Electric multifunctional building overlay decorating machine

A multi-functional, electric motor technology, applied in the field of cleaning walls or sanding, electric multi-functional building finishing machine, plastering, putty scraping, and spraying construction devices, can solve problems such as inability to solve the problem of cement smearing construction, etc. Achieve a firm connection, easy to scrape, and achieve the effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

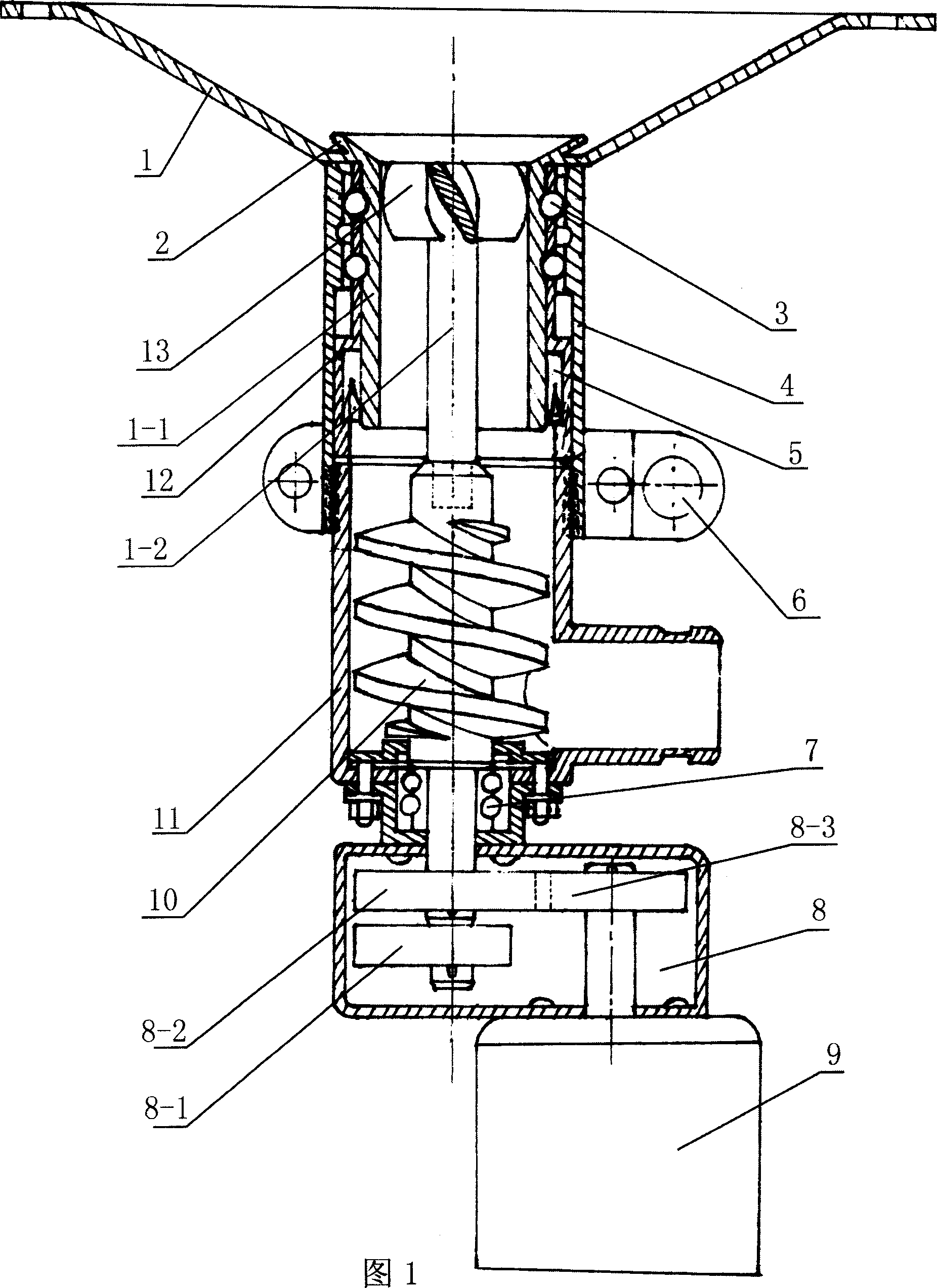

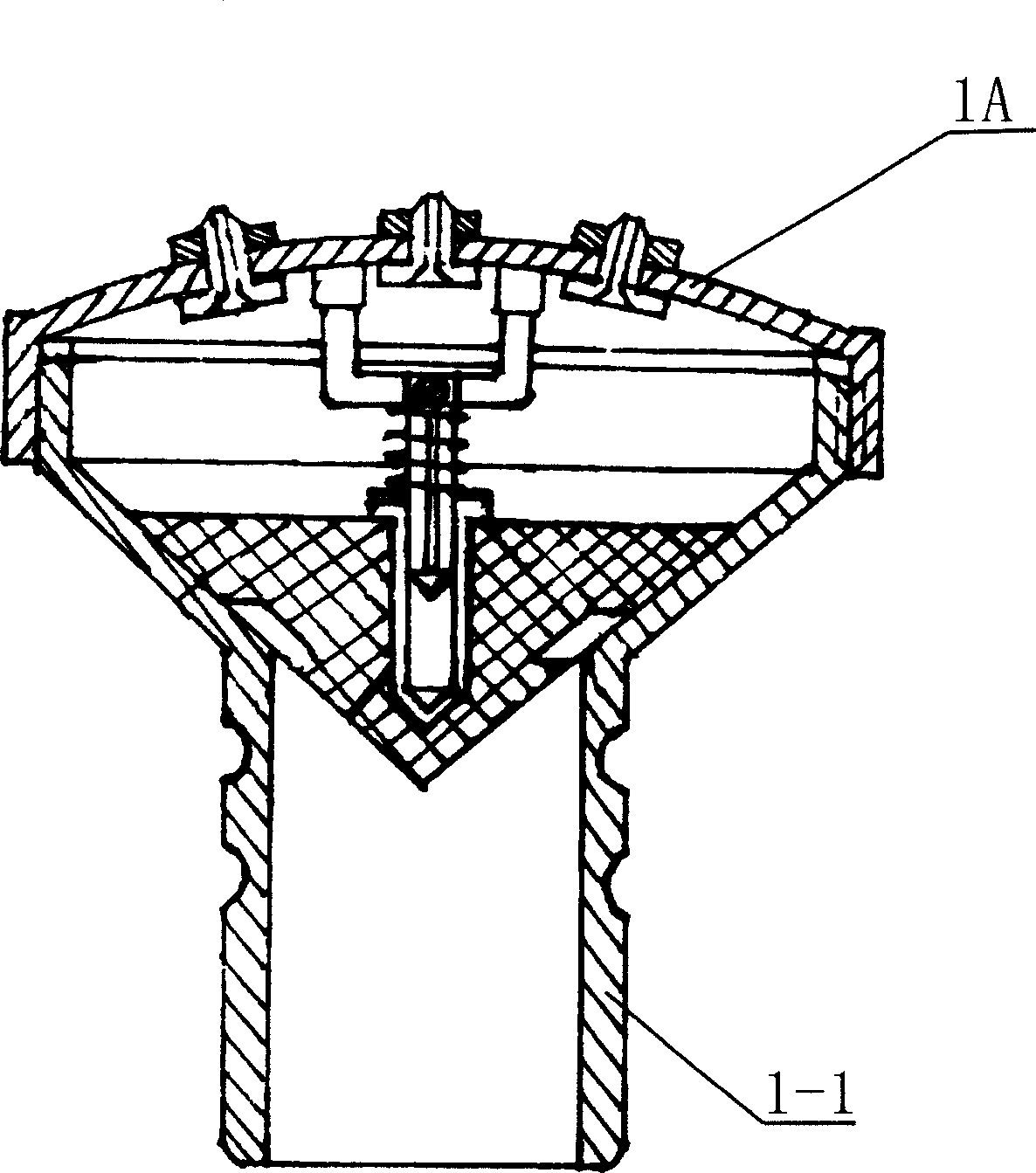

[0018] In the embodiment shown in Fig. 1, the mortar pump casing 11 and the screw conveying rod 10 constitute the main body of the mortar pump, the screw conveying rod 10 is installed in the mortar pump casing 11, and the position of the conveying end of the screw rod 10 corresponds to the position of the mortar pump casing 11. The cylindrical discharge port 4, the discharge port 4 and the mortar pump casing 11 can be a separate structure, and the two are connected by threads; the side of the mortar pump casing 11 is provided with a feed inlet.

[0019] The tail journal of the screw conveying rod 10 extends out of the bottom of the mortar pump casing 11, and is installed in the externally connected double-row roller bearing housing 7, the reduction box 8 is fixedly connected with the double-row roller bearing housing 7, and the reduction box The output gear 8-2 and the input gear 8-3 meshed in 8 are respectively fixed on the output shaft of the screw conveyor rod 10 and the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com