Bubble-type liquor dispensing mixer

A mixer and liquid dispensing technology, which is applied to mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve the problems of many impurities in the solution, waste, and materials are easily adhered to the barrel wall of the mixing barrel. Ease of use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

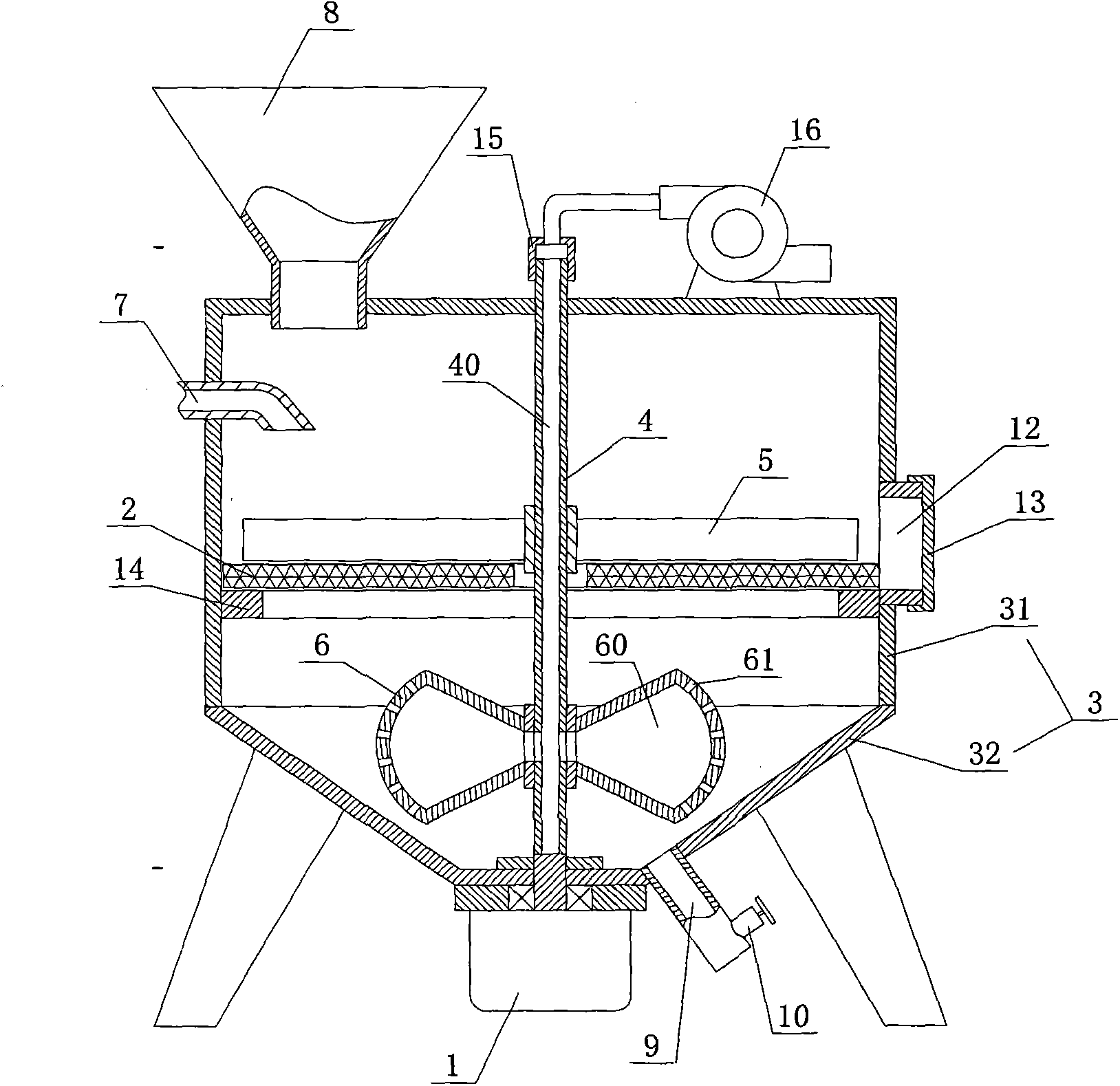

[0014] Referring to the accompanying drawings, the bubble type liquid mixing mixer of the present invention comprises a mixing tank 3 and a drive motor 1, the mixing tank 3 is composed of an upper cylinder 31 and a cone 32 at the bottom, and the bottom opening of the cylinder 31 is connected with the cone. The top of the cylinder body 32 is open and connected, the top of the cylinder body 31 and the bottom of the cone cylinder body 32 are closed, the filter screen-2 is installed in the inner cavity of the cylinder body 31, and the mixing tank 3 is provided with a penetrating cylinder body 31 The inner cavity and the inner cavity of the cone body 32 and the rotating shaft 4 passing through the middle part of the above-mentioned filter screen 2, the rotating shaft 4 is a hollow structure with a top opening and a sleeve 15 is rotated on the top opening of the rotating shaft 4, and the sleeve 15 is connected. There is a blower 16, the bottom end of the rotating shaft 4 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com