Digital full-automatic die-casting equipment

It is a fully automatic and equipment technology, which is applied in the configuration of casting equipment, metal processing equipment, indicating equipment/measuring equipment, etc. It can solve the problems of reducing the completion of injection material, inaccurate clamping position, instability and other problems, and achieve complete stability The effect of mold clamping, high mold clamping stability and high hydraulic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose, the specific implementation modes of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

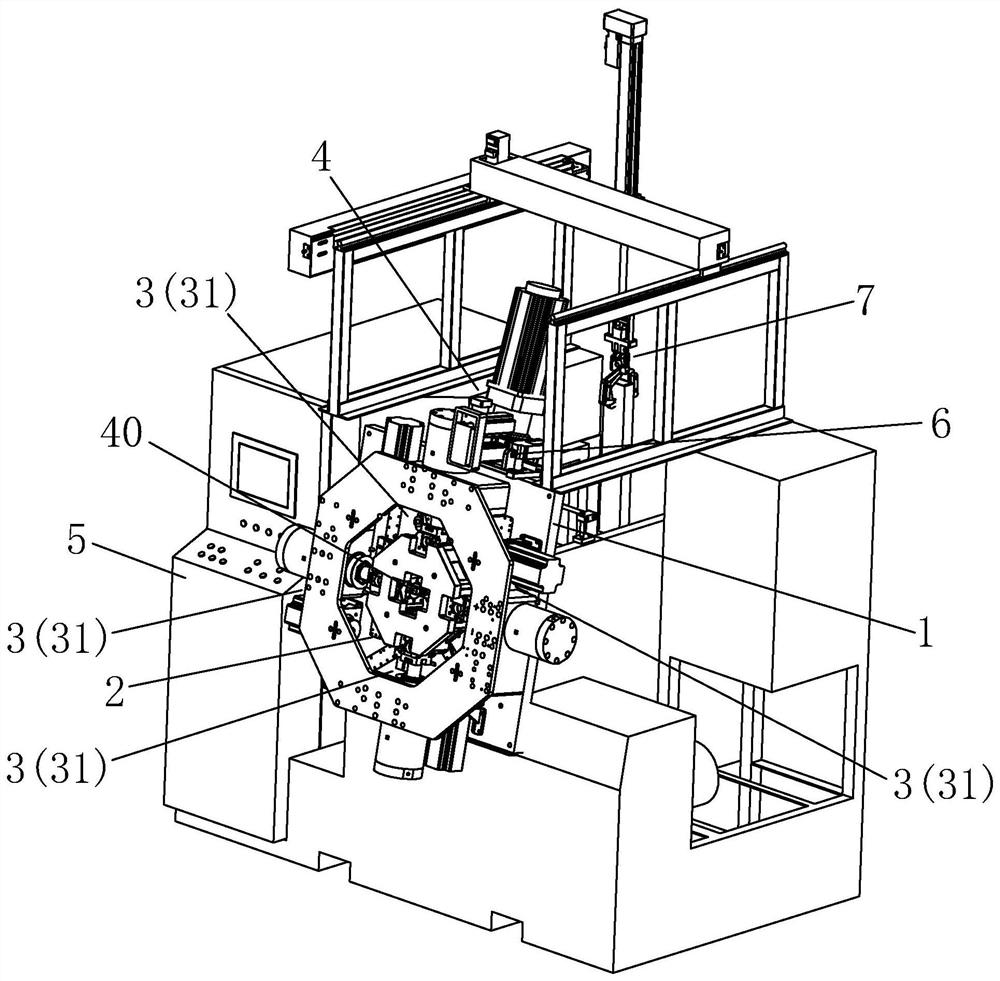

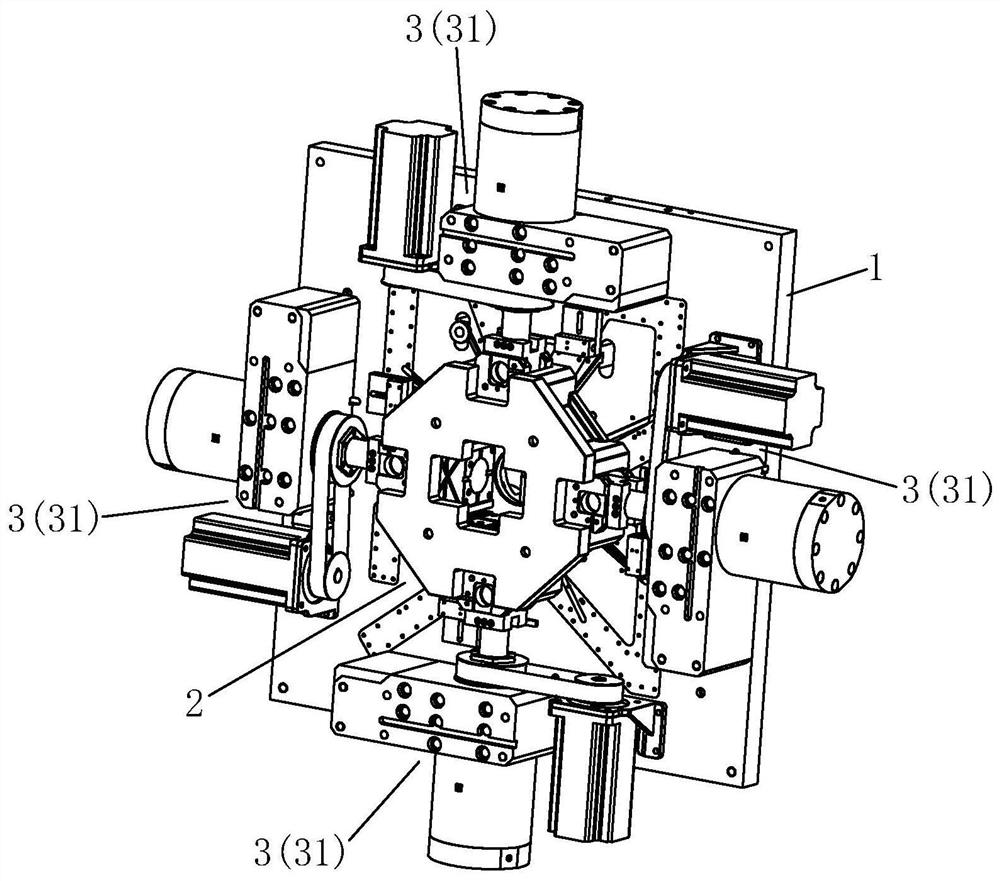

[0065] Please refer to Figure 1 to Figure 4 , the embodiment of the present invention provides a digital automatic die-casting equipment, including:

[0066] a longitudinal mounting plate 1;

[0067] A mold 2, which is arranged on the front side of the longitudinal mounting plate 1;

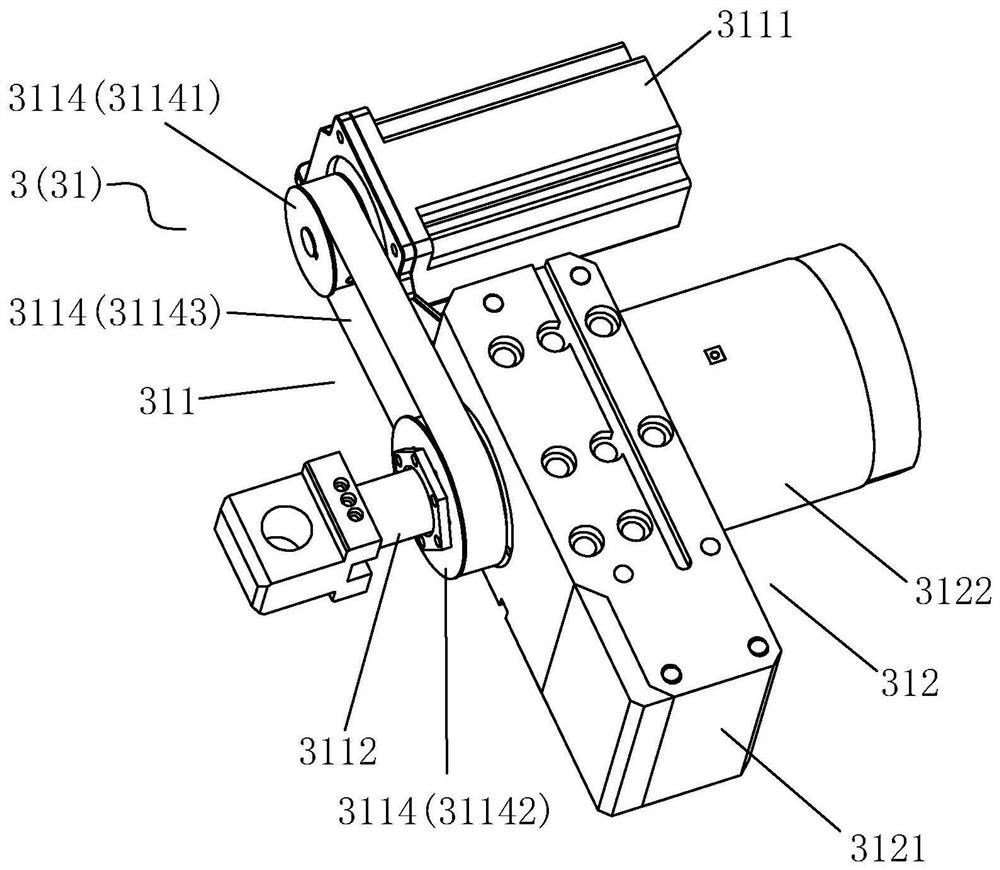

[0068]A clamping device 3, which includes several clamping mechanisms 31 surrounding the periphery of the mold 2;

[0069] A injection device 4, which is arranged on the back of the longitudinal mounting plate 1, the injection nozzle 40 of the injection device 4 extends into the mold 2; after the clamping mechanism 31 completes the mold locking action, the injection device 4 completes injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com