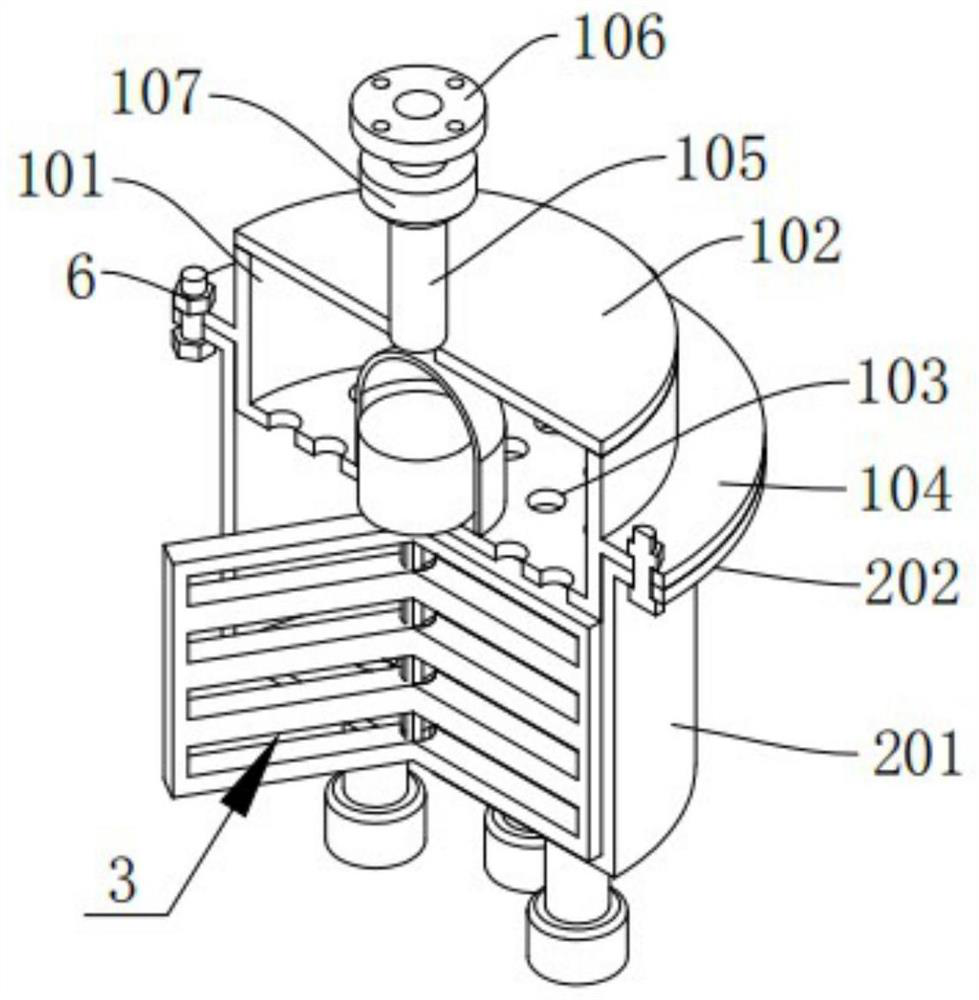

Group-III nitride crystal growing device

ActiveCN105113004AWith stirring effectStir wellPolycrystalline material growthFrom normal temperature solutionsNitrideGrowth velocity

The invention discloses a group-III nitride crystal growing device. The group-III nitride crystal growing device comprises a reaction kettle, wherein a crystal seed template is arranged in the reaction kettle; the reaction kettle is connected with a rolling driving device; the rolling driving device is used for driving the reaction kettle to rotate in the horizontal direction or a direction oblique to the horizontal direction. According to the group-III nitride crystal growing device, the disadvantage that N sources are not sufficient in a nitride crystal growing process of a traditional reaction device is effectively overcome, and the problems of N vacancies, poor crystal quality, low growth velocity and the like of nitride crystals can be effectively avoided.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV

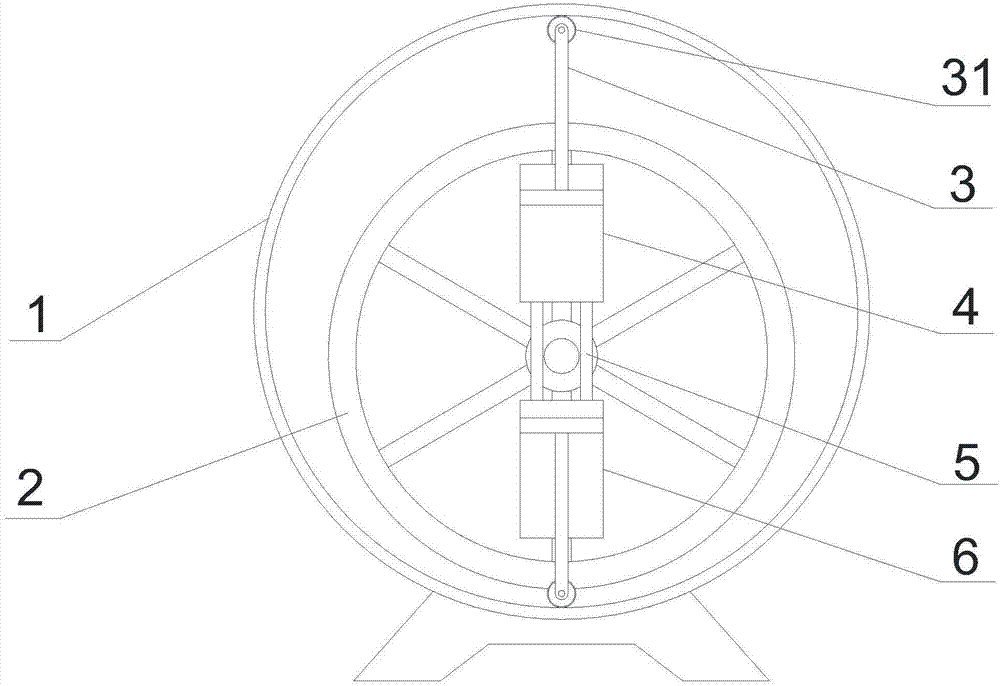

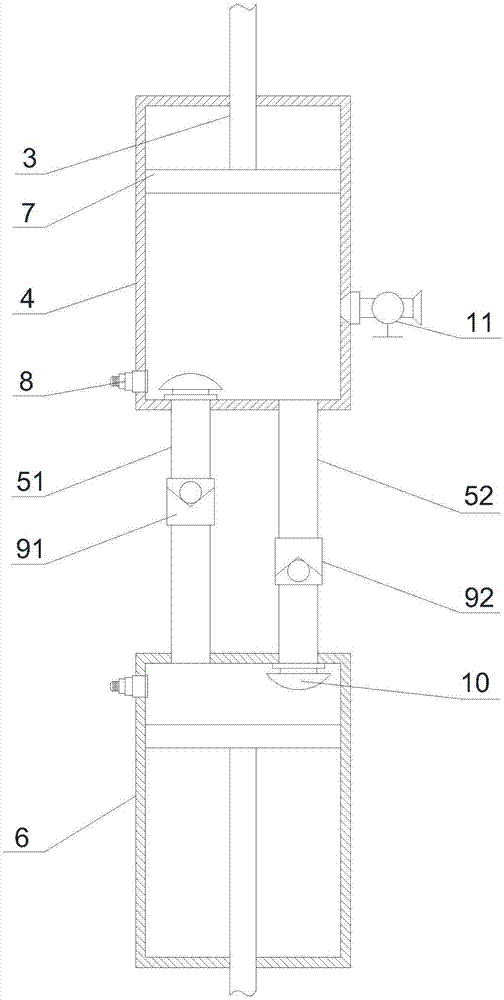

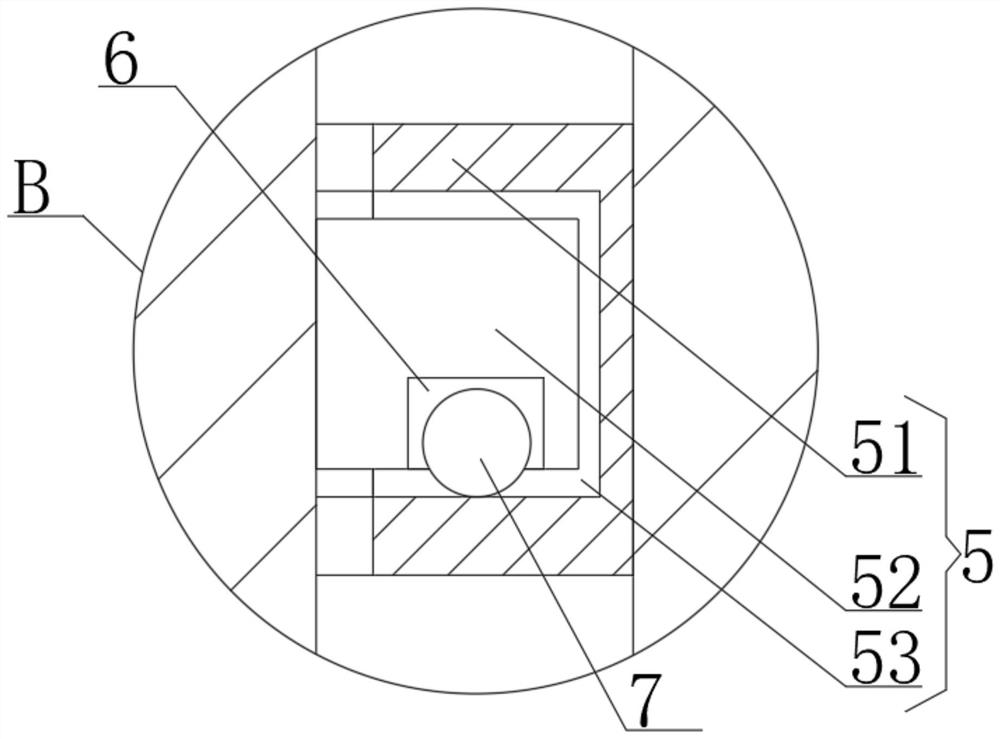

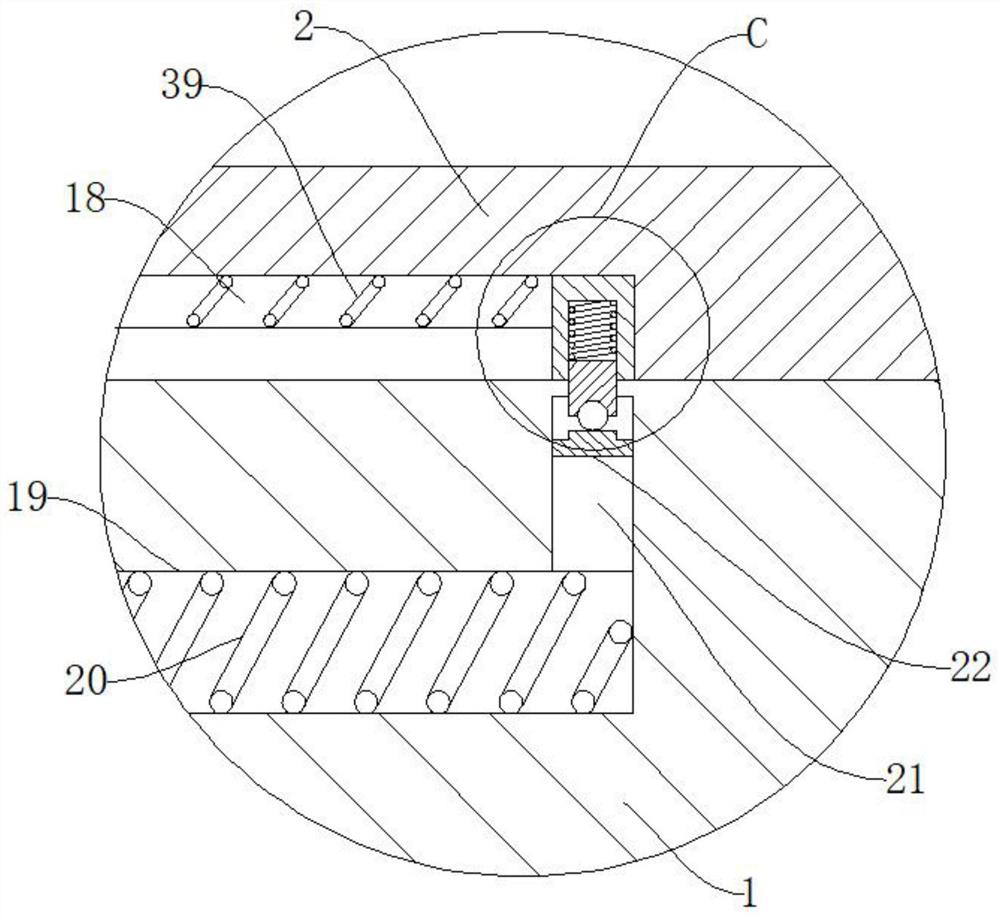

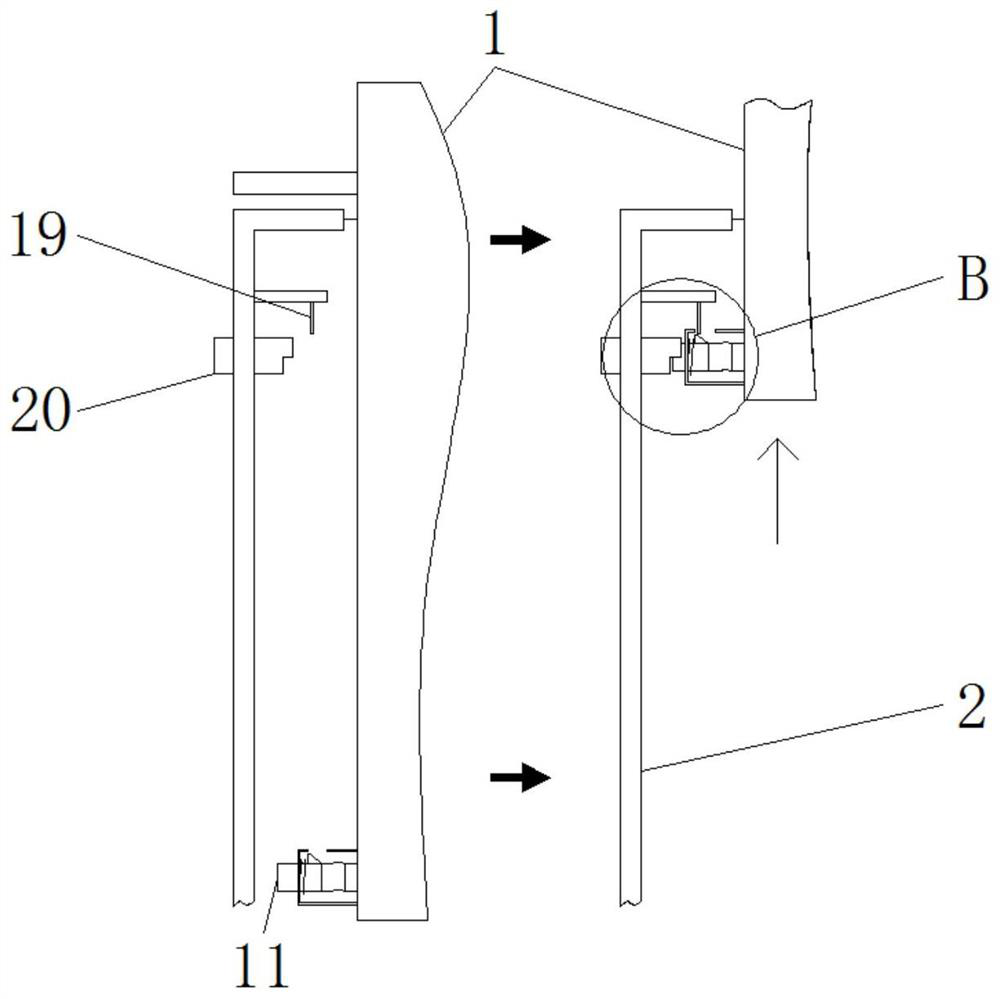

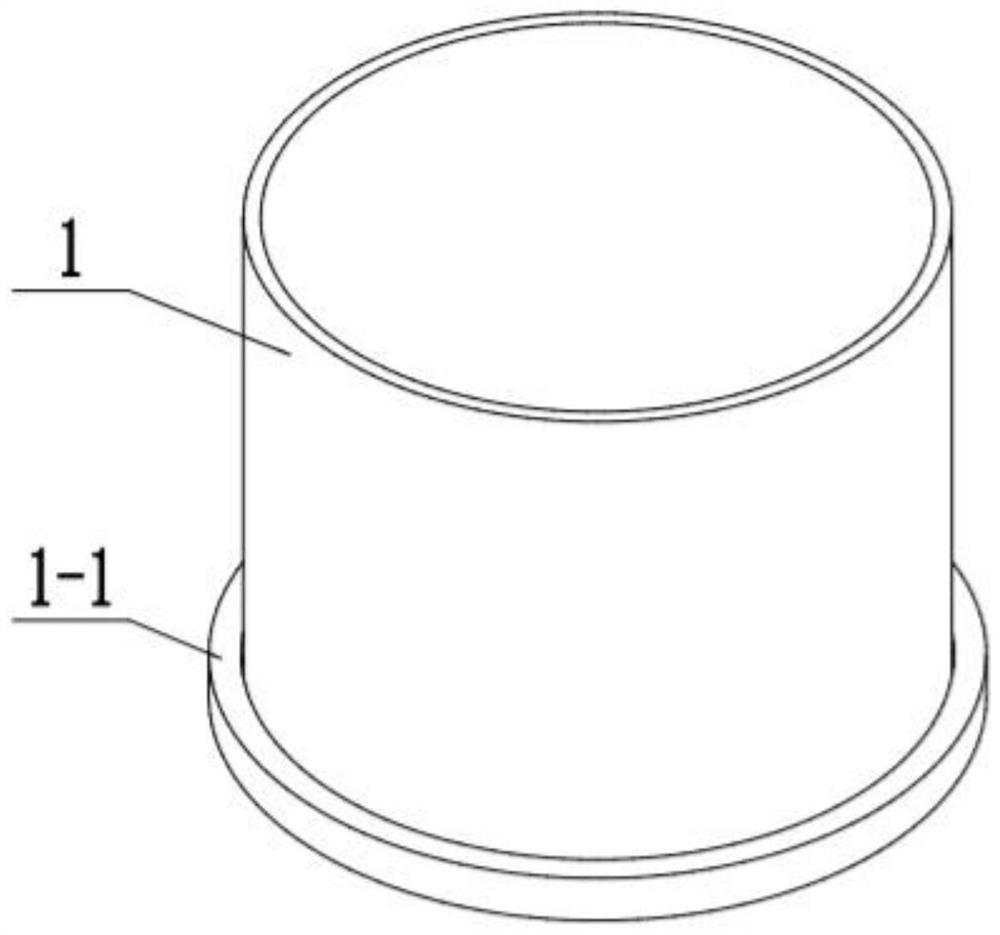

Improved structure of stirring device

InactiveCN107961703AWith stirring effectImprove the mixing effectRotary stirring mixersTransportation and packagingEngineering

Owner:绵阳正耀久生物科技有限公司

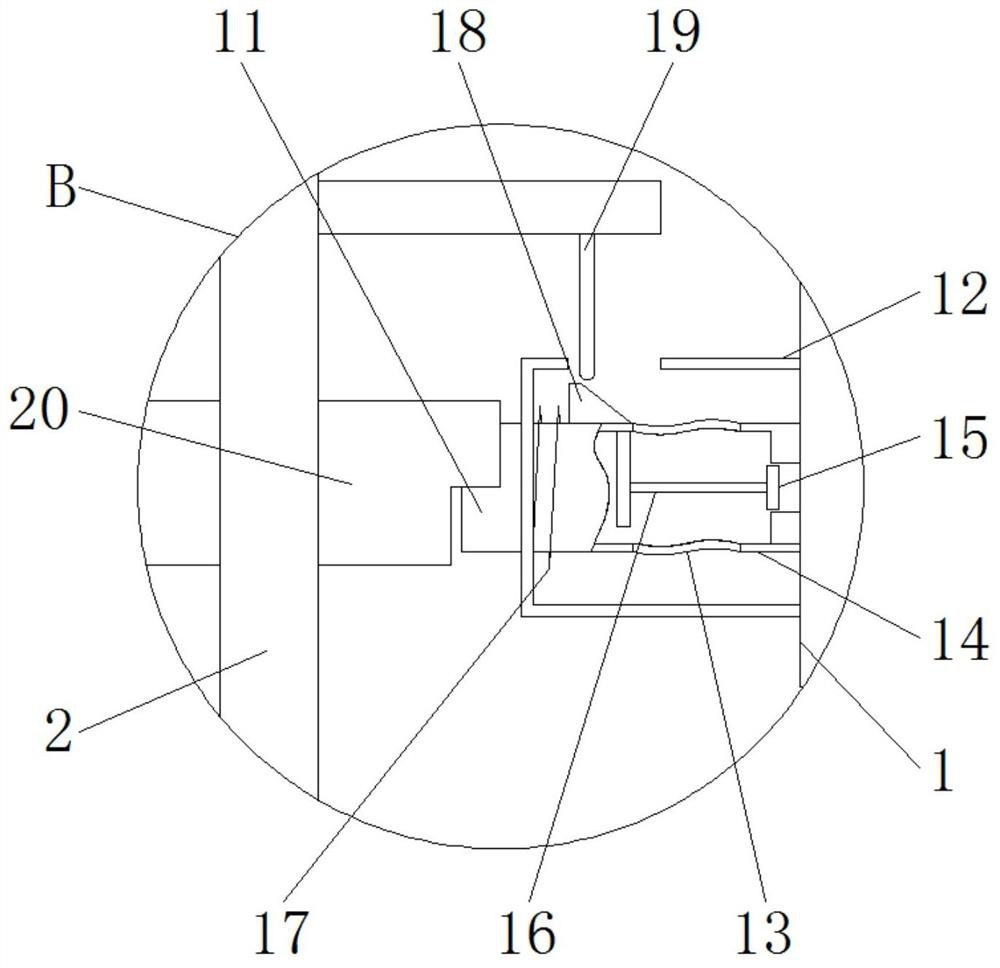

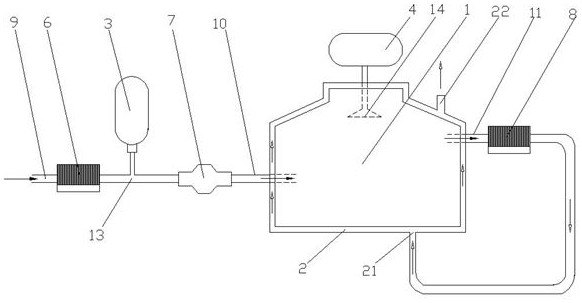

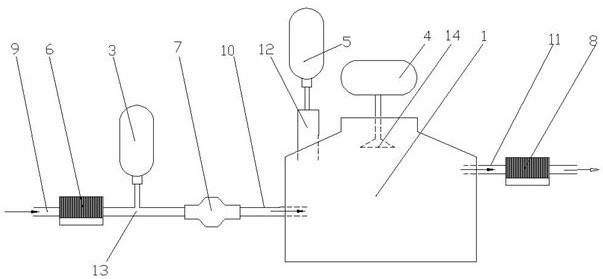

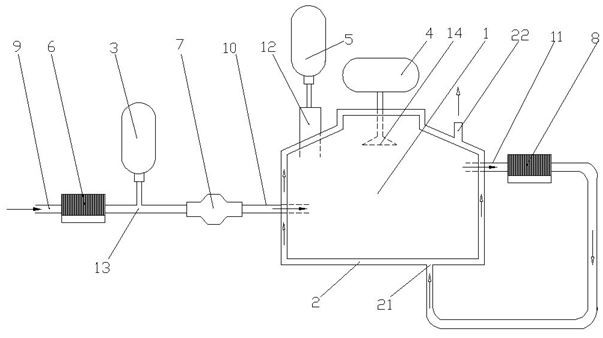

Mixed beverage production and processing equipment

ActiveCN110917974AMeet the needs of the expected concentrationNo wasteTransportation and packagingMixer accessoriesEngineeringProcess engineering

The invention belongs to the technical field of mixed beverage production, and discloses mixed beverage production and processing equipment. The equipment comprises a blending device, which comprisesa water distribution box and a material mixing box. A water pump is connected between the water distribution box and the material mixing box. A water spraying assembly is arranged in the material mixing box and is connected to the water outlet end of the water pump. The equipment also comprises a proportioning device. The inlet end of the proportioning device is connected to the blending device, the joint is provided with a second electromagnetic valve. The equipment further comprises a mixing device, which is connected to the outlet end of the proportioning device, and the joint is provided with a third electromagnetic valve. A backflow assembly is connected between the mixing device and the proportioning device. The equipment also comprises a controller. Through the technical scheme mentioned above, the provided equipment only needs one blending device and one proportioning device, the volume of the equipment is effectively reduced; at the same time, due to twice blending of the blending device, a basic beverage with an expected concentration can be prepared, and at the same time, the blending device is cleaned.

Owner:TIANJIN SHANHAIGUAN BEVERAGE CO LTD

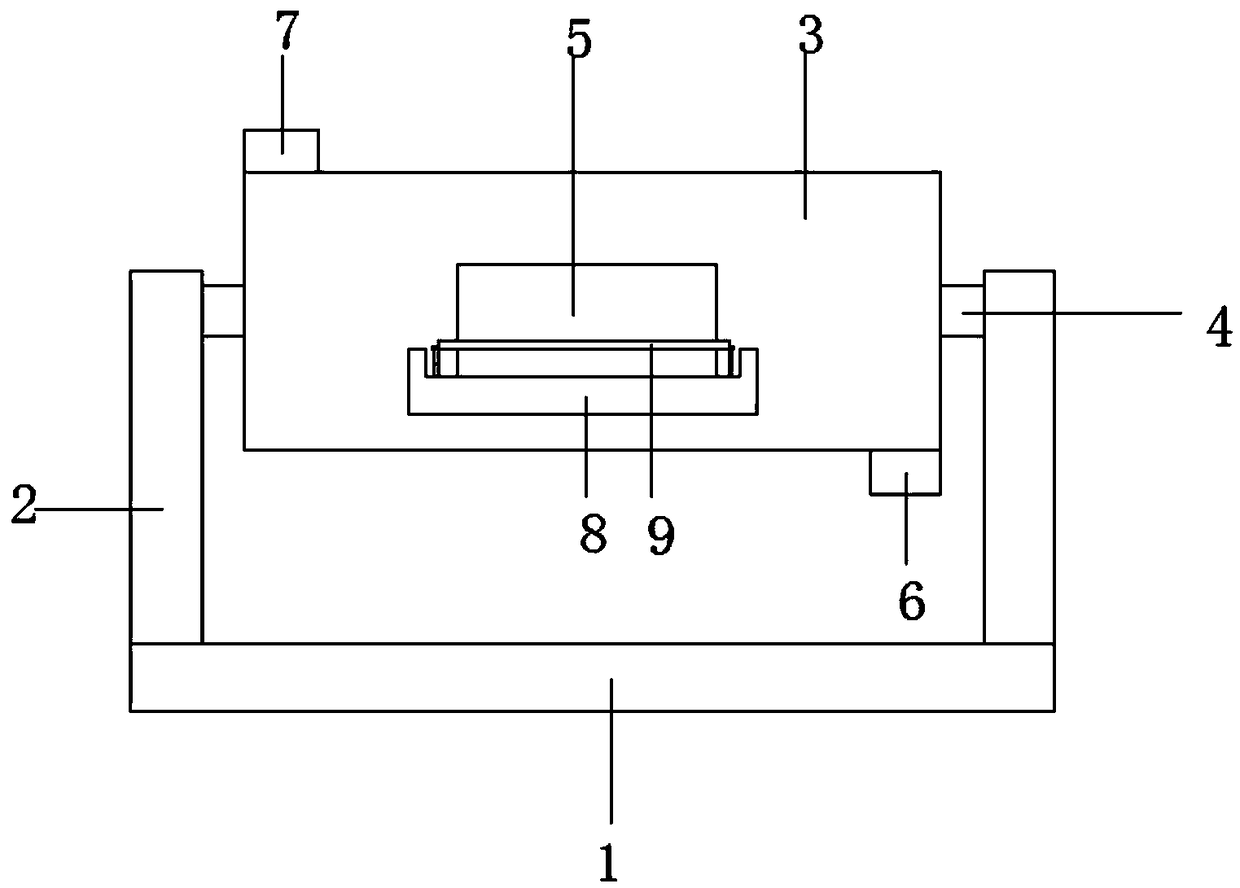

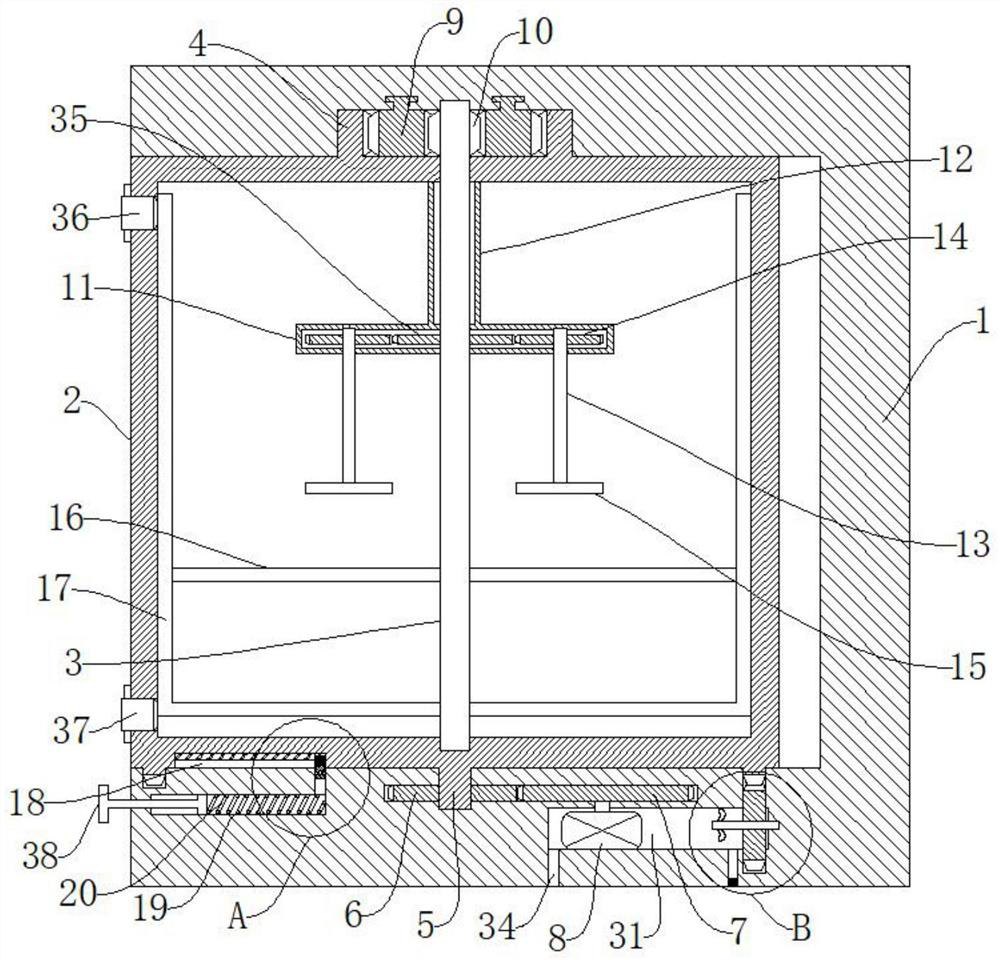

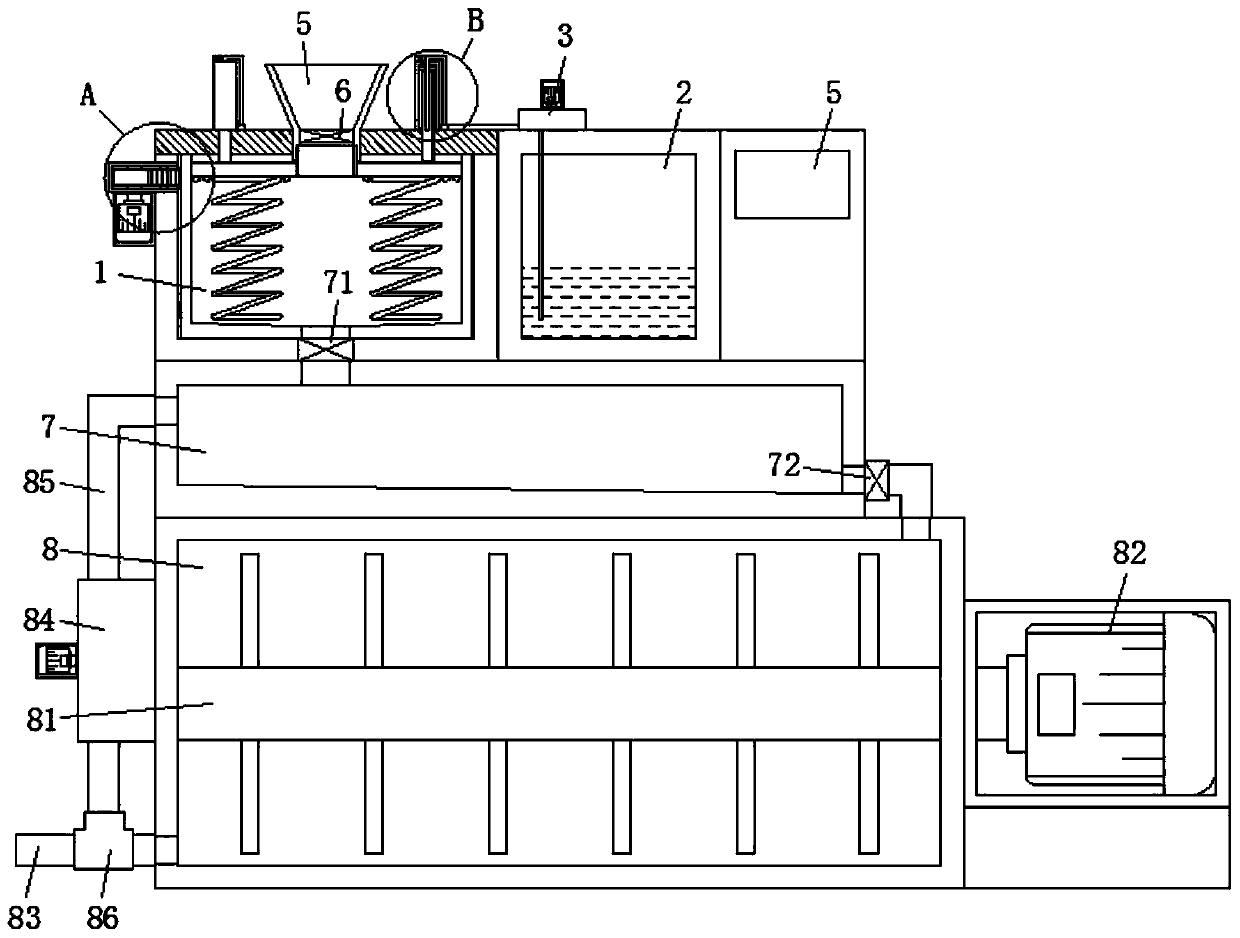

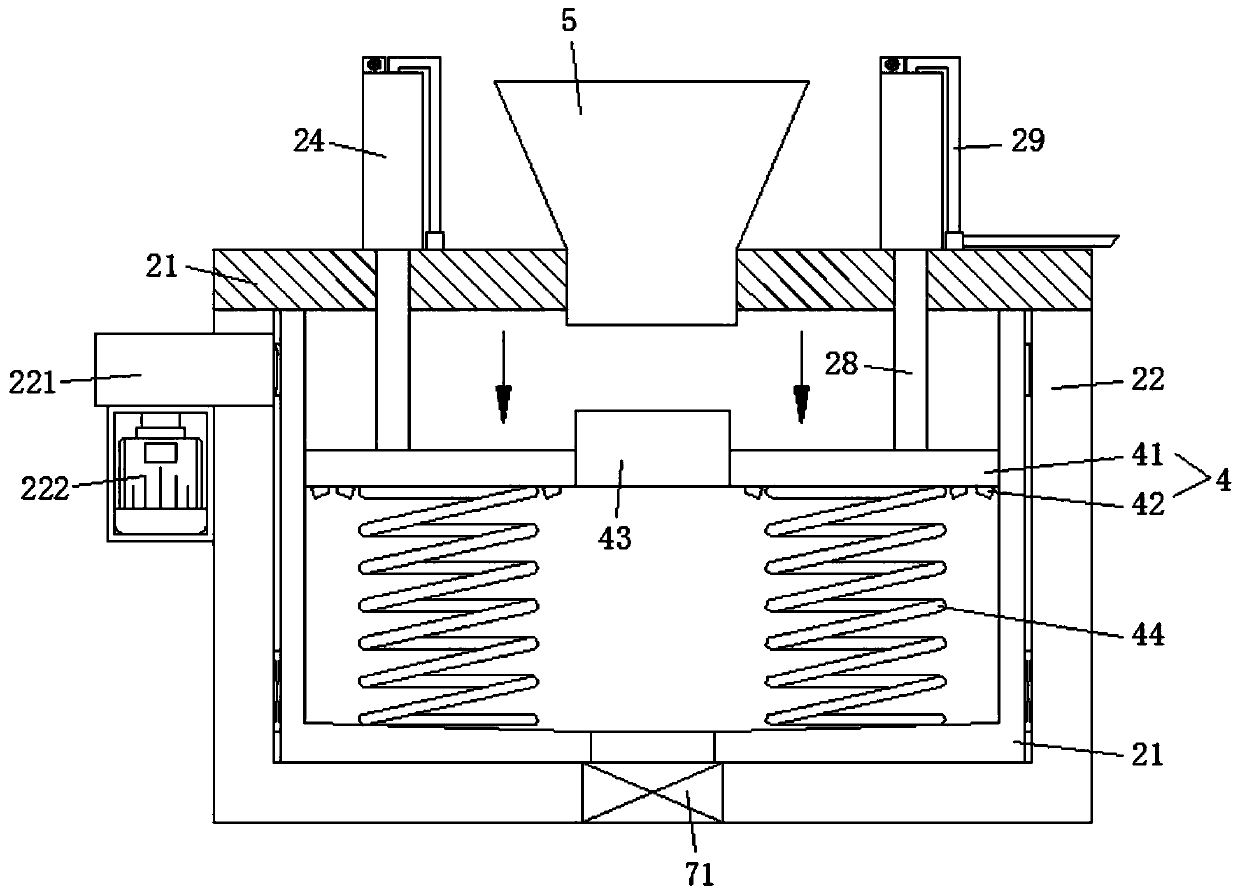

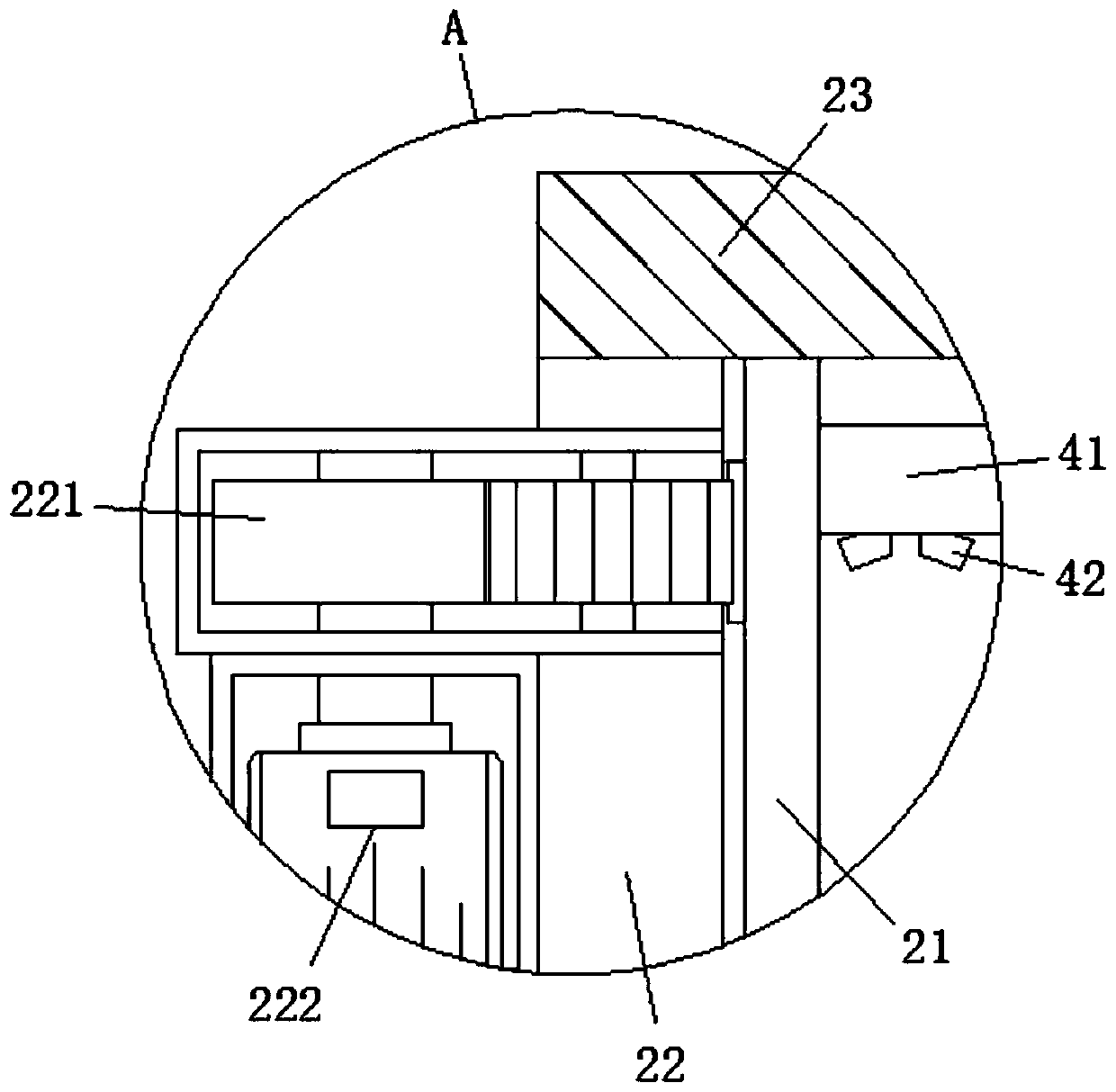

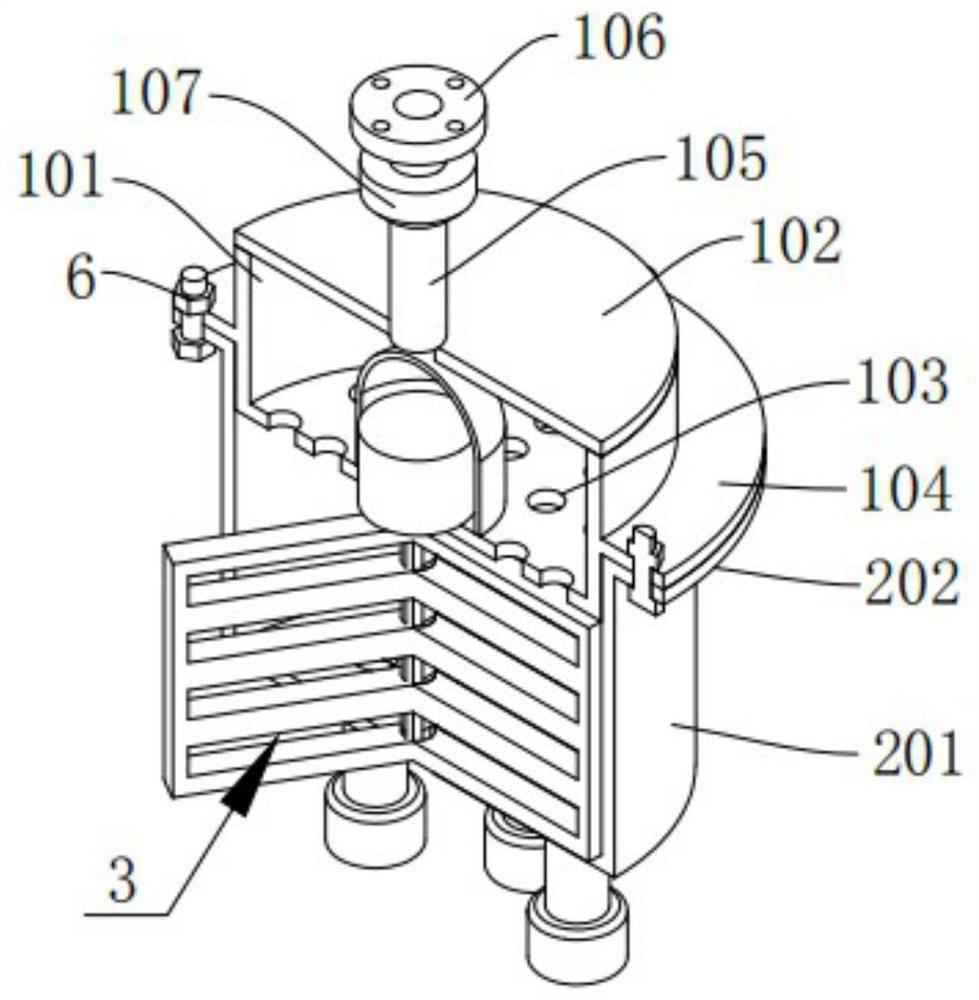

A kind of buried organic fertilizer biological fermentation device

ActiveCN111333445BEfficient mixingEfficient dischargeBio-organic fraction processingOrganic fertiliser apparatusAgricultural engineeringEnvironmental engineering

The invention discloses a buried organic fertilizer biological fermentation device comprising a fermentation tank vertically arranged in an outer-layer tank. A first transverse pipe and a second transverse pipe which are horizontally distributed are mounted on the back surface of the bottom of the fermentation tank; a horizontally-distributed discharging pipe is installed on the side of the top ofthe outer-layer tank, a notch matching the first transverse pipe is formed in the lower portion of the inner end of the outer-layer tank, the outer diameter of the first transverse pipe matches the inner diameter of the discharging pipe. A main shaft is rotatably installed in the center of the interior of the fermentation tank, and a stirring shaft is rotatably installed on the side edge of the main shaft. According to the buried organic fertilizer biological fermentation device, on the basis of the double-layer tank body structure, the fermentation tank on the inner layer can be driven by amotor to ascend or descend; meanwhile, efficient stirring of internal materials can be achieved through power of the same motor under transmission of a corresponding structure, and when the fermentation tank rises to a certain degree, the internal space of the tank body can correspondingly communicate with the discharging pipe, so that efficient discharging of the fermented materials is facilitated.

Owner:荆门华牧生物科技有限公司

Dense-phase semi-dry flue gas desulfurization device and method thereof

InactiveCN112844002AReduce concentrationHigh desulfurization rateGas treatmentDispersed particle separationFlue gasProcess engineering

The invention discloses a dense-phase semi-dry flue gas desulfurization device and a method thereof. The dense-phase semi-dry flue gas desulfurization device comprises a desulfurization tower, a first dust remover, a second dust remover, a flue gas pipeline, a desulfurizer raw material tank and a water tank, wherein the two sides of the desulfurization tower are connected with a gas inlet pipe and a gas outlet pipe respectively, the flue gas pipeline is connected with the first dust remover, the first dust remover is connected with a gas inlet pipe of the desulfurization tower through two horizontal ports of a three-way pipe, the other port of the three-way pipe is connected with a desulfurizer raw material tank, a preheater is arranged between the gas inlet pipe of the desulfurization tower and the three-way pipe, a spray head is arranged at the top end in the desulfurization tower, and the spray head is connected with a water tank outside the desulfurization tower through a water pipe. A gas outlet pipe of the desulfurization tower is connected with a second dust remover. According to the dense-phase semi-dry flue gas desulfurization device and the method thereof provided by the invention, the desulfurization device and process are improved, and the desulfurization tower interlayer and the buffer filler are arranged, so that the desulfurization rate can be improved, and the wall wetting phenomenon can be reduced.

Owner:江西新金叶实业有限公司

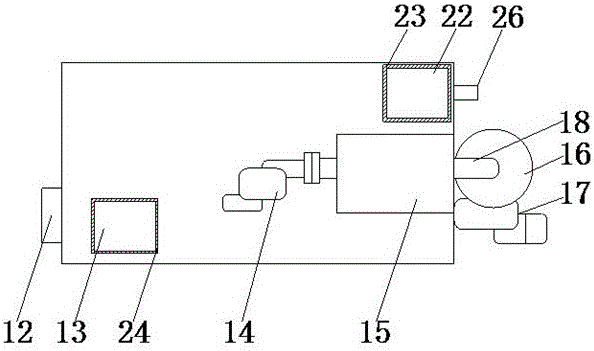

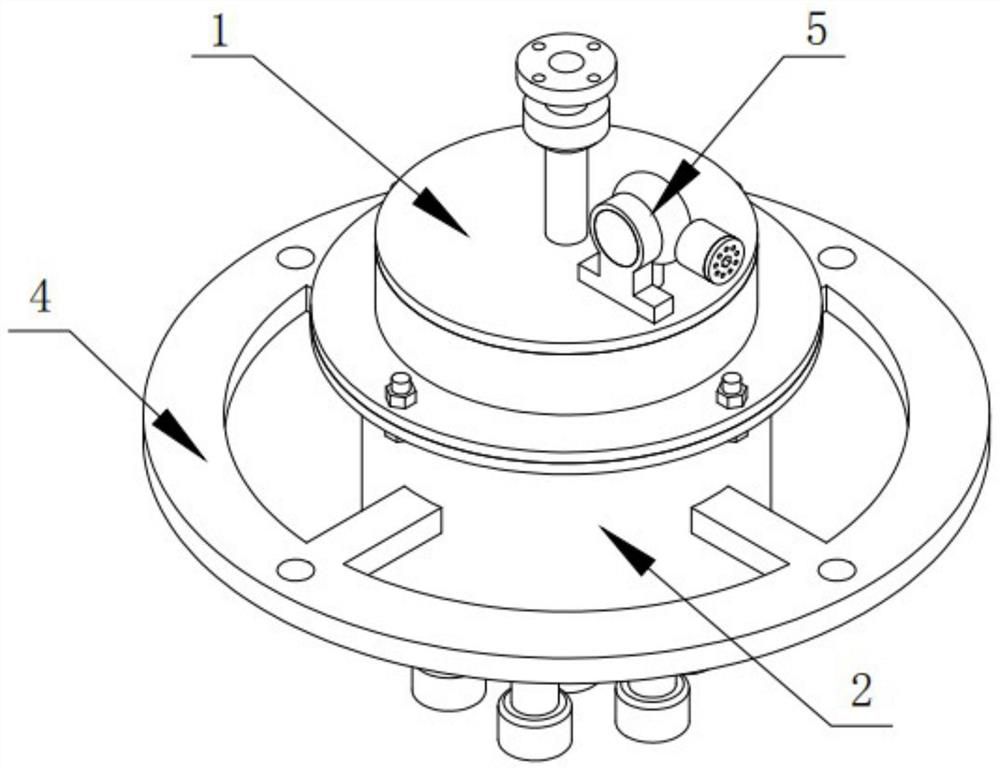

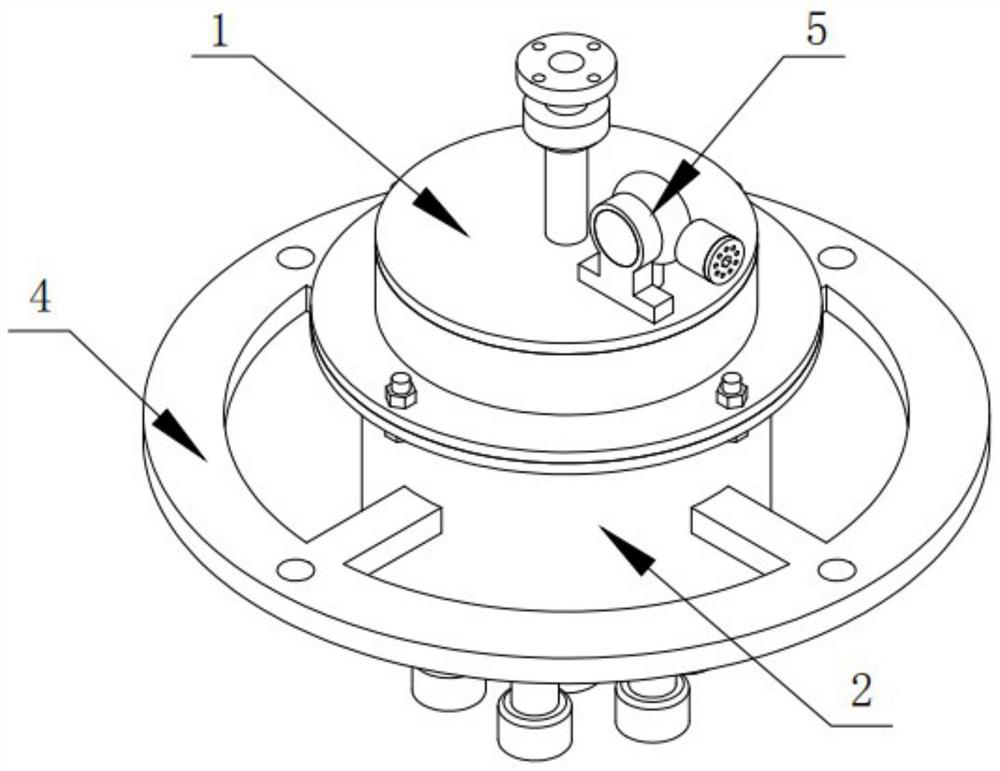

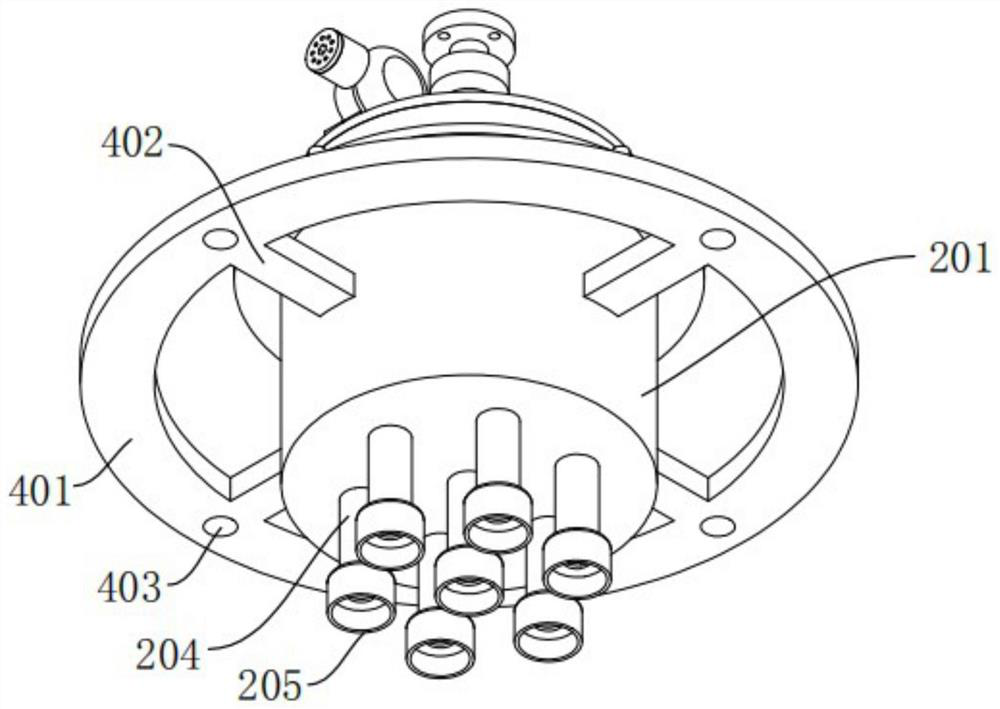

Multi-layer liquid distribution device and method of falling-film-type reboiler

The invention discloses a multi-layer liquid distribution device of a falling-film-type reboiler. The multi-layer liquid distribution device comprises a first-layer liquid distribution mechanism and asecond-layer liquid distribution mechanism, wherein the first-layer liquid distribution mechanism comprises a first cylindrical shell body, an upper cover plate and a liquid inlet pipe. According tothe multi-layer liquid distribution device, the uniformity of the liquid supplied to the falling-film-type reboiler can be ensured to be good; liquid in a liquid supply system can be prevented from being polluted, the bad phenomenon of liquid leakage at the joint of the device and the falling-film-type reboiler can be effectively prevented, more importantly, the situation that the liquid distribution is uneven, bias current is generated, a falling film pipe is prone to coking, and even the bad phenomenon of dry wall of local falling film pipe occurs can be avoided, the defect that a traditional liquid distributor is prone to scale formation and blockage can be overcome, the purpose that liquid with good uniformity quickly enters the falling-film-type reboiler can be achieved, the work efficiency is effectively improved, installation is convenient, effective fixing can be achieved, and therefore it is guaranteed that work performance is stable.

Owner:WUXI CHEM EQUIP CO LTD

Application of tetrandrine and extraction method of tetrandrine

ActiveCN110179799BReduced average escape latencyEnhance the spirit of explorationOrganic active ingredientsNervous disorderTetrandrinBrain damage

The invention discloses an application of tetrandrine, and an extraction method of the tetrandrine, in particular to an application of the tetrandrine to treatment of microwave radiation brain damageof mice, and the extraction method of the tetrandrine. The tetrandrine can notably reduce the escape latency period of the mice, improve the spatial learning memory capacity of the mice and reinforcethe exploration spirit and the autonomic activity behavior of the mice.

Owner:ACADEMY OF MILITARY MEDICAL SCI

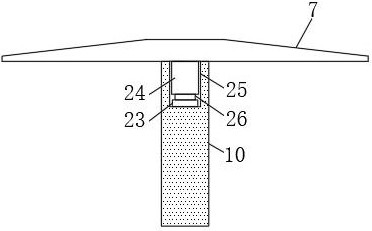

A rapid cooling container

ActiveCN110522275BImprove heat exchange efficiencyImprove cooling efficiencyDrinking vesselsThermodynamicsEngineering

The invention discloses a rapid cooling container, which comprises an outer shell and an inner tank fixedly connected with the inner wall of the upper end of the outer shell, the inner wall of the inner tank is screw-connected with a cover, and the outer shell and the inner tank jointly form a vacuum heat-insulating cavity. The bottom of the shell is provided with a liquid storage chamber, and the middle part of the upper end of the liquid storage chamber is embedded with a tubular pressure plate. The plate, the pressure plate and the liquid storage chamber together form a sealed space, and the sealed space is filled with superconducting liquid accounting for 1 / 2 of its volume. The middle part of the upper end of the piston plate is fixedly connected with a pressure magnet. Multiple heat exchange channels are provided. The advantage is that it can quickly cool down the boiling water introduced into the inner tank, and it can be drunk after waiting for a few minutes. In addition, it has a stirring effect, which can stir the soluble beverage of solid particles, accelerate the dissolution, and dissolve thoroughly and quickly.

Owner:新昌县知贝机械有限公司

Leather liming device

InactiveCN108998591AEasy to put inEasy to take outPre-tanning chemical treatmentLeather/skins/hides/pelt chemical treatment apparatusEngineeringDrive motor

The invention discloses a leather liming device. The leather liming device comprises a base, a liming cylinder and a driving motor. Support frames are arranged at the two ends of the base, and shaft holes are formed in the support frames. The liming cylinder is a cylindrical tube, and rotating shafts are arranged on the two end faces of the liming cylinder. The axes of the rotating shafts coincidewith the axis of the liming cylinder, and the liming cylinder is mounted on the support frames in a matched mode through the rotating shafts and the shaft holes, so that the axis of the liming cylinder is parallel to the base. A feeding door, a sewage draining exit and a medicine feeding inlet are arranged on the side faces of the liming cylinder. The driving motor is connected to the rotating shafts. The device can automatically perform rotary stirring, facilitates placement and removal of raw material leather, facilitates the addition of medicaments, facilitates the discharge of sewage, shortens consumed time of the liming process, saves manpower, and ensures environmental sanitation.

Owner:芜湖兴远新材料有限公司

Multilayer liquid distribution device and method for falling film reboiler

The invention discloses a multi-layer liquid distribution device of a falling film reboiler, which comprises a first-layer liquid distribution mechanism and a second-layer liquid distribution mechanism; the first-layer liquid distribution mechanism includes a first cylindrical shell and an upper cover plate and inlet tube. The present invention can ensure that the uniformity of the liquid supplied to the falling film reboiler is better, can avoid the liquid inside the liquid supply system from being polluted, and can effectively prevent leakage at the connection between the device and the falling film reboiler. It is especially important to avoid uneven distribution of liquid, resulting in partial flow, causing the falling film tube to coke easily, and even the occurrence of local dry wall of the falling film tube, which can make up for the traditional liquid distributor itself that is easy to scale and The disadvantage of clogging can achieve the purpose of quickly entering the falling film reboiler with better uniformity of liquid, effectively improve work efficiency, facilitate installation, and be able to be effectively fixed, so as to ensure relatively stable work performance.

Owner:WUXI CHEM EQUIP CO LTD

A kind of three-group nitride crystal growth device

ActiveCN105113004BWith stirring effectStir wellPolycrystalline material growthFrom normal temperature solutionsEngineeringCrystal growth

The invention discloses a group III nitride crystal growth device, which comprises a reaction kettle, the reaction kettle is provided with a seed crystal template, the reaction kettle is connected with a rolling driving device, the rolling driving device drives the reaction kettle to rotate, and the rolling driving device Drive the reactor to roll in the horizontal direction, or roll in the direction of an oblique angle with the horizontal direction. The invention effectively overcomes the shortcomings of insufficient N source in the process of growing nitride crystals in traditional reaction devices, and can effectively avoid problems such as N vacancies, poor crystal quality, and low growth rate in nitride crystals.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV

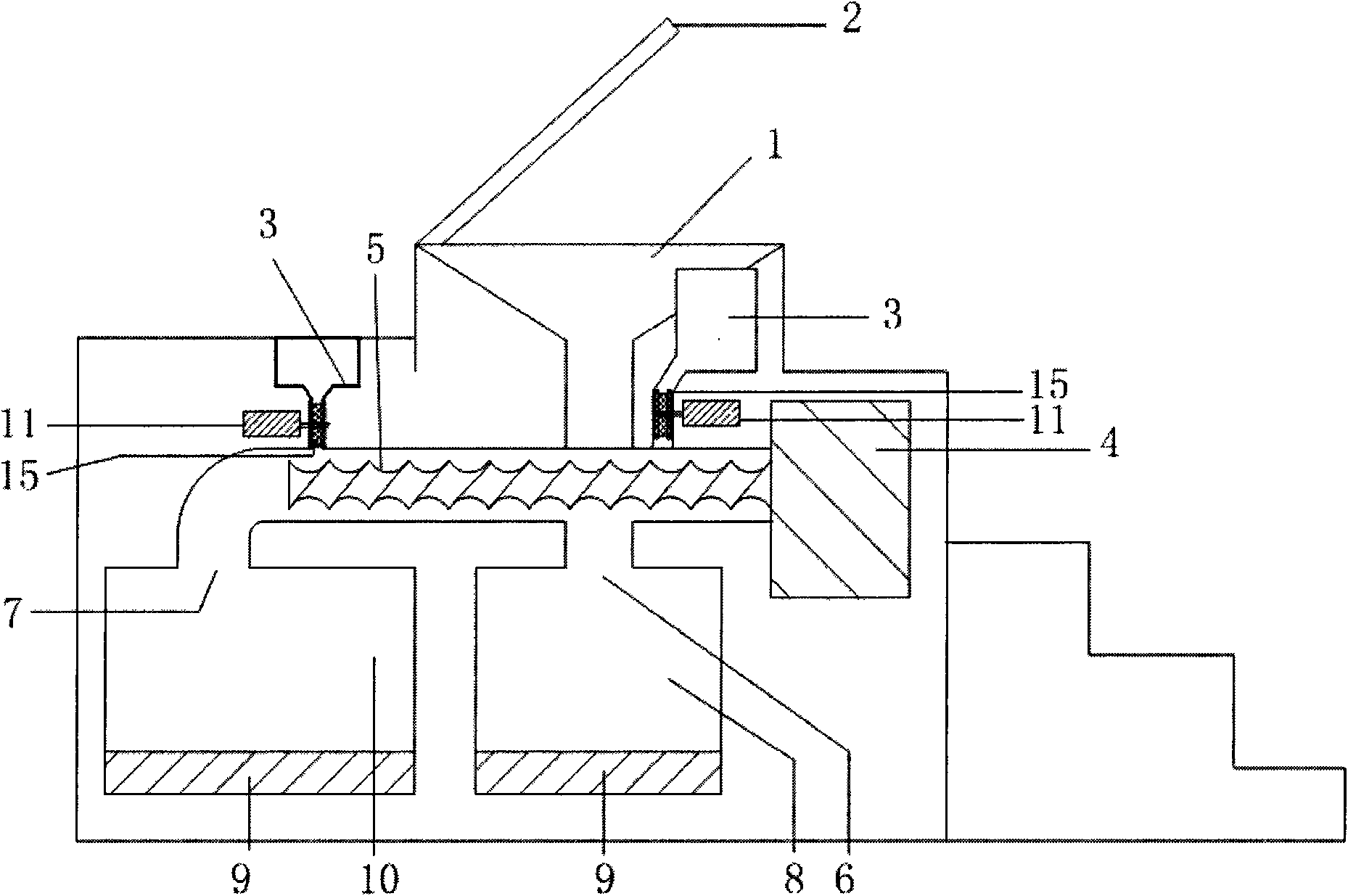

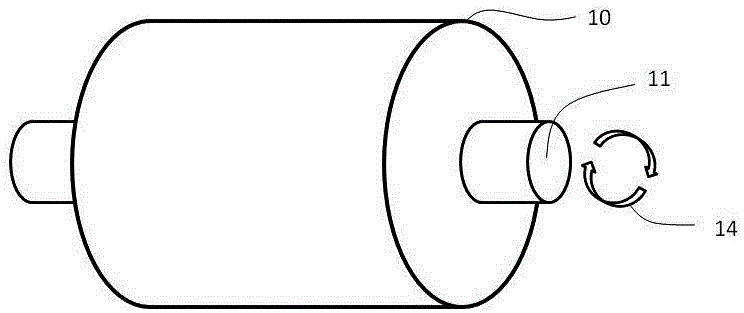

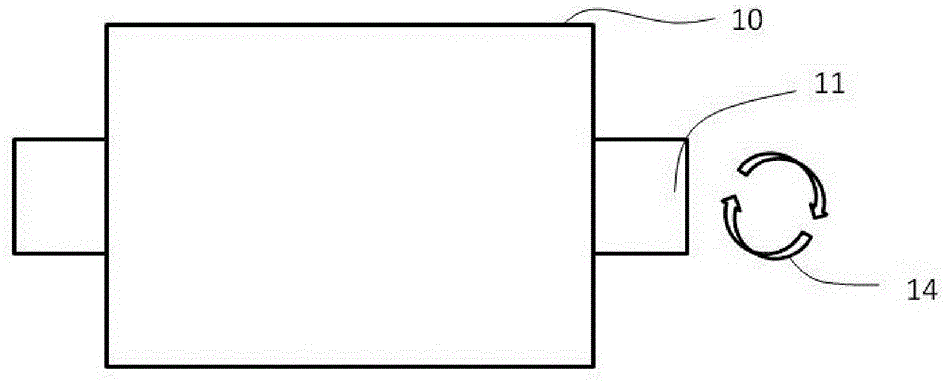

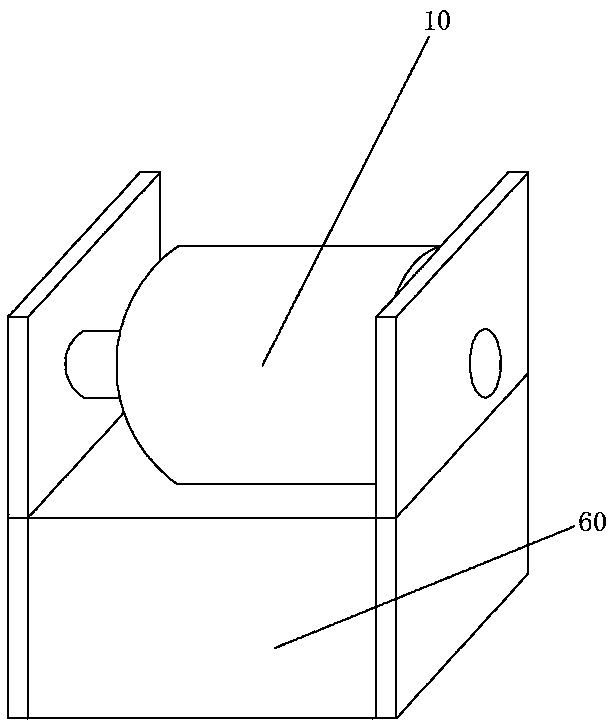

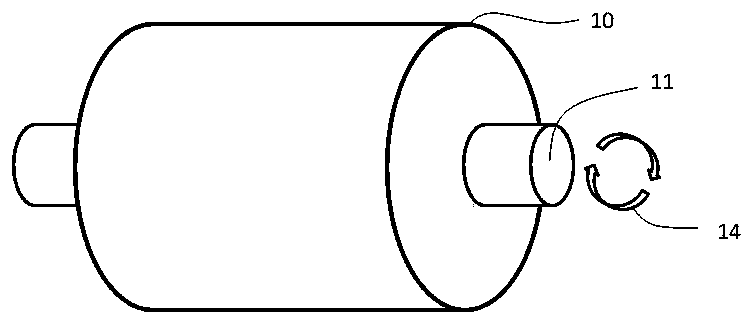

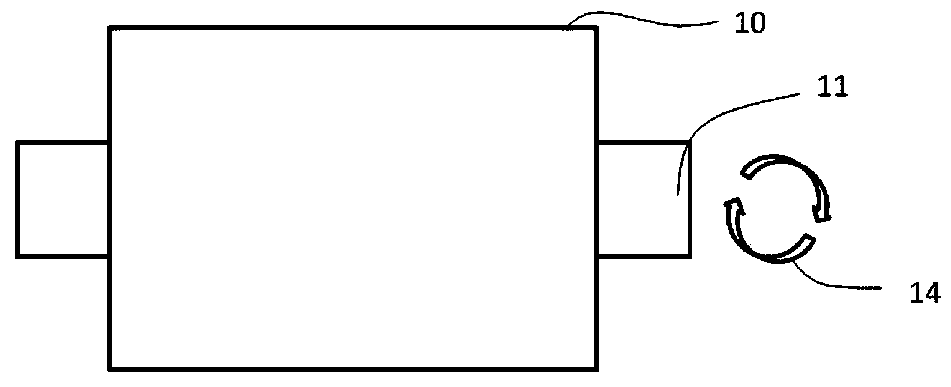

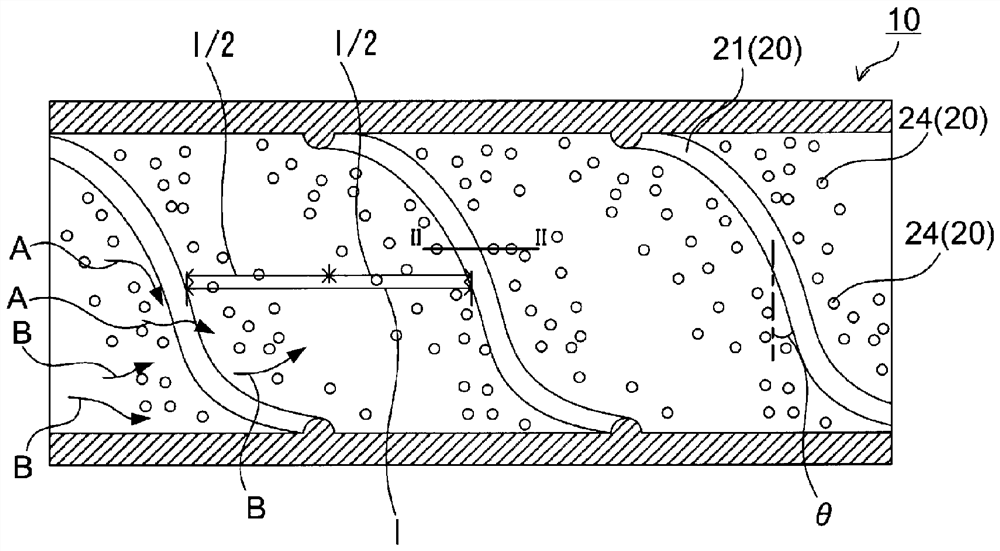

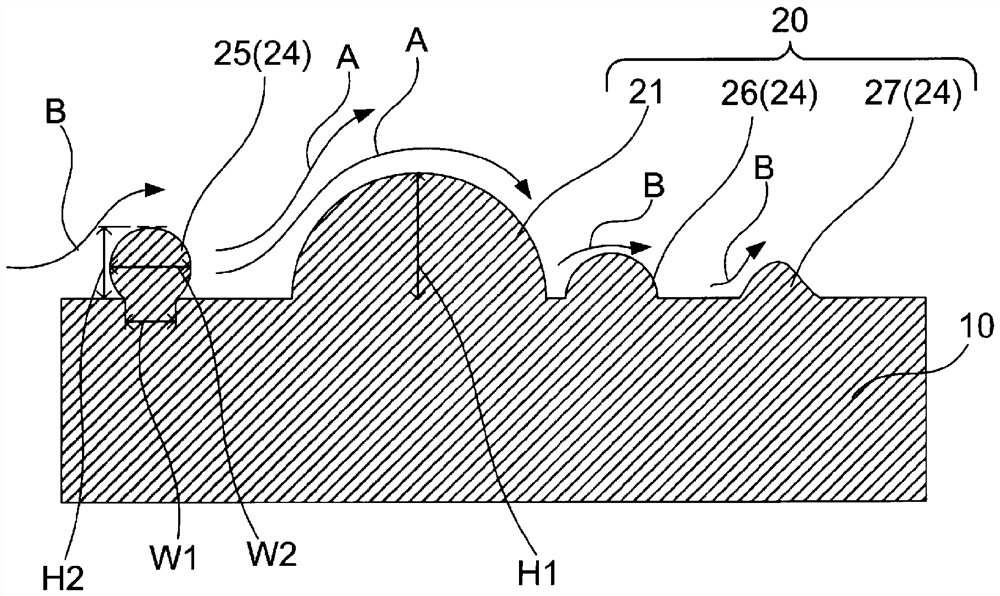

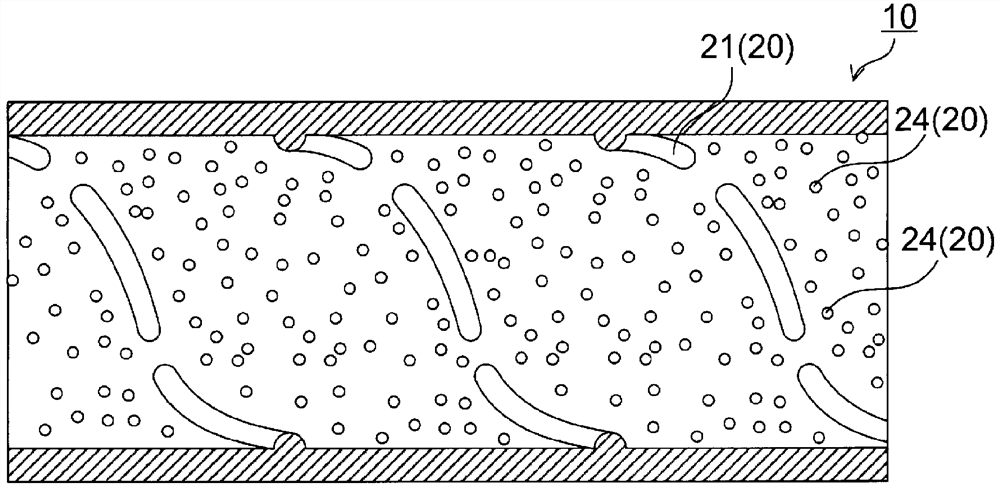

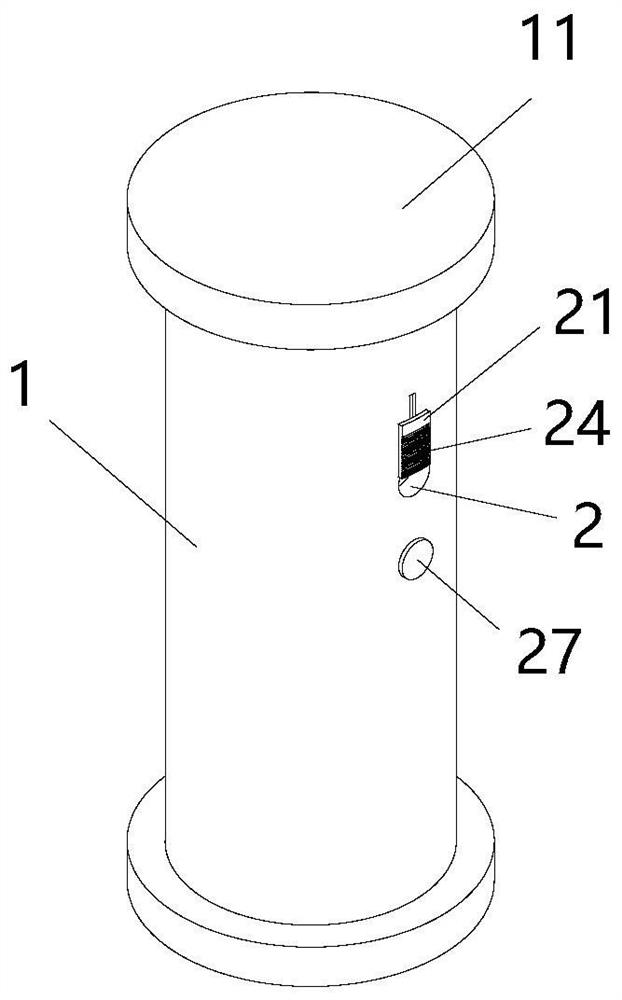

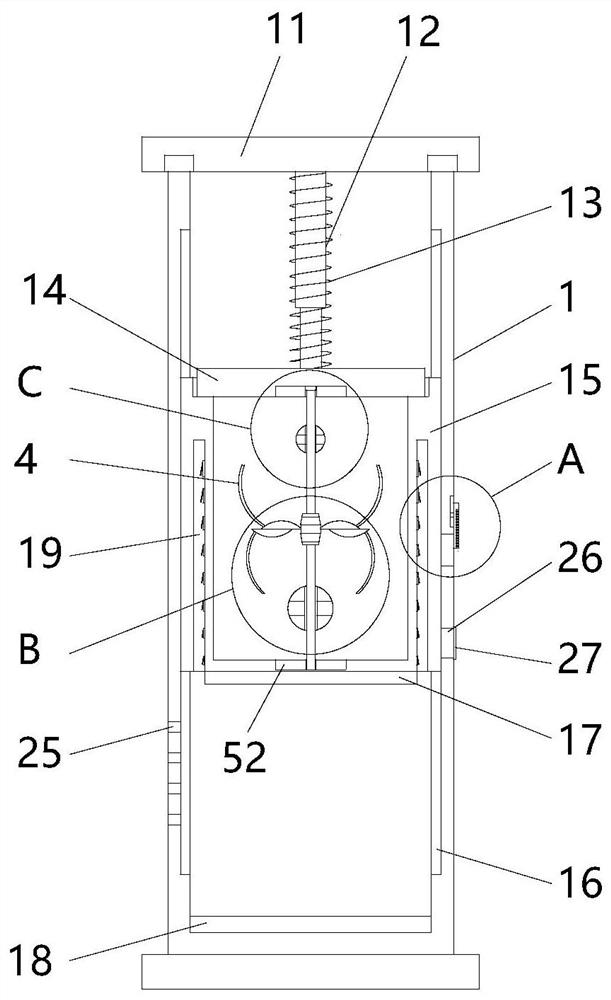

Thermal decomposition tube with fluid stirring element

PendingCN114829865AAvoid overheatingImprove heat transfer efficiencyThermal non-catalytic crackingIndirect heat exchangersPhysicsThermal decomposition

Provided is a thermal decomposition tube which has an effect of stirring a fluid in the tube and which is capable of preventing overheating due to the occurrence of laminar flow. This thermal decomposition tube (10) provided with stirring elements (20) is configured in such a manner that one or more fluid stirring elements protrude inward on the inner surface of the tube, and the stirring elements comprise: protrusions (21) that extend along the inner surface of the tube and that protrude inward from the inner surface of the tube, and protrusions (24) that protrude inward from the inner surface of the tube and that protrude inward from the inner surface of the tube; the protrusions (24) protrude inward from the inner surface of the tube at the peripheral portions of the ridges. The peripheral portion of the ridge preferably includes the upstream side and / or the downstream side of the ridge in the direction in which fluid flows in the pipe.

Owner:KUBOTA LTD

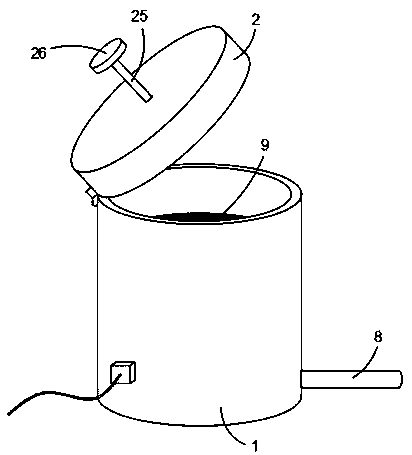

Intelligent extraction equipment for extracting wool fat from wool

InactiveCN111154550ATo achieve the effect of separation and precipitationEfficient separationFatty substance recovery/refiningFatty substance recoveryProcess engineeringMechanical engineering

The invention belongs to the technical field of wool fat, and particularly relates to intelligent extraction equipment for extracting wool fat from wool. The equipment comprises a liquid taking barrelbody and a barrel cover, and the barrel cover is rotationally connected to the upper end of the liquid taking barrel body. A driving chamber is arranged in the liquid taking barrel body. Two openingand closing mechanisms are sequentially arranged in the vertical direction. The two groups of opening and closing mechanisms penetrate through the inner wall of the liquid taking barrel body to the driving chamber and are fixedly connected with a moving plate. A liquid discharging mechanism is arranged on the liquid taking barrel body and fixedly connected with the bottommost opening and closing mechanism. A filter screen matched with the liquid taking barrel body is fixedly connected into the liquid taking barrel body and located between the topmost opening and closing mechanism and the barrel cover, and an extrusion mechanism is arranged on the barrel cover. The intelligent extraction equipment has the advantages that when the equipment is used, wool grease on wool can be completely leftin turbid liquid, waste is not likely to be caused, meanwhile, upper-layer grease and lower-layer pollutants can be effectively separated during separation and preparation, and the separation and subsequent extraction effects are improved.

Owner:YANTAI ENG & TECH COLLEGE YANTAI TECHNICIAN INST

Quick cooling container

ActiveCN110522275AImprove heat exchange efficiencyImprove cooling efficiencyDrinking vesselsEngineeringDissolution

The invention discloses a quick cooling container. The quick cooling container includes a shell and an inner container that is fixedly connected with the inner wall of the upper end of the shell; theinner wall of the inner container is in screwed connection with a sealing cover; a vacuum heat insulation cavity is formed between the shell and the inner container. A liquid storage cavity is formedin the bottom of the shell; a tubular pressurizing plate is embedded in the middle of the upper end of the liquid storage cavity; a piston plate is connected to the inner wall of the pressurizing plate in a sealed and sliding mode in the vertical direction, wherein the piston plate, the pressurizing plate and the liquid storage cavity jointly form a sealed space; the sealed space is filled with superconducting liquid accounting for the volume / volume of the sealed space; a pressurizing magnet is fixedly connected to the middle of the upper end of the piston plate, and a plurality of heat exchange channels are formed in the inner container in the circumferential direction. The cup has the advantages that boiled water guided into the inner container can be rapidly cooled and can be drunk after several minutes, in addition, the cup has a stirring effect, solid particle soluble beverage can be stirred, dissolution is accelerated, and dissolution is thorough, rapid and convenient.

Owner:新昌县知贝机械有限公司

An energy-saving and environment-friendly pulping equipment for papermaking and printing

ActiveCN110552222BAffect the blending effectEasy to cleanRaw material divisionPapermakingElectric machinery

The invention discloses an energy-saving and environment-friendly pulping device for papermaking and printing. The pulping device comprises a box body, the lower end of the box body is fixedly connected with a plurality of supporting feet, a discharge port is arranged at the middle and lower position of the side wall of the box body, the middle part of the upper end of the box body is provided with a feed inlet, the upper end of the box body is fixedly connected with a feed hopper at a position corresponding to the feed port, the lower end of the box body is fixedly connected with a motor, theend of the output shaft of the motor penetrates through the lower end of the box body and is fixedly connected with a rotating rod, the output shaft of the motor is rotatably connected with the box body, a plurality of crushing knives are arranged at equal intervals along the axial direction on the outer side of the rotating rod, a rotating plate is sleeved on the rotating rod, and the two are fixedly connected. The invention has reasonable structural design, can disperse materials into the inside of the box body, is beneficial to improving the pulping effect, can fully mix the materials, andcan also prevent the materials from adhering to the inner wall of the box body.

Owner:温州市金龙纸业有限公司

Music wine mixing device used in leisure bar

InactiveCN112322433AAchieve hybridAdd funAlcoholic beverage preparationEngineeringMechanical engineering

The invention relates to the technical field of wine mixing, and discloses a music wine mixing device used in a leisure bar. The device comprises an outer cylinder; a telescopic rod is fixedly installed at the center of the bottom of an outer cover; an inner cover is fixedly installed at the bottom of the telescopic rod; and an inner cylinder is arranged on the inner wall of the outer cylinder. According to the music wine mixing device used in the leisure bar, through the arrangement of an air inlet hole, a sound hole and a pased film, when a bartender holds the outer cylinder with hands to shake wine up and down, the inner cylinder vibrates in the opposite direction inside an outer cylinder cavity, mixing of mixed wine and ice blocks is achieved, and when the inner cylinder is relativelyand rapidly pressed down in the outer cylinder cavity, a vibration effect is formed on air at the bottom in the outer cylinder cavity in a short time, so that the pasted film is driven to vibrate through vibration air flow, crisp and melodious music is played from the sound hole, the bartender has more fun in the wine mixing process can be increased, music with a certain rhythm can be played, a certain atmosphere is generated in the leisure static bar, and auditory and visual enjoyment is brought to customers.

Owner:赵迎迎

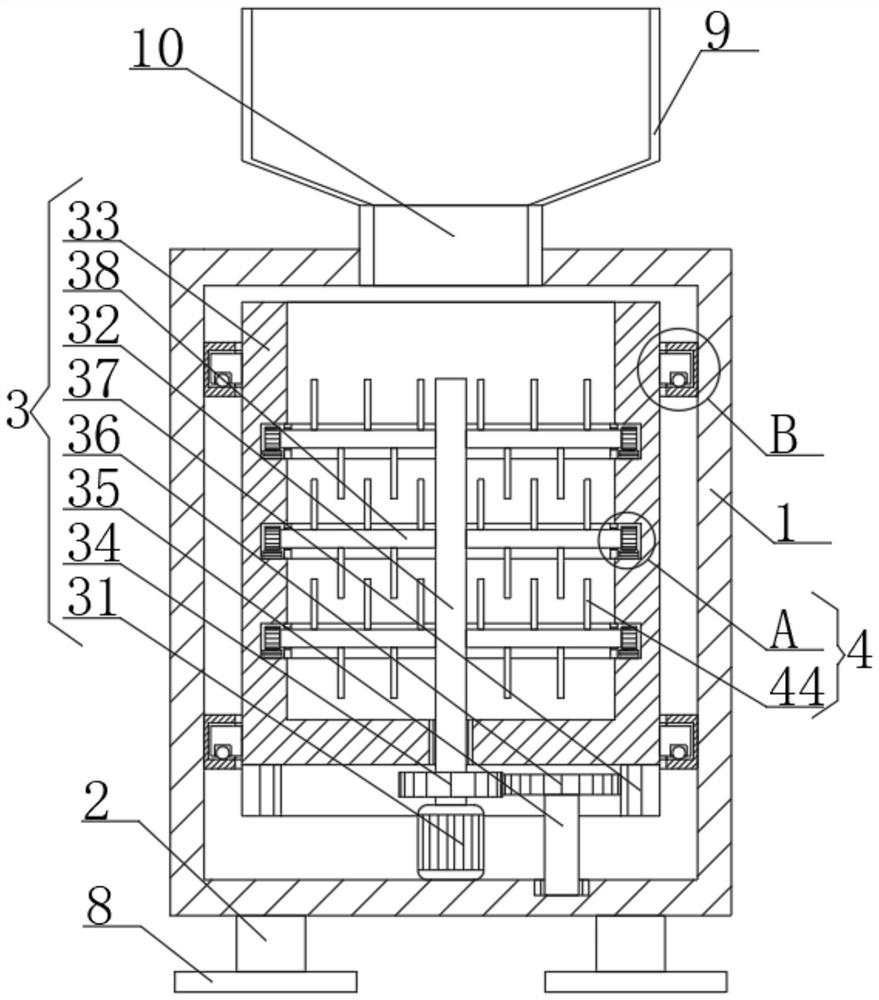

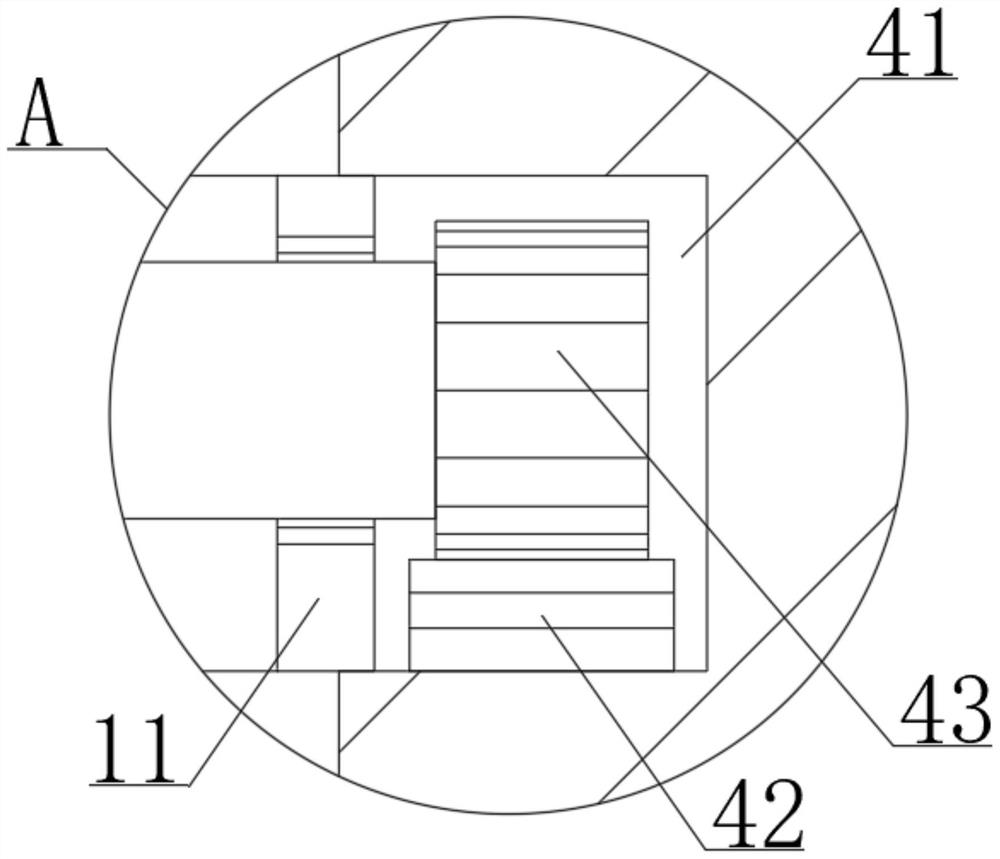

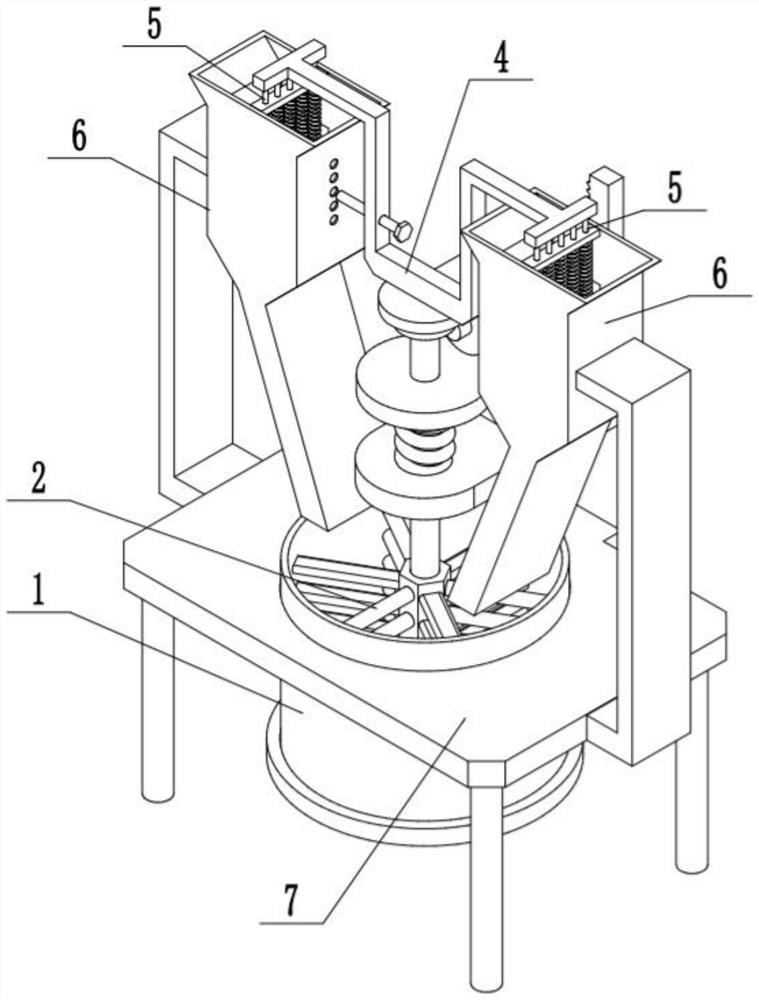

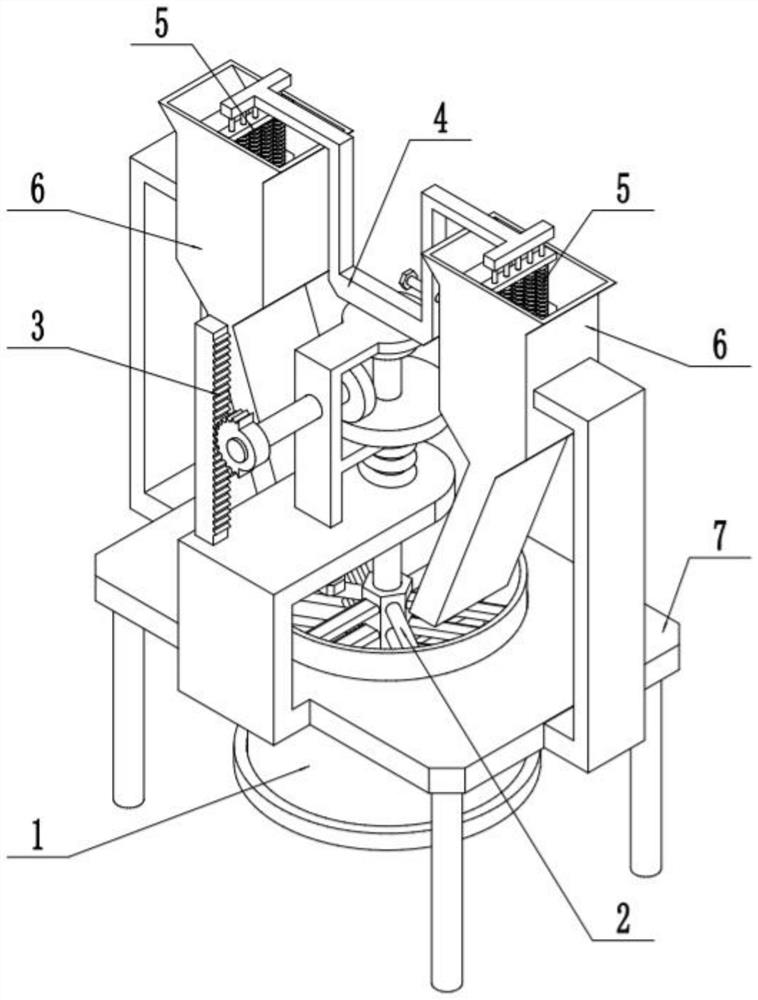

A kind of compound fertilizer and its production device and production method

ActiveCN110756102BQuality improvementWith stirring effectShaking/oscillating/vibrating mixersTransportation and packagingPhosphateReciprocating motion

A kind of composite fertilizer and its production device and production method of the present invention, in this composite fertilizer, each raw material comprises 50 parts by weight of urea, 20 parts of ammonium phosphate, 30 parts of potassium chloride, 5 parts of zinc stearate, zeolite 4 parts of powder, 4 parts of phosphate rock powder, 3 parts of seaweed powder and 2 parts of potassium dihydrogen phosphate. The production method is as follows: Step 1: put the raw materials for producing compound fertilizer into two raw material boxes respectively; Step 2: connect the agitator to the power supply and start it; Carry out reciprocating movement in the up and down direction; Step 4: When the agitator moves upwards, press the transmission linkage frame and control the two feed controllers through the linkage frame to discharge the raw materials in the two raw material boxes; Step 5: The raw materials pass through After the raw material box enters the interior of the sub-mixing drum, the compound fertilizer described above is obtained after being stirred by the agitator. The device includes a mixing drum with an open top, an agitator, a rack, a linkage frame, a feed controller, a raw material box and a frame.

Owner:WUHAN NATURES JOY PLANT NUTRI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com