Manufacturing method for toothbrush and toothbrush

A manufacturing method and toothbrush technology, applied in the field of toothbrush manufacturing, can solve the problems of inconvenient recycling, small size of metal fixing parts, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

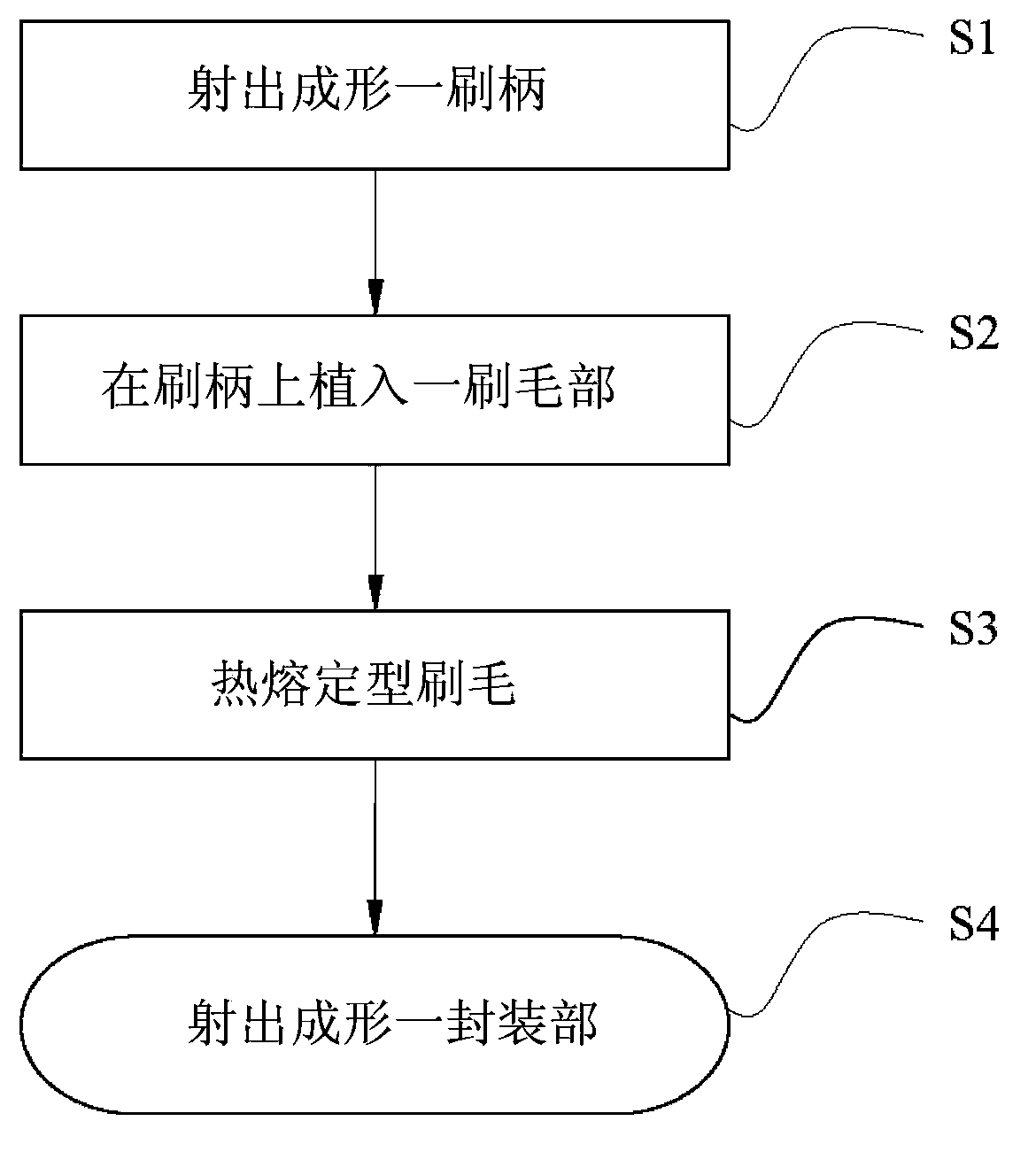

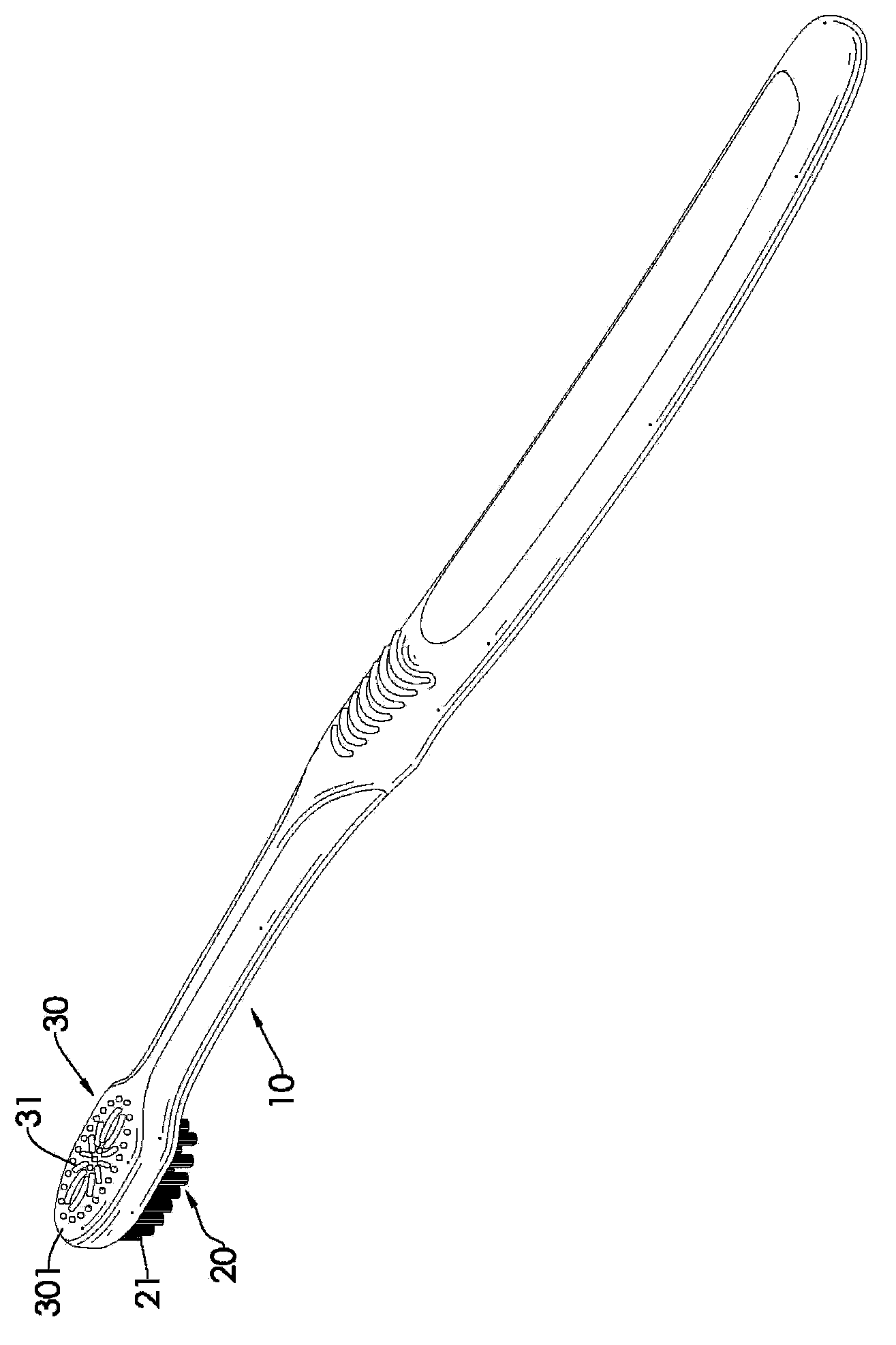

[0046] see figure 1 As shown, in this embodiment, the steps of the manufacturing method of the toothbrush of the present invention include injection molding a brush handle S1, implanting a bristle part S2 on the brush handle, hot-melt positioning each bristle S3, and injection molding a packaging part S4; see figure 2 As shown, the present invention is used to manufacture the toothbrush shown in the figure, which includes a handle 10 , a bristle portion 20 and a packaging portion 30 .

[0047] Each step of the manufacturing method of described toothbrush is described in detail as follows:

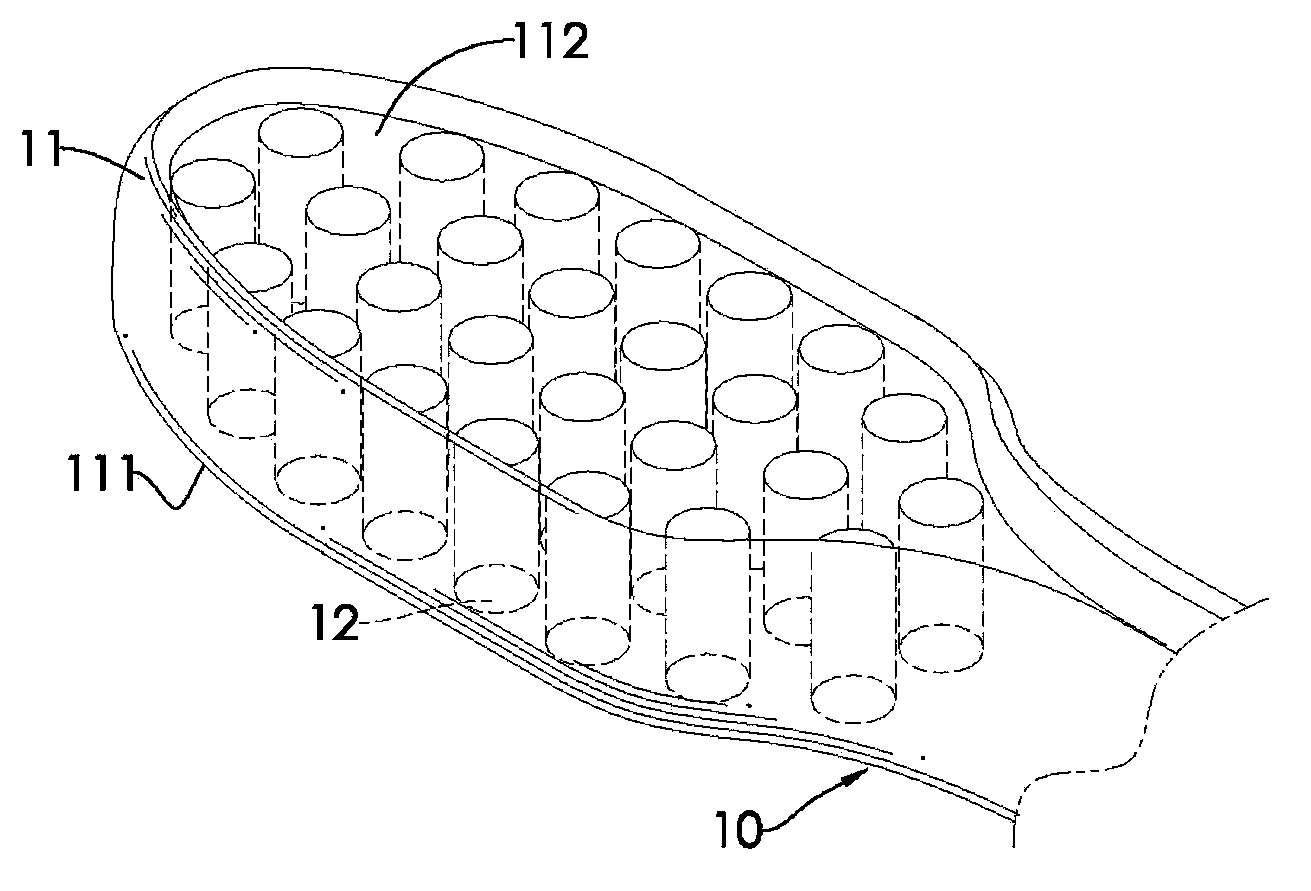

[0048] S1, injection molding a brush handle 10: inject liquid plastic into the first mold with injection molding technology, the first mold is a figure 2 and image 3 The mold corresponding to the shape of the brush holder 10 shown in the figure will be formed after the liquid plastic is cooled and solidified. figure 2 Brush handle 10 shown in ; see image 3 and Figure 4 As shown,...

no. 2 example

[0054] In the present embodiment, the manufacturing method of toothbrush of the present invention is characterized in that:

[0055] In injection molding a brush handle 10A step, see Figure 7 , Figure 8 Figure 9 and Figure 10 As shown, a sheet 13A is formed between the first side 121A of each bristle hole 12A and the second side 112A of the brush head 11A, and a number of recesses are formed on each sheet 13A adjacent to the opposite bristle hole 12A. Each sheet 13A has four rupture portions 131A, each rupture portion 131A extends outward from the center of each sheet 13A, and each rupture portion 131A is connected to form a cross;

[0056] In the step of implanting a bristle portion 20A on the handle 10A, please refer to Figure 9 Figure 10 and Figure 11 As shown, by means of the tufting machine, each bristle 21A penetrates each thin piece 13A of the brush head 11A, so that each thin piece 13A is broken to form several thin fragments 14A, and each bristle 21A is r...

no. 3 example

[0060] In the present embodiment, the manufacturing method of the toothbrush of the present invention is characterized in that, in the injection molding-handle step, please refer to Figure 13 As shown, each sheet 13B has six breakouts 131B, and each breakage 131B is connected to form a radial shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com