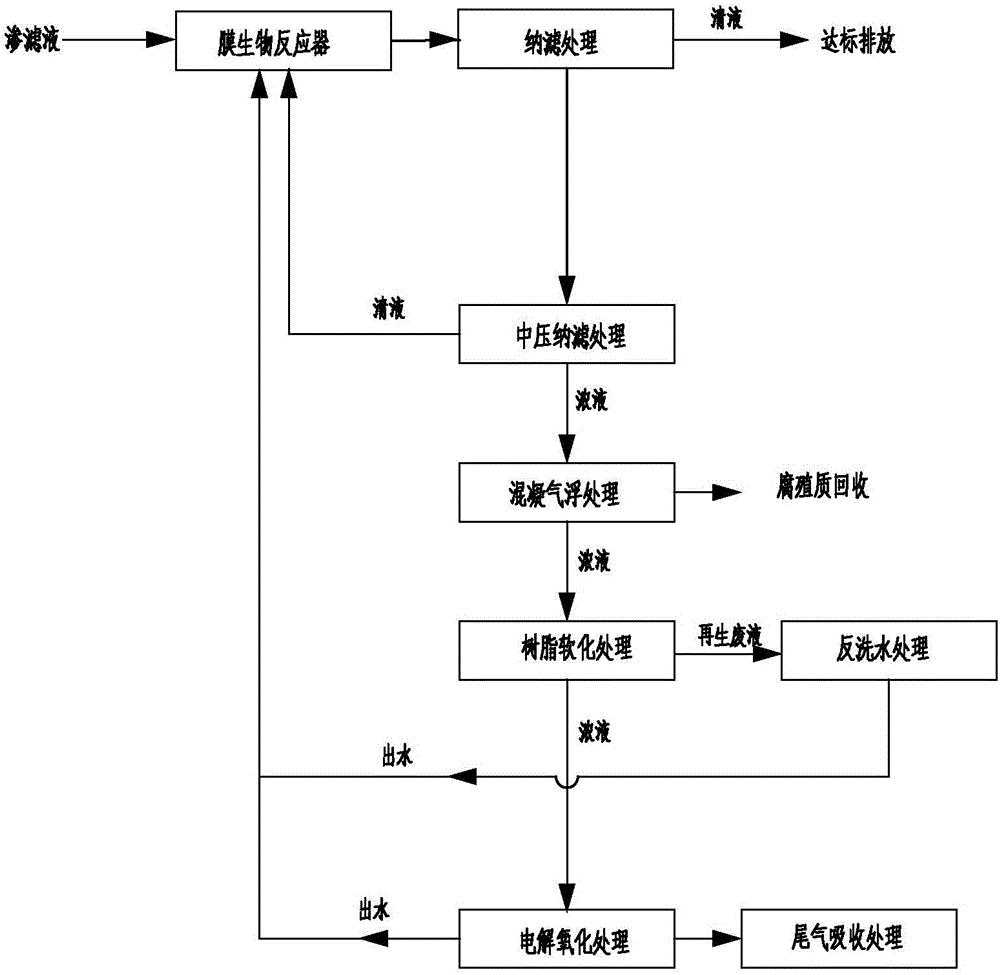

Treatment method for nanofiltration concentrated liquor of landfill leachate

A technology for landfill leachate and a treatment method, which is applied in the field of landfill leachate nanofiltration concentrate treatment, can solve the problems of membrane pollution, non-removal, membrane tube pressure rise, etc., so as to reduce the degree of membrane pollution, reduce the treatment cost, and increase the flow rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A landfill leachate treatment plant has a treatment capacity of 500m 3 / d, using MBR+NF method to treat landfill leachate, producing 100m 3 / d nanofiltration concentrated liquid, for the detection of nanofiltration concentrated liquid, its COD is 3000mg / L, the ratio of BOD / COD is 0.03, the chloride ion is 6000mg / L, the total hardness is 7000mg / L, the ammonia nitrogen is 10mg / L, and the total nitrogen is 300mg / L.

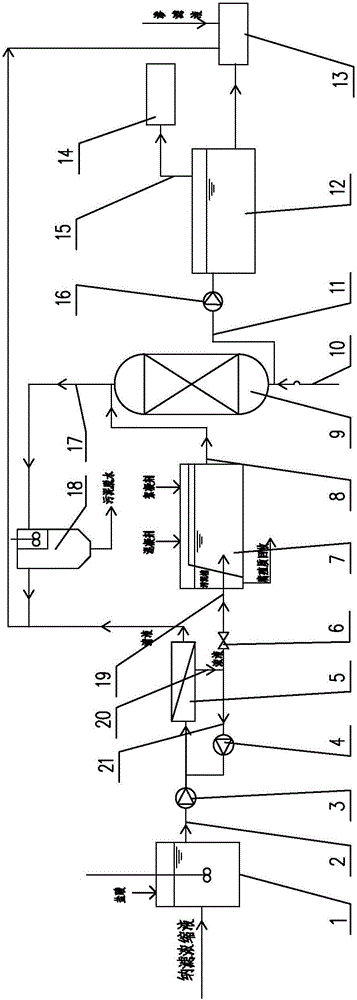

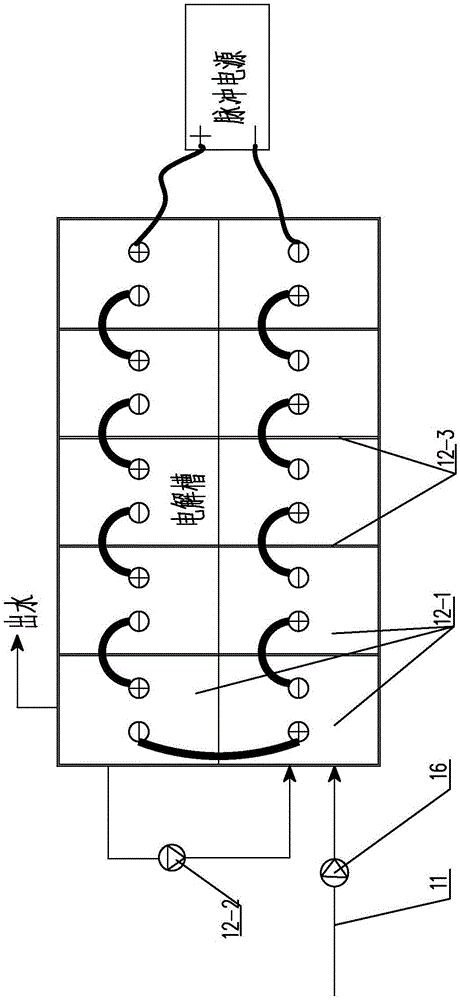

[0046] Treat by the landfill leachate nanofiltration concentrated solution treatment method of the present invention, the nanofiltration concentrated solution is sent into the medium-pressure nanofiltration membrane element 5 through the high-pressure pump 3, and carries out the medium-pressure nanofiltration treatment, and the medium-pressure nanofiltration membrane element 5 The operating pressure is 15bar, the water production rate is 50%, and the circulation pump 4 flow rate is 16m 3 / h, the medium-pressure nanofiltration membrane element 5 is a three-s...

Embodiment 2

[0055] Treat by the landfill leachate nanofiltration concentrated solution treatment method of the present invention, the nanofiltration concentrated solution is sent into the medium-pressure nanofiltration membrane element 5 through the high-pressure pump 3, and carries out the medium-pressure nanofiltration treatment, and the medium-pressure nanofiltration membrane element 5 The operating pressure is 20bar, the water production rate is 55%, and the circulation pump 4 flow rate is 20m 3 / h, the medium-pressure nanofiltration membrane element 5 has a two-stage structure in the concentrated water, adjusts the pH value of the nanofiltration concentrated solution at 6-6.5, and uses an 8-inch roll-type nanofiltration membrane to circulate the 18wt% concentrated solution after treatment. The rest is sent to the coagulation air flotation tank 7, and the membrane scale inhibitor is continuously added. The dosage of the membrane scale inhibitor is 0.8L / h, and the medium pressure nanofi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com