Environment-friendly sewage treatment device

A sewage treatment device and sewage treatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, multi-stage water treatment, etc., can solve the problems of speeding up replacement frequency, inconvenience for workers, and inconvenient disassembly of filter plates, and achieve Avoid blockage, convenient and fast operation, convenient assembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

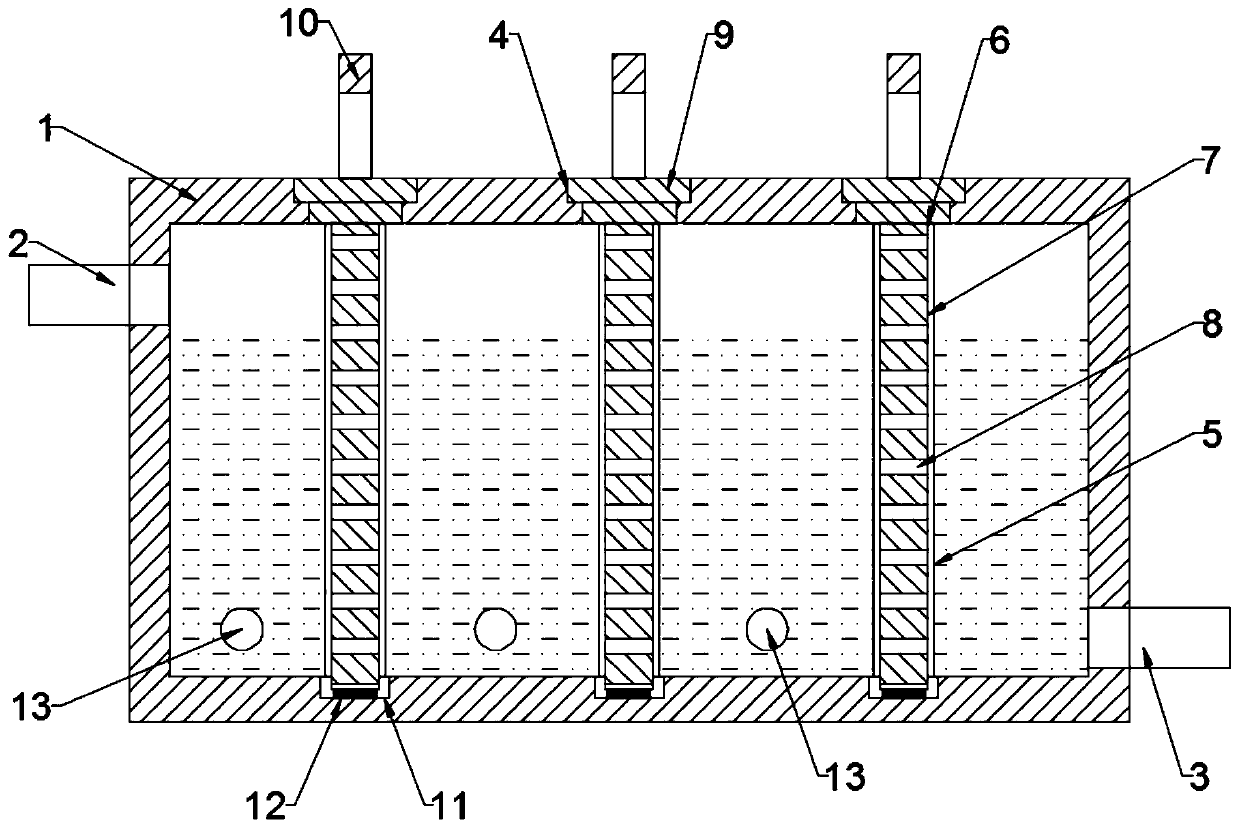

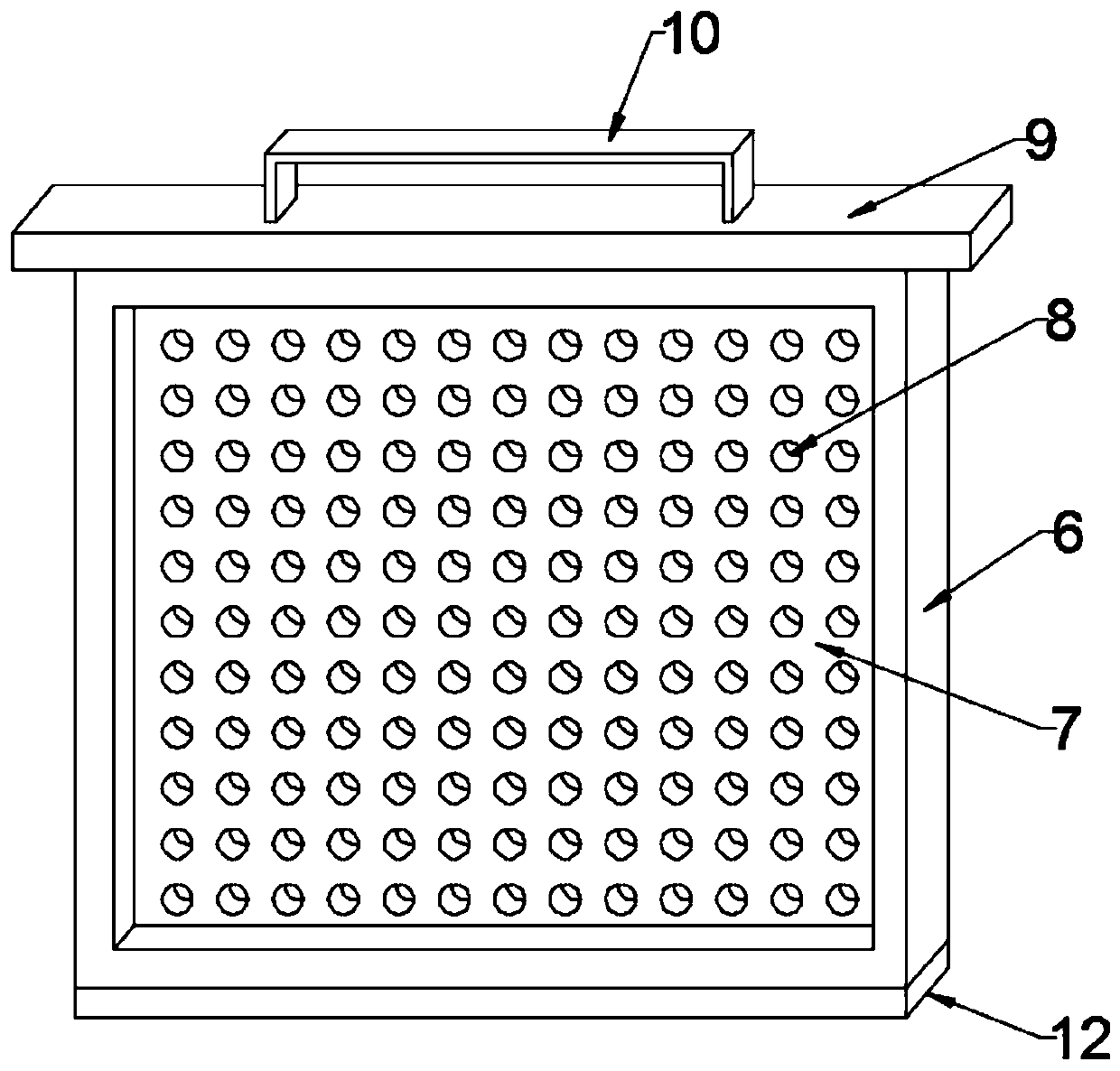

[0026] see Figure 1 ~ Figure 2 , an environment-friendly sewage treatment device, comprising a sewage treatment box 1 and a filter grid plate 7, the upper side of one end of the sewage treatment box 1 is connected with a water inlet pipe 2, and the lower side of one end of the sewage treatment box 1 is connected with a water outlet pipe 3, wherein , the water inlet pipe 2 is used to transport the sewage containing impurities to the sewage treatment tank 1, and the outlet pipe 3 is used to discharge the treated sewage; the sewage treatment tank 1 is equipped with a filter grid plate 7, and the filter grid plate 7 is Filter holes 8 are provided, and the number of filter grid plates 7 is at least one. In the embodiment of the present invention, the number of filter grid plates 7 is three and the diameter of the filter holes 8 is from the water inlet pipe 2- The side to the water outlet pipe 3 side gradually narrows down to facilitate step-by-step filtration of impurities in the ...

Embodiment 2

[0032] see Figure 1 ~ Figure 2 , an environment-friendly sewage treatment device, comprising a sewage treatment box 1 and a filter grid plate 7, the upper side of one end of the sewage treatment box 1 is connected with a water inlet pipe 2, and the lower side of one end of the sewage treatment box 1 is connected with a water outlet pipe 3, so A filter grid plate 7 is installed in the sewage treatment tank 1, and a filter hole 8 is arranged on the filter grid plate 7. The filter grid plate 7 divides the inside of the sewage treatment tank 1 into a plurality of filter chambers, and each filter A sewage outlet 13 is arranged on the sewage treatment tank 1 at the bottom side of the cavity, and the sewage outlet 13 is connected with a sewage pipe 14 .

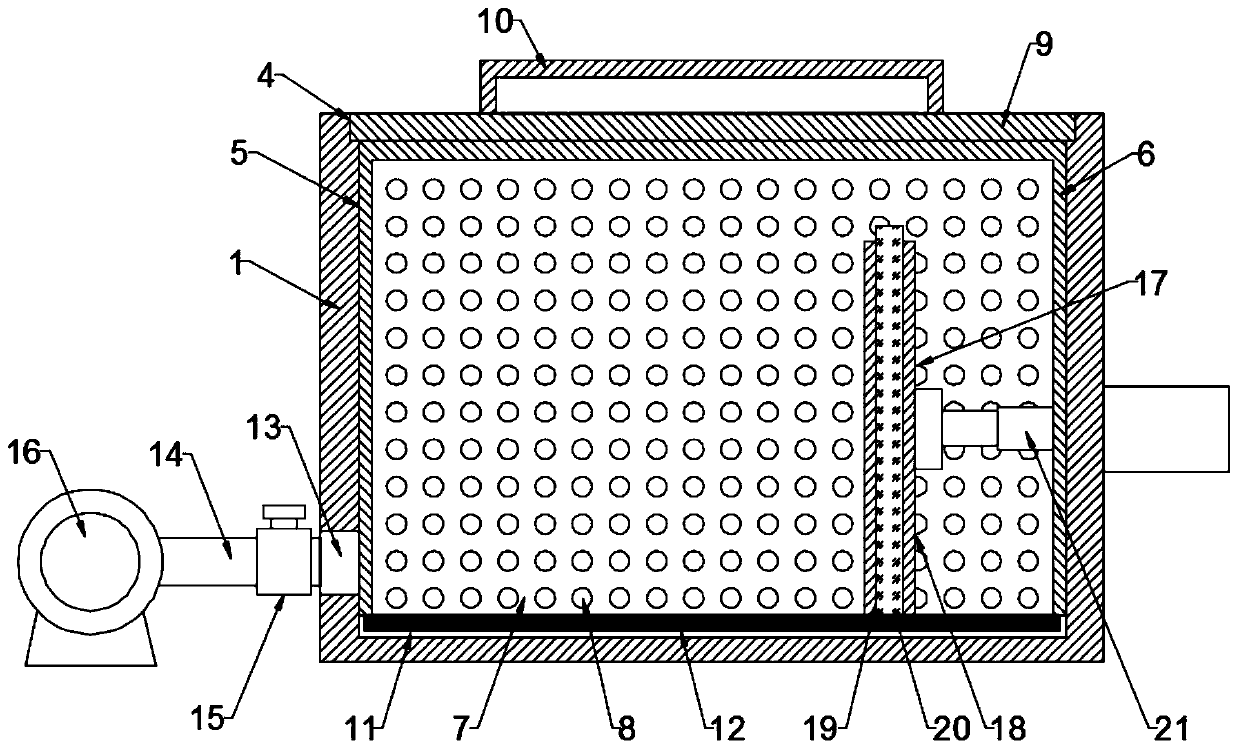

[0033] In order to prevent impurities from adhering to the filter grid plate 7 and filter holes 8, and impurities deposited at the bottom of the sewage treatment tank 1 cannot be extracted through the sewage pipe 14; see image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com