X70MS ERW welded pipe having excellent anti SSCC stress corrosion and manufacturing method thereof

A technology of stress corrosion and manufacturing methods, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve problems such as SSCC and corrosion, and achieve the effects of reducing residual stress, ensuring continuity, and reducing welding power parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

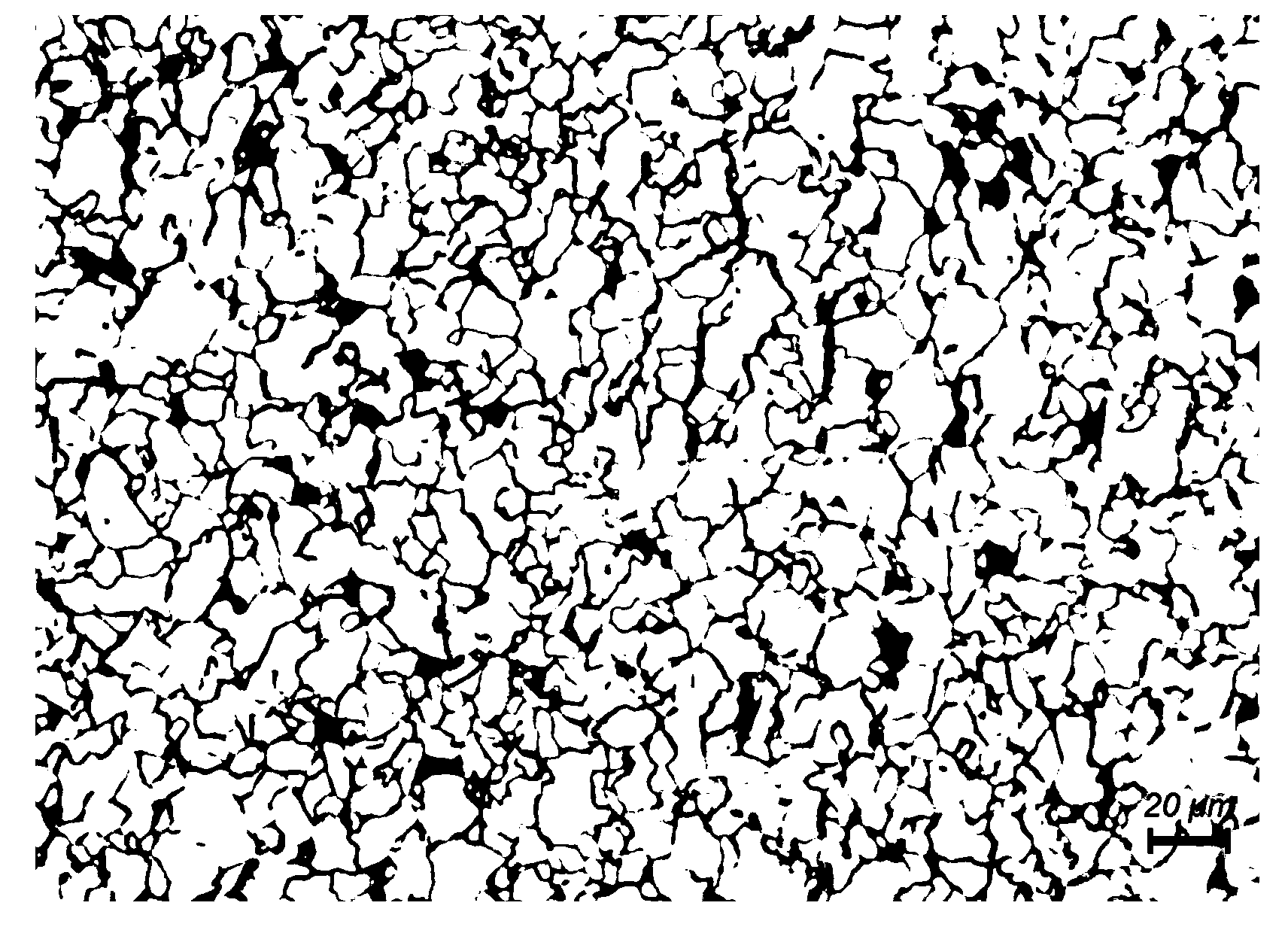

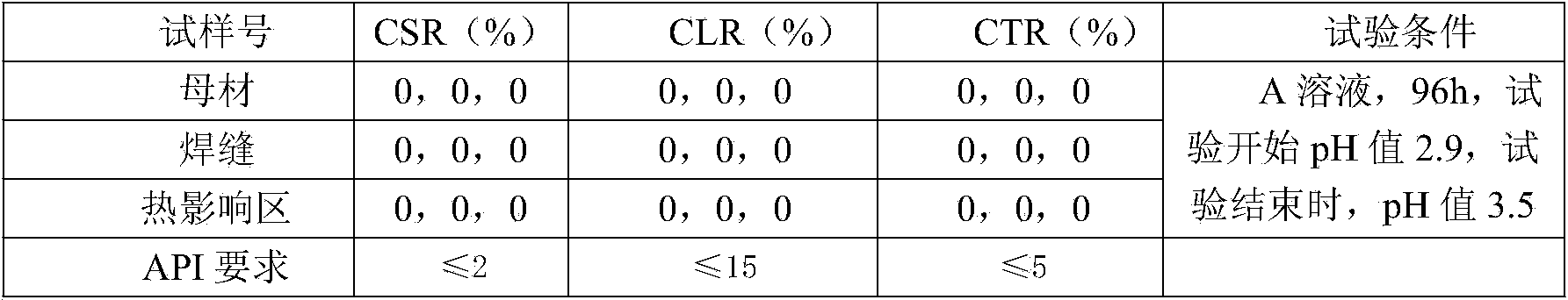

[0024] Example 1: Φ406.4×8mm X70MS steel grade ERW welded pipe resistant to SSCC stress corrosion and its manufacture

[0025] 1) Raw material: X70MS steel plate with a wall thickness of 8mm is used, and its chemical composition is analyzed as follows (wt%):

[0026] Table 1X70MS chemical composition analysis (wt%)

[0027] C Mn Si P S Al Ti V Nb Cu+Ni+Cr 0.03 112 0.18 0.009 0.0007 0.0039 0.014 0.05 0.049 0.32

[0028] 2) Production: X70MS hot-rolled coils are used to produce ERW welded steel pipes with an outer diameter of 406.4mm and a wall thickness of 8mm. After uncoiling, leveling and edge milling, the strip width is precisely controlled to be between 1283 and 1285mm. Adjust welding current and voltage process parameters. Adjust and control the extrusion amount of the welding seam to 4.5mm, so that the material can produce a welding seam metal flow rising angle of 65° to 80°. Control the opening angle, the welding speed is 22m / m...

Embodiment 2

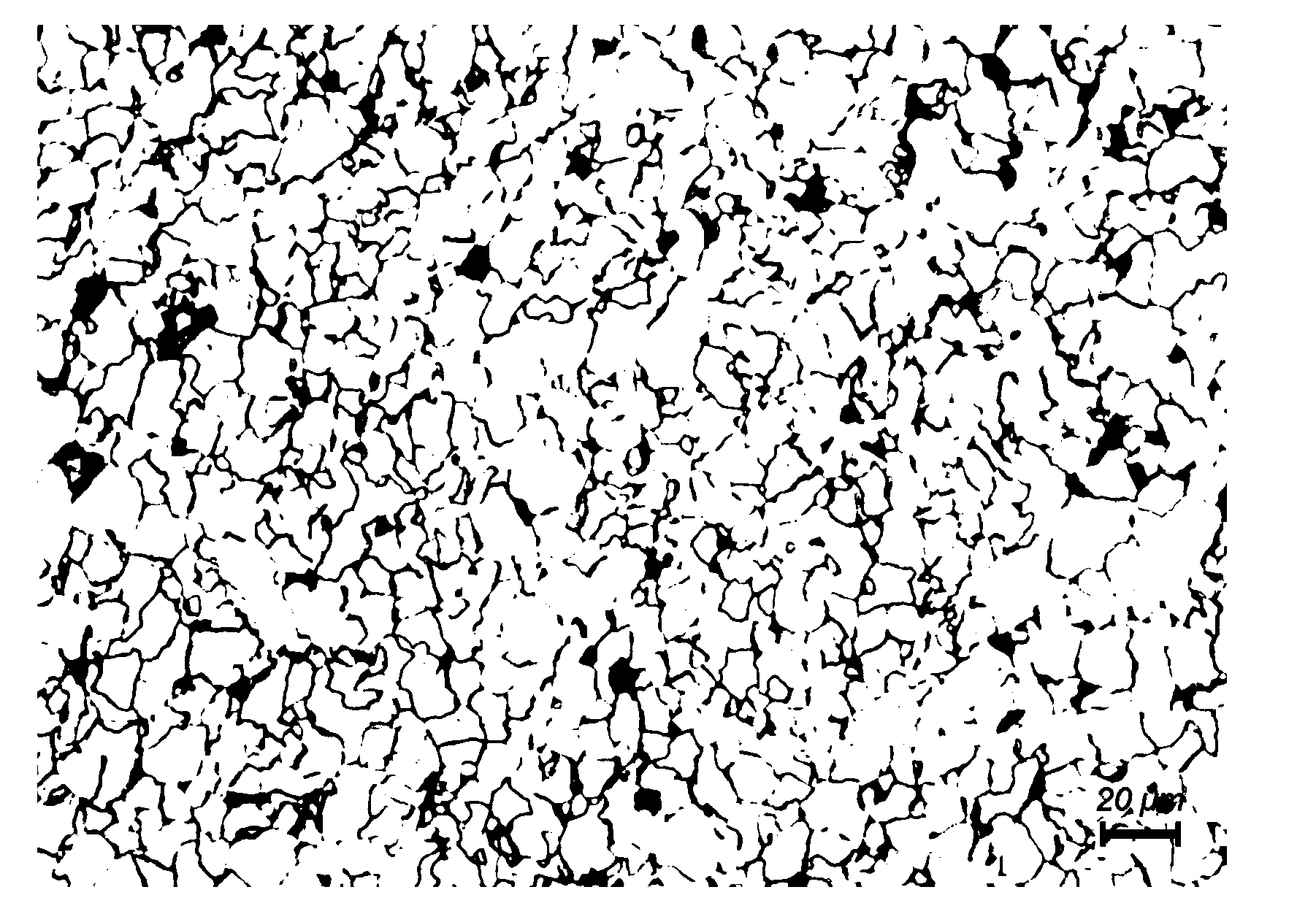

[0037] Example 2: Φ219.1×12.7mm X70MS steel grade ERW welded pipe resistant to SSCC stress corrosion and its manufacture

[0038] 1) Raw material: X70MS steel plate with a wall thickness of 12.7mm is used, and its chemical composition is analyzed as follows (wt%):

[0039] Table 4X70MS chemical composition analysis (wt%)

[0040] C Mn Si P S Al Mo Ti V Nb Cu+Ni+Cr 0.04 112 0.19 0.004 0.0007 0.0036 0.09 0.015 0.02 0.42 0.45

[0041] 2) Production: X70MS hot-rolled coils are used to produce ERW welded steel pipes with an outer diameter of Φ219.1mm and a wall thickness of 12.7mm. After uncoiling, leveling and edge milling, the width of the strip is precisely controlled at 686-687mm, and the edge of the strip is milled, and the edge of the strip is controlled by roll forming. Adjust welding current and voltage process parameters. Adjust and control the extrusion amount of the welding seam to 6mm, so that the material can produce a weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com