Patents

Literature

201results about How to "Guaranteed stirring effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

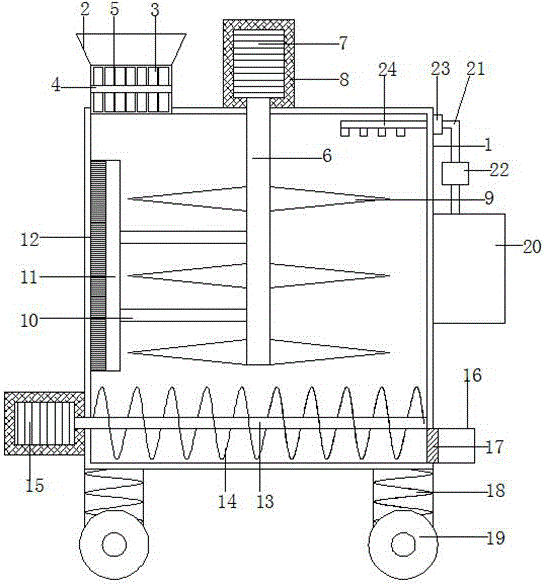

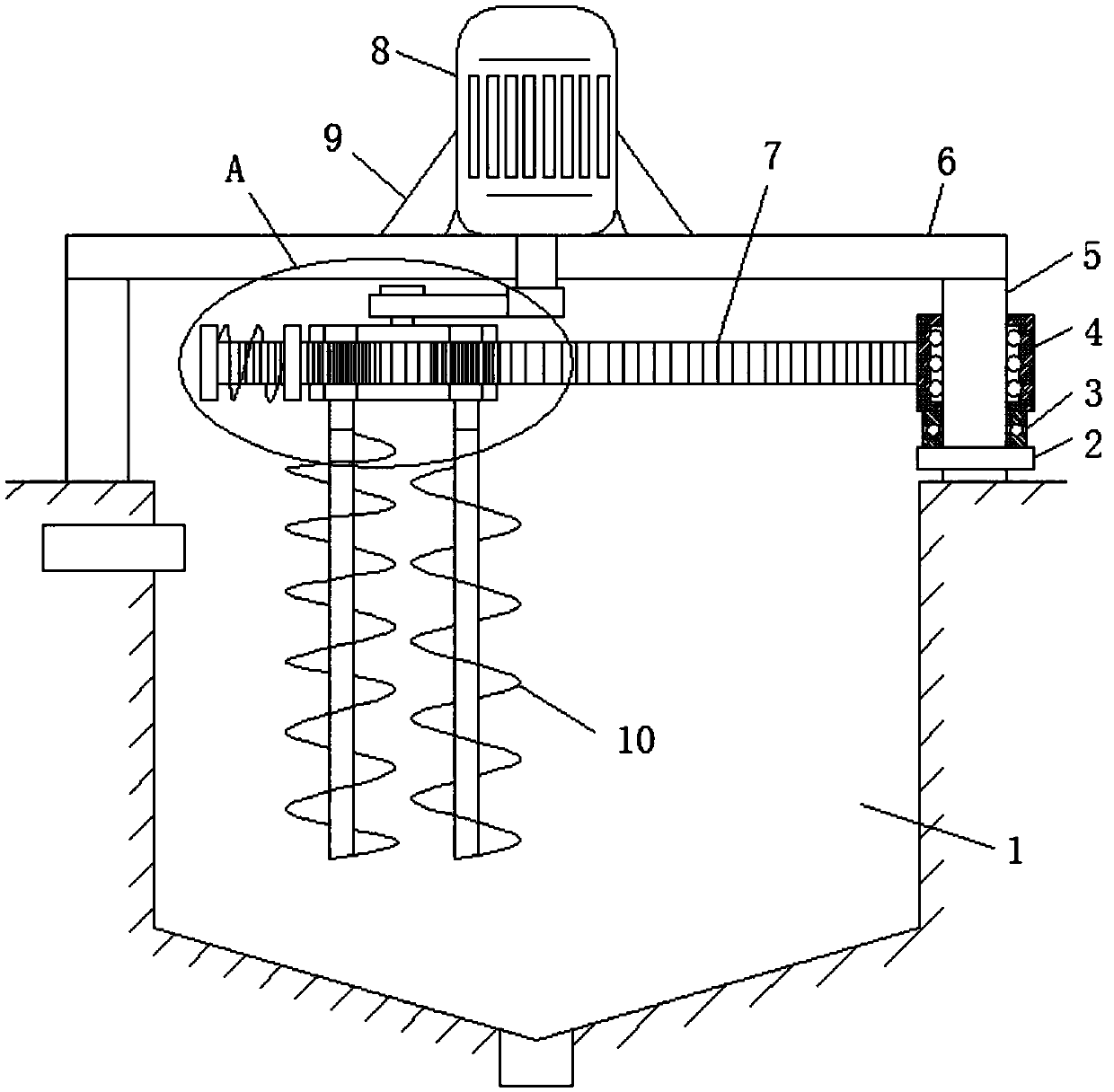

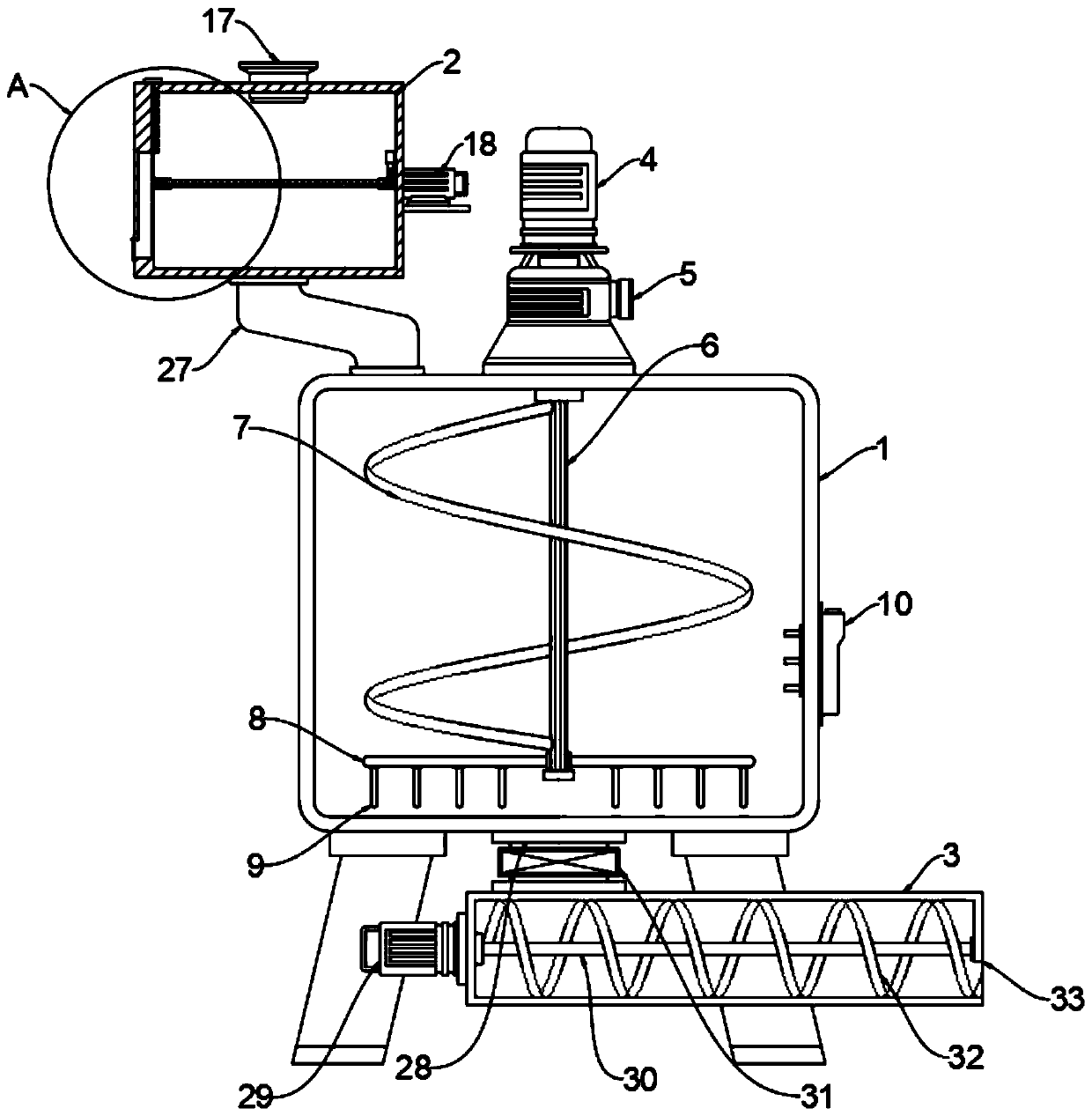

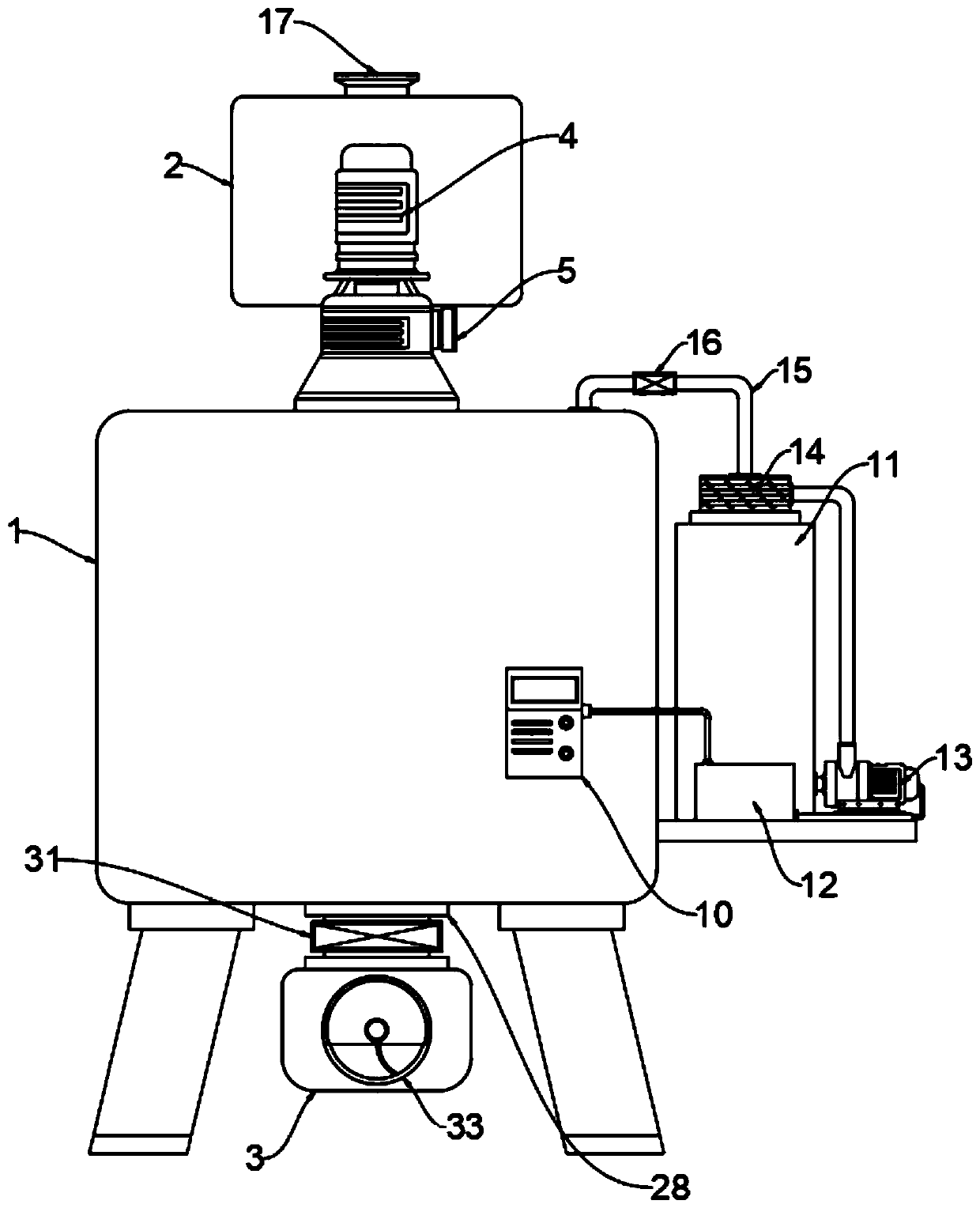

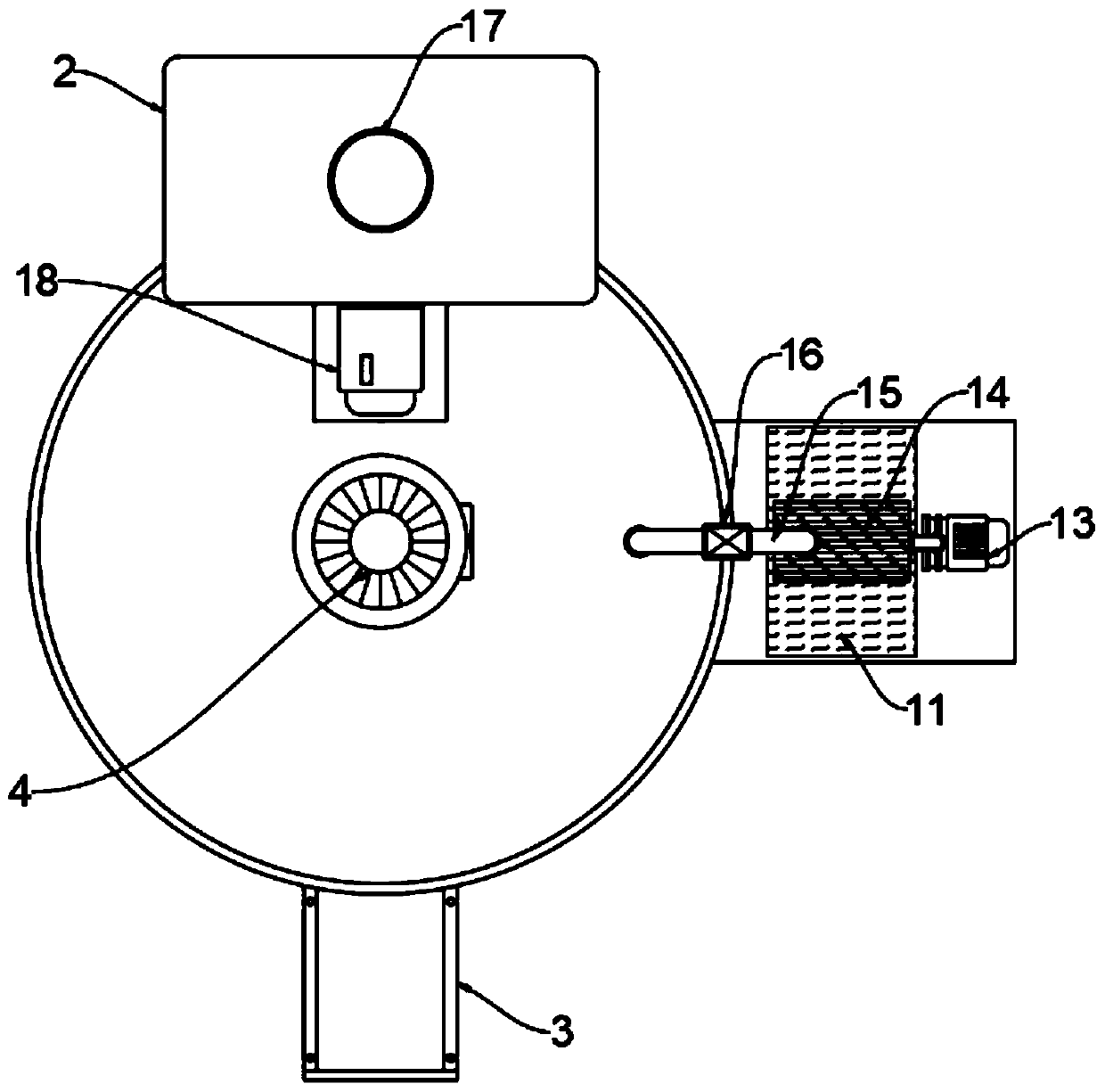

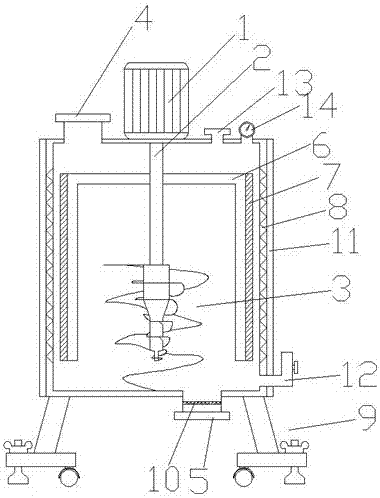

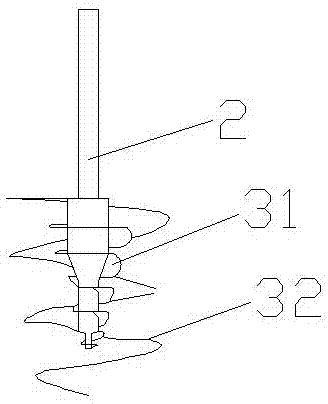

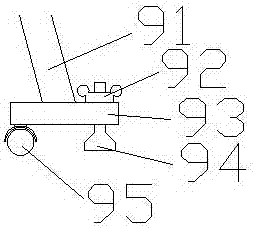

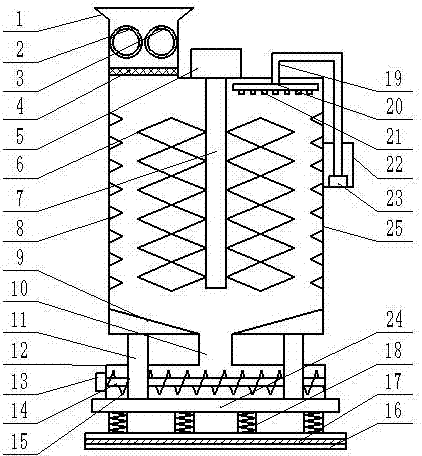

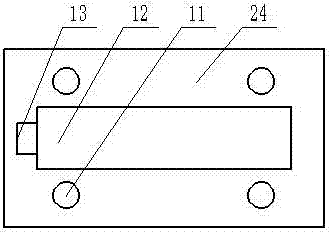

High-efficiency agitation device for chemical production

InactiveCN106378029AQuality assuranceQuality improvementTransportation and packagingRotary stirring mixersHelical bladeIron removal

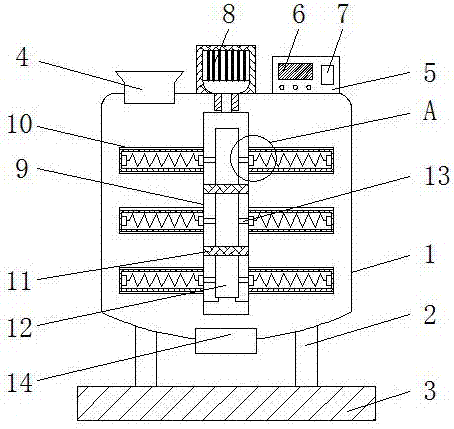

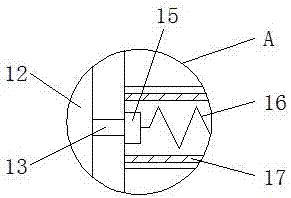

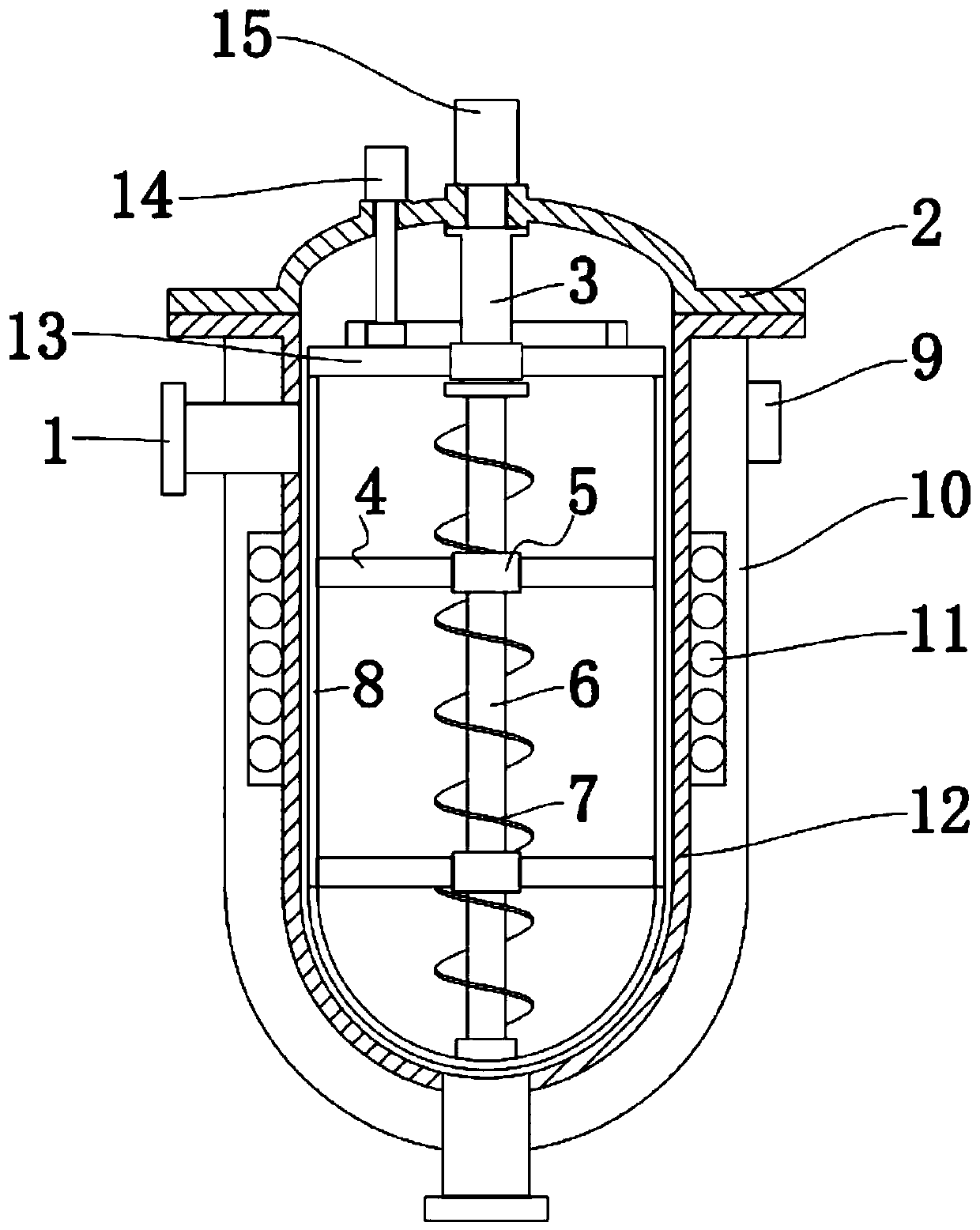

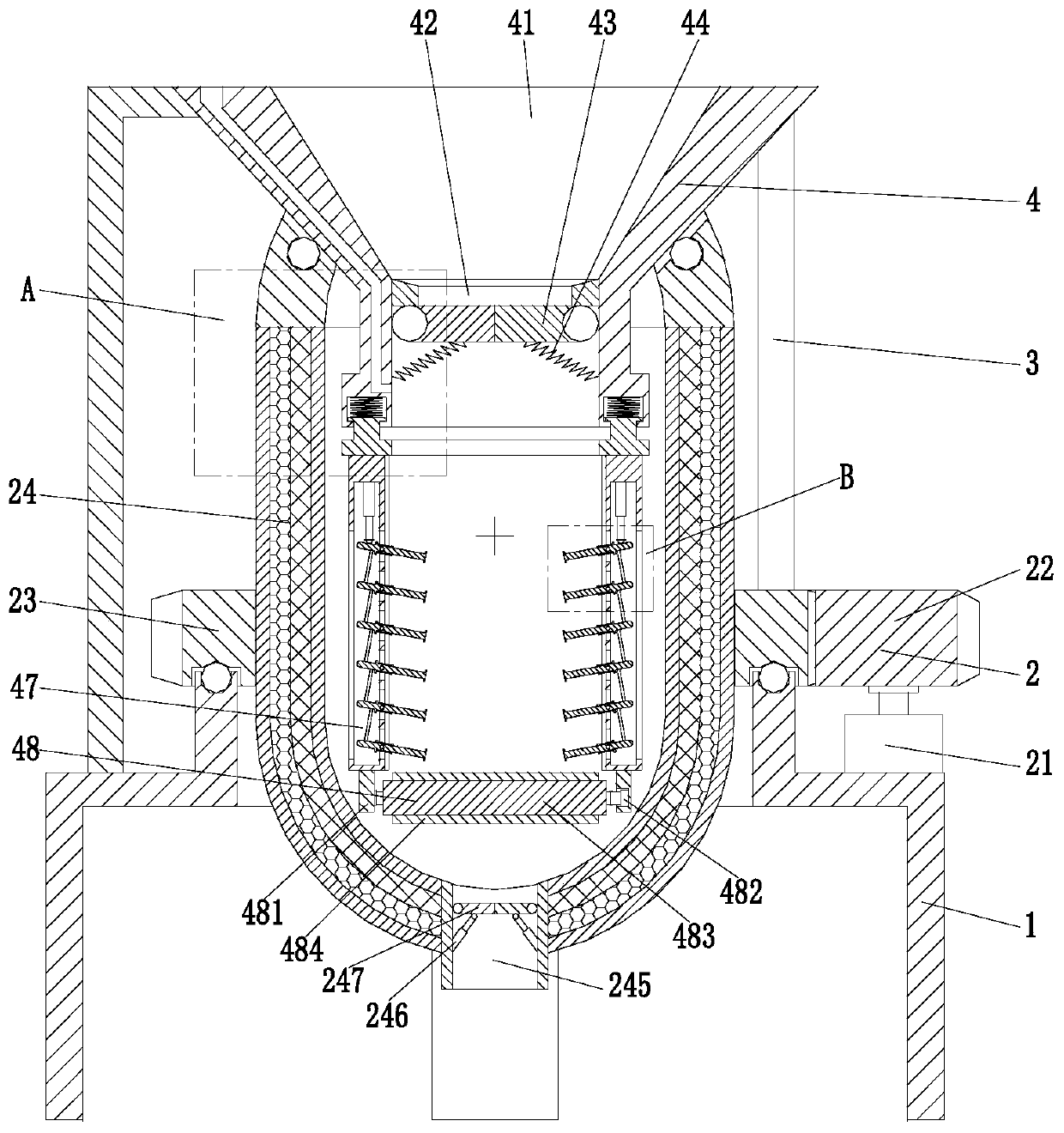

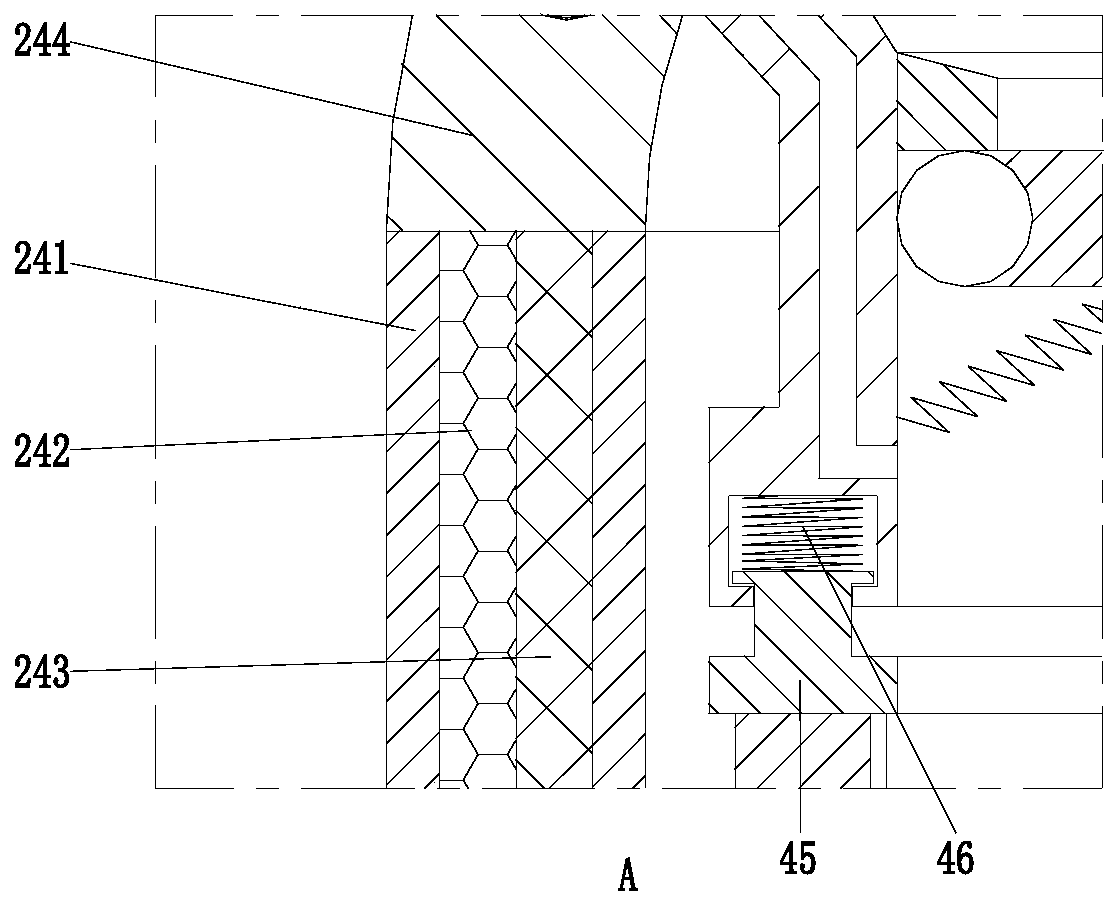

The invention discloses a high-efficiency agitation device for chemical production. The high-efficiency agitation device comprises an agitation barrel, wherein the left end of the upper side of the agitation barrel is provided with a material feeding hopper; the lower side of the material feeding hopper is connected with an iron removal cavity; an iron removal rotating shaft is horizontally arranged in the center of the interior of the iron removal cavity; the outer wall of the iron removal rotating shaft is provided with permanent magnet sheets in a longitudinal symmetry manner. By using a high-efficiency pre-crushed chemical material agitator, the iron removal can be carried out on a raw material of a chemical material; in an agitation process, the scraping and the washing can be carried out on the chemical material, which is adhered to an inner wall, by a scraping and washing hairbrush; the waste which is caused as the chemical material is adhered to the inner wall is avoided; the material discharge can be carried out when a helical blade positively rotates; the agitation and the mixing can be carried out on the chemical material at a bottom when the helical blade negatively rotates; the agitation effect and efficiency are improved; the automatic and quantitative water addition can be realized; the quality of the material is guaranteed; the effective shock absorption can be realized by a spring pillar; further, the movement is more convenient and quicker; the practicability and the convenience are high.

Owner:GUANGXI UNIV

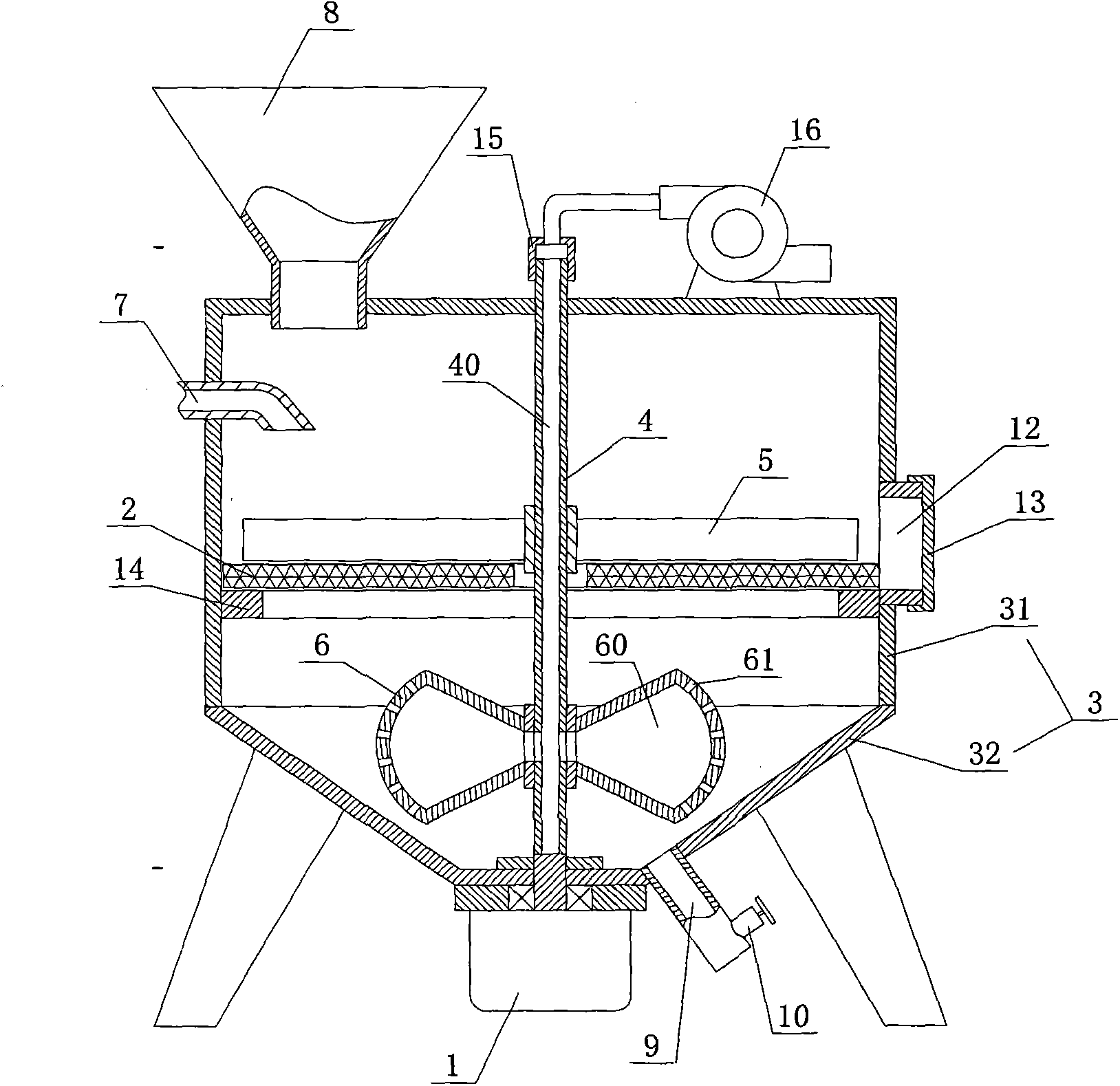

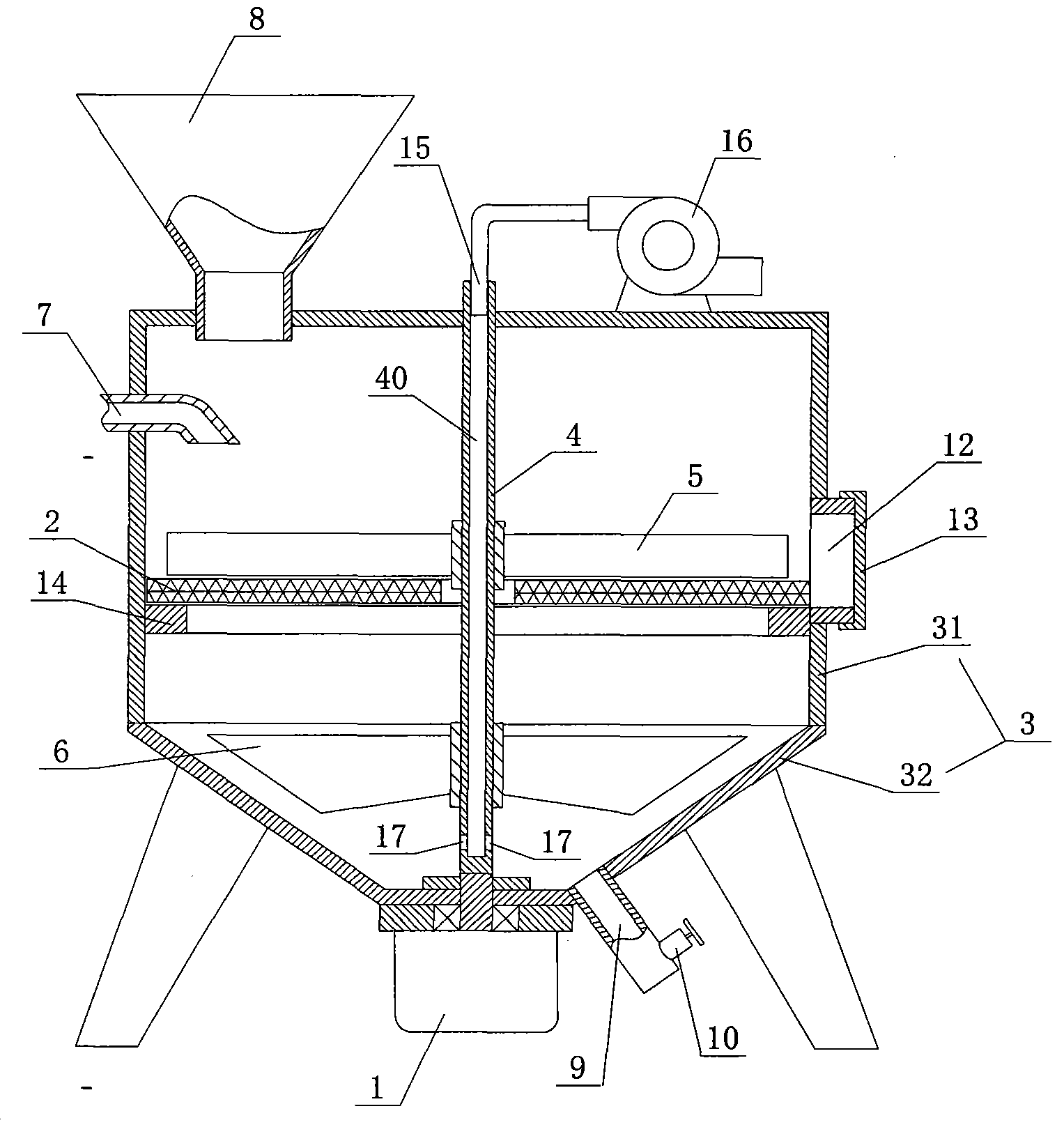

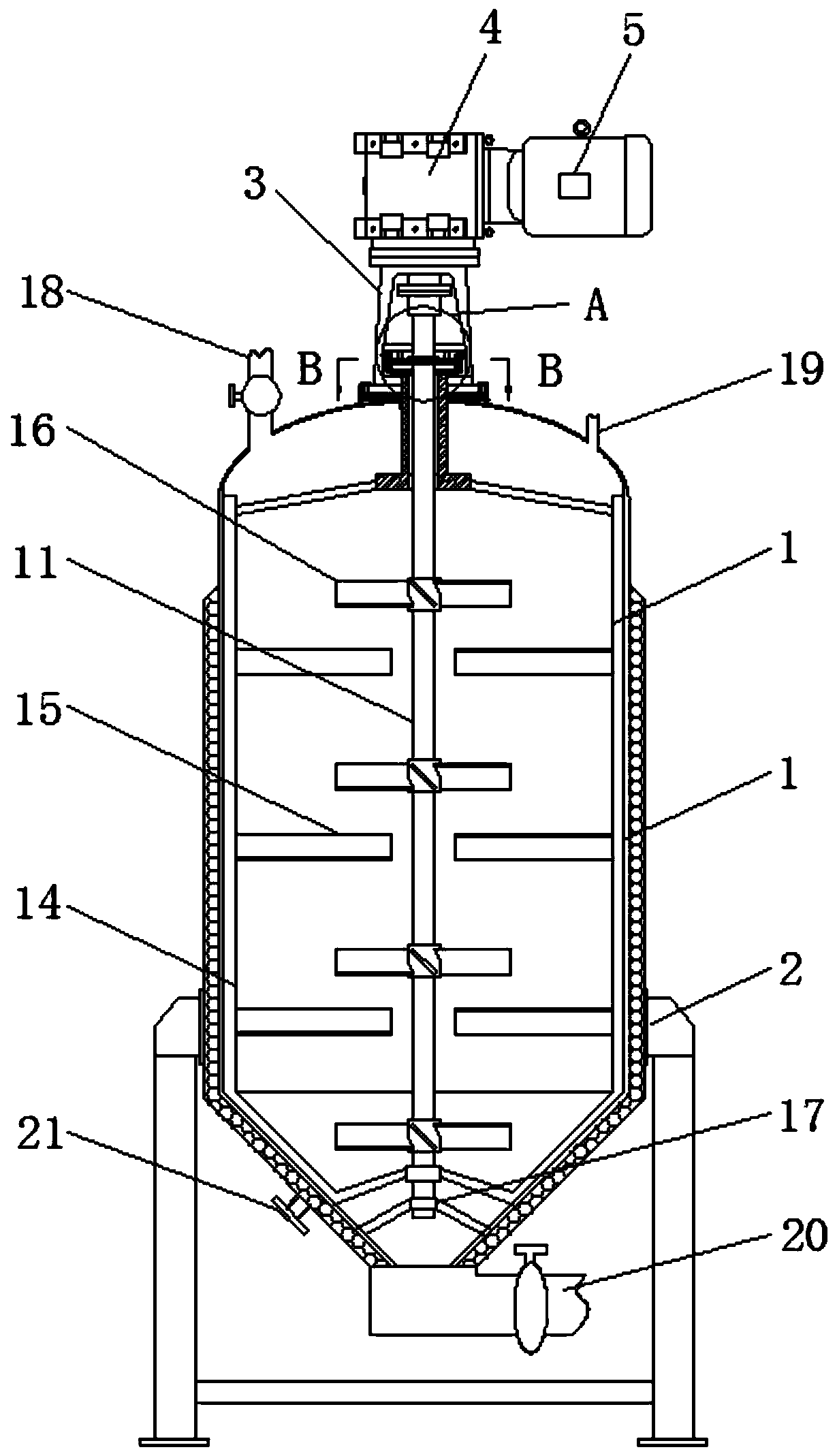

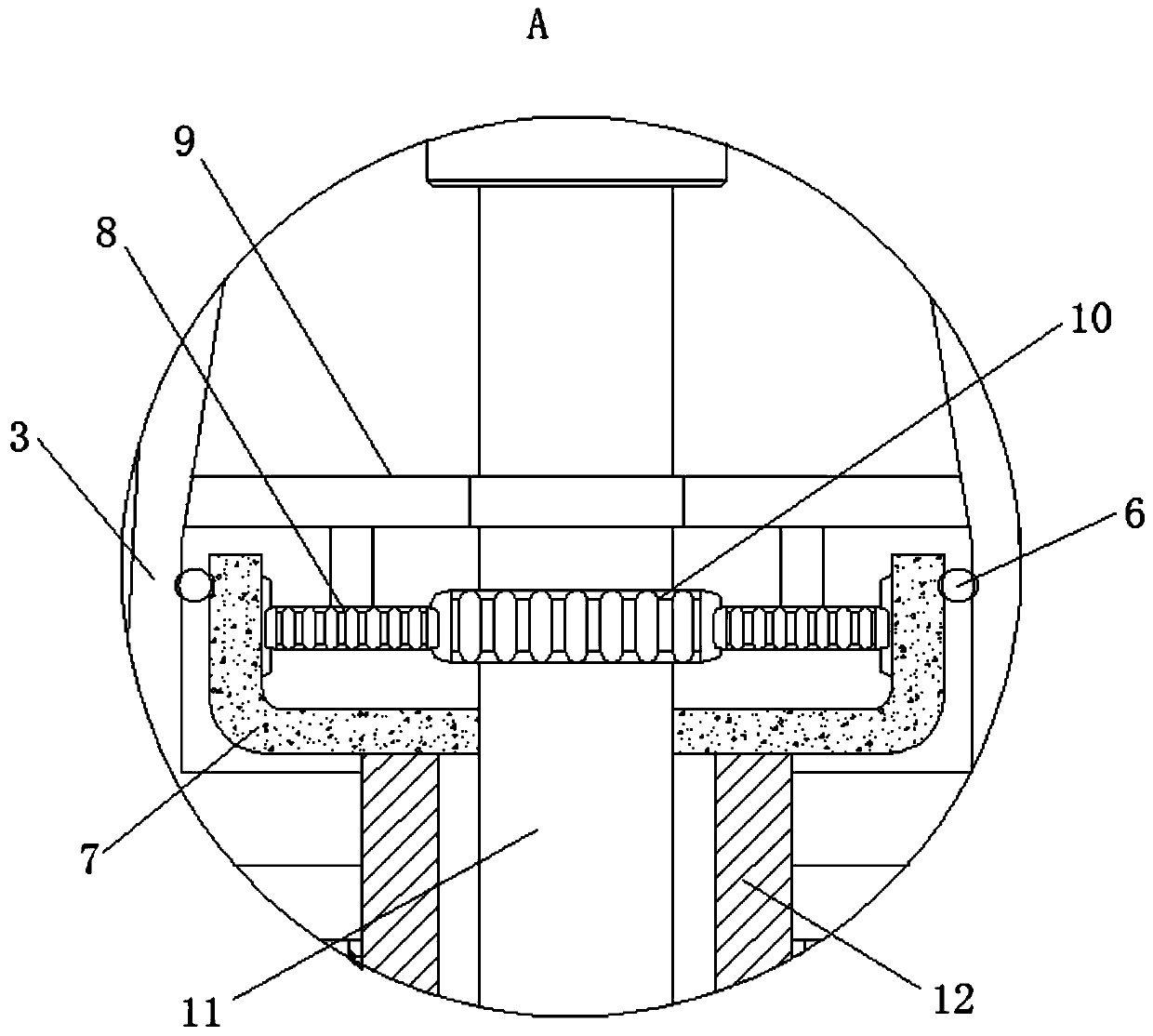

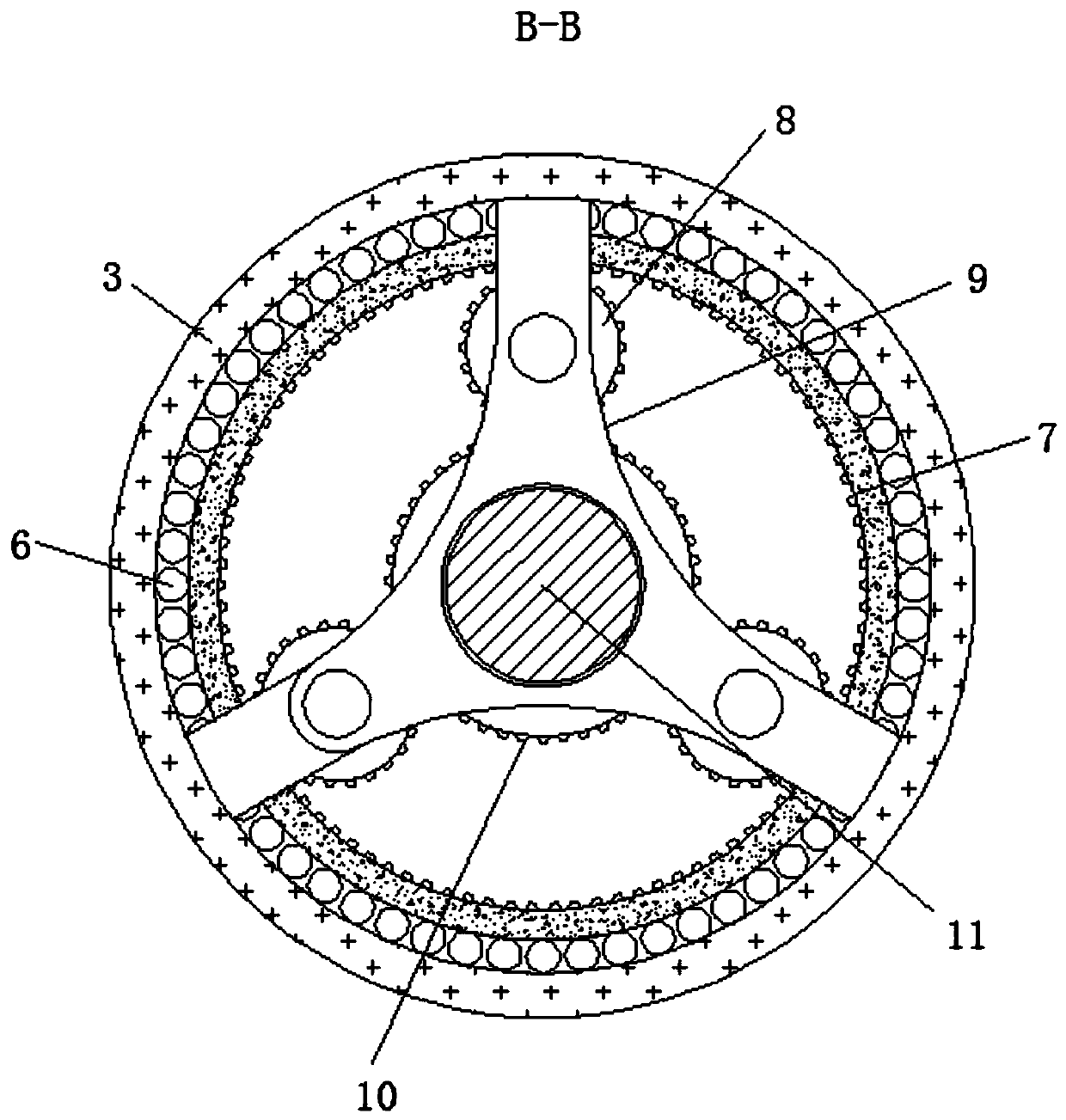

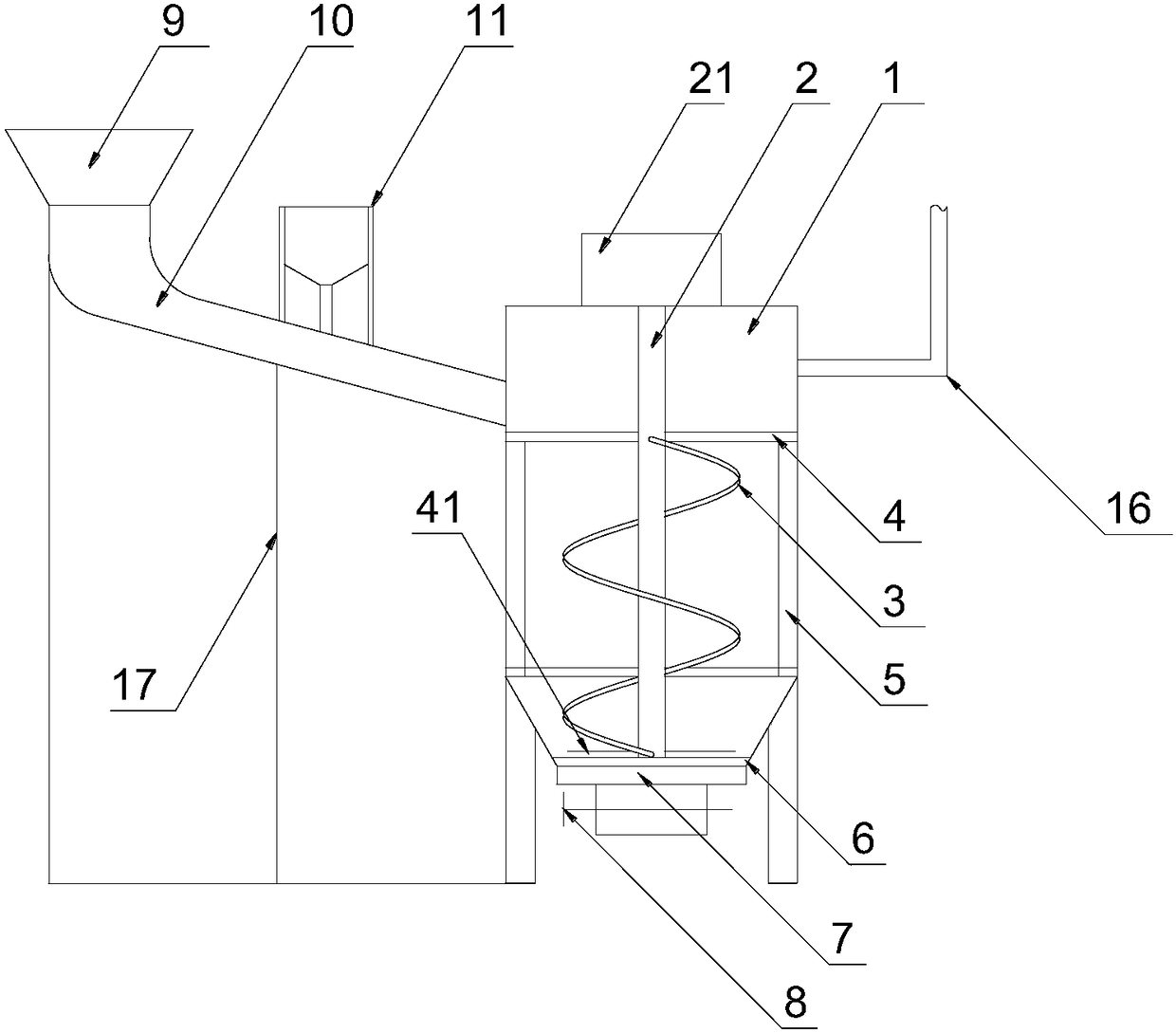

Bubble-type liquor dispensing mixer

InactiveCN103611449ASimple structureEasy to useRotary stirring mixersMixer accessoriesHollow coreDrive motor

The invention relates to a bubble-type liquor dispensing mixer, which comprises a stirring barrel and a driving motor, the stirring barrel is composed of a cylinder at top and a cone cylinder at bottom, an opening at the bottom of the cylinder is communicated with an opening at the top of the cone cylinder, the top of the cylinder and the bottom of the cone cylinder are enclosed, a filter screen is arranged in a core chamber of the cylinder, a rotating shaft which is passed through the core chamber of the cylinder and the core chamber of the cone cylinder is arranged in the stirring barrel, and the rotating shaft is passed through the center of the filter screen, the rotating shaft is a hollow structure with the opening at top, and a sleeve is rotationally sleeved on the opening at the top of the rotating shaft, a blower is connected on the sleeve, the end of the rotating shaft is dynamically connected to the driving motor, a sector blade is fixed in the cone cylinder on the rotating shaft, a wind chamber communicated to the hollow core chamber of the rotating shaft is opened in the sector blade, and a plurality of wind apertures communicated with the wind chamber are opened on the sector blade. The bubble-type liquor dispensing mixer has the advantages of simple structure, convenient usage, uniform stirring and large granule impurity removal.

Owner:SHANDONG ZHENGTAI HEAVY IND TECH

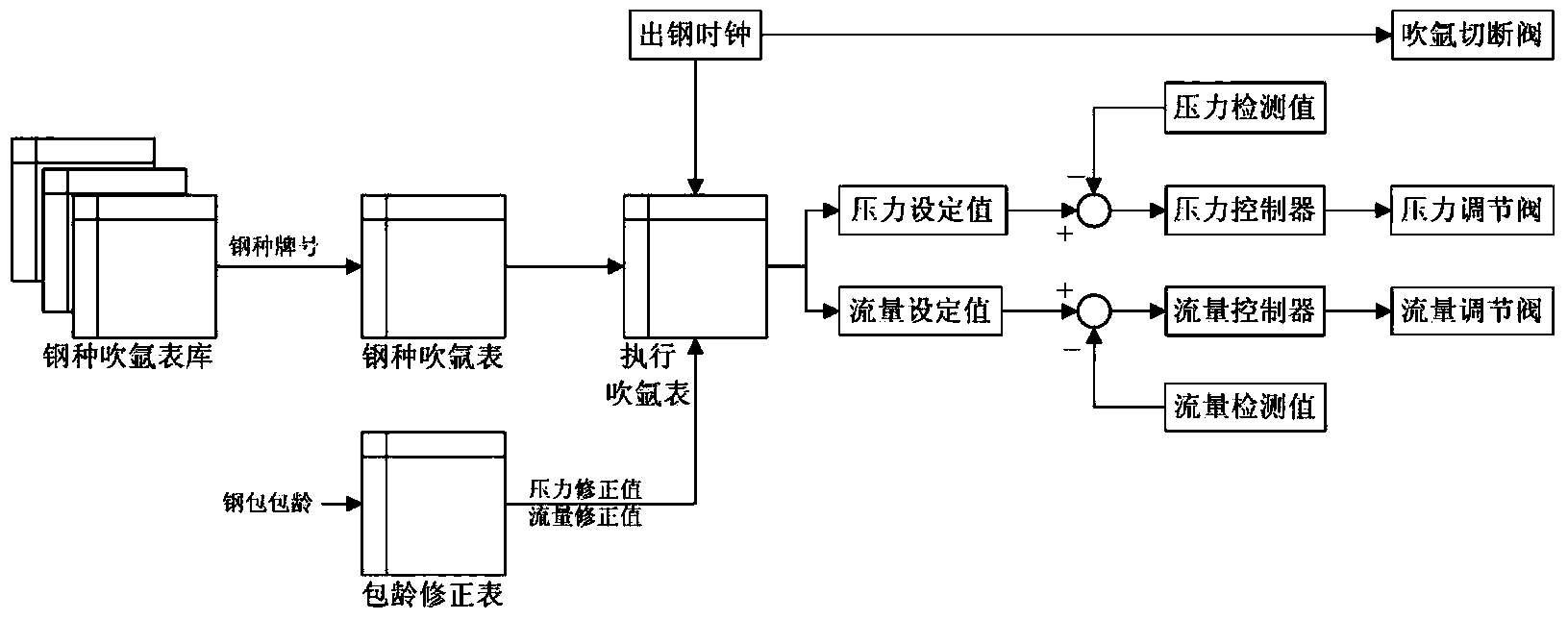

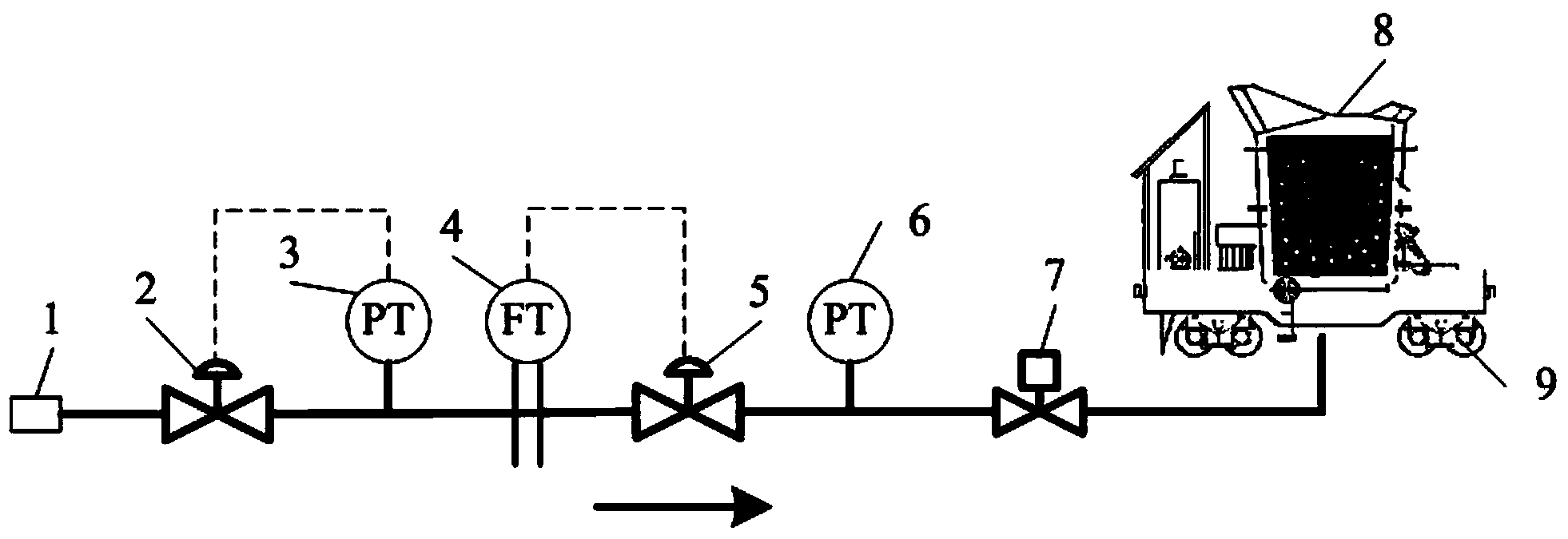

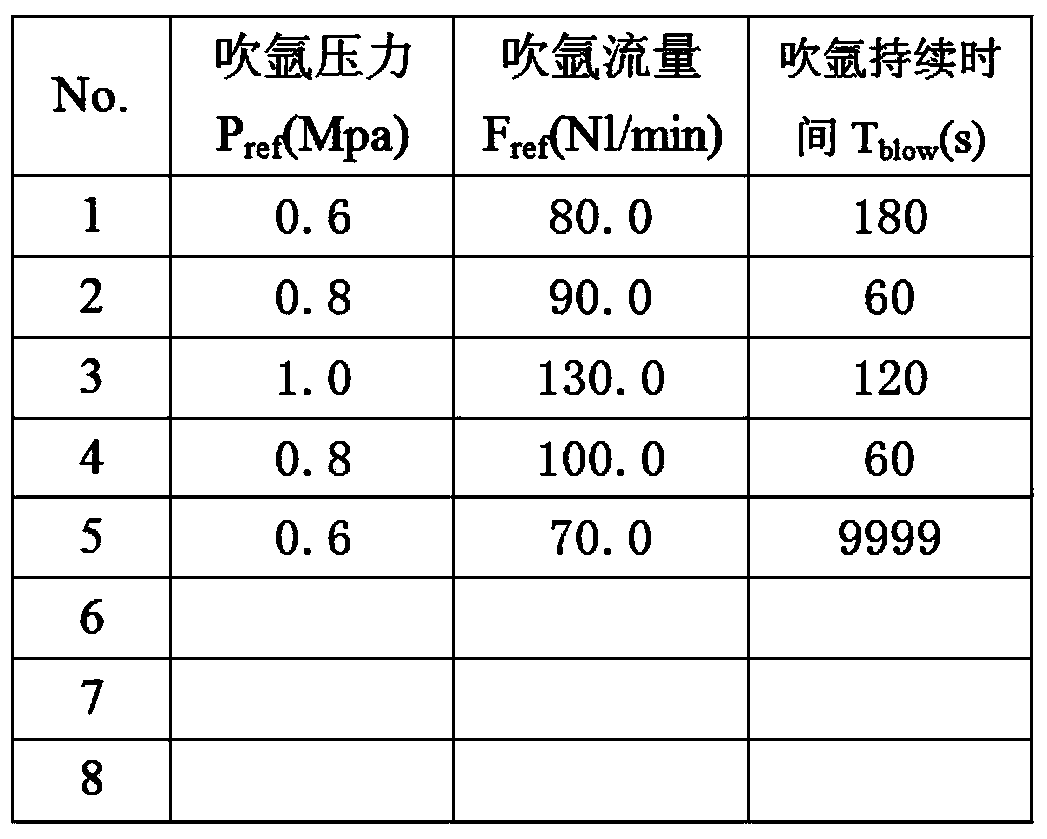

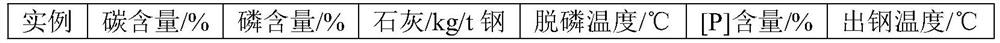

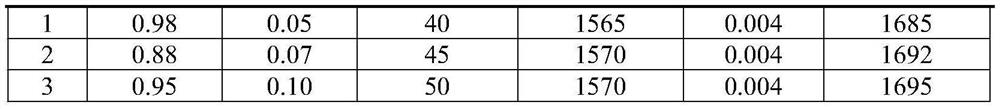

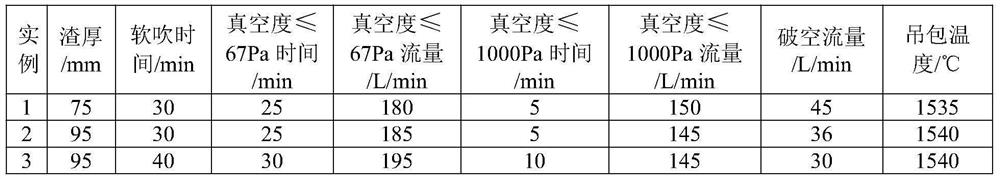

Automatic control method for ladle bottom argon blowing of converter

ActiveCN104073588AOvercome operational experience differencesCode of PracticeManufacturing convertersSteelmakingAutomatic control

The invention discloses an automatic control method for ladle bottom argon blowing of a converter and belongs to the technical field of automatic steelmaking. The method comprises the following steps: (1) establishing a database for storing steel grade argon blowing tables and ladle life correction tables; (2) selecting the specific steel grade argon blowing table according to the smelting steel grade trademark, obtaining the pressure correction value and the flow rate correction value from the ladle life correction tables according to the actual ladle life of the steel ladle and generating the argon blowing pressure, the argon blowing flow rate, the switching time and other information of an actuating argon blowing table; (3) controlling automatic opening and closing of an argon gas cut-off valve and automatic adjustment of both an argon blowing pressure regulating valve and an argon blowing flow control valve according to the argon blowing pressure, the argon blowing flow rate and the switching time in the actuating argon blowing table, as well as the steel tapping clock; (4) repeating the step (2) and the step (3) to complete automatic control of ladle bottom argon blowing of molten steel in multiple converters. The automatic control method provided by the invention can realize full-automatic control of ladle bottom argon blowing of a converter, relieve the labor intensity for operators, regulate the bottom argon blowing operation and improve the quality of argon gas mixed molten steel.

Owner:WISDRI ENG & RES INC LTD

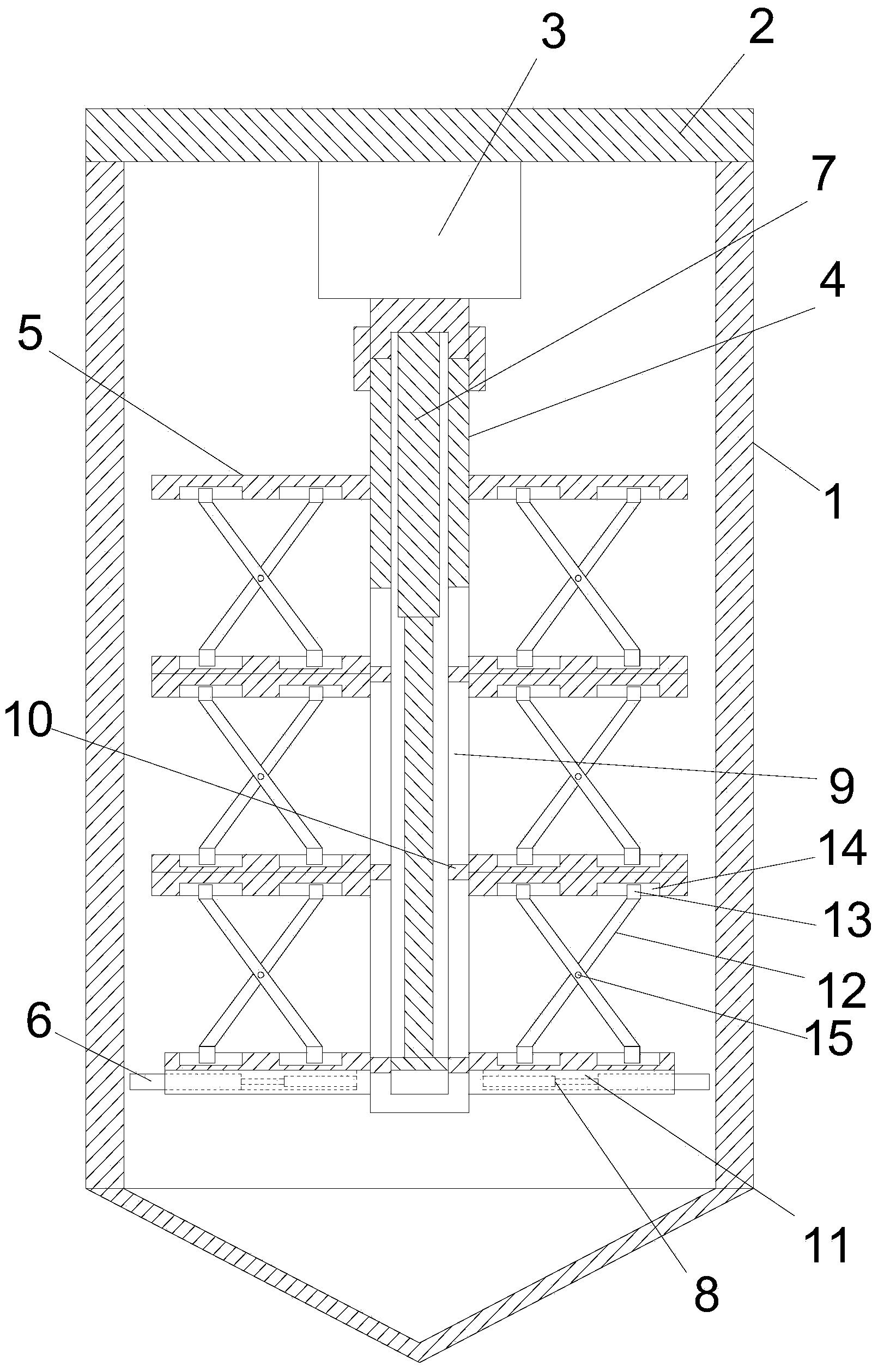

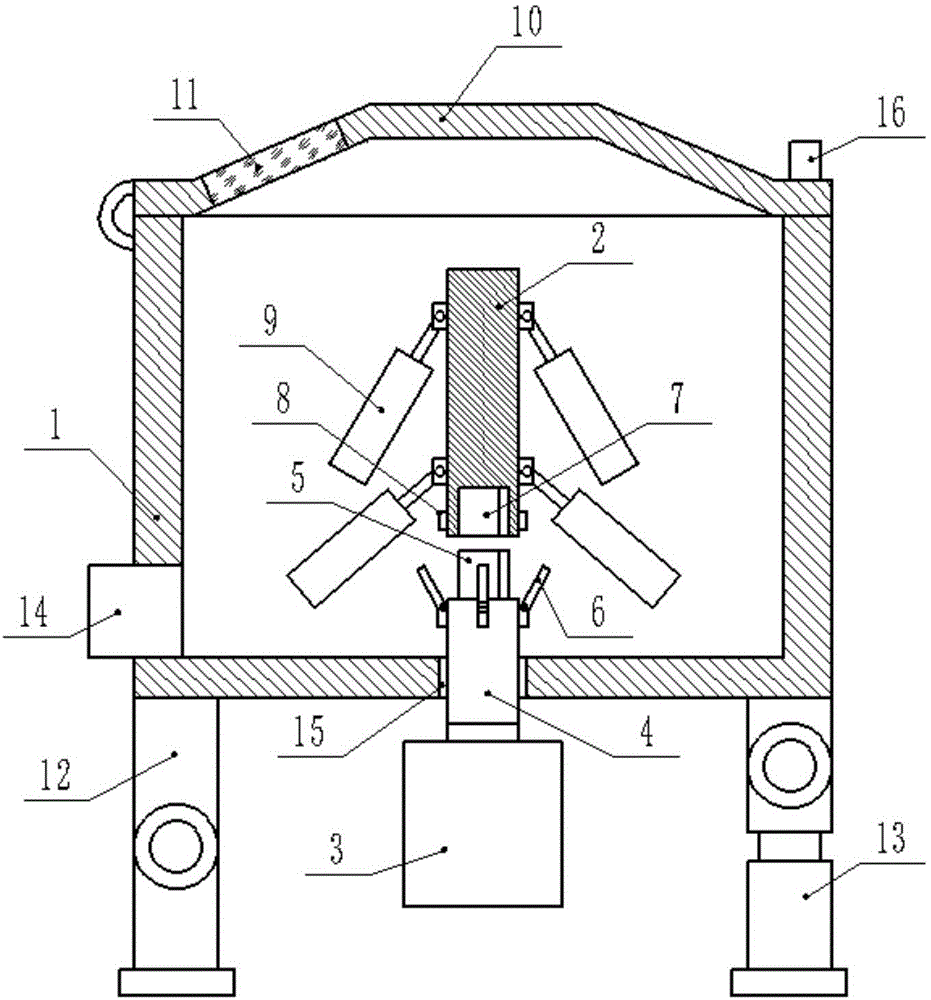

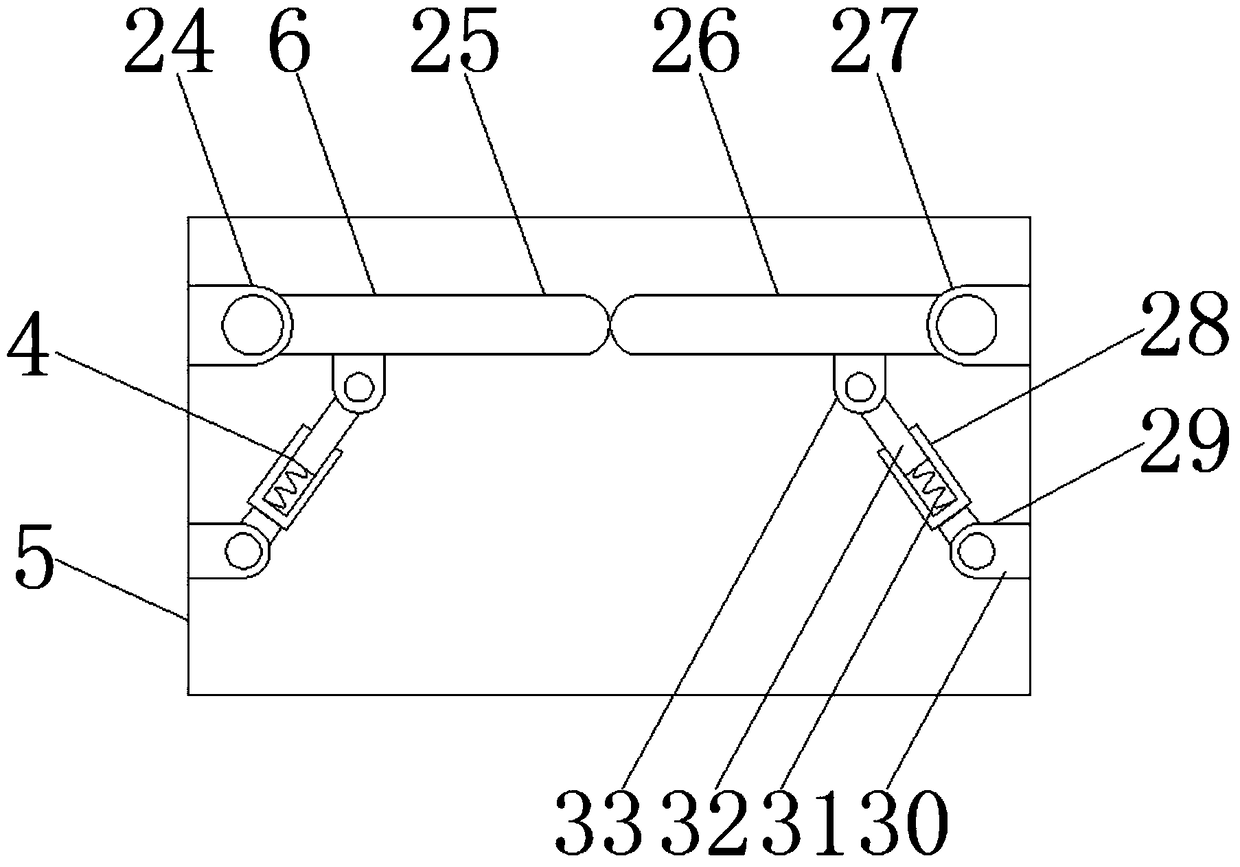

Stirring device with cleaning structure

InactiveCN104338464AReduce labor intensityReasonable structural designRotary stirring mixersEngineeringUltimate tensile strength

The invention relates to a stirring device with a cleaning structure. The stirring device comprises a tank body, an upper cover and a stirring structure arranged in the tank body, wherein the stirring structure comprises a motor fixed on the upper cover, a stirring shaft fixedly connected with a motor shaft and a plurality of layers of stirring blades which sleeve the stirring shaft and are sequentially arranged vertically; the upper and lower adjacent stirring blades are connected by a movable connecting mechanism; the stirring blades at the uppermost layer are fixed on the stirring shaft; the stirring blades below the uppermost layer can slide vertically along the stirring shaft; the tank body is internally provided with a vertical telescopic mechanism which is fixedly connected with the bottommost layer of stirring blades and can stretch vertically; the stirring blades at the bottommost layer are provided with a telescopic sheet which can be telescopic left and right and is in contact with the inner wall of the tank body and a horizontal telescopic mechanism for driving the telescopic sheet to stretch. According to the invention, the positions of the stirring blades can be adjusted according to the depth of raw materials in the tank body, and the stirring efficiency and effect are improved, the inner wall of the tank body can be cleaned automatically, the labor intensity of workers can be lowered, and the stirring device is convenient to use.

Owner:常州西夏墅工具产业创业服务中心

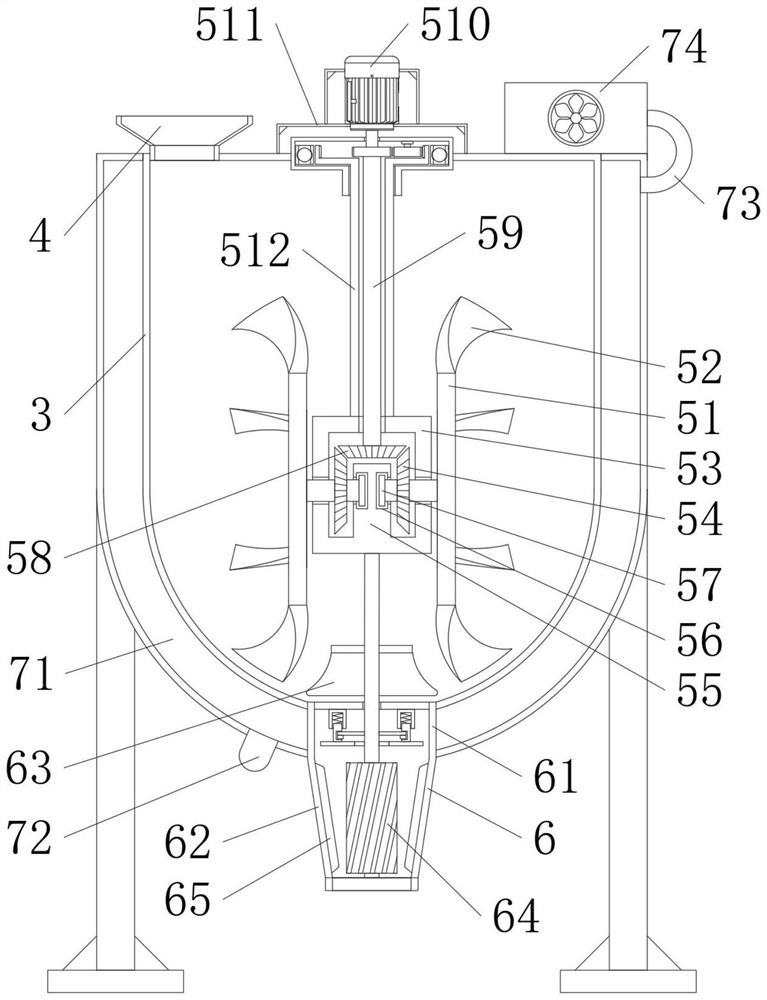

High-efficient sewage stirring device

InactiveCN107824096ACushion the shockReduce frictionRotary stirring mixersTransportation and packagingBiochemical engineeringSewage

The invention discloses a high-efficient sewage stirring device, which comprises a sewage pond; an end opening part of the sewage pond is fixedly connected with paired upright posts, and one end of each of the paired upright posts far from the sewage pond is fixedly connected with a cross plate; one side of the cross plate far from the upright post is provided with a motor, and the motor is fixedly connected with the cross plate through a motor frame; an output shaft of the motor crosses through the cross plate and extends to the sewage pond, one end of the motor output shaft extended to the sewage pond axially is fixedly sleeved with a crank; one end of the crank far from the motor is hinged with a lug, one end of the lug far from the crank is fixedly connected with a slide block; a rackis glidingly connected to the slide block. By means of a swaying guide rod mechanism, the revolution of the stirrer in the sewage pond is realized; the rack meshed with the gear is arranged on the guide rod, thus the stirrer acquires power from the rack, the revolution and autogiration of the stirrer are realized; the high-efficient sewage stirring device is simple in structure, good in stirring effect, high in efficiency and easy to popularize.

Owner:合肥挺泰环保科技有限公司

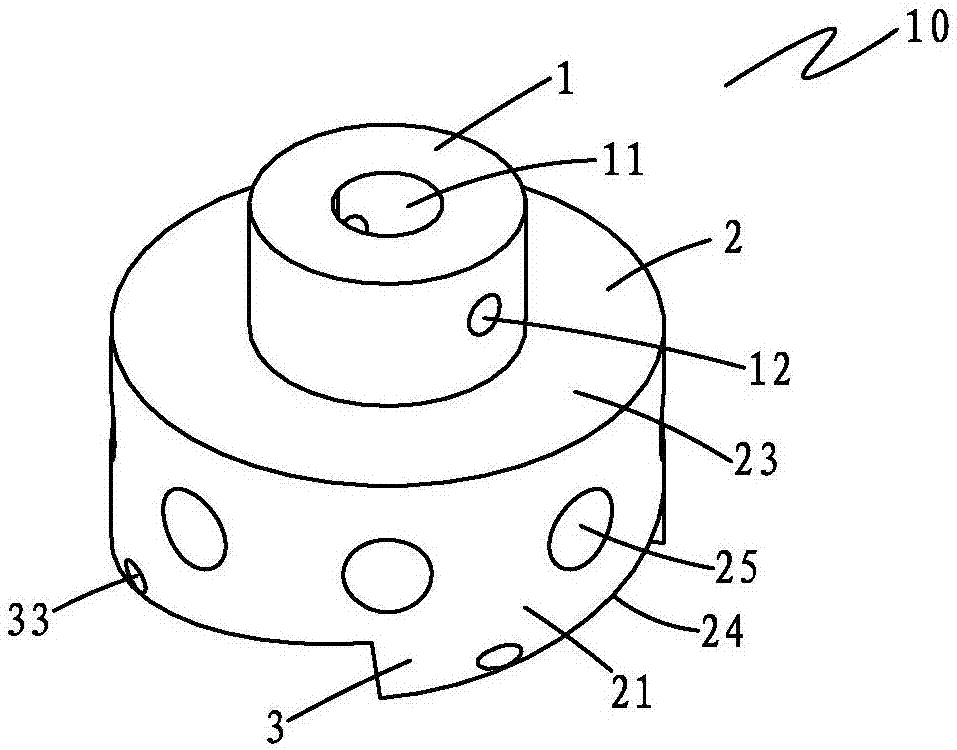

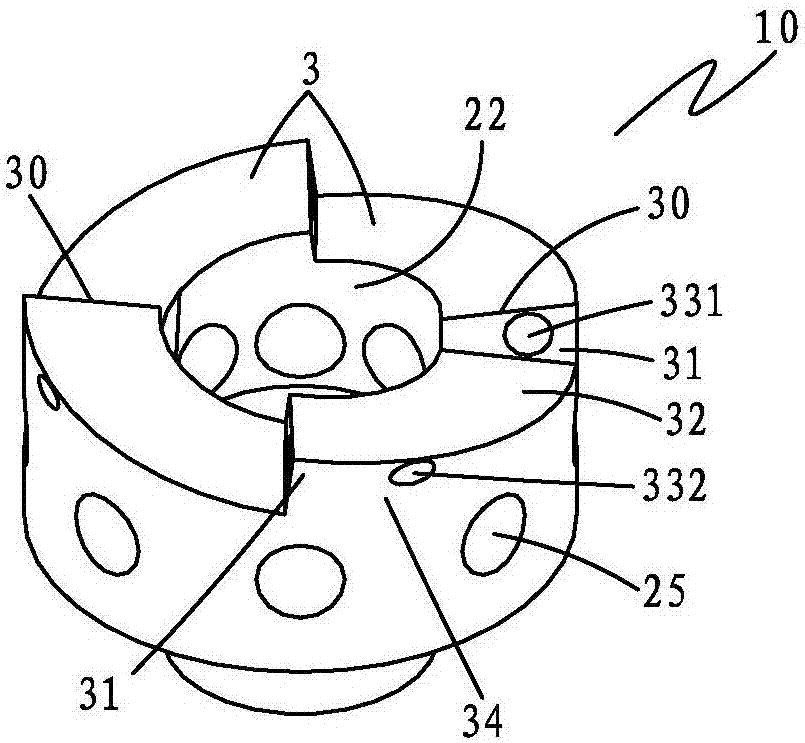

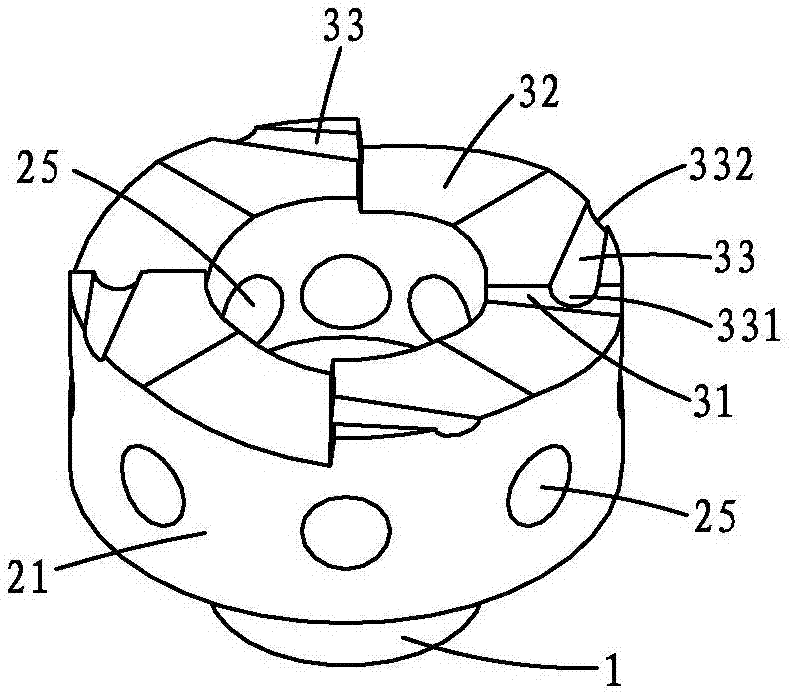

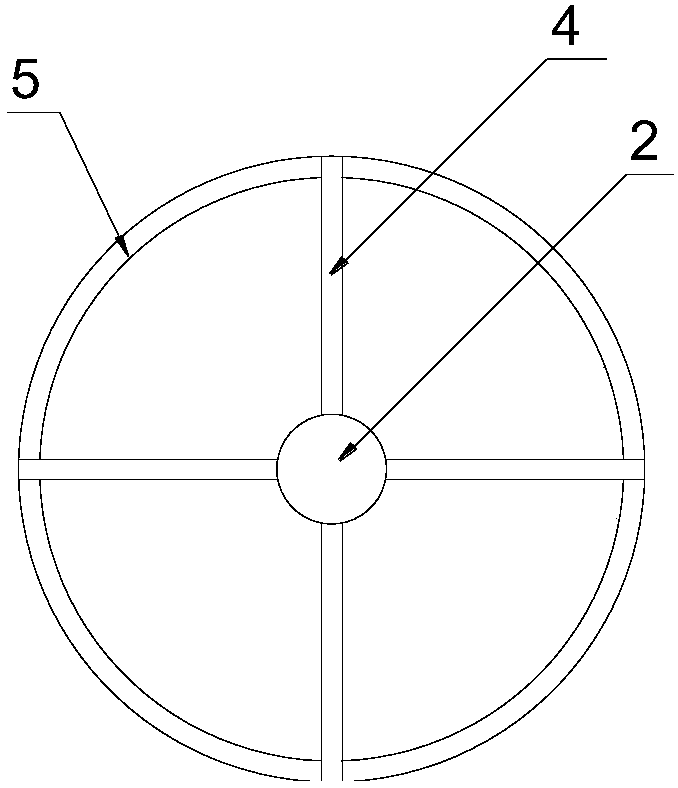

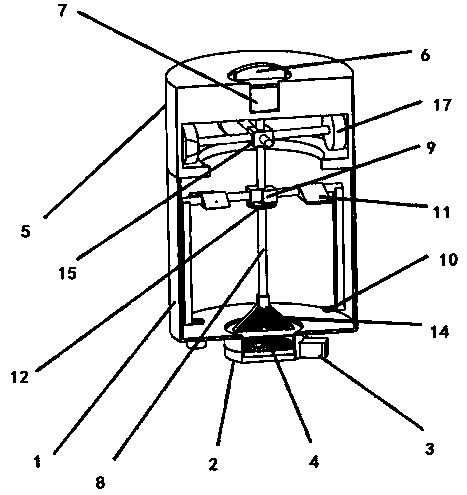

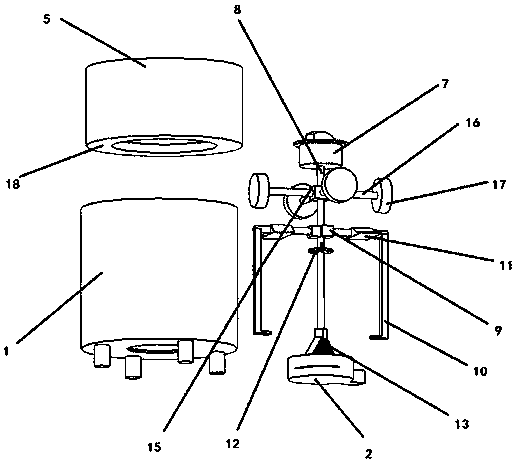

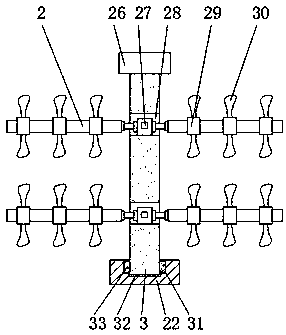

Separable conveniently-washed mixer

InactiveCN106422877AGuaranteed stirring rangeGuaranteed stirring effectRotary stirring mixersTransportation and packagingDrive shaftAgricultural engineering

The invention discloses a separable conveniently-washed mixer which comprises a mixing barrel and a mixing shaft. A motor is fixedly connected at the lower end of the mixing barrel, a driving shaft is rotatably connected at the center of the mixing barrel and connected with the motor in a transmission manner, a fixed spline shaft is fixedly connected at the upper end of the driving shaft, a fixed spline groove matched with the fixed spline shaft is formed in the lower end of the mixing shaft, a plurality of mixing blades arte vertically and rotatably connected on the side wall of the mixing shaft, a cover door is connected at the upper end of the mixing barrel through hinges, an observation window is embedded into one side of the cover door, four supporting legs are fixedly connected at the lower end of the mixing barrel, and a discharging valve is communicated with the lower end of the left side wall of the mixing barrel. The mixing blades of the mixer is unfolded under the action of centrifugal force, mixing ranges and mixing effect are ensured, and the mixing blades droop or is directly disassembled when the mixer stops, so that the mixer is manually and conveniently cleaned and more conveniently used.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Air-type ingredient stirring machine

InactiveCN103611455ASimple structureEasy to useMixersStationary filtering element filtersHollow coreDrive motor

The invention relates to an air-type ingredient stirring machine, which comprises a stirring barrel and a driving motor, the stirring barrel is composed of a cylinder at top and a cone cylinder at bottom, an opening at the bottom of the cylinder is communicated with an opening at the top of the cone cylinder, the top of the cylinder and the bottom of the cone cylinder are enclosed, a filter screen is arranged in a core chamber of the cylinder, a rotating shaft which is passed through the core chamber of the cylinder and the core chamber of the cone cylinder is arranged in the stirring barrel, and the rotating shaft is passed through the center of the filter screen, the rotating shaft is a hollow structure with the opening at top, and an air-supply pipe is rotationally sleeved on the opening at the top of the rotating shaft, a blower is connected to the air-supply pipe, a plurality of air outlets communicated to the hollow core chamber are opened at the bottom of the rotating shaft; the bottom of the rotating shaft is dynamically connected to the driving motor, and a scraper plate blade positioned right above the filter screen and a stirring blade positioned in the cone cylinder are fixedly connected on the rotating shaft. The air-type ingredient stirring machine has the advantages of simple structure, convenient usage, uniform stirring and large granule impurity removal.

Owner:SHANDONG ZHENGTAI HEAVY IND TECH

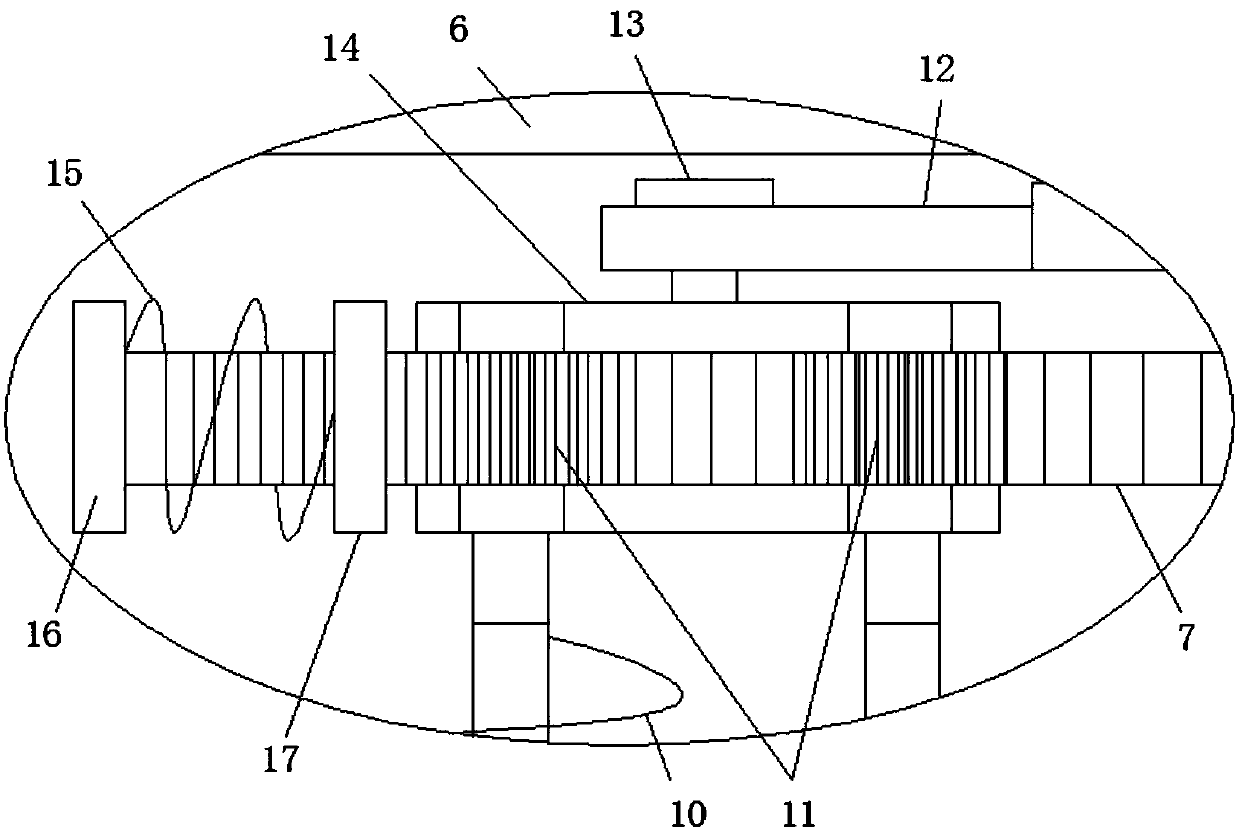

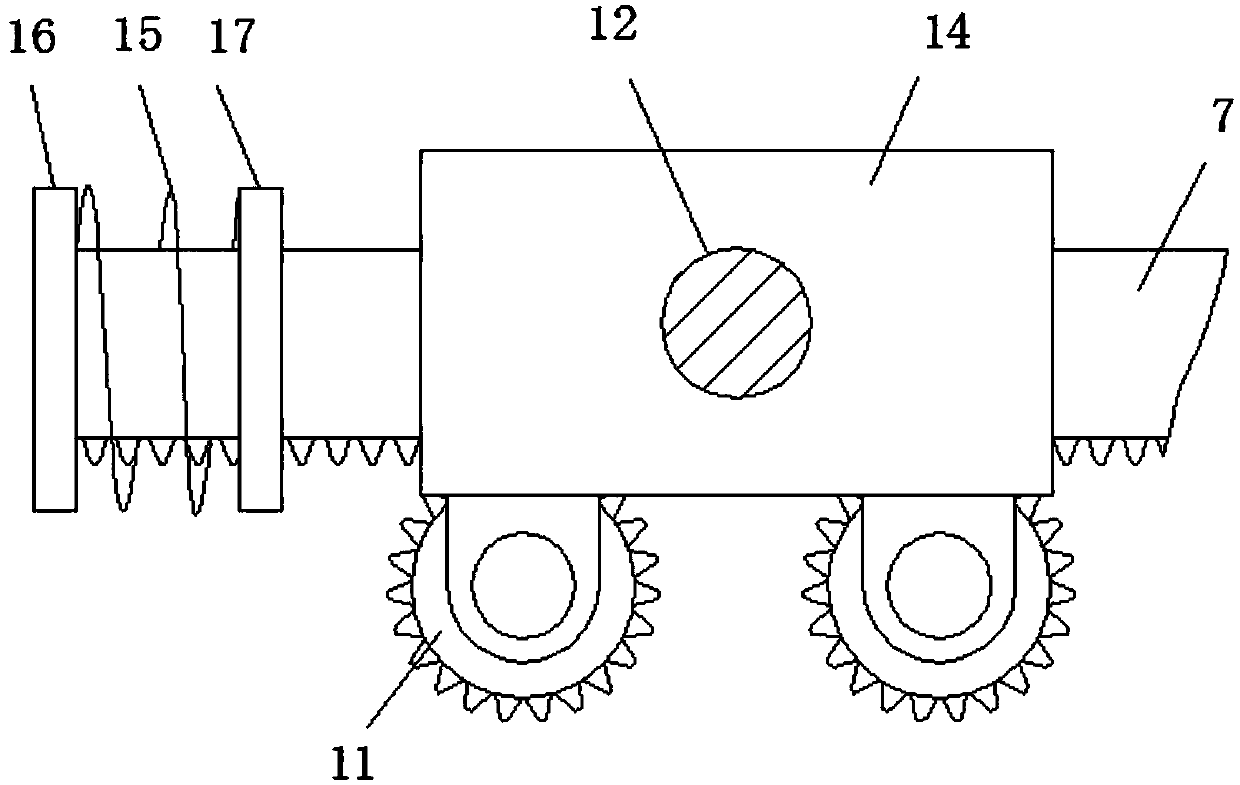

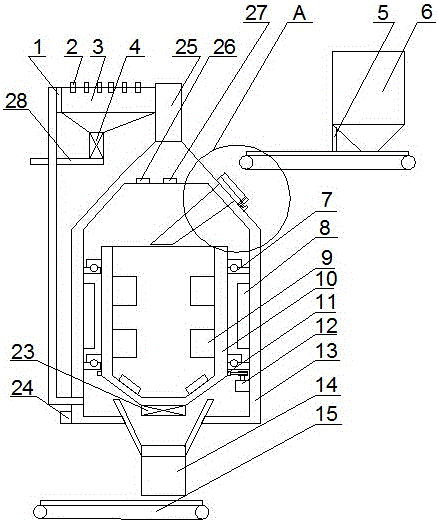

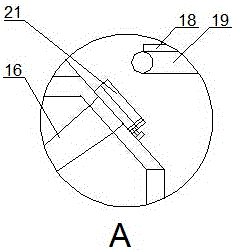

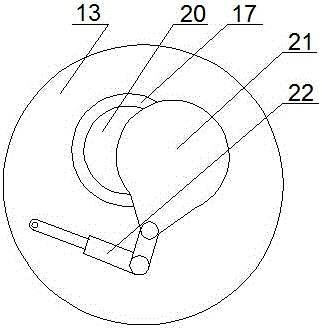

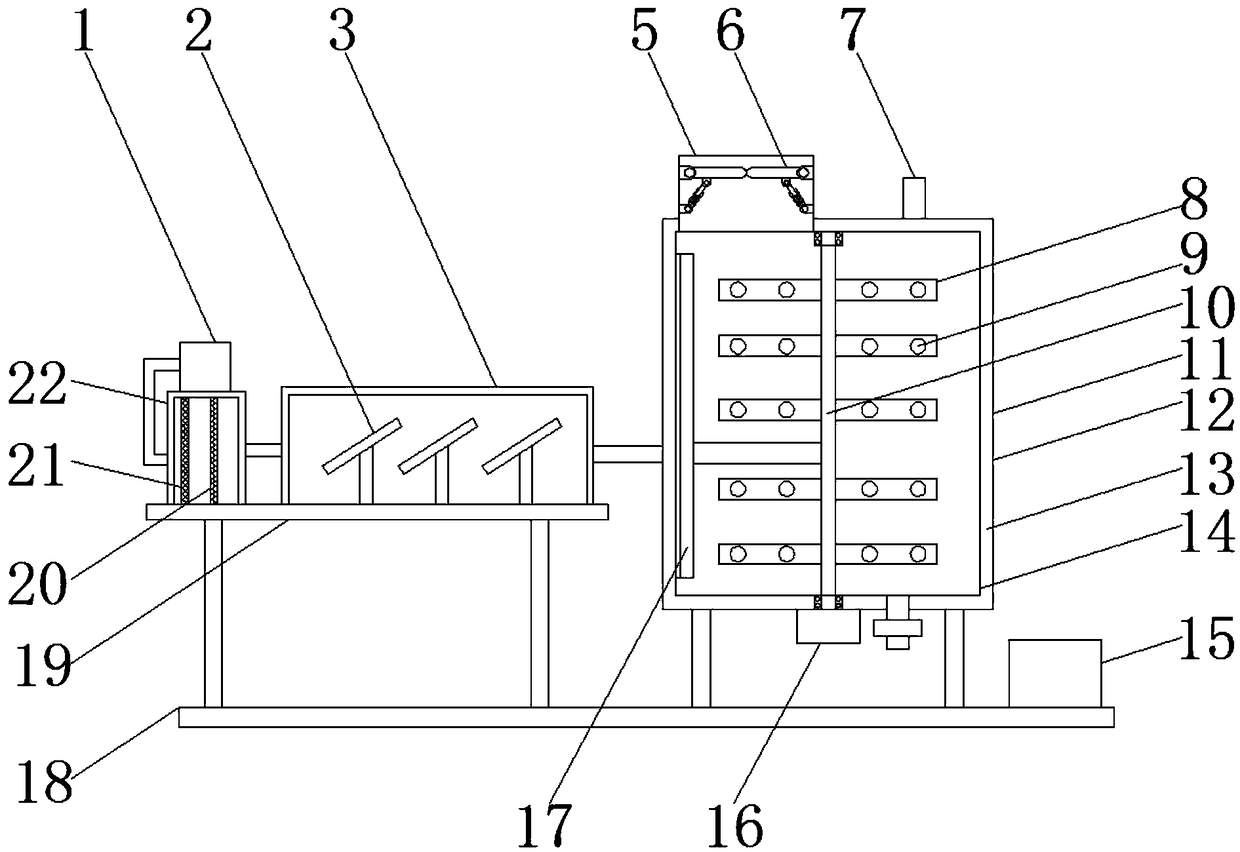

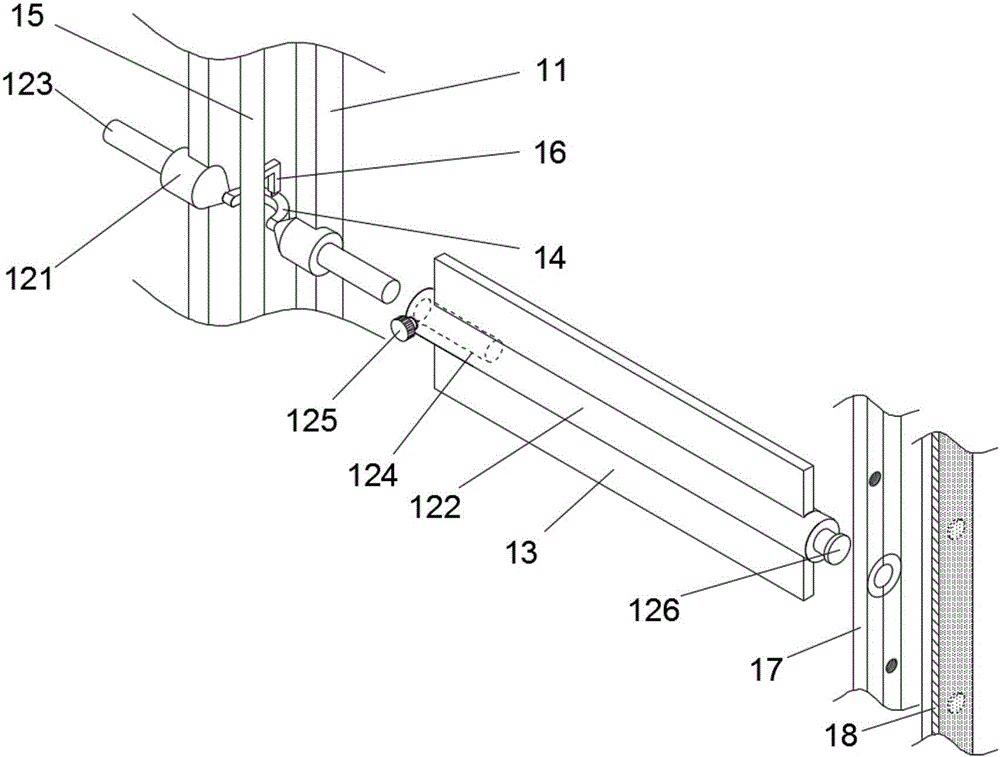

Particle material drying robot

InactiveCN106802066AAchieve conversionAchieve recyclingDrying solid materials with heatGranular material dryingEngineeringMechanical engineering

The invention provides a particle material drying robot which comprises a feeding mechanism, a stoving mechanism arranged on the rear portion of the feeding mechanism, a drying mechanism arranged on the upper portion of the drying mechanism, a discharging mechanism arranged on the rear portion of the stoving mechanism, and a control mechanism in signal connection with the feeding mechanism, the stoving mechanism, the drying mechanism and the discharging mechanism. To avoid the phenomena that in the prior art, drying efficiency is low and energy consumption is high during drying, the stoving mechanism is used for stoving materials, the feeing mechanism and the discharging mechanism are used for feeding and outputting the materials, the drying mechanism is used for rapidly recovering moisture in the materials, energy conversion and recovery are achieved while moisture is condensed and falls through a heat exchanger, and the drying effect is guaranteed while rapid drying is achieved.

Owner:ZHONGZHOU UNIV

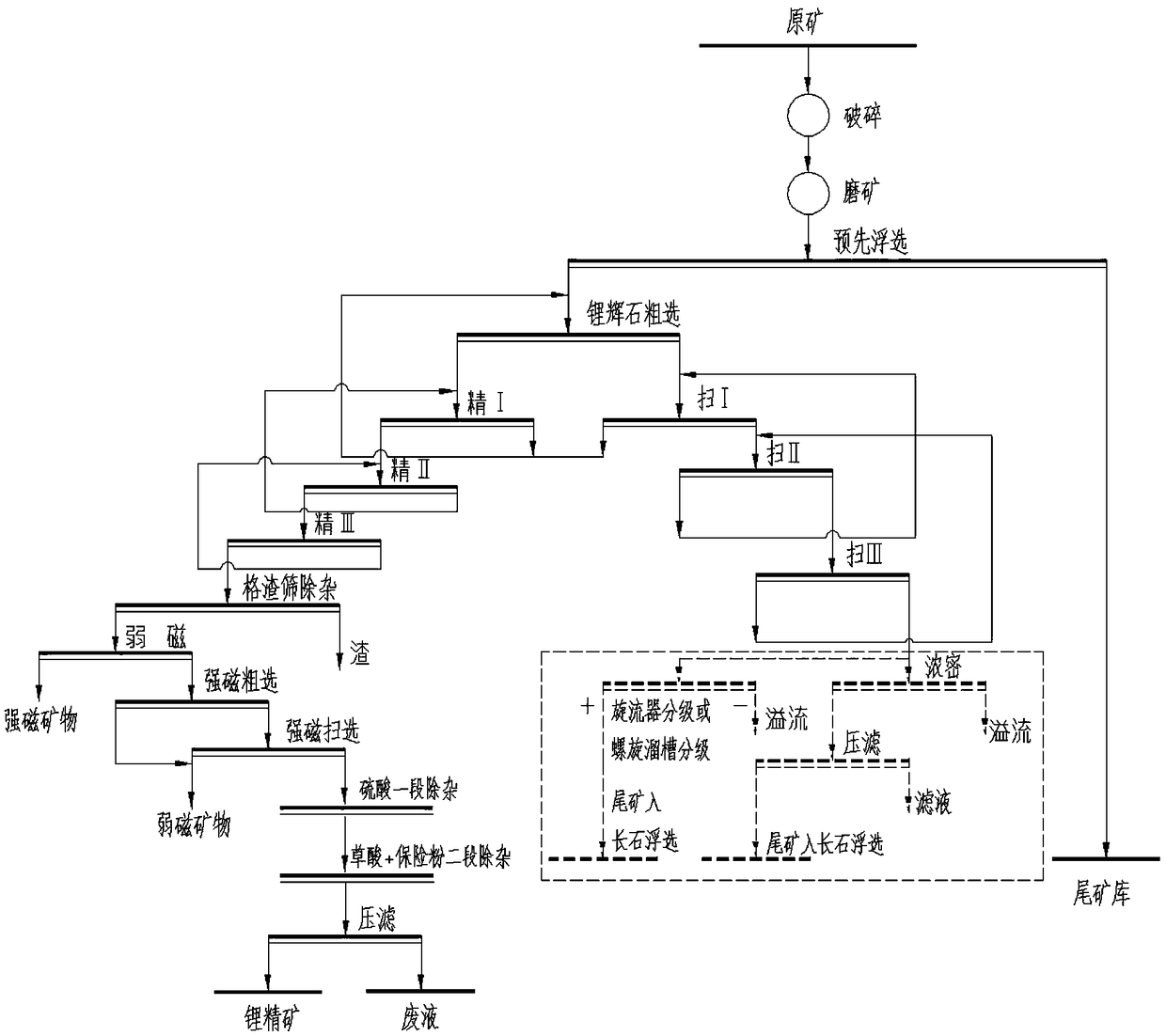

Spodumene ore beneficiation sorting process

The invention discloses a spodumene ore beneficiation sorting process, and belongs to the technical field of multi-metal beneficiation. The spodumene ore beneficiation sorting process comprises the following steps: (1) a SAB crushing flow is adopted to grind raw ores; (2) a CCF flotation column is used for preflotation of ore grinding products to obtain preflotation raw ores; (3) the flotation isperformed on the preflotation raw ores; a flow of one-roughening, three-refining and three-scavenging is adopted; and oxidized paraffin soap, sulfonated soap and naphthenic acid soap are used in mixedcollecting agents in the roughening operation; (4) the solid-liquid separation is performed on flotation tailings; and (5) impurities of spodumene after flotation are removed; and lithium concentrates are obtained by adopting a process of cell slag screening-magnetic separation-acid impurity removal. Through the process of SAB crushing flow+preflotation by the CCF flotation column+spodumene slofation+impurity removal of the concentrates, when the selecting grade of the raw ores is 1.0-1.5%, the recovery rate of the spodumene concentrates is 80-85%; the grade is 5.5-6.0%; and the content of iron trioxide in the concentrates is lower than 0.3%. The process can provide guidance for production of similar mines.

Owner:CINF ENG CO LTD

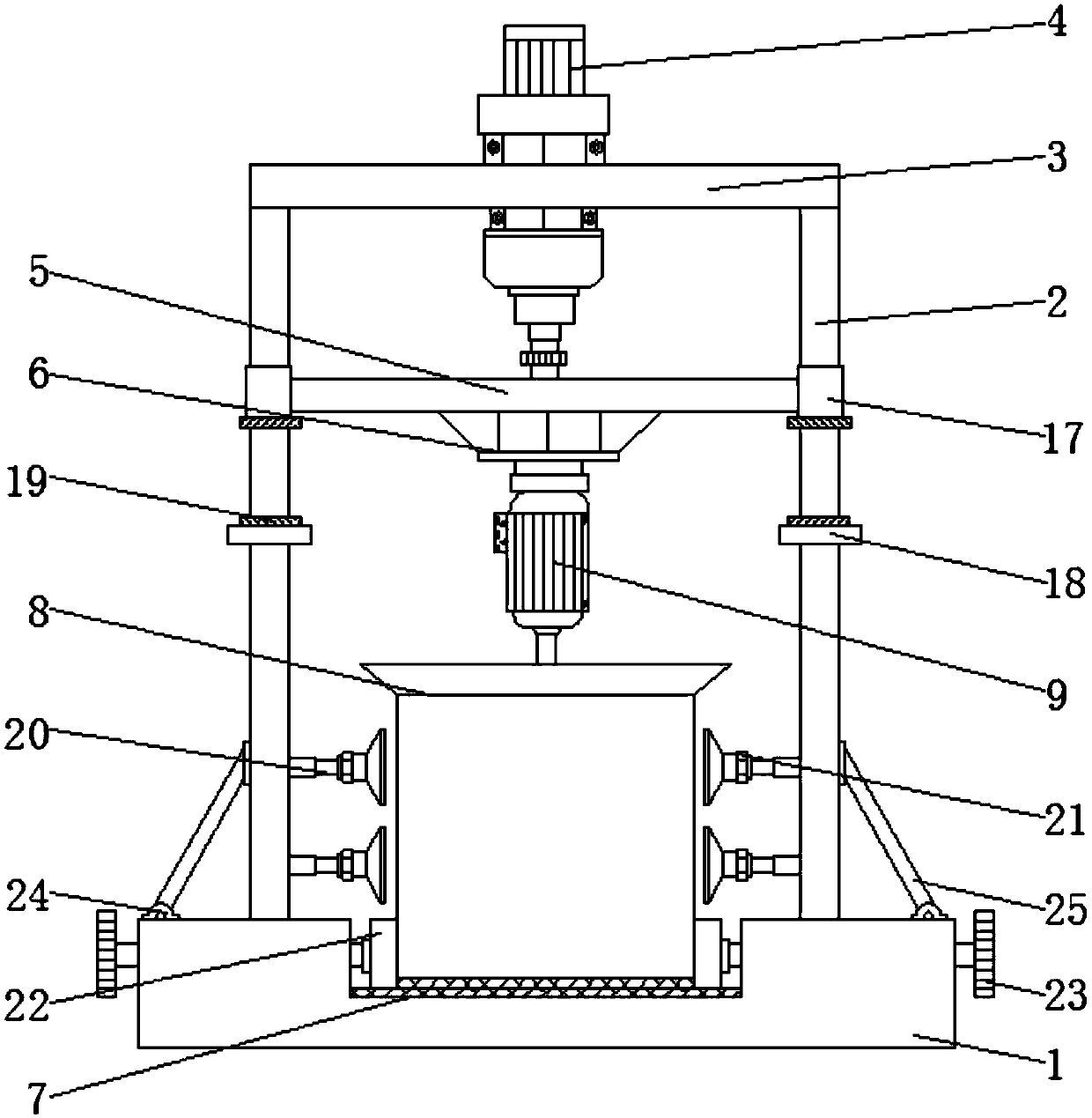

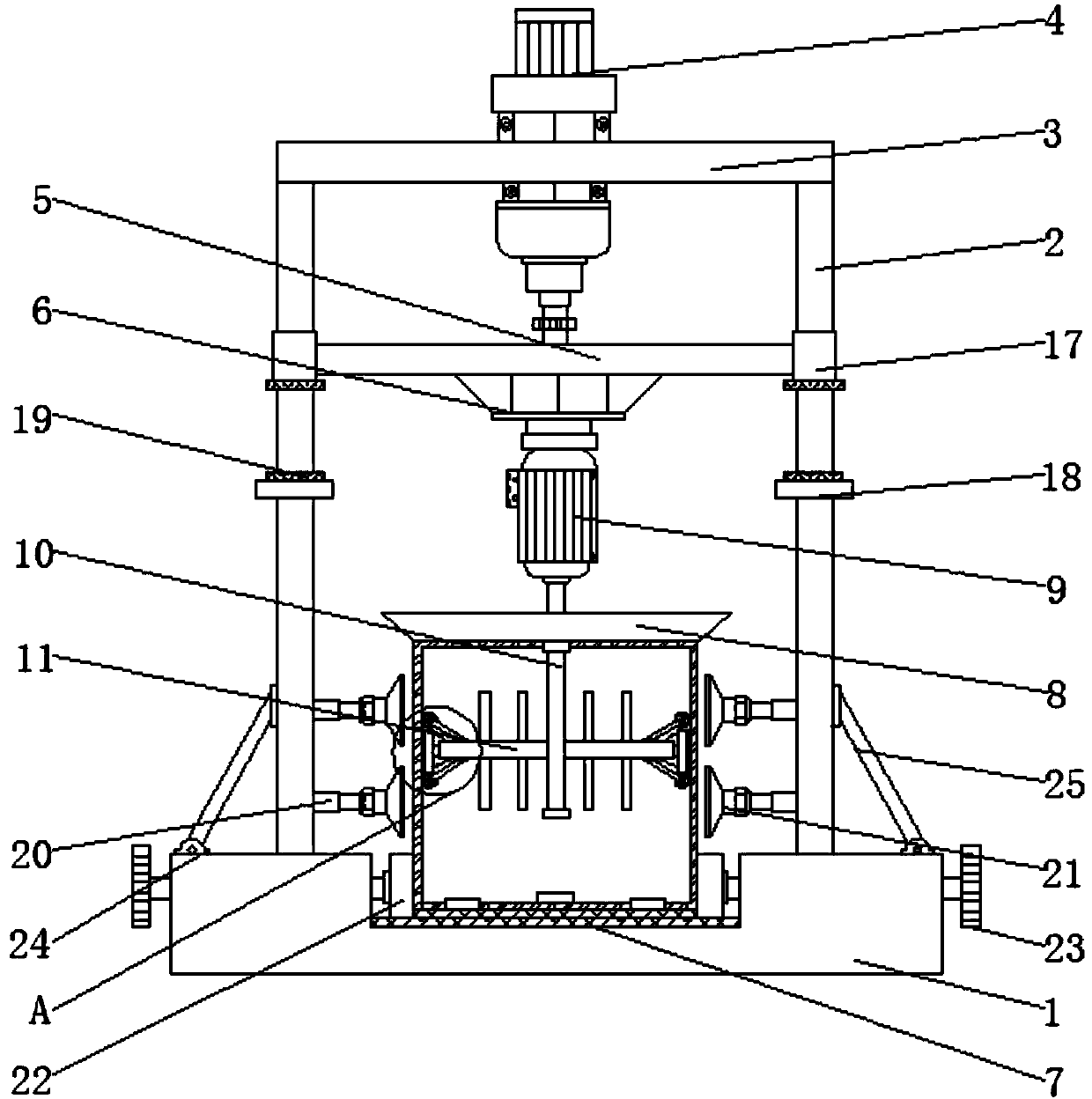

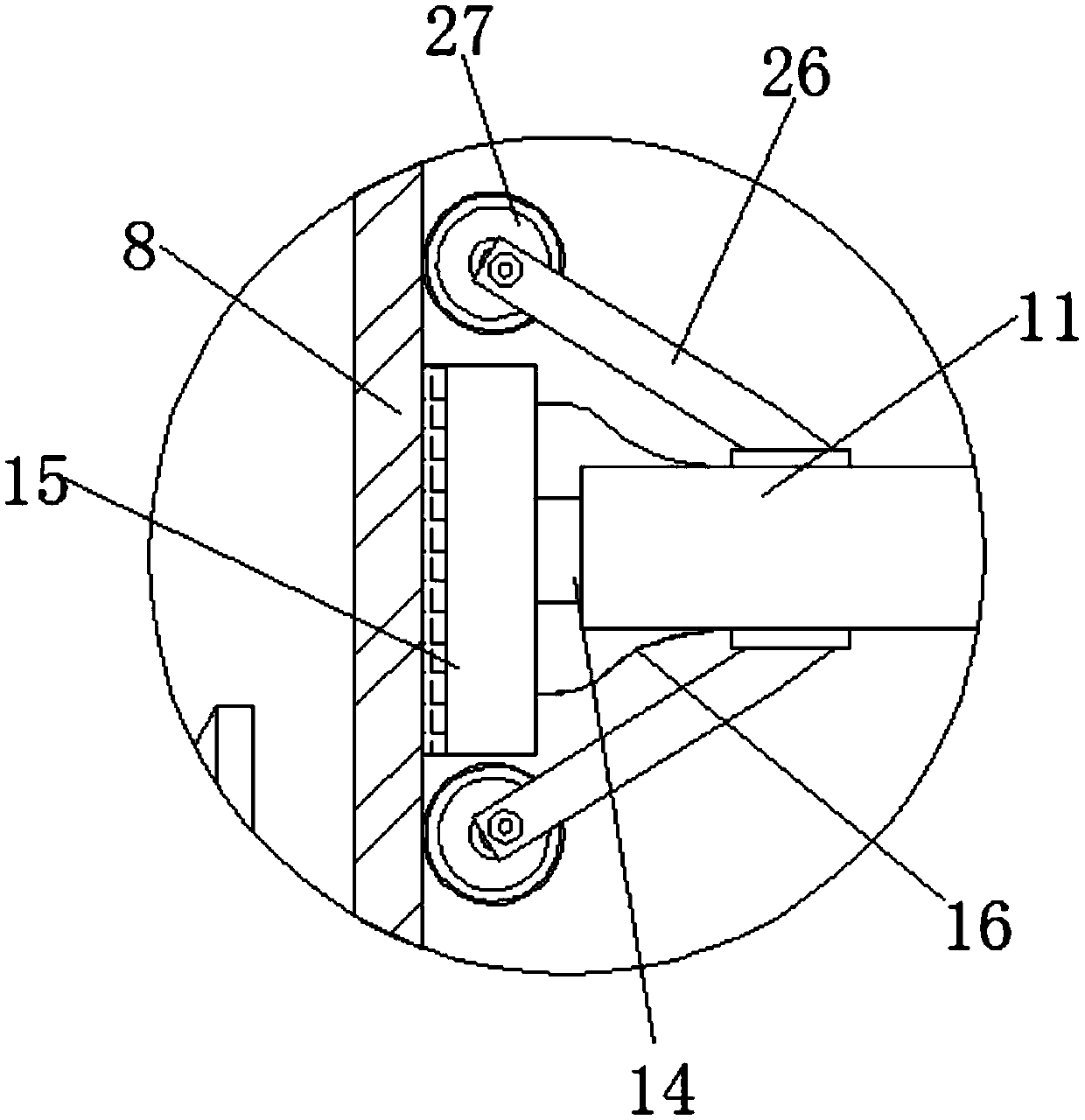

Stirring machine used for rubber production

InactiveCN108031345AEasy to scrapeReduce wasteRotary stirring mixersTransportation and packagingSlurryEngineering

The invention discloses a stirring machine used for rubber production, which includes a pedestal. Sliding rods are fixedly connected to two sides of the top of the pedestal. A fixing plate is fixedlyconnected between the top ends of the two sliding rods. An air cylinder is fixedly connected to the top of the fixing plate. The output end of the air cylinder penetrates through the fixing plate andis extended to the bottom of the fixing plate. The invention relates to the technical field of rubber slurry stirring machine. By means of the stirring machine, rubber raw materials, which are attached to the inner wall of a stirring box, can be scratched away well, so that proportioning accuracy during rubber stirring process is increased and waste on the rubber raw materials is reduced. The stirring machine is convenient to use, is safe and reliable, has excellent scratching function and is improved in stirring effect, can reduce labor intensity, is convenient and quick to use, has excellentfixing function, and is good in convenience.

Owner:ZHONGSHAN RNICE COMML ELECTRIC CO LTD

Stirring device for concrete production

PendingCN111015946AQuality improvementImprove the mixing effectSievingDischarging apparatusSpiral bladeElectric machine

The invention discloses a stirring device for concrete production, and relates to the technical field of concrete production. The device solves the problem during existing stirring, water is prone tolosing. A concrete humidity detection instrument is mounted outside a stirring cylinder, a water tank is mounted on the rear end of the stirring cylinder, an adjusting switch is mounted on one side ofthe water tank, a water pump is mounted on the rear end of the water tank, a flow control sensor is mounted on the upper end of the water tank, a connecting pipe is mounted between the stirring cylinder and the flow control sensor, a screening device is mounted on the upper end of one side of the stirring cylinder, a screening plate is mounted in the screening device, springs are mounted on the two ends of the screening plate, a vibration motor is arranged on one side of the outer portion of the screening device, a cleaning rod is mounted above the screening plate, a discharging device is arranged below the stirring cylinder, the output end of a second driving motor is provided with a second rotating shaft, and spiral blades are arranged outside the second rotating shaft.

Owner:邓婧

Environment-friendly material stirring device with dustproof function

InactiveCN108745102AQuick sealAvoid pollutionRotary stirring mixersTransportation and packagingEngineeringSolar heat

The invention discloses an environment-friendly material stirring device with a dustproof function. The environment-friendly material stirring device comprises a scraping plate, a brush, solar heat collection plates, a stirring tank and a base. The environment-friendly material stirring device has the advantages that the scraping plate is used for scraping materials adhered on the inner wall of the stirring tank, accordingly, effects of stirring materials can be guaranteed, and wastage of the materials can be prevented; effects of scraping the materials adhered on the inner wall of the stirring tank further can be improved by the brush, and accordingly the practicality of the environment-friendly material stirring device can be improved; the solar heat collection plates are used for absorbing solar energy, and accordingly air in a heat-insulation cover can be heated; external air can flow into a filter tank by the aid of an exhaust fan and can be heated by the aid of the solar heat collection plates, accordingly, energy can be saved, and environments can be protected; air in a cavity further can be exhausted via a gas outlet pipe, accordingly, hot air in the cavity can be continuously circulated, the purposes of continuously heating and drying the materials in the stirring tank further can be achieved, and the practicality of the environment-friendly material stirring device further can be improved.

Owner:张梅梅

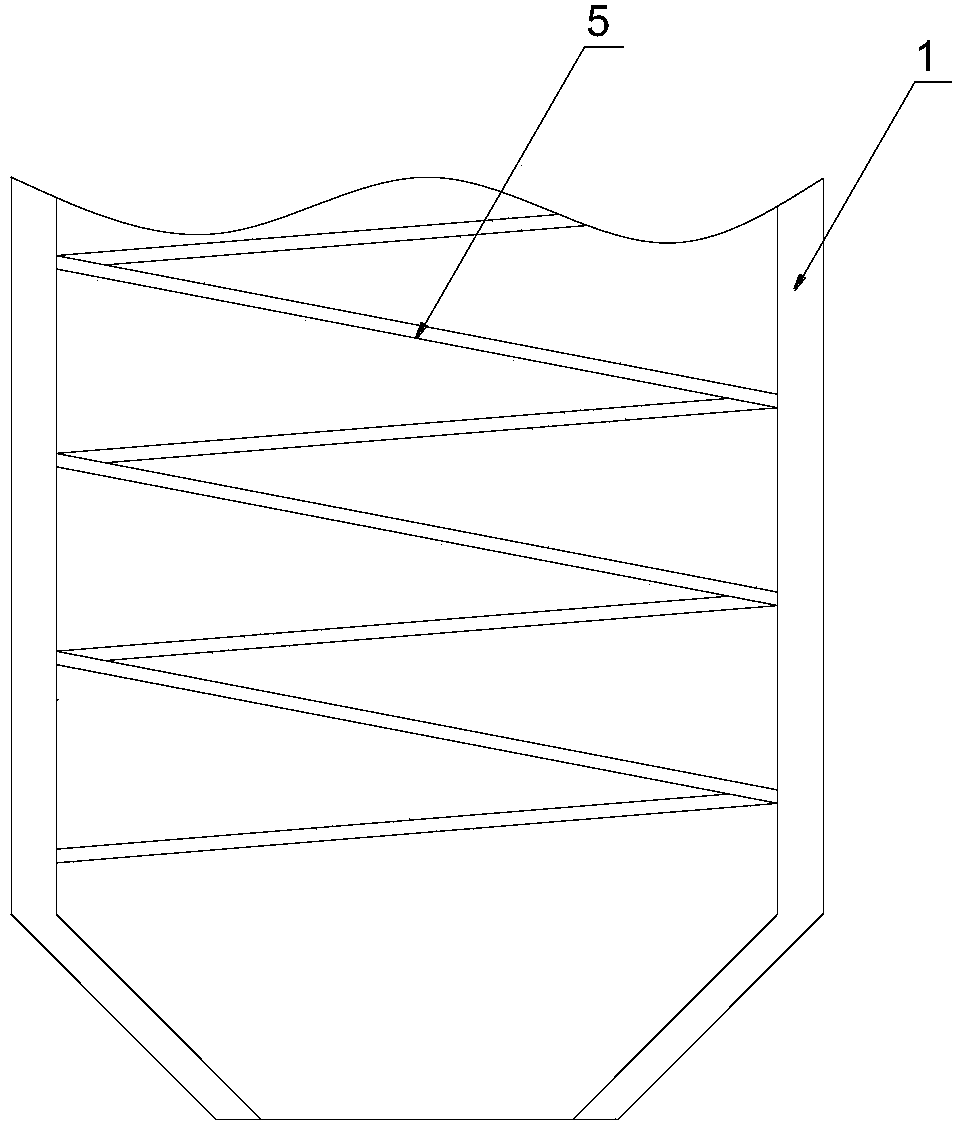

Stirring device for yoghurt production

The invention relates to a stirring device for yoghurt production. The stirring device comprises a stirring barrel, a stirrer disposed in the stirring barrel and a mobile device arranged at the bottom of the stirring barrel. The stirrer includes a stirring shaft vertically disposed in the stirring barrel and a stirring paddle arranged on the stirring shaft. The top of the stirring barrel is equipped with a motor, the stirring shaft pass through the stirring barrel upward and is in transmission connection with the motor. The stirring paddle adopts a spiral blade. A spiral heating plate extends from the bottom of the stirring barrel upward, and the spiral blade is surrounded by the heating plate. The spiral blade has a varying pitch that gradually increases from the end to the central part. An inverted U-shaped paddle is also fixed on the stirring shaft, a longitudinal barrel wall scraper is fixed on the side edge of the U-shaped paddle, and the space between the sides of the barrel wall scraper and the stirring barrel inner wall is 1cm. The stirring device for yoghurt production provided by the invention has the characteristics of simple structure and novel conception, can greatly improve the quality of yoghurt products and ensure the benefits of enterprises in the practical application process.

Owner:浙江美丽健乳业有限公司

End surface bulge type wing-less stirring disc and wing-less stirring device

PendingCN107469661AGuaranteed stirring effectComplementary stirring effect is goodRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention provides an end surface bulge type wing-less stirring disc and a wing-less stirring device. The end surface bulge type wing-less stirring disc comprises a first shaft sleeve and a disc body, wherein the shaft sleeve is arranged in the center of the upper end surface of the disc body; the outer side surface of the disc body is a columnar surface; no stirring blade is needed; and stirring bulges are arranged at at least one of the upper end surface and the lower end surface of the disc body. As no stirring corner angle is arranged on the outer side surface of the disc body of the wing-less stirring disc, and the bulges are arranged on end surfaces of the disc body, a stirring effect is ensured, and furthermore over-loading is not easily caused.

Owner:吴云萍

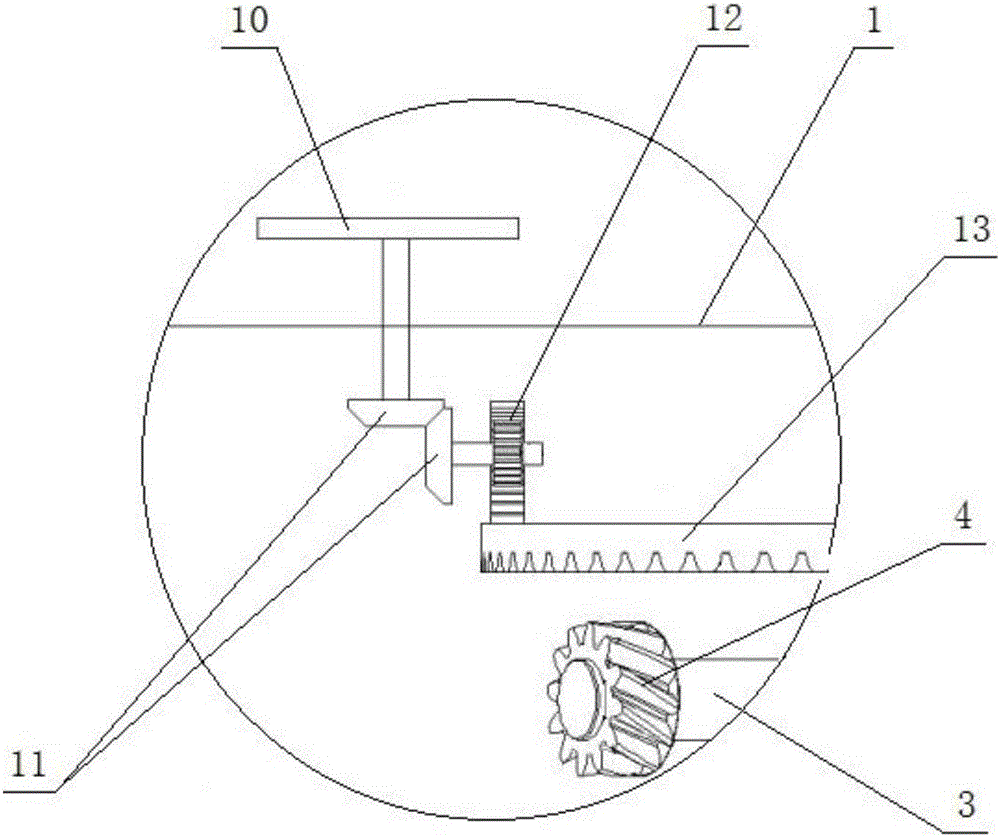

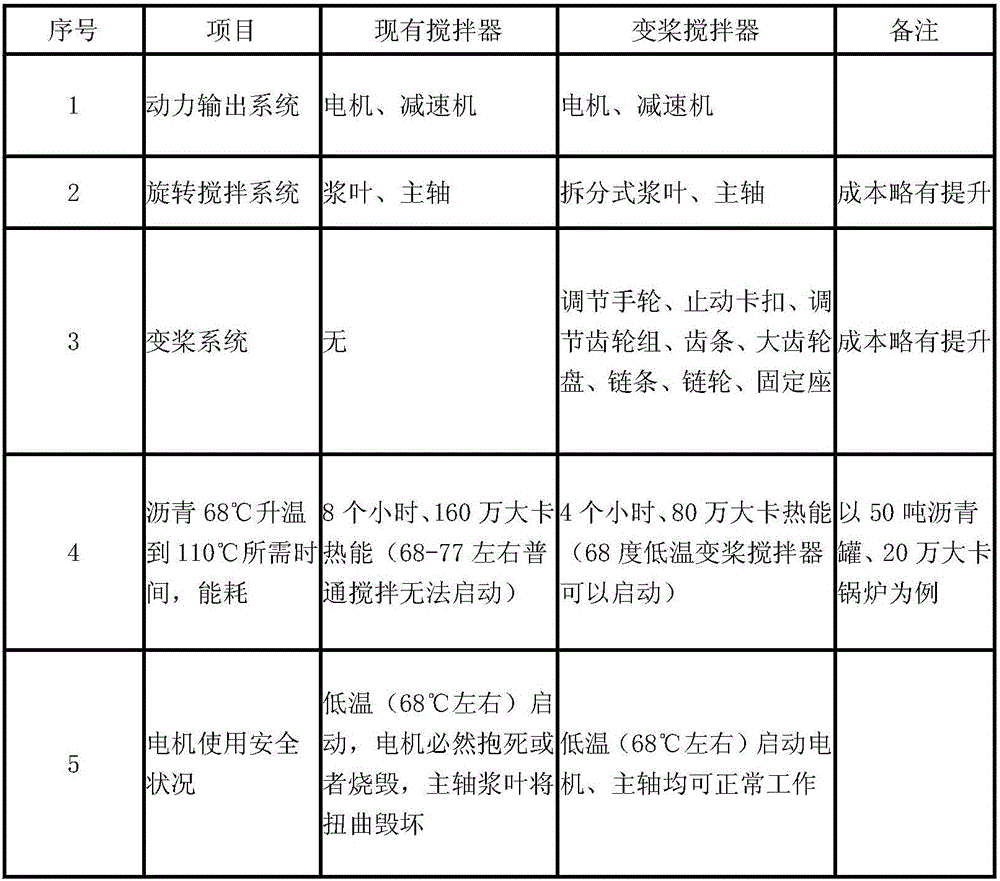

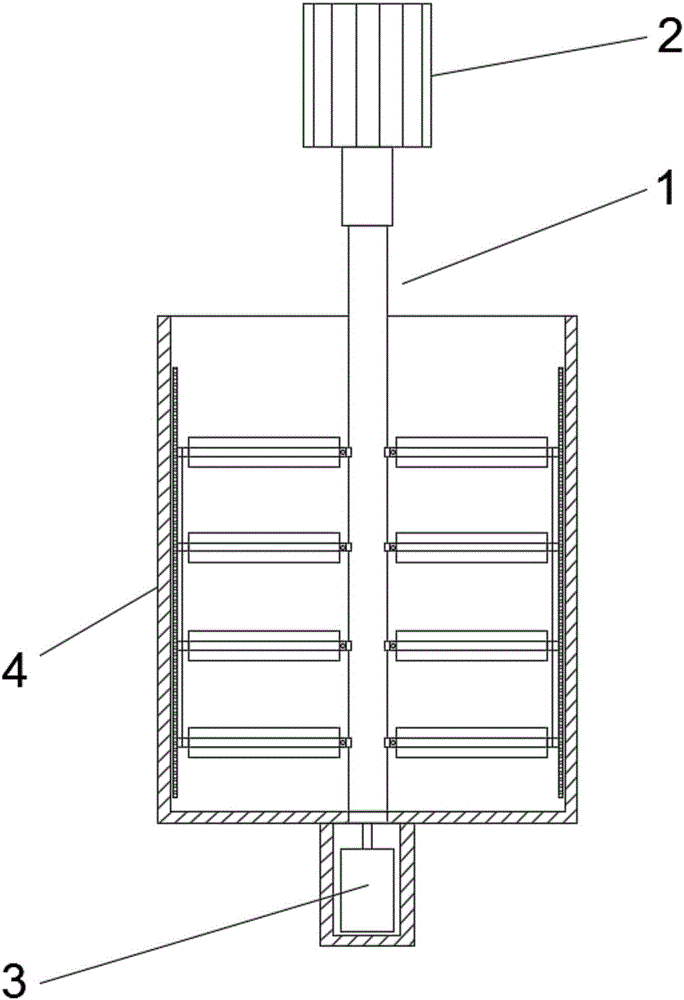

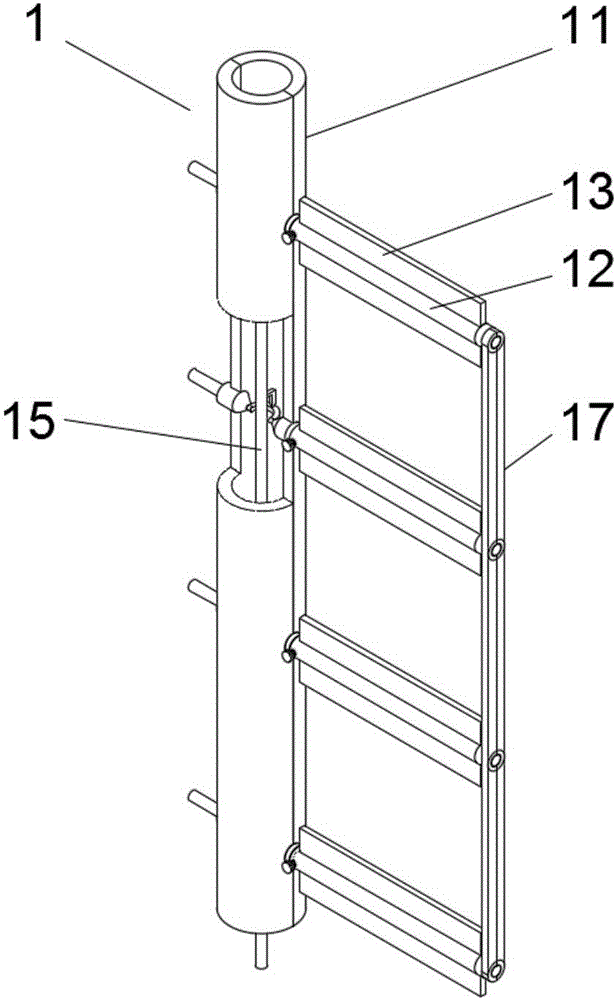

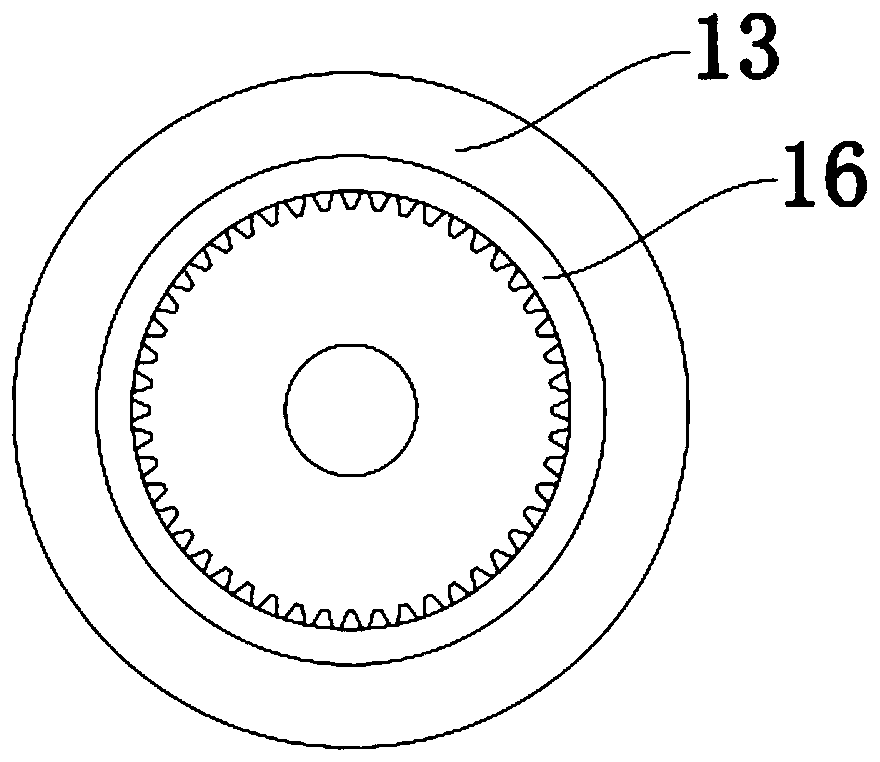

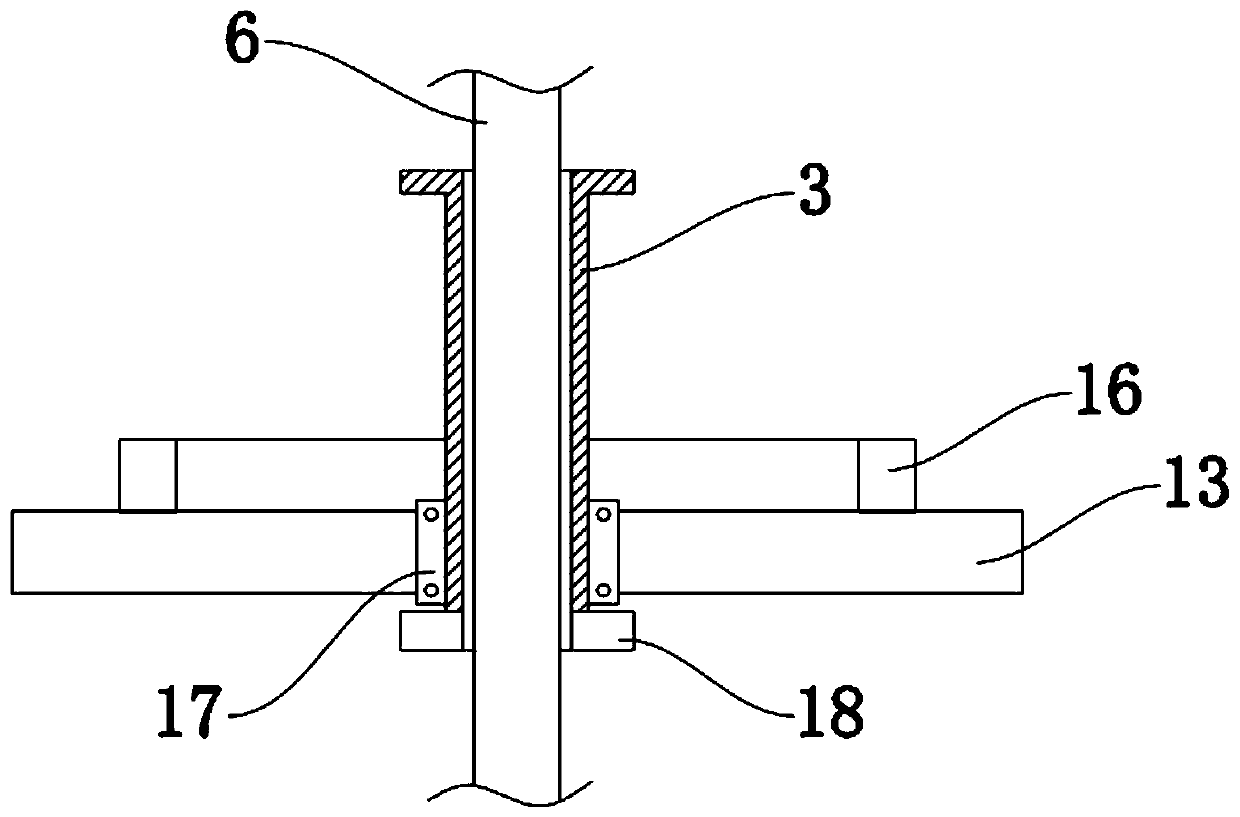

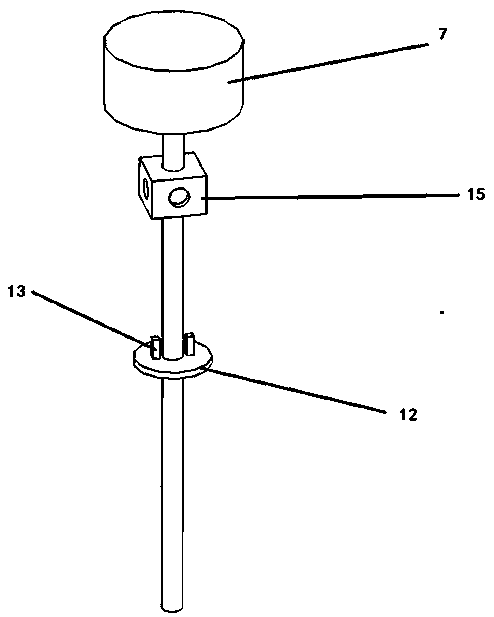

Asphalt tank pitch-variable stirrer

PendingCN106582380AReduce energy consumptionImprove work efficiencyTransportation and packagingRotary stirring mixersAgricultural engineeringAsphalt

The invention discloses an asphalt tank pitch-variable stirrer. The asphalt tank pitch-variable stirrer comprises a power output system arranged outside an asphalt tank and a rotary stirring system arranged in the asphalt tank. The power output system is mainly composed of a motor and a speed reducer connected with the motor through a coupling. The rotary stirring system is mainly composed of a vertically arranged spindle and blades perpendicularly fixed to the spindle. The speed reducer is connected with the spindle through another coupling. The stirrer further comprises a pitch variable system. The pitch variable system is composed of an adjusting hand wheel, an adjusting gear set, a rack, a big gear plate, a small gear, a short shaft, a fixing base, a chain wheel and a chain. According to the stirrer, the mounting angle of the blades of the stirrer can be adjusted in real time according to the temperature, density and viscosity changes of asphalt in the tank, effective stirring of asphalt with different temperatures, densities and viscosities can be achieved, the production efficiency of the asphalt can be effectively improved, the energy consumption is reduced, the equipment damage probability is lowered, and the asphalt tank pitch-variable stirrer has prominent practicability and remarkable economic value.

Owner:湖北安捷路桥技术有限公司

Self-cleaning type agitating vessel

InactiveCN106540613ATimely replacementAvoid depositionTransportation and packagingRotary stirring mixersPulp and paper industryScrub brushes

The invention relates to a self-cleaning type agitating vessel. The self-cleaning type agitating vessel comprises a cylinder body; wherein a stirring paddle is arranged in the cylinder body, the stirring paddle comprises a hollow stirring shaft; stirring rods are distributed on the stirring shaft in pairs; each stirring rod comprises a fixing part and an inserting connection part; a convex column is arranged on each fixing part; a hollow slot is arranged in each inserting connection part; stirring blades are arranged on the inserting connection parts respectively; an axis location of the interior of the stirring shaft is also provided with an adjusting connecting rod; the interior of the stirring shaft is also provided with a semicircle adjusting handle; the fixing parts are connected with two ends of the adjusting handle; the adjusting connecting rod is hinged to the middle part of the adjusting handle; fixing clamp pairs of the inserting connection parts of the stirring rods arranged on the same side are provided with fixed splints in a clamping way, the outer side surface of the fixing splints are fixed with scrubbing brushes. The angle of the stirring blades in the invention can be changed in real time to change the stressing flow direction in the cylinder body, so that the stirring effect is better; when the stirring rods are damaged, the stirring rods can be replaced in time by adopting an inserting connection manner; the end part of the stirring rod is fixed through the fixing splints, so that the stability is enhanced and the stirring effect is ensured.

Owner:苏州柯米智能科技有限公司

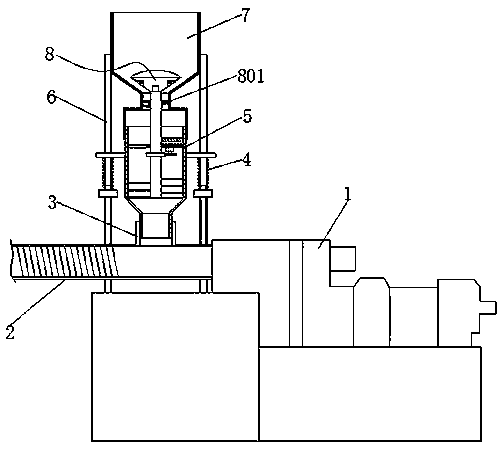

Sewage stirring treatment device utilizing planetary gear transmission principle

InactiveCN111302413AEasy to handleTo achieve the effect of reverse rotationRotary stirring mixersTransportation and packagingReduction driveElectric machine

The invention relates to the technical field of sewage treatment. The invention further discloses a sewage stirring treatment device utilizing a planetary gear transmission principle. The device comprises a stirring kettle, and a support frame is fixedly connected to the outer part of the stirring kettle. The top of the stirring kettle is fixedly connected with an adjusting frame. The top of the adjusting frame is fixedly connected with a speed reducer. A motor is fixedly connected to the exterior of the speed reducer. Balls are movably connected into the adjusting frame. The outer portions ofthe balls are movably connected with an outer gear ring. The interior of the outer gear ring is connected with transition gears in an engaged mode. The outer gear ring, the transition gears and a central gear are matched for use, so that the effect that a sleeve shaft and a center shaft rotate reversely is achieved, outer stirring blades and inner stirring blades rotate reversely, the stirring effect is improved, the stirring efficiency is improved, sewage and liquid medicine are fully mixed, the sewage treatment effect is improved, frequent reverse rotation of the motor is avoided, it is guaranteed that the motor rotates in the same direction all the time, and the service life of the motor is guaranteed.

Owner:彭子君

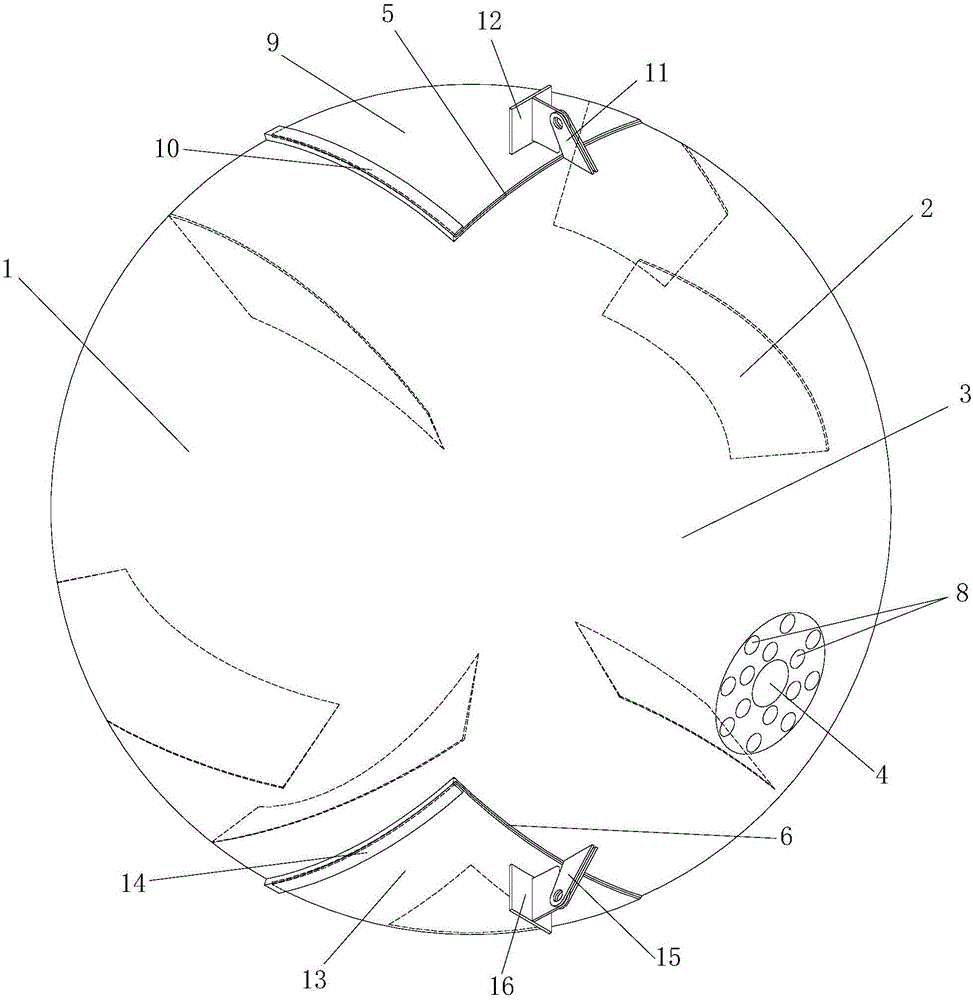

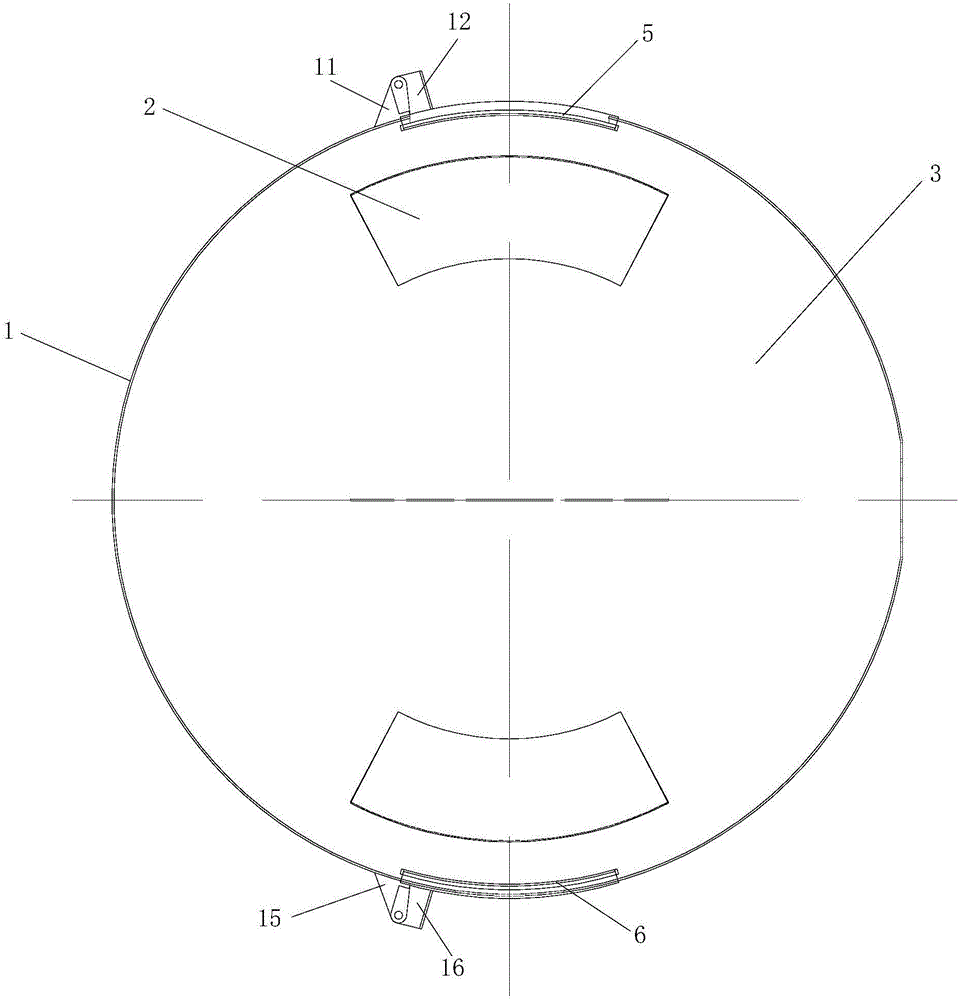

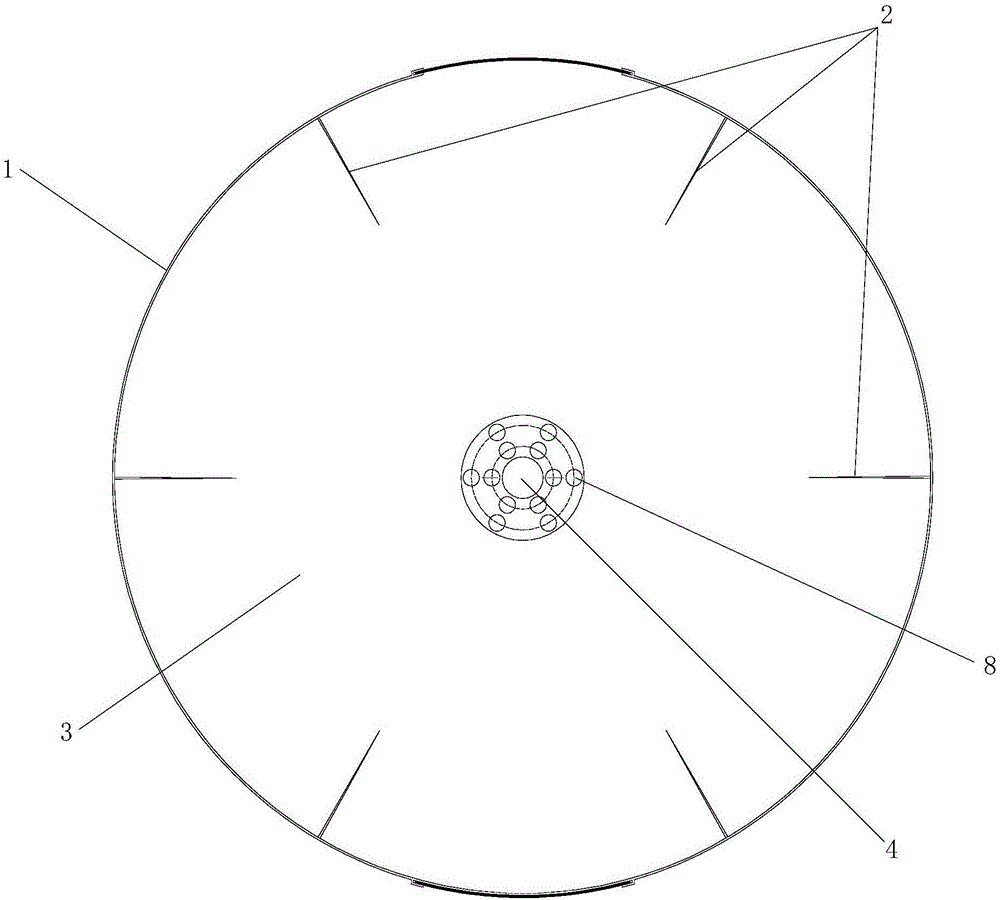

Spherical stirring device

InactiveCN106076180AIncrease gravitational potential energyImprove mixing effectRotating receptacle mixersTransportation and packagingAccess portMechanical engineering

The invention discloses a spherical stirring device. The spherical stirring device comprises a spherical tank and a plurality of stirring plates, wherein a stirring cavity is formed in the spherical tank, the stirring plates are evenly installed in the stirring cavity, rotary shaft holes allowing a rotary shaft to pass through are formed in the two ends of the spherical tank, a material access port and a water drainage port are formed between the rotary shafts holes in the two ends, a plurality of ventilation holes are formed in the periphery of one rotary shaft hole, and a plurality of mist spray holes are formed in the periphery of the other rotary shaft hole. The spherical stirring device is simple in structure, convenient to operate and good in stirring effect.

Owner:SOUTH CHINA UNIV OF TECH

Smelting method of electrode bar base material for non-protective-atmosphere electroslag remelting of H13 steel

The invention discloses a smelting method of an electrode bar base material for non-protective-atmosphere electroslag remelting of H13 steel, and belongs to the field of ferrous metallurgy. The smelting method of the electrode bar base metal for non-protective-atmosphere electroslag remelting of the H13 steel comprises the steps of electric furnace steelmaking, LF furnace refining, VD vacuum degassing, pouring and the like. According to the smelting method, by increasing the content of [Al] in the steel, adjusting the composition of the LF slag, and adjusting a VD argon soft blowing system to be proper, the content of inclusions in the molten steel can be effectively reduced, and the cleanliness of the electrode bar base material is improved. By the adoption of the electrode bar base material prepared through the method, secondary oxidation of molten steel in the electroslag remelting process can be avoided, so that the content of oxidation-system inclusions in the H13 steel manufactured through non-protective-atmosphere electroslag remelting is reduced, and the quality of steel obtained after non-protective-atmosphere electroslag remelting is improved. The problems that an existing electrode bar base material used for non-protective-atmosphere electroslag remelting of the H13 steel is low in cleanliness and prone to secondary oxidation in the non-protective-atmosphere electroslag remelting process can be effectively solved.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

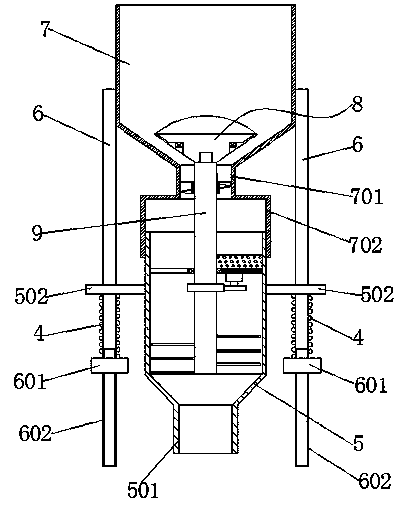

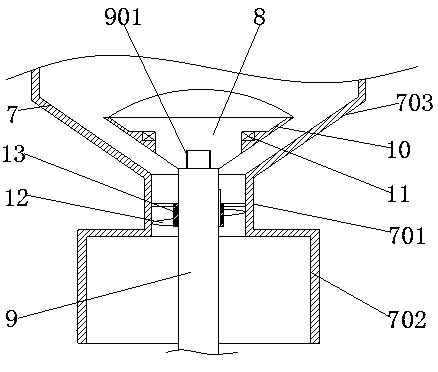

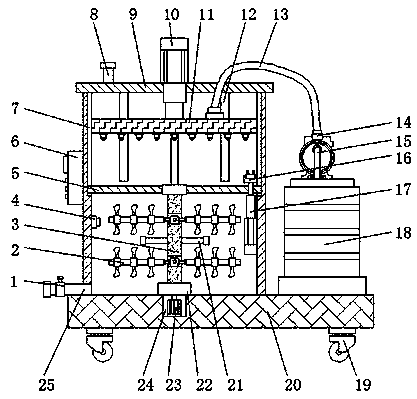

Pre-crushing concrete mixing device

InactiveCN107471441AGuaranteed stirring effectIncrease the mixing areaDischarging apparatusMixing operation control apparatusEngineeringConoid

The invention discloses a pre-crushing concrete mixing device comprising a shell, a bottom plate and a base. The left side of the upper end of the shell communicates with a feeding hopper; a first crushing roller and a second crushing roller are arranged in the feeding hopper; a first motor is fixedly mounted in the middle of the upper end of the shell; an output shaft of the first motor is connected with a stirring shaft; a plurality of stirring blades are welded to the stirring shaft; a conical bottom plate is arranged at the bottom of the shell; the bottom end of the conical bottom plate communicates with a discharging pipe; a bottom plate is arranged below the shell, an extruding cylinder is arranged in the middle of the bottom plate, and the upper end of the extruding cylinder communicates with the shell through the discharging pipe; the base is arranged below the bottom plate; and the base and the bottom plate are connected through a plurality of damping spring columns. The structure is simple, the design is reasonable, it is guaranteed that the subsequent mixing and stirring effects are good through pre-crushing, meanwhile, the pre-crushing concrete mixing device is good in damping performance, automatic discharging can be further achieved, and manual operation is not needed.

Owner:俞纪洪

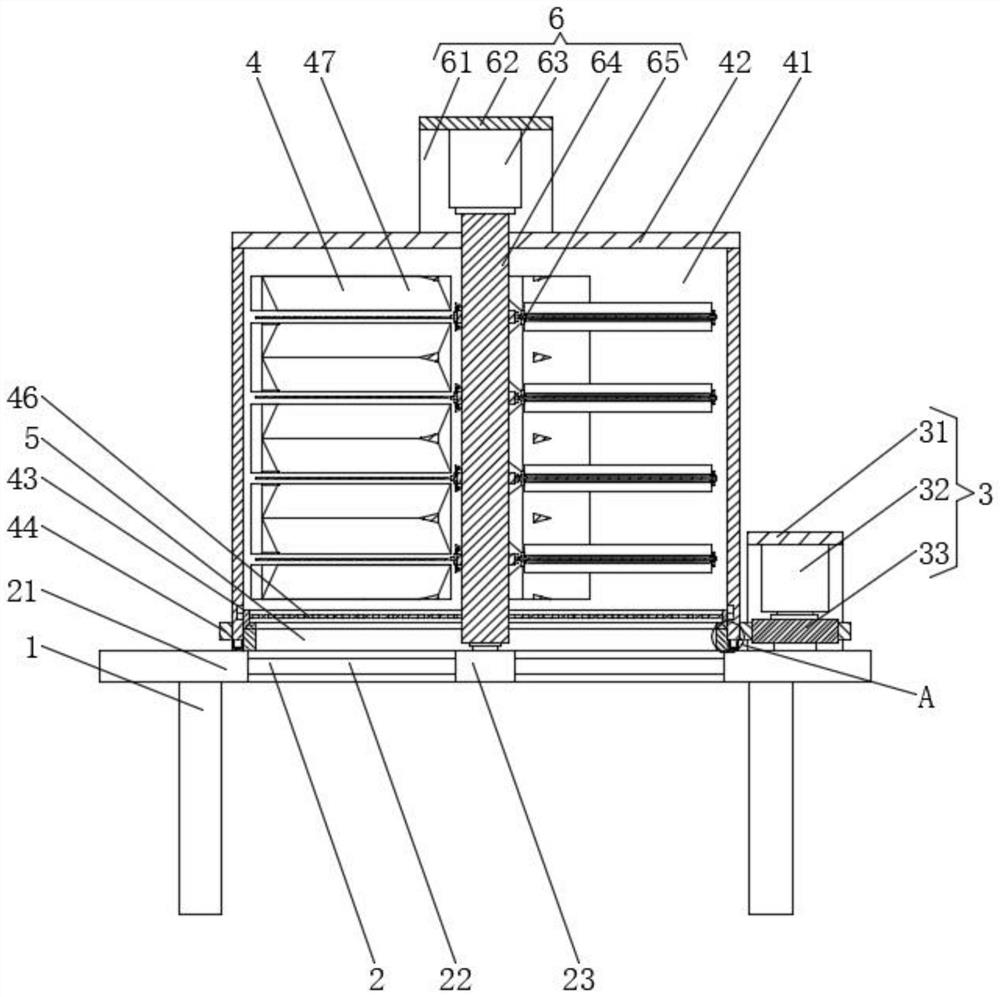

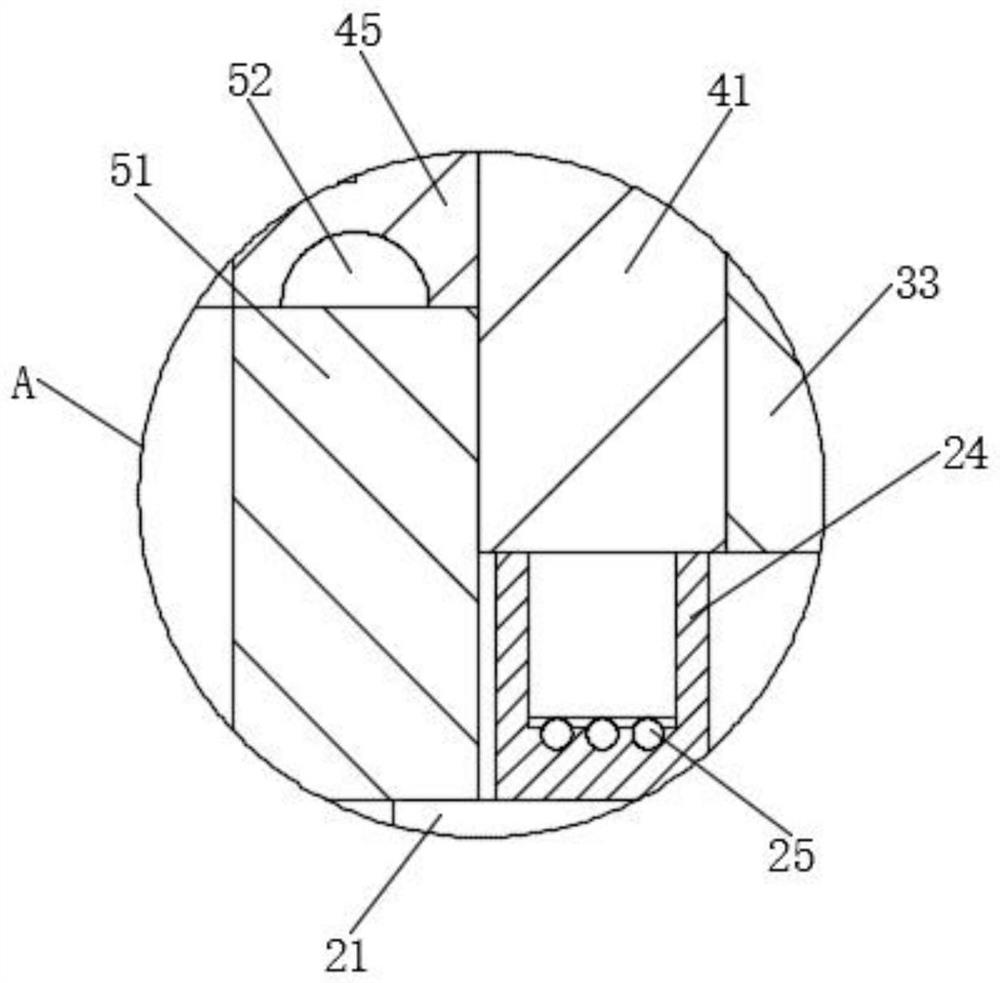

Shaving board manufacturing raw material pretreatment process

ActiveCN112440361AGuaranteed stirring effectImprove stirring effectSievingScreeningMechanical engineeringIndustrial engineering

The invention relates to a shaving board manufacturing raw material pretreatment process. Equipment included in the shaving board manufacturing raw material pretreatment process comprises supporting legs, an upper table top, an external driving device, an outer stirring ring, a vibration agitation base and a chopping device, wherein the upper table top is fixedly mounted at the top ends of the supporting legs. According to the shaving board manufacturing raw material pretreatment process, inner stirring blocks are fixedly arranged in the outer stirring ring at intervals, each inner stirring block is provided with an inclined surface structure, the inclined surfaces between every two adjacent inner stirring blocks are in a shape of a tip which is concave inwards in the rotating direction, and the whole outer stirring ring can be driven by the external driving device to rotate, so that the stirring effect of internal raw materials is guaranteed, the situation that a cutter only crushes raw materials on the layer where the cutter is located is avoided, meanwhile, the stirring effect of the raw materials can be further improved through overall rotation of the outer stirring ring, and moreover, the cutter is further provided with a flapping plate capable of flapping for flapping and mixing the raw materials, so that the crushing uniformity is improved.

Owner:万华禾香板业(韶关)有限公司

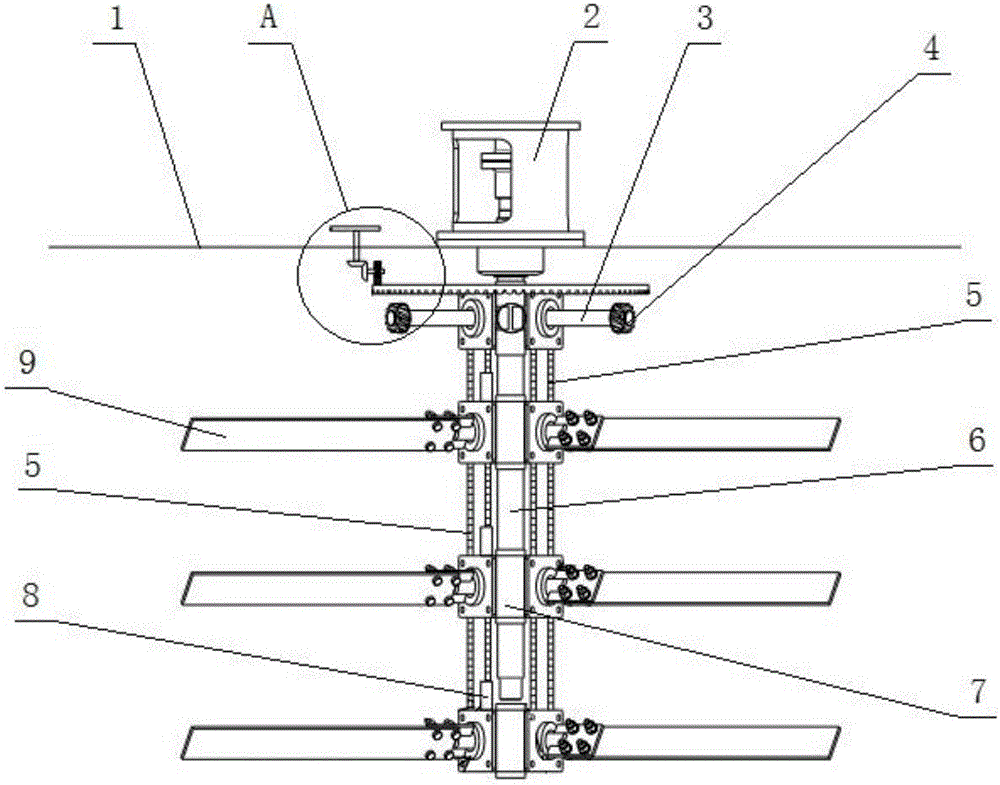

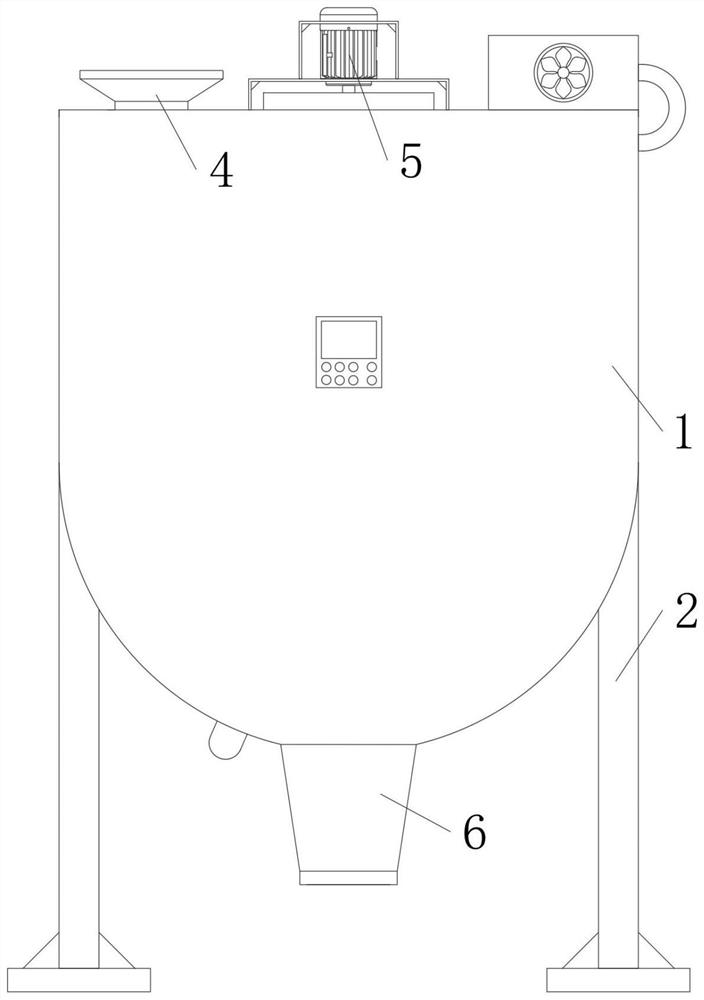

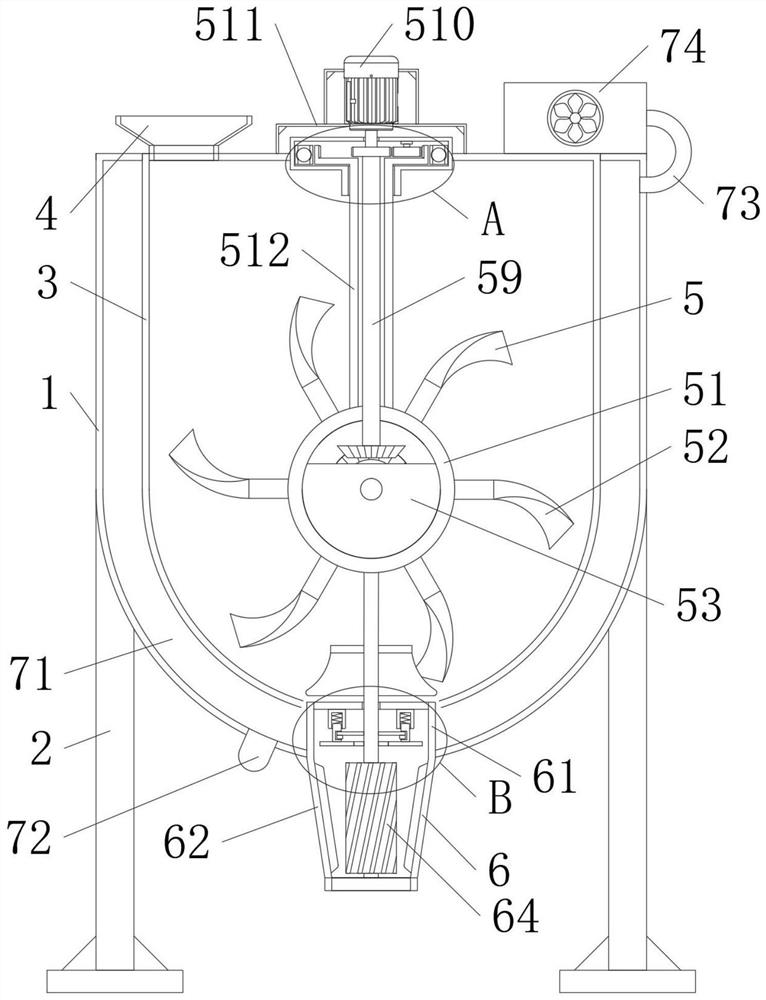

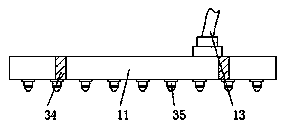

High-efficiency dispenser of marine paint

InactiveCN107081090AEasy to disperse and mixImprove practicalityTransportation and packagingRotary stirring mixersEngineering

Owner:朱德金

Donkey-hide gelatin blood-nourishing granule raw material mixing process and mixing device thereof

PendingCN113694800AWell mixedImprove the mixing effectRotary stirring mixersMixer accessoriesMedicinal herbsColla corii asini

The invention discloses a donkey-hide gelatin blood-nourishing granule raw material mixing process and a mixing device thereof. The mixing device comprises a hollow mixing tank and a plurality of supporting legs installed at the lower end of the mixing tank, an inner tank is arranged in an inner cavity of the mixing tank, a feeding hopper is inserted in one side of the top wall of the inner tank in a penetrating mode, and a mixing mechanism is arranged in the inner cavity of the inner tank and penetrates through the top wall of the inner tank; a discharging mechanism connected with the mixing mechanism is also arranged in the inner cavity of the inner tank; the mixing mechanism comprises stirring wheels which are symmetrically and rotatably mounted in an inner cavity of the inner tank, a plurality of stirring claws are arranged on the stirring wheels at equal intervals, the center shafts of the stirring wheels extend towards the close sides and are rotatably connected with a rotating box in a penetrating mode, and the center shafts of the stirring wheels all penetrate through the side wall of the rotating box and are fixedly sleeved with driven bevel gears. The problems that in the prior art, the mixing efficiency is low, pasty raw materials cannot be mixed, medicinal raw materials are likely to splash out, mixing dead angles are likely to be generated, and the mixing quality is poor are solved. The device is especially suitable for fully mixing the donkey-hide gelatin blood-nourishing granules.

Owner:HUIYINBI GROUP ANHUI PHARMA

Stirring machine capable of preventing materials from adhering to wall

ActiveCN108582480AWell mixedGuaranteed stirring effectTransportation and packagingMixer accessoriesPulp and paper industryConical surface

The invention discloses a stirring machine capable of preventing materials from adhering to the wall. The stirring machine comprises a stirring machine body, a stirring shaft, a stirring paddle, fixing frames, scraping plates, a discharging outlet, a flow valve, a feeding hopper, a feeding channel and an additive feeding device; a motor is fixedly installed on the outer side of the top of the stirring machine body and drives the stirring shaft to rotate; the stirring paddle is installed on the periphery of the stirring shaft; the bottom of the stirring machine body is provided with a conical surface, the lowermost position of the conical surface of the stirring machine body is provided with the discharging outlet, and the flow valve is installed at the discharging outlet; one side of the stirring machine body is connected with a water feeding pipe; the upper portion of the stirring machine body is provided with a feeding inlet, and the feeding inlet is connected with the feeding channel; the feeding hopper is installed at the high end of the feeding channel; the additive feeding device is fixed to the middle of a discharging channel through a bracket of the additive feeding device;a storage bin is arranged on the upper portion of the additive feeding device, and a stirring device is arranged in the storage bin; and a discharging pipe communicates with the discharging channel.According to the stirring machine, the material stirring effect is ensured, mixing is uniform, additives are uniformly mixed and achieve the best efficacy, and the effect that the quality of concreteis the best is ensured.

Owner:来安县塔鑫建材有限公司

Glove processing raw material ingredient stirring device and stirring process thereof

InactiveCN110341064AAvoid stratificationImprove the mixing effectAdditive ingredientMedium frequency

The invention discloses a glove processing raw material ingredient stirring device and a stirring process thereof. The device comprises a rotating shaft, a metal inner tank and a driving disc, a sealing cover is fixed at the top of the metal inner tank through a flange, a supporting sleeve pipe is fixed at the bottom of the sealing cover through bolts, the top of the sealing cover is provided witha second motor, the output end of the second motor is fixedly connected with the rotating shaft penetrating through the supporting sleeve pipe and extending into the metal inner tank, the driving disc is rotationally installed on the supporting sleeve pipe through a second bearing, a gear ring is fixed on the upper surface of the driving disc, a scraping rod is fixedly welded to the lower surfaceof the driving disc, and a medium-frequency heating coil is wound around the outer wall of the middle of the metal inner tank. According to the device and the process, a middle tank body of the metalinner tank can be heated by means of the medium-frequency heating coil, so that materials in the metal inner tank are heated and melted, and a vertical stirring speed and a longitudinal stirring speed can be independently controlled according to different viscosities of the mixture, so that the stirring effect of ingredients is ensured.

Owner:江苏顶洁医疗器械有限公司

Powder coating extruder

ActiveCN111495271AImprove the mixing effectGuaranteed stirring effectShaking/oscillating/vibrating mixersTransportation and packagingElectric machineryMechanical engineering

The invention relates to the technical field of powder coating production equipment, in particular to a powder coating extruder. A storage cylinder is arranged directly above a barrel; a shaft body ofa penetrating shaft is rotationally connected with a fixed plate; a motor is fixed at the bottom of the fixed plate; a scraping plate is fixed on the shaft body of the penetrating shaft; the lower surface of the scraping plate is attached to the surface of the fixed plate; a plurality of connecting rods are fixed on the outer ring of a second bearing; the tail end of each connecting rod is fixedin a material storing and discharging pipe; a baffle ring is arranged on a rod body of a supporting rod; one end of a spring presses the lower end surface of a fixing sleeve; and the other end of thespring is pressed on a baffle ring. When the powder coating extruder is used, dynamic speed regulation of the feeding speed of a premixing barrel is achieved to guarantee that the premixing barrel isnot filled, the stirring effect of the premixing barrel is guaranteed, the uniformity of powder coating is improved, the functions of stirring and feeding pushing can be achieved through a single power mechanism, the structure is simple, and the equipment cost is reduced.

Owner:广东睿智环保科技股份有限公司

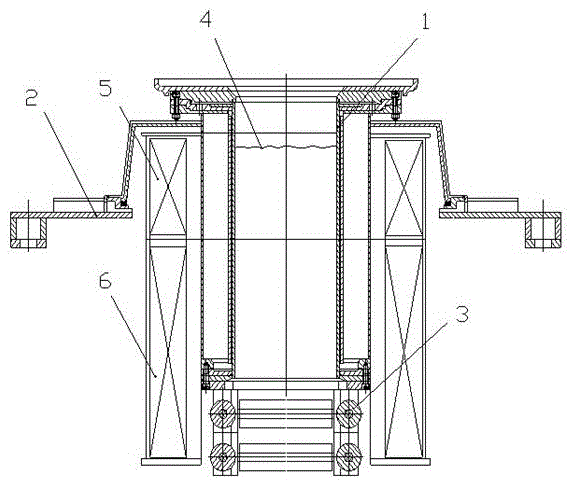

Multi-zone electromagnetic stirring device and method for continuous casting machine crystallizer

The invention discloses a multi-zone electromagnetic stirring device and a multi-zone electromagnetic stirring method for a continuous casting machine crystallizer, and belongs to the technical field of continuous casting equipment and the continuous casting method, and the device and the method are used for improving the electromagnetic stirring effect of the whole crystallizer area. According to the technical scheme, the invention adopts a combined structure of an upper electromagnetic stirring coil and a lower electromagnetic stirring coil, and a stirring method, so that the stirring effect of molten steel at the meniscus of the crystallizer is guaranteed, and the stirring zone of the molten steel is prolonged. The upper electromagnetic stirring coil can be started for steel types with high surface quality requirements, the lower electromagnetic stirring coil can be started for steel types with strict subcutaneous and segregation requirements, and the two groups of electromagnetic stirring coils are simultaneously started to work for the steel types with casting blank surface quality requirements and internal quality requirements. The structure of the conventional electromagnetic stirring device and the stirring method are broken through, the electromagnetic stirring metallurgical requirements of different zones of the crystallizer can be improved in a targeted mode, requirements of different steel types on equipment performances can be met, the quality of the casting blank can be effectively improved, and the economic benefits are remarkable.

Owner:SHIJIAZHUANG IRON & STEEL

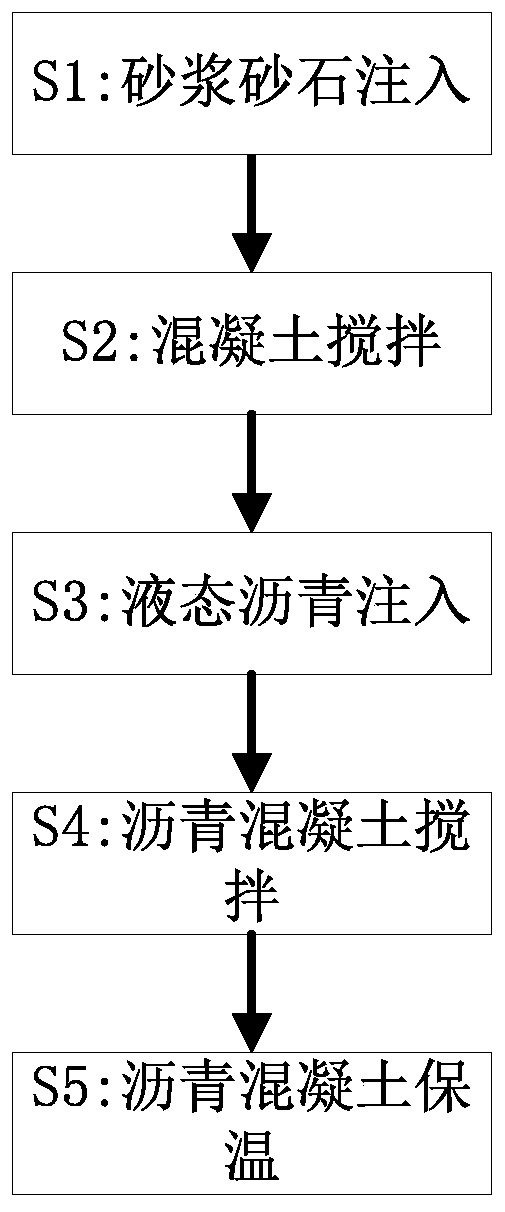

Asphalt concrete preparation technology

ActiveCN111497014AWell mixedIncrease temperatureCement mixing apparatusLiquid stateMechanical engineering

The invention provides an asphalt concrete preparation technology. A lower support, a drive unit, an upper support and a stirring unit are cooperated to complete the preparation of an asphalt concrete. The asphalt concrete preparation technology provided by the invention can solve the problems mainly existed in the process of preparing the asphalt concrete through existing stirring equipment: a, when liquid-state asphalt is mixed and injected into the concrete so as to be stirred, the asphalt and the concrete are mixed non-uniformly due to the restriction of the viscosity of the asphalt and the gradual hardening along with the temperature reduction of the liquid-state asphalt; and b, when the inner asphalt concrete is mixed and stirred through a stirring rod, the inner mixture is easy to adhere onto the stirring rod so as to affect the stirring carried out on the inner mixture by the stirring rod, the existing stirring rod is used for stirring the inner mixture through circumferentialmovement, the nonuniformity is caused by the stirring through circumferential movement, the sufficiency in stirring cannot be realized since the inner mixture cannot be thoroughly turned over, and thelike.

Owner:宁波东兴沥青制品有限公司

Traditional Chinese medicine dryer based on rotary ascending type stirring hooks and drying method of traditional Chinese medicine dryer

ActiveCN109631528AImprove the mixing effectGuaranteed stirring effectDrying solid materialsDrying machines with non-progressive movementsBiochemical engineeringTraditional Chinese medicine

The invention discloses a traditional Chinese medicine dryer based on rotary ascending type stirring hooks and a drying method of the traditional Chinese medicine dryer. The traditional Chinese medicine dryer comprises a drying box body, a heating chamber is formed in the bottom of the drying box body, and a power supply interface is formed in one side of the heating chamber; the heating chamber is internally provided with a heater connected with the power supply interface; a drying box cover is arranged on the upper part of the drying box body, a motor groove is formed in the middle of the drying box cover, a motor is arranged in the motor groove, and the output end of the motor is connected with a rotating shaft; a Z-shaped swing piece is slidably arranged on the rotating shaft, the L-shaped stirring hooks are arranged on the two sides of the swing piece correspondingly, and wings are arranged on transverse rods of the stirring hooks; the rotating shaft is further provided with a fixing disc located on the lower part of the swing piece, two vertical protrusions are arranged on the fixing disc, and the protrusions and the two side faces of the swing piece are matched; and a stirring brush is further arranged at the end of the rotating shaft. The traditional Chinese medicine dryer has the characteristic of high drying speed, and is simple and compact in structure, easy to mountand convenient to operate.

Owner:WENZHOU MEDICAL UNIV

Separating device used for processing heparin sodium and processing technology

The invention discloses a separating device used for processing heparin sodium. The separating device comprises a separating tank, a water suction tray, a water collecting tank and a base. Rolling wheels are separately installed at four corners of the bottom end of the base, and a groove is formed in the top end of the base. A stirring motor is installed in the groove. The separating tank is installed at the position, above the stirring motor, at the top end of the base, and a discharge pipe is installed at the bottom end of one side of the separating tank. A valve is installed on the discharge pipe. A controller is installed at the position, above the discharge pipe, on the separating tank, and an electric cylinder is installed at the middle position of the top end of the separating tank.An exhaust pipe is installed at the position, on one side of the electric cylinder, at the top end of the separating tank. The separating device is provided with the stirring motor, a stirring shaft,a turntable, double-shaft motors, stirring rods, impellers and spiral blades, so that the full dispersion of a heparin sodium solution is conveniently accelerated through the vertical and horizontalbidirectional rotation of the stirring rods and the spiral blades in order to improve the precipitation efficiency of the heparin sodium solution, and separation is convenient.

Owner:JIANGSU JIUHUI FOOD PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com