Stirring machine capable of preventing materials from adhering to wall

A mixer and anti-sticking wall technology, which is applied in the direction of mixer accessories, cement mixing devices, mixers, etc., can solve problems such as sticking walls, affecting quality, and affecting concrete quality, achieving the effect of good quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

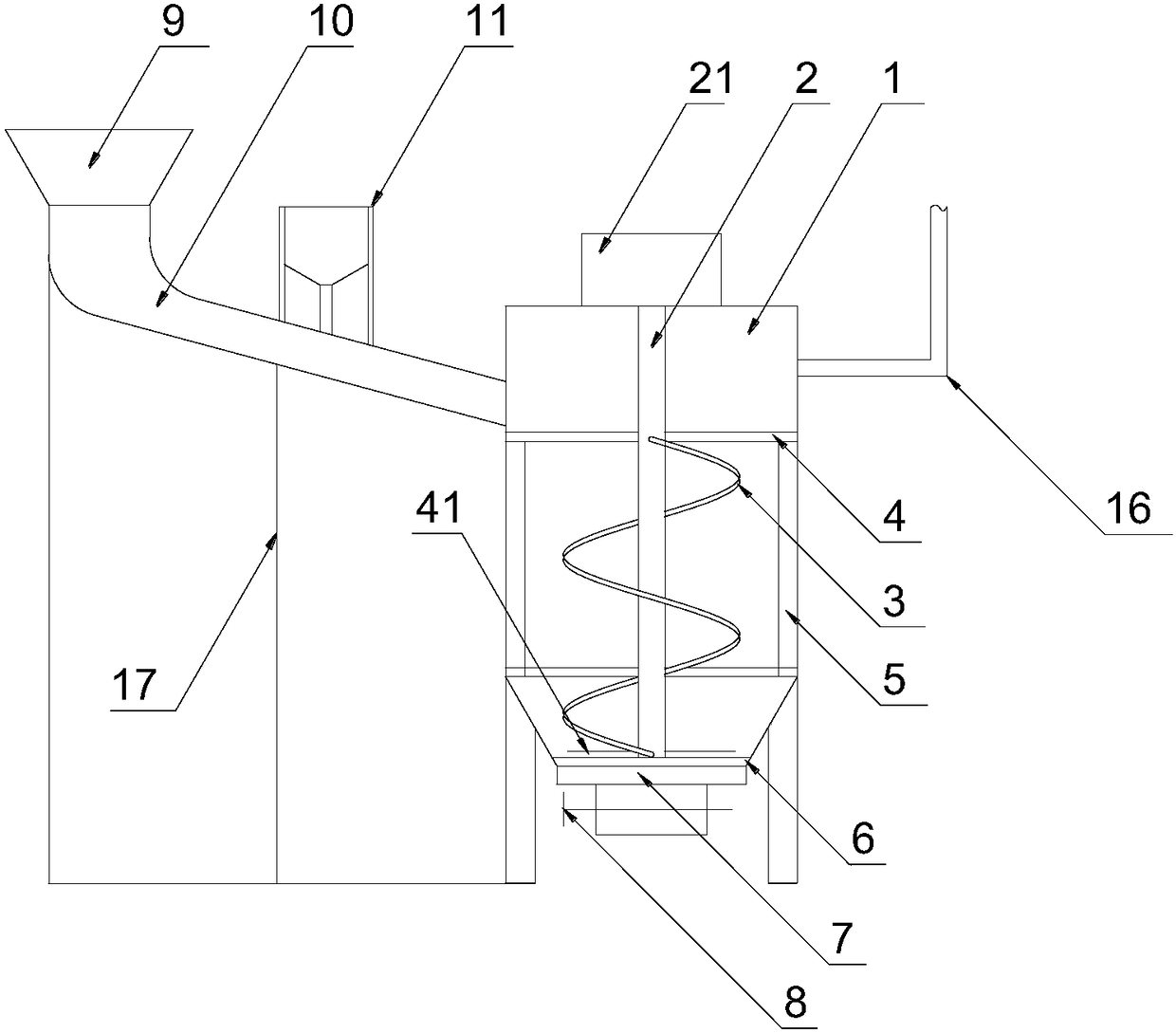

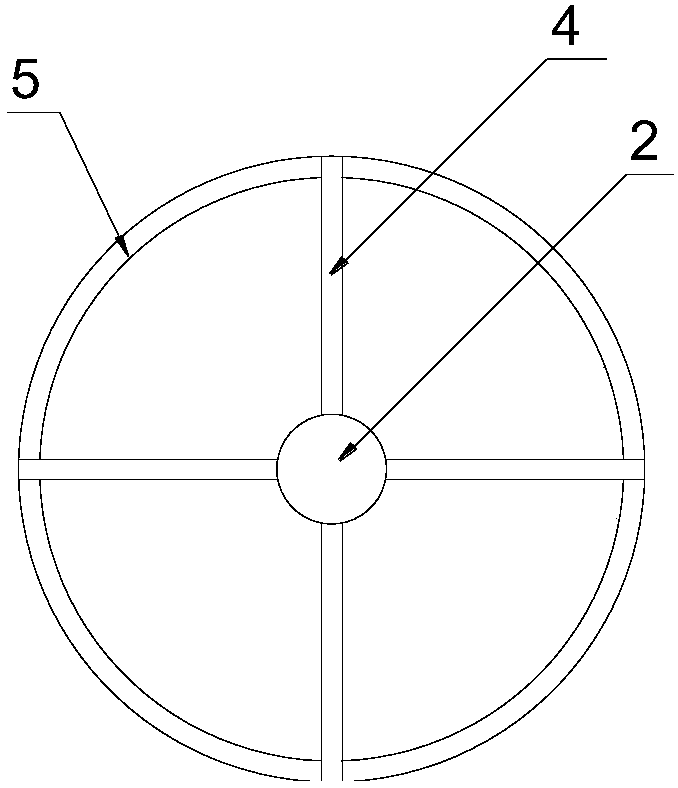

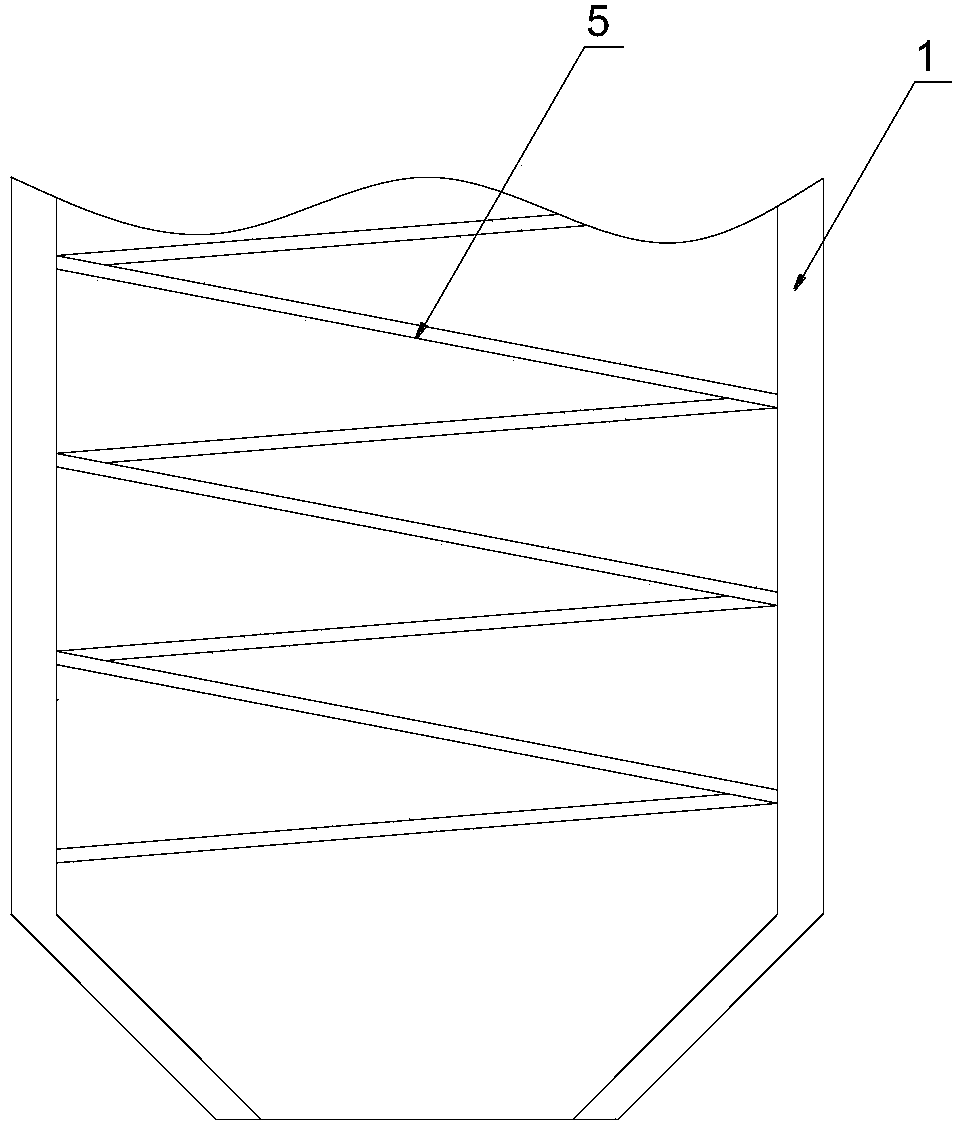

[0025] like Figure 1-5 as shown, figure 1 It is a structural representation of a kind of anti-sticking wall mixer proposed by the present invention, figure 2 It is the top view of the installation of the scraper in the anti-sticking wall mixer proposed by the present invention, image 3 It is the front view of the installation of the scraper in the anti-sticking wall mixer proposed by the present invention, Figure 4 It is a partial schematic view of scraper in the anti-sticking wall mixer proposed by the present invention, Figure 5 It is a schematic diagram of the additive feeding device in the anti-sticking wall mixer proposed by the present invention.

[0026] refer to Figure 1-5 , a kind of anti-sticking wall mixer that the present invention proposes, comprises mixer 1, stirring shaft 2, stirring paddle 3, fixed frame 4, scraper 5, discharge port 7, flow valve 8, feed hopper 9, feed channel 10 and additive feeding device 11;

[0027] A motor 21 is fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com