Patents

Literature

761results about How to "Easy to scrape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

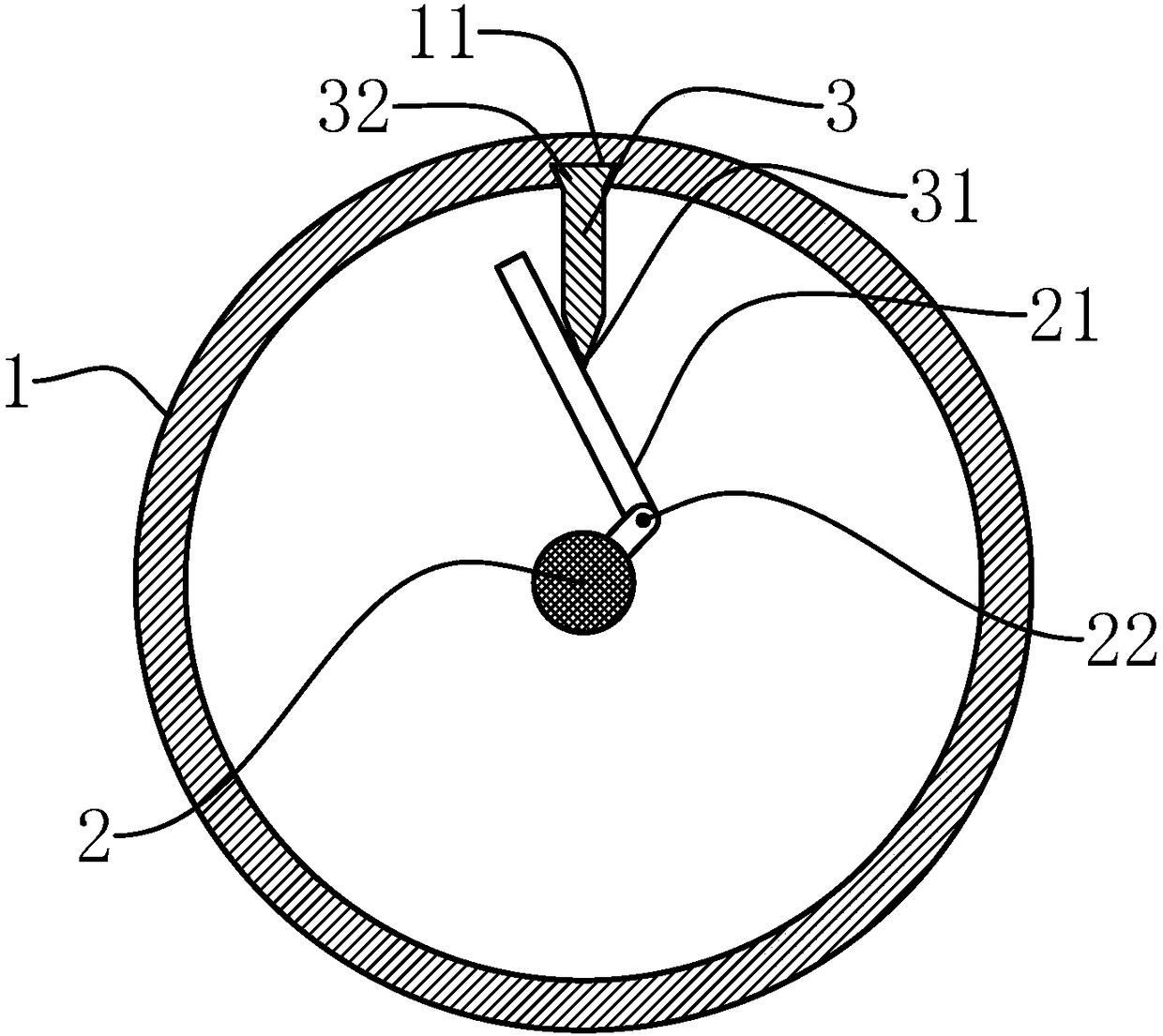

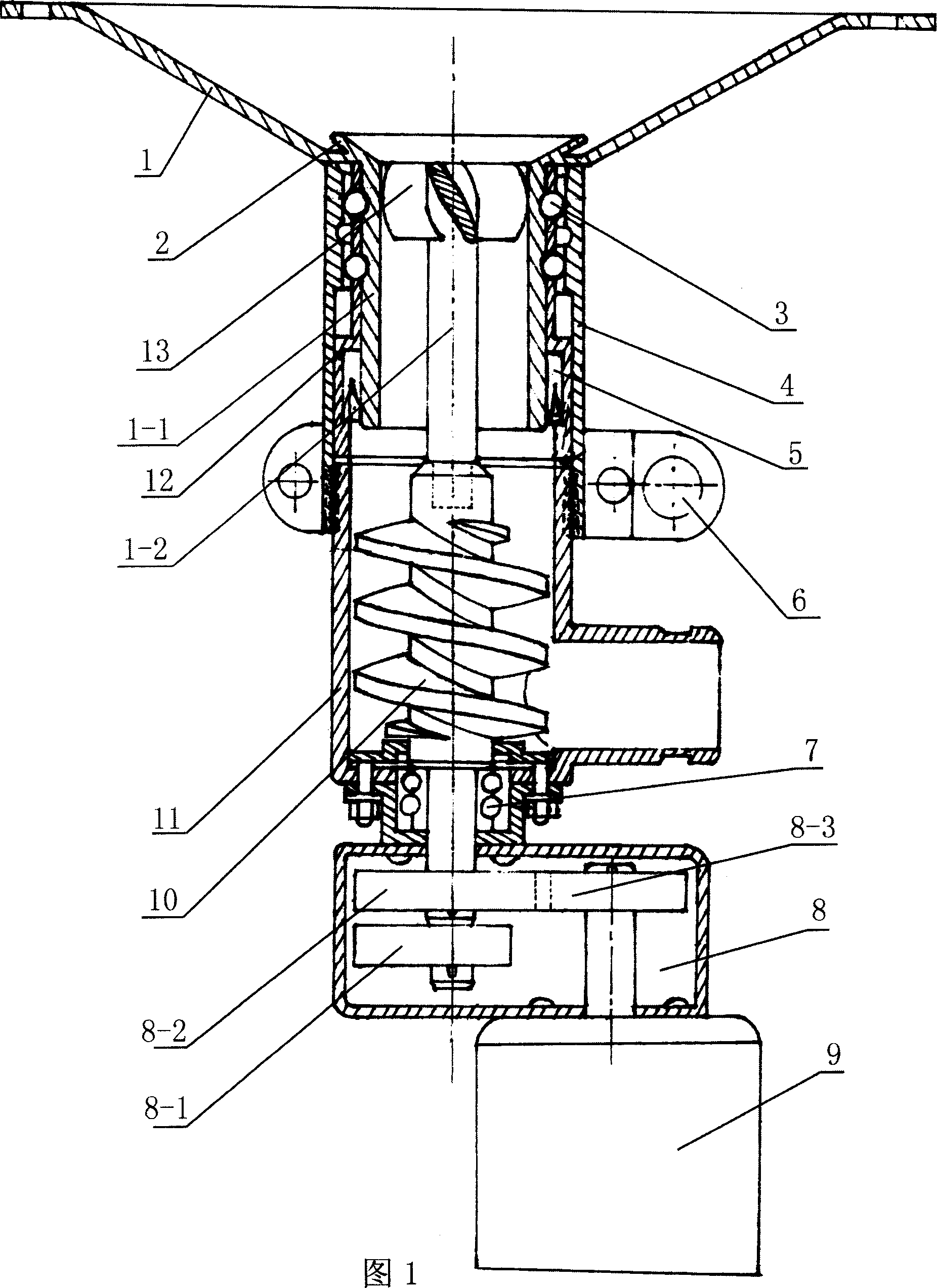

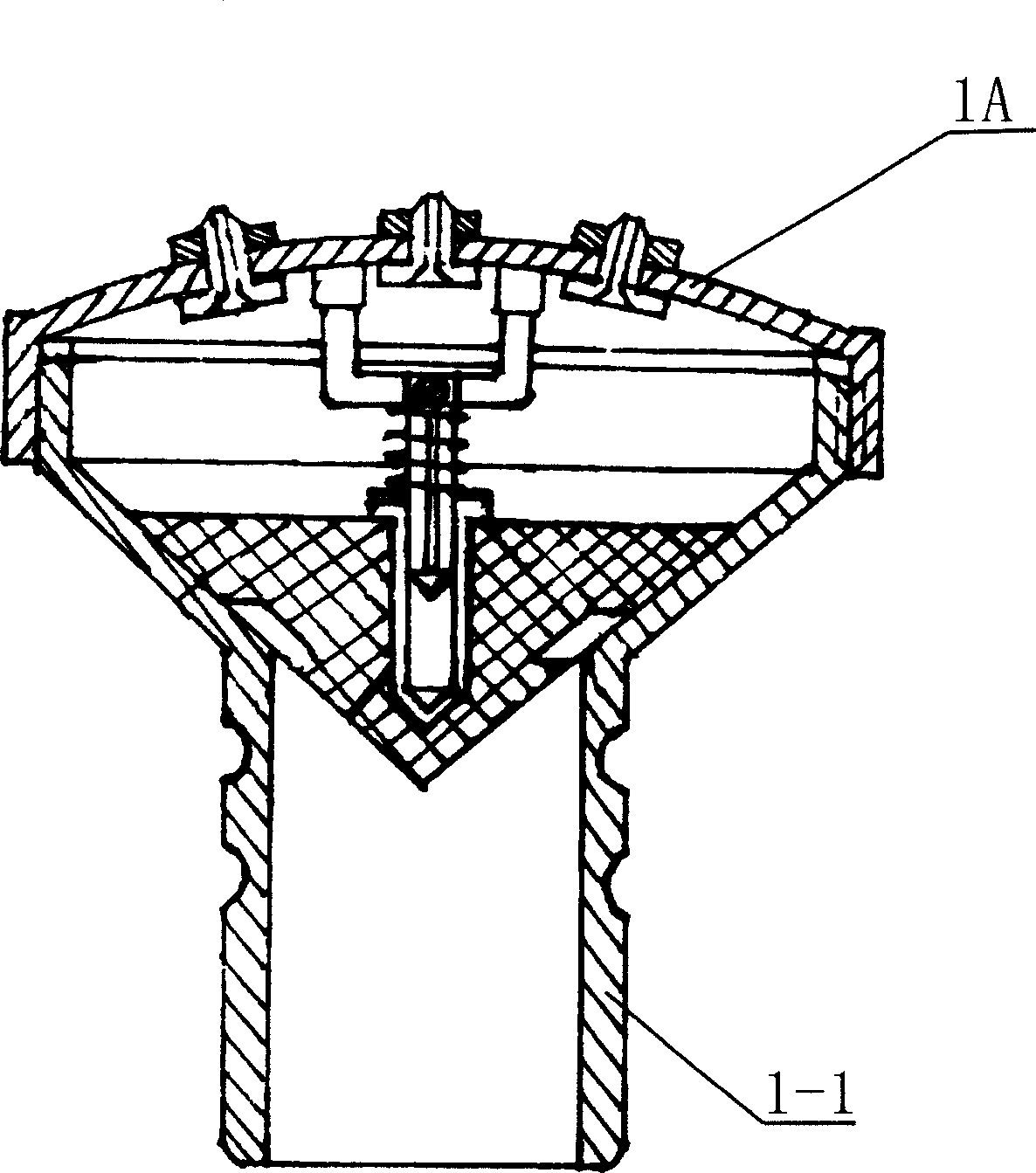

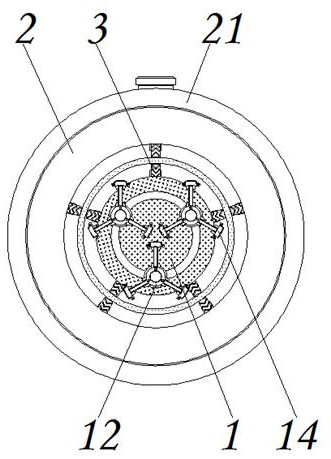

Cleaning device for adhesions on inner wall of pipeline

InactiveCN105642621AAvoid harmObserve the situation in real timeLighting elementsHollow article cleaningEngineeringMechanical engineering

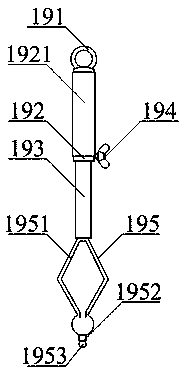

The invention discloses a cleaning device for adhesions on the inner wall of a pipeline. The cleaning device comprises a small-sized servo motor, a shift ring, at least two long handles and short handles, wherein an extending shaft of the small-sized servo motor is provided with threads; the shift ring is provided with balls; the balls slide in a threaded groove of the extending shaft of the small-sized servo motor; one end of each long handle is connected onto the shift ring, and the other end of each long handle extends; a scraper is arranged at the extending end; a polyester fabric covers the outer sides of the long handles; the number of the short handles is identical with that of the long handles; the short handles are used for supporting the corresponding long handles; and an illuminating lamp, a camera, a control device and a push-pull tube are arranged on the small-sized servo motor. According to the cleaning device disclosed by the invention, the device is mounted into the pipeline by the push-pull tube; the adhesions are found by pushing and pulling the push-pull tube; the small-sized servo motor is started, the long handles drive the polyester fabric to be opened, and the adhesions on the inner wall of the pipeline are scratched by outer ends of the long handles; and the scratched adhesions are collected in the hopper-like polyester fabric, and the push-pull tube is drawn to withdraw from the pipeline. According to the cleaning device disclosed by the invention, the adhesions on the inner wall of the pipeline are removed by adopting a physical method, so greenness and environmental protection are realized; and working efficiency and economic benefits of pipeline maintenance departments or enterprises are improved.

Owner:XIAMEN KINGTOP INFORMATION TECH

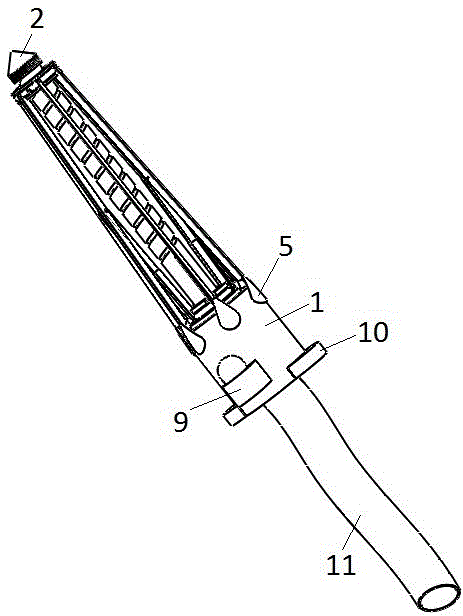

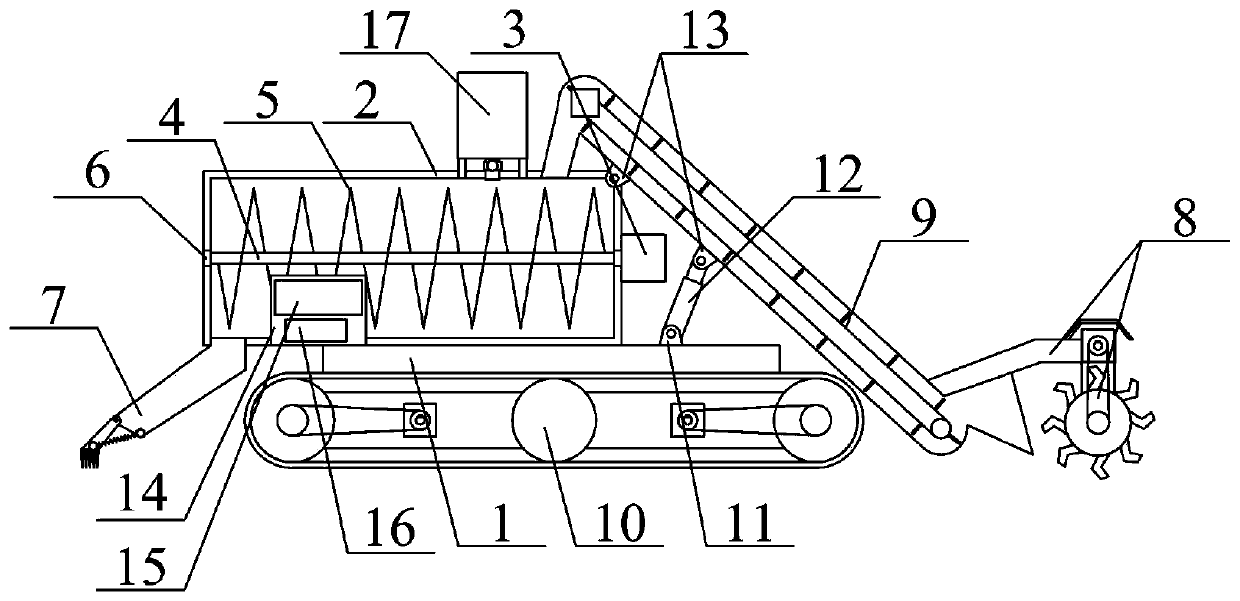

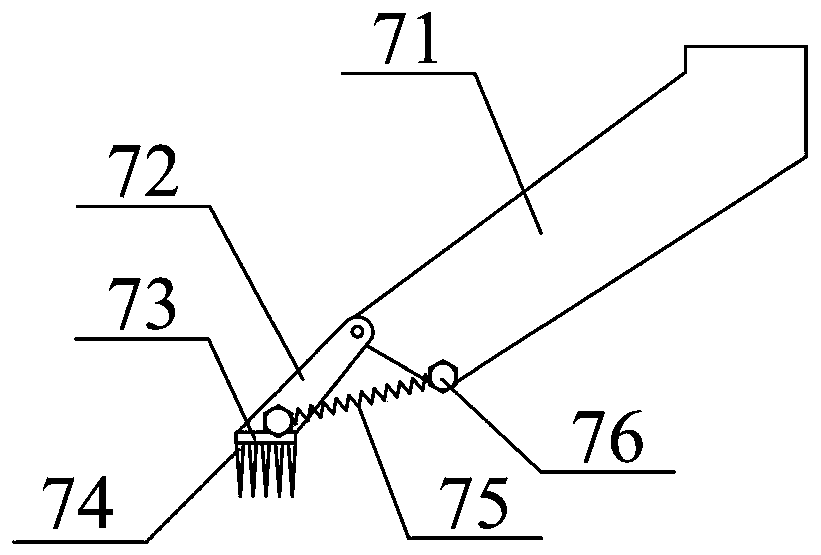

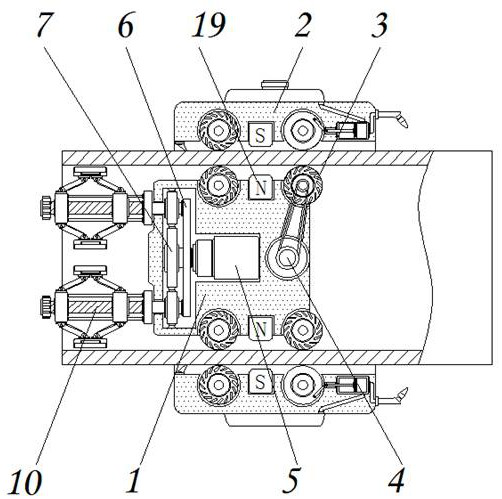

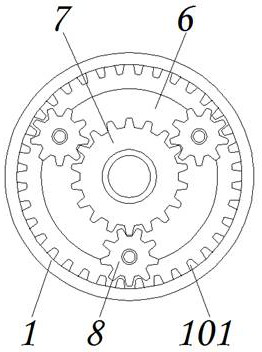

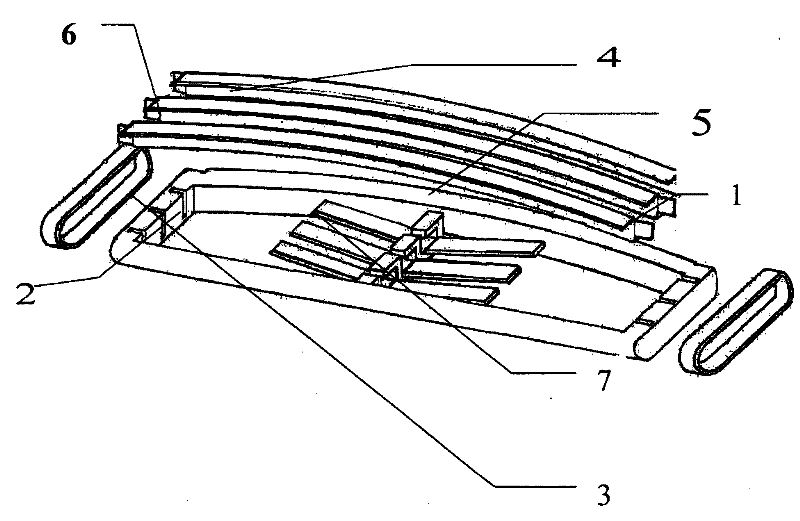

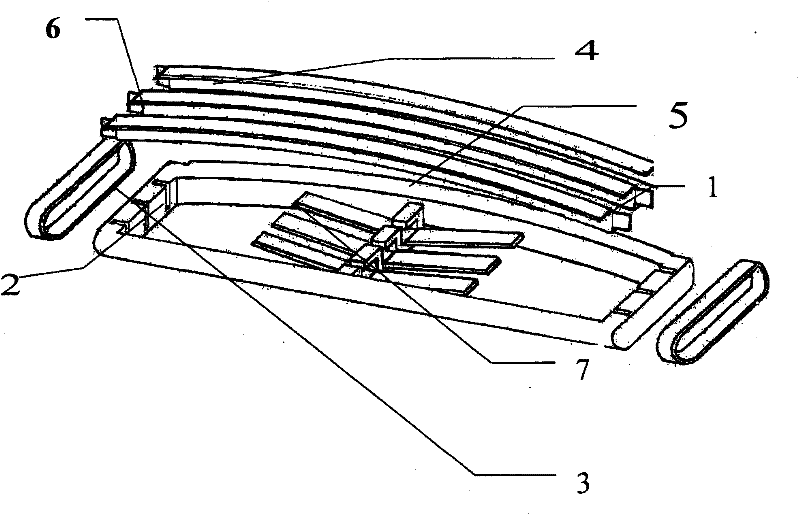

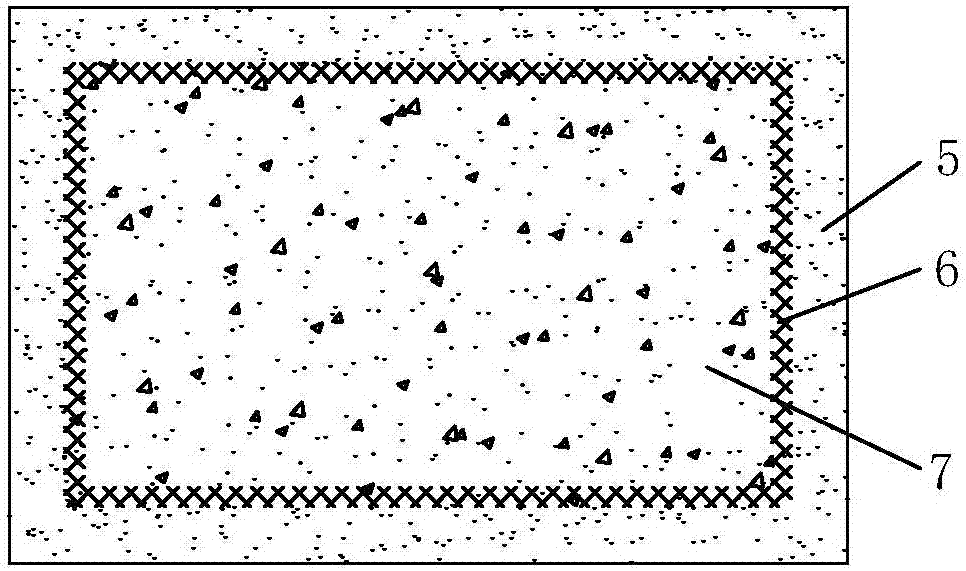

Excrement scraper for livestock breeding

InactiveCN105248290AEasy to scrapeEasy to operateAnimal housingBird housingsVehicle frameLivestock breeding

The invention discloses an excrement scraper for livestock breeding. The excrement scraper comprises a gear, a double-row chain, a crawler belt, an excrement scraping device, a front wheel, a vehicle frame, an excrement tank, scraping plates, a water spraying pipe, a rotating plate, a universal wheel, an electromotor and a water tank, wherein the gear is in mesh connection with the double-row chain; the gear is in rotary connection with a bearing through a coupling axle; the crawler belt is arranged on the double-row chain; the front wheel is fixedly connected with the gear through the coupling axle; the excrement scraping device is fixedly connected with the vehicle frame through a supporting rack; the water spraying pipe penetrates through the vehicle frame, and is connected with the water tank; the rotating plate is in rotary connection with a driven wheel through a rotating shaft; a driving wheel is in transmission connection with the driven wheel through a belt; the universal wheel and the vehicle frame are connected through a supporting leg. The excrement scraper can scrape excrement to be transported into the excrement tank through transmission of the double-row chain, the scraping plates can conduct secondary floor cleaning, the rotating plate and a brush can conduct cleaning and sterilization on the floor, and the excrement scraper can control the proceeding direction at will, and is complete in cleaning, convenient to use and high in practicability.

Owner:LEIYANG XINGNONG ANIMAL HUSBANDRY CO LTD

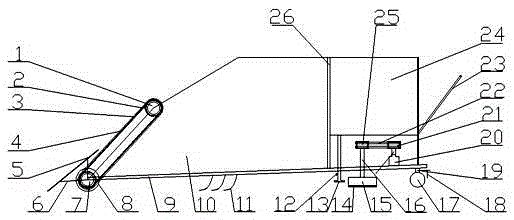

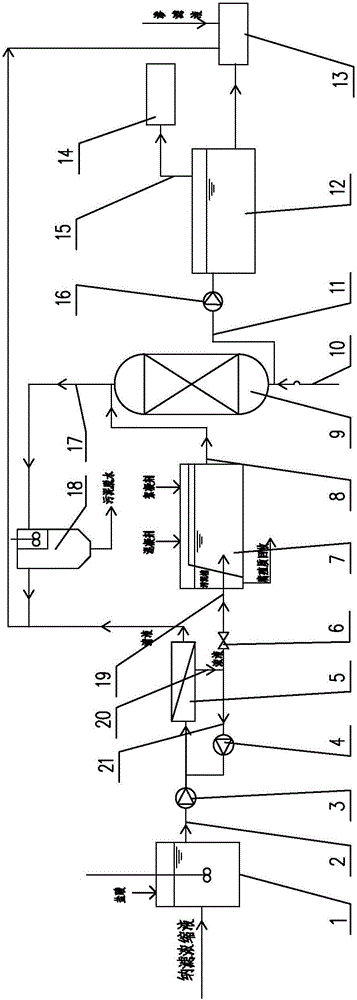

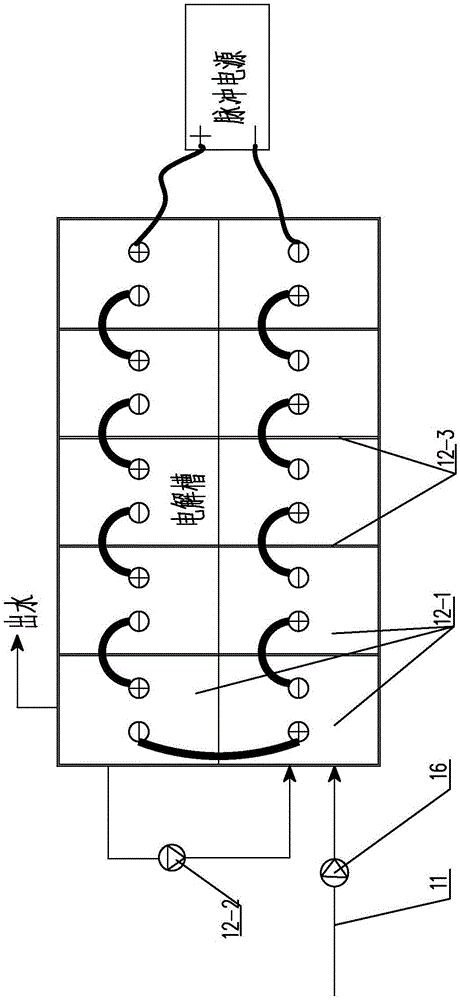

Treatment method for nanofiltration concentrated liquor of landfill leachate

ActiveCN106277591AGuaranteed uptimeIncrease flow rateWater contaminantsMultistage water/sewage treatmentElectrolysisResource utilization

The invention relates to a treatment method for nanofiltration concentrated liquor of landfill leachate, which comprises the following steps: carrying out medium-pressure nanofiltration treatment first for minimization, carrying out coagulation air floatation treatment for the concentrated liquor after the medium-pressure nanofiltration treatment to recycle humous larger molecular organics for resource utilization, carrying out resin-based softening treatment to reduce the hardness of the concentrated liquor after the coagulation air floatation treatment, performing electrolytic oxidation treatment on the concentrated liquor after the resin-based softening treatment and treating back washing water, feeding the clear liquid from the medium-pressure nanofiltration, yielding water from the regenerated waste liquor and yielding water after the electrolytic oxidation to membrane bioreaction treatment, performing tail gas absorption treatment on gases generated from the electrolytic oxidation, and absorbing chlorine gas in tail gases before up-to-standard emission. The treatment method for nanofiltration concentrated liquor of landfill leachate is reasonable in treatment process with a good treatment effect, and relatively low in investment and operation costs; the problem of accumulation of humic acids and hardness ions in the biochemical system is avoided, and the difficulty in treating the nanofiltration concentrated liquor of the landfill leachate is solved; and the treatment method is applicable to treating the nanofiltration concentrated liquor generated in the 'MBR+nanofiltration' treatment process for the landfill leachate.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

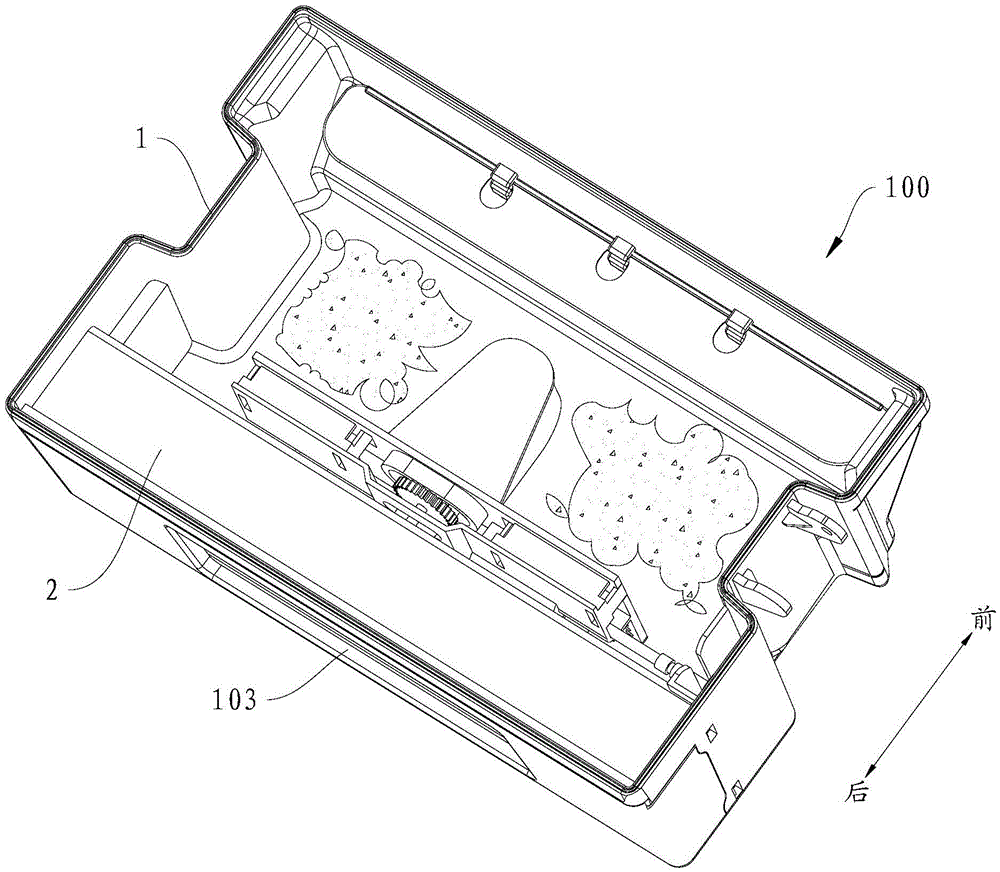

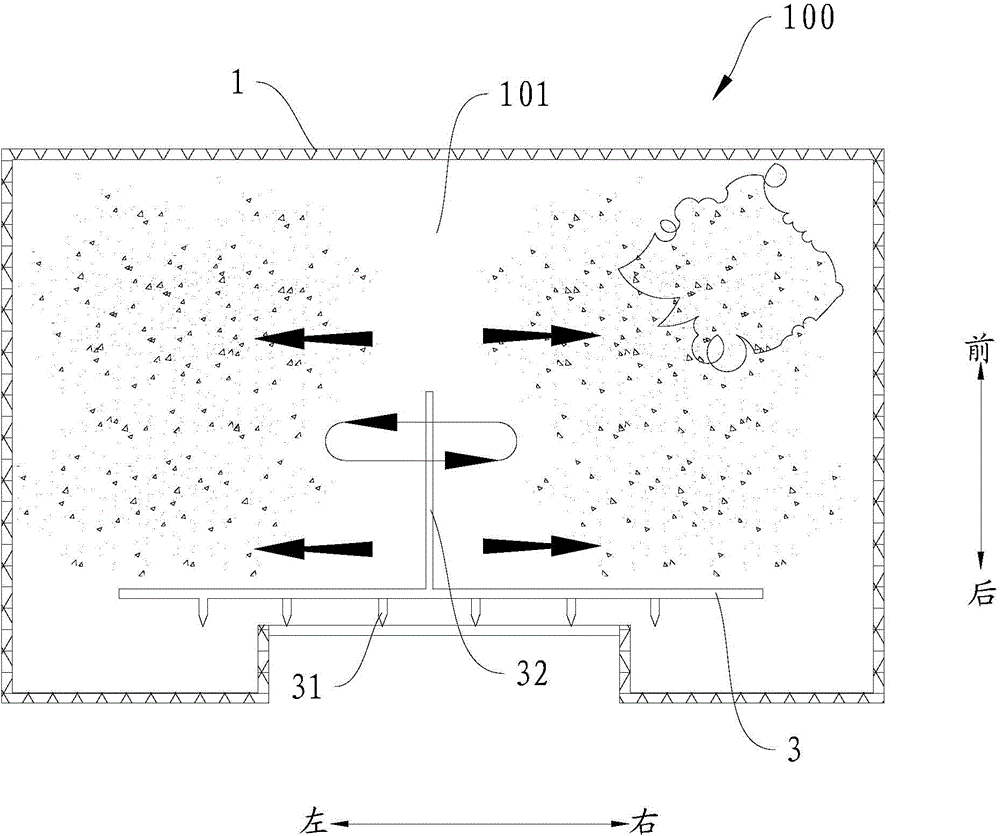

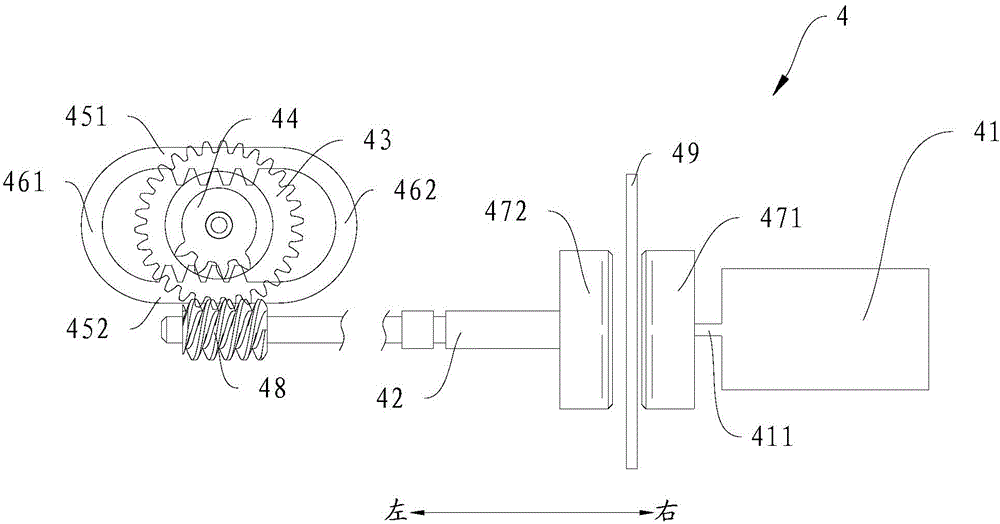

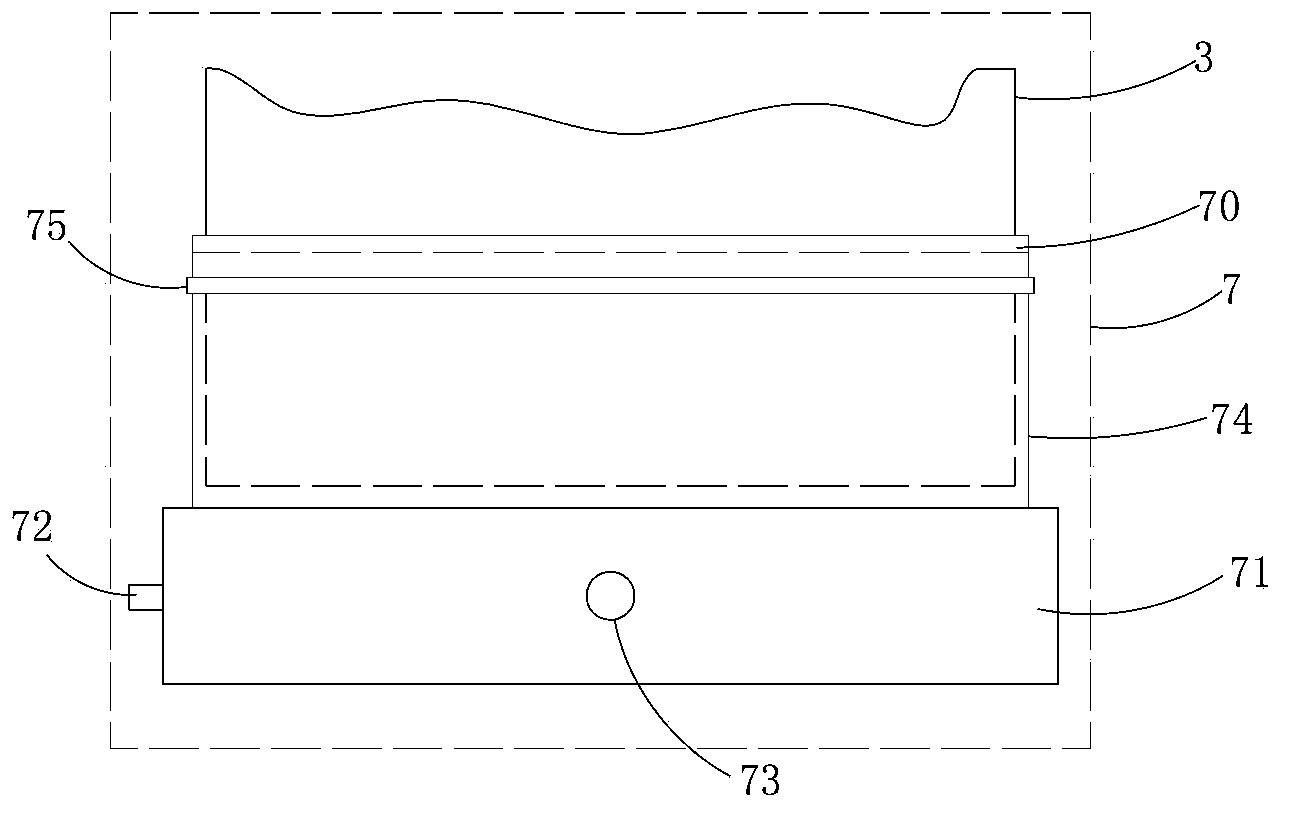

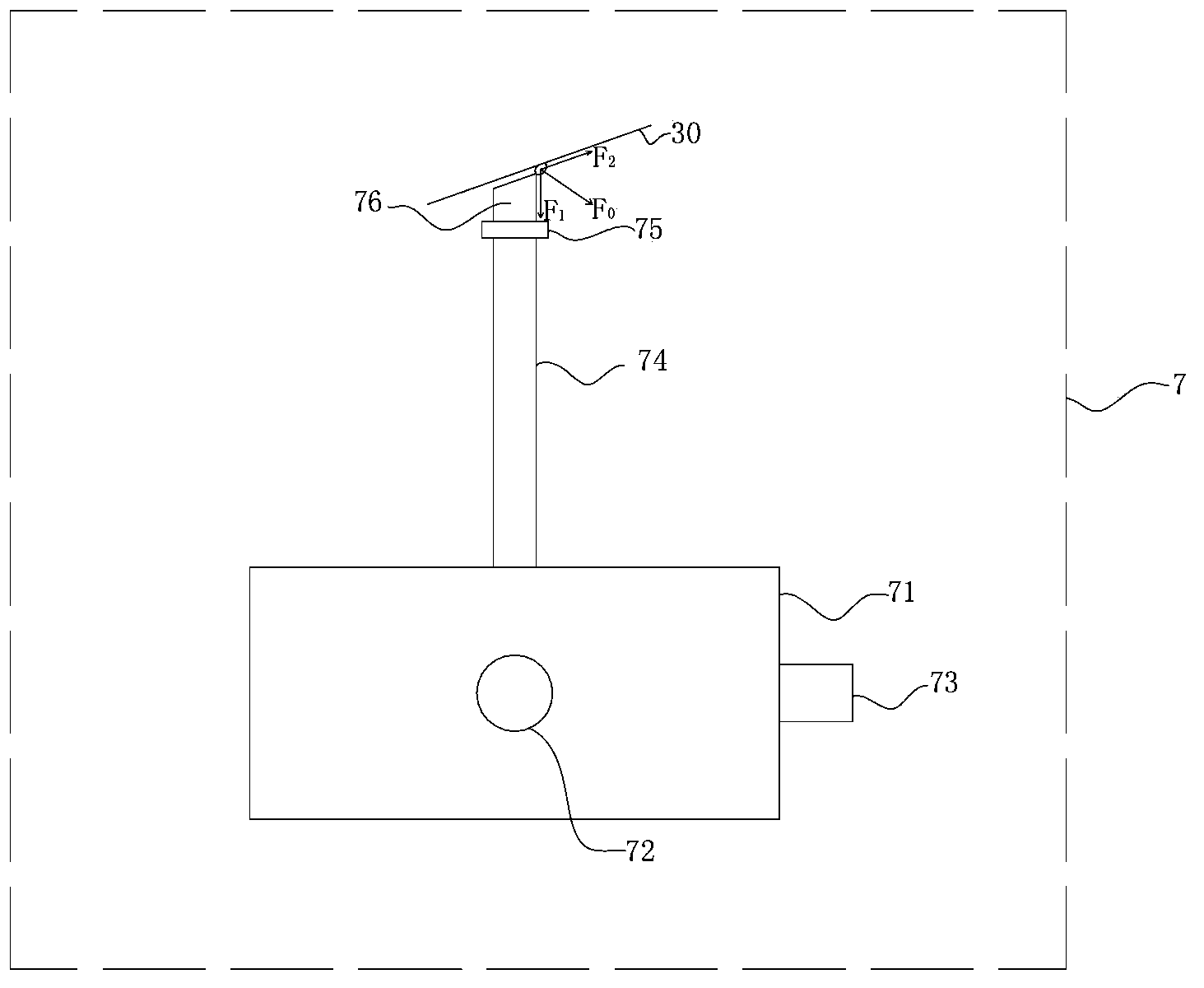

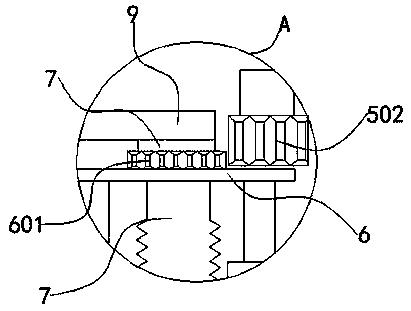

Intelligent dust collector and dust box assembly thereof

ActiveCN105078367AExtended use timeKeep breathableCleaning filter meansSuction filtersEngineeringReciprocating motion

The invention discloses an intelligent dust collector and a dust box assembly thereof. The dust box assembly of the intelligent dust collector comprises a dust box, a filter device, a dust scraper and a driving device. An accommodating cavity is formed in the dust box, a dust collecting opening which is communicated with the accommodating cavity is formed in the front wall of the dust box, and an exhaust port which is communicated with the accommodating cavity is arranged on the rear wall of the dust box; the filter device is arranged in the accommodating cavity, and the exhaust port can be closed by the filter device; the dust scraper is movably arranged at the front of the filter device along the left-right direction and is parallel to the front surface of the filter device, dust scraping ribs which are used for removing dust are arranged on the surface, which faces the filter device, of the dust scraper, and the side edges of the dust scraping ribs cling onto the surface of the filter device; the driving device is connected with the dust scraper and is used for driving the dust scraper to reciprocate. The intelligent dust collector and the dust box assembly in an embodiment of the invention have the advantages that the dust on the front surface of the filter device can be conveniently scraped, accordingly, the permeability of the filter device can be kept for a long time, and air flow channels of the dust box can keep smooth.

Owner:MIDEA ROBOZONE TECH CO LTD

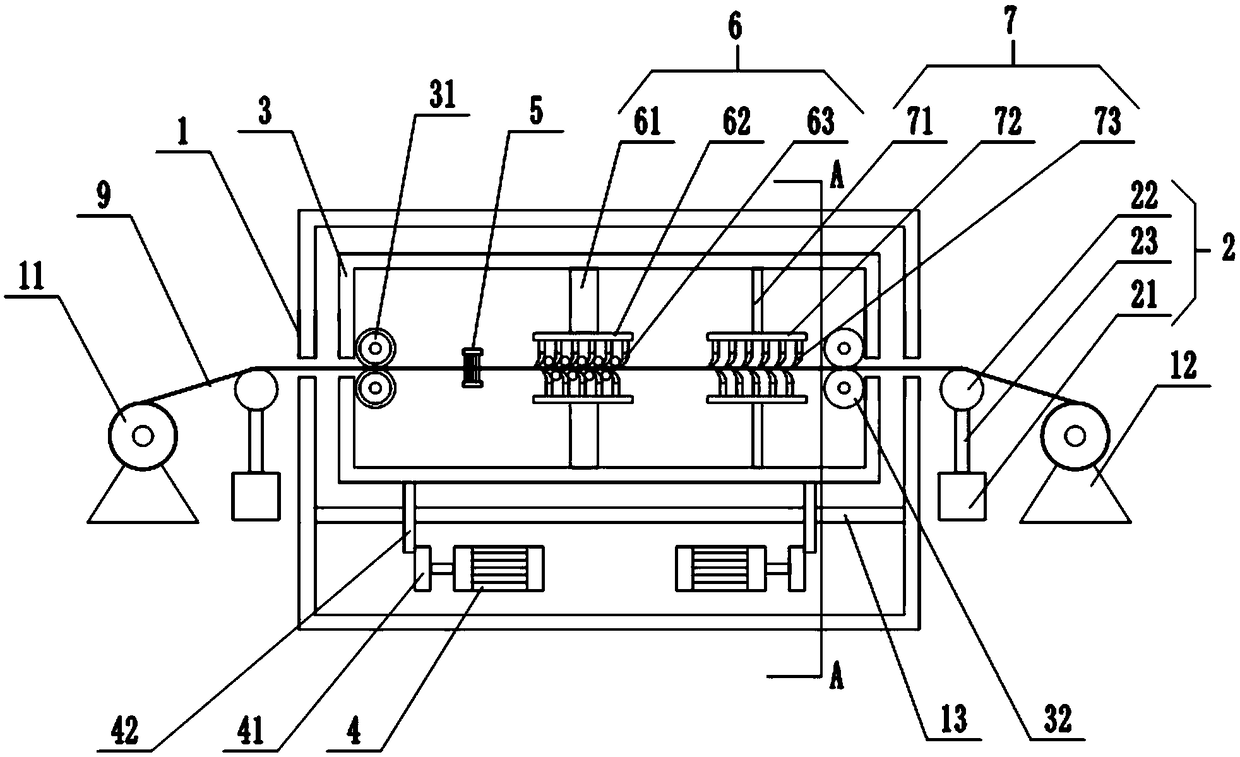

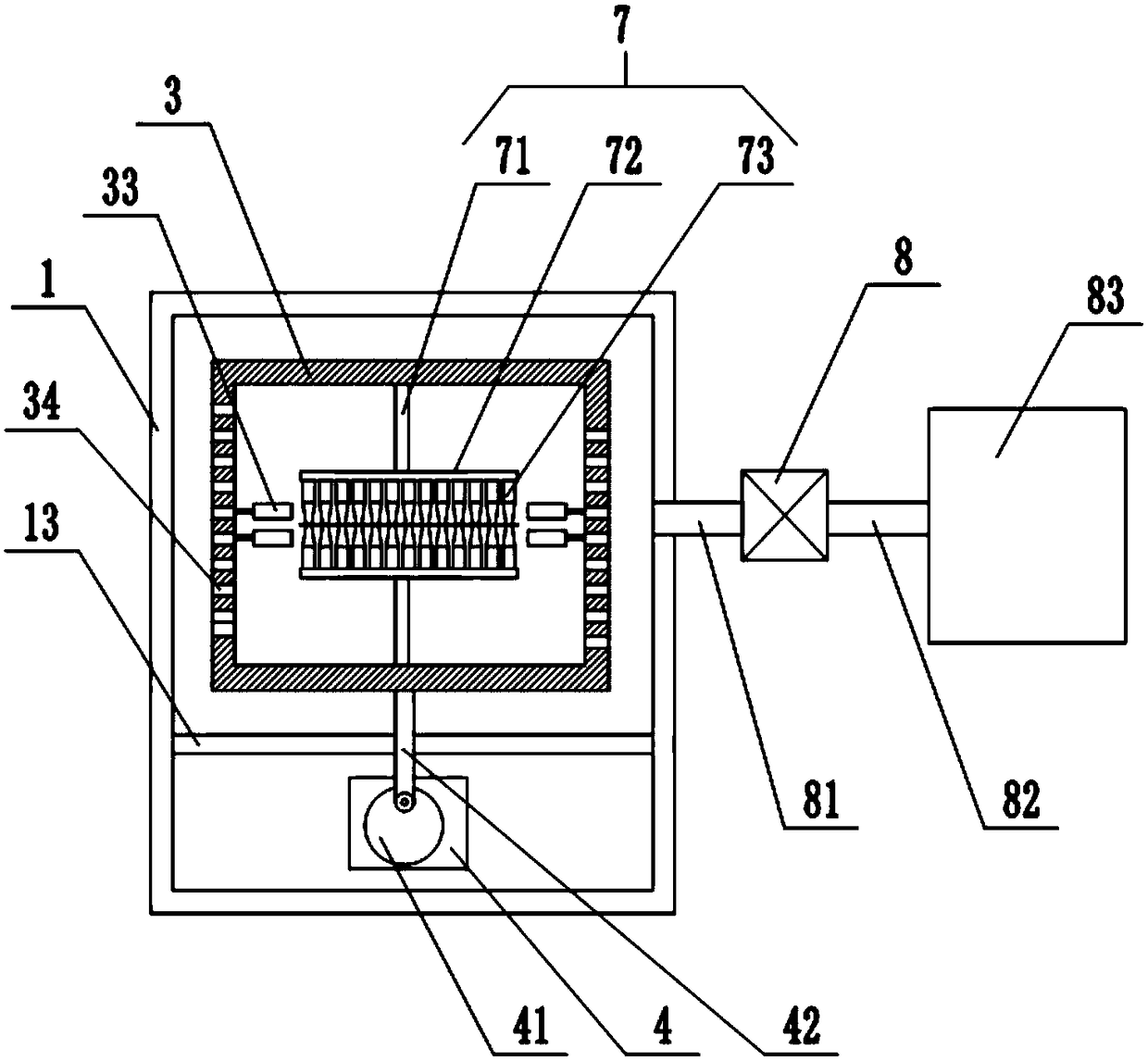

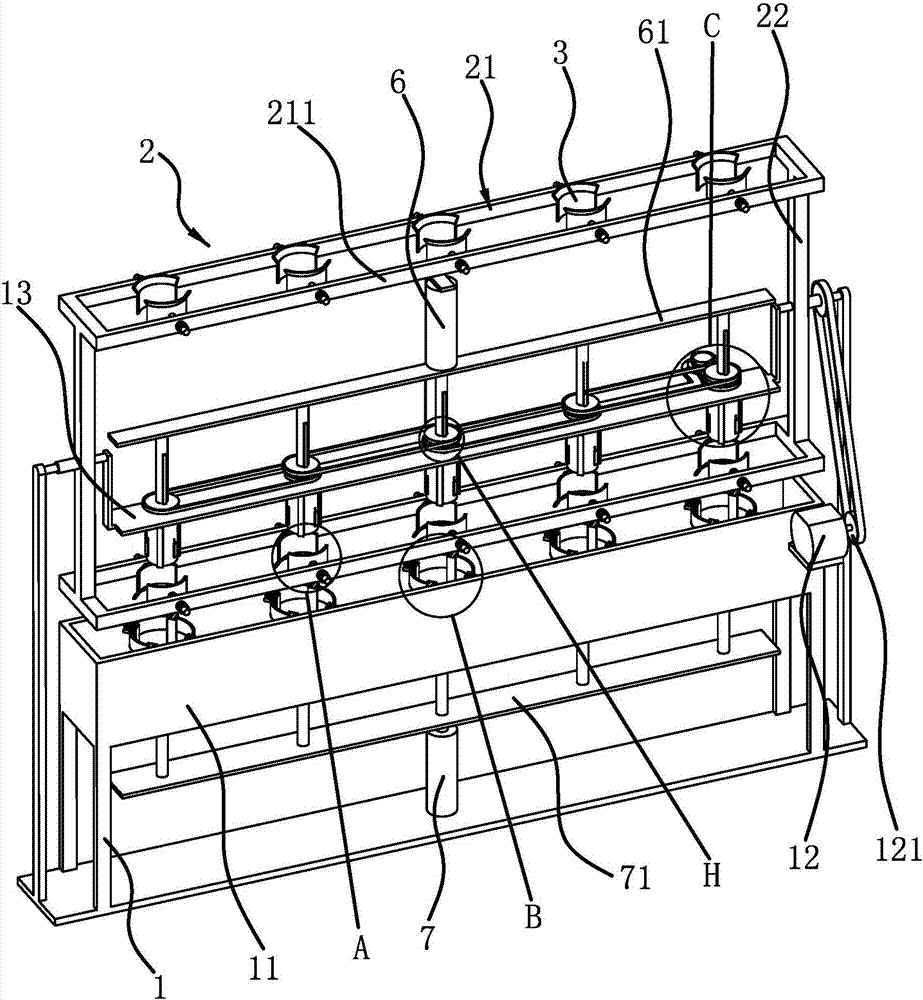

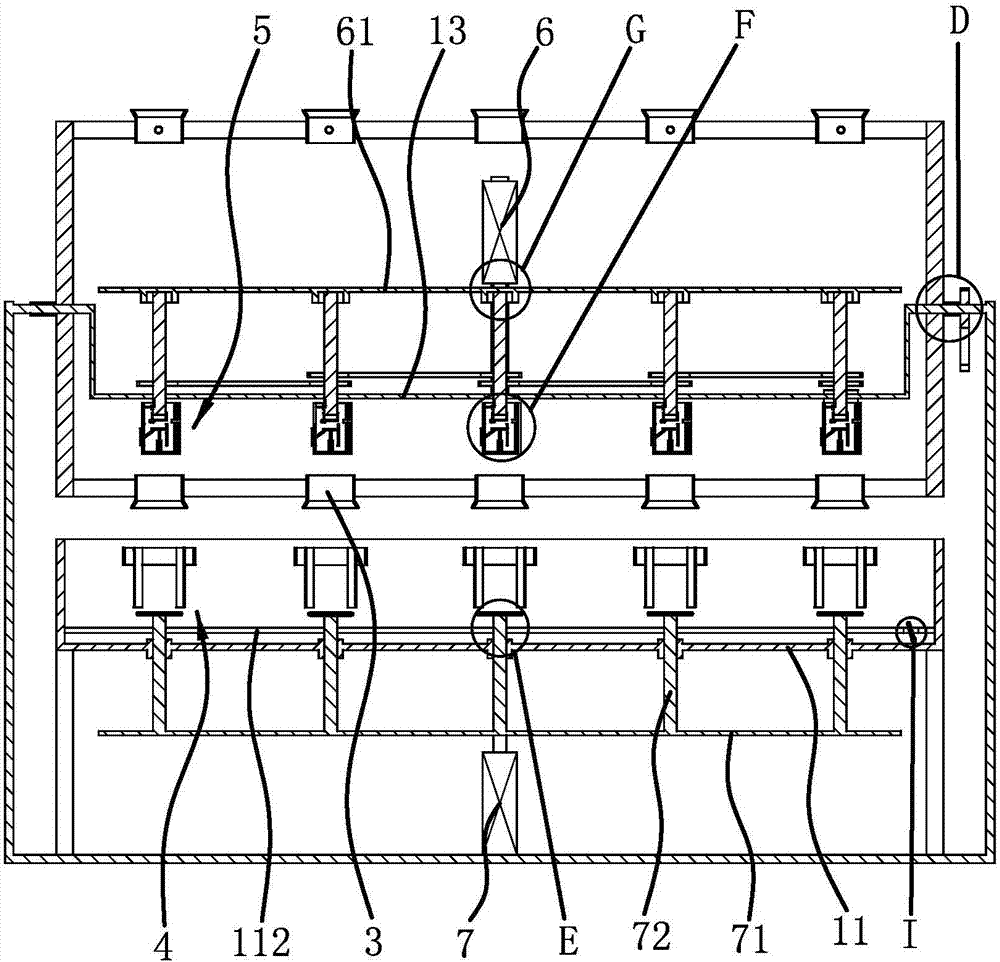

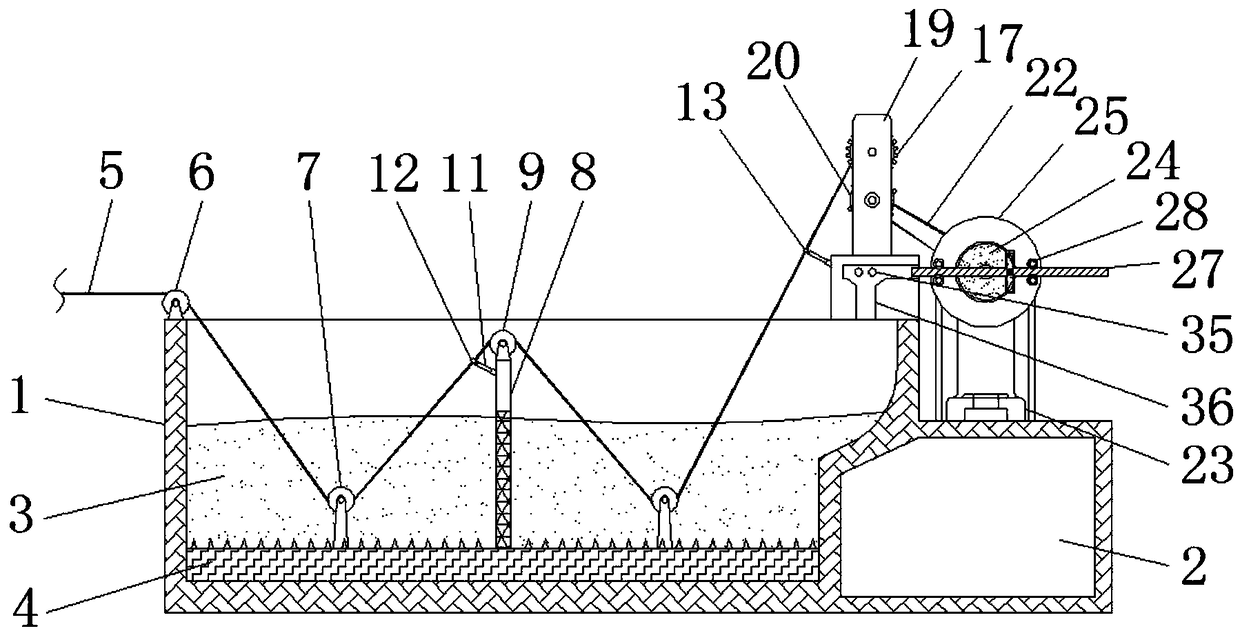

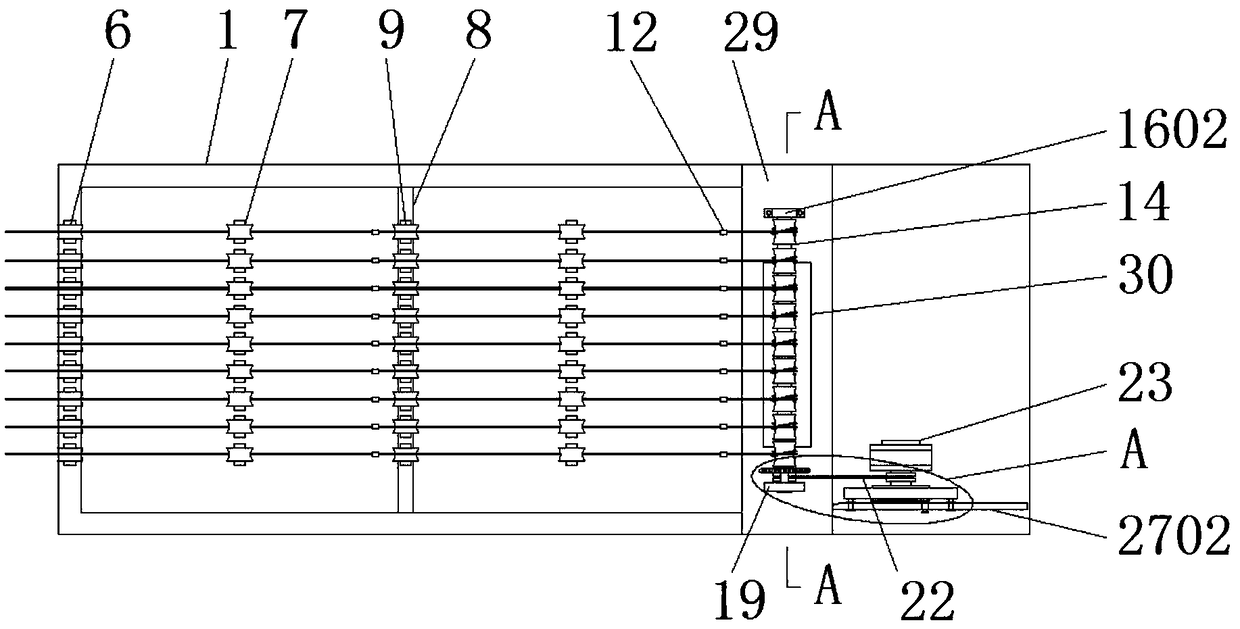

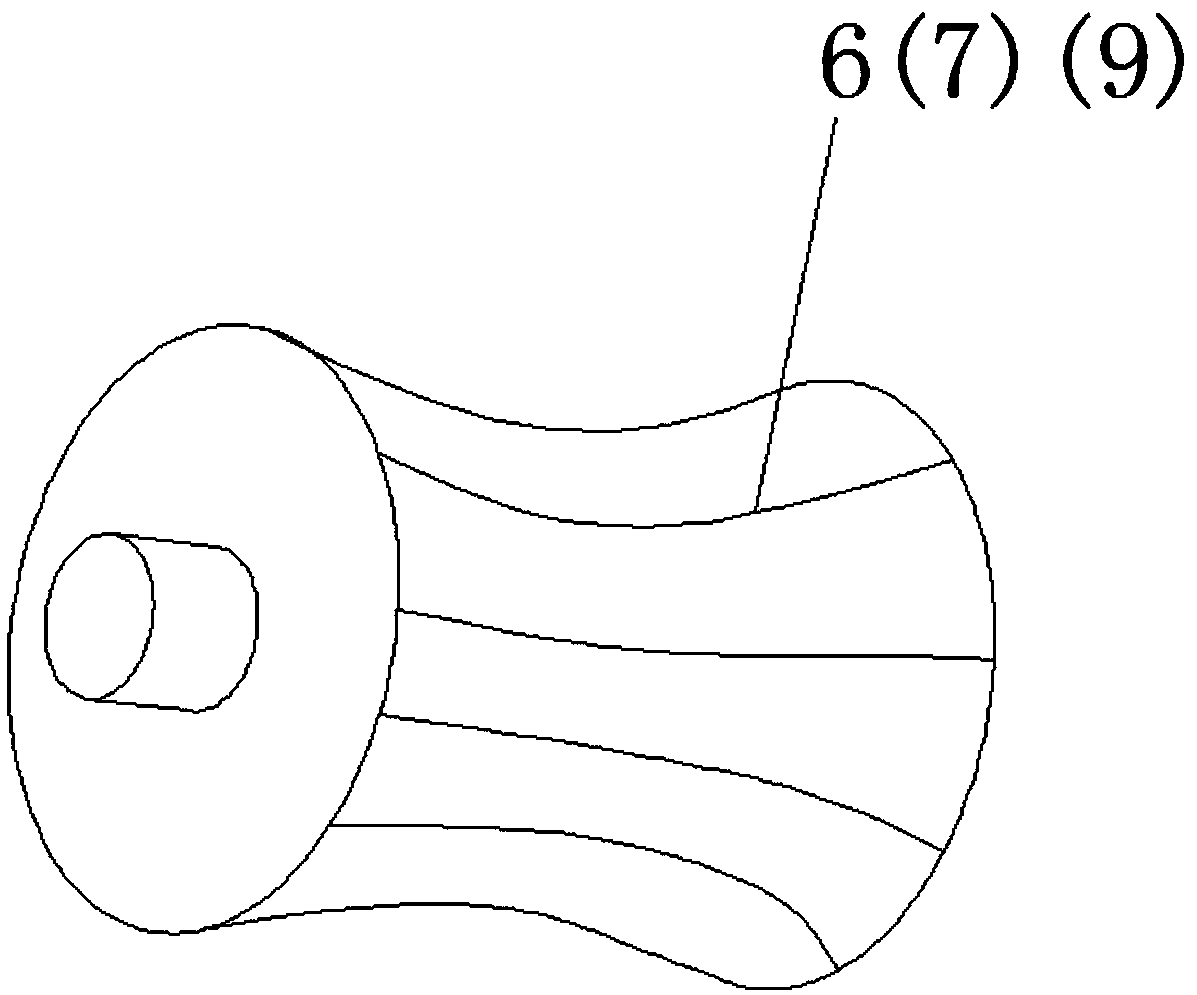

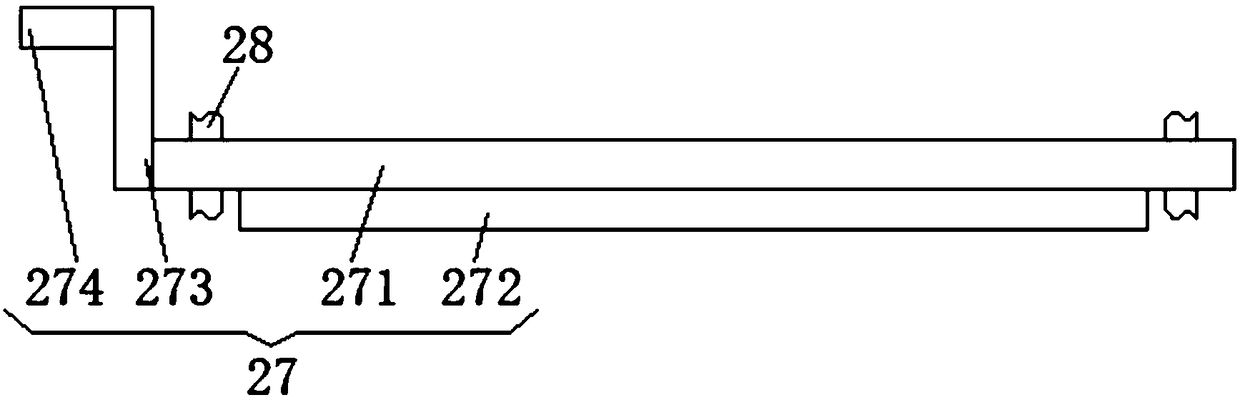

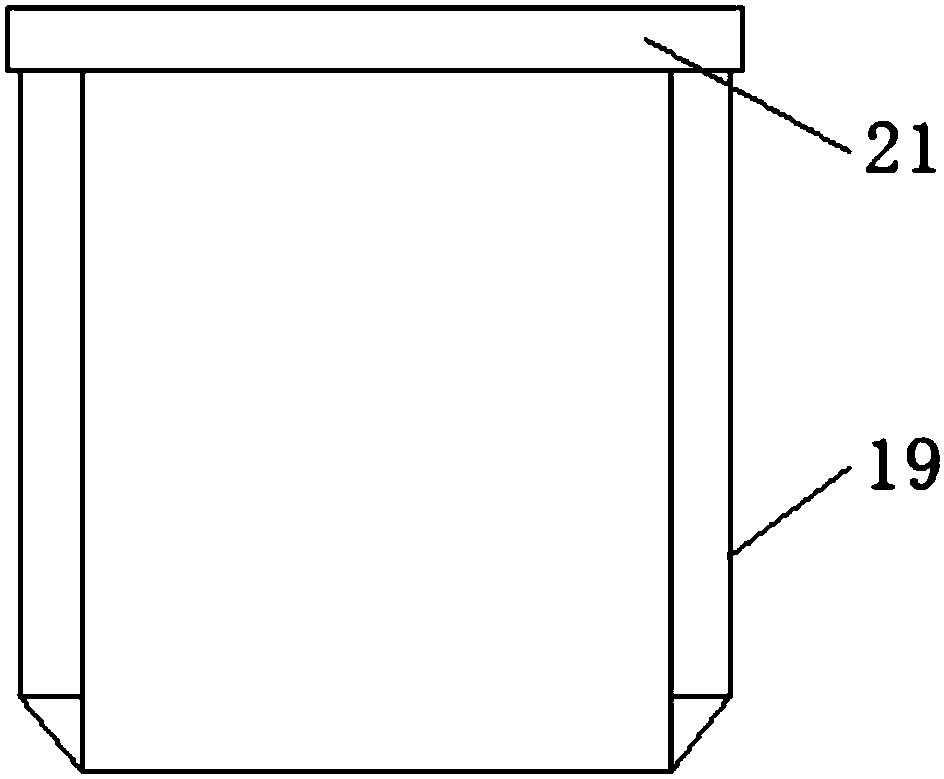

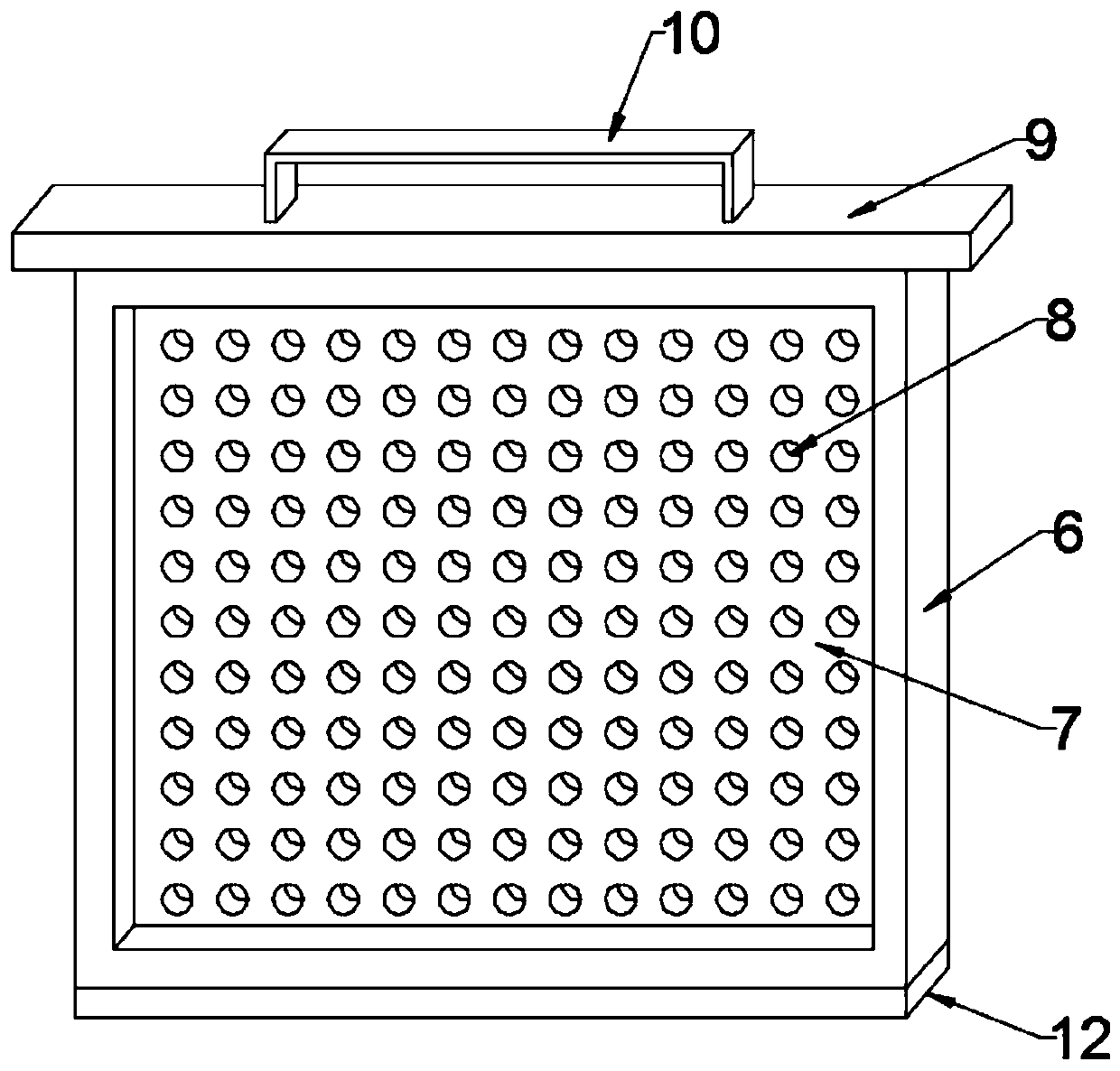

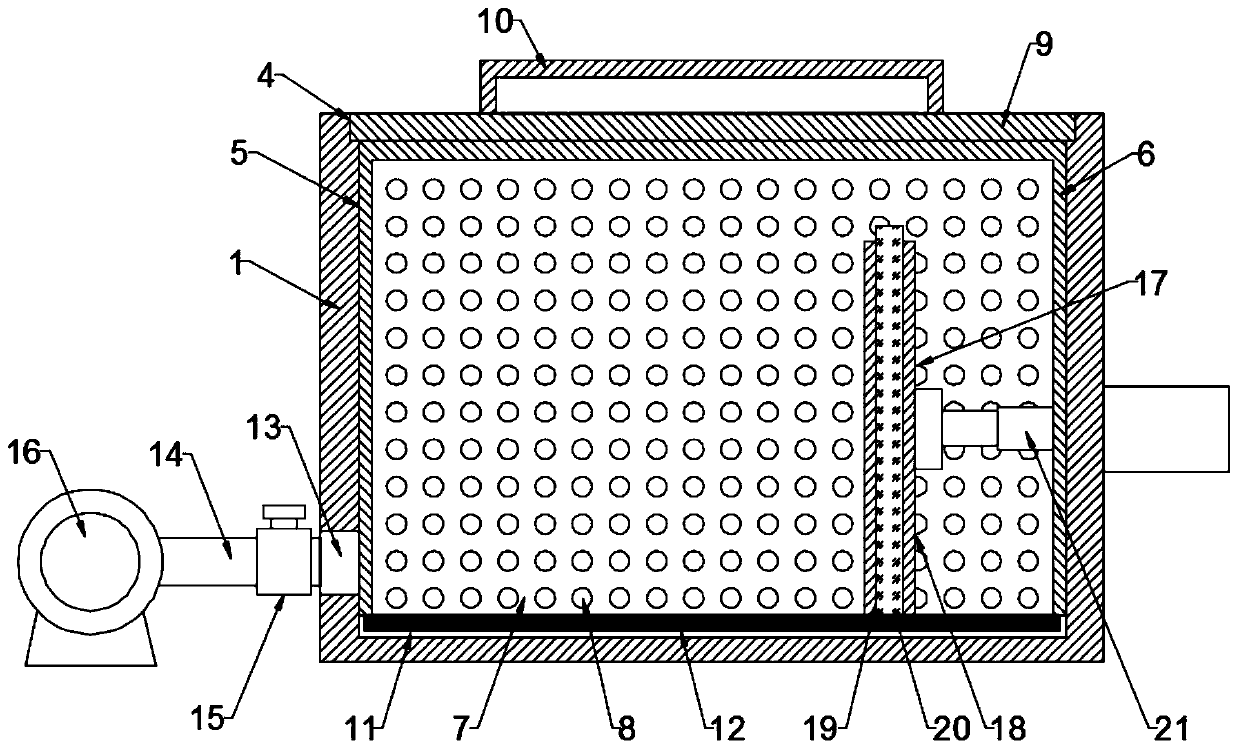

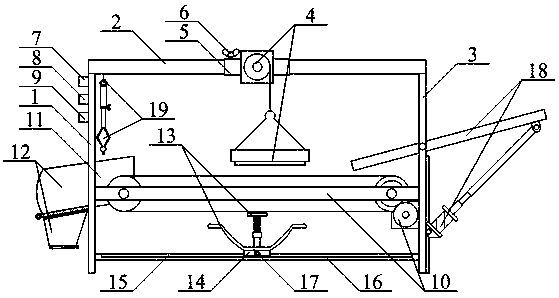

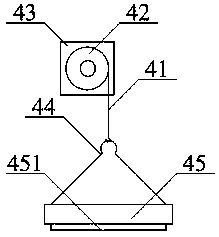

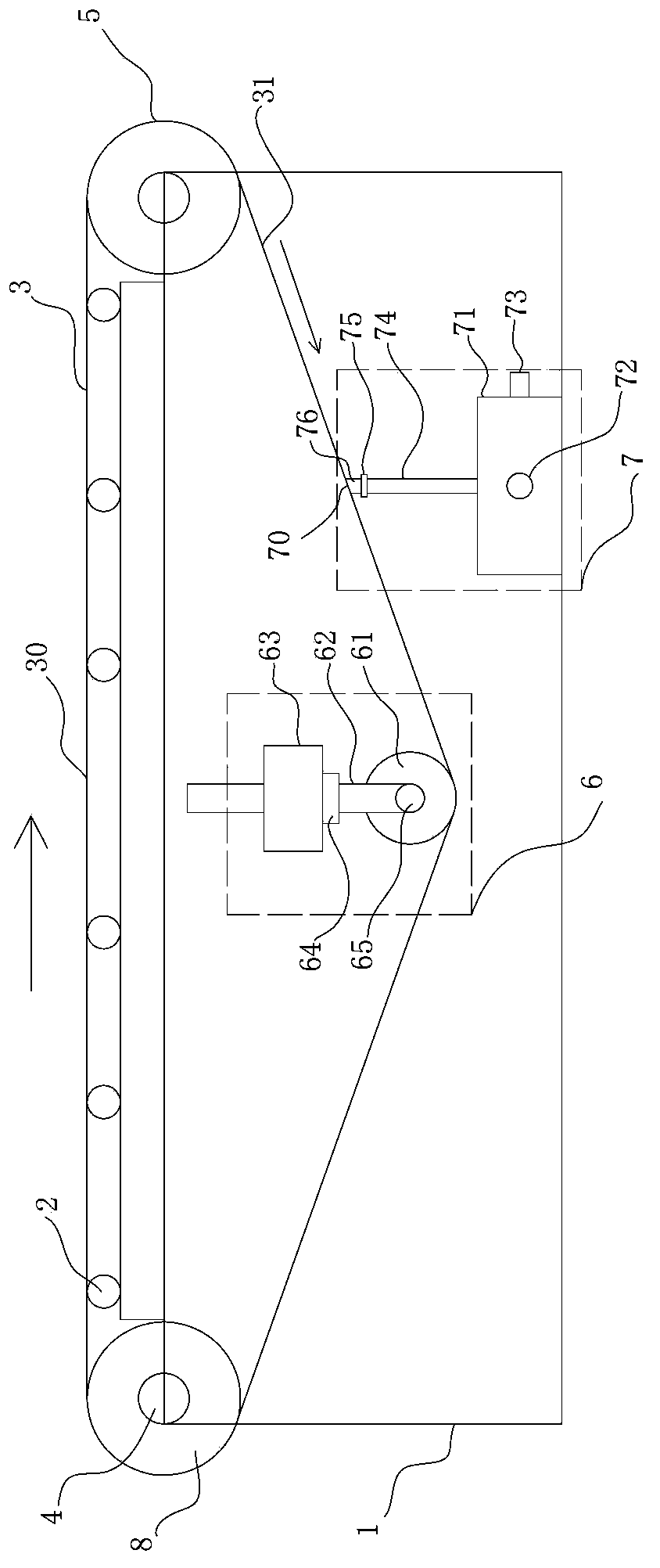

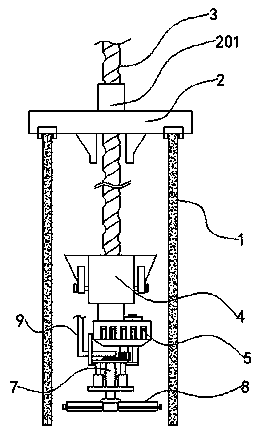

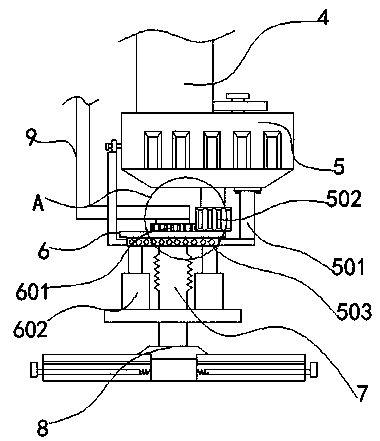

Hair ball removing device for wool cloth

ActiveCN109230785AEasy to scrapeEasy to cleanCleaning using toolsArticle deliveryEngineeringConductor Coil

The patent application relates to the technical field of textile machinery, and discloses a hair ball removing device for wool cloth. The hair ball removing device comprises a tensioning mechanism, anouter box body, a cloth unwinding mechanism and a cloth winding mechanism, wherein the box body is provided therein with a separating plate for dividing the box body into an upper chamber and a lowerchamber; an inner box body is slidably connected in the upper chamber; a first clamping roller group, a hairbrush assembly, a first hair ball remover, a second hair ball remover and a second clampingroller group are successively arranged in the inner box body along a cloth conveying direction; a draught fan is arranged in a frame; the air inlet of the draught fan is connected with an air inletpipe; and the air outlet of the first draught fan is connected with a collecting box. The cloth is combed by the hairbrush assembly, and then the hair balls of the cloth are scraped off by the first hair ball remover preliminarily, and are scraped off by the second ball remover secondarily. Thus, the cloth is finally wound around the cloth winding mechanism in order that the hair balls on the surface of a wool sweater are cleaned.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

Cup cleaning device

ActiveCN107411676AImprove cleaning efficiencyImprove applicabilityTableware washing/rinsing machine detailsEngineering

Owner:石家庄万维贸易有限公司

Gypsum heat preservation painting mortar construction process

The invention relates to a gypsum heat preservation painting mortar construction process which comprises the steps that firstly, a base-layer wall is processed; secondly, according to the smoothness and perpendicularity of the surface of the base-layer wall, one wall is used as the datum, and a perpendicular square-setting elastic control line is hoisted; thirdly, gypsum bases are painted with mortar and used as angle beads; fourthly, the gypsum bases are painted with mortar and used as ash cakes and punching ribs; fifthly, gypsum heat preservation painting mortar is sprayed; sixthly, the gypsum heat preservation painting mortar is flattened and compacted, wherein the step of hanging nets on the junctions of different materials is further included between the second step and the third step; in the fourth step, after the ash cakes are manufactured and hardened, distribution cakes are manufactured and arranged through flax threads by controlling the ash cakes, so that the horizontal spacing between all the distribution cakes is not larger than 1500 mm; the steps of rib grinding and rib alignment are further included between the fourth step and the fifth step. Compared with the prior art, the gypsum heat preservation painting mortar construction process has the advantages that construction is convenient, plastering, scraping and repair are easy, the labor intensity is low, material consumption is lowered, the construction period is shortened, and construction cost is saved.

Owner:SHANGHAI LONGZHEN CONSTR ENG CO LTD

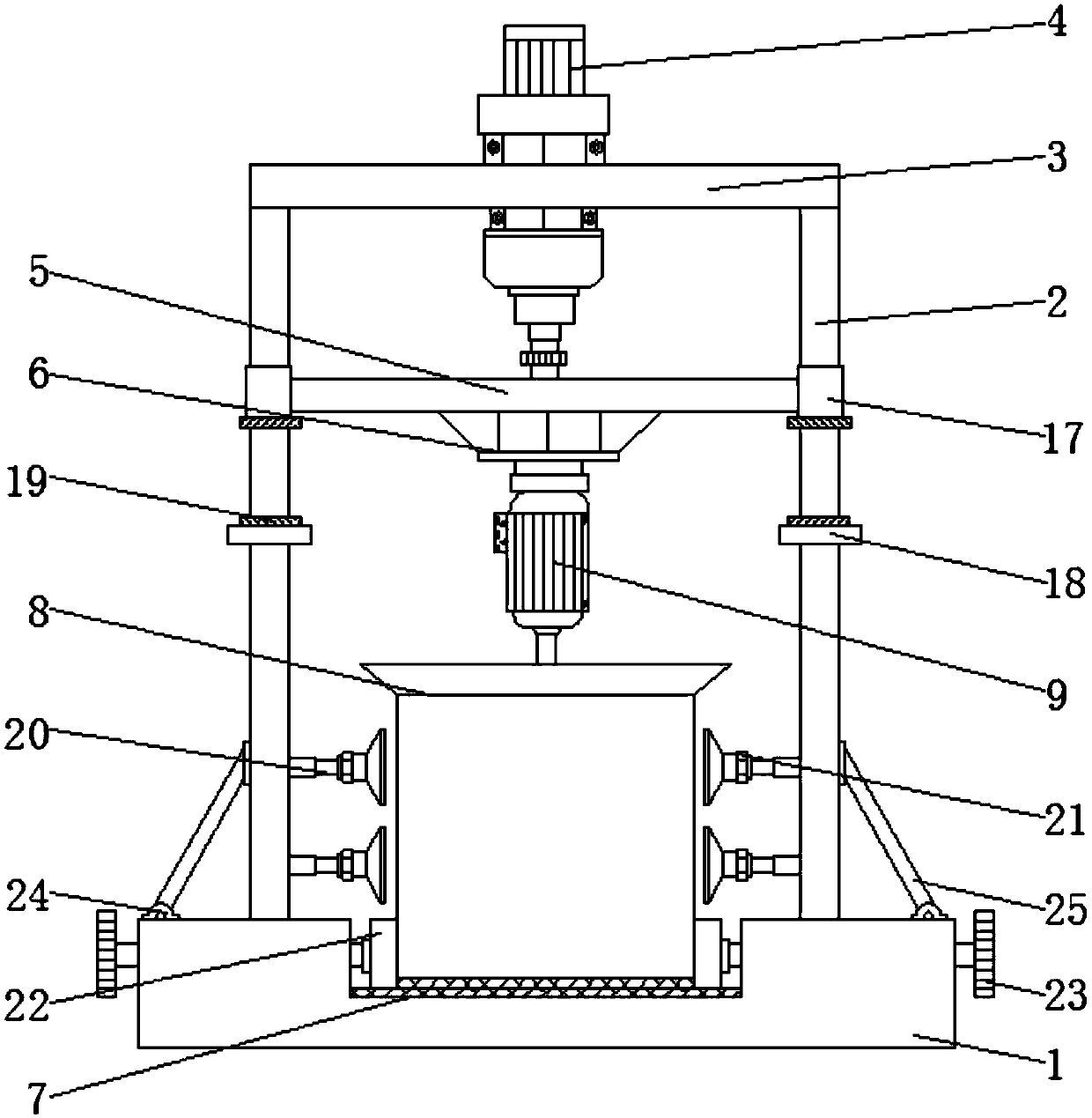

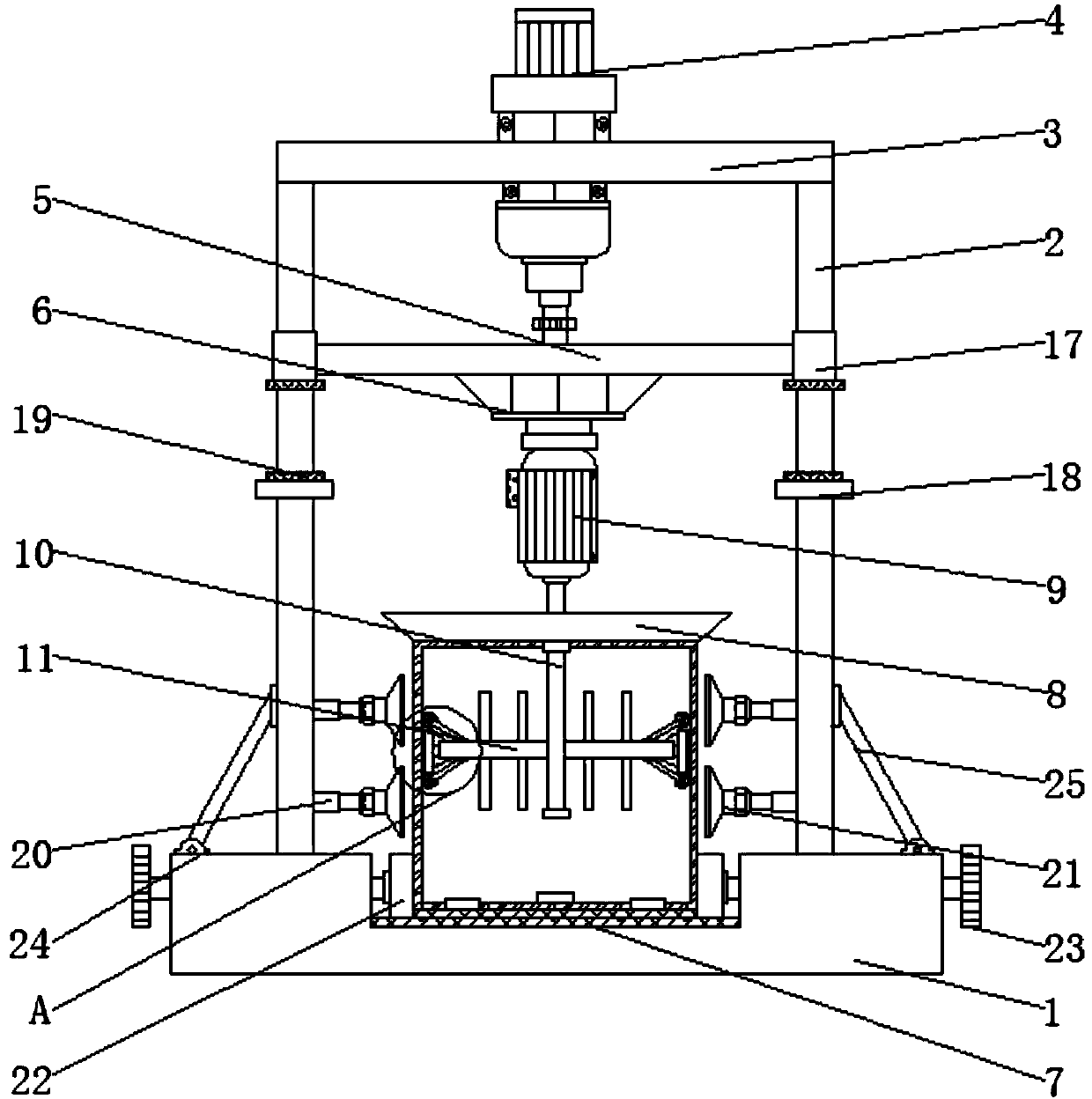

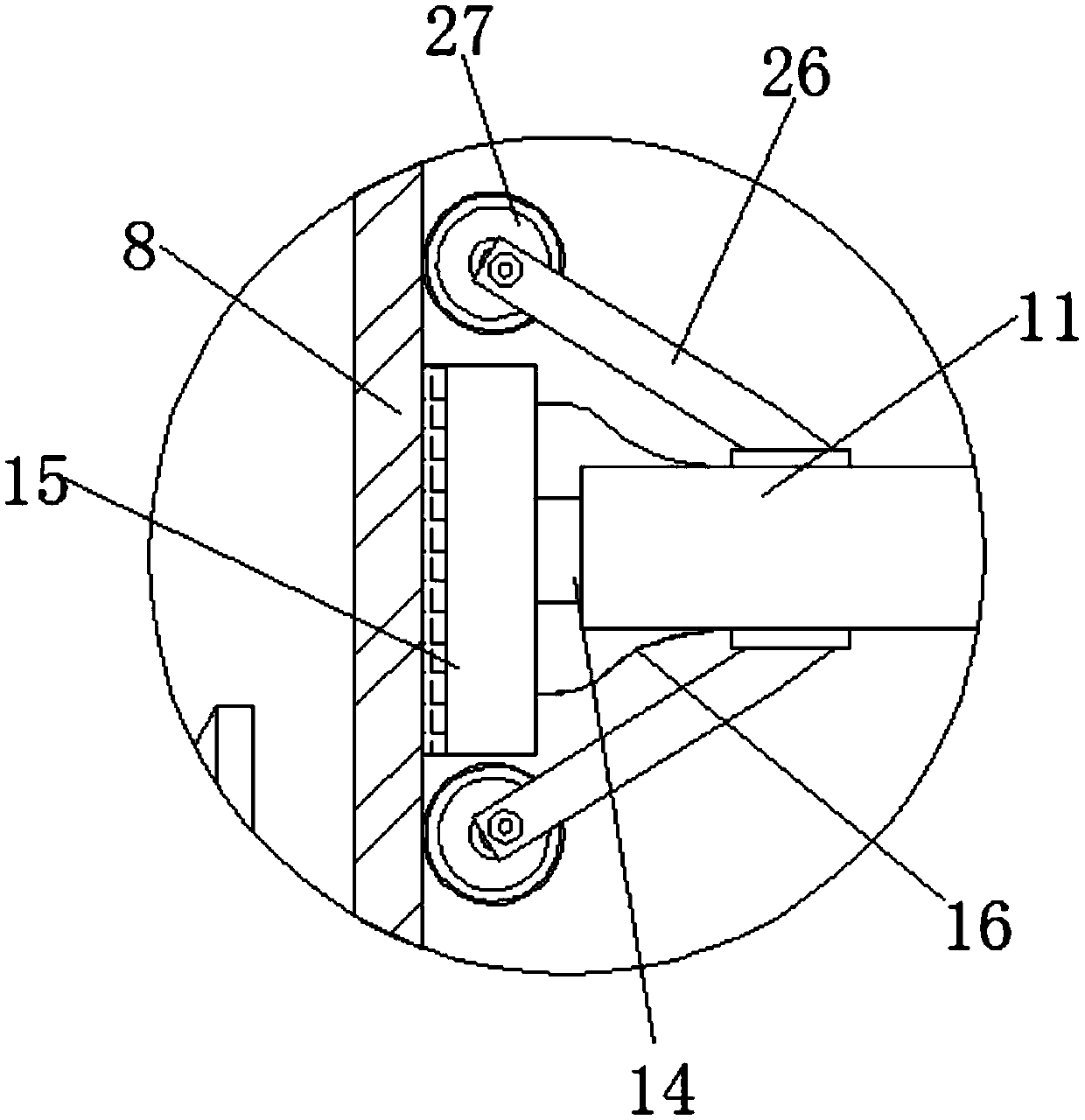

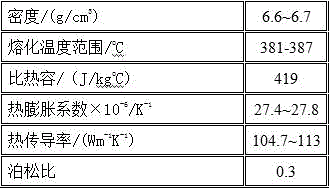

Feed processing equipment

The invention discloses feed processing equipment. The feed processing equipment comprises a grinding tank and a driving motor, wherein a rotating shaft is rotatably connected to the center of the topof the grinding tank; the top end of the rotating shaft is fixedly connected with an output shaft of the driving motor through a coupling; a square connecting rod is fixed to the bottom end of the rotating shaft and located in the center of the interior of the rotating shaft; deflector rods are fixed to the surface of the square connecting rod; a grinding device is arranged at the bottom end of the square connecting rod, the grinding device is in sliding connection with the square connecting rod; and a sieve plate is fixed to the position, close to the bottom of the grinding device, in the grinding tank. The invention relates to the technical field of feed processing. According to the feed processing equipment, the effects of uniform grinding and adhesion prevention are achieved; elasticpressing can be carried out, and the grinding space is automatically and moderately increased, so that large and small granular materials uniformly leak, and grinding is rapid and uniform; and meanwhile, sticky materials on the inner wall can be automatically scraped off, so that the working efficiency and the use performance are improved.

Owner:莱阳和美华饲料有限公司

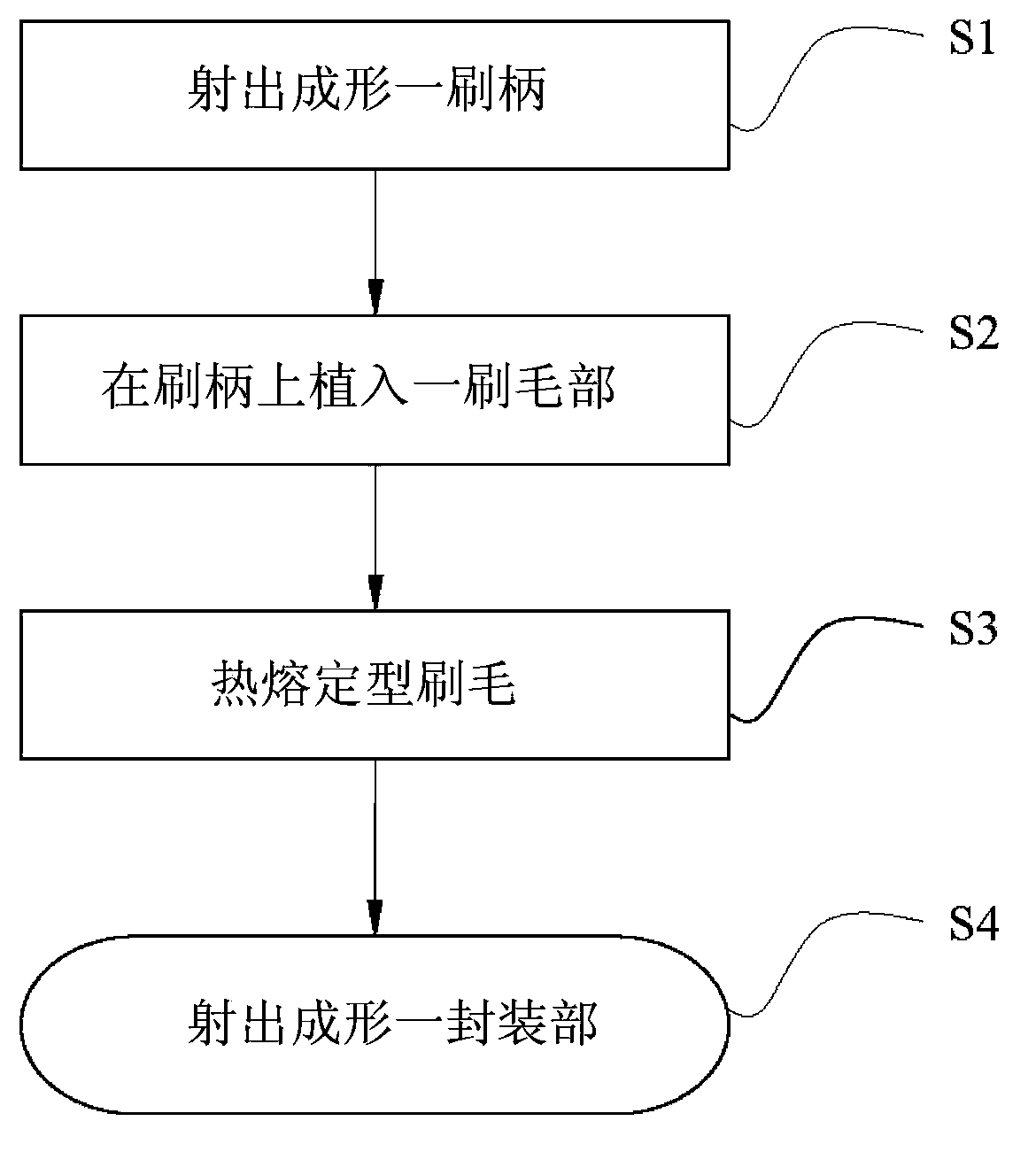

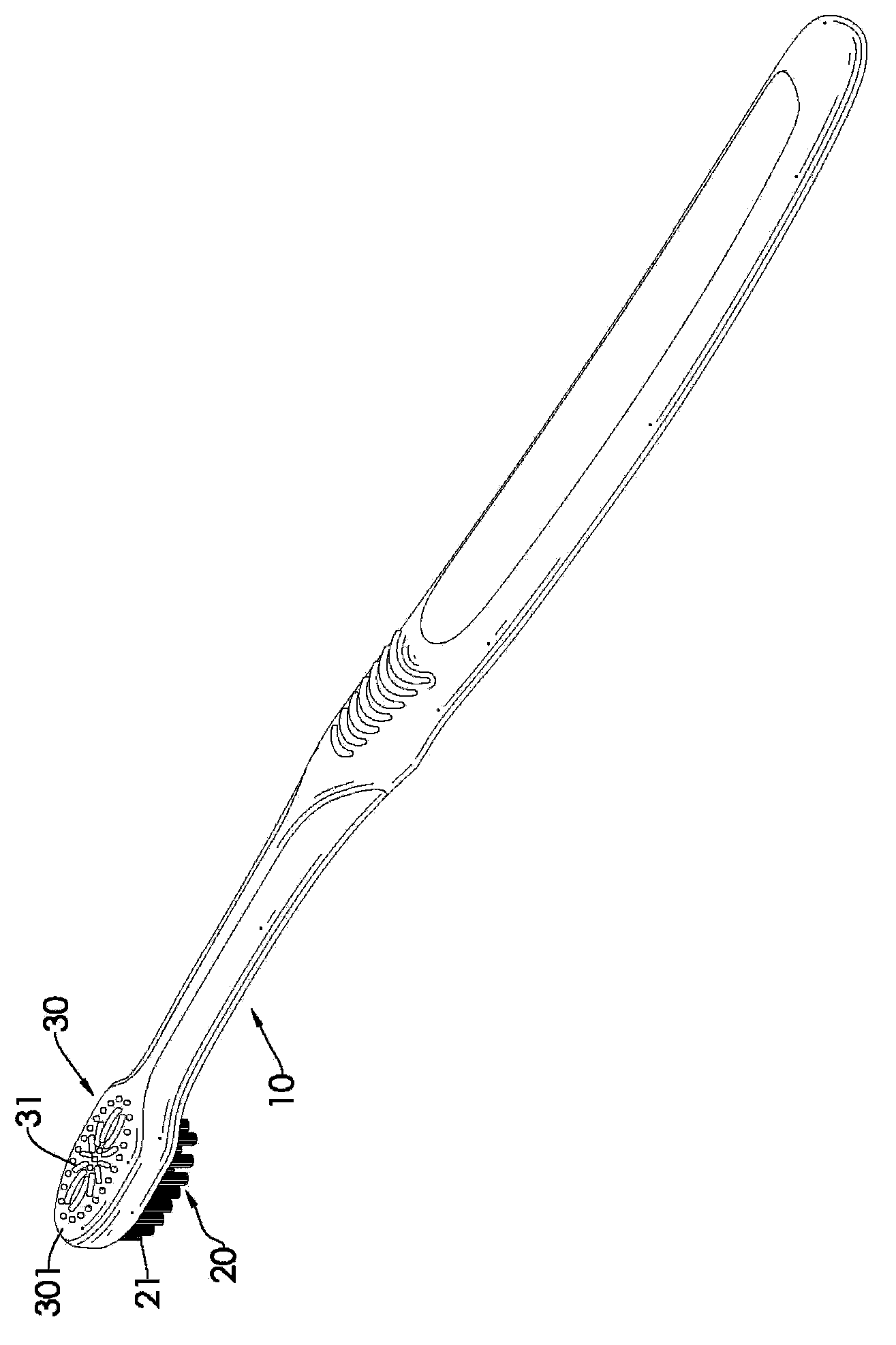

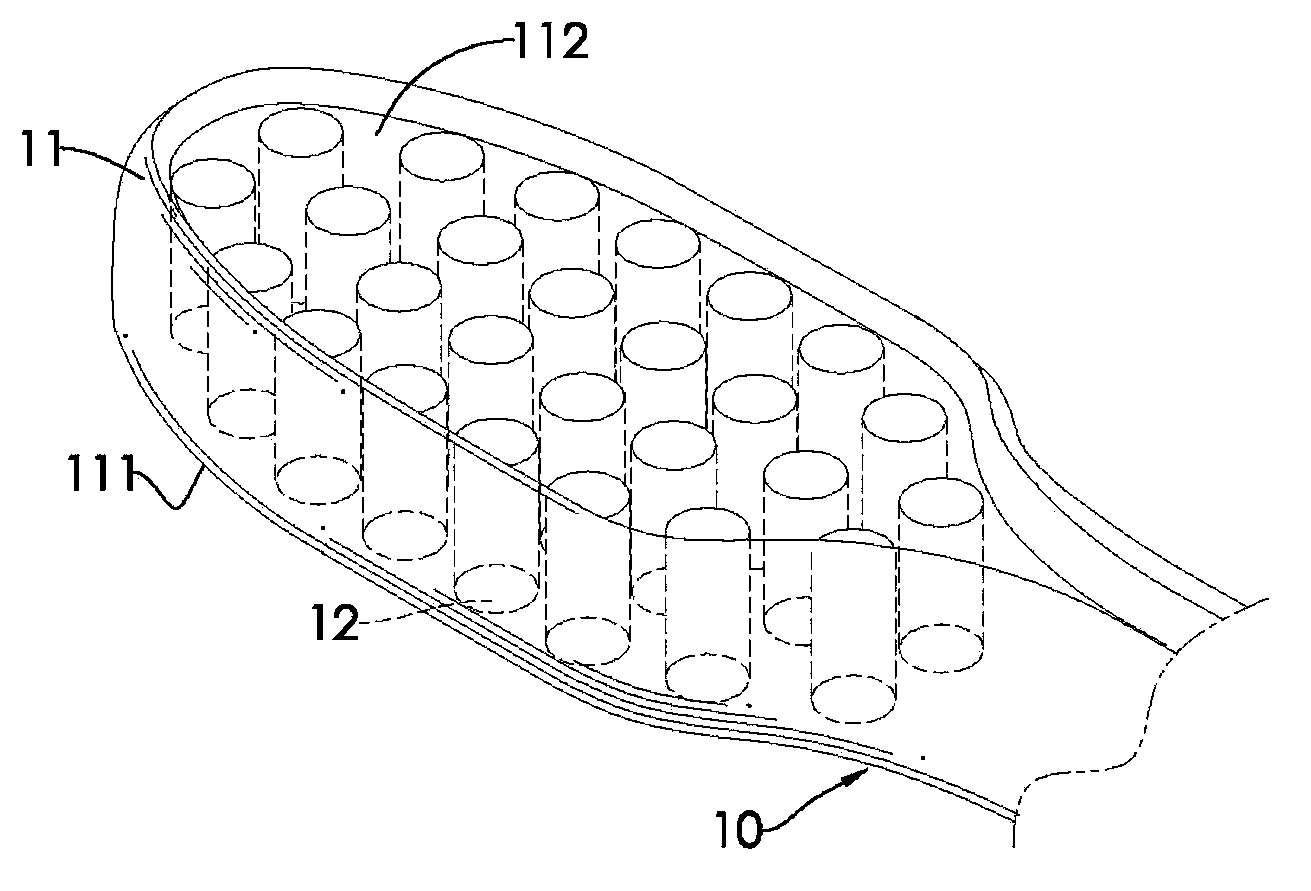

Manufacturing method for toothbrush and toothbrush

The invention relates to a manufacturing method for a toothbrush and the toothbrush manufactured with the method. According to the manufacturing method, a brush holder is formed first through injection molding, a brush head is formed at one end of the brush holder and is provided with multiple brush bristle holes formed integrally, a brush bristle part is implanted in the brush head, the brush bristles of the brush bristle part protrude from a second side face of the brush head, the brush bristles and corresponding thin fragments are fixed to the brush head through hot melting shaping, and finally, an encapsulating part is formed on the brush holder and the second side face of the brush head through injection molding. The toothbrush made with the method, the whole toothbrush is completely made of plastic, the toothbrush can be directly recycled when abandoned, the number of recovery processing steps is reduced and resources are saved.

Owner:ACUMEN

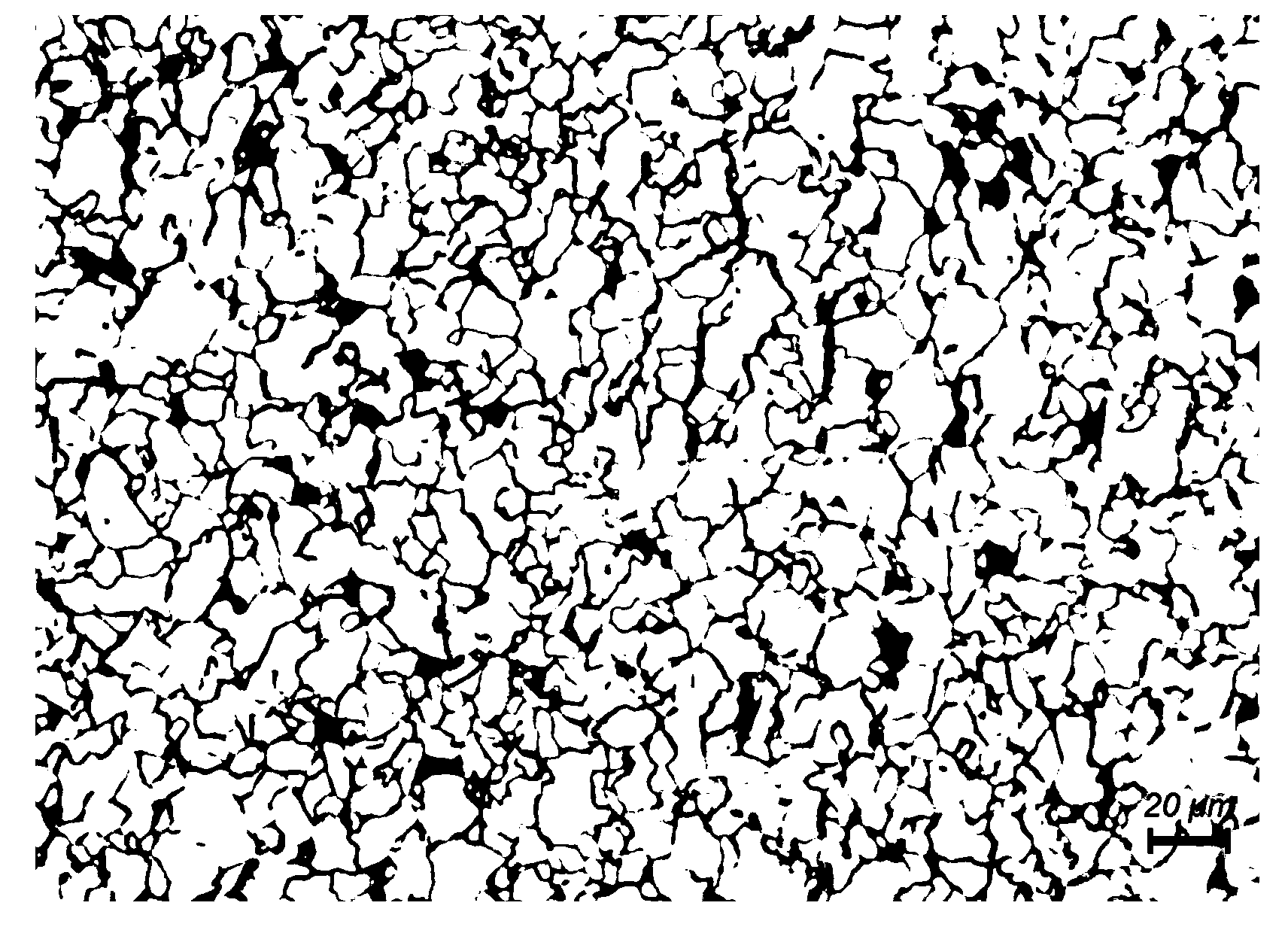

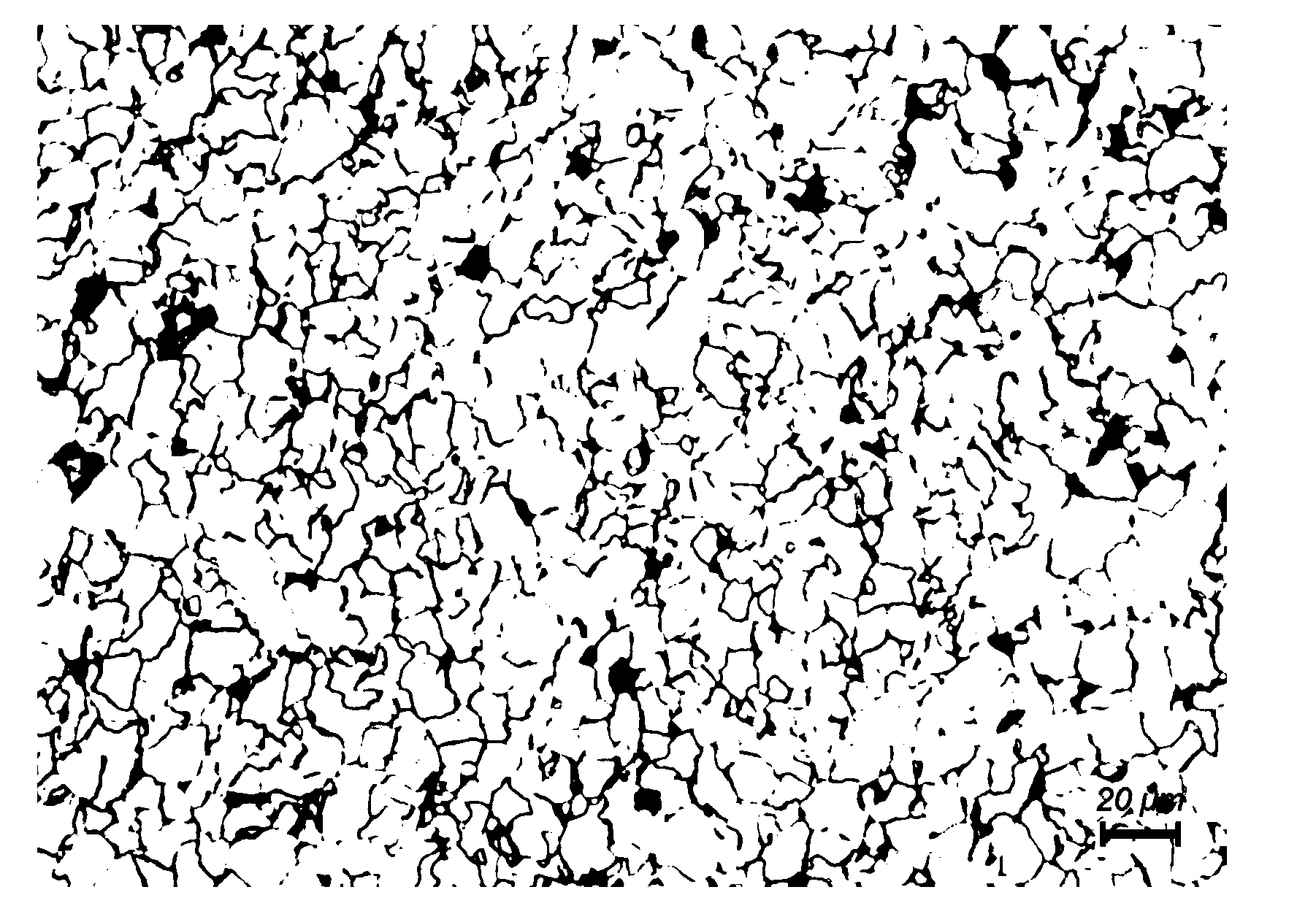

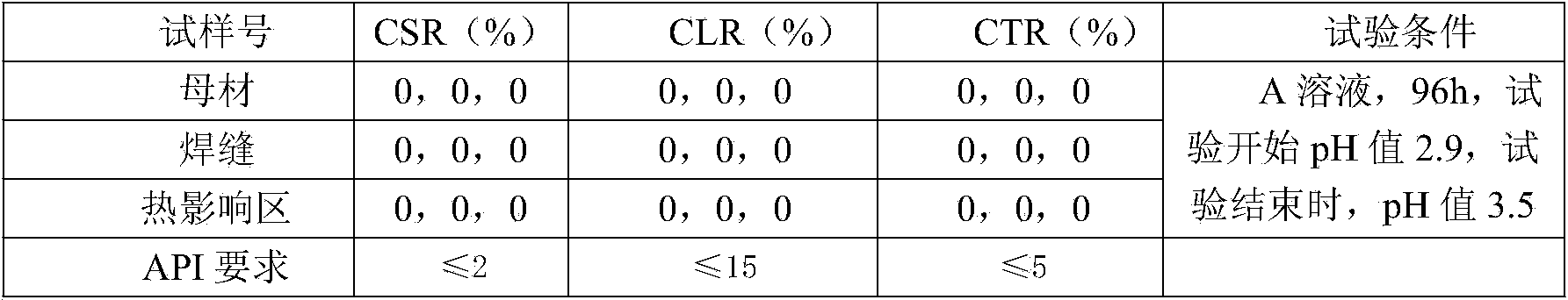

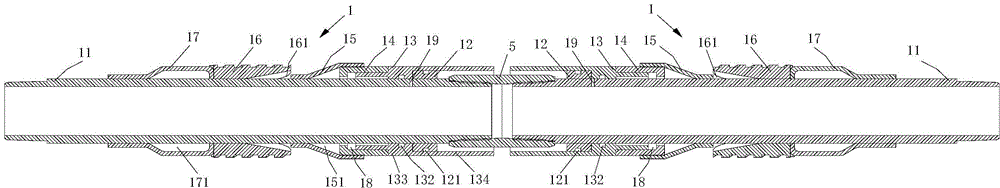

X70MS ERW welded pipe having excellent anti SSCC stress corrosion and manufacturing method thereof

ActiveCN103526108AImprove roundnessEasy to scrapeFurnace typesHeat treatment furnacesButt weldingPipe welding

The invention discloses an X70MS ERW welded pipe having excellent anti SSCC stress corrosion and a manufacturing method thereof. The manufacturing method comprises the steps of uncoiling and butt welding, edge planning, molding, high-frequency welding, heat treatment, sizing and flying shear, pipe cutting, straightening and other procedures. The high-frequency welding frequency is 400+ / -30 KHZ, the welding speed is 20+ / -5 m / min, the normalizing temperature of the heat treatment is 920-980 DEG C, and the cooling rate after the heat treatment is 3-15 DEG C / s. The X70MS ERW welded pipe and the manufacturing method have the beneficial effects that the reasonable molding technology is adopted to ensure board edge end faces achieve parallel H-shaped abutting joint, so as to reduce residual stress in the molding process; with adopting of a smaller squeeze amount and an opening angle, a welding power parameter is reduced, so that burrs are formed uniformly on the outer surface and the inner surface during the steel pipe welding process, so as to be beneficial for scraping and interrupting the burrs and guarantee the continuity of online production.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Movable equipment for soil improvement

The invention provides movable equipment for soil improvement. The equipment comprises a transverse frame, a stirring mixing box, a stirring motor, a rotating sleeve, spiral stirring blades, a ball bearing, a discharge buffering scraper structure, a soil crushing frame structure, a soil conveying frame structure, a movable bottom frame structure, a bottom shaft frame, a retractable air cylinder, an upper side shaft frame, a control box, a touch screen, a controller and a feeding box structure, wherein the stirring mixing box is mounted on the left side of the upper portion of the transverse frame through bolts. Through arrangement of soil overturning teeth, improvement of the crushing effect on soil blocks in soil is facilitated; through arrangement of the upper side shaft frame, a material conveying frame, the stirring mixing box, the retractable air cylinder and a lower side shaft frame, convenience is provided for opening the retractable air cylinder to make the retractable air cylinder move upward to reach the height of the right side of the material conveying frame during use, and at the same time, the height of the entire soil crushing frame structure is increased so that thesituation can be avoided that the soil overturning teeth are in contact with a road surface and thus movement is affected during use of the equipment on the normal road surface.

Owner:田艺江

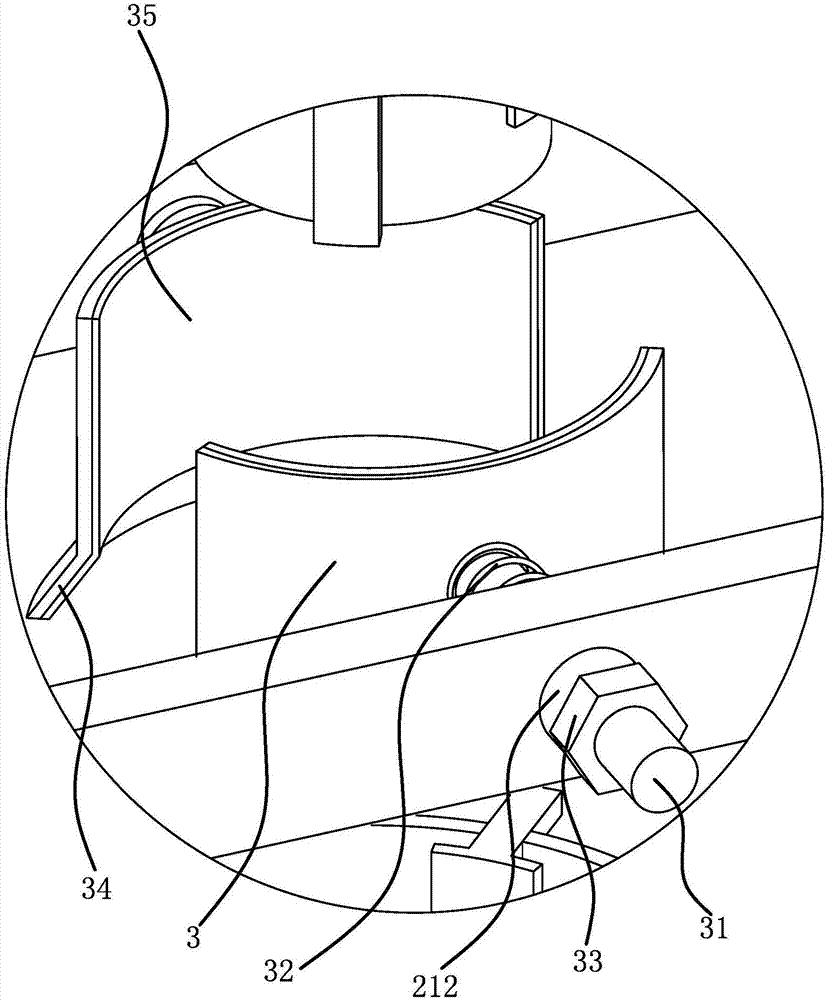

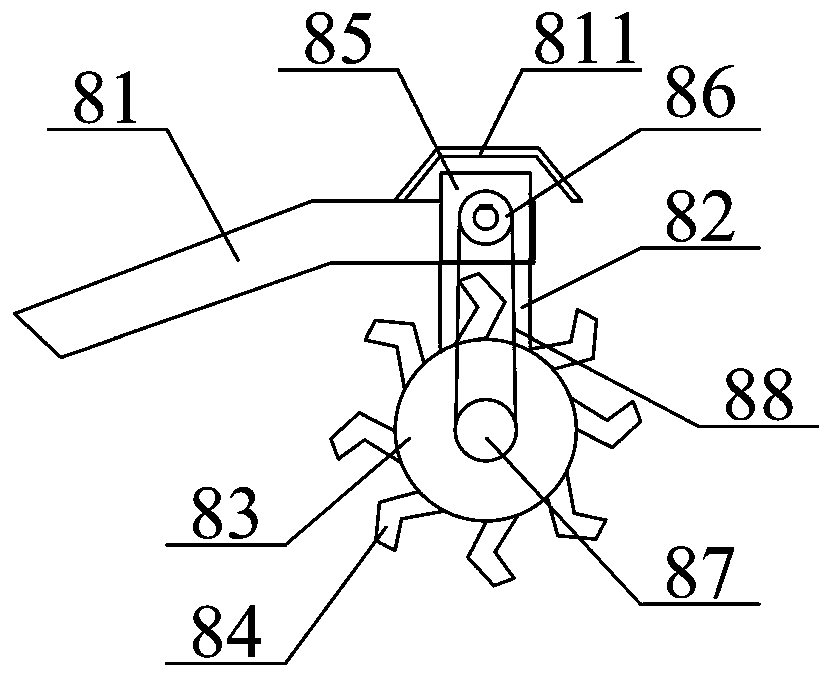

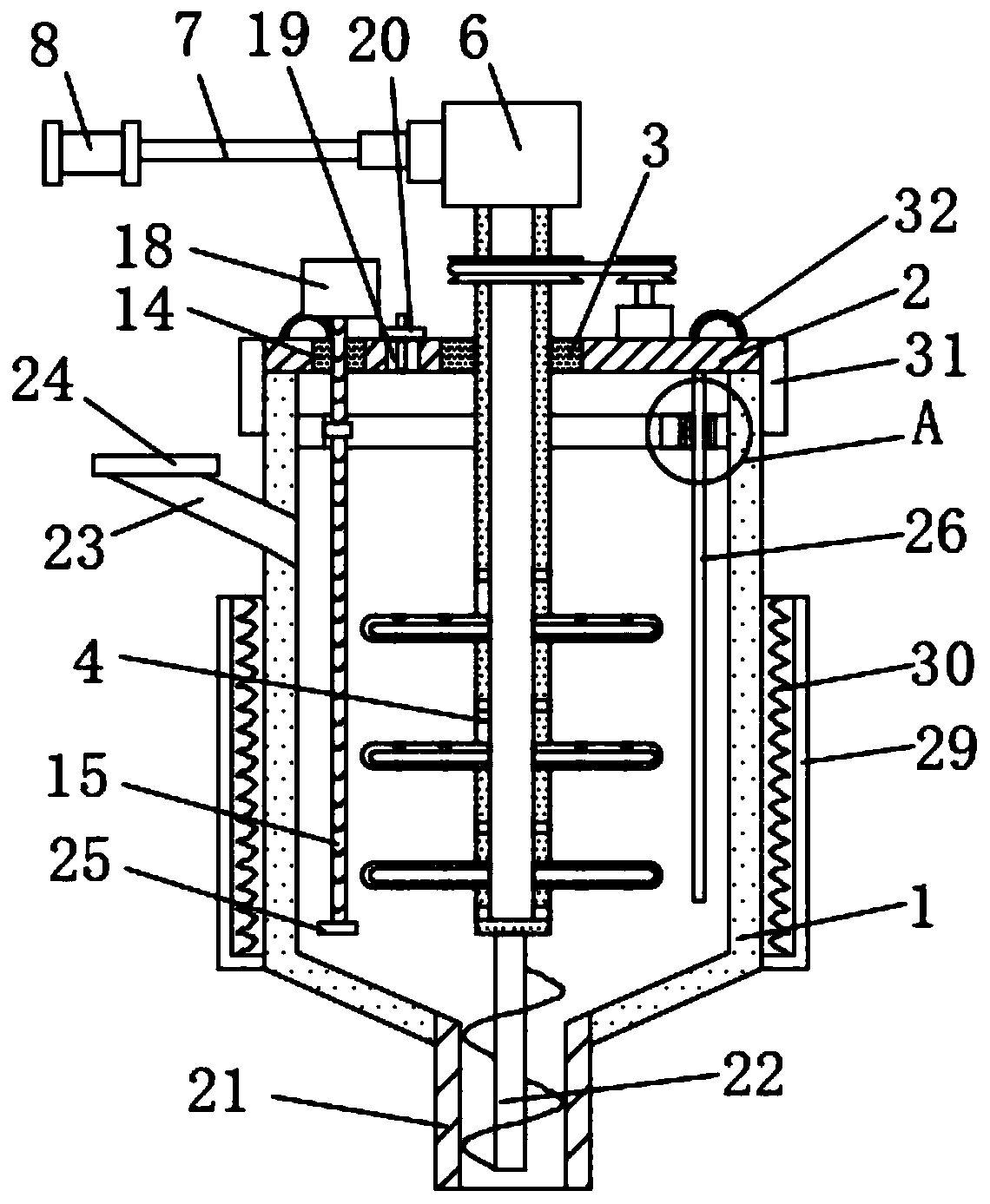

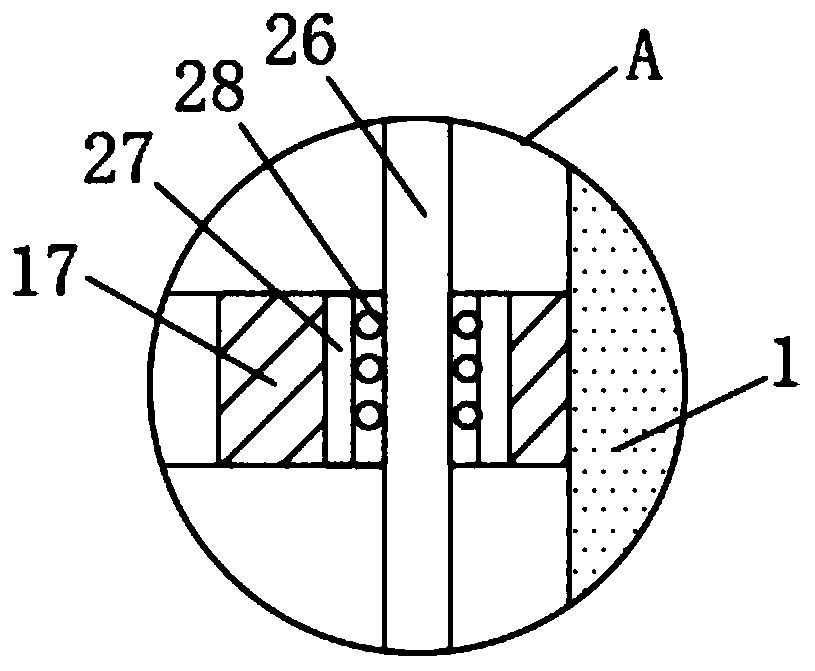

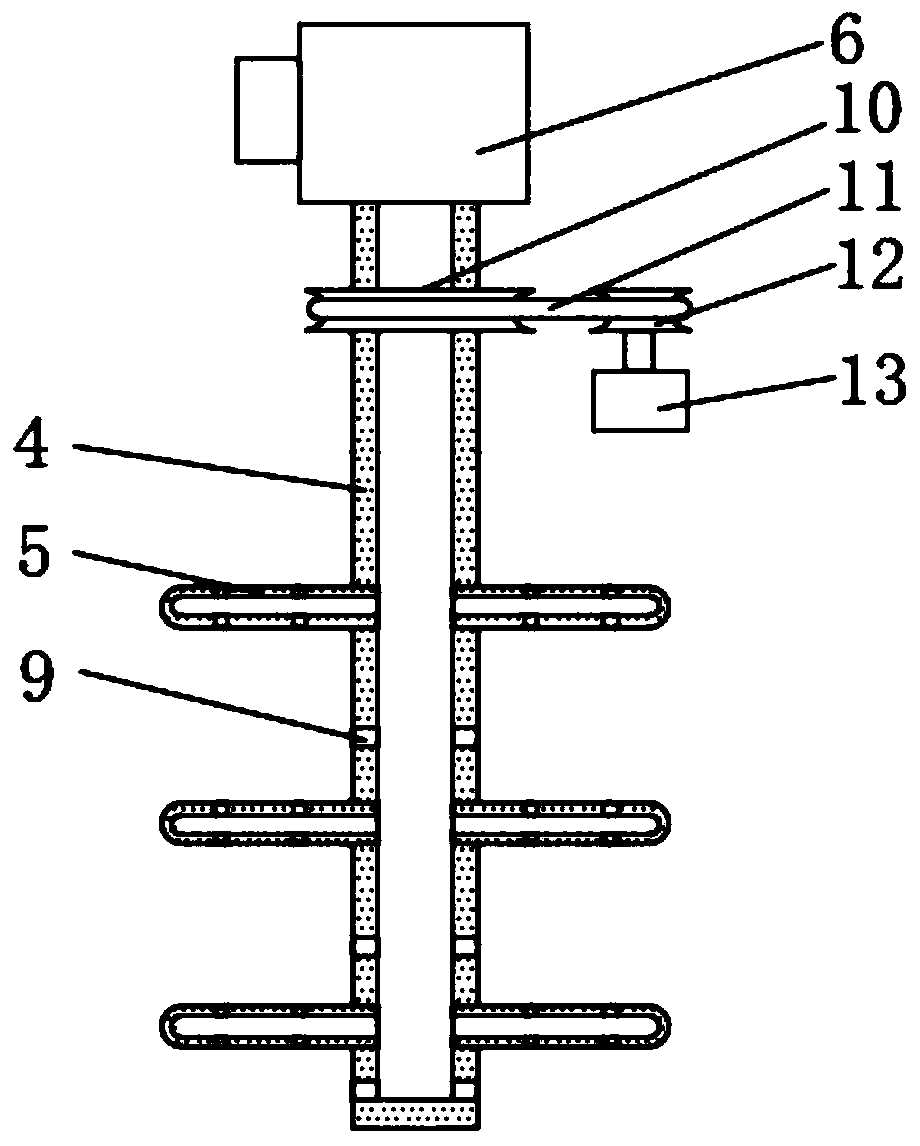

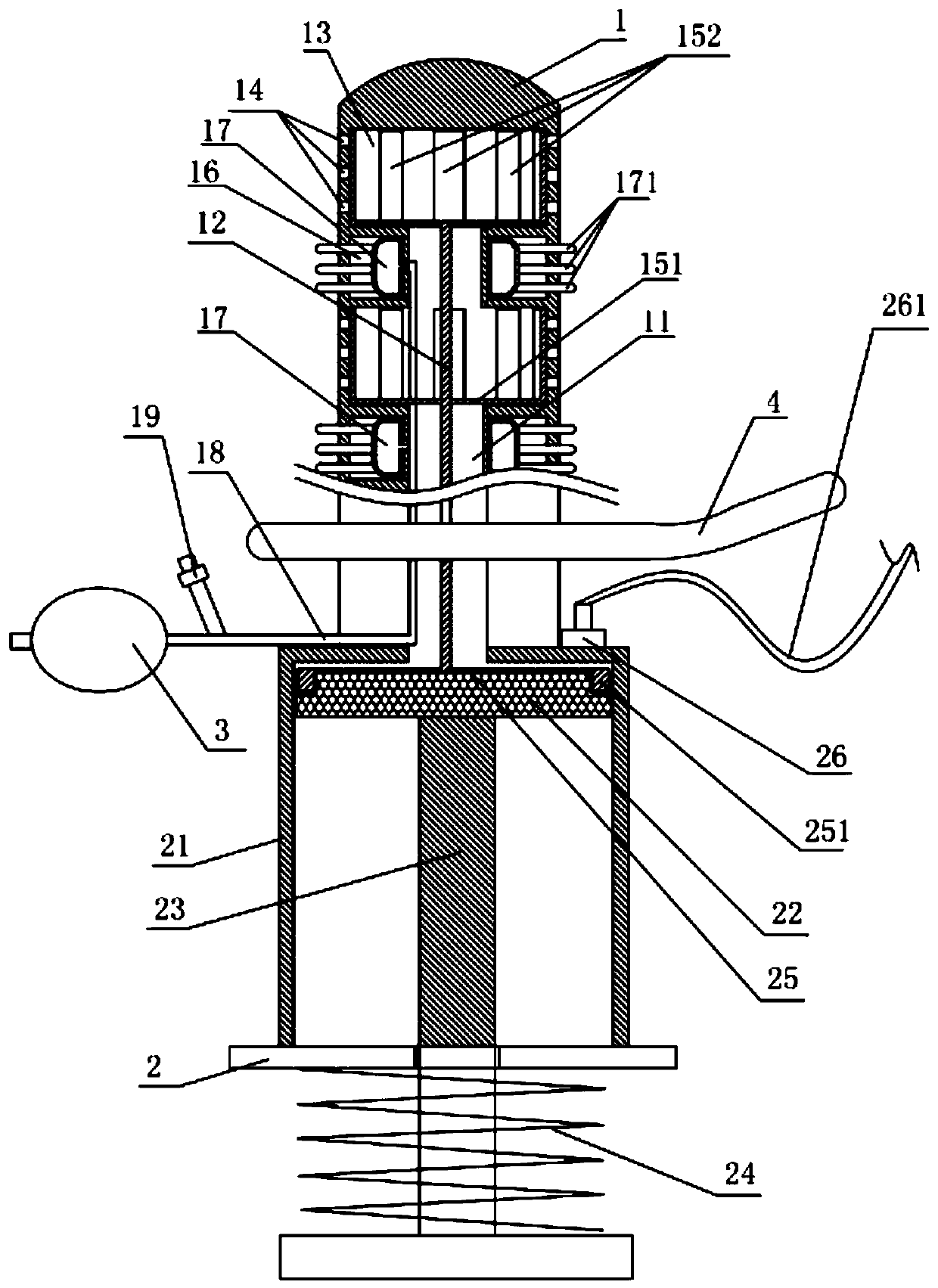

Self-cleaning stirring mechanism of stirrer for medicine preparation

InactiveCN108067112AQuick resetEasy to scrapeRotary stirring mixersTransportation and packagingEngineeringSelf cleaning

The invention provides a self-cleaning stirring mechanism of a stirrer for medicine preparation, belongs to the field of stirring devices for medicine preparation, and solves the problem that existingstirring mechanisms are troublesome to clean. The self-cleaning stirring mechanism of the stirrer for medicine preparation comprises a stirring barrel and a stirring shaft, a stirring blade is arranged on the stirring shaft, one side of the stirring blade is hinged to the stirring shaft, the rotating axis of the hinging part is parallel to the axis of the stirring shaft, a two-way tension springis arranged between the stirring blade and the hinging part, a scraping plate is detachably fixed on the inner wall of the stirring barrel and arranged in the radial direction of the stirring barrel,the scraping plate has a strip-shaped scraping blade facing the stirring shaft, the length direction of the scraping blade is parallel to the axis of the stirring shaft, and the stirring shaft can berotated clockwise or anticlockwise, so that the scraping blade scrapes dirt on one side or the other side of the stirring blade. When the stirring blade touches the scraping plate, the stirring bladecan rotate around the hinging part, the scraping blade can scrape the dirt on one side or the other side of the stirring blade, and therefore, articles adhering to the stirring blade are convenientlyscraped.

Owner:XINCHANG YUANZHOU IND DESIGN CO LTD

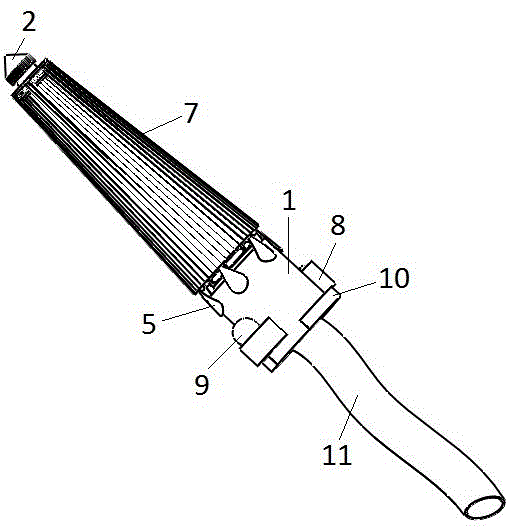

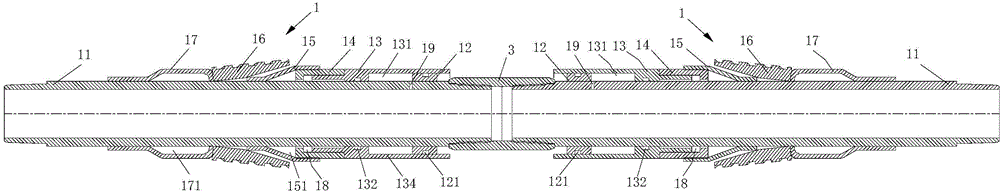

Drifting and scraping integrated tool

ActiveCN104653154AIt has the function of opening the wellEasy to scrapeSurveyCleaning apparatusHydraulic cylinderEngineering

The invention provides a drifting and scraping integrated tool. The drifting and scraping integrated tool comprises a scraping section and a drifting connector, wherein a sealing assembly is arranged in the inner cavity of the drifting connector; the scraping section comprises a cutter barrel, a scraping cutter, a hydraulic cylinder and a supporting reed; the cutter barrel is connected with the drifting connector; the inner cavity of the cutter barrel is communicated with the inner cavity of the drifting connector, and a pressure-keeping chamber is formed by the sealing assembly; the scraping cutter is arranged on the outer side wall of the cutter barrel; one end of the scraping cutter is a fixed end connected with the outer side wall of the cutter barrel, and the other end of the scraping cutter is a free end; the hydraulic cylinder is arranged on the outer side wall of the cutter barrel and is communicated with the pressure-keeping chamber; the supporting reed is arranged on the outer side wall of the cutter barrel and is located between the scraper cutter and the hydraulic cylinder; one end of the supporting reed is connected with the hydraulic cylinder; the pressure of the pressure-keeping chamber is controlled, so that the hydraulic cylinder drives the supporting reed to be inserted between the scraper cutter and the cutter barrel by the free end; the supporting reed is used for expanding the scraper cutter to form a scraping outer diameter. The drifting and scraping integrated tool has drifting and scraping functions and can be used for strongly scraping an important scraping part.

Owner:PETROCHINA CO LTD

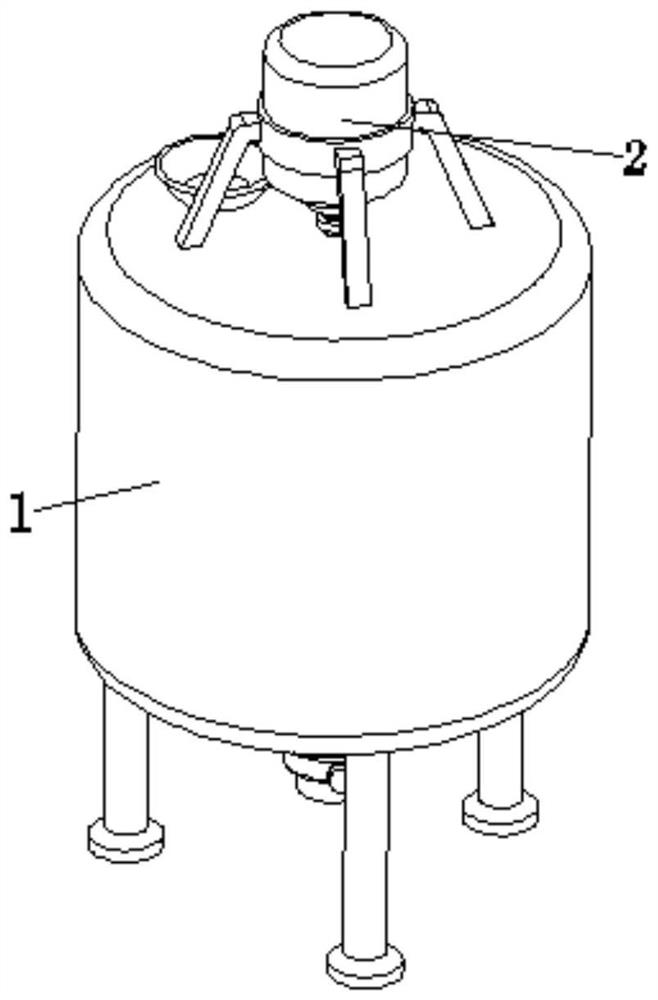

Raw material mixing device for 3D printing consumable processing

InactiveCN110960998AImprove mixing efficiencyReduce wasteRotary stirring mixersTransportation and packagingElectric machineryEngineering

The invention discloses a raw material mixing device for 3D printing consumable processing. The raw material mixing device comprises a mixing barrel, a barrel cover is arranged at the top of the mixing barrel; a stirring rod is welded on the outer side of a stainless steel pipe; air outlet holes are formed in the outer parts of the stirring rod and the stainless steel pipe; a rotary joint is mounted at the upper end of the stainless steel pipe; one side of the rotary joint is communicated with an air pipe, the end of the air pipe is communicated with an air booster pump, the outer portion of the stainless steel pipe is in key connection with a first belt wheel, the first belt wheel is in transmission connection with a second belt wheel through a triangular belt, and the second belt wheel is in key connection with an output shaft of a first motor; the first motor is used for driveing the stainless steel pipe to rotate, meanwhile, high-pressure gas is introduced into the stainless steelpipe and the stirring rod through the air booster pump, when the stainless steel pipe and the stirring rod are used for stirring, the high-pressure gas can roll over materials, and the mixing efficiency of the materials is improved.

Owner:安徽三绿实业有限公司

Mechanical yarn waxing device used for spinning machine and beneficial to rapid production

The invention discloses a mechanical yarn waxing device used for a spinning machine and beneficial to rapid production. The mechanical yarn waxing device used for the spinning machine and beneficial to rapid production comprises a main body, a textile yarn and a driving disc. A storage bin is fixedly welded to the right side of the main body. A supporting device is connected to the tail end of a winding shaft. A connecting rod is arranged on the front side of a driven disc. A shifting rod is mounted on the outer side of the driving disc. A wax box is arranged on the left side of a scraping device. A mounting groove is formed in the wax box. A fixing base is mounted at the top end of a spring. A fixing hole is formed in the outer side of the top of a wax rod. According to the mechanical yarn waxing device used for the spinning machine and beneficial to rapid production, yarns can be protected and can be kept in order; the yarns can be sufficiently soaked in liquid wax, so that the waxing uniformity is ensured; and the liquid wax can be kept sufficient all the time in use and can be kept in the liquid state, so that rapid waxing is facilitated, and the production efficiency is improved.

Owner:吴子侠

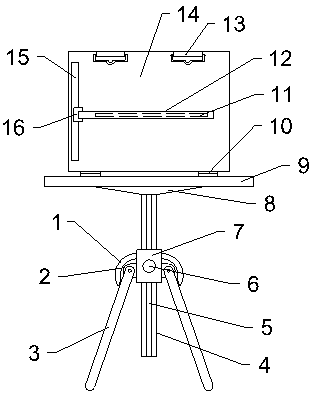

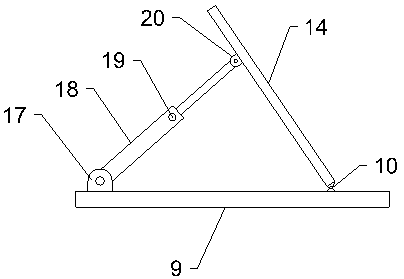

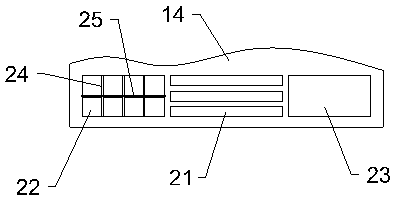

Stable and adjustable drawing board for art design

InactiveCN108567230AGuaranteed cleanlinessEasy to operateFurniture partsDrawing desksPigmentDrawing board

The invention discloses a stable and adjustable drawing board for art design. The stable and adjustable drawing board comprises a platen and a drawing board body, wherein a pigment groove, a pen groove and a tool groove are formed in the front side of the top of the platen, the rectangular drawing board body is hinged to the rear side of the top of the platen through a hinge, an elastic clamp is installed at the upper end of the drawing board body, a sliding rail mechanism is installed on the left side of the drawing board body, a scale plate is installed on a sliding block of the sliding railmechanism, a telescopic rod is arranged on the rear side of the drawing board body, a conical support is arranged at the bottom of the platen, the upper end of a supporting rod is fixed to the middleof the bottom of the conical support and is in sleeved connection with a sleeve, and multiple supporting legs are circumferentially arranged on the outer side of the sleeve. The stable and adjustabledrawing board is stable in supporting and convenient to adjust in height and drawing board inclination angle, facilitates placement of pigments, pens and tools, facilitates scraping of excessive pigments on the pens, can achieve size comparison through the scale plte and is convenient to use and operate.

Owner:SHIYAN DEYUAN TECH DEV

Sand screening device for building equipment

InactiveCN108435553APromote shakingAvoid affecting the efficiency of sand screeningSievingScreeningArchitectural engineeringDrive motor

The invention relates to the technical field of building equipment, and discloses a sand screening device for building equipment. The sand screening device comprises a bottom plate, wherein hydrauliclifting rods which are symmetrical with each other are uniformly distributed on the bottom of the bottom plate; the bottoms of the hydraulic lifting rods are fixedly equipped with circular table supporting discs; a gasket between the hydraulic lifting rods is uniformly distributed on the bottom of the bottom plate; universal wheels are fixedly mounted on the bottom of the gasket; four supporting plates which are symmetrical with each other fixedly sleeve the top of the bottom plate; the tops of the four supporting plates are fixedly connected through the bottom of a rack plate; and the back surfaces of the two supporting plates are fixedly connected with the front surfaces of the two supporting plates through the two sides of a fixed plate. According to the sand screening device for building equipment disclosed by the invention, a drive motor, a rotary rod and an extrusion wheel are matched for use, so that sand poured to the top of a sieve tray is conveniently vibrated to vibrate anddrop sand, and the problem that sand screening efficiency is affected as the sand is blocked on a screen and cannot drop is avoided.

Owner:徐佳东

Ceramic slurry for photocuring and preparation method thereof

InactiveCN110128116AHigh solid contentImprove reaction efficiencyAdditive manufacturing apparatusPentaerythritolMetallurgy

The invention discloses ceramic slurry for photocuring and a preparation method thereof. By controlling the contents of the main ceramic slurry, a dispersing agent, a monomer and a photoinitiator, thehigh-solid-content ceramic slurry for photocuring is prepared; wherein the dispersing agent can enable the solid to be better dispersed in the liquid, so that the dispersion of the main ceramic slurry in the monomer is more uniform; the monomer is selected from a mixture of free radical type photosensitive resin and cationic type photosensitive resin with different functions and reaction efficiencies; wherein hexahydro-o-phthalic acid diglycidyl ether can make the finally prepared ceramic slurry for light curing not liable to deform, the 1,6-hexanediol diacrylate can make the viscosity of a monomer to be suitable for uniform dispersion of ceramic powder in the monomer and improves the solid phase content of the slurry; and dipentaerythritol hexaacrylate can improve the reaction efficiency; by selecting each substance in the monomer, the prepared ceramic slurry has high solid-phase content, high reaction efficiency and high printing precision.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Electric multifunctional building overlay decorating machine

The invention discloses an electric multifunctional architecture cover finishing device to brush wall, which is characterized by the following: the spiral conveying rod of mortar pump connects between motor and connection seat which does synchronous rotary with the spiral conveying rod; the spiral conveying rod is put in the mortar pump case with charging opening and discharging opening; the mortar pump case discharging opening can connect the connection seat or sprayer disassembly; the connection seat can set different working head to supply coating material. The device can be used in plaster, putty and lacquer brushing operation.

Owner:徐光

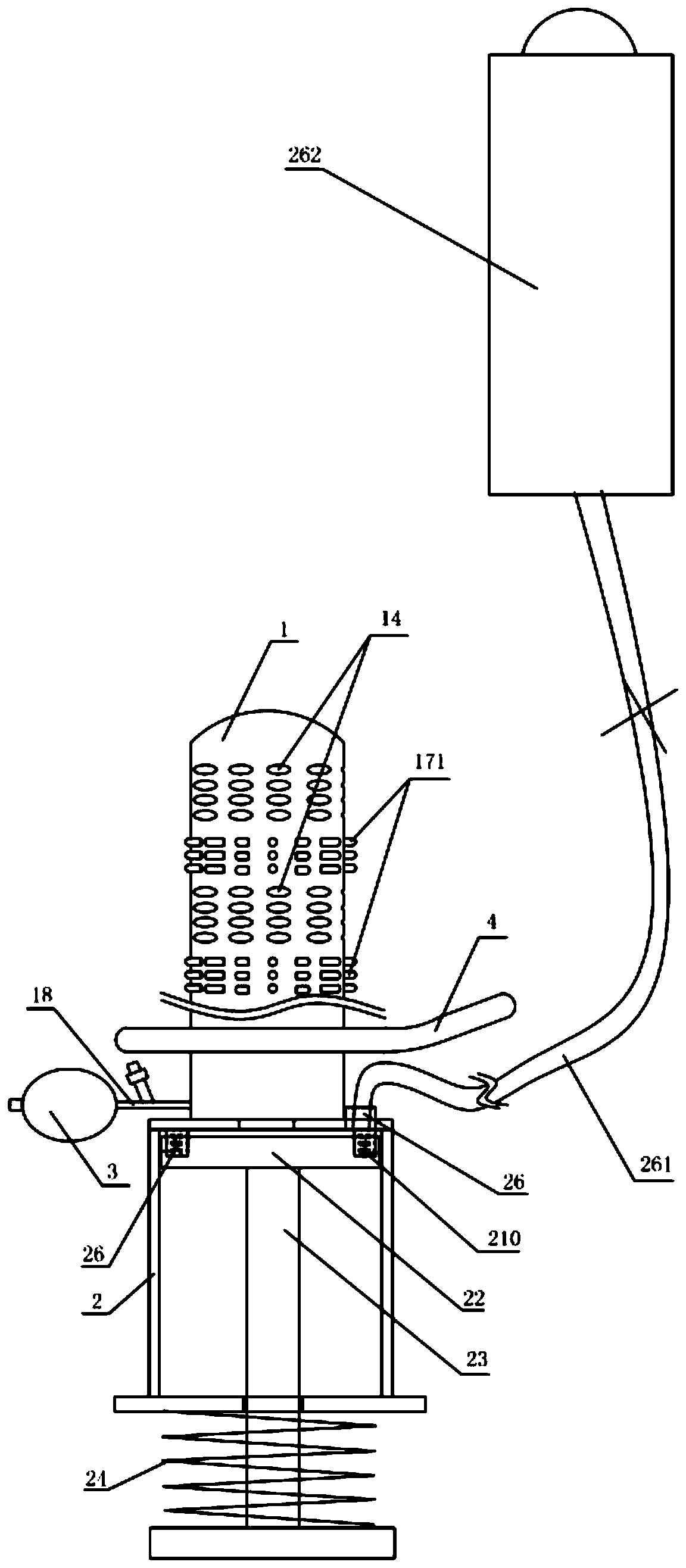

Device for flushing anorectum

InactiveCN109999252AEasy to adjust the sizeNovel and effective structureCannulasEnemata/irrigatorsRelief valveEngineering

The invention belongs to the technical field of medical instruments, and particularly relates to a device for flushing the anorectum. A push rod can be rotated to control a limiting block and then control a vertical rod to rotate, the vertical rod rotates to control an arc-shaped piece to shield a liquid outlet to different degrees to form different spraying conditions, the size of the liquid outlet is convenient to adjust, different spraying effects can be achieved without replacing nozzles, the structure is novel and effective, the operation is easy and convenient, meanwhile, a rubber rod can be controlled to stretch out and shrink through an inflating airbag and a pressure relief valve, dirt in the anorectum can be scraped away when the rubber rod stretches out, flow of flushing liquidcannot be affected, and in the plugging and unplugging process, the discomfort of a patient is reduced when the rubber rod shrinks.

Owner:青岛市黄岛区中心医院

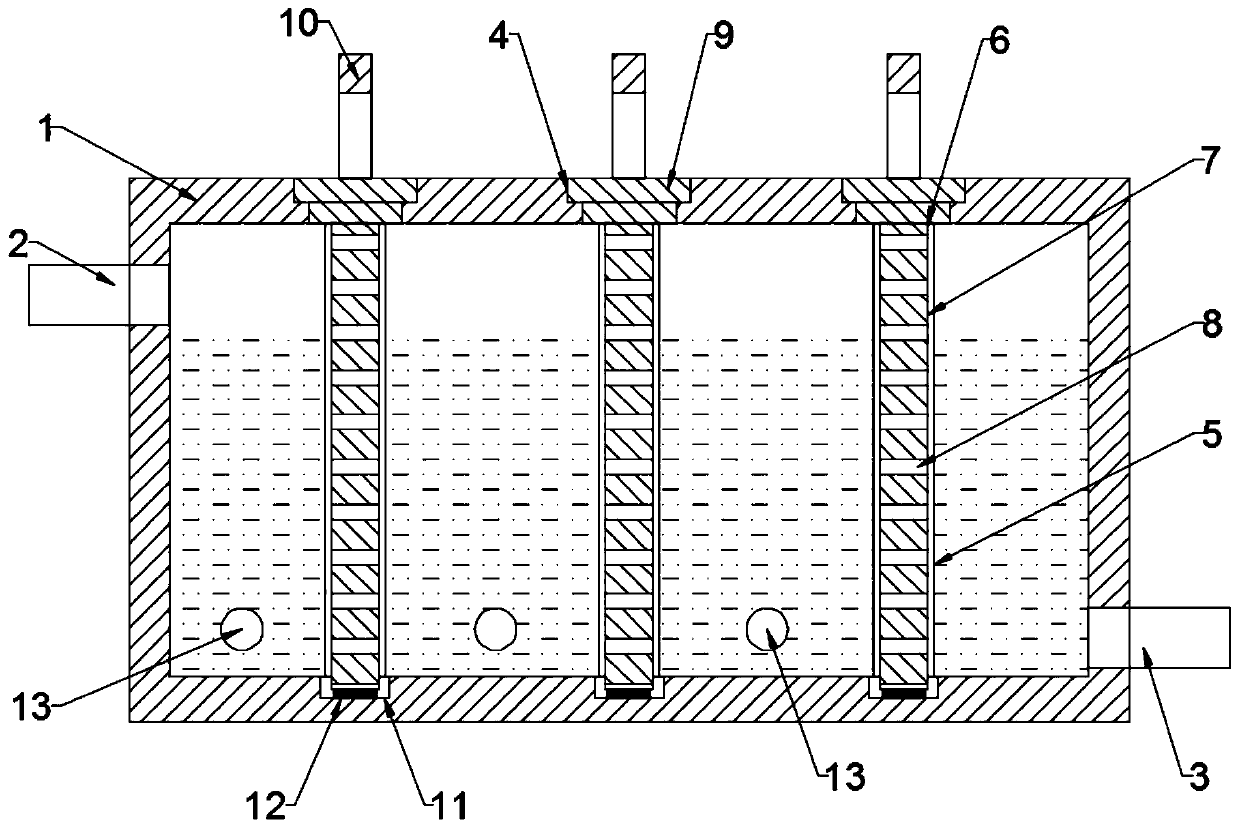

Environment-friendly sewage treatment device

PendingCN111054108AEasy to assemble and replaceEasy to operateTreatment involving filtrationStationary filtering element filtersSewage treatmentSewage

The invention discloses an environment-friendly sewage treatment device, which belong to the technical field of sewage treatment, the problems that when sewage treatment is carried out, impurity filtration cannot be carried out step-by-step , clogging is easily generated, a grating plate is not easy to replace and impurities are not easy to clean are solved. Technical key points are that: the device is characterized by comprising a sewage treatment tank and a filter grating plate, the upper side of one end of the sewage treatment tank is connected with a water inlet pipe; a water outlet pipe is connected below one end of the sewage treatment tank; a filtering grating plate is mounted in the sewage treatment box; the filter grating plates are provided with filter holes, the filter grating plates divide the interior of the sewage treatment box into a plurality of filter cavities, the filter cavities are internally provided with sludge discharge assemblies, and by arranging the drawing type filter grating plates, sewage can be conveniently filtered step by step, the filter grating plates can be conveniently assembled and replaced, and the operation is convenient and fast; impurities and sludge can be conveniently pumped out through a blow-off pipe, impurities attached to the surface of the filtering grating plate can be conveniently scraped away, and filtering holes are preventedfrom being blocked.

Owner:吴晓敏

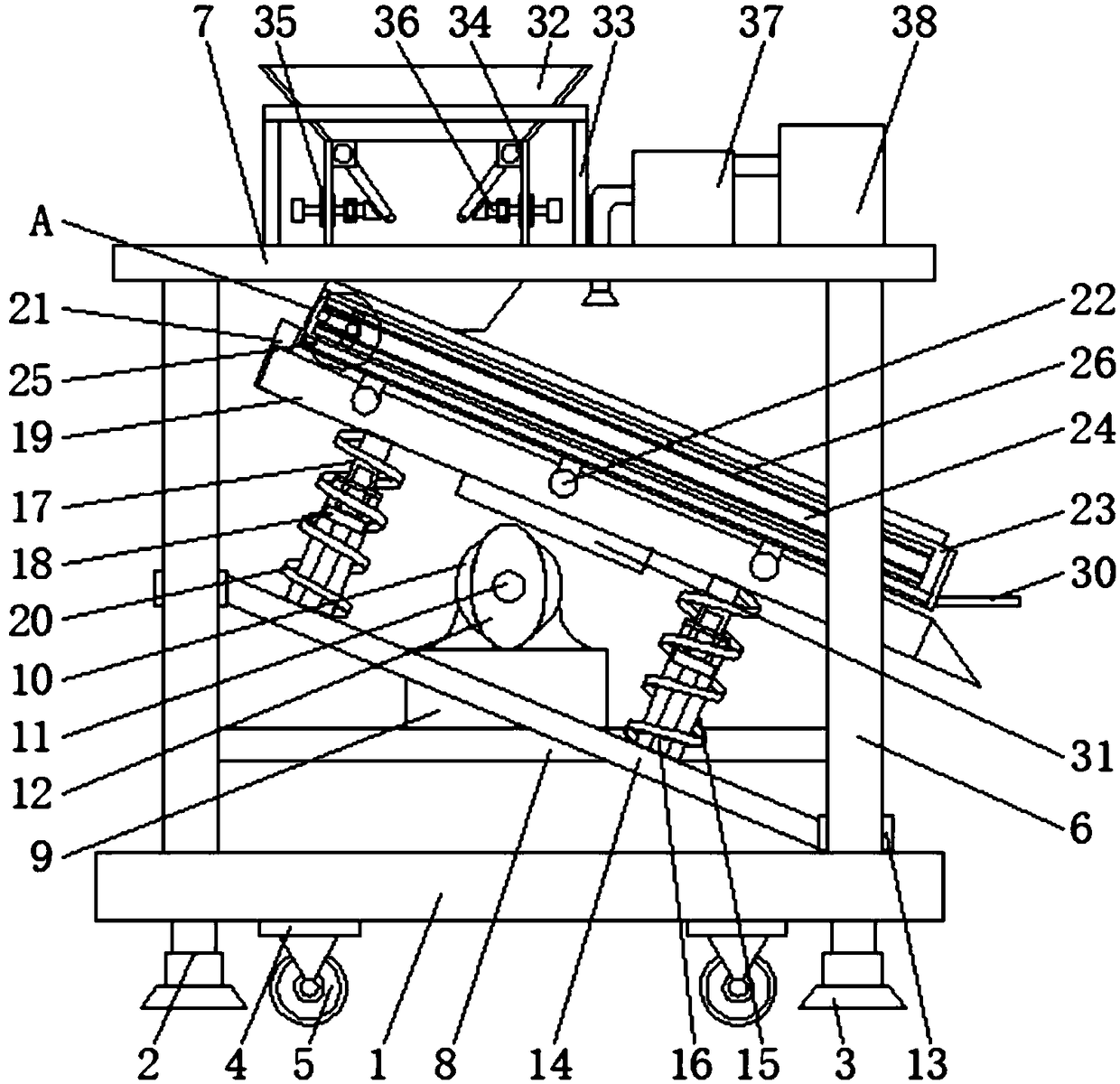

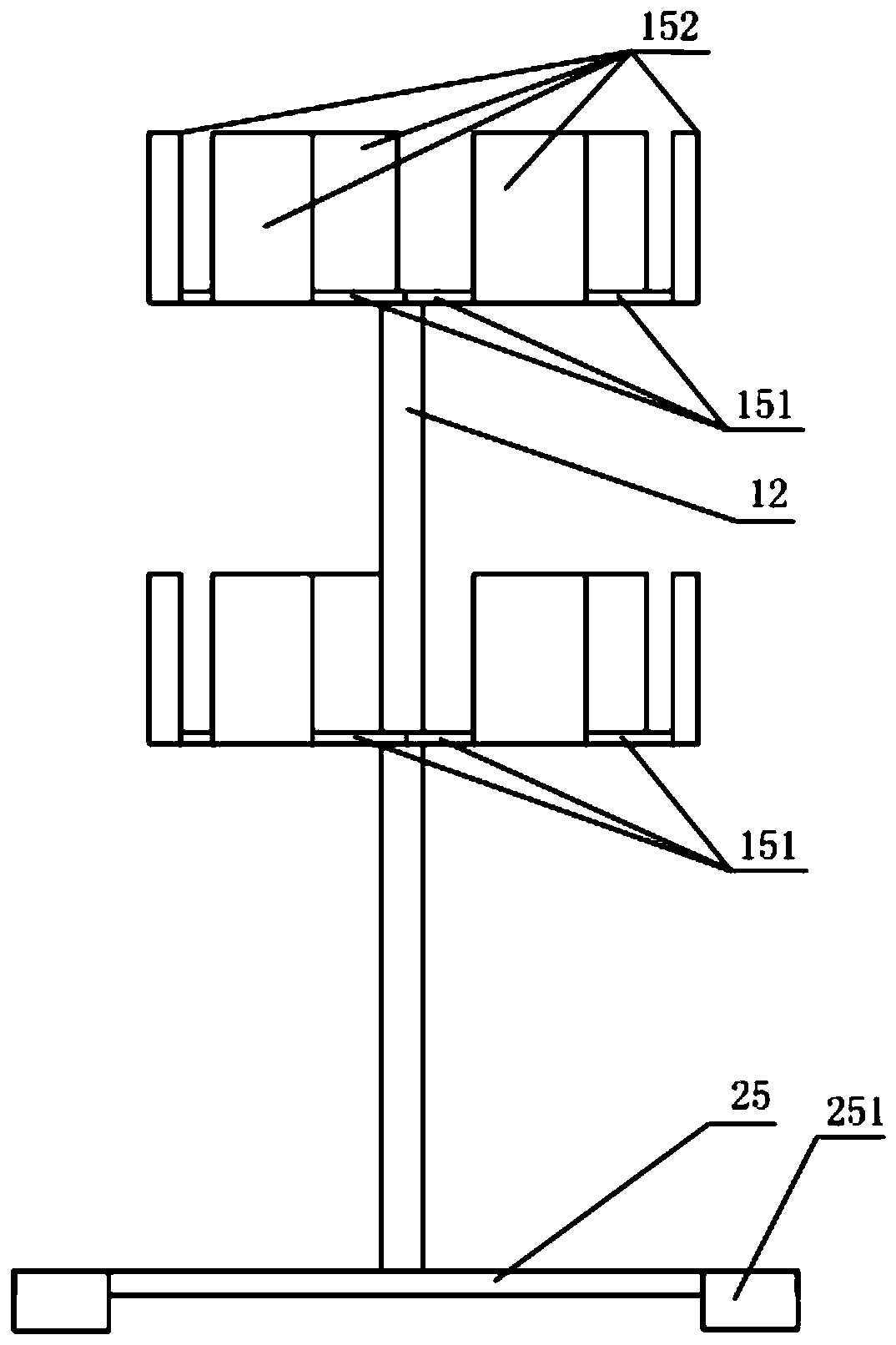

Multi-function mineral resource comprehensive utilization equipment

ActiveCN108554628AHeight adjustableMagnetic selection works smoothlyWithdrawing sample devicesCleaningMineral SourcesEngineering

The invention discloses multi-function mineral resource comprehensive utilization equipment. The multi-function mineral resource comprehensive utilization equipment comprises a first stage bracket, ahorizontal column, a second stage bracket, a strong magnetic separation iron elevator, a sliding tube, an adjusting bolt, a first stage switch, a second stage switch, a third stage switch, an ore-transmitting conveyor, an ore-transmitting hopper, a impunity-removing filter hopper structure, a scraper structure, a sliding block, a sliding groove, a bottom block, a fastening bolt, a ore hauling conveyor and a sampling rod structure. The first stage bracket is longitudinally installed on the lower left portion of the horizontal column in a bolted mode. The second stage bracket is longitudinally installed on the lower right portion of the horizontal column in a bolted mode. The arrangement of a connecting rope with a hook, a winding wheel, a winding motor, a cable and a strong magnetic separation iron plate is conducive to adjusting the height of the strong magnetic separation iron plate according to the magnetic separation demand, so as to facilitate the smooth magnetic separation work; the strong magnetic separation iron plate is made of a round stainless steel plate; and a strong magnetic sheet adopts circular permanent magnet sheet and is conducive to the rapid absorption of iron impurities in the mineral resources, so as to guarantee the purity of the mineral resources.

Owner:滦平县聚源矿业有限责任公司

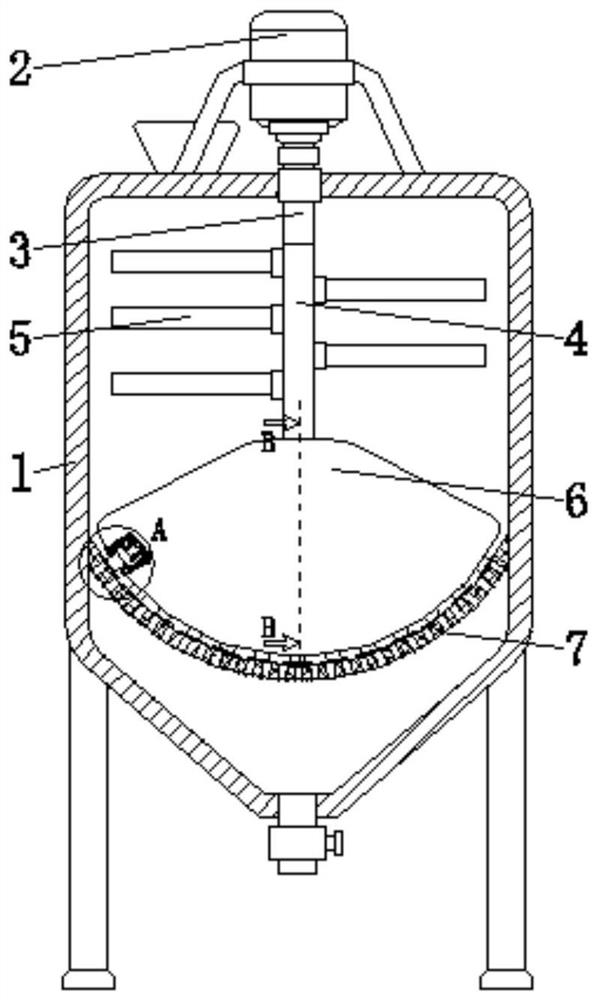

Stirring machine used for rubber production

InactiveCN108031345AEasy to scrapeReduce wasteRotary stirring mixersTransportation and packagingSlurryEngineering

The invention discloses a stirring machine used for rubber production, which includes a pedestal. Sliding rods are fixedly connected to two sides of the top of the pedestal. A fixing plate is fixedlyconnected between the top ends of the two sliding rods. An air cylinder is fixedly connected to the top of the fixing plate. The output end of the air cylinder penetrates through the fixing plate andis extended to the bottom of the fixing plate. The invention relates to the technical field of rubber slurry stirring machine. By means of the stirring machine, rubber raw materials, which are attached to the inner wall of a stirring box, can be scratched away well, so that proportioning accuracy during rubber stirring process is increased and waste on the rubber raw materials is reduced. The stirring machine is convenient to use, is safe and reliable, has excellent scratching function and is improved in stirring effect, can reduce labor intensity, is convenient and quick to use, has excellentfixing function, and is good in convenience.

Owner:ZHONGSHAN RNICE COMML ELECTRIC CO LTD

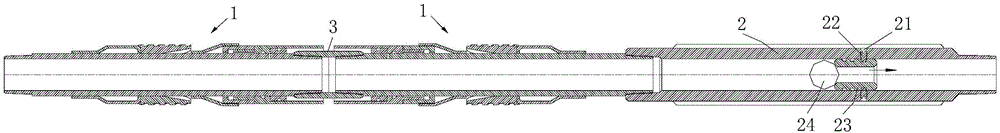

Pipe wall rust removal device applied to water conservancy project conveying pipeline repair

ActiveCN112497011AEasy to operateImprove rust removal efficiencyGrinding wheel securing apparatusGrinding drivesStructural engineeringThreaded rod

The invention discloses a pipe wall rust removal device applied to water conservancy project conveying pipeline repair. The device comprises an inner treater, an outer treater, a threaded rod, a grinding seat, a first magnet and a second magnet, wherein the outer side of the inner treater is provided with the outer treater, and the first magnet is embedded into the outer wall of the inner treater;the second magnet is embedded into the inner wall of the outer treater, a liquid storage bin is arranged on the outer side of the outer treater, a spray head is arranged on the outer side of the right end of the outer treater, a liquid suction barrel is arranged in the outer treater, liquid conveying pipes are connected between the liquid suction barrel and the liquid storage bin and between theliquid suction barrel and the spray head, and a piston is arranged on the inner side of the liquid suction barrel; and a push rod is fixed to the left side of the piston through a bolt. The pipe wallrust removal device applied to water conservancy project conveying pipeline repair adopts an internal and external split structure, can synchronously carry out rust removal and repair on the inner wall and the outer wall of a pipeline, and is convenient to operate, high in rust removal efficiency and good in effect.

Owner:CHENGDE JINLONG CONVEYOR MACHINERY

Speed-adjustable self-cleaning conveyor

Owner:HUZHOU QIANJIN BAOYUN MACHINERY CASTING

Novel efficient paint mist flocculant and preparation method thereof

InactiveCN103848489AAchieve separationEnhanced tack-free effectWater/sewage treatment by flocculation/precipitationWastewaterMelamine

The invention relates to a chemical agent for removing excessively sprayed oil paint waste water and a preparation method of the chemical agent, a novel efficient paint mist flocculant is characterized by comprising an adhesive-eliminating agent A and a flocculant B in volume ratio of 0.5: (0.5-1), the adhesive-eliminating agent A is polysilicic acid modified tripolycyanamide prepared from tripolycyanamide, alkali metal silicate, aldehydes and an auxiliary C, the flocculant B is a polymer formed by non-ionic monomers through polymerization. The paint mist flocculant prepared by the method is low in free formaldehyde content, low in cost and high in paint mist removing rate.

Owner:WUHAN UNIV OF TECH

Garbage incinerator tube wall cleaning device

InactiveCN109724091AImprove fitEasy to scrapeIncinerator apparatusSolid removalArchitectural engineeringDrive motor

The invention provides a garbage incinerator tube wall cleaning device. The garbage incinerator tube wall cleaning device comprises a furnace tube and a top plate. The top of the furnace tube is movably connected with the top plate, a lead screw motor penetrates through the middle part of the top plate, the inside of the lead screw motor is movably connected with a lead screw, the lower end of thelead screw is fixedly connected with a connecting end piece through bolts, the lower part of the connecting end piece is fixedly connected with a driving motor through bolts, the lower part and the outer side of the driving motor are fixedly connected with driving teeth and a bearing frame separately, and rollers are embedded on the upper part of the bearing frame. According to the garbage incinerator tube wall cleaning device, the surface of the outer edge of a mud scraping plate is in an arc shape, and an opening of a dirt storage cavity is in a lower lower-part and upper high-part shape; as the surface of the outer edge of the mud scraping plate is in an arc shape, the adhesion degree between the outer edge of the mud scraping plate and the inner wall of the furnace tube is higher, sothat the ash on the inner wall of the furnace tube is more convenient to scrape; and meanwhile, the dirt storage cavity with the opening in a lower lower-part and upper high-part shape is more suitable for collecting dust falling by gravity.

Owner:黄景波

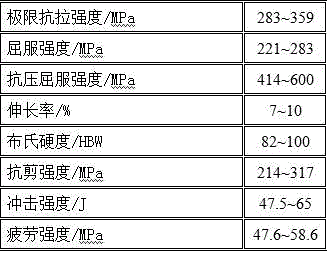

Efficient zinc alloy block production method

ActiveCN106735133ARapid productionImprove qualityCasting plantsCasting cleaning apparatusZinc alloysAir cooling

The invention relates to an efficient zinc alloy block production method which comprises the following steps: 1) smelting a zinc alloy solution through a smelting furnace; 2) scooping up the zinc alloy solution from the smelting furnace, and casting the zinc alloy solution into a forming die arranged on a circulation conveying system; 3) scraping an oxide layer on the surface of the zinc alloy solution in the forming die; 4) carrying out forced cooling on the zinc alloy solution in the forming die to enable the zinc alloy solution to be solidified to form a zinc alloy block; and 5) sending out the formed zinc alloy block through a conveying mechanism. The efficient zinc alloy block production method is convenient to produce the zinc alloy block.

Owner:福建龙翌合金有限公司

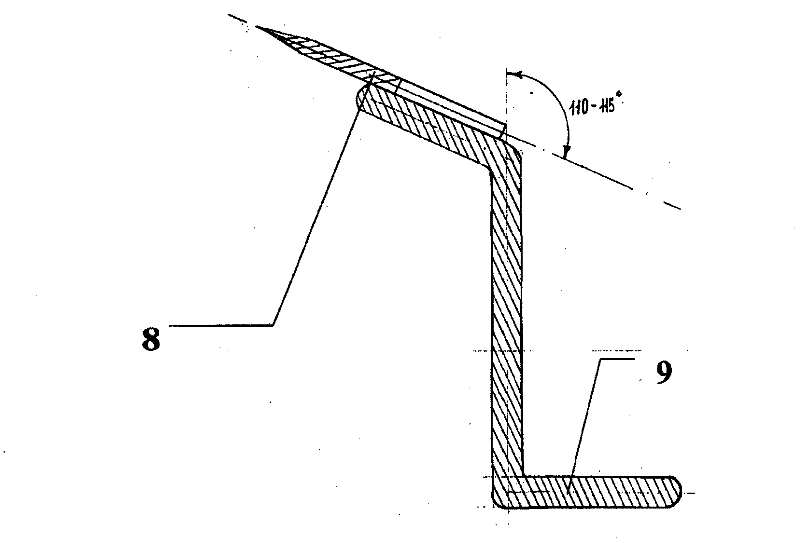

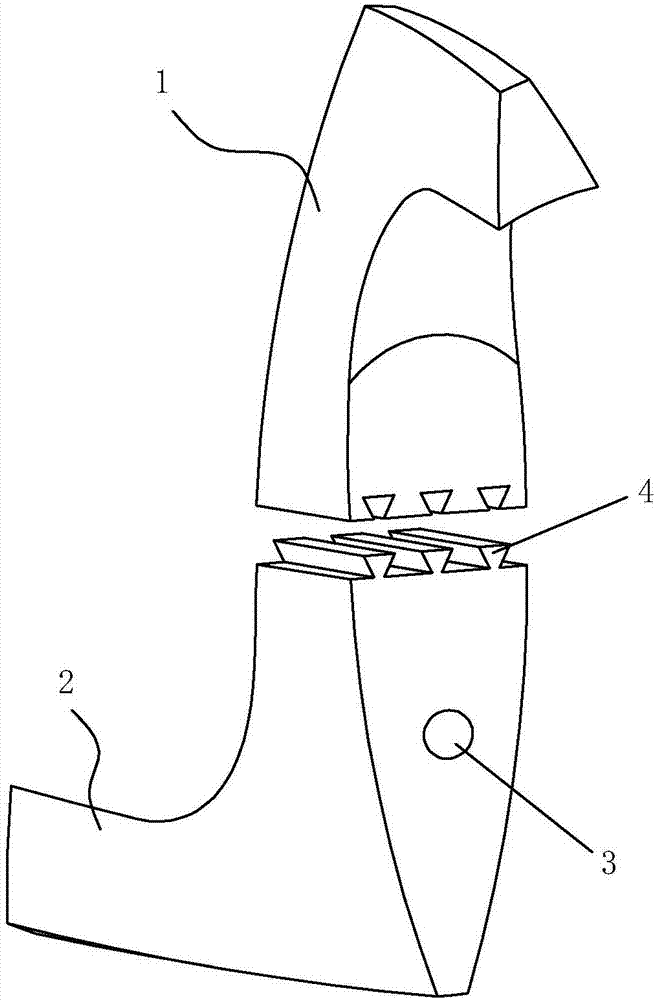

Blade unit for a safety razor

A blade unit for a safety razor comprises a plurality of elongated blades (4) with a continuously curved cutting edge (8). The shape of the cutting edge (8) is defined according to the formula Rcur=k*L, where Rcur is the bending radius of the blade; k is a coefficient of proportionality ranging from 1 to 5; and L is the chord length of a curve with a radius of Rusr. The blades (4) have a third support point. This provides for easy and effective shaving.

Owner:亚历山大·塔拉索维奇·沃罗丁

Casting die based on 3D printing and preparation method thereof

ActiveCN107096882AImproves strength and hardnessReduce weightAdditive manufacturing apparatusFoundry moulding apparatusFiber layerCOMPONENT II

The invention provides a casting die based on 3D printing. The casting die based on 3D printing comprises a component I and a component II obtained through 3D printing. A cavity of the component I and a cavity of the component II are each filled with a resin fiber layer, a fiber layer and a foaming layer from outside to inside in sequence. A preparation method of the casting die comprises the steps of (1) modeling: segmenting a model into a plurality of components connected through dovetail grooves; (2) using a 3D printer to conduct printing to obtain a plurality of components of a hollow structure; (3) machining a filling port in the plane of each component; (4) filling up a cavity of each component with a mixture of slow dry resin and reinforce fiber; (5) adding glass fiber into the cavity of each component; (6) injecting a foam material into the cavity of each component; (7) connecting the components through the dovetail grooves; and (8) filling up gaps of the dovetail grooves with A / B glue, conducting coating of epoxy resin and then conducting grinding and polishing. The casting die based on 3D printing and the preparation method thereof have the advantages that the precision is high, the preparation cycle is short, the weight is low, the die strength is high, and the production cost is low.

Owner:柳州智云科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com