Mixed beverage production and processing equipment

A technology for processing equipment and beverages, applied in mixers, dissolution, food science, etc., can solve problems such as low concentration, waste of waste water based beverages, and changes in mixing ratios, to meet the needs of expected concentrations, ensure accuracy, and realize cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

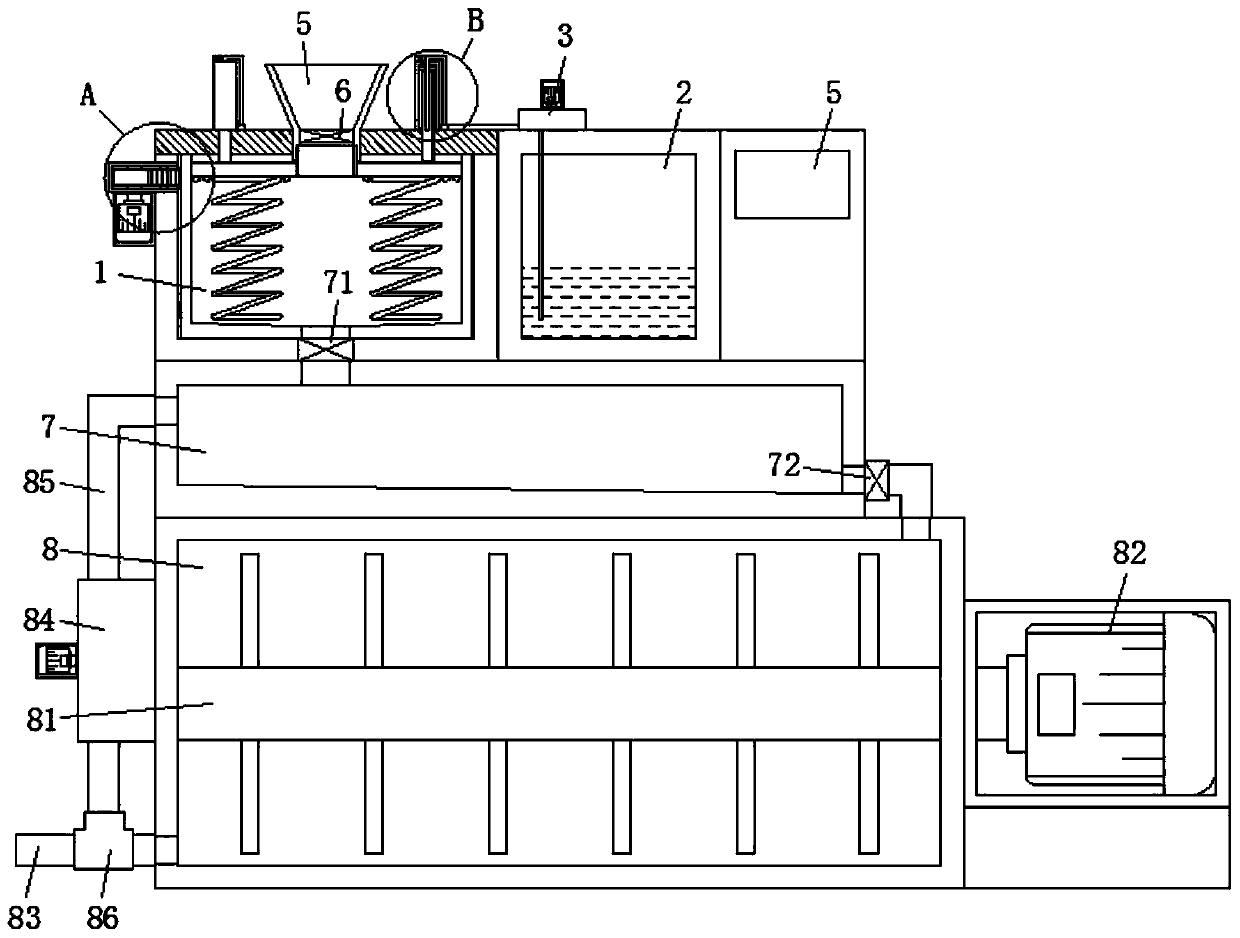

[0036] see figure 1 As shown, the present embodiment provides a mixed beverage production and processing equipment, including:

[0037] A blending device, which realizes two blends of each basic beverage, and the two blends respectively form a phase liquid with a concentration higher than the expected concentration and a proportioning liquid with a lower concentration than the expected concentration; the blending device includes a water distribution tank 1 and a mixing tank 2, and A water pump 3 is connected between the water distribution tank 1 and the mixing tank 2, and a water spray assembly 4 is installed in the mixing tank 2, and the water spray assembly 4 is connected to the water outlet of the water pump 3; a lower hopper is installed on the top of the mixing tank 2 5, and the first solenoid valve 6 is installed in the lower hopper 5;

[0038] A proportioning device 7, the inlet end of which is connected to the blending device, and a second electromagnetic valve 71 is ...

Embodiment 2

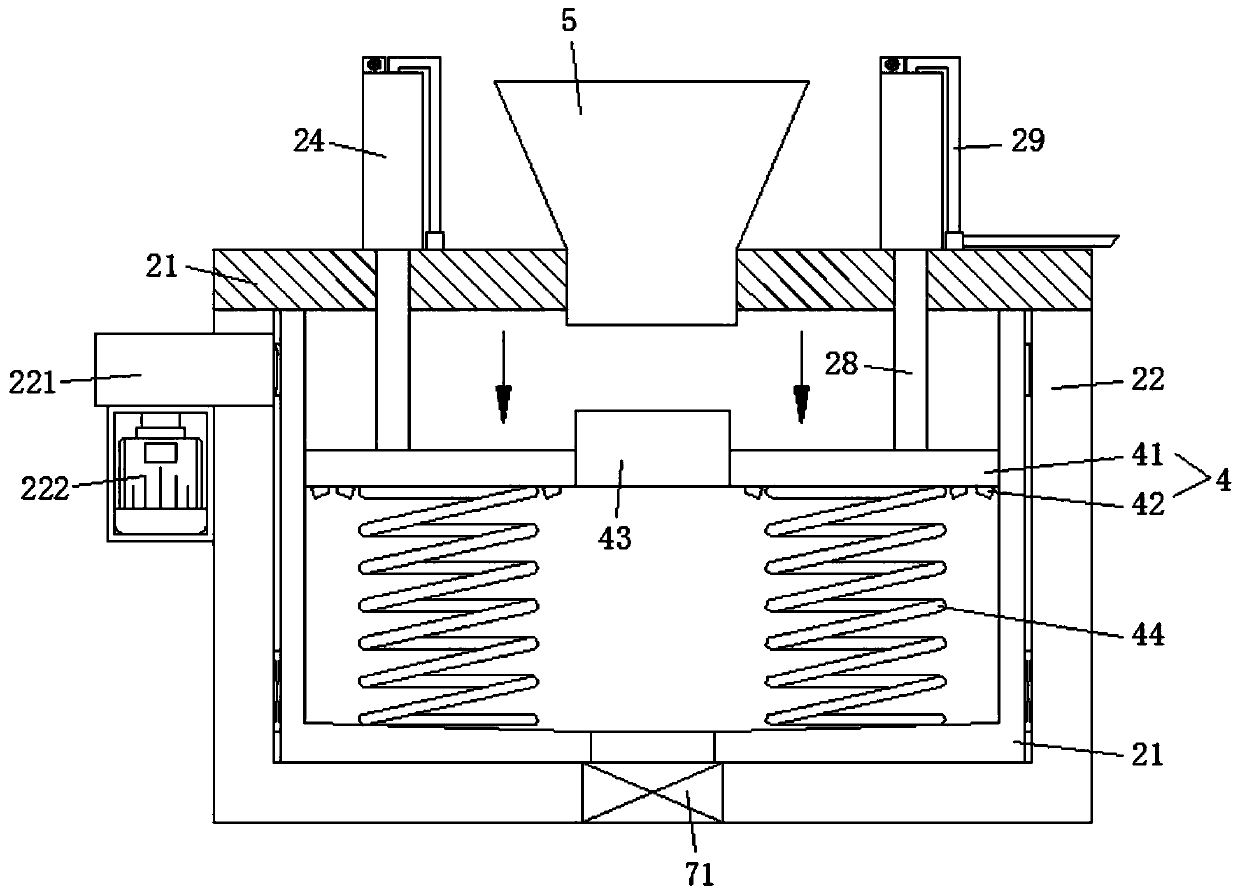

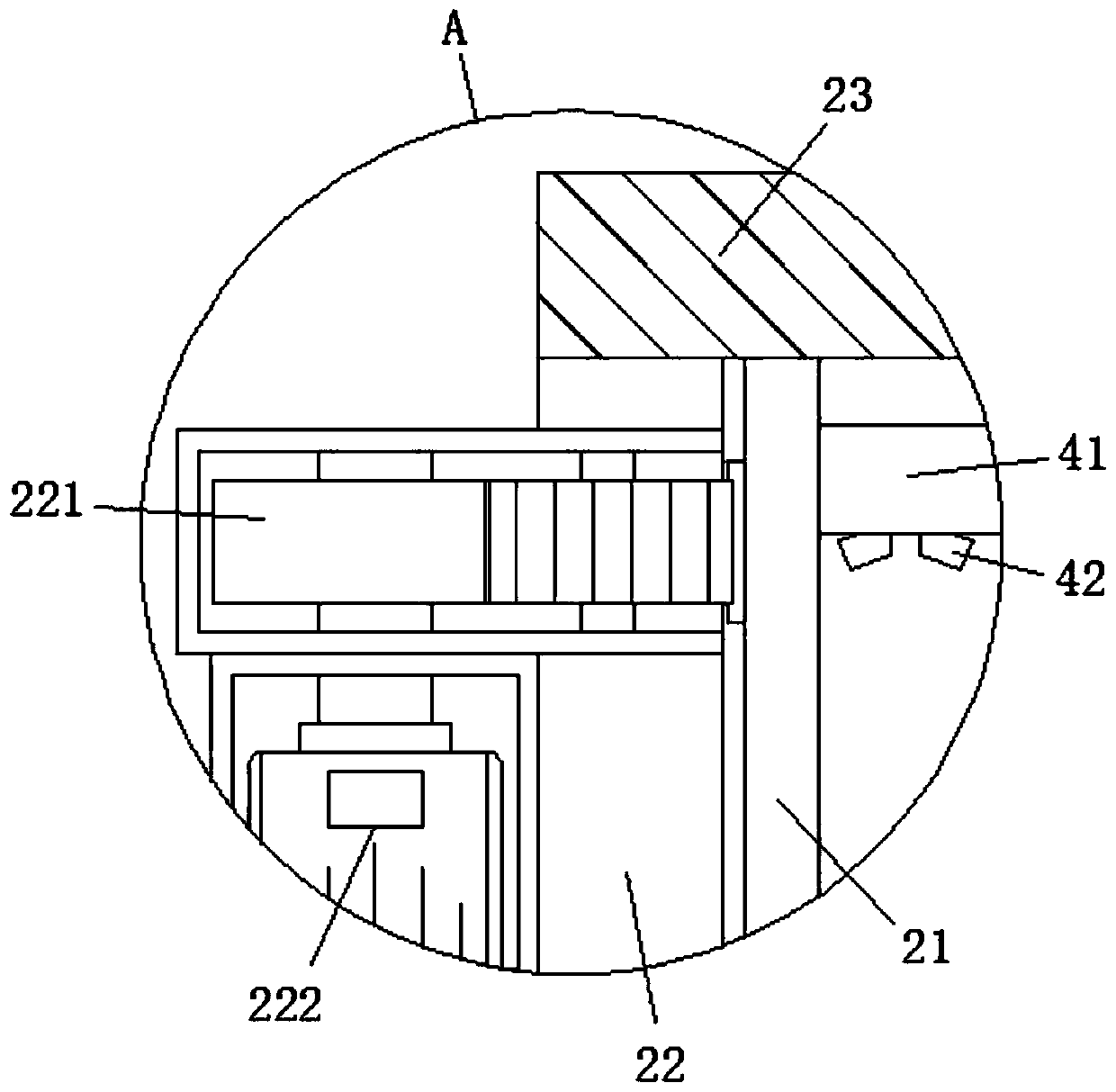

[0049] see Figure 1-Figure 3 As shown, based on Embodiment 1, in this embodiment, the preferred mixing box 2 includes an inner cylinder 21, an outer cylinder 22 and an upper end cover 23, wherein the inner cylinder 21 is installed in the outer cylinder 22 and can be rotated, and the upper end cover 23 It is installed on the top of the outer cylinder 22 , and the lower hopper 5 runs through the middle part of the upper end cover 23 .

[0050] Further, a gear box 221 and a rotating motor 222 are installed on the side wall of the outer cylinder 22, and the gear box 221 runs through the side wall of the outer cylinder 22; A plurality of gears, and one of the gear sets is rotationally connected with the rotating motor 222, and the other gear is meshed with the gear ring to realize the rotational drive of the inner cylinder 21.

[0051] In this embodiment, when the above-mentioned basic beverage is mixed and prepared in the mixing tank 2, based on the rotation of the inner cylinde...

Embodiment 3

[0053] see Figure 1-Figure 4 As shown, based on the second embodiment, in this embodiment, the preferred water spray assembly 4 includes a scraper 41 and a plurality of nozzles 42, and the plurality of nozzles 42 are installed on the bottom of the scraper 41, and are inclined; 41 is defined inside the inner cylinder 21 , and a guide sleeve 43 runs through the middle of the scraper 41 , and the guide sleeve 43 fits with the bottom of the lower hopper 5 .

[0054] In this example, the setting of the guide sleeve 43 can effectively ensure that the component materials in the lower hopper 5 enter the inner cylinder 21, and the multiple nozzles 42 arranged obliquely can realize the introduction of water on the one hand, and are used for mixing with other components. On the other hand, it is used for cleaning the inner cylinder 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com