Efficient zinc alloy block production method

A production method, zinc alloy technology, applied in metal processing equipment, equipment for feeding molten metal into molds, mechanical cleaning, etc., can solve problems affecting the quality of zinc alloy warehouses, low production efficiency, floating zinc alloy blocks, etc. , to achieve the effect of high work efficiency, quality improvement and rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of efficient production method of zinc alloy block, comprises the following steps:

[0032] 1) Melting the zinc alloy solution through a melting furnace;

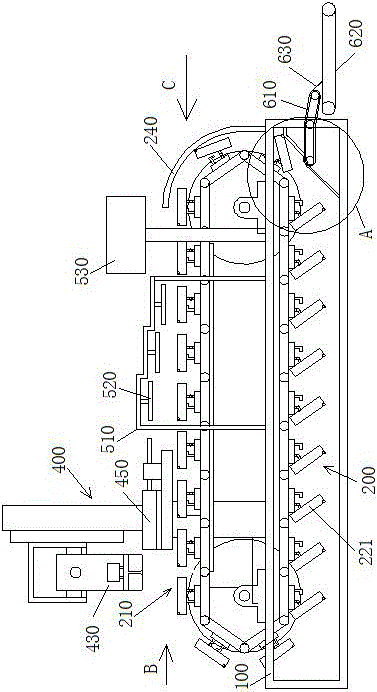

[0033] 2) Scoop the zinc alloy solution from the melting furnace, and pour the zinc alloy solution into the forming mold set on the circulation conveying system;

[0034] 3) scrape off the oxide layer on the surface of the zinc alloy solution in the forming mold;

[0035] 4) Forced air cooling of the zinc alloy solution in the forming mold to solidify the zinc alloy solution into a zinc alloy block;

[0036] 5) Send out the formed zinc alloy block through the conveying mechanism.

[0037] In the present embodiment, in the step 1, the mass fraction ratio of 3:3:4 zinc ingots, intermediate alloy aluminum ingots and intermediate alloy copper ingots is added to the dissolution furnace during the first blanking, and heated for 125min to dissolve Heat the furnace to 570°C to complete the melting of zinc ingots, a...

Embodiment 2

[0042] A kind of efficient production method of zinc alloy block, comprises the following steps:

[0043] 1) Melting the zinc alloy solution through a melting furnace;

[0044] 2) Scoop the zinc alloy solution from the melting furnace, and pour the zinc alloy solution into the forming mold set on the circulation conveying system;

[0045]3) scrape off the oxide layer on the surface of the zinc alloy solution in the forming mold;

[0046] 4) Forced air cooling of the zinc alloy solution in the forming mold to solidify the zinc alloy solution into a zinc alloy block;

[0047] 5) The formed zinc alloy blocks are sent out through the conveying mechanism for subsequent palletizing.

[0048] In the present embodiment, in the step 1, the mass fraction ratio of 3:3:4 zinc ingots, intermediate alloy aluminum ingots and intermediate alloy copper ingots is added to the dissolution furnace during the first blanking, and heated for 126min to dissolve Heat the furnace to 580°C to complet...

Embodiment 3

[0053] A kind of efficient production method of zinc alloy block, comprises the following steps:

[0054] 1) Melting the zinc alloy solution through a melting furnace;

[0055] 2) Scoop the zinc alloy solution from the melting furnace, and pour the zinc alloy solution into the forming mold set on the circulation conveying system;

[0056] 3) scrape off the oxide layer on the surface of the zinc alloy solution in the forming mold;

[0057] 4) Forced air cooling of the zinc alloy solution in the forming mold to solidify the zinc alloy solution into a zinc alloy block;

[0058] 5) Send out the formed zinc alloy block through the conveying mechanism.

[0059] In the present embodiment, in the step 1, the mass fraction ratio of 3:3:4 zinc ingots, intermediate alloy aluminum ingots and intermediate alloy copper ingots is added to the dissolution furnace during the first blanking, and heated for 127min to dissolve Heat the furnace to 590°C to complete the melting of zinc ingots, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com