Asphalt tank pitch-variable stirrer

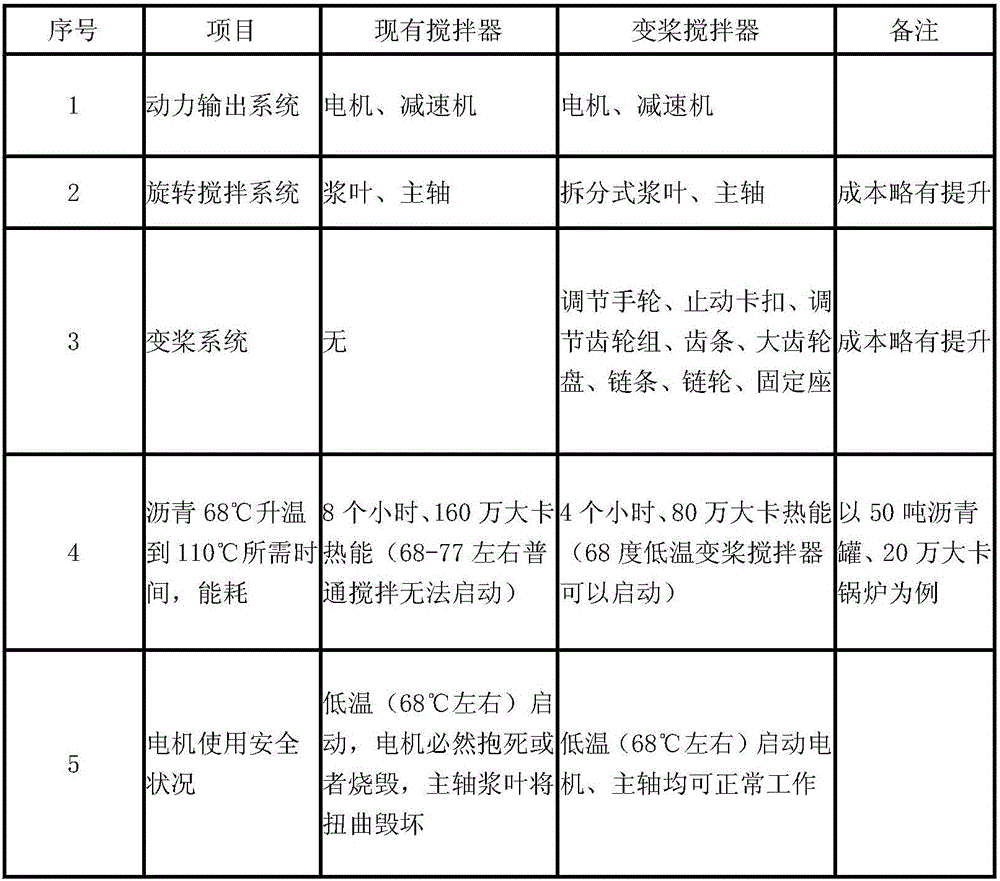

A mixing technology of asphalt tanks and paddles, applied to mixers with rotating mixing devices, chemical instruments and methods, mixers, etc., can solve problems such as inability to adjust the installation angle, high working pressure of the agitator, and overflow of the agitator power. Achieve the effect of gaining energy saving and environmental protection requirements, reducing heating time and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

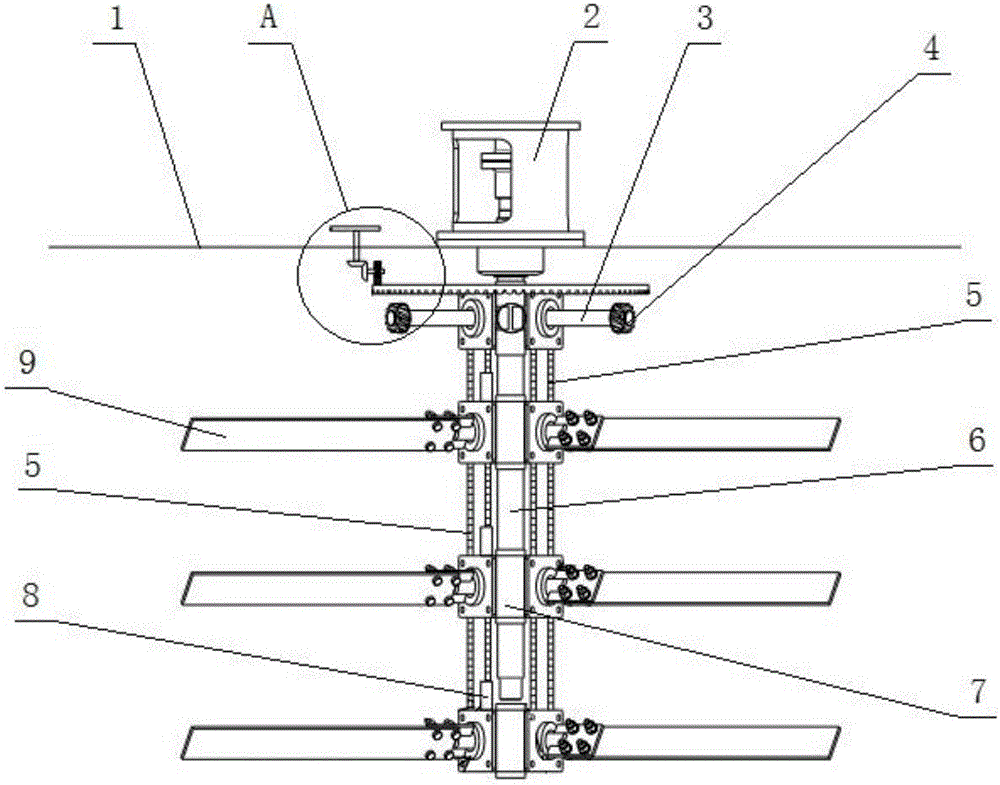

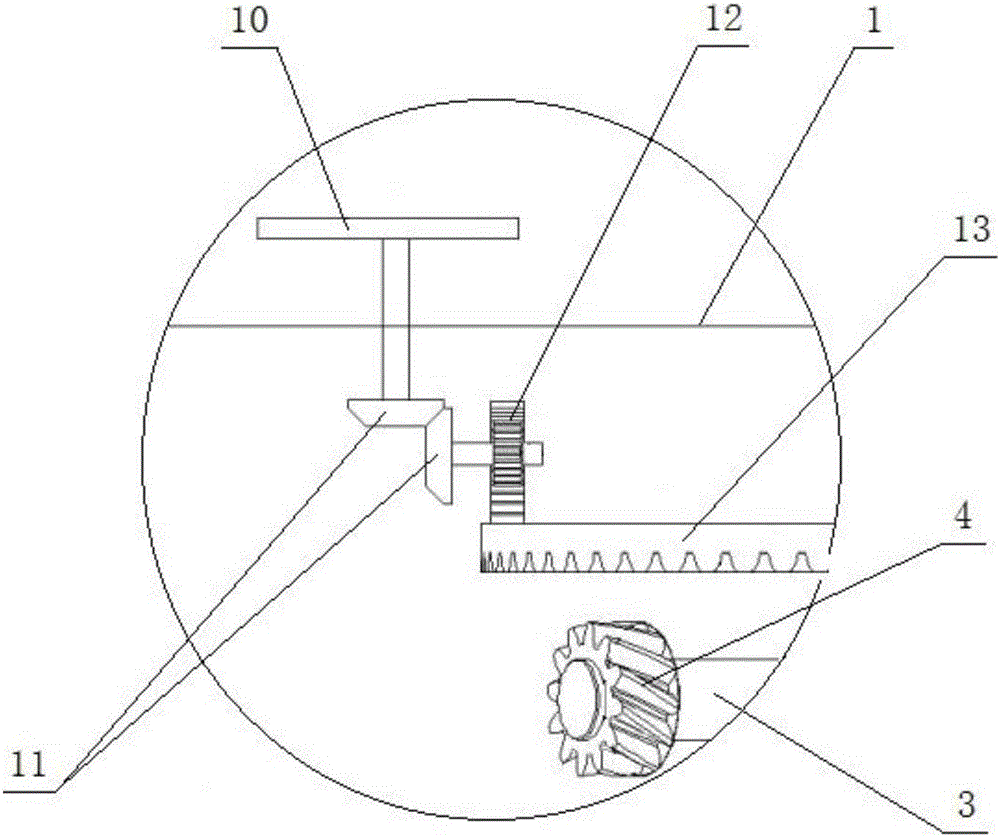

[0037] Such as figure 1 and figure 2 Shown: a pitch mixer for an asphalt tank, including a power output system placed outside the asphalt tank 1, a rotary mixing system and a pitch system placed inside the asphalt tank 1. The power output system is composed of a motor and a reducer, and the motor and the reducer are connected through a coupling. The rotary mixing system consists of a vertically arranged main shaft 6 and paddles 9 vertically fixed on the main shaft 6. The reducer is placed on the top of the asphalt tank 1 through the reducer base 2. The reducer and the main shaft 6 are connected by another coupling . Pitch change system is made up of adjusting hand wheel 10, adjusting gear set 11, rack 12, large gear plate 13, pinion 4, short shaft 3, fixed seat 7, sprocket wheel and chain 5.

[0038]In the pitch control system, the adjusting handwheel 10 is placed outside the asphalt tank 1, and the asphalt tank 1 is provided with a stop buckle for the adjusting handwheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com