Garbage incinerator tube wall cleaning device

A technology for waste incinerators and cleaning devices, which is applied to incinerators, treatment of combustion products, combustion methods, etc., can solve the problems of inconvenient use, single function, inconvenient use, etc., achieve convenient portability and storage, and improve the scope of work , high degree of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

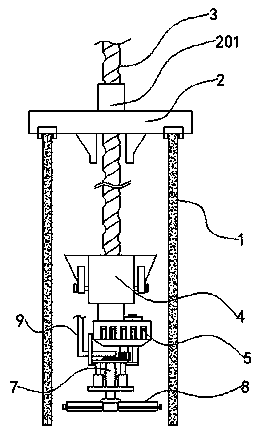

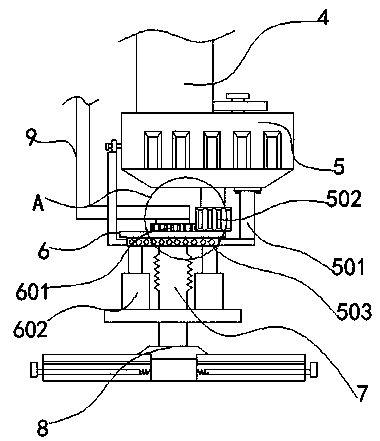

[0035] as attached figure 1 to attach Figure 6 Shown:

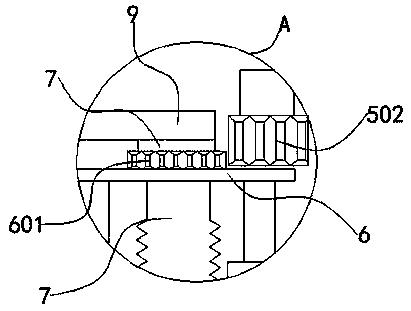

[0036] The invention provides a tube wall cleaning device for a garbage incinerator. The tube wall cleaning device for a garbage incinerator includes a furnace tube 1 and a top plate 2; The screw motor 201 is internally connected with a lead screw 3, the lower end of the lead screw 3 is fixedly connected with a connecting end piece 4, the bottom of the connecting end piece 4 is fixedly connected with a drive motor 5, and the bottom and outside of the drive motor 5 are respectively fixedly connected with Drive teeth 502 and a transfer frame 501, and a roller 503 is embedded above the transfer frame 501;

[0037] The upper part of the roller 503 is rotatably connected with the connection plate 6, the middle part of the connection plate 6 is welded with a passive tooth 601, and the lower part of the passive tooth 601 is fixedly connected with a hydraulic telescopic rod 602, and the middle part of the connection plate 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com