Spodumene ore beneficiation sorting process

A technology of spodumene ore and spodumene, which is applied in flotation, solid separation, wet separation, etc., can solve the problems of high mud content, deterioration of ore floatability, and mud pollution of beneficiation environment, etc. The effect of impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

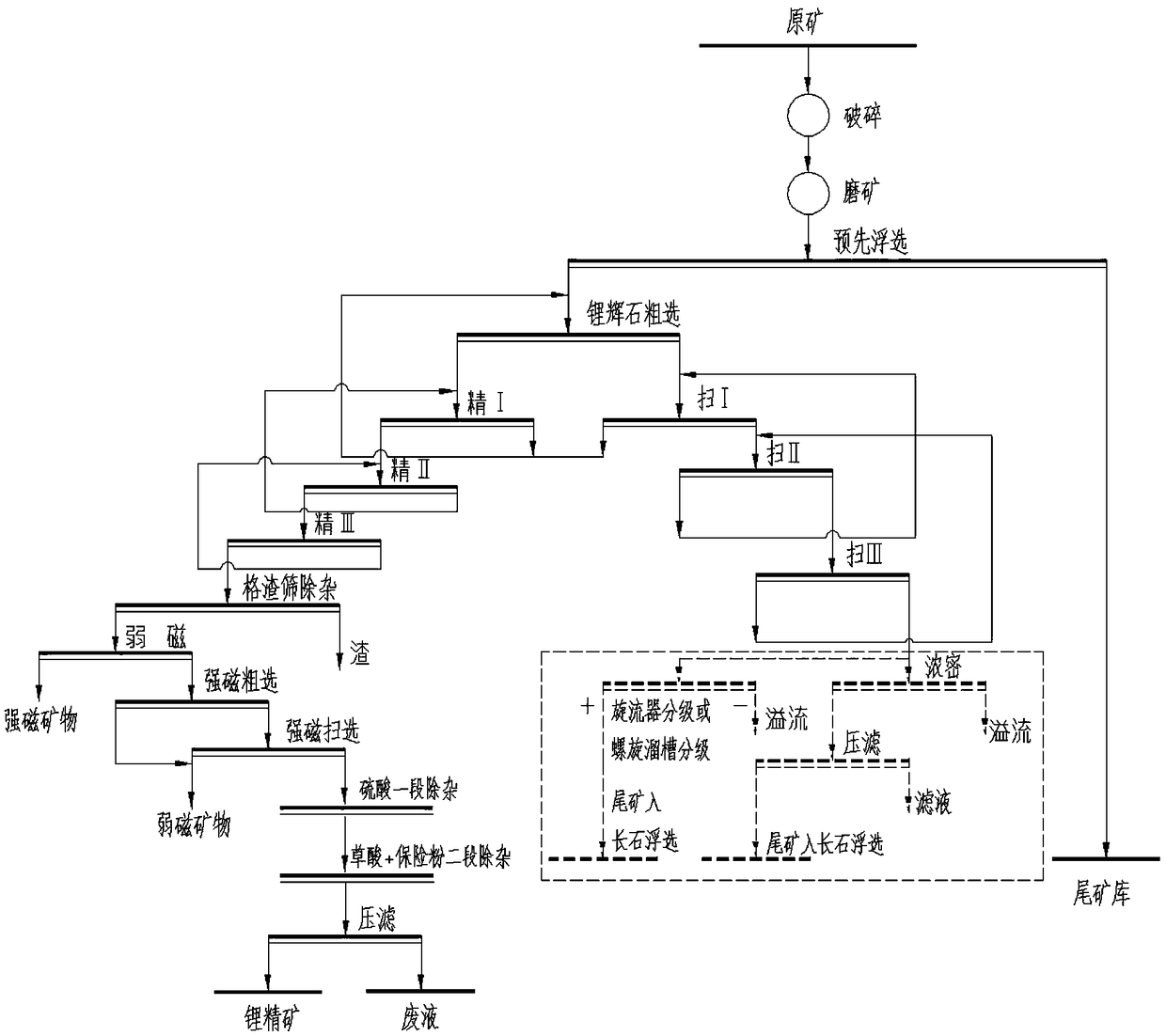

[0032] Taking spodumene from a certain place in Hunan as an example, the original ore contains Li 2 O is 1.2%, adopts technological process of the present invention, as figure 1 As shown, the specific steps are as follows:

[0033] (1) Using the SAB crushing process, the raw ore is ground to a fineness of -200 mesh, accounting for 75%;

[0034] (2) Use the CCF flotation column to carry out pre-flotation on the grinding product. The dosage of the agent used is: sodium carbonate 800g / t, water glass 150g / t, naphthenic acid soap 100g / t. After sliming, the desliming rate reaches 95%, and the pre-flotation coarse ore is obtained;

[0035] (3) The pre-flotation coarse ore is used for flotation operation, adopting a rough three-sweeping three-sweeping process, and the pharmaceutical system for the roughing operation is: sodium carbonate 200g / t, sodium hydroxide 400g / t, oxidized paraffin wax soap, sulfur Chemical soap and naphthenic acid soap are formulated into mixed collectors acc...

Embodiment 2

[0039] Taking spodumene in a certain place in Jiangxi as an example, the original ore contains Li 2 O is 1.35%, adopts technological process of the present invention, and concrete steps are as follows:

[0040] (1) Using the SAB crushing process, the raw ore is ground to a fineness of -200 mesh, accounting for 78%;

[0041] (2) Use the CCF flotation column to pre-float the grinding product. The dosage of the agent used is: sodium carbonate 600g / t, water glass 120g / t, naphthenic acid soap 85g / t, and the CCF flotation column removes After sliming, the desliming rate reaches 90%, and the pre-flotation coarse ore is obtained;

[0042] (3) The pre-flotation coarse ore is used for flotation operation, using a rough three-sweeping three-sweeping process, and the pharmaceutical system for the roughing operation is: sodium carbonate 205g / t, sodium hydroxide 450g / t, oxidized paraffin wax soap, sulfur Chemical soap and naphthenic acid soap are formulated into mixed collectors according...

Embodiment 3

[0046] Taking spodumene in a certain place in Sichuan as an example, the original ore contains Li 2 O is 1.40%, adopts technological process of the present invention, and concrete steps are as follows:

[0047] (1) Using the SAB crushing process, the raw ore is ground to a fineness of -200 mesh, accounting for 72%;

[0048] (2) Use the CCF flotation column to carry out pre-flotation of the grinding product. The dosage of the agent used is: sodium carbonate 200g / t, water glass 120g / t, naphthenic acid soap 95g / t, and the product is removed by the CCF flotation column. After sliming, the desliming rate reaches 90%, and the pre-flotation coarse ore is obtained;

[0049] (3) The pre-flotation coarse ore is used for flotation operation, adopting a rough three-sweeping three-sweeping process, and the pharmaceutical system for the roughing operation is: sodium carbonate 340g / t, sodium hydroxide 540g / t, oxidized paraffin wax soap, sulfur Soap and naphthenic acid soap are formulated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com