Small motor

A technology for small motors and casings, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of loss, motor damage, cumbersome disassembly of the motor, etc., achieve the effect of convenient replacement and assembly, and avoid damage to the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

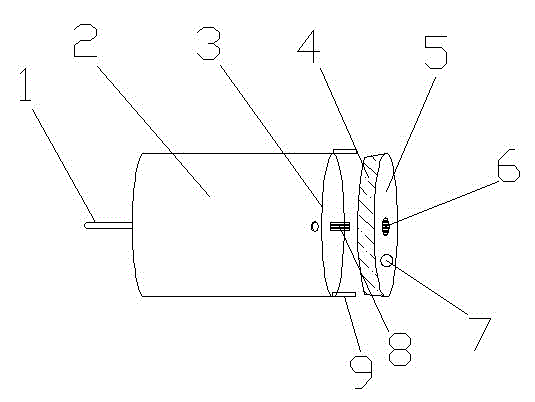

[0010] like figure 1 As shown, the present invention discloses a small motor, including a rotating shaft 1, a casing 2, a brush box 5 and a pin 3, the rotating shaft 1 is arranged in the center of the casing 2, the brush box 5 is connected to the casing 2, and the The pin 3 is arranged on the casing 2, the casing 2 and the brush box 5 are connected by threads, the casing 2 is provided with a baffle 9, the rotating shaft 1 is provided with a thread 8, and the brush box A groove 6 and a cooling fin 7 are also arranged in the groove 5, and the groove 6 is arranged in the groove 6 to match the screw thread 8 provided on the rotating shaft 1.

[0011] It should be noted that the length of the baffle plate 9 is consistent with the thickness of the brush box 5 .

[0012] It should be noted that the position of the pin 3 is set within the connection range between the casing 2 and the brush box 5 .

[0013] When the invention is assembled, it is only necessary to connect the brush bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com