Casting die based on 3D printing and preparation method thereof

A 3D printing and mold technology, which is applied in casting molding equipment, additive processing, etc., can solve the problems of unguaranteed product quality, poor precision of wooden models, scrapped wooden models, etc., to achieve low production costs, reduce weight, and improve The effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

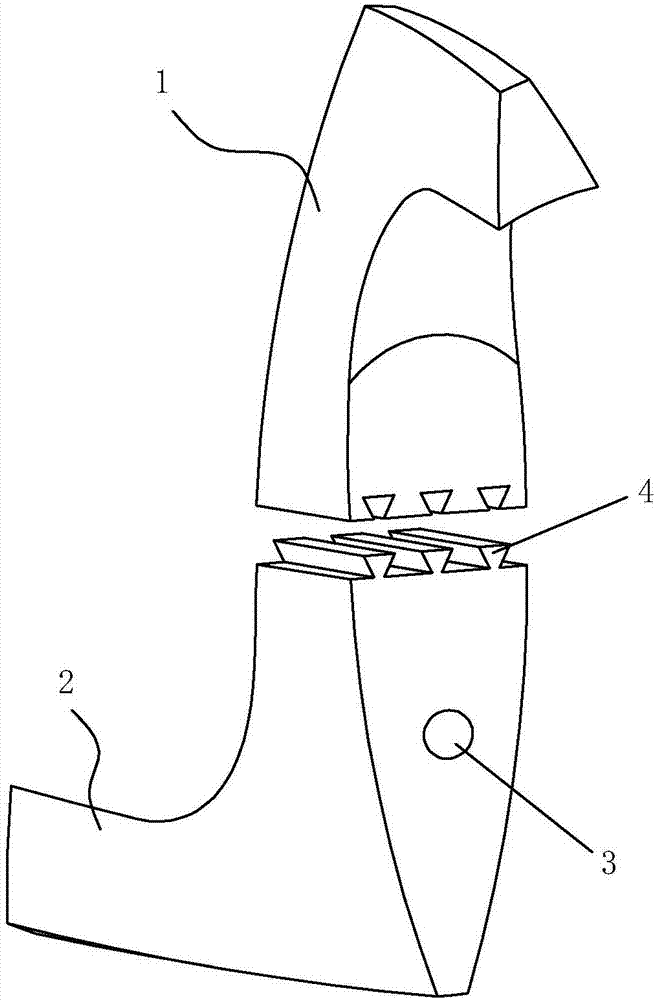

[0035] Such as figure 1 , figure 2 As shown, a casting mold based on 3D printing of the present invention includes parts I1 and parts II2 obtained by 3D printing. The 3D printing materials of parts I1 and parts II2 of the present invention are PLA or ABS materials, and the thermal softening temperature of the printing materials is greater than 80°C; the component I1 and component II2 are connected as a whole through the dovetail groove 4 .

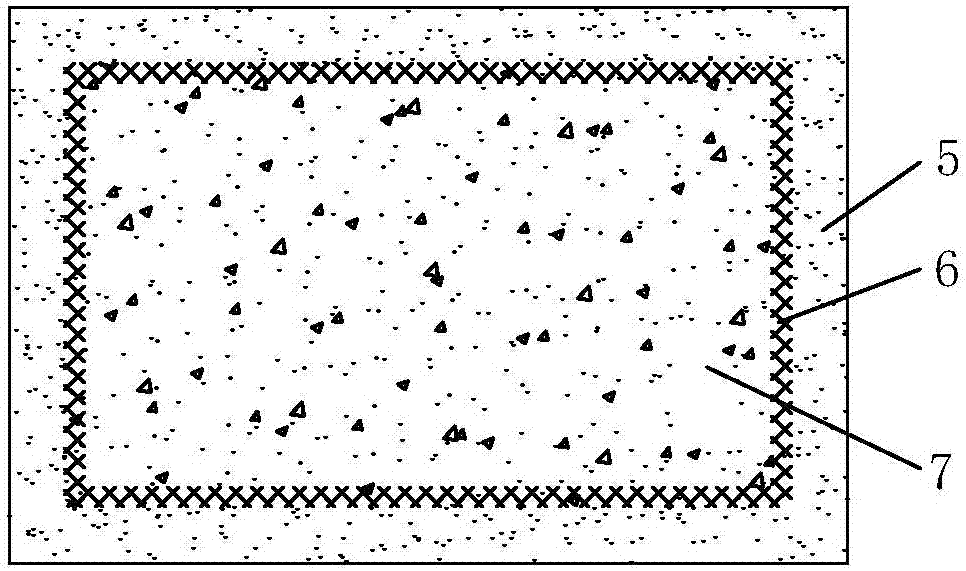

[0036] Part I1 and part II2 of the present invention are both cavity structures, and the planes of part I1 and part II2 are provided with pouring openings 3, through which pouring openings 3 are filled with resin fiber layers 5, Fiber layer 6 and foam layer 7. The pouring opening 3 is arranged on the plane of the component, and after the composite material is filled into the cavity, it is easy to perform grinding treatment on the pouring opening 3 .

[0037] In this embodiment, the resin fiber layer 5 is a mixture of slow-drying resin ...

Embodiment 2

[0042] A method for preparing a casting mold based on 3D printing described in embodiment 1, comprising the following steps:

[0043] (1) Use modeling software to model to obtain the overall model of the casting mold, divide the overall model into several parts connected by dovetail grooves, and export several parts as STL format files;

[0044] (2) Import the STL format files into the slicing software for slicing processing, and print the slicing data with a 3D printer to obtain several hollow structural parts;

[0045] (3) Process a perfusion opening with a diameter of 10-20 mm at the plane of each component obtained in step (2), and process a vent hole with a diameter of 1-5 mm at the dead corner of each component where the gas does not easily flow;

[0046] (4) Fill the cavity of the part obtained in step (3) with the mixture of slow-drying resin and reinforcing fiber respectively through the pouring opening, and shake the part so that a layer of resin fiber layer is evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat softening temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com