Speed-adjustable self-cleaning conveyor

A self-cleaning, conveyor technology, applied in the direction of conveyors, conveyor objects, cleaning devices, etc., can solve the problems of easy wear, damage, and poor scraping effect of scrapers, so as to avoid damage, reduce production costs, and reduce parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

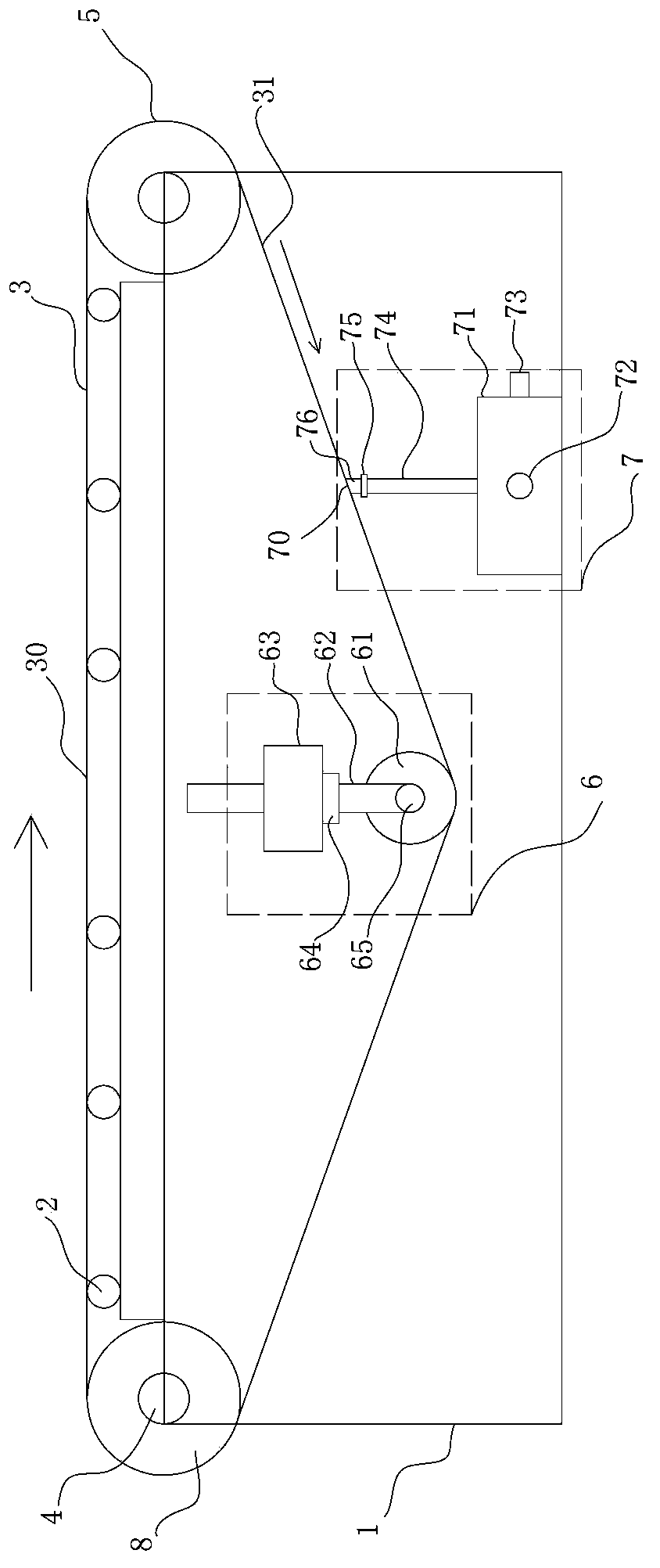

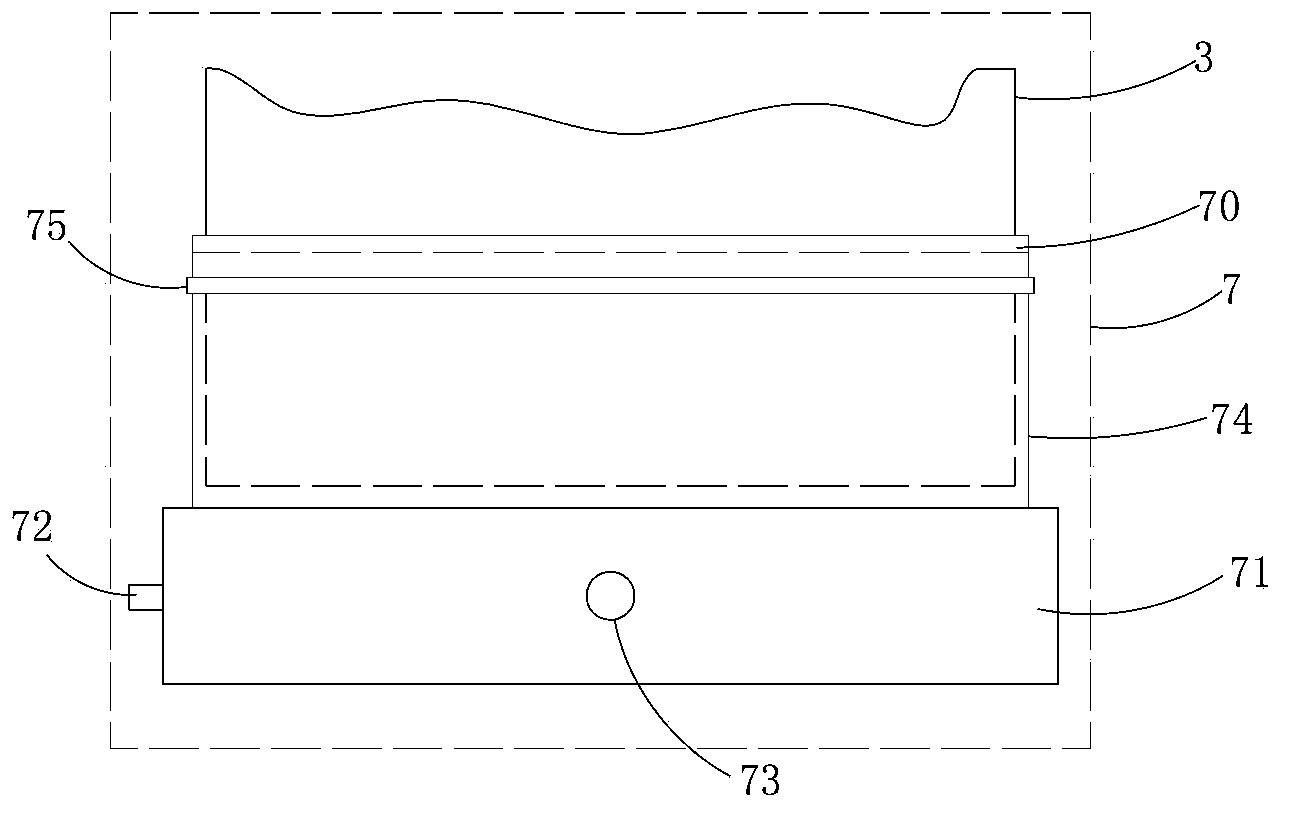

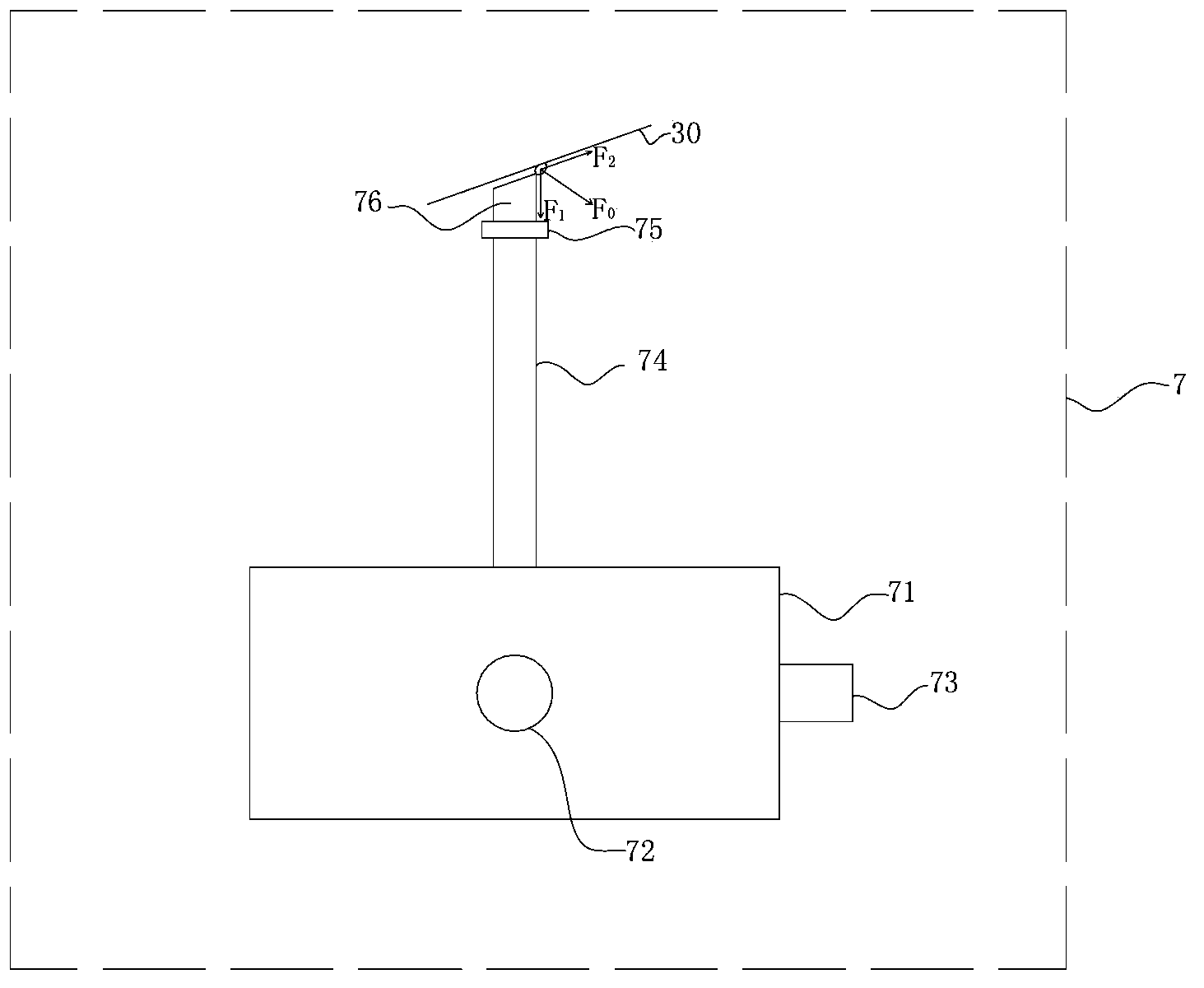

[0030] Example 1. A speed-adjustable self-cleaning conveyor constructed as Figure 1-3 As shown, it includes a frame 1, and the frame 1 is provided with a driving device 4, a driving roller 8, a reversing roller 5, an idler group 2, a conveyor belt 3, and also includes an adjusting device 6 and a cleaner 7, and the adjusting device 6 is set Under the frame 1, the conveying tape 3 is supported downwards to make it triangular. The conveying tape 3 includes an upper part 30 positioned on the top surface of the frame 1 for conveying materials and a lower part 31 positioned below the frame 1. The adjusting device 6 Adjust the tension of conveying tape 3 by moving up and down; Cleaner 7 is arranged below the lower part 31 of conveying tape and near the conveyor discharge port, and sweeper 7 has a bottom surface parallel with the lower part 31 of conveying tape The cleaning surface 70 is connected to the drive device 4 with the frequency converter 9 .

[0031] like figure 1 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com