Patents

Literature

97 results about "Injection - action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

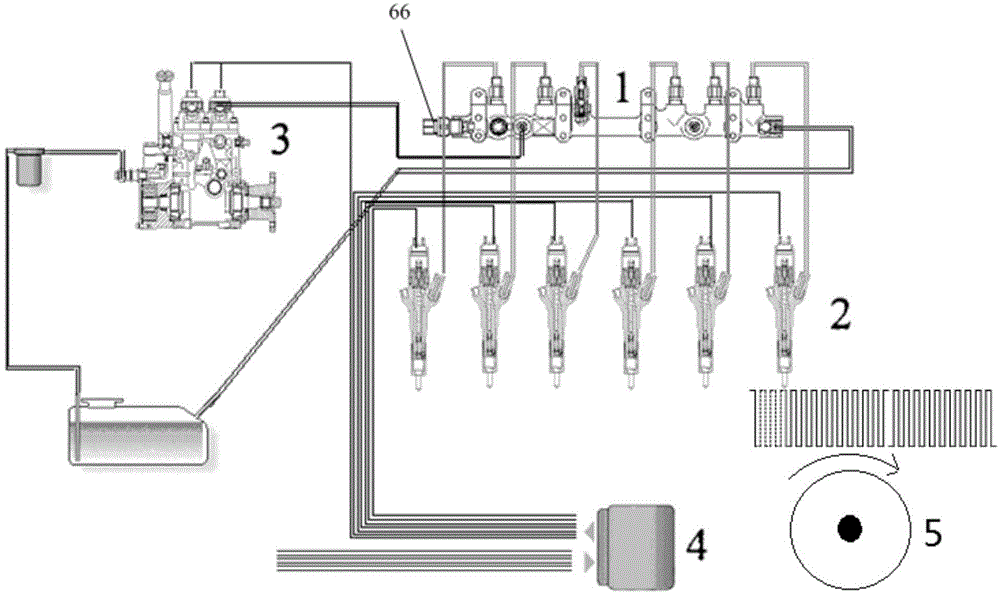

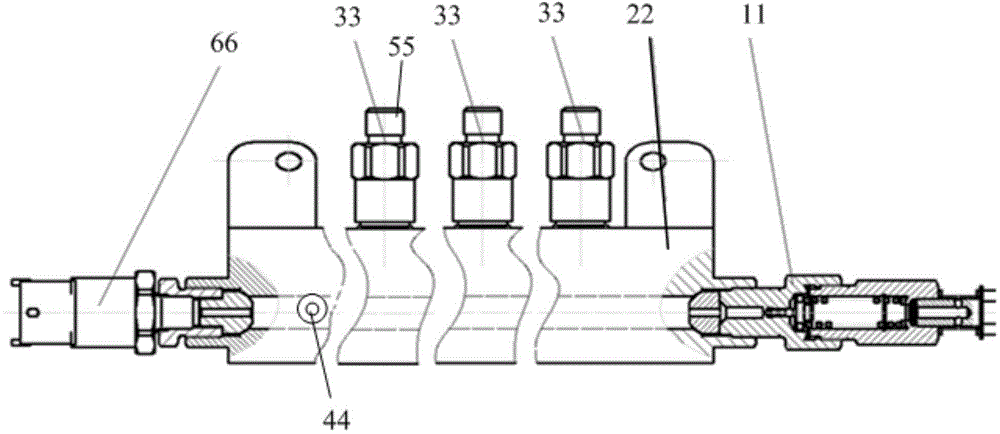

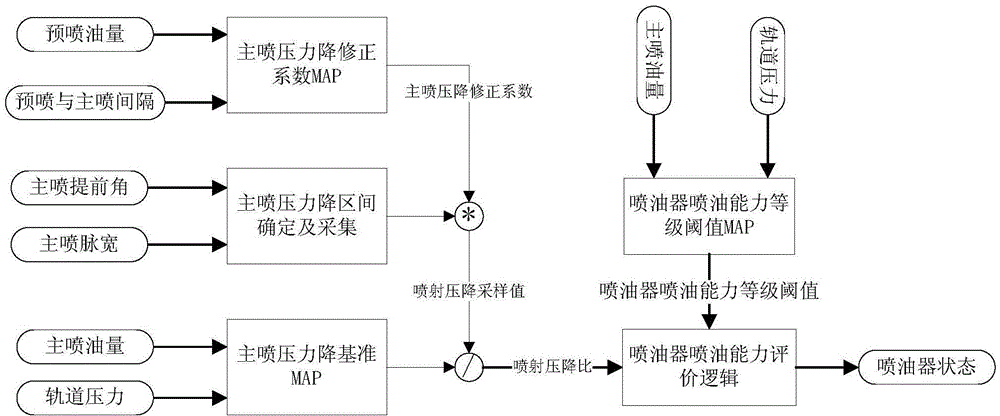

Online diagnosis method for uniformity of common-rail oil injectors

ActiveCN104481769AAvoid instantaneous speedWeakly correlated parameters such as the exhaust gas composition of the avoiderEngine testingFuel injection apparatusInjection pressureWork cycle

The invention provides an online diagnosis method for uniformity of common-rail oil injectors. The online diagnosis method includes the following steps: step one, under the condition that pressure in a common-rail pressure storage rail meets requirements, collecting and calculating pressure drop of a main injection action in the pressure storage rail; step two, acquiring a main injection pressure drop reference value of a current work cycle, and dividing the collected and calculated main injection pressure drop by the main injection pressure drop reference value to acquire an injection pressure drop ratio of the common-rail injectors in this time of injection; step three, comparing oil injection capability grade threshold values of a set of the oil injectors according to the determined injection pressure drop ratio of the common-rail oil injectors, determining oil injection capability grade, of the common-rail oil injector, calculated in this time, and using a statistical method to finally determine the oil injection capability grade of the common-rail oil injectors. By the online diagnosis method, oil injector aging degree can be calculated accurately without increasing extra cost.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

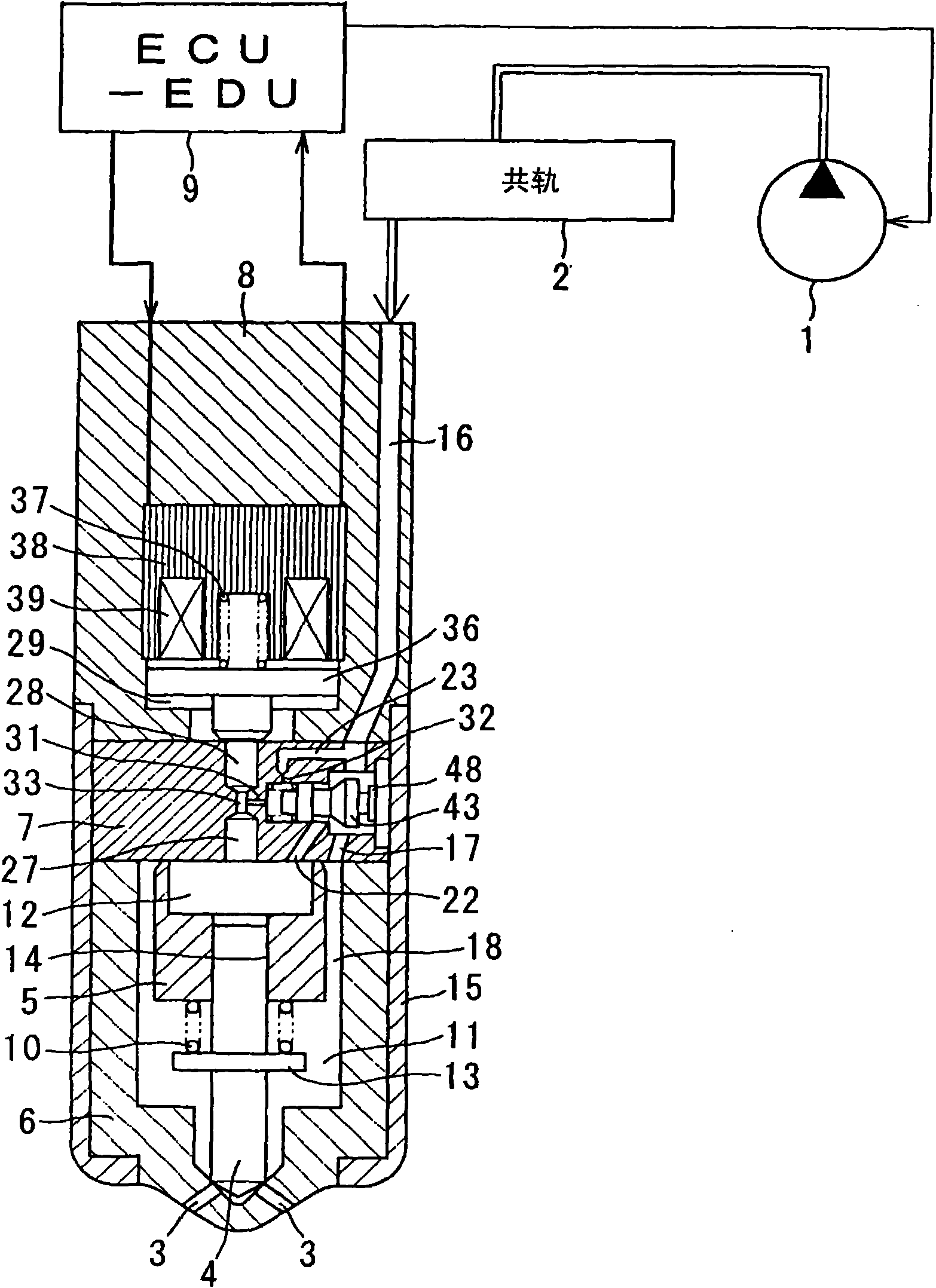

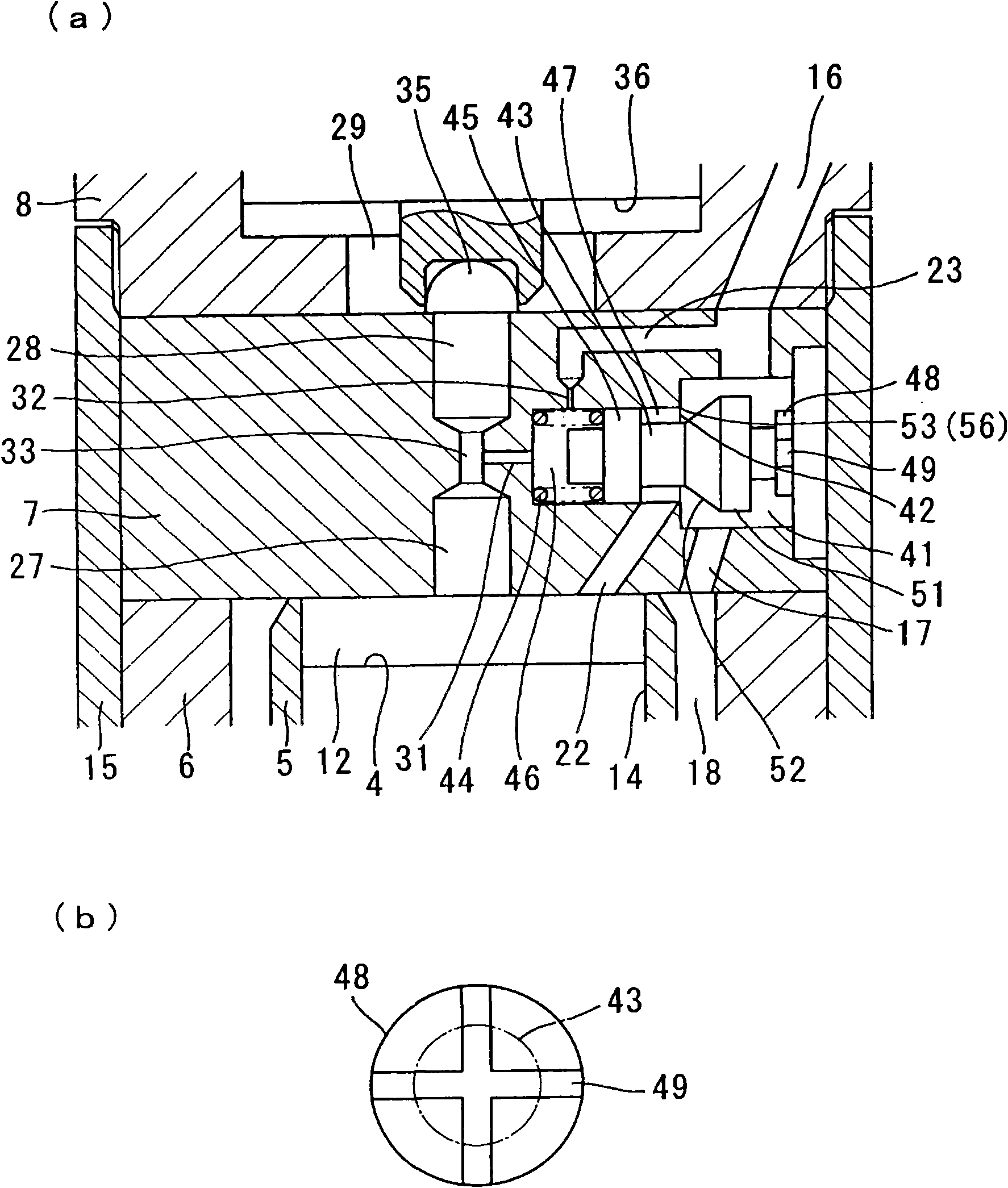

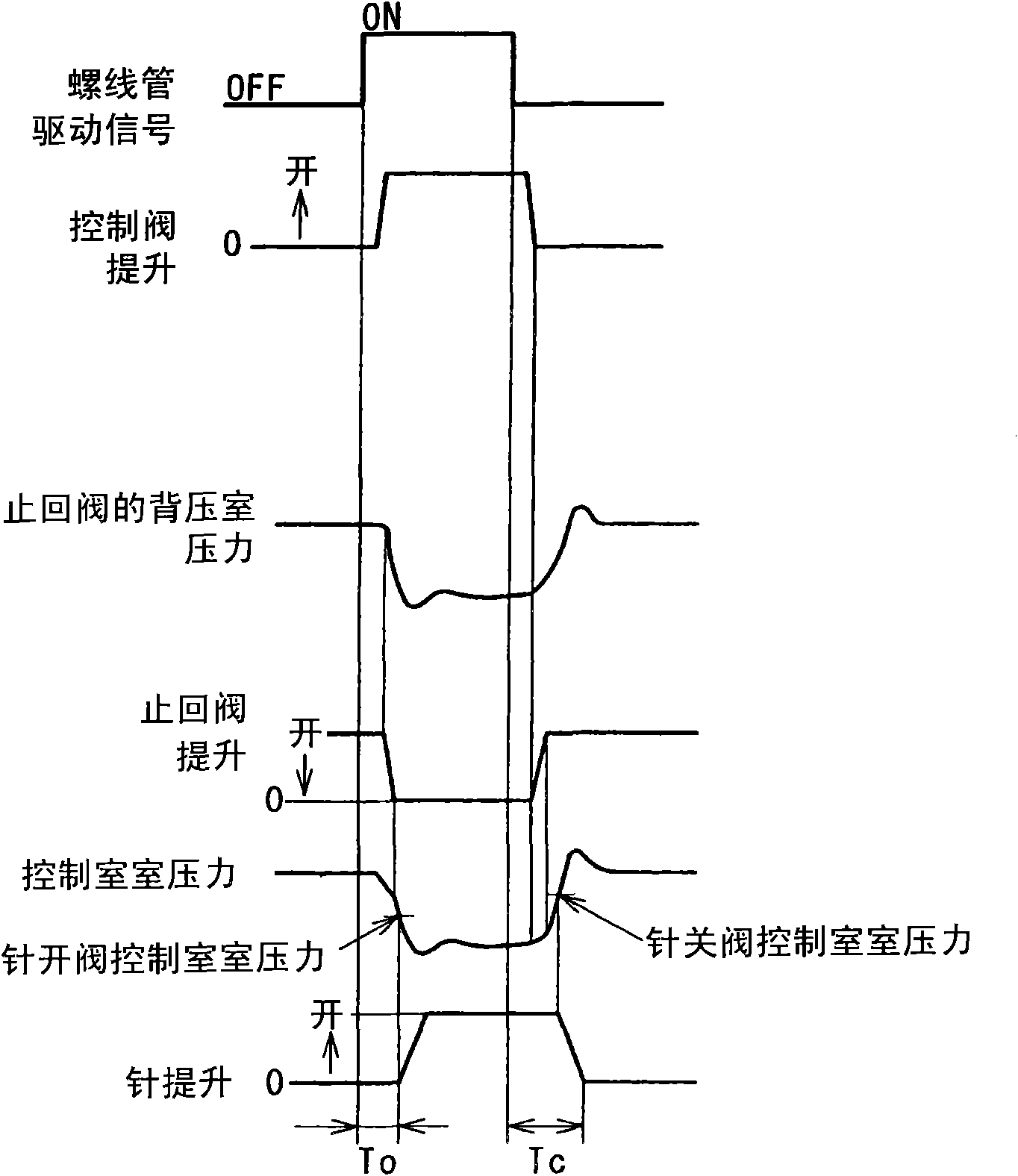

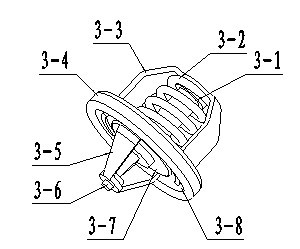

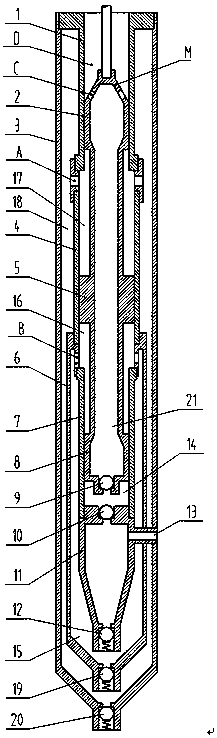

Fuel injection device

ActiveCN102108927AImprove valve closing responsivenessImproved valve opening responsivenessFuel injection apparatusMachines/enginesVena contracta diameterCombustion chamber

A fuel injection device is provided, wherein a fuel introducing flow path (22) for introducing high-pressure fuel into a control room (12) from a fuel supplying flow path (16), and a check valve for controlling the opening and the closing of a clearance (42) are formed inside an orifice plate (7). Therefore, the time (valve-opening response time) from the opening of a solenoid-controlled valve tothe opening of a needle (4) is shortened. In addition, the time (valve-closing response time) from the closing of the solenoid-controlled valve to the closing of the needle (4) is shortened. The closing of the needle (4) is accelerated, and the valve-closing responsiveness is improved. Additionally, in an injection period that the solenoid-controlled valve is opened, the check valve is closed andthe needle (4) is opened, the check valve closes the fuel introducing flow path (22) with a larger flow path section area, so abnormal injection actions such as the closing of the needle (4) can be prevented during the fuel injection into a combustion chamber of a cylinder of an engine.

Owner:DENSO CORP

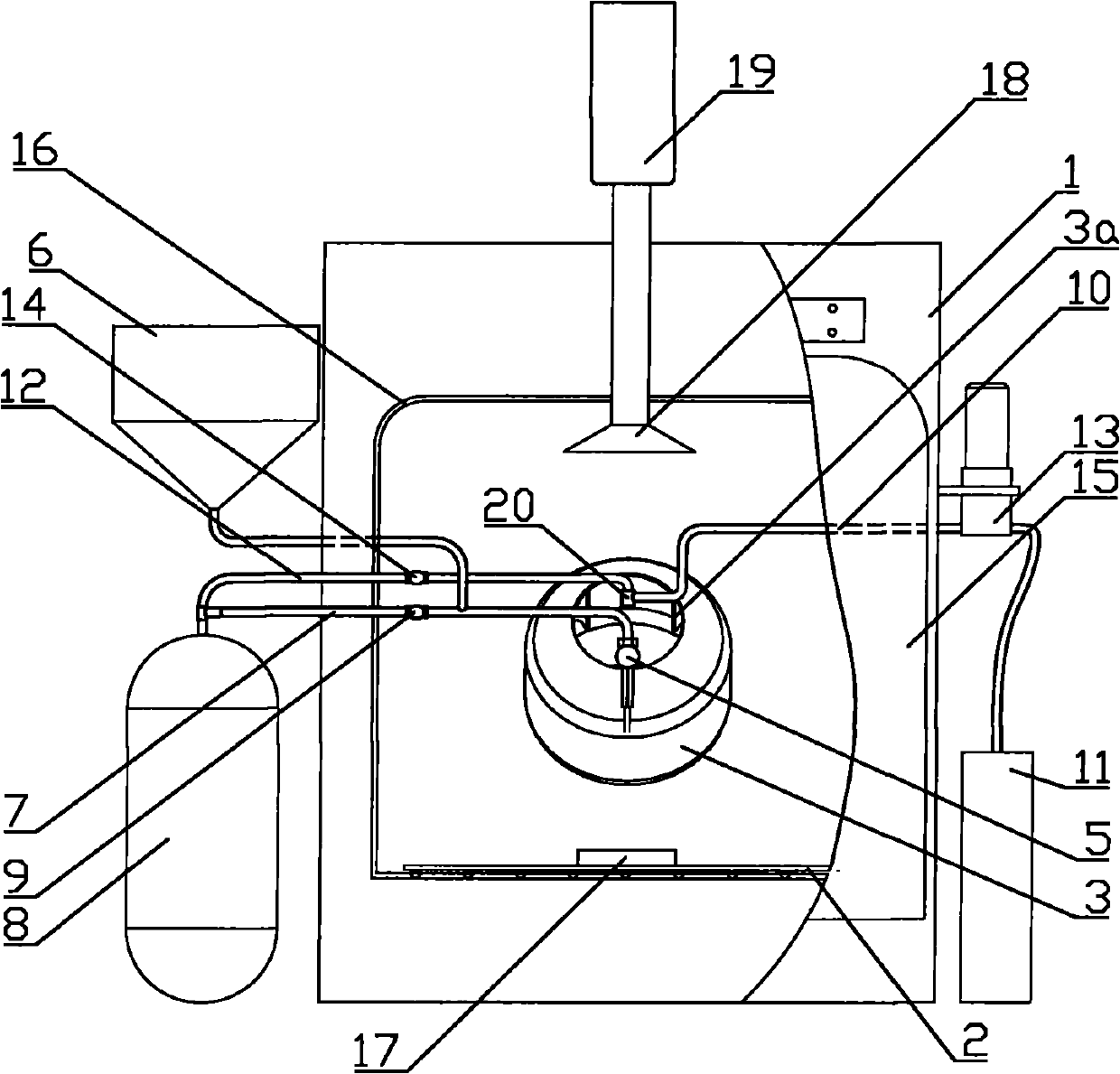

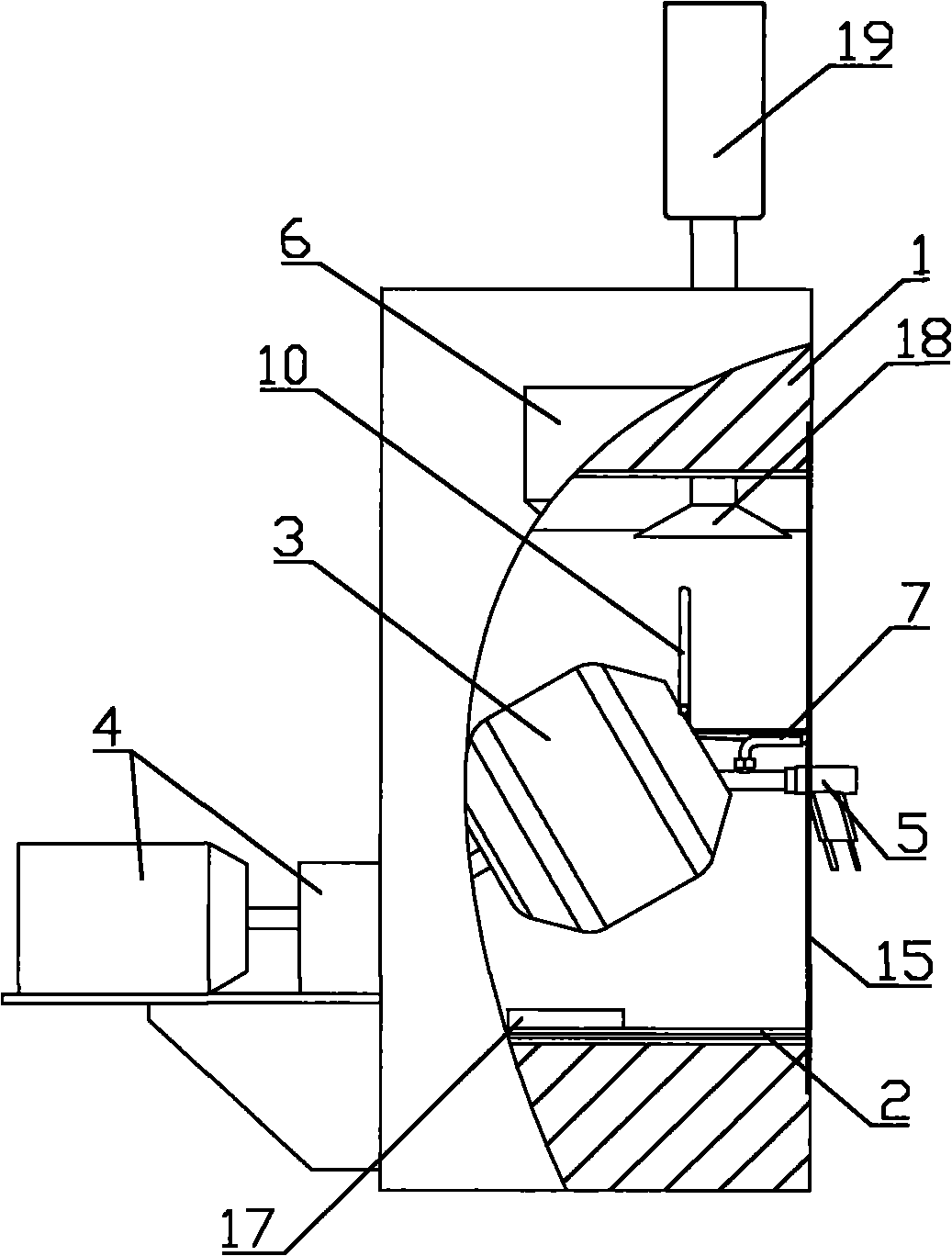

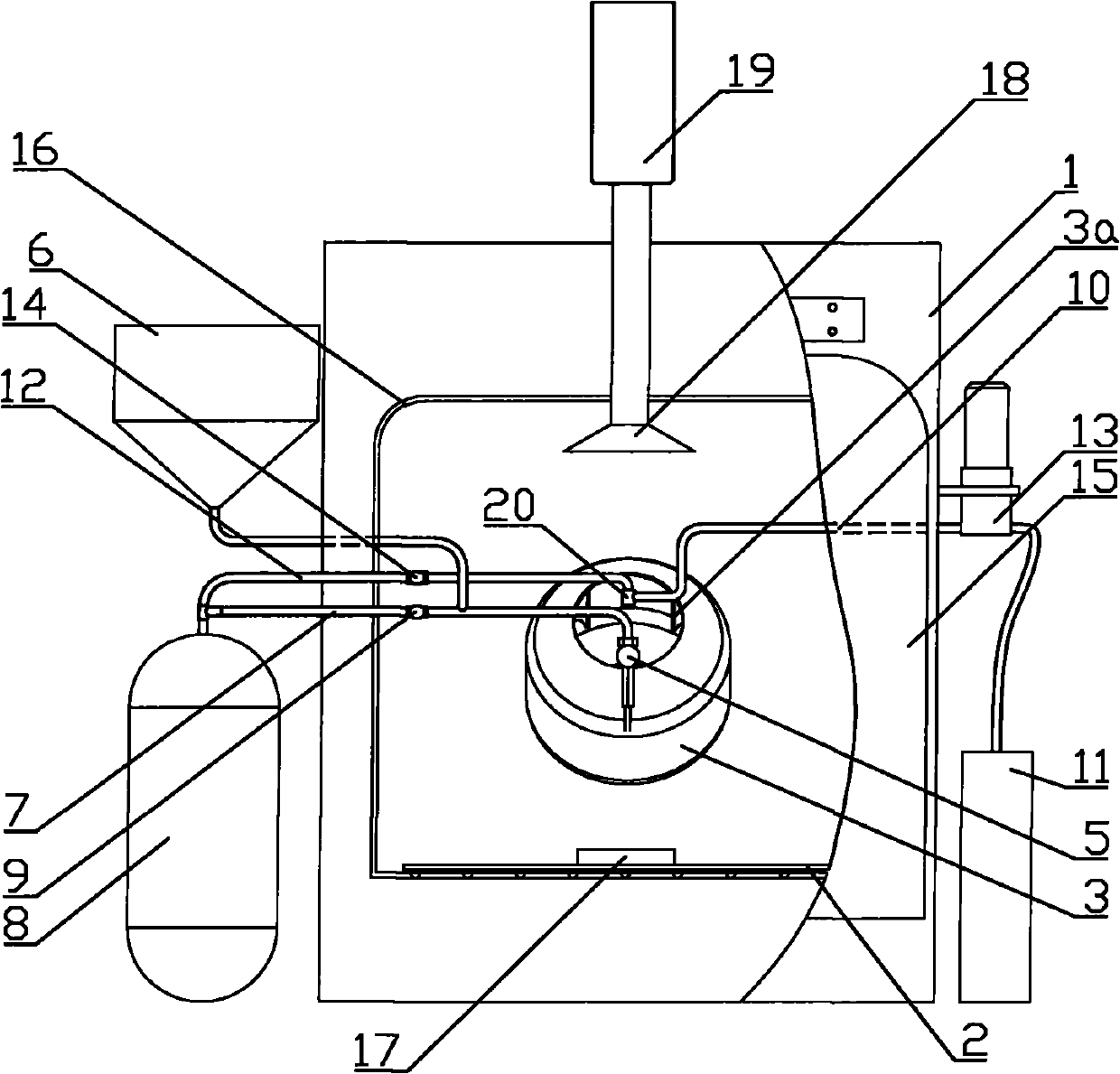

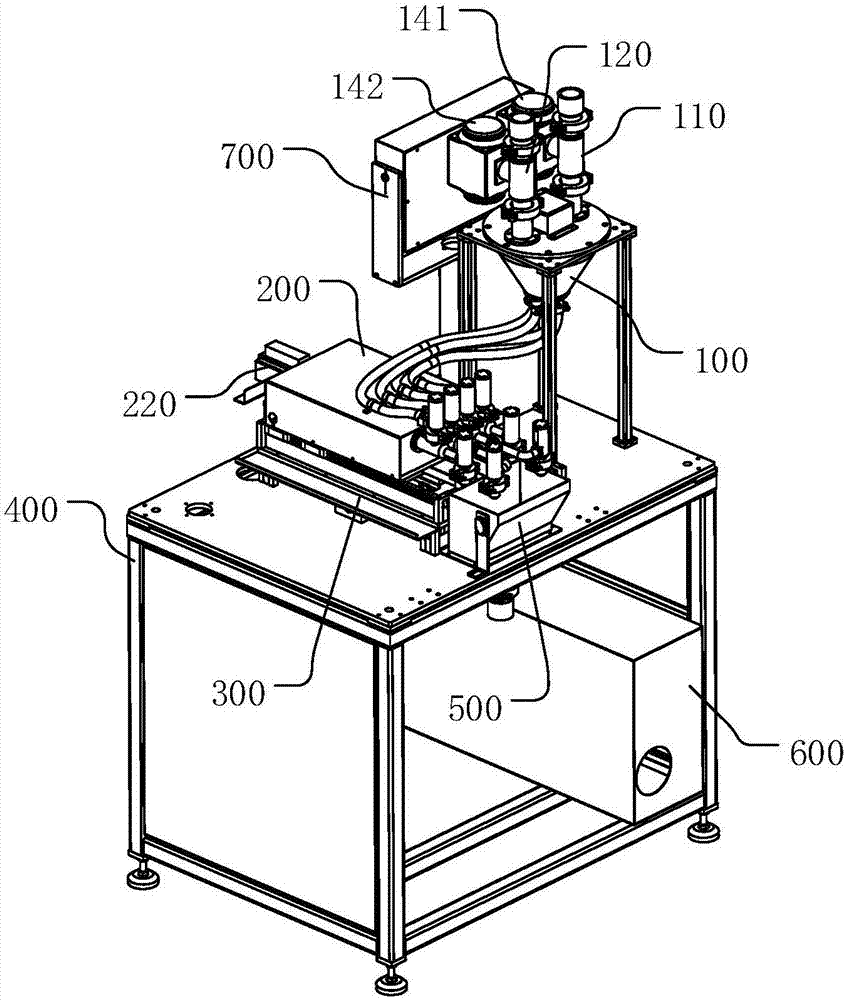

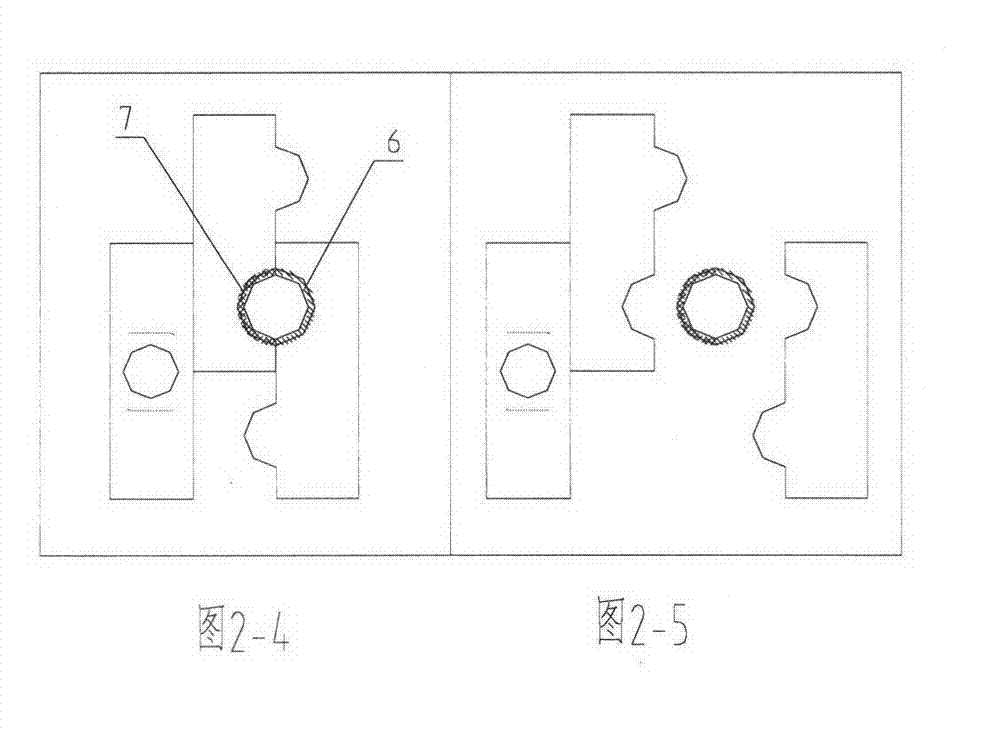

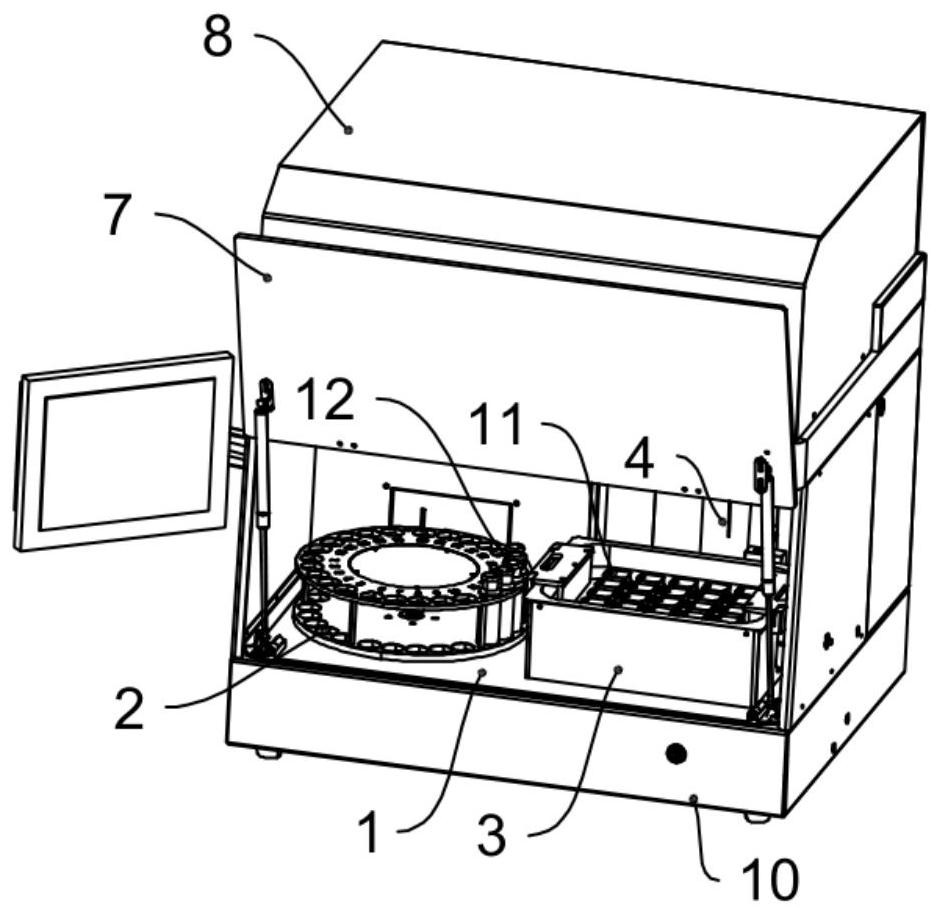

Dry-method coating machine

InactiveCN101766537AEfficient coatingSimple structurePharmaceutical product form changeAfter treatmentMetallurgy

The invention discloses a dry-method coating machine which comprises a box body, a coating device, a dry powder directionally feeding device and an auxiliary material feeding device; when the dry-method coating machine is used, powder in a dry powder box enters into an electrostatic spray gun under the injection action of airflow in a dry powder conveying pipe and is electrified after treatment so as to form a potential difference with a grounded coating pan, and dry powder directionally enters into the coating pan under the driving of electric field force; meanwhile, an auxiliary material, such as a plasticizer, and the like is conveyed into an atomizer through a liquid conveying pipe under the action of a metering pump to form evenly-dispersed fog, the fog simultaneously or stepwise enters into the pan with the dry powder and contacts with a solid preparation in the pan, the dry powder is evenly adhered to the outer surface of the solid preparation with the rotation of the coating pan, and the dry powder can be rapidly softened to form a coating by regulating to appropriate ambient temperature so as to achieve the aim of highly-efficient coating; and in addition, the invention has simple structure, low manufacturing cost and environment protection and is suitable for industrialized coating production.

Owner:罗彦凤

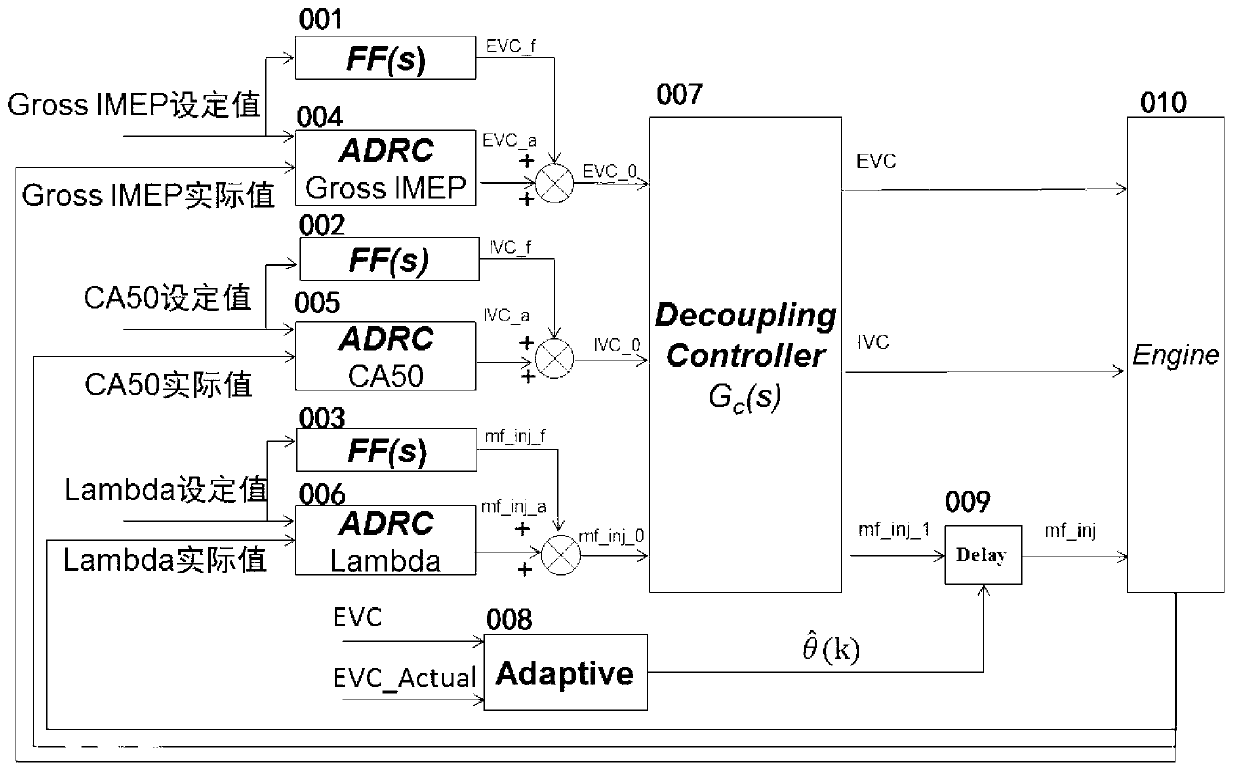

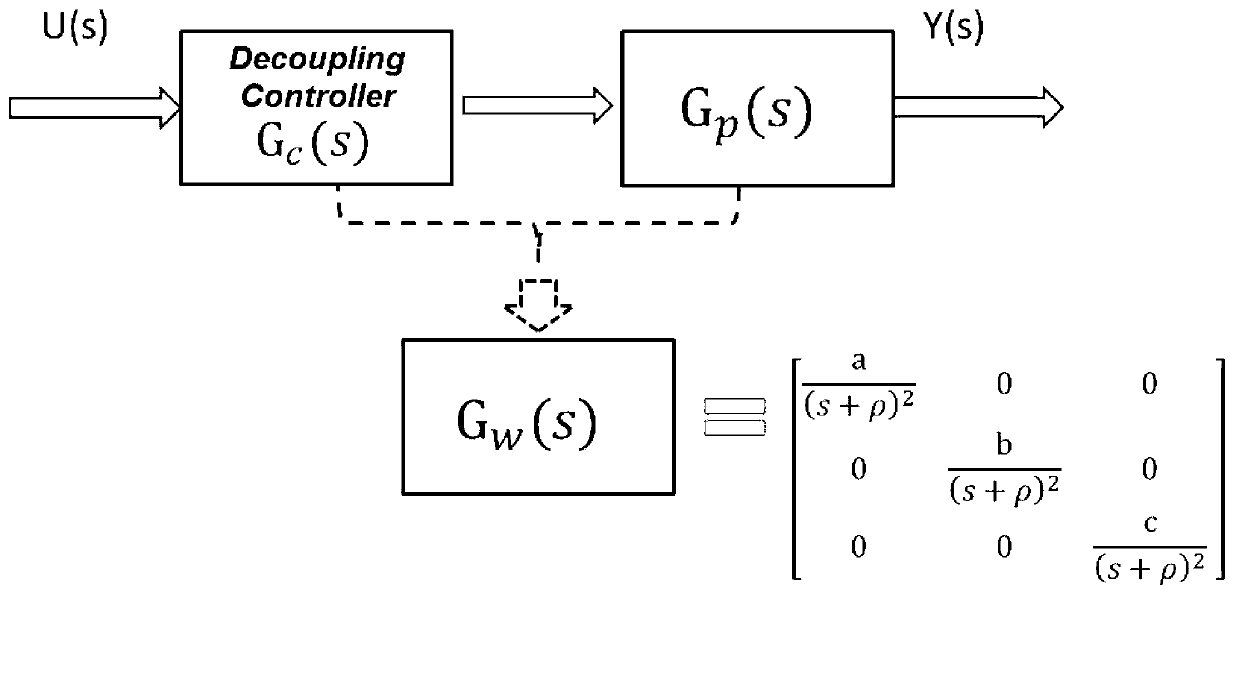

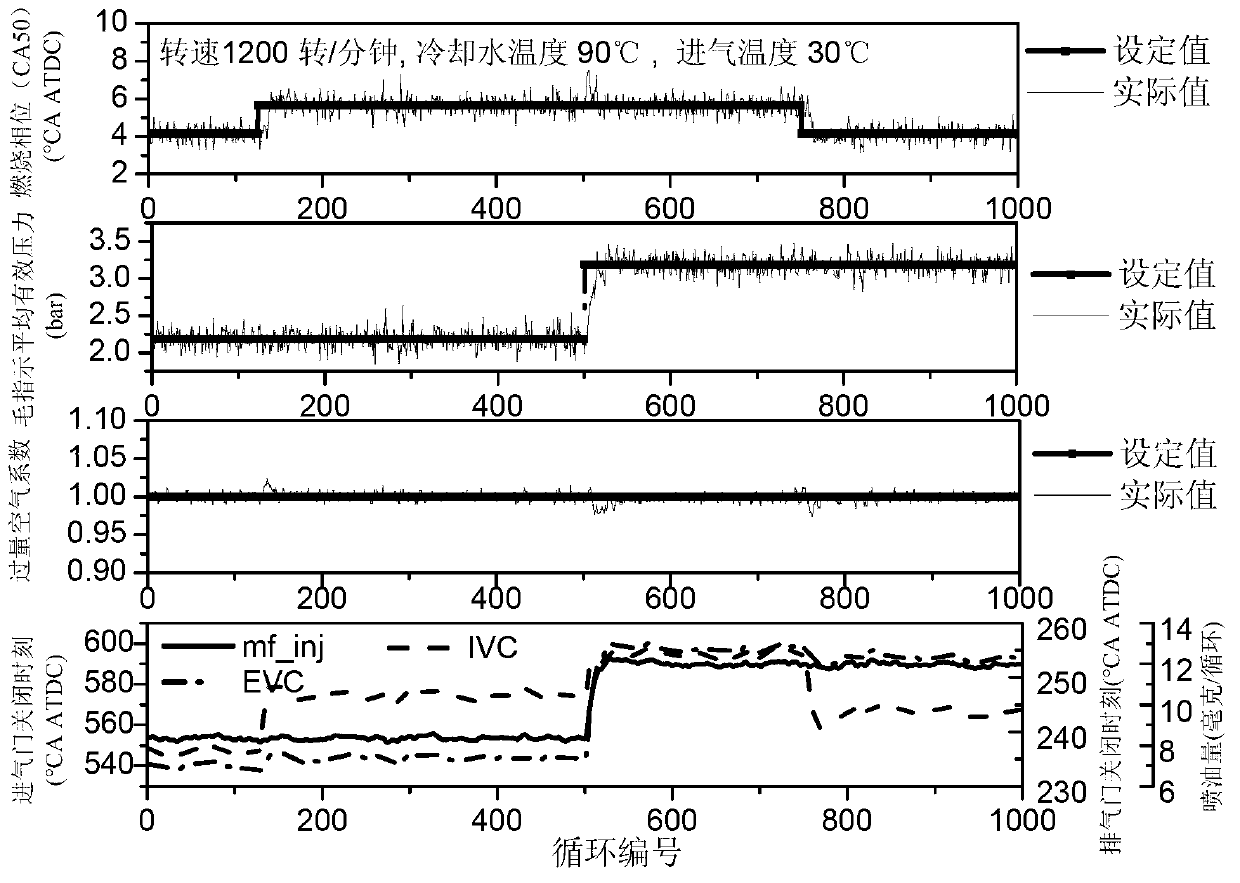

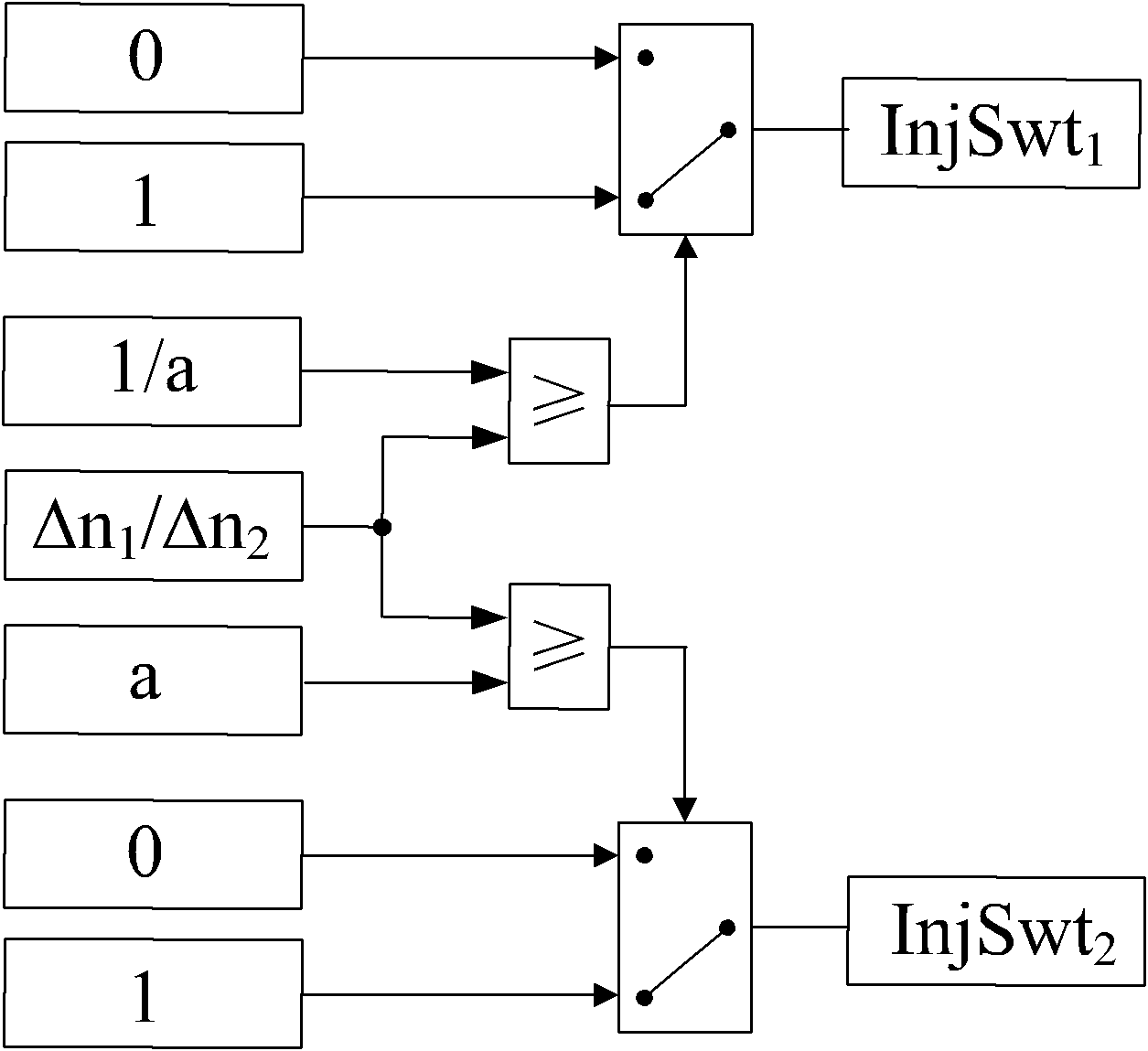

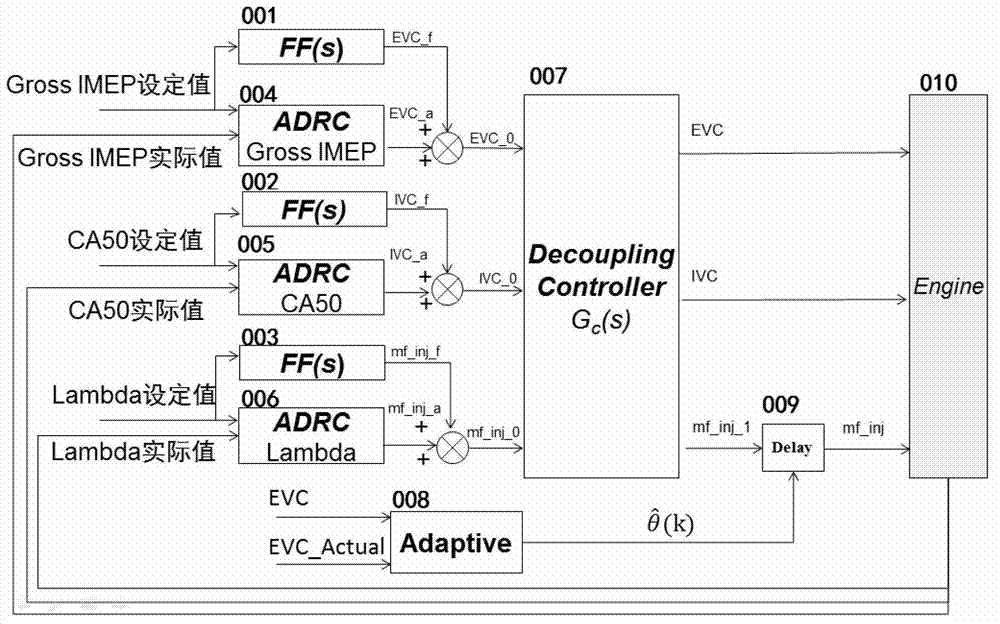

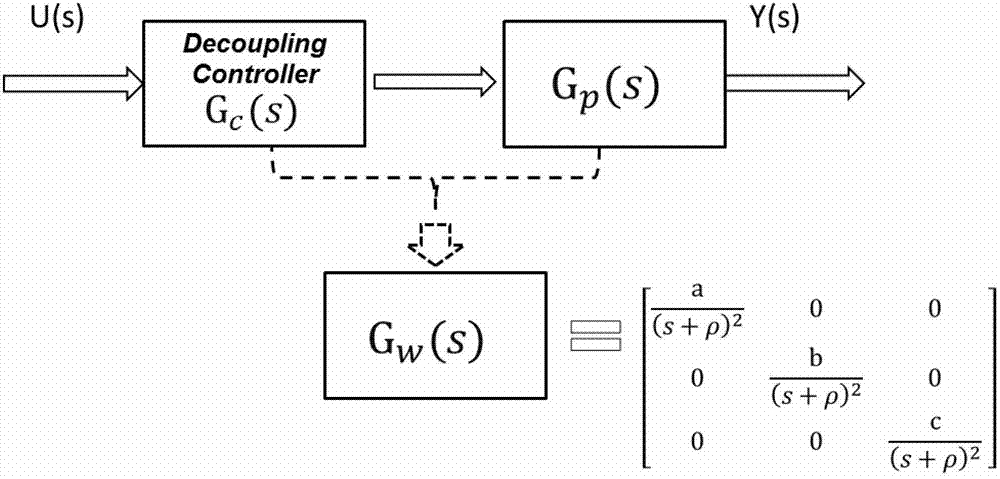

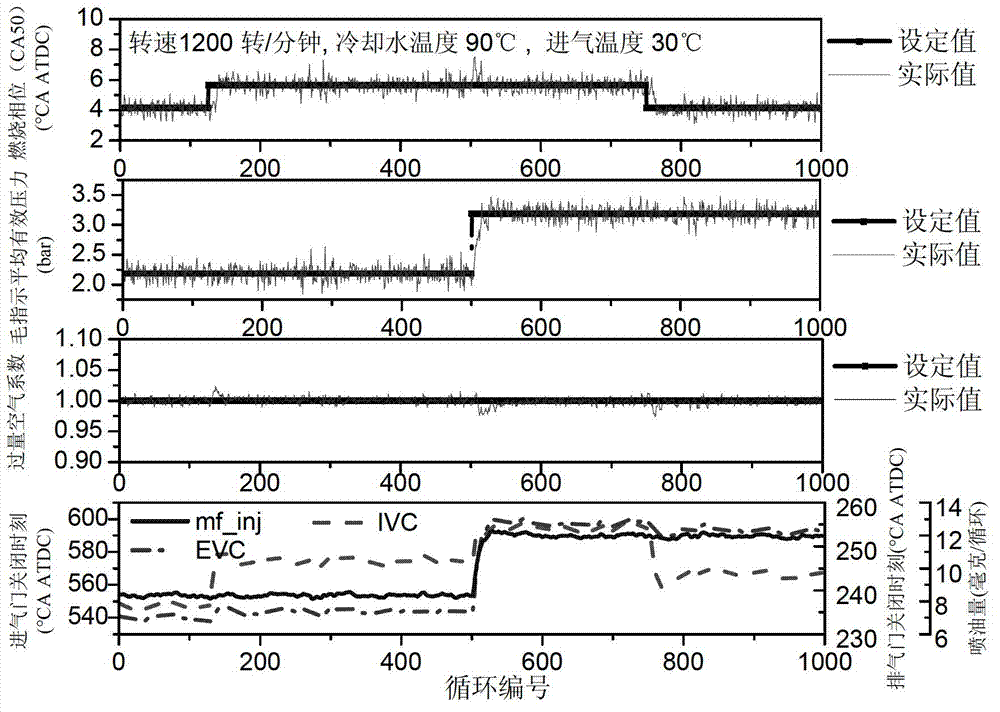

Model-based decoupling and disturbance-rejection control method for homogeneous charge compression ignition (HCCI)

ActiveCN103195599AReduce workloadReduce dependenceElectrical controlMachines/enginesHcci combustionActive disturbance rejection control

The invention discloses a model-based decoupling and disturbance-rejection control method for HCCI. The method comprises model-based decoupling control, active disturbance rejection control (ADRC), feed-forward control and self-adaptation compensation control for valve mechanism action delay. The method comprises the steps of designing a decoupling compensator on the basis of a control model of the HCCI, and converting an HCCI system into a plurality of independent single-input single-output (SISO) systems; conducting inversion on transfer functions of all SISO systems to obtain a feed-forward controller; designing ADRC controllers for all SISO systems respectively, and observing and compensating deviations of the model and random disturbance of the outside in real time; and estimating the action delay of a valve mechanism in real time, actively delaying an oil injection action, and obtaining the response speed which is the same as that of the valve mechanism. By the aid of the method, the modeling burden of the HCCI control model and the standard workload of controller parameters can be reduced greatly, the robustness for engine working condition variations is high, and the ignition process control is stable.

Owner:TIANJIN UNIV

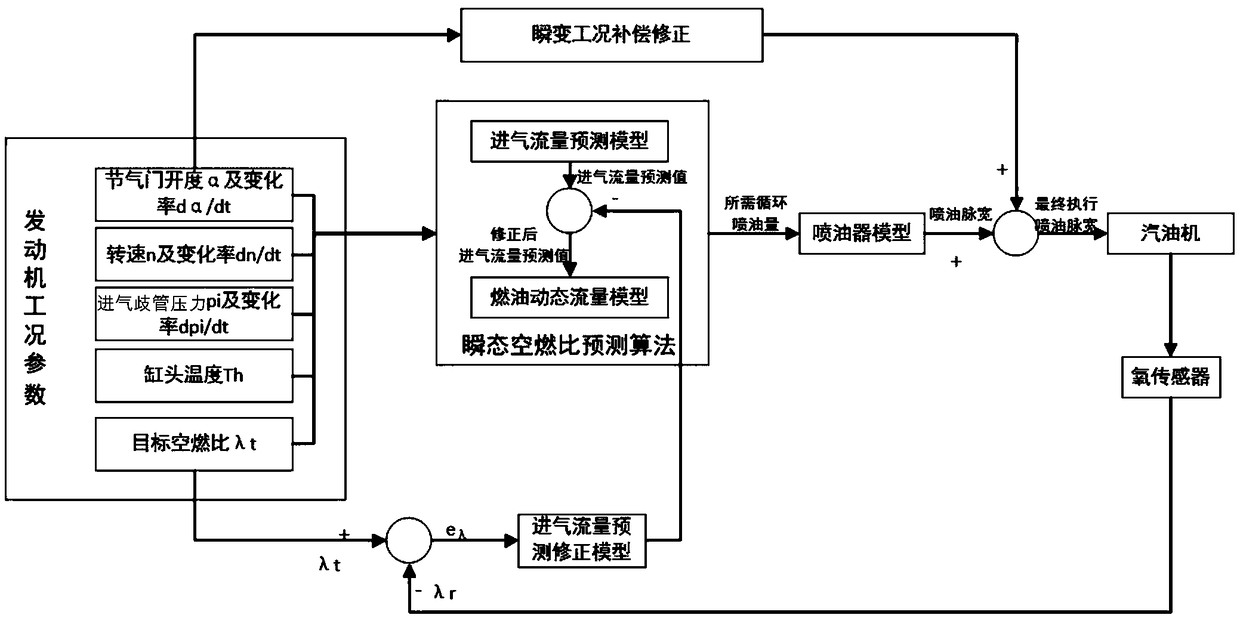

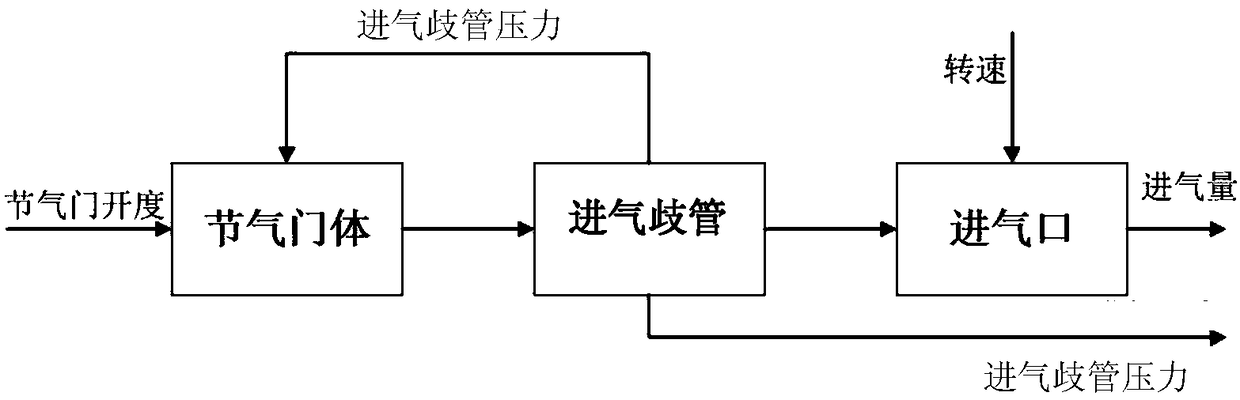

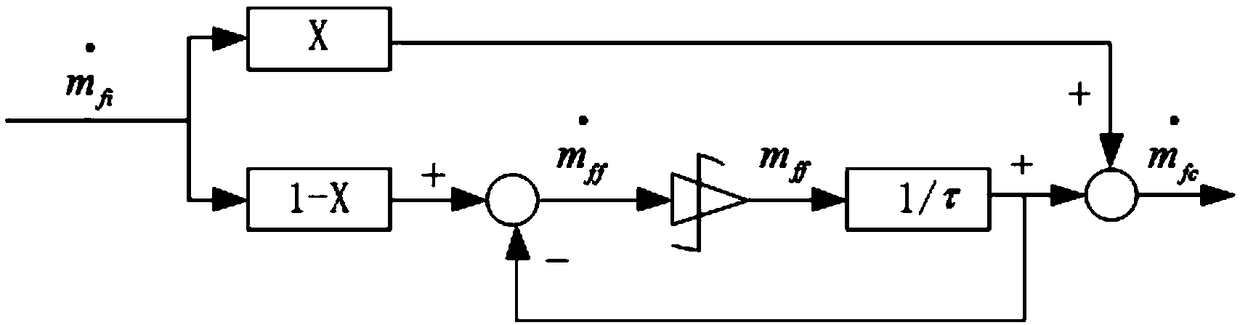

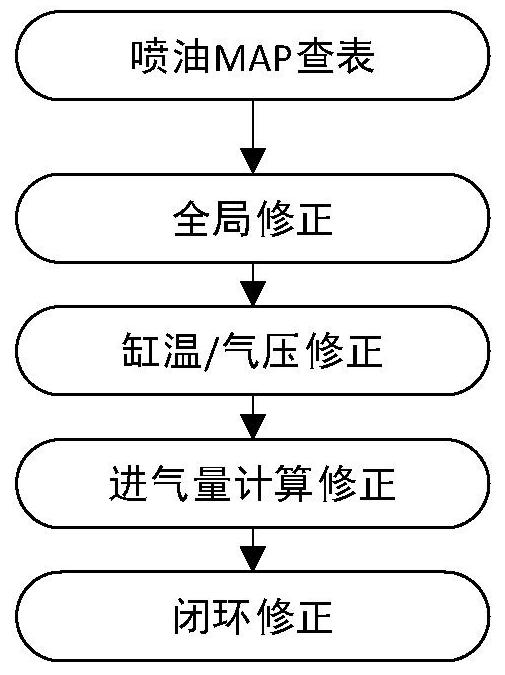

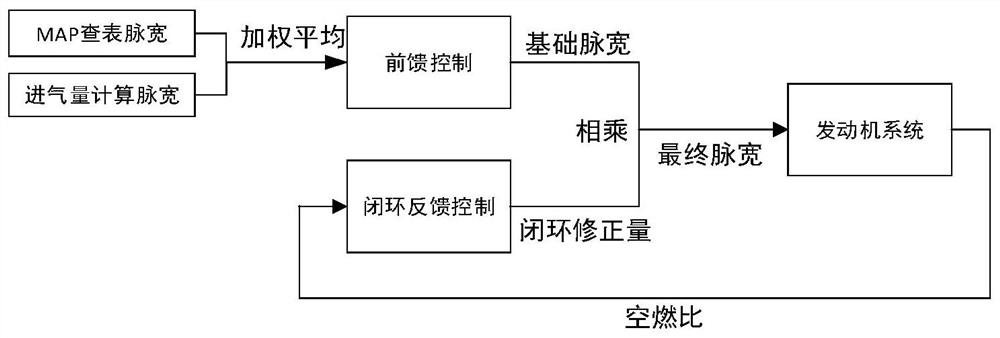

High-speed gasoline engine instantaneous condition air-fuel ratio control method

ActiveCN109184932ASmall steady state errorEmission reductionElectrical controlMachines/enginesFuel oilFeedback control

The invention discloses a high-speed gasoline engine instantaneous condition air-fuel ratio control method. The high-speed gasoline engine instantaneous condition air-fuel ratio control method comprises the following steps of acquiring gasoline engine instantaneous condition parameters, determining the key influence factors influencing instantaneous air-fuel control through multi-parameter sensitivity analysis, and building an intake air flow predication model; building a fuel oil dynamic flow model according to dynamic flow characteristics, spray characteristics and the evaporation rate of anoil atomizer; building an air-fuel ratio predication algorithm through the intake air flow predication model and the fuel oil dynamic flow model; correcting an intake air flow prediction model through an oxygen sensor feedback control algorithm; carrying out model training optimization to obtain instantaneous air-fuel ratio control strategy; calculating oil atomizer oil injection pulse width according to the set target air-fuel ratio, and using the oil injection pulse width as an oil injection instruction to carry out oil injection actions; and repeating the steps. With the high-speed gasoline engine instantaneous condition air-fuel ratio control method, variation trend of intake air flow can be predicated quickly and accurately on the high-speed gasoline engine instantaneous conditions,accurate control over the instantaneous air-fuel ratio is effectively achieved, emission is reduced, and the good dynamic property is guaranteed at the same time.

Owner:天津内燃机研究所(天津摩托车技术中心)

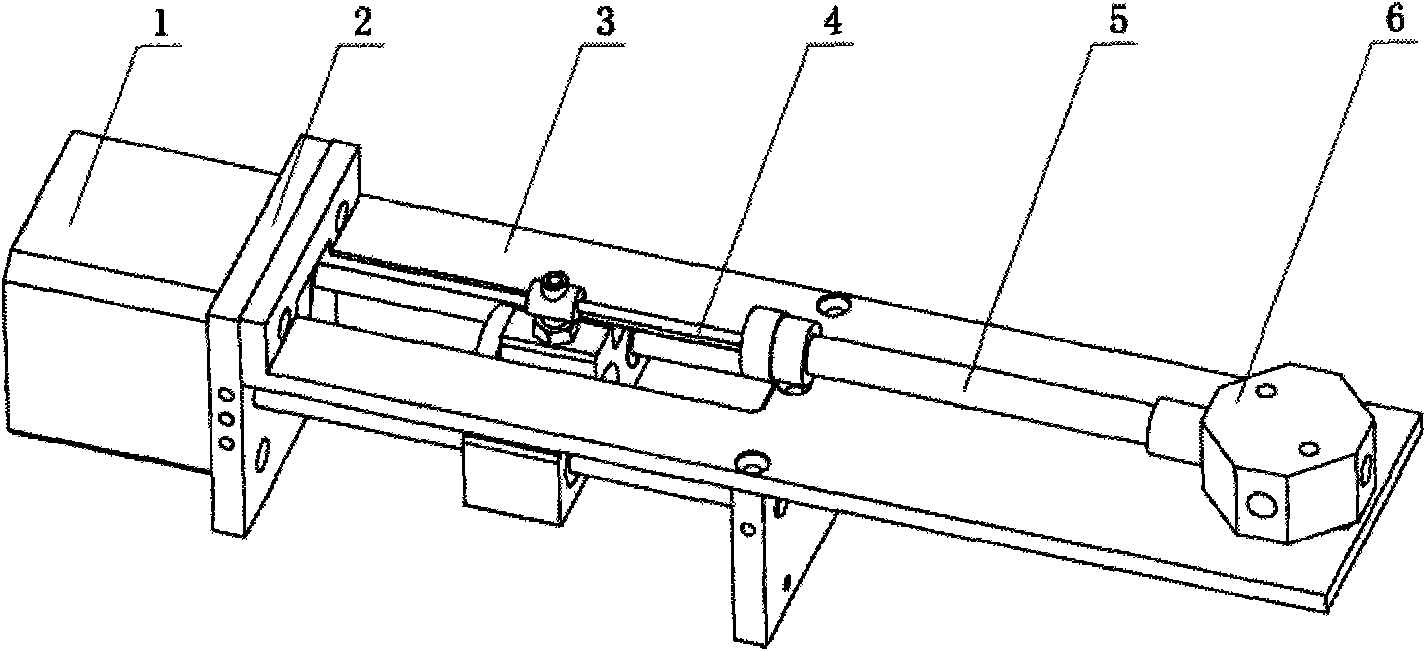

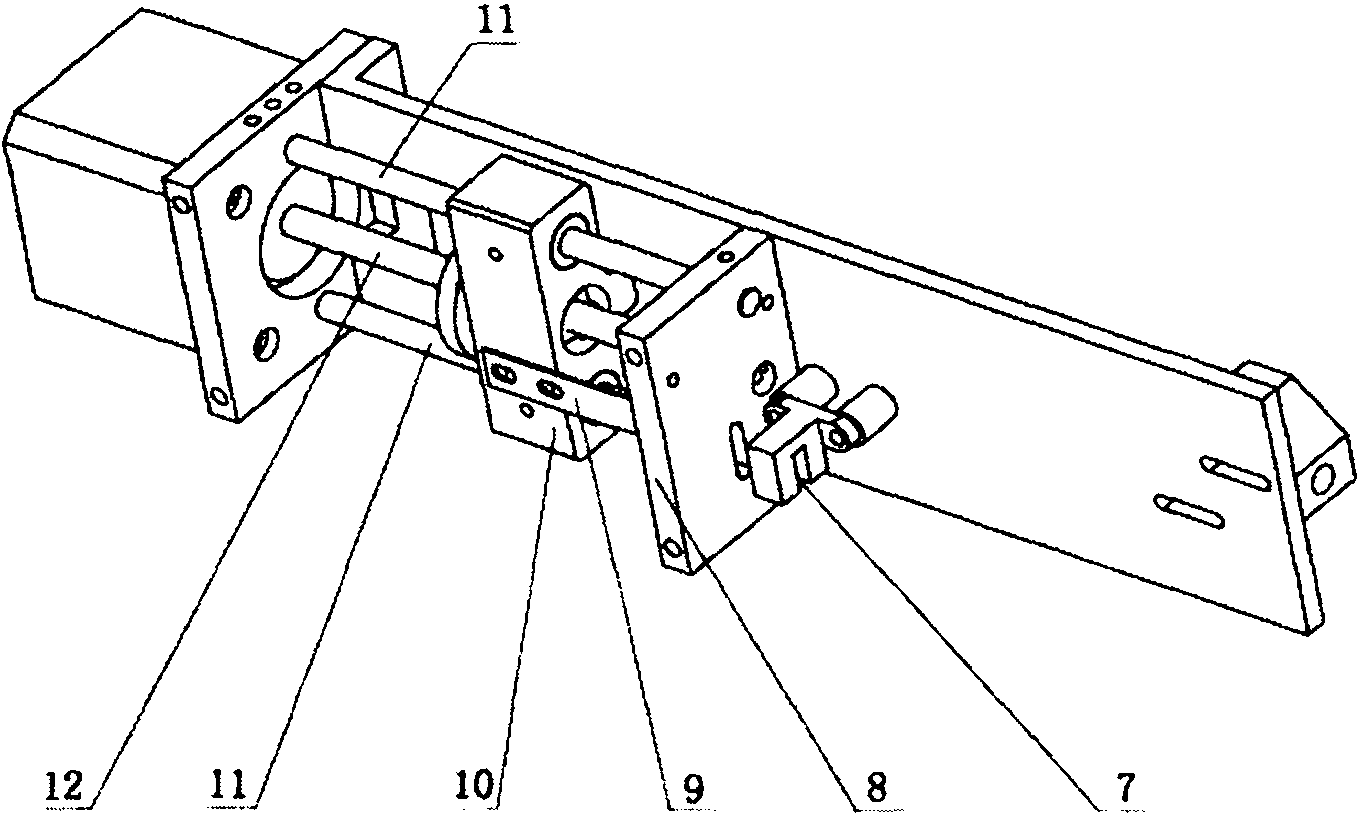

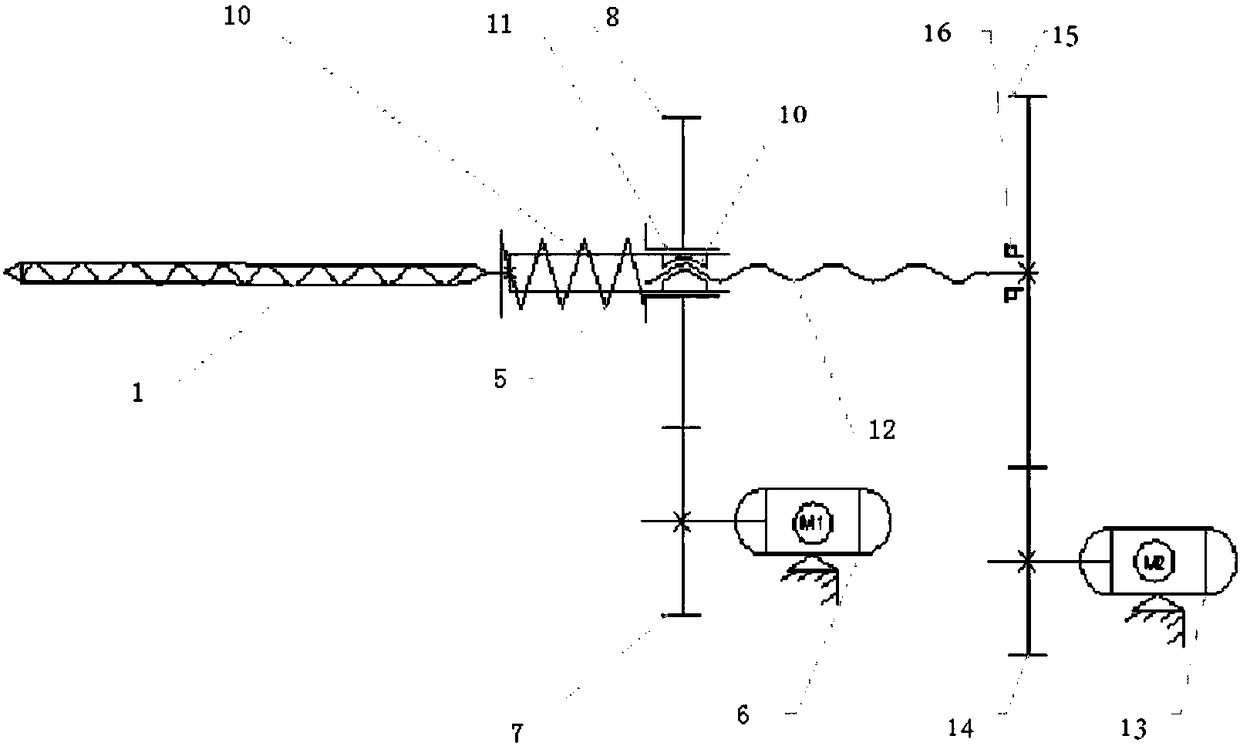

Automatic precision loading device

The invention relates to an automatic precision loading device of immunoassay technology. The automatic precision loading device comprises a stepping motor, a screw, a motor clamping plate, a motor front plate, an optical axis guide rail, an injection sliding block, a motor baffle plate, an injector, an optical coupling sensor, an optical coupling sheet and a three-way block, and is characterized in that: the stepping motor and a precision screw kinematic pair are taken as transmission components; the injection sliding block is connected with a piston of the injector and performs back-and-forth linear motion along the optical axis guide rail; and a trigger point of the optical coupling sensor is taken as a completion point of injection action and an initial point of a next action cycle. The design ensures the precision of the device, and particularly reliably ensures repeated precision; and the automatic precision loading device has a simple structure, is convenient to maintain and can realize full automatic quantitative loading of an instrument. The loading device is widely suitable for loading mechanisms such as luminescence detection analyzers, biochemical analyzers, electrolytic analyzers and the like which need quantitative loading instruments.

Owner:北京量质科技有限公司

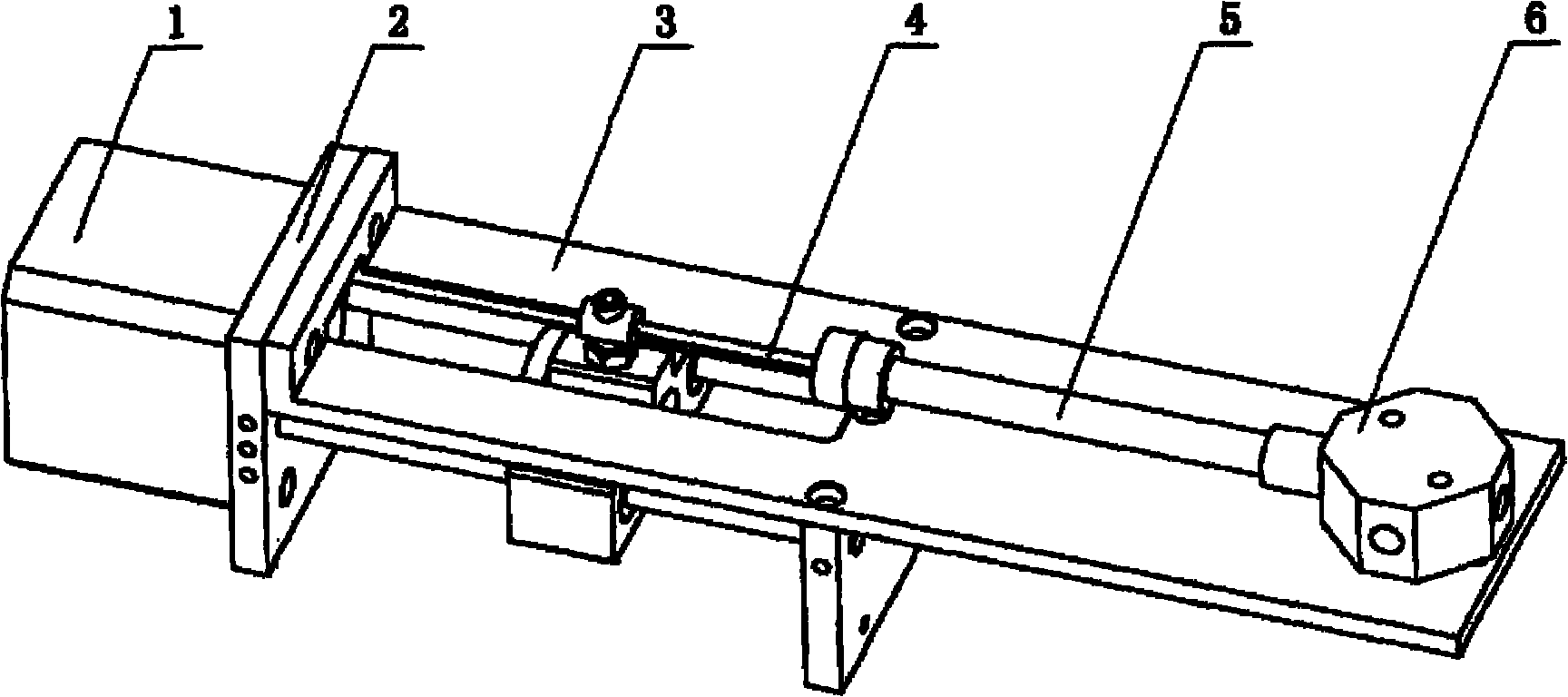

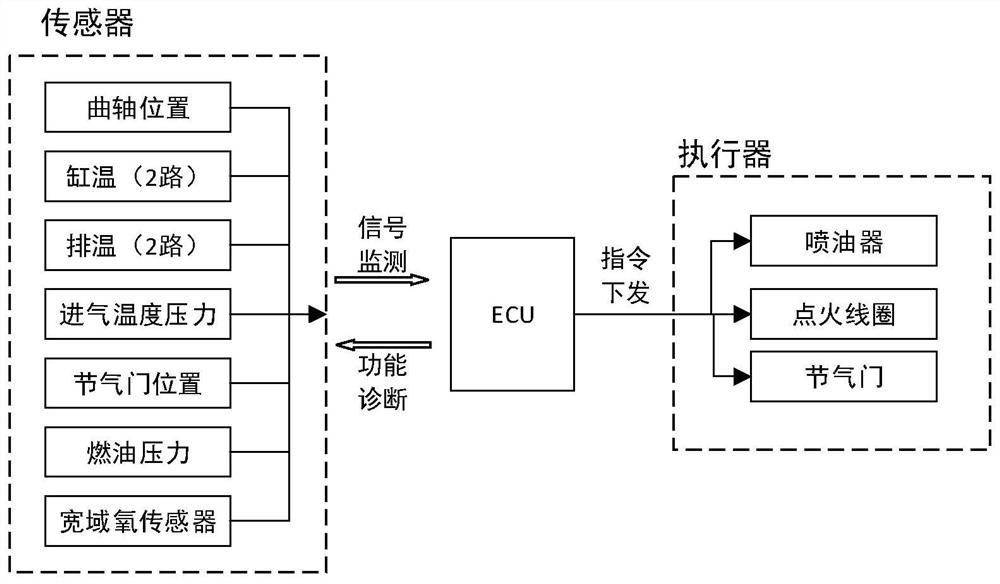

Control system and fault diagnosis method of aviation piston two-stroke supercharged engine

ActiveCN112664319AImprove performanceReduce closed-loop calculation timeElectrical controlInternal combustion piston enginesControl mannerControl system

Owner:AEROSPACE TIMES FEIHONG TECH CO LTD +1

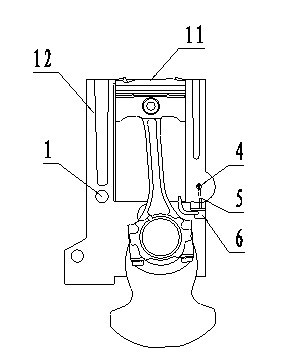

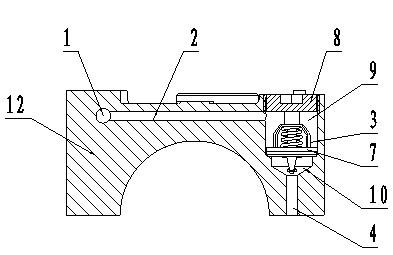

Engine piston cooling device

InactiveCN102678250AControl circulationReach circulationLiquid coolingMachines/enginesCooling effectInjection - action

An engine piston cooling device is used for solving the cooling problem of an engine in different operating conditions and comprises a control valve, a cylinder body main oil passage, a cylinder body auxiliary oil passage, a communicating oil passage, a cooling nozzle oil passage and a piston cooling nozzle assembly, wherein the one-way open / close of the control valve is controlled by sending the engine oil temperature, the control valve is installed at the tail of the communicating oil passage between the cylinder body main oil passage and the cylinder body auxiliary oil passage, the cylinder body main oil passage is communicated with an engine lubrication system element, and the cylinder body auxiliary oil passage is communicated with the piston cooling nozzle assembly through the cooling nozzle oil passage. According to the invention, the oil injection action is jointly controlled by the control valve and the pressure limiting valve of the piston cooling nozzle assembly, so as to ensure that the piston part can achieve the optimal cooling effect in different operating conditions of the engine.

Owner:GREAT WALL MOTOR CO LTD

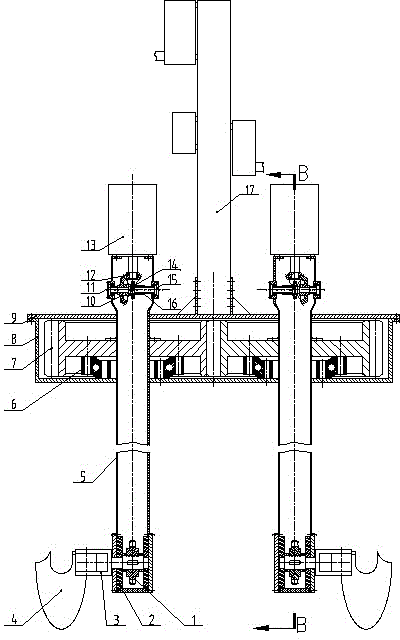

Puncture and intervention dual-effect assisting injection and suction method

InactiveCN108451601ARealize fully automatic extractionImprove securitySurgical needlesVaccination/ovulation diagnosticsDual effectInjection - action

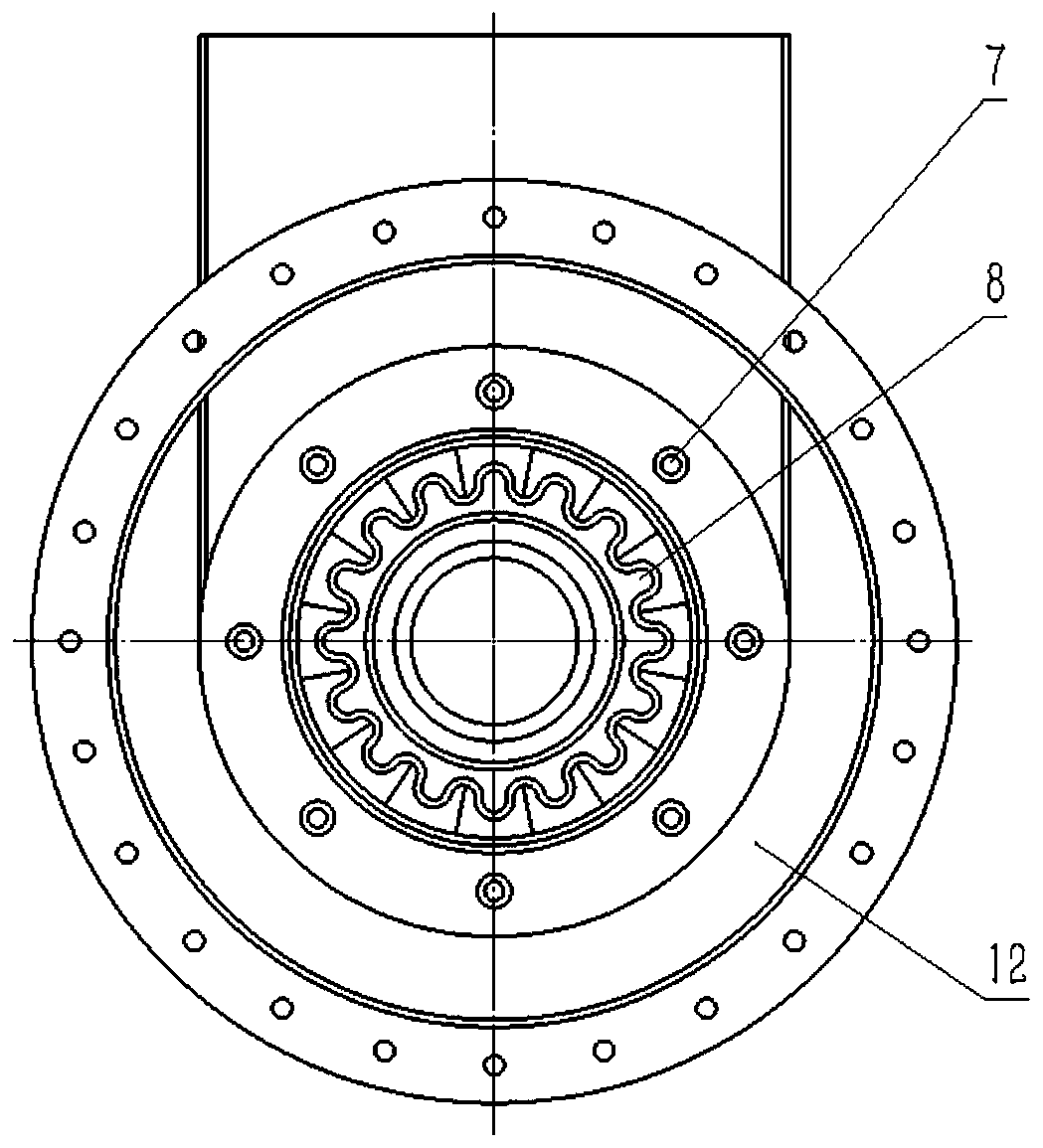

The invention provides a puncture and intervention dual-effect assisting injection and suction method, and belongs to the technical field of medical instruments and apparatuses. The method structurally involves an injector and further involves a speed adjustment advancing and retreating mechanism. A miniature forward and backward rotation low-speed motor conducts outputting to drive a driving gear. The driving gear is meshed with a driven gear constantly. The miniature forward and backward rotation low-speed motor rotates forward and backward to drive an inclined rotating shaft to rotate forward and backward. The inclined rotating shaft rotates forward and backward for outputting to drive a slider to rotate forward and backward. The slider rotates forward and backward opposite to the forward and backward rotation of a rotary rolling conical roller body for outputting to drive a through shaft to rotate forward and backward. The through shaft rotates forward and backward together with the forward and backward rotation of a threaded section through shaft to drive a nut to horizontally slide forward and backward along a linear rail key. The nut horizontally slides forward and backwardto drive a piston rod to move forward and backward. The piston rod acts on an injector cylinder body, so the injection action or suction action is realized; full-automatic suction is realized, safetyis high, intermittent controllable injection or suction can be realized, and the design is ingenious.

Owner:刘振波

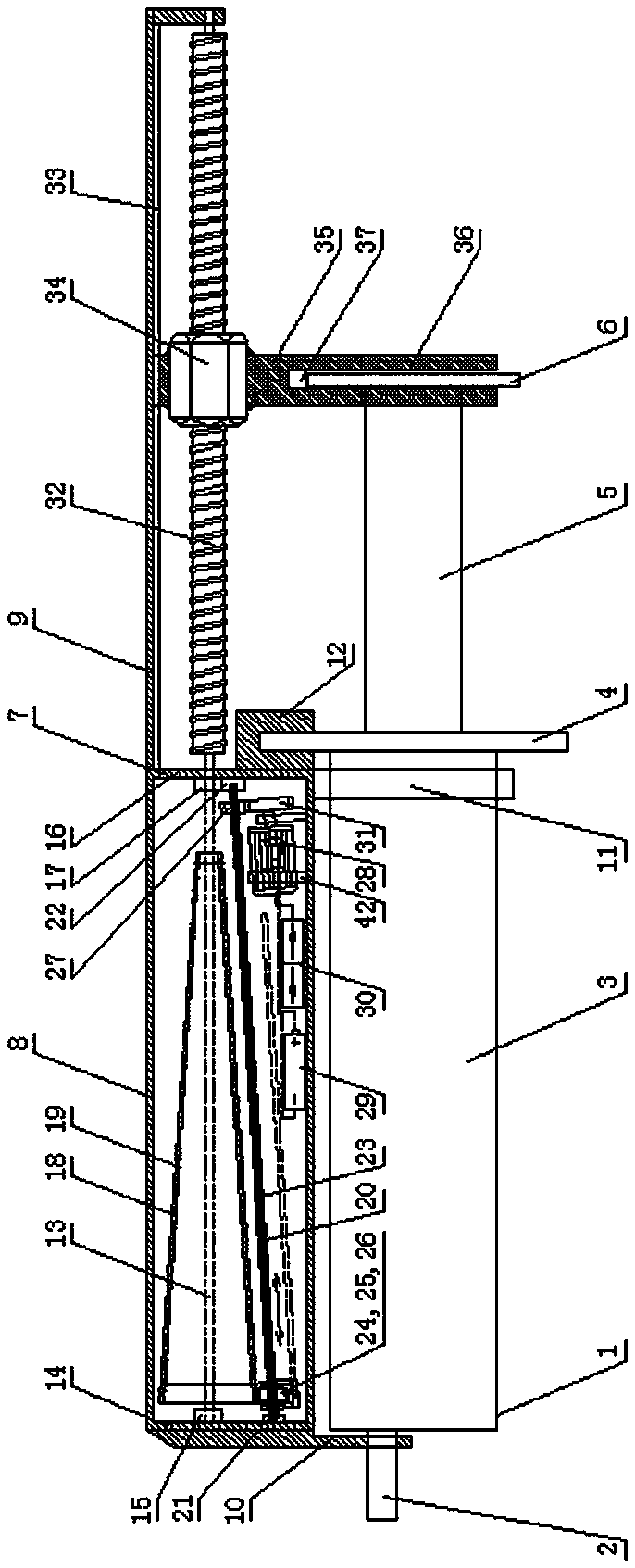

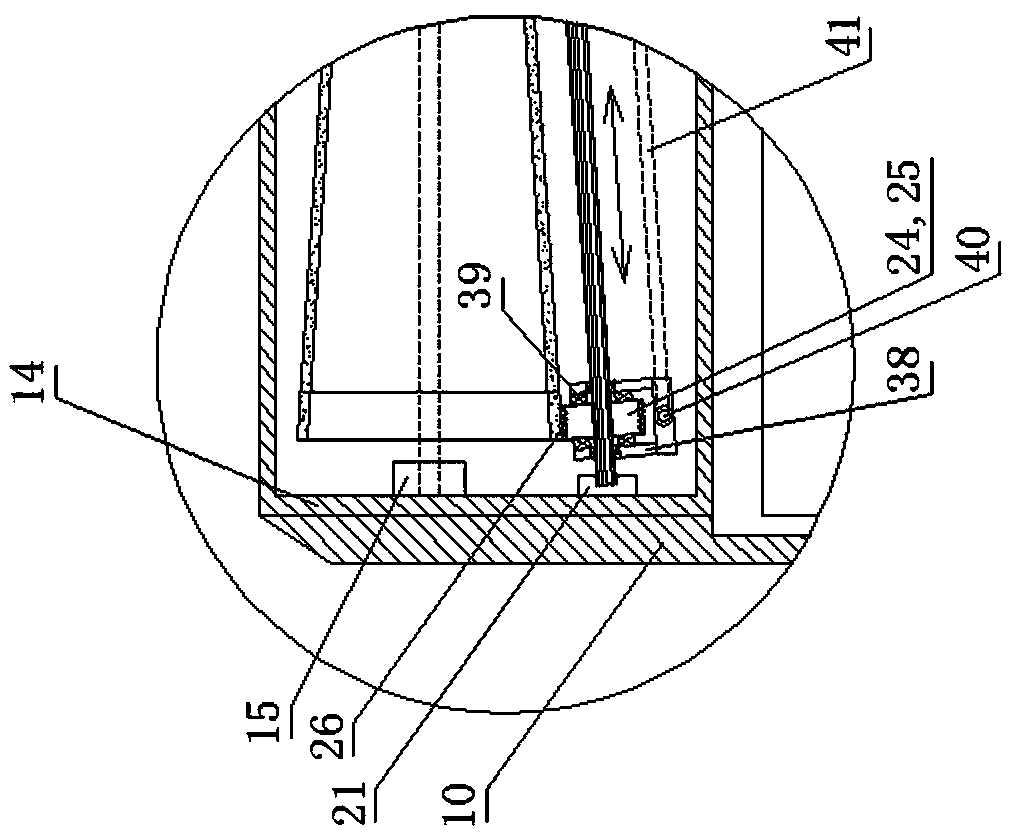

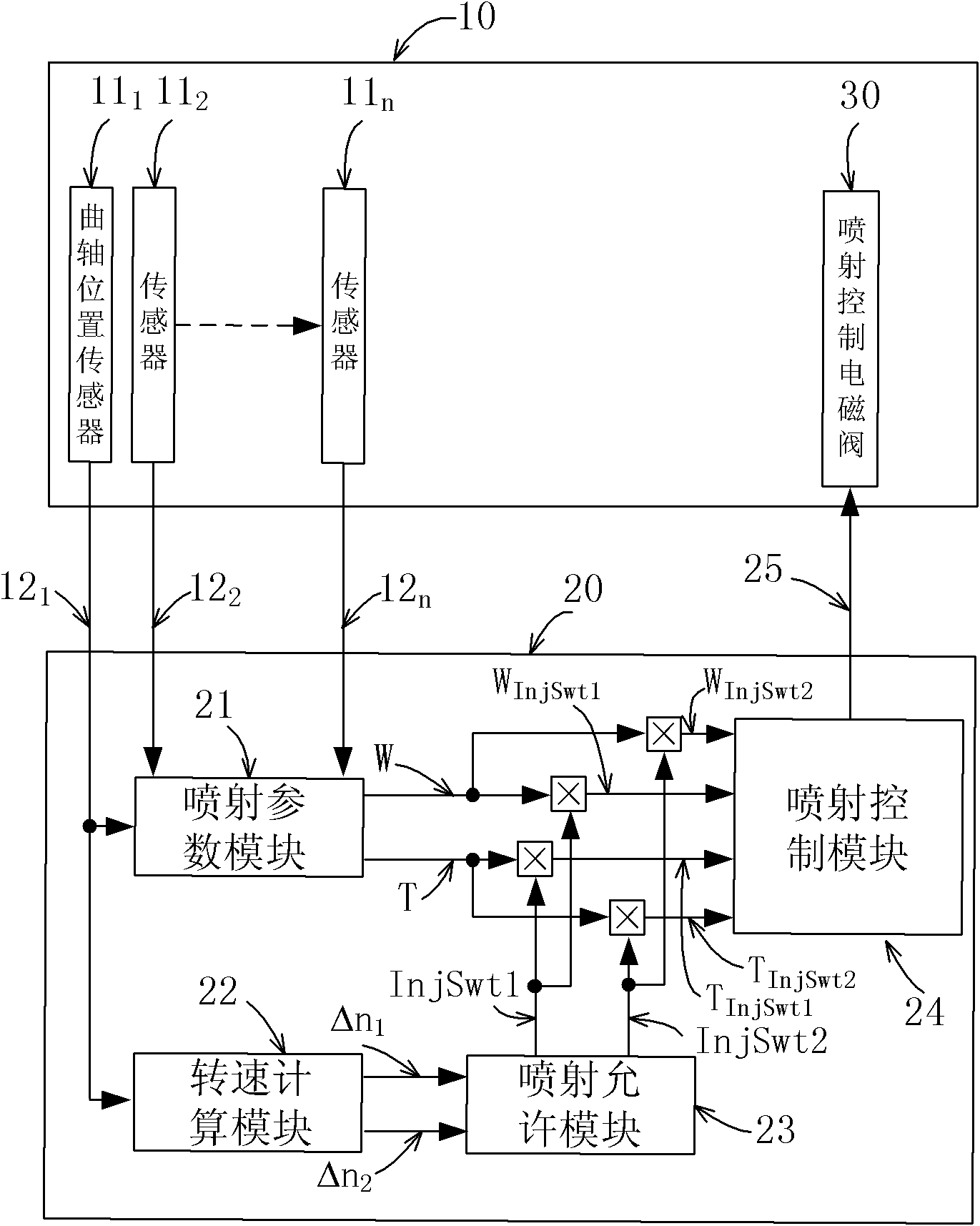

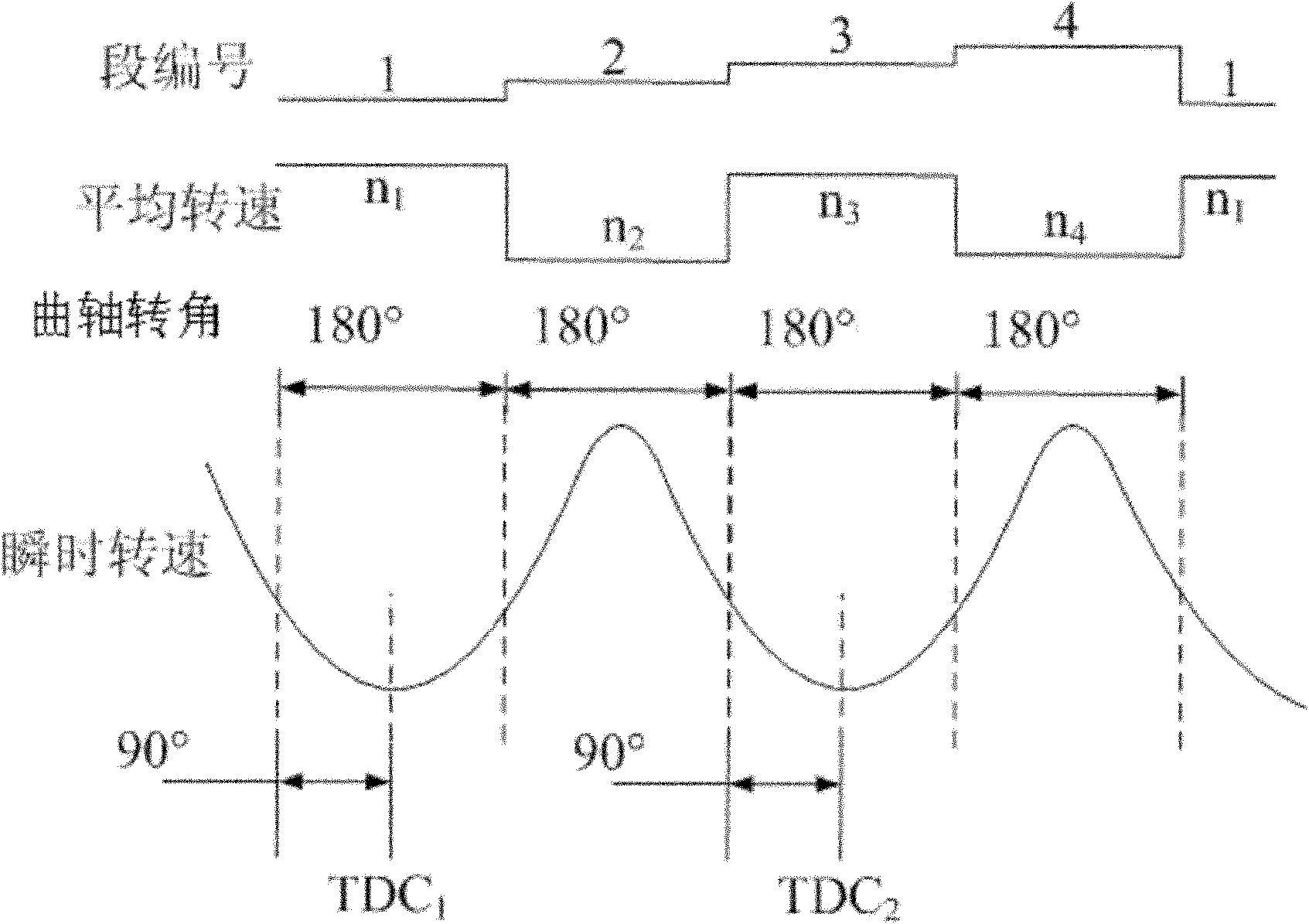

Fuel injection control method and system for four-stroke electronic-control single cylinder diesel

ActiveCN102128098APerformance impactLow costElectrical controlMachines/enginesTop dead centerSolenoid valve

Owner:TSINGHUA UNIV +1

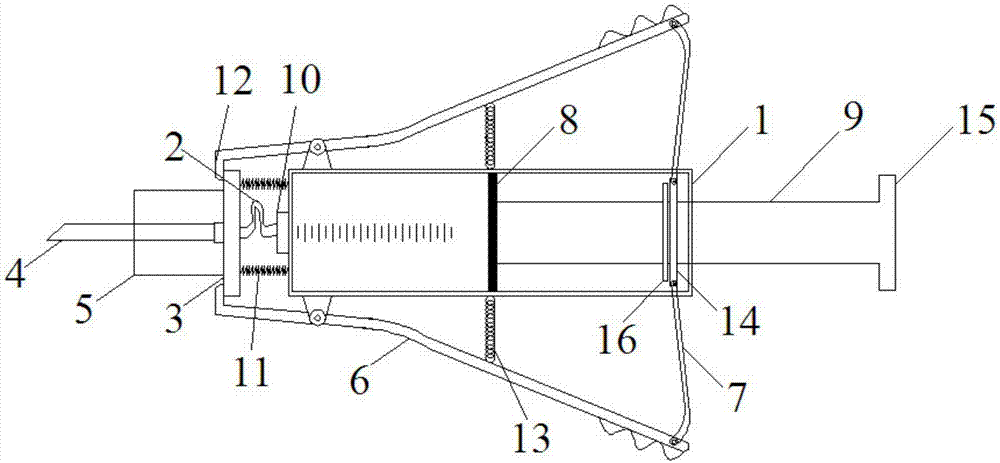

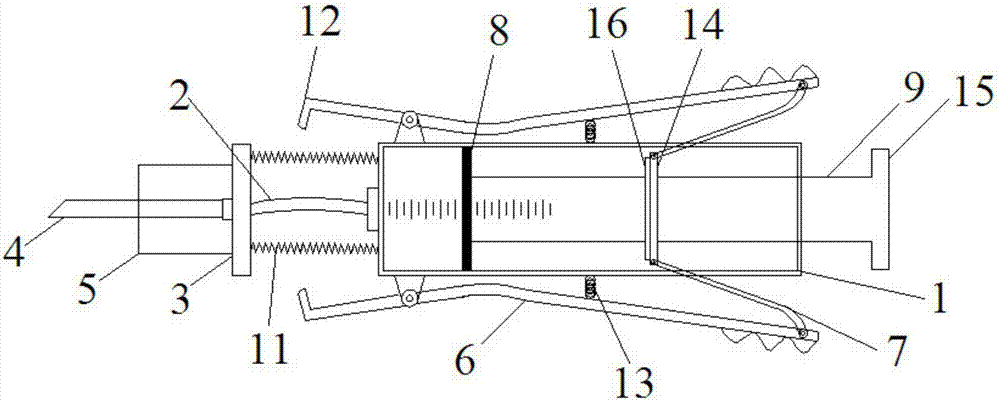

Veterinary injector

InactiveCN107397606APrevent bent needlesTo prevent the phenomenon of needle breakageVeterinary instrumentsInjection - actionSyringe needle

The invention provides a veterinary injector and belongs to the technical field of medical devices. The veterinary injector comprises an injection cylinder, an infusion hose, a needle seat, a needle, a limiting ring, a pivot-rotating device, a piston and a piston rod. The limiting ring is arranged on the output end face of the needle seat; the input end face of the needle seat is connected with the output end face of the injection cylinder through a plurality of first springs; and the pivot-rotating device comprises levers and pushing rods, the front ends of the levers are provided with a stop piece, and the rear ends of the levers are connected with one ends of the pushing rods in a pivoted mode. According to the veterinary injector, the needle with the hose is conveniently pricked into an animal body through the springs; the length of the needle into the animal body is limited through the limiting ring; meanwhile, the phenomenon that the needle shakes, thus the needle is deviated or falls off can be prevented through the limiting ring; through the pivot-rotating device, the needle pricking and injection action is sequentially completed at a time, and the situation that in the needle pricking process, a medicine is pushed out is avoided; and through the pivot-rotating device, the labor is relatively saved in medicine pushing, and operation is quite convenient.

Owner:XINYANG AGRI & FORESTRY UNIV

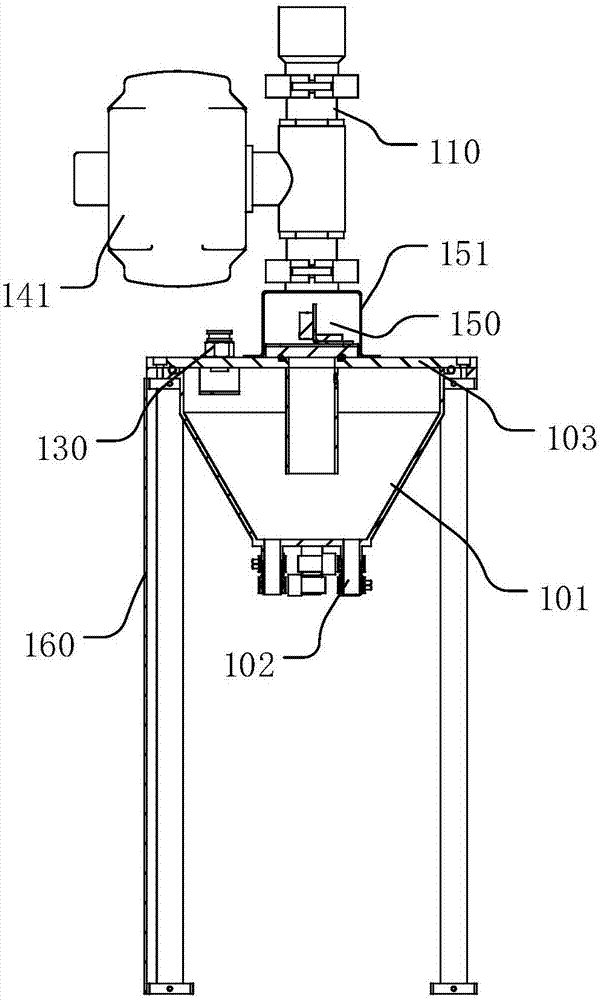

Slurry injection device and control method thereof

The invention discloses a slurry injection device and a control method thereof. The slurry injection device comprises a slurry container and a slurry quantification part. The slurry container is provided with a slurry inlet, a slurry outlet and an inflation port. The slurry quantification part has a slurry absorption port and a slurry injection port. The slurry outlet is communicated with the slurry absorption port. The slurry quantification part absorbs slurry from the slurry container by a slurry absorption action and completes slurry injection through the slurry injection port by a slurry injection action. The inflation port is connected to an inflation device. According to the slurry injection device, through arrangement of the slurry container, slurry is pressurized in the slurry container and then injected into a piston pump; and under pressure action, the piston pump is filled with the slurry so as to guarantee uniform and stable slurry injection of the piston pump.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

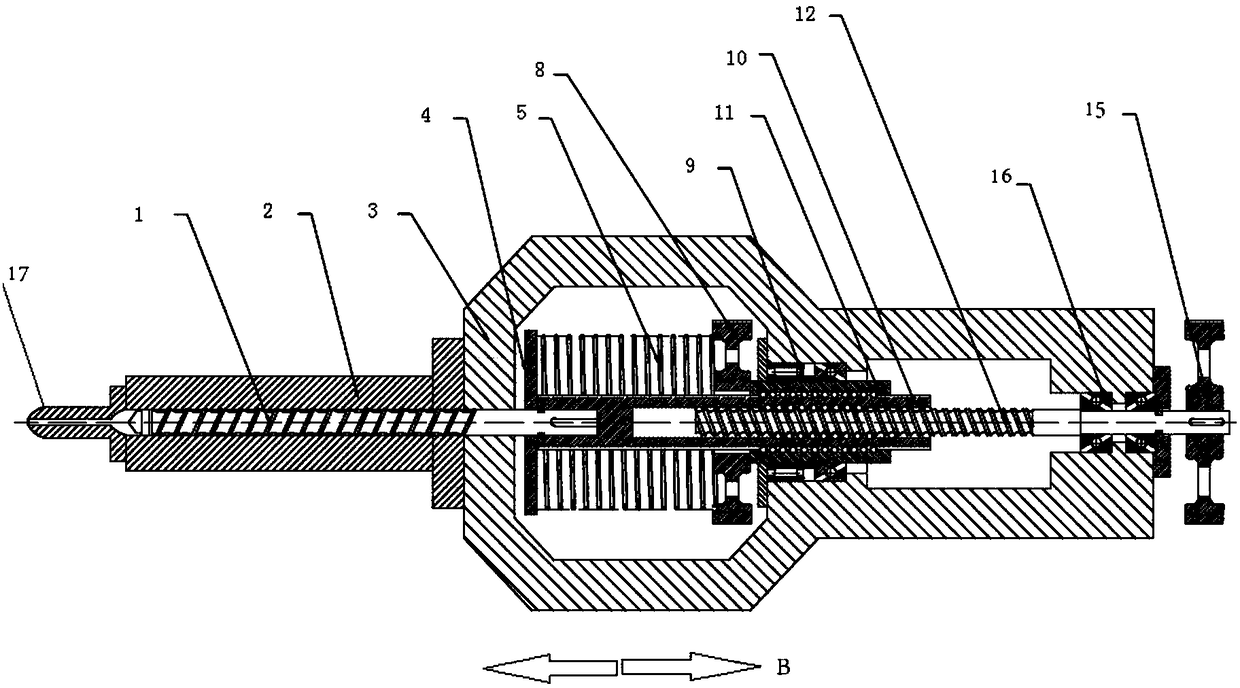

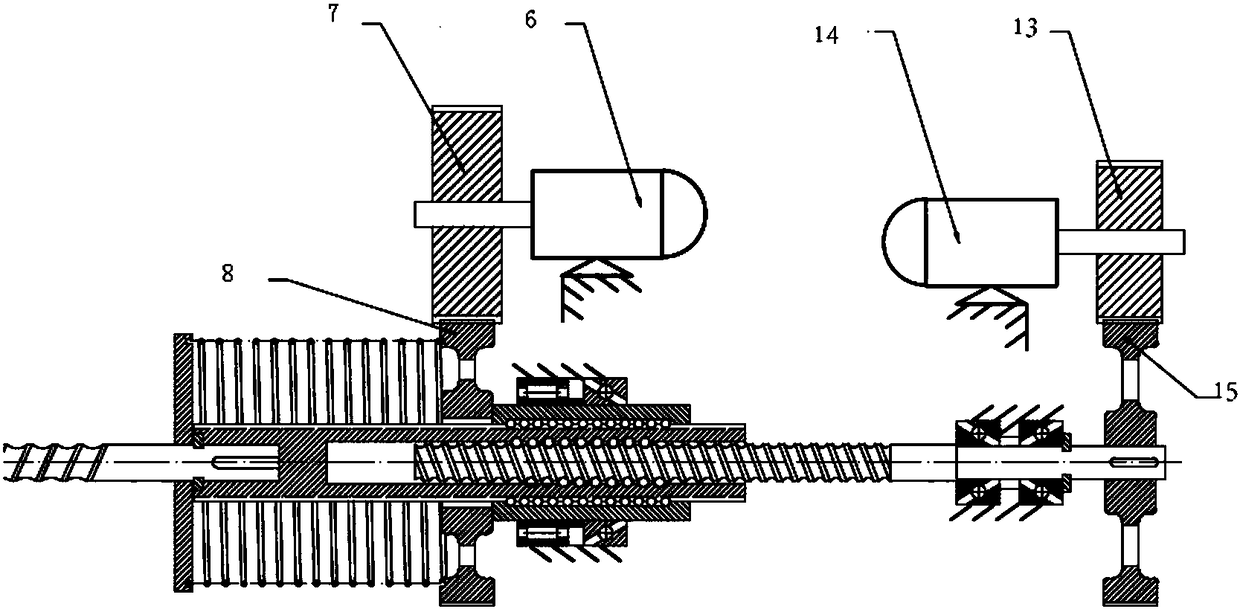

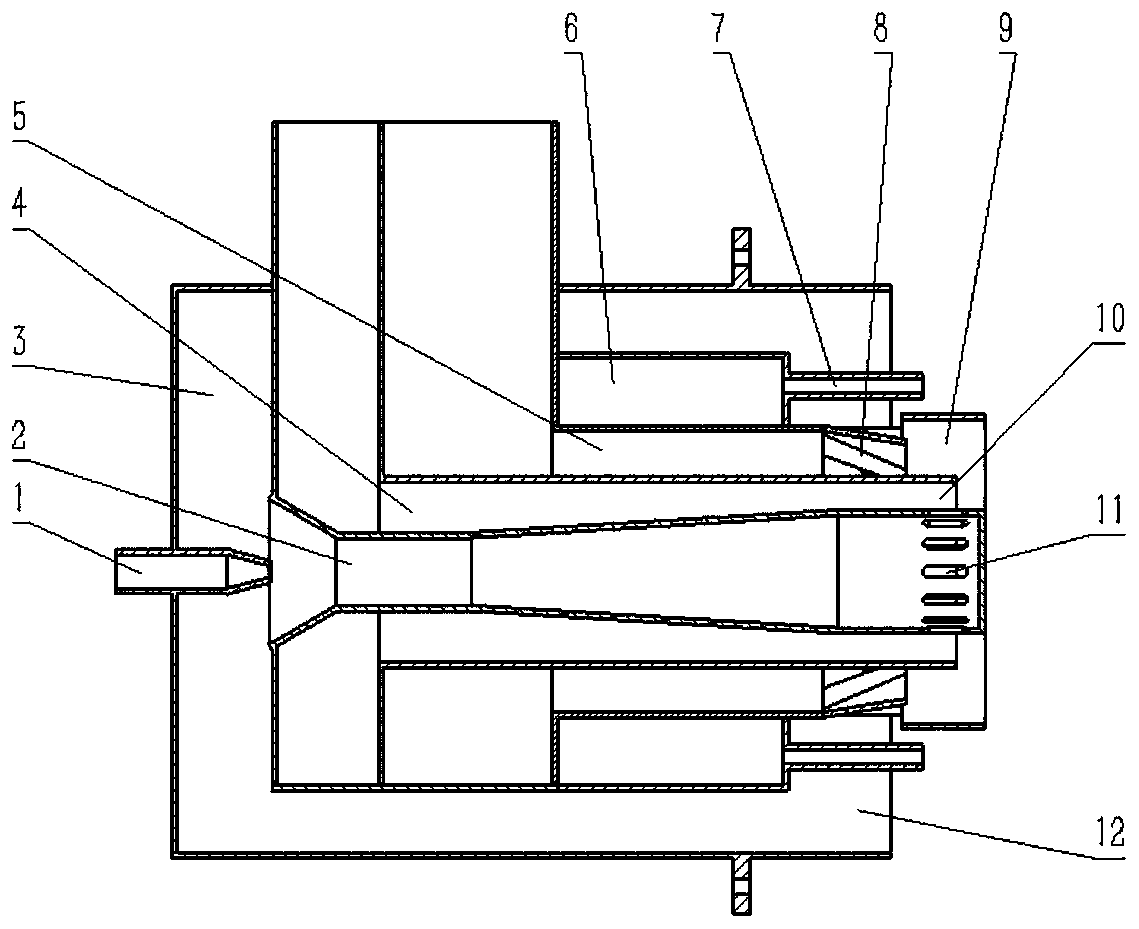

High-performance electric injection molding device

PendingCN108943624AReduce coefficient of frictionImprove injection accelerationInjection - actionInjection molding machine

The invention provides a high-performance electric injection molding mechanism and an injection molding machine. The injection molding mechanism comprises a screw, a screw driving shaft, a ball screwand an axial guiding mechanism, wherein the screw driving shaft comprises a ball spline and a ball nut. When the injection molding mechanism and the injection molding machine provided by the inventionperform injection action, only a small number of parts, including the screw, the screw driving shaft and the like, need to move, and the other driving and transmission parts do not move axially withthe injection action; and the mechanism has light weight during injection movement, so movement inertia is greatly reduced, and thus, the response speed and accuracy of the injection action are greatly improved, and driving power is also greatly reduced.

Owner:GIENKEE PLAS SCI & TECH SUZHOU

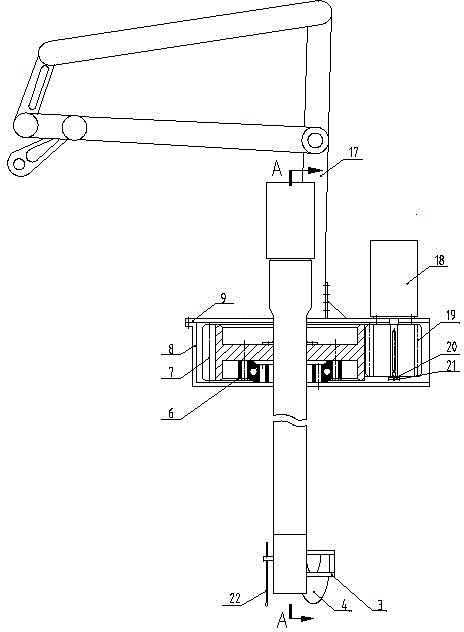

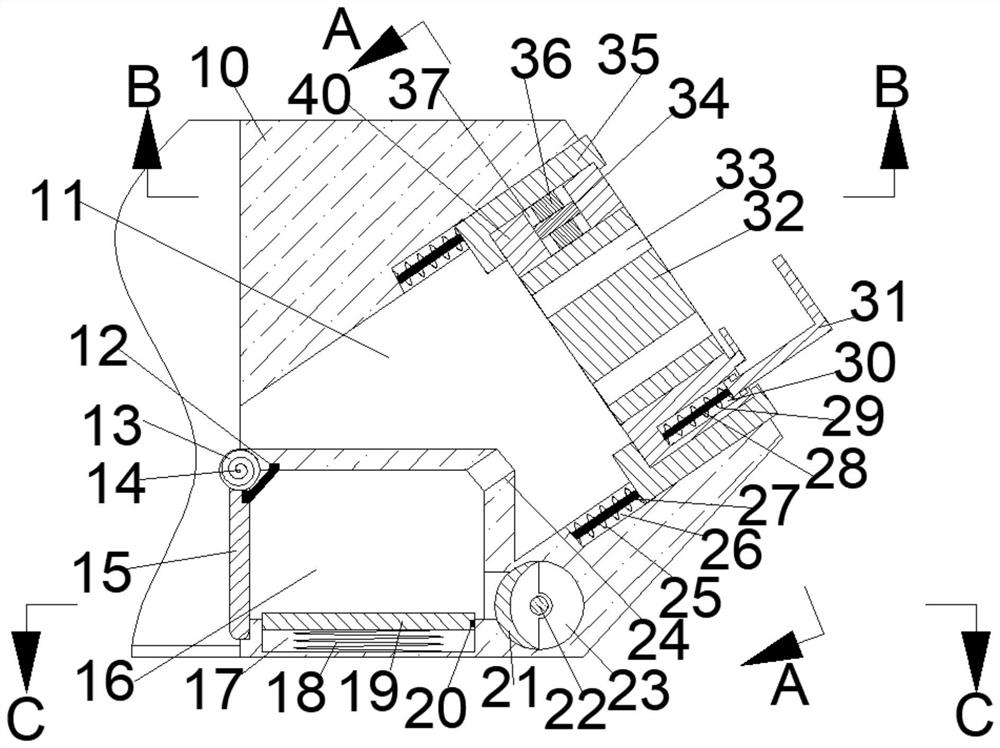

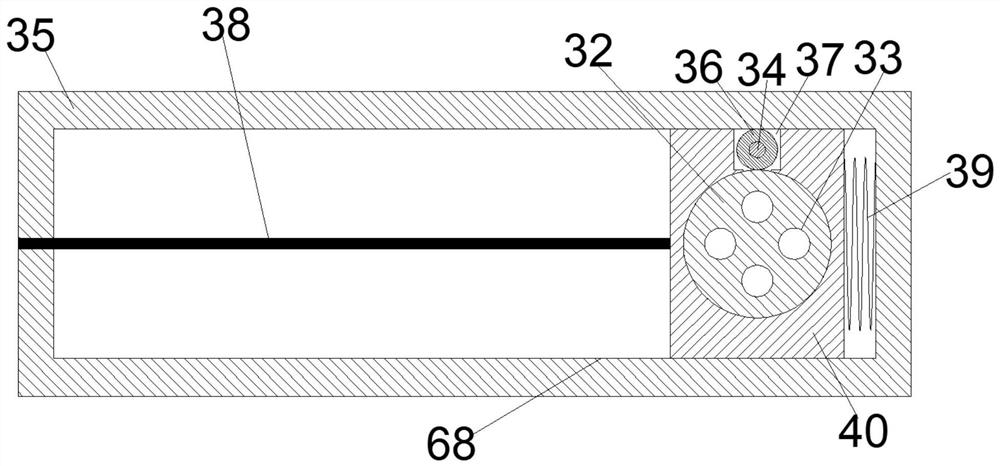

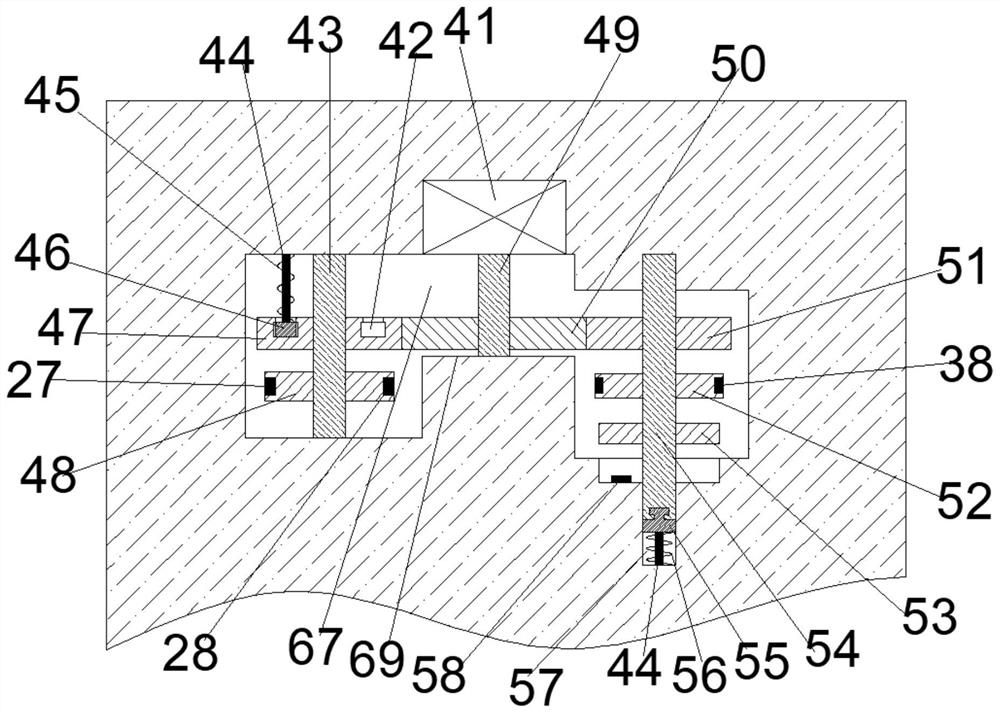

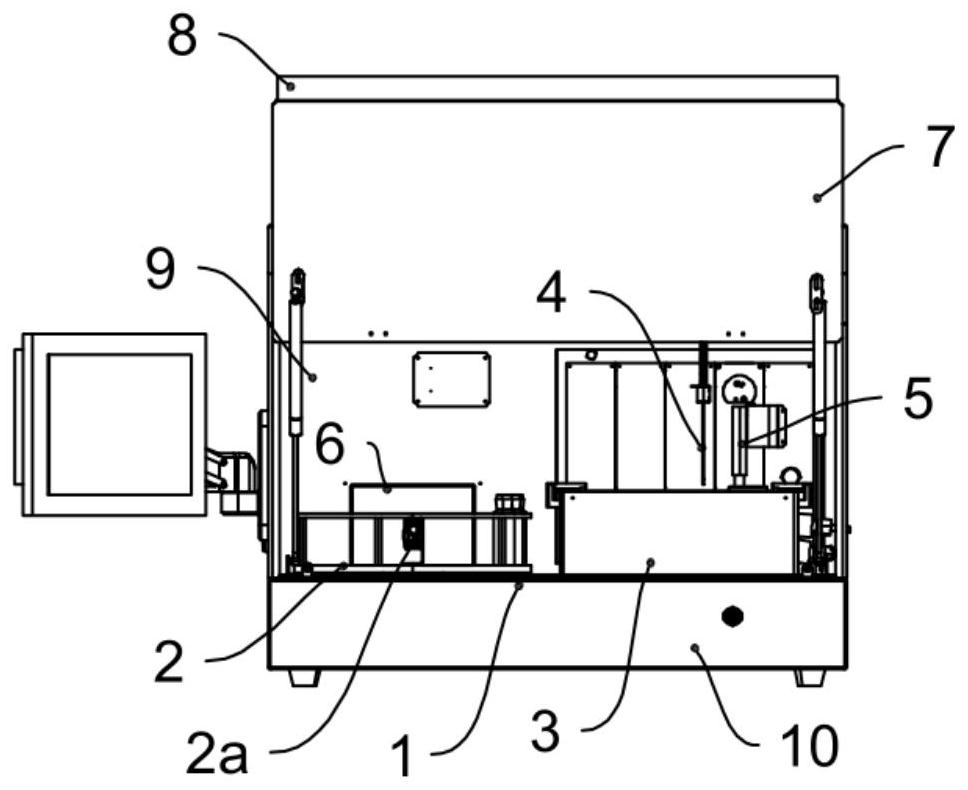

Five-rod fluid feeding machine double-pony ladle mechanical arm

ActiveCN103949623AAvoid interferenceSave production spaceMolten metal conveying equipmentsGear wheelEngineering

The invention discloses a five-rod fluid feeding machine double-pony ladle mechanical arm. The five-rod fluid feeding machine double-pony ladle mechanical arm comprises an arm driving mechanism and a pony ladle driving mechanism, wherein the arm driving mechanism is connected to a fixed plate; a gear mechanism is driven to rotate by a servo motor so as to drive the rotation of the mechanical arm; the pony ladle driving mechanism utilizes the servo motor to drive the gear mechanism to realize meshing motion, sprocket wheels on a sprocket shaft are driven, a sprocket wheel chain mechanism is driven, a pony ladle adjusting plate and a pony ladle are driven to rotate, and fluid fetching and injection actions are realized; the micro change of a position is realized by changing mounting holes in the adjusting plate, and the position is more accurate. The five-rod fluid feeding machine double-pony ladle mechanical arm is matched with a solution furnace with a small size for use, the problem that a mechanical arm double-pony ladle device intervenes with the solution furnace is solved, moulds with different distance sprues are poured, the mechanical arm can be mounted on a five-rod fluid feeding machine for use, the production cost is reduced, and the production efficiency is improved.

Owner:东台城东科技创业园管理有限公司

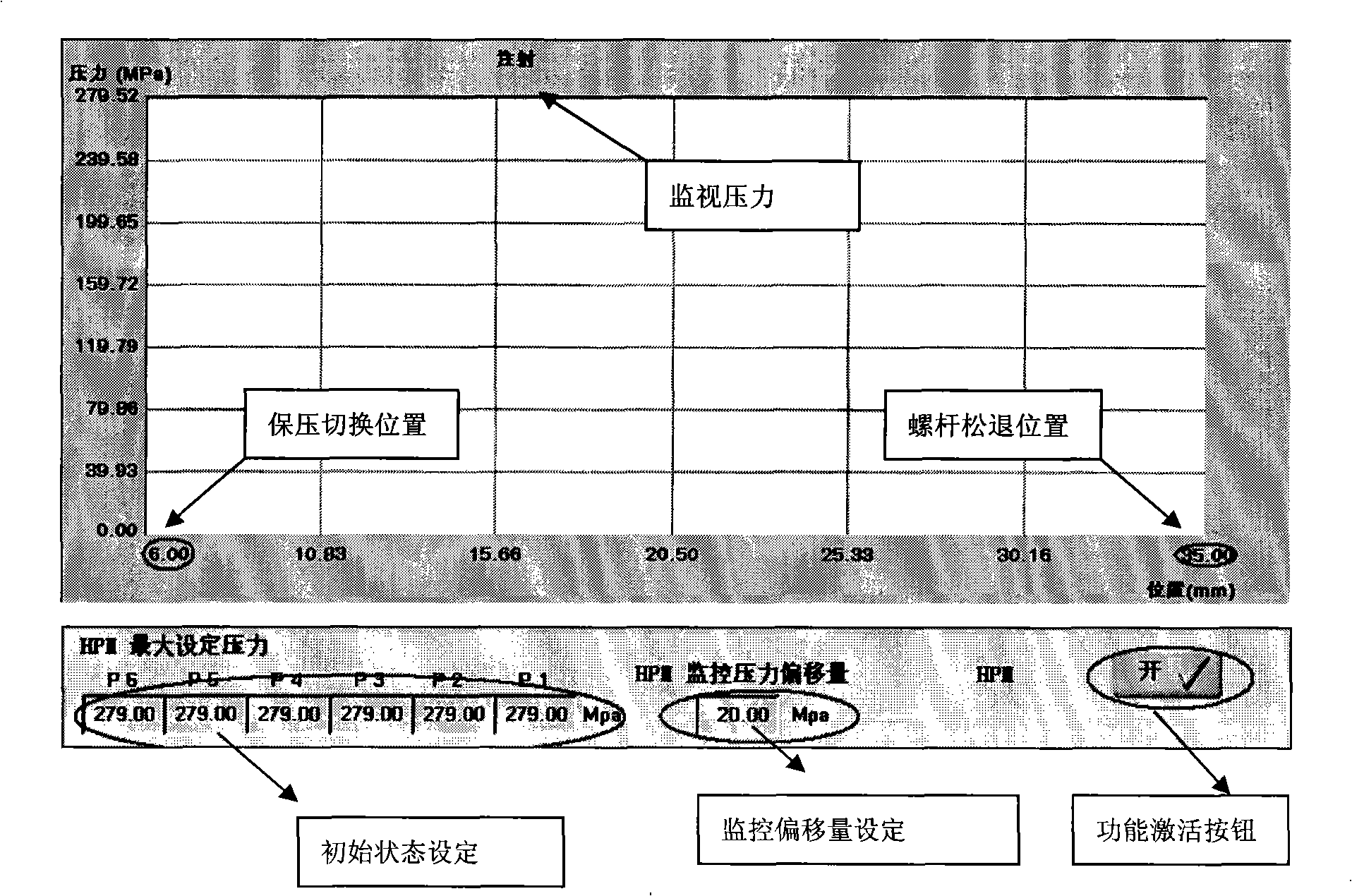

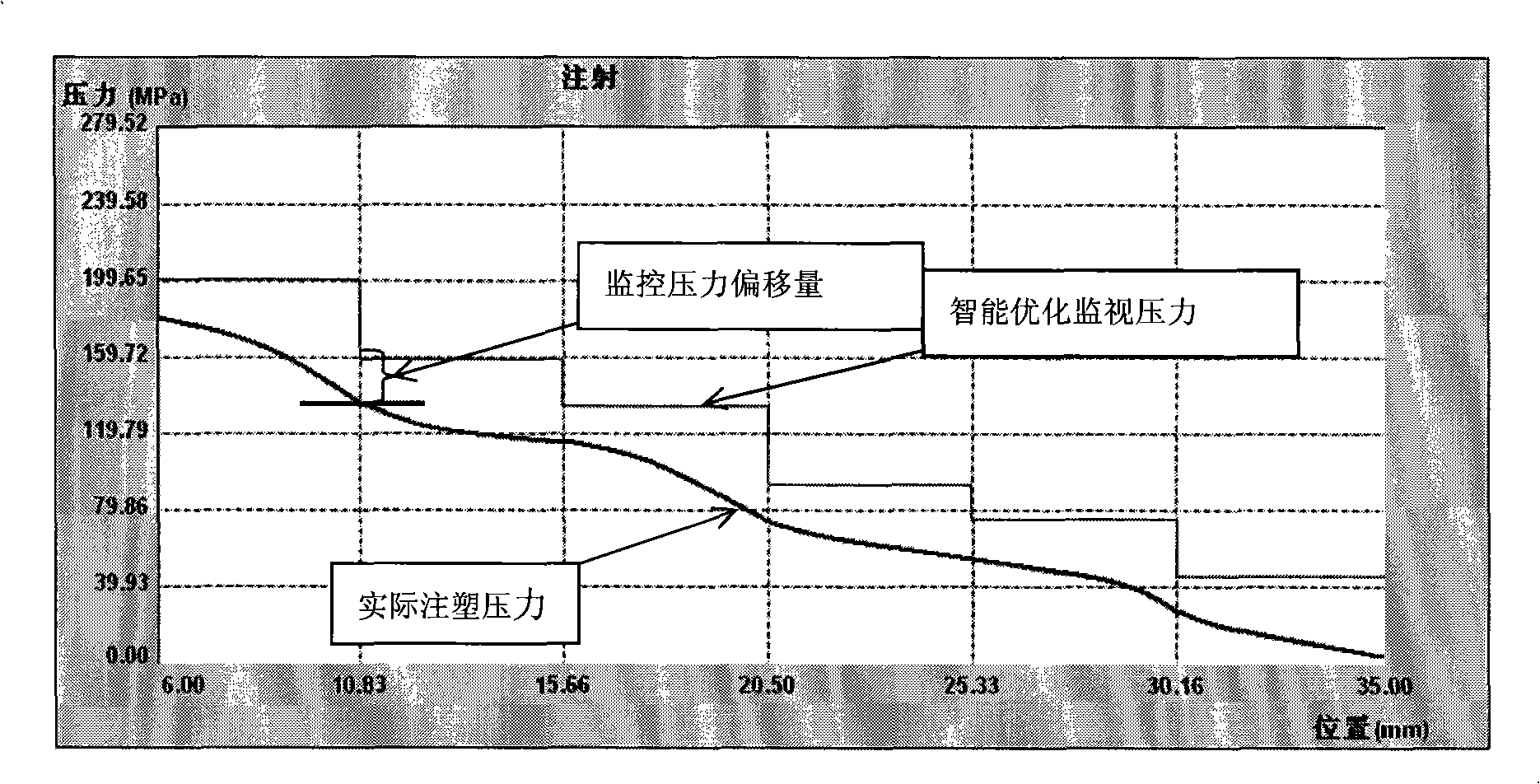

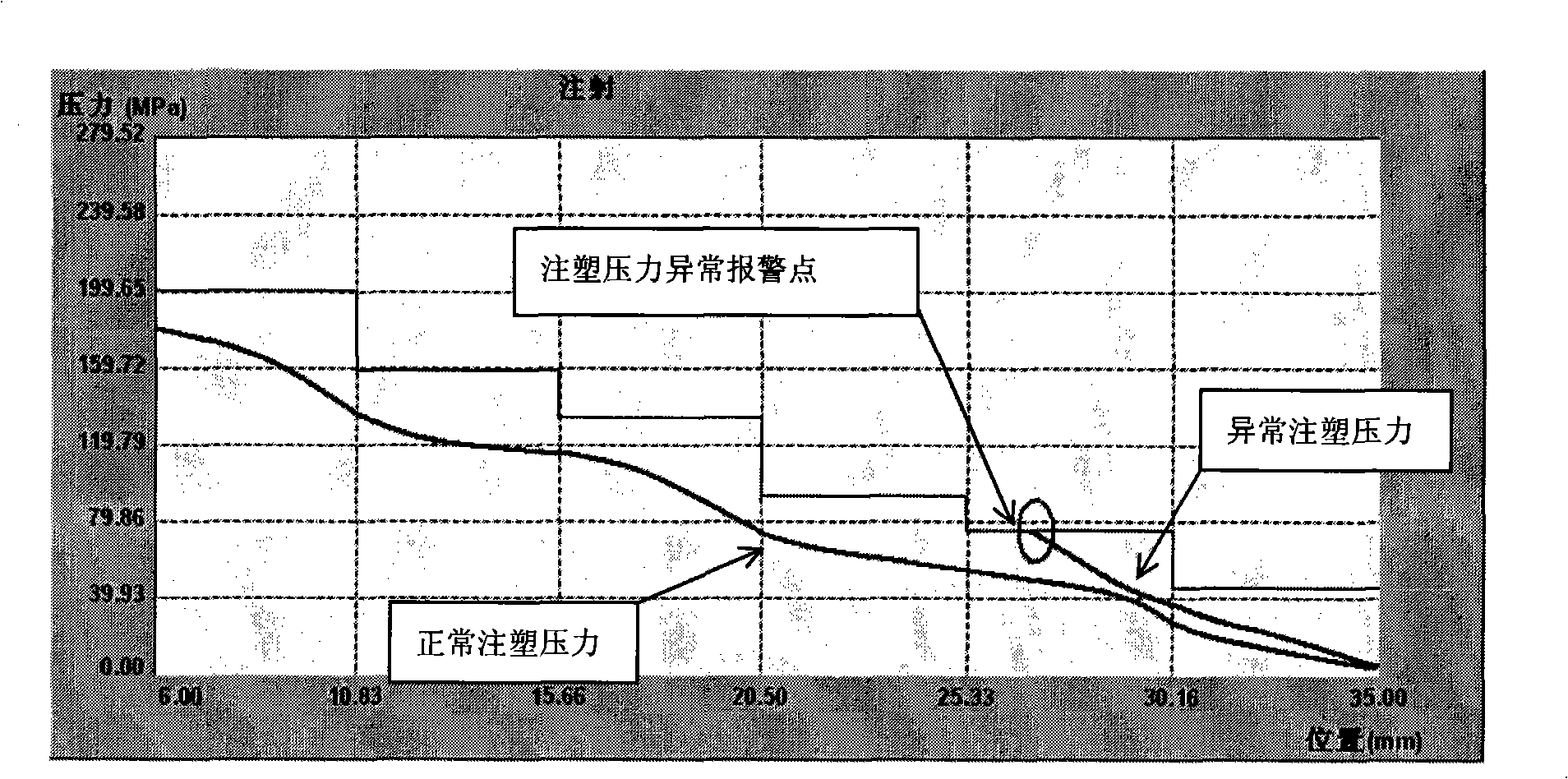

Injection pressure monitoring method of full electric injection molding machine

The invention relates to an injection pressure monitoring method of a full electric injection molding machine, comprising the following steps of: (1) setting of a monitoring initial curve for injection pressure, with the longitudinal coordinate of monitoring value of injection pressure and horizontal ordinate of injection position; (2) setting of a monitoring curve for injection pressure; and (3) monitoring of practical injection pressure. The method has the advantages that a stepped pressure monitoring curve is formed for a pressure curve in the normal injection process, therefore, in the practical production process, once the injection pressure reaches monitoring pressure, the injection molding machine stops the injection actions immediately and gives an alarm, thus effectively preventing serious results that the mold and equipment are damaged due to abnormal high pressure.

Owner:NINGBO ZHAFIR PLASTICS MACHINERY

Upstream injection sucker-rod pump same well mining and injecting device

ActiveCN107687413AAvoid injection difficultiesAvoid Pole BendingPositive displacement pump componentsFlexible member pumpsInjection - actionEngineering

The invention discloses an upstream injection sucker-rod pump same well mining and injecting device. The upstream injection sucker-rod pump same well mining and injecting device comprises two following components including a separation component and a swabbing component, wherein by means of the separation component, a stock solution generated in a working well can be separated into different separation products with main components being different in performance underground; and by means of the swabbing component, two functions can be achieved in the upstream process of a movement assembly contained in the swabbing component, one function is that power needed by stock solution separation and a temporary storage space for the separation products are provided for the separation component, and the other function is that the different separation products generated in the previous working circulation are pressurized at the same time. The upstream injection sucker-rod pump same well mining and injecting device is used for a sucker-rod pump mining well, the components of the products in the well are separated underground, when a working bolt support moves upwards, the separation product with relatively large expected component content is mined, the separation product with relatively large unexpected component content is synchronously reinjected, the mining and injection actions can acquire sufficient power through ground hoisting equipment, and the mining and injecting flow ratio can be directly and effectively controlled through a working cavity volume ratio inside the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

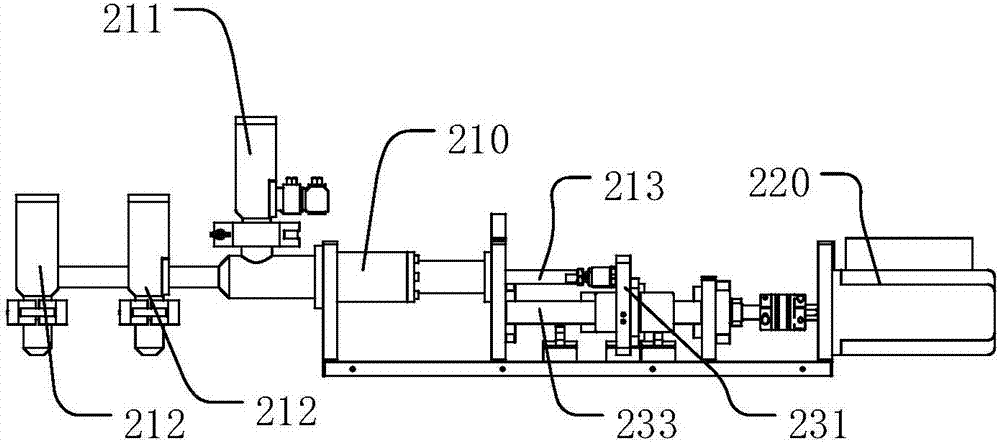

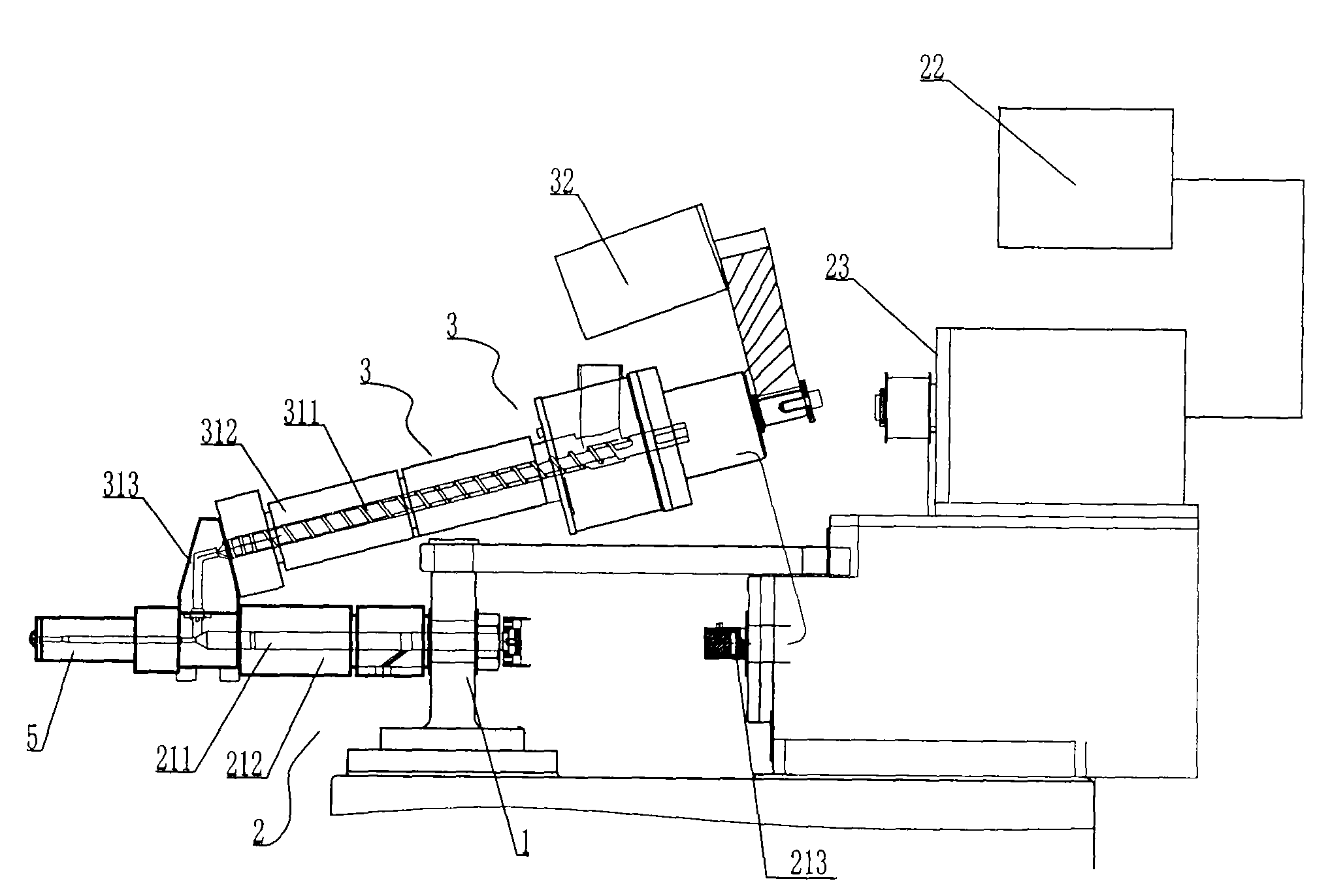

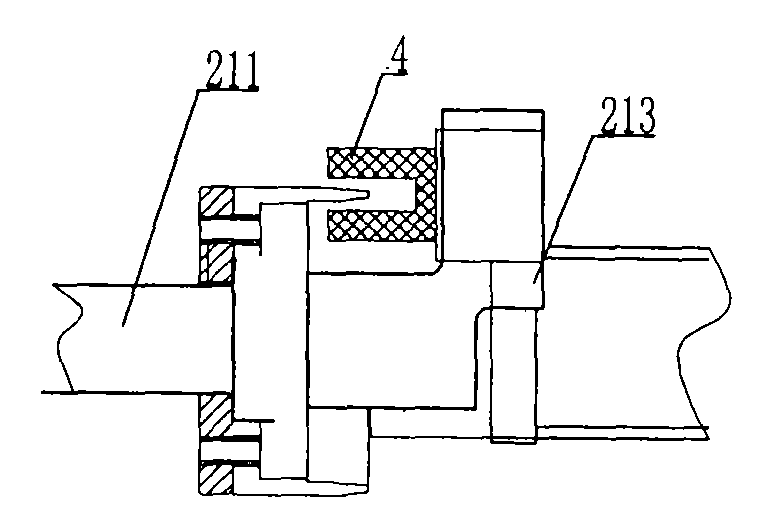

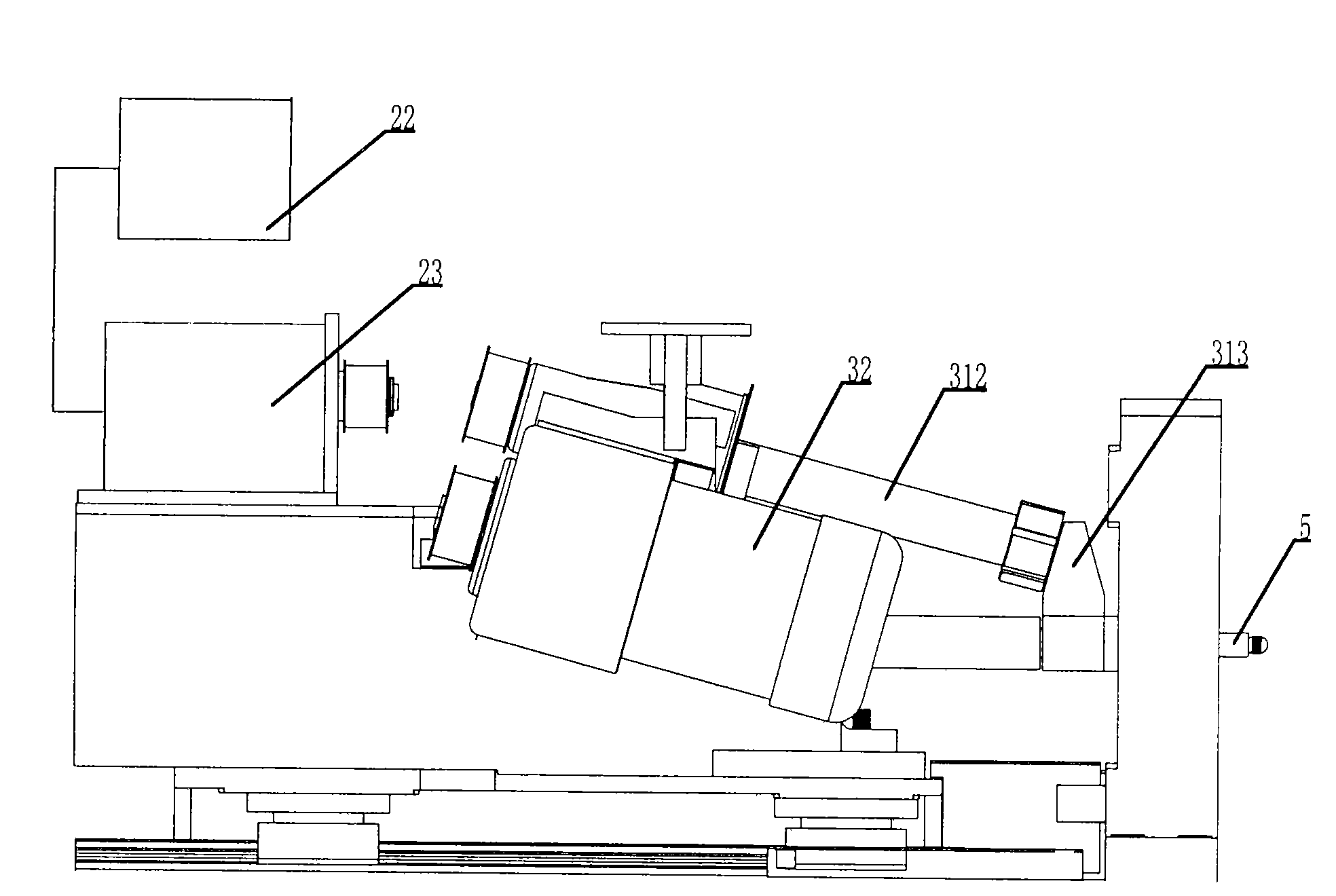

Metering control device for pre-molding type electric injection molding machine

The invention relates to a metering control device for a pre-molding type electric injection molding machine, which comprises a stander, an injection mechanism and a pre-molding mechanism, wherein the injection mechanism and the pre-molding mechanism form a triangular structure, an injection tube of the injection mechanism is fixedly arranged on the stander, and the front end of the injection tube is communicated with a discharge port of an intermediate body of the pre-molding mechanism; and the rear end of a movable plunger rod positioned in the injection tube can be mutually matched with a ball screw to propel each other. The front end of the ball screw is provided with a sensing device which can receive the position information of the plunger rod and transmit the position information to a central controller of the machine; and the ball screw is driven by an injection motor. The metering control device achieves the aim of metering control by using a precise control device of the injection mechanism according to the characteristics that the injection mechanism and the pre-molding mechanism of the pre-molding type electric injection molding machine are respectively independent in mechanical construction, avoids the necessary of adopting two sets of precise control mechanisms to the pre-molding actions and injection actions structurally, and can reduce the facility cost while achieving the aim of the same precise control.

Owner:广州博新机械有限公司

Excellent-appearance chemical foaming injection molding process

ActiveCN106985329AInjection foaming process is simple and controllableLow costDomestic articlesFoaming agentInjection moulding

The invention relates to an excellent-appearance chemical foaming injection molding process. The process comprises the following steps: (1) 0.5-1% of white mineral oil and 0.3-0.7% of a foaming agent are added in a PP modified material for full and uniform mixing; and (2) the uniformly-mixed raw materials are injected in an unloading barrel of an injection molding machine; the temperature of a charging barrel of the injection molding machine is set within 210-240 DEG C; the screw rod injection retreating is omitted in the plastifying process; a back pressure value is set according to the product weight and the adding ratio of the foaming agent; the injecting speed and the injecting quantity are increased by using a supercharger, so that the injecting action is finished within 1.5 s; the mold surface temperature is controlled within 35-50 DEG C; and after the product is totally cooled, the product is taken out after mold opening. An injection molding part prepared by the process is excellent in appearance quality, and has no air marks on the surface.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

Gas burner with reinforced smoke internal circulation

PendingCN111520716AReduce oxygen concentrationReduce concentrationFluegas recirculationNon-combustible gases/liquids supplyThermodynamicsEngineering

The invention provides a gas burner with reinforced smoke internal circulation. Through the negative pressure formed under the injection action of high-speed jet of fuel and combustion air, furnace smoke is sucked into the gas burner to be mixed with the fuel and the combustion air respectively. By mixing the smoke with the fuel and tempering the fuel, the heat value of the fuel is reduced; and bymixing the smoke with the combustion air and tempering the combustion air, the oxygen concentration of the combustion air is reduced. By mixing the tempered fuel with the tempered combustion air forcombustion, the combustion temperature is effectively reduced, the oxygen concentration is reduced, the concentration of CH ionic groups is reduced, and the aim of low nitrogen emission is realized.

Owner:江苏蓝创环保科技有限公司

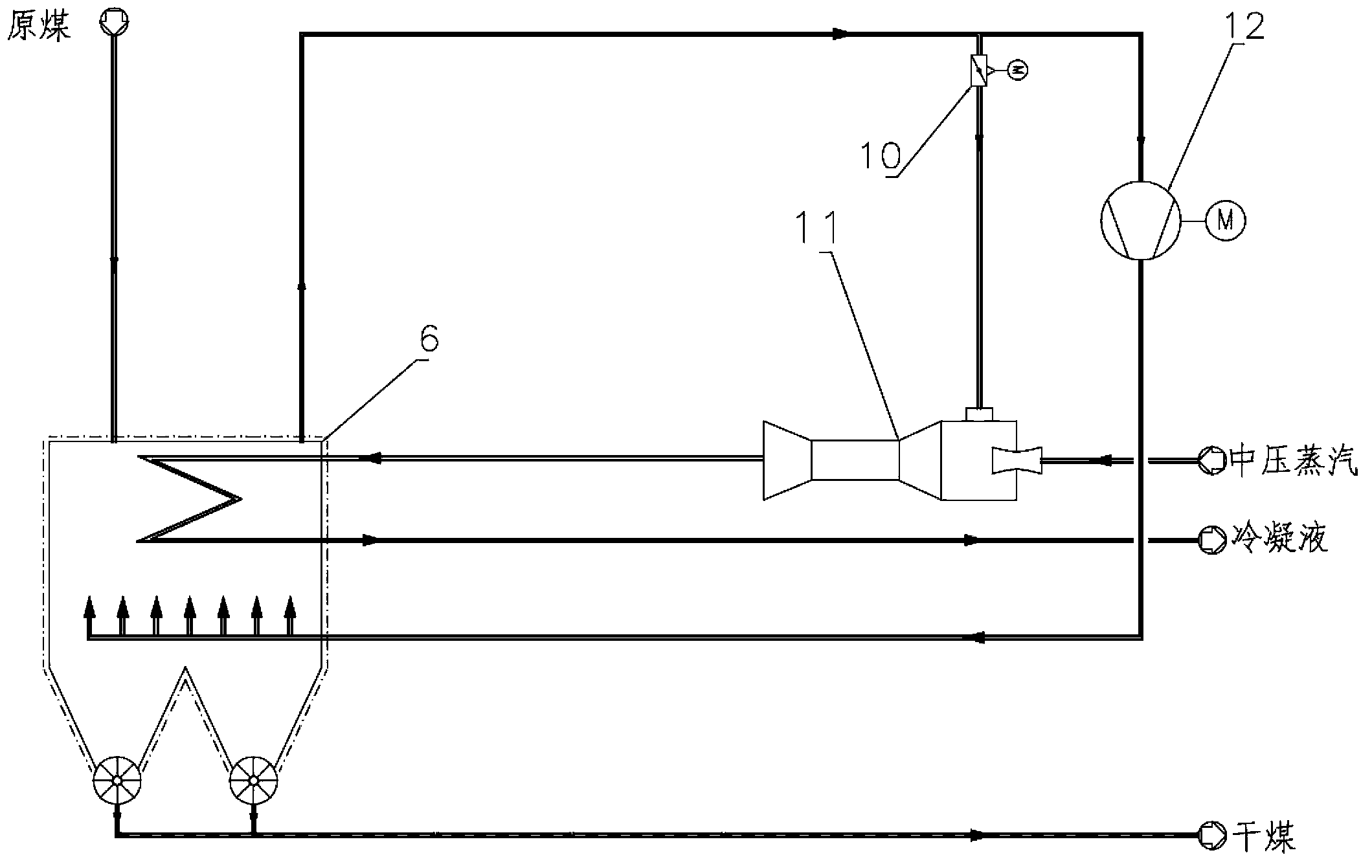

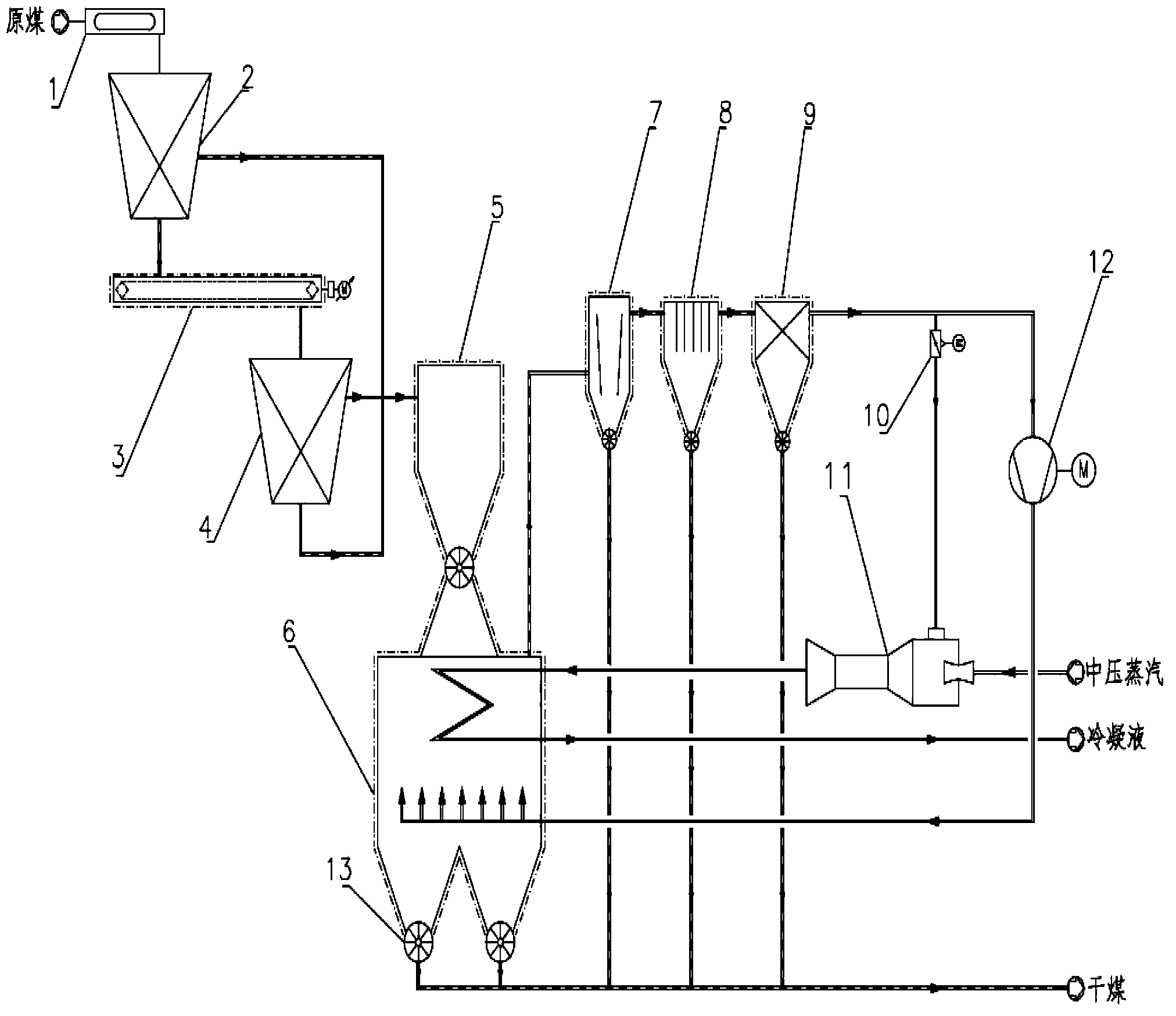

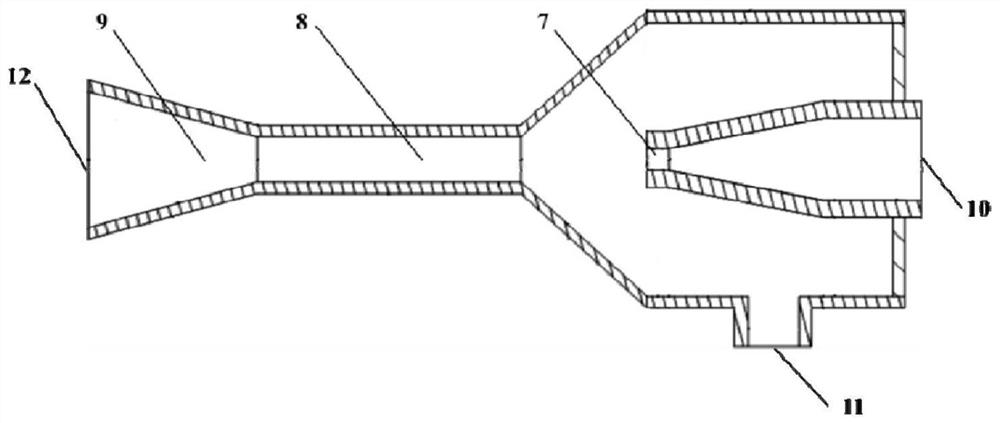

Steam fluid bed drying device and steam fluid bed drying method

InactiveCN103822440AAchieve dryingImprove utilization efficiencyDrying solid materials with heatHearth type furnacesEngineeringInjection - action

The invention relates o a steam fluid bed drying device and a steam fluid bed drying method. Crushed coal is fluidized at the bottom of a dryer (6) under the action of blown in steam and is subjected to heat exchange with a heat exchange pipe inside the dryer (6); water steam from drying of the coal is separated into two ways: the water steam in one way enters an ejector (11) via an adjusting air valve (10), and is recycled to a drying tube in the dryer (6) to supply heat energy for drying after being subjected to temperature and pressure rising under an injection action of medium pressure steam; the water steam in the other way is pressurized by a fan (12), recycled to the bottom of the dryer (6) and blown into raw coal to supply fluidizing power. The steam fluid bed drying device and the steam fluid bed drying method are applicable to drying of low-rank coal like brown coal and have the advantages of energy conservation, environment friendliness and the like.

Owner:CHANGZHENG ENG

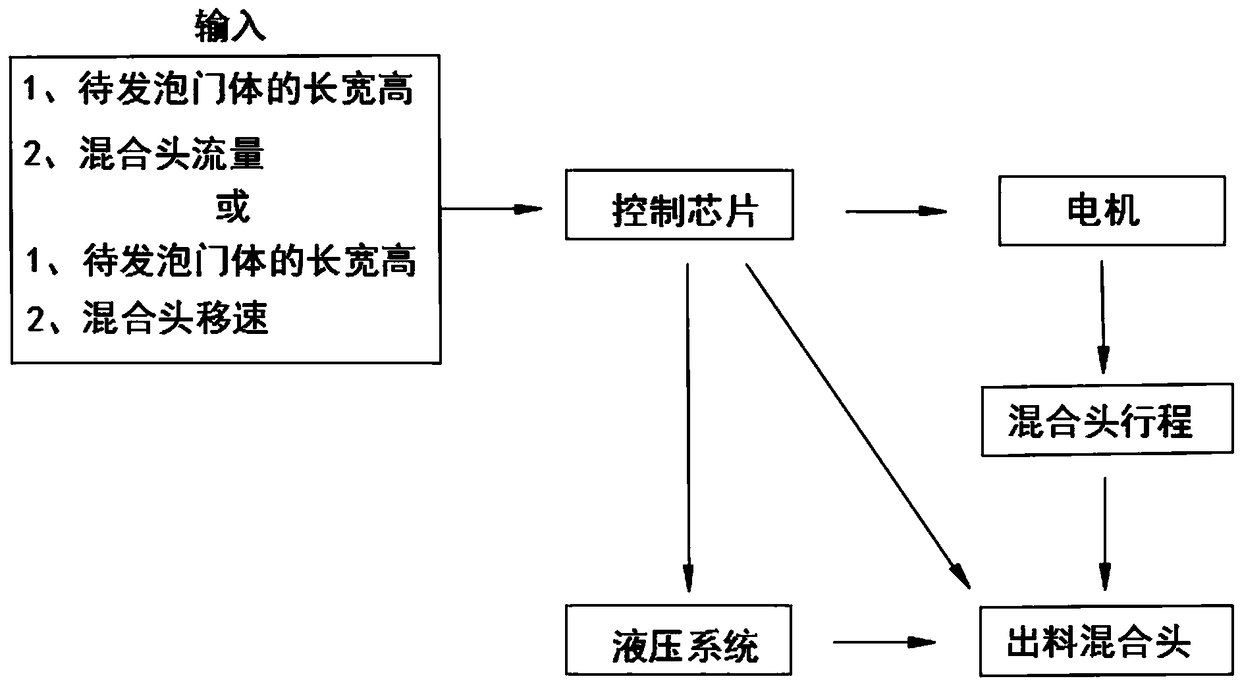

Intelligent mixing head injection system

InactiveCN108908835AHigh degree of automationSave materialDomestic articlesGrey boxMathematical model

The invention discloses an intelligent mixing head injection system, and relates to the field of refrigerator manufacturing. The intelligent mixing head injection system includes a control chip and aninjection action unit; the control chip includes a database module for inputting foaming process parameters of different types of door bodies, a modeling module for establishing a mathematical modelfrom injection parameters corresponding to different sizes of door bodies through a grey-box principle, and a calculation module for matching a corresponding mathematical model according to the user-inputted length, width and height of a door body to be foamed, calculating corresponding injection parameters and outputting parameter signals to the injection action unit. By inputting the length, width and height of the door body to be foamed and the flow rate of a mixing head, or inputting the length, width and height of the door body to be foamed and the moving speed of the mixing head, and through the inputted process parameter module in advance through matching, a calculation result is fed back to the injection action module, the injection action is automatically completed by the system,the degree of automation of the system is improved, materials are saved, and the production costs are reduced.

Owner:CHANGHONG MEILING CO LTD

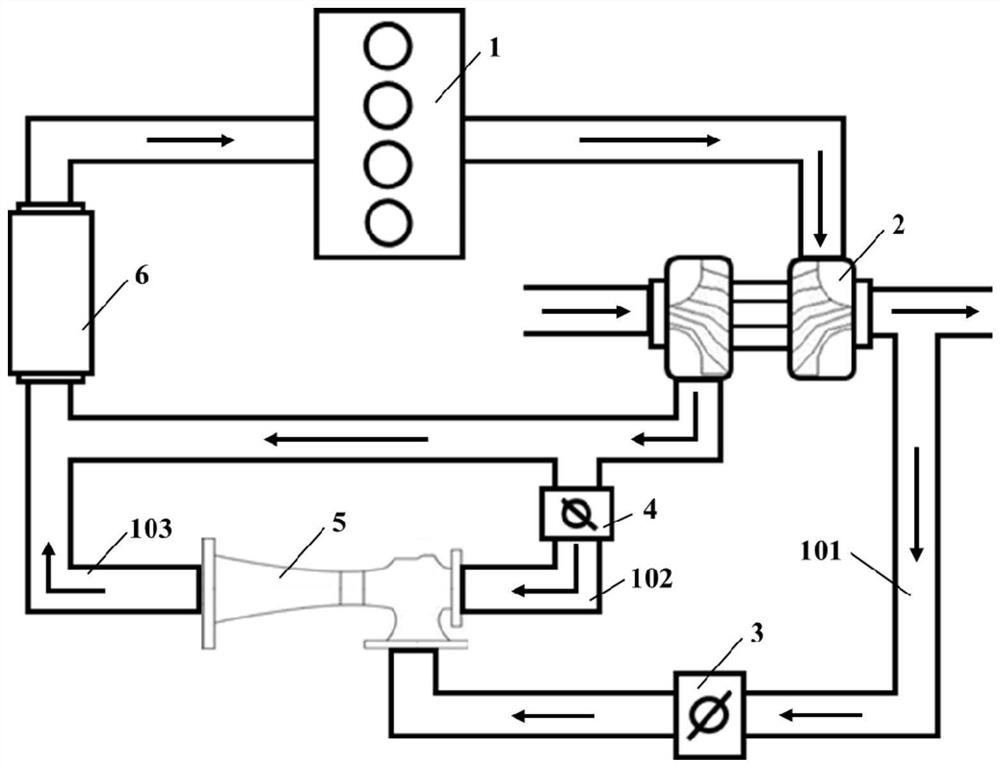

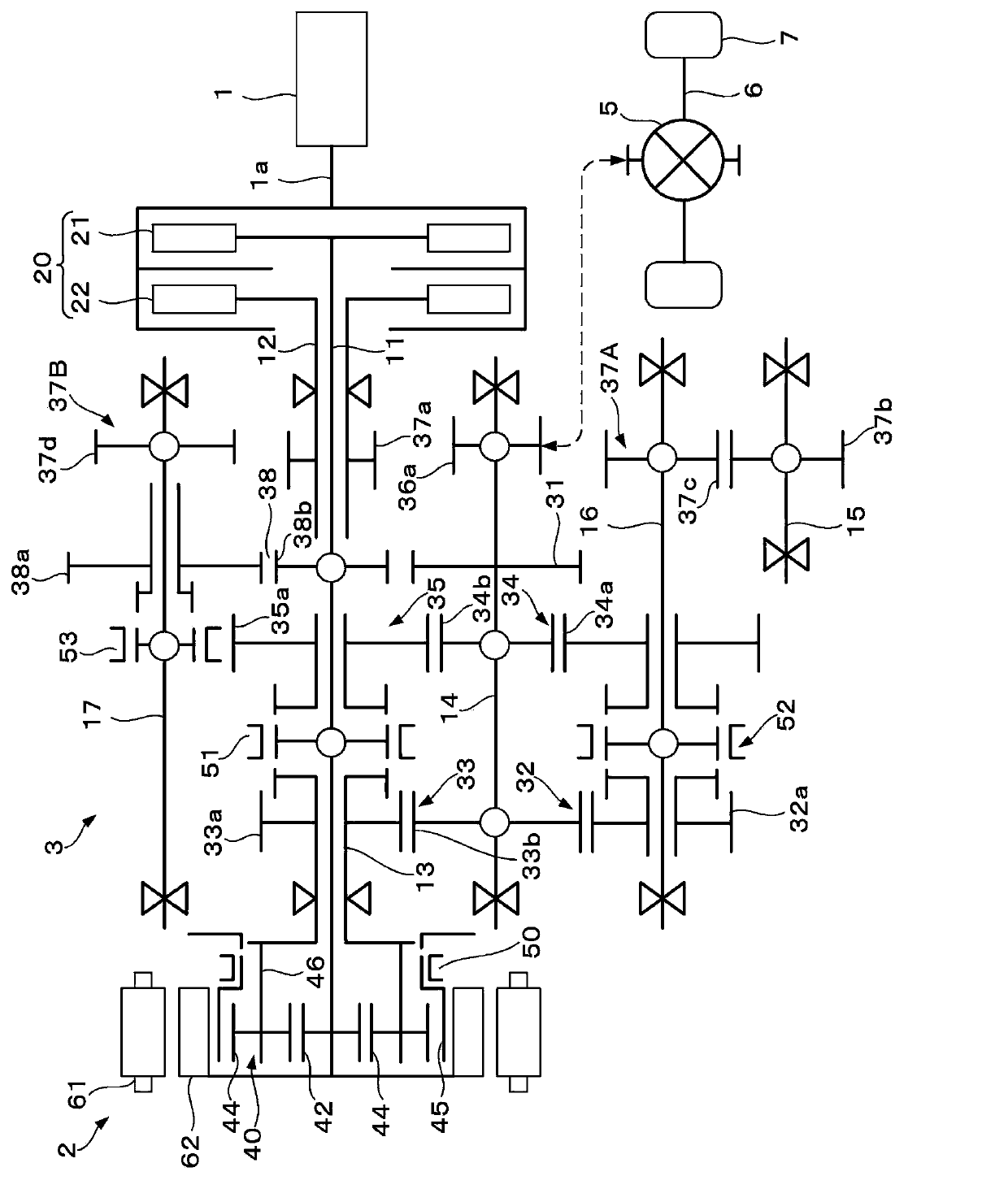

System for flexibly adjusting EGR rate of supercharged diesel engine and adjusting method

InactiveCN112211757AAchieve inhibitionIncrease EGR rateElectrical controlExhaust gas recirculationFluid controlWorking fluid

The invention aims to provide a system for flexibly adjusting the EGR rate of a supercharged diesel engine and an adjusting method. The system comprises the diesel engine and a turbocharger, wherein an exhaust pipe of the diesel engine is connected with a turbine of the turbocharger, an outlet of the turbine is connected with the atmosphere and a driving fluid inlet pipe, the driving fluid inlet pipe is connected with an injector through a driving fluid control valve, a compressor outlet of the turbocharger is connected with a working fluid inlet pipe and a mixed fluid exhaust pipe, the working fluid inlet pipe is connected with the injector through a working fluid control valve, the injector is connected with the mixed fluid exhaust pipe, and the mixed fluid exhaust pipe is connected withan air inlet pipe of the diesel engine through an intercooler. According to the system, low-pressure useless waste gas passing through the turbine is led back into an air cylinder by aid of high-pressure air according to the injection action of the injector, a flexible EGR rate of the diesel engine and particularly a high EGR rate under a large-load working condition are realized on the premise that the working efficiency of the turbocharger is not affected, and the contradiction between turbocharging and the EGR rate of the diesel engine under the large-load working condition is solved.

Owner:HARBIN ENG UNIV

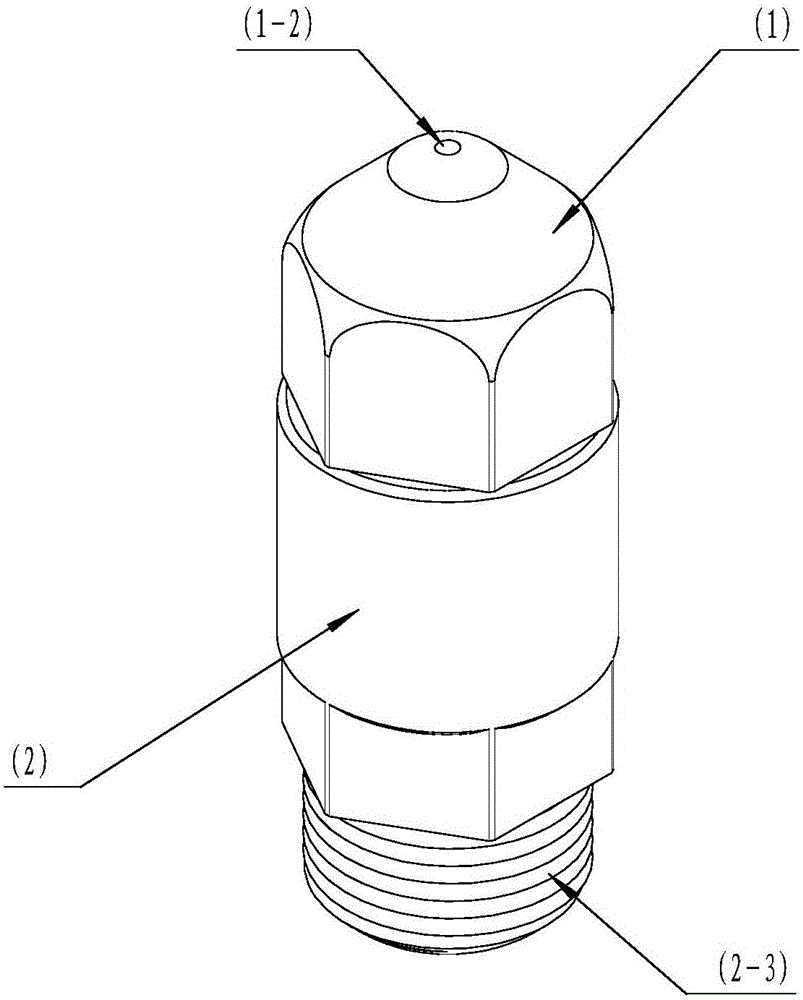

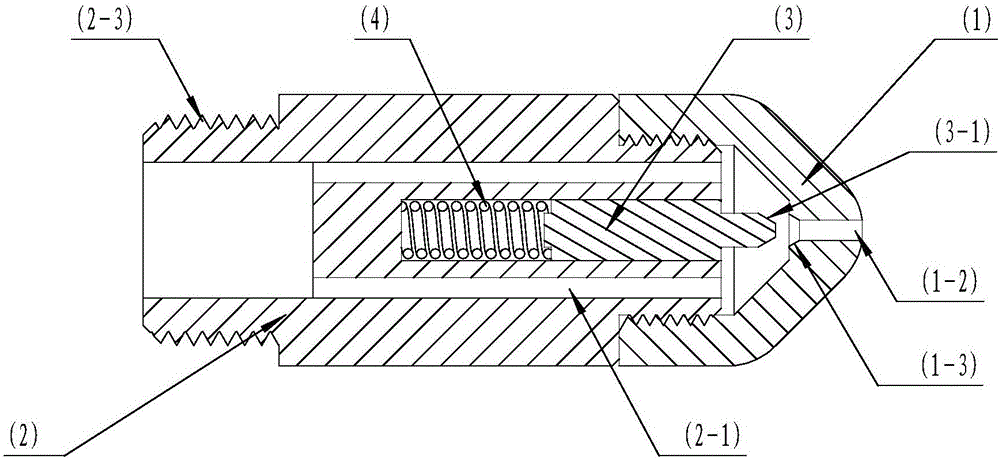

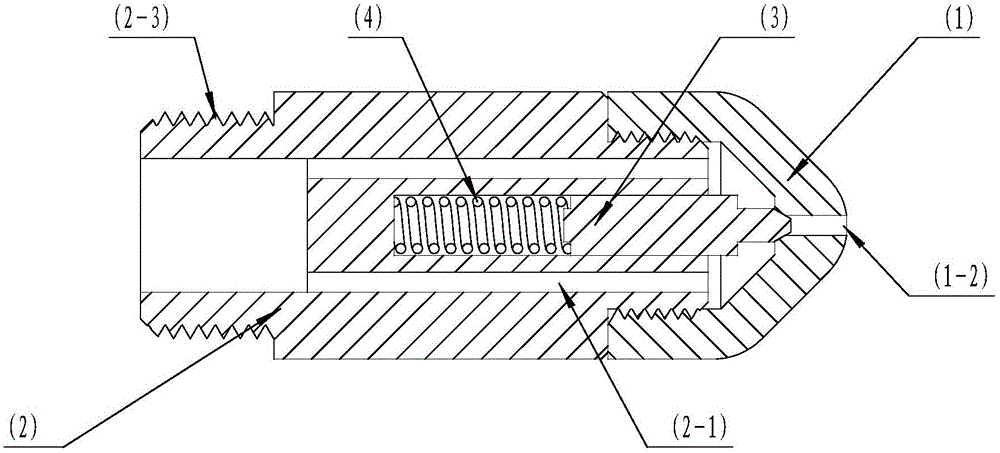

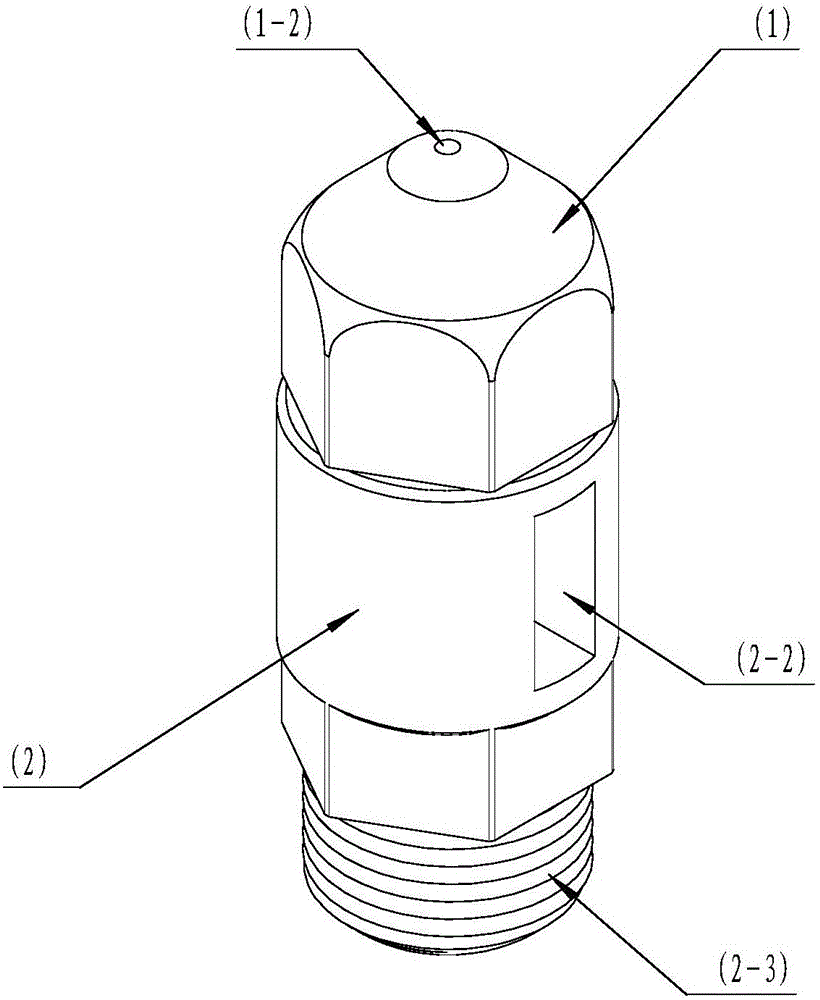

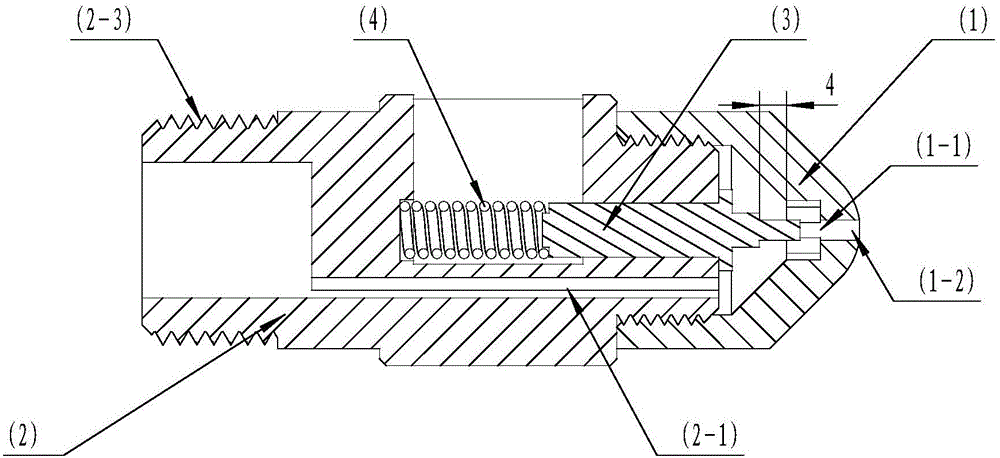

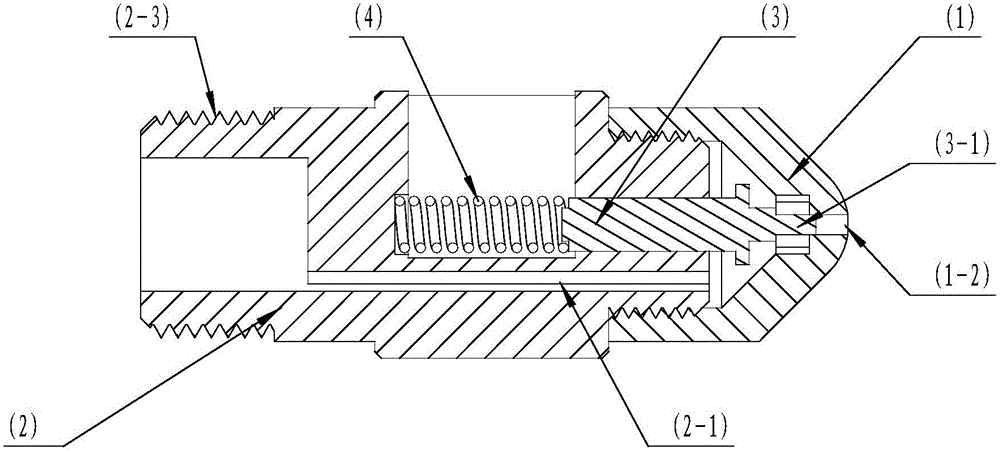

Self-recovery type anti-overflow spray nozzle

The invention discloses a self-recovery type anti-overflow spray nozzle. The self-recovery type anti-overflow spray nozzle is composed of main components including a spray nozzle cap, a spray nozzle body, a valve element and a spring. The self-recovery type anti-overflow spray nozzle is characterized in that in the plastic injection process, a hydraulic device pushes a threaded rod to move forward, and a high-pressure plastic injection glue melting area is formed in the spray nozzle cap which is sealed originally; high-pressure molten glue acts on the stress surface of the valve element, thrust is generated, the spring is compressed, and the valve element is made to move towards the spring; the blocking slope of the valve element retreats from a corresponding anti-overflow slope at the inner side of the spray nozzle cap at the moment, and a plastic injection channel is in an opened state; the molten glue is injected into a cavity in a die through the plastic injection channel in the spray nozzle body until plastic injection is completed; when the glue melting process starts, due to the fact that the hydraulic device drives the threaded rod to retreat, the pressure in the high-pressure glue melting area in the spray nozzle cap is relieved, under the effect of elastic force of the spring, the blocking slope of the valve element is pushed towards the corresponding anti-overflow slope again and attached to the anti-overflow slope, and the plastic injection channel is in a closed state; the plastic injection channel is blocked, so that the molten glue cannot overflow from the plastic injection channel, and it is guaranteed that the production process of products can be completed smoothly.

Owner:林勇

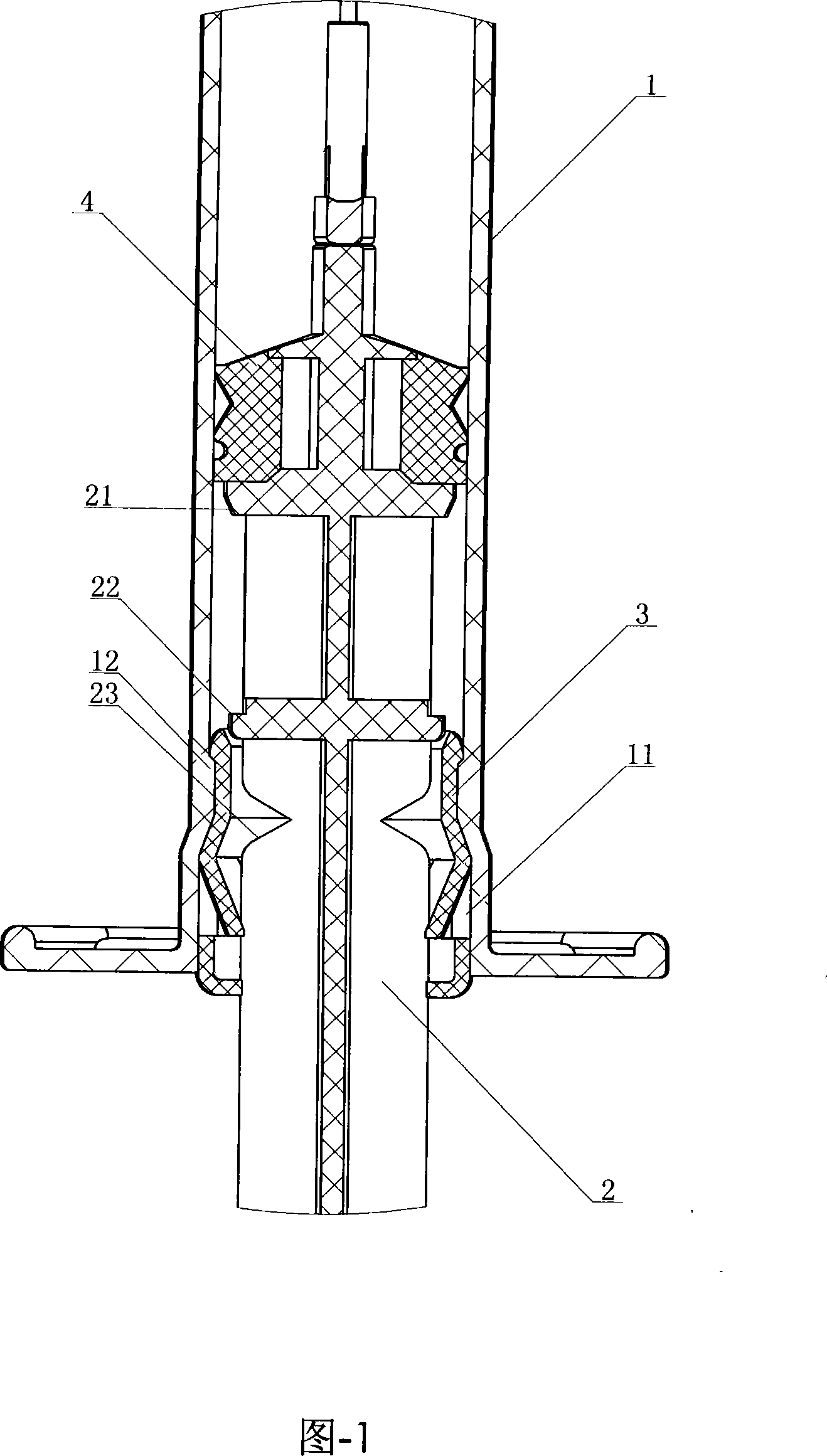

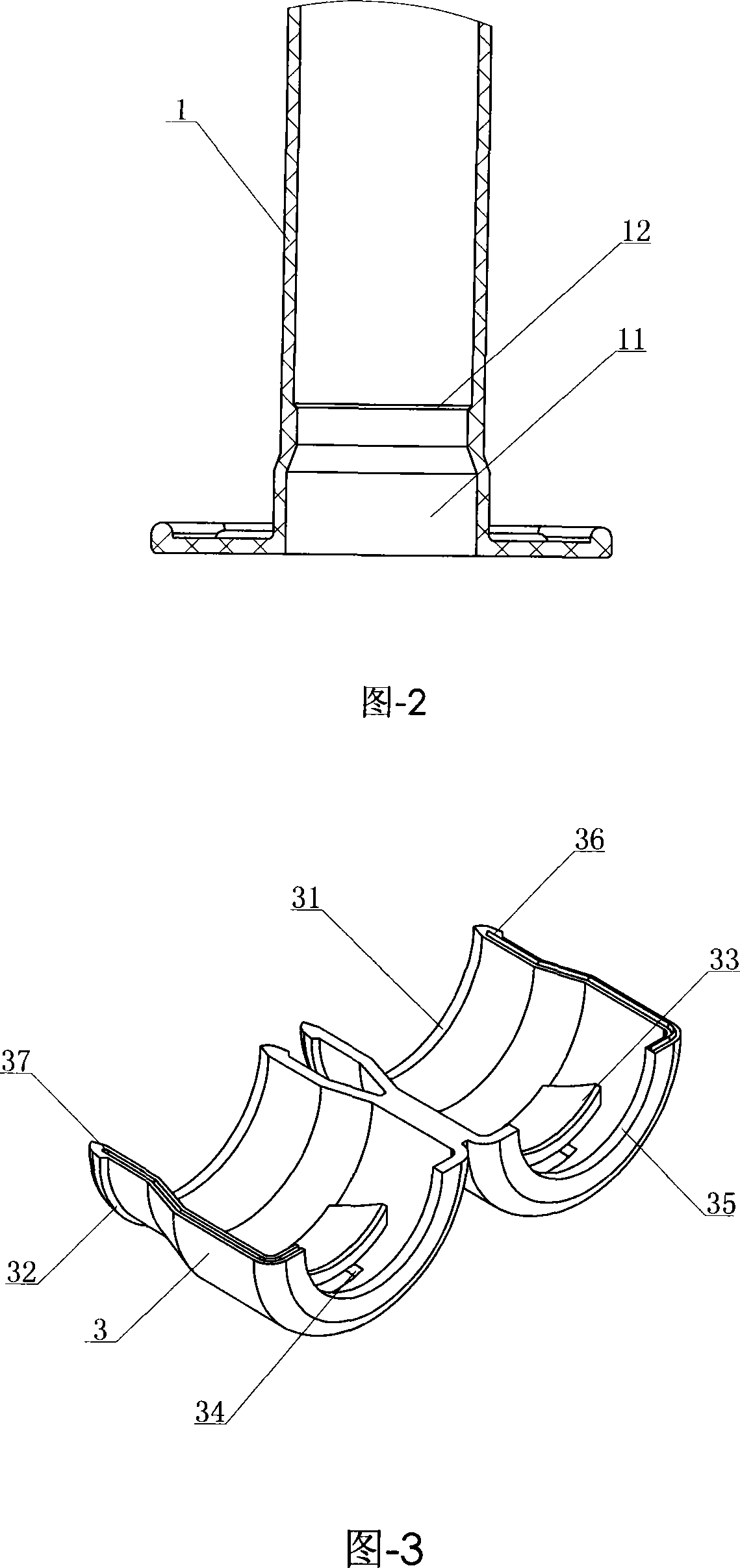

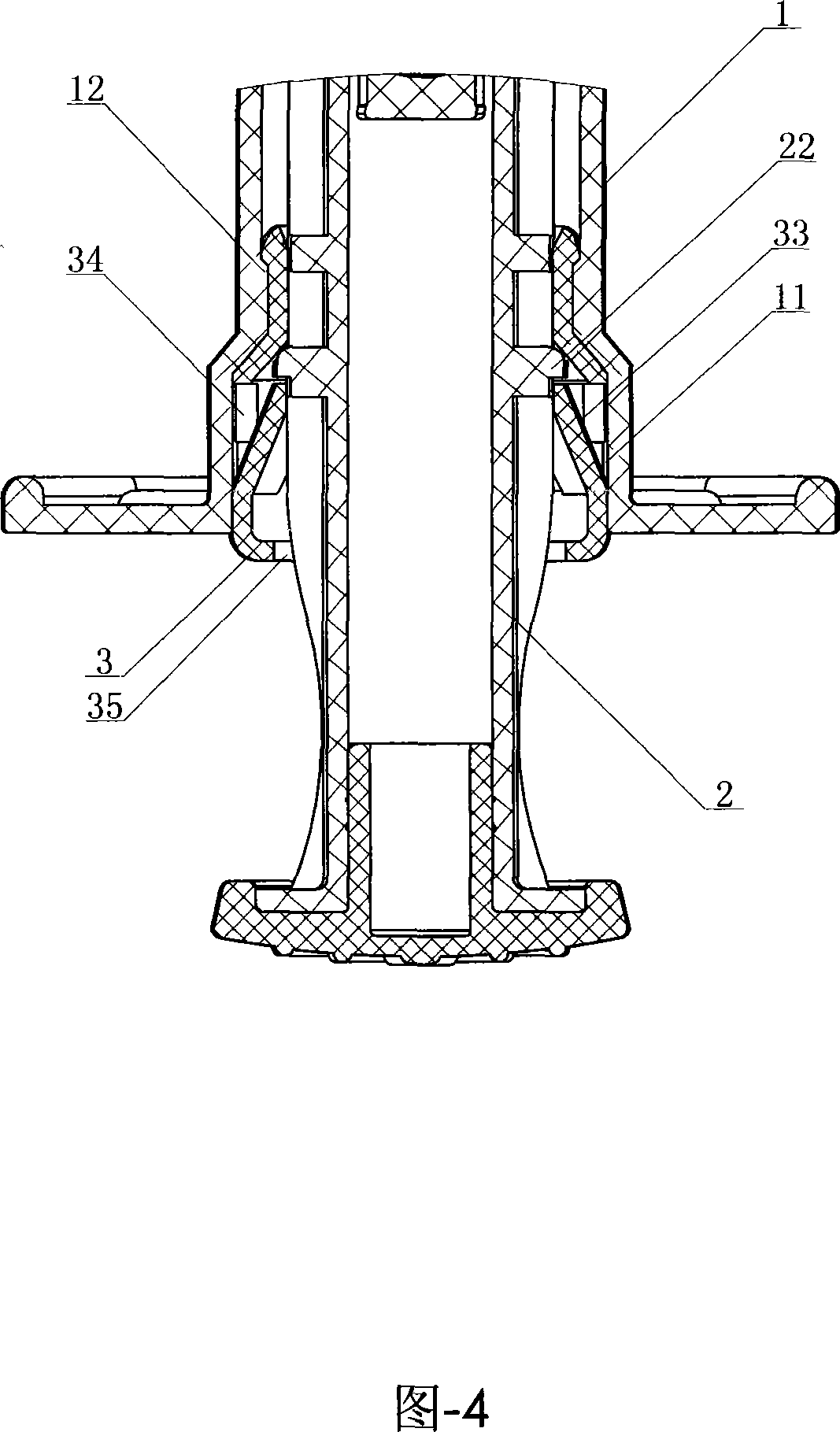

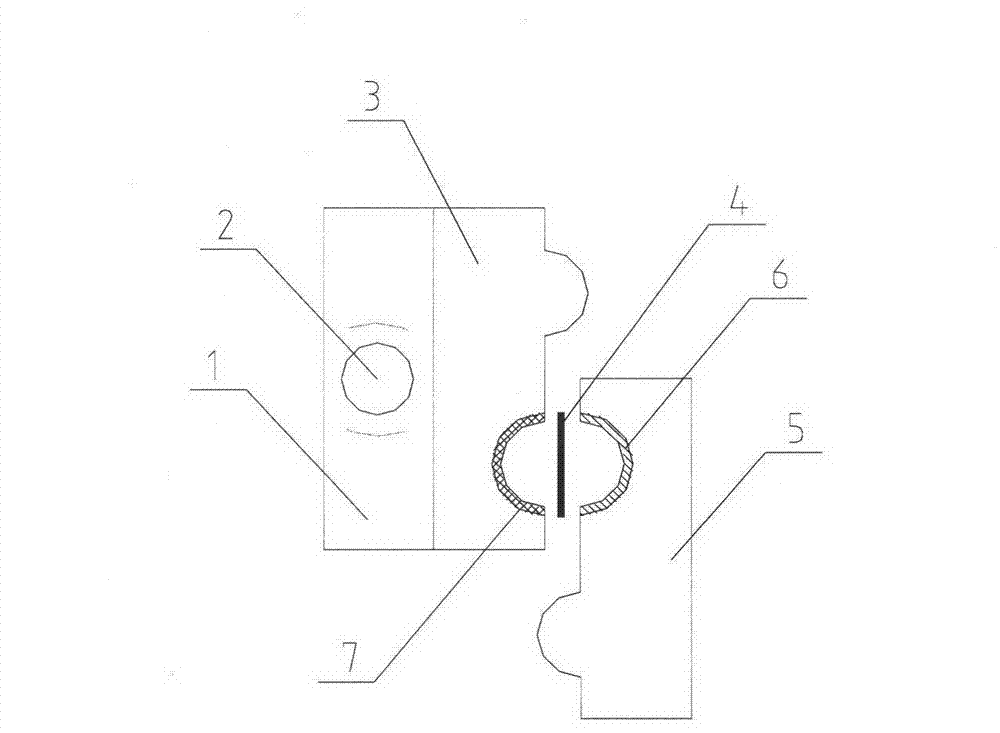

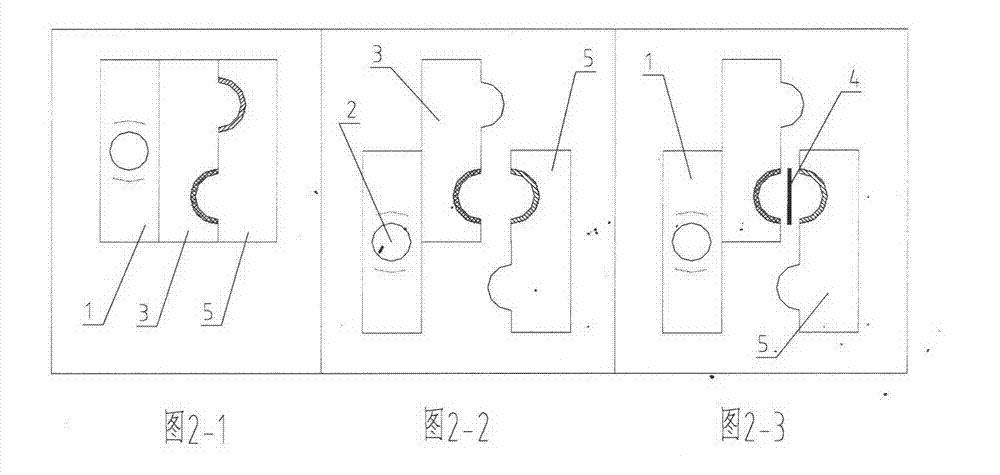

Safety injector core bar lockup device

InactiveCN101229406AReliable lockingAchieve self-destructIntravenous devicesInjection - actionEngineering

The invention relates to a core pin locking device for a safety syringe, which comprises an outer sleeve, a piston and a core pin, wherein, the rear part of the outer sleeve is provided with a locking ring for the core pin which is a cavity through ring composed by two integrated or split semi-circular rings. An elastic damping claw which inclines inwards is arranged on the locking ring, the tail end of the elastic damping claw integrated with a wall body of the locking ring for the core pin as a whole; a positioning boss which is used for positioning by coordination with the elastic damping claw is correspondingly arranged on the core pin; an internal cavity at the front end of the locking ring for the core pin is provided with a concave arc face and a stop boss which is matched with the core pin is correspondingly arranged on the core pin. After the injection action of the invention is finished, the core pin when drawn back can drive a syringe head component to retract to the internal cavity of the outer sleeve, and then to the position of the locking ring for the core pin at the rear end of the outer sleeve; meanwhile, the core pin and the locking ring for the core pin coordinate for locking and the core pin fails to move forwards or backwards. The core pin locking device of the invention has reasonable structure, convenient and stable application and high safety as well as reasonability of the locking of the core pin, and can realize self-disposal after one-off injection.

Owner:房东森

A Model-Based Decoupling and Anti-disturbance Control Method for HCCI Combustion

ActiveCN103195599BReduce workloadReduce dependenceElectrical controlMachines/enginesHcci combustionActive disturbance rejection control

Owner:TIANJIN UNIV

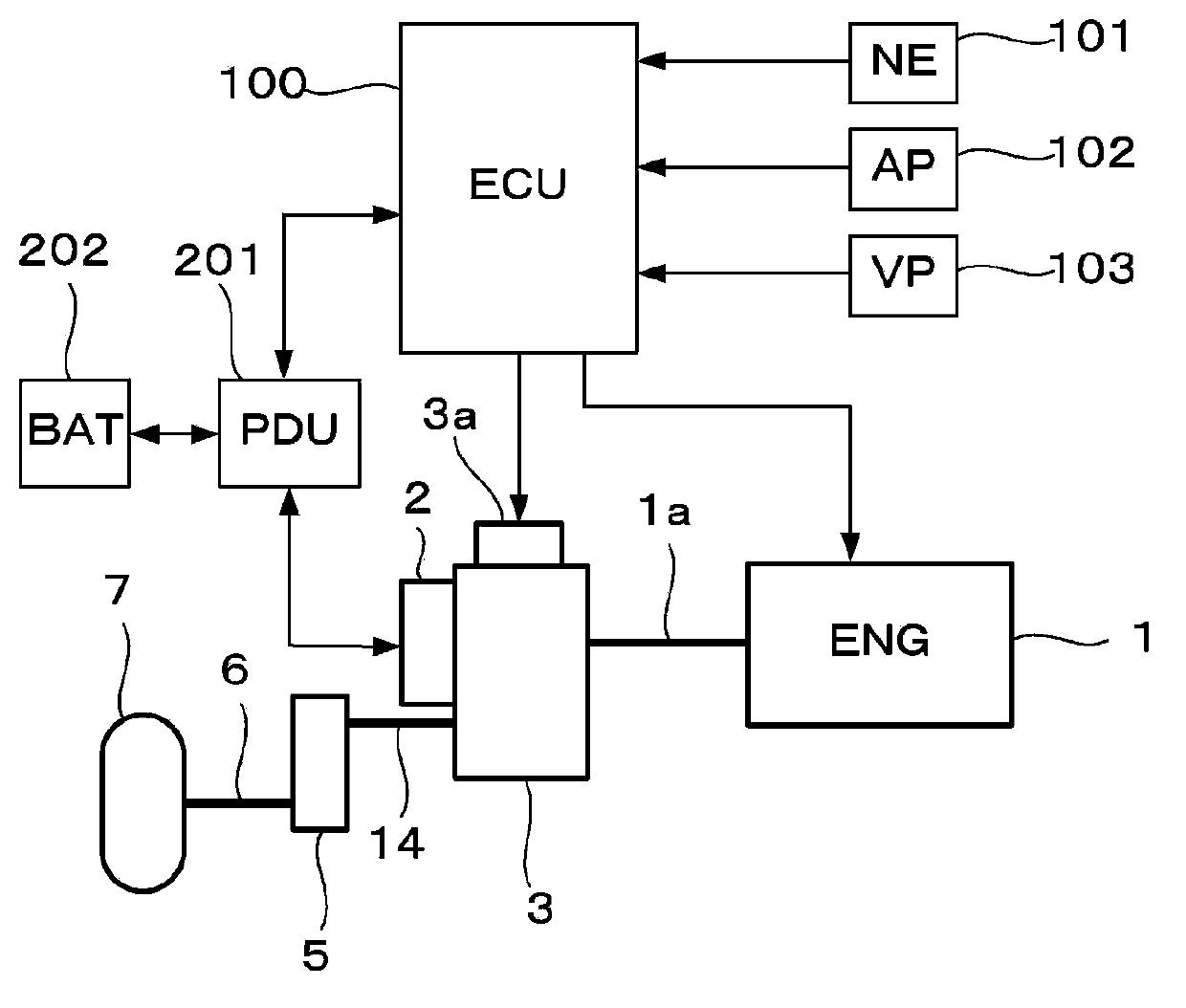

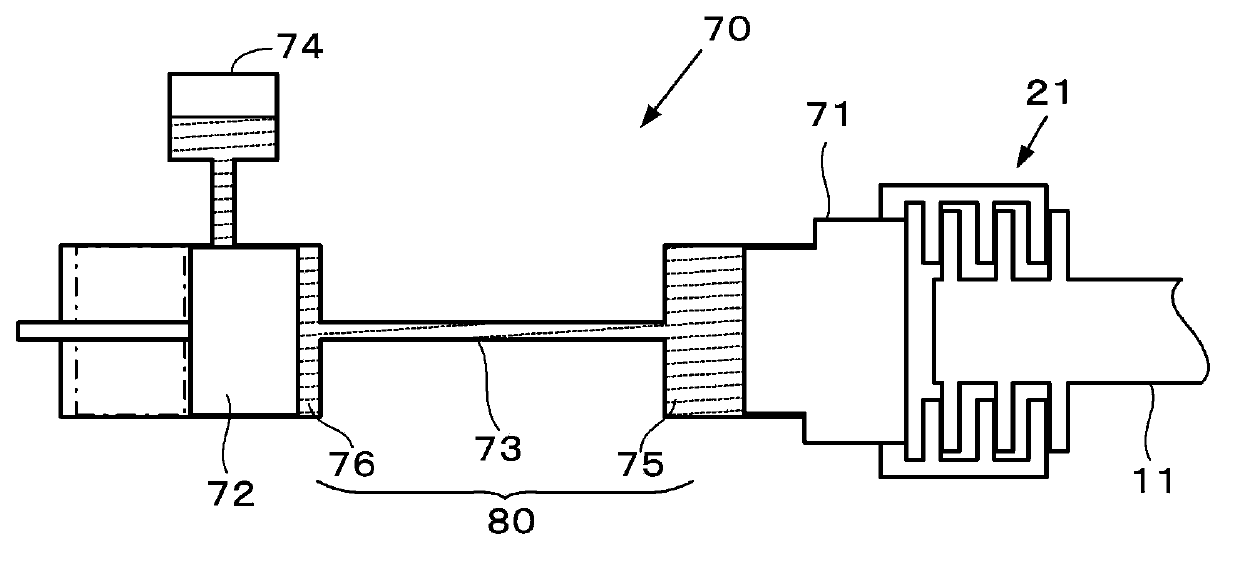

Control device of vehicle driving apparatus

ActiveCN103373341ASmall driving forceImprove drivabilityPropulsion using engine-driven generatorsVehicular energy storageInjection - actionActuator

The invention provides a control device of a vehicle driving apparatus, allowing a clutch to carry out injection action on an oil pressure actuator for driving and suppressing discomfort caused to driver. The vehicle driving apparatus comprises a generator (1) and a motor (2), wherein the generator (1) drives the vehicle through a clutch, and the motor (2) is configured to drive the vehicle without the clutch. Following injection action is carried out when the injection action request is sent. When a vehicle can be driven through the motor (2), the vehicle driving torque is compensate based on the motor (2) and the clutch in a joint state is broken off, and an enclosed oil pressure loop (80) corresponding to the breaking clutch communicates with a work oil storage tank (74). Since the vehicle driving torque is compensate through the motor (2) when the clutch is broken off, the lowering of vehicle driving torque due to injection action can be prevented, thereby maintaining excellent vehicle driving performance.

Owner:HONDA MOTOR CO LTD

Intramode butt fusion type secondary processing method

InactiveCN103112172AImprove fit tightnessSave manpower and material resourcesCoatingsInjection - actionMaterial resources

The invention relates to an intramode butt fusion type secondary processing method comprising a movable mould, an auxiliary mould driving device, an auxiliary mould, a heating butt fusion device and a fixed mould. The intramode butt fusion type secondary processing method is characterized in that after the movable mould, the auxiliary mould and the fixed mould are closed, an injection molding machine performs an injection action and opens the moulds to necessary distances after the injection procedure, the movable mould drives the auxiliary mould to match a next working station through the auxiliary mould driving device, and then, the heating butt fusion device enters the mould region to heat originally separated and different component products, the heating butt fusion device retreats, and finally, the injection molding machine closes the moulds to fuse the originally separated and different component products together so as to finish the intramode butt fusion type secondary processing procedure and assemble plastic products. According ot the intramode butt fusion type secondary processing method, the procedures needing secondary processing, particularly, components needing butt fusion, are designed to be executed in the moulds, so that the plastic products are finished products when leaving the die cavity, which improves the assembly quality, stability and cooperation firmness of the products and saves the manpower and material resources and the factory building space.

Owner:BORCH MACHINERY

Chip removal type anti-overflowing nozzle

The invention discloses a chip removal type anti-overflowing nozzle. The chip removal type anti-overflowing nozzle comprises the main components including a nozzle cap, a nozzle body, a valve element and a spring. The chip removal type anti-overflowing nozzle is characterized in that a screw is pushed by a hydraulic device to advance during injection molding, an injection molding high-pressure molten plastic area is formed in the nozzle cap which is originally sealed, high-pressure molten plastic acts on the stress surface of the valve element, pushing force is generated and compresses the spring so that the valve element can move towards the spring till the limiting surface of the valve element is attached to the nozzle body, a blocking column of the valve element retreats from an injection molding channel of the nozzle cap completely at the moment, the molten plastic is injected into a cavity of a mold through the injection molding channel of the nozzle body at the moment till injection is completed, then the hydraulic device drives the screw to retreat, pressure in the high-pressure molten plastic area in the nozzle cap is released, the blocking column of the valve element is inserted into the injection molding channel again under the action of the elastic force of the spring, and the injection molding channel is blocked, so that molten plastic cannot overflow from the injection molding channel. In this way, a product can be produced smoothly.

Owner:林勇

Rearing cage for unified injection of experimental mice

InactiveCN113142069ASimple structureEasy to operateAnimal housingVeterinary instrumentsLaboratory mouseAnimal science

The invention discloses a rearing cage for unified injection of experimental mice. The rearing cage comprises a machine shell, wherein a driving cavity is formed in the upper portion of the machine shell, a driving mechanism is arranged in the driving cavity, an injection action cavity with an opening in the right cavity wall is formed in the middle of the machine shell, an injection action block groove communicating with the injection action cavity is formed in the injection action cavity, an injection action block is connected to the interior of the injection action block groove in a sliding mode, and an injection mechanism is arranged in the injection action block. The cage is simple in structure and convenient and fast to operate, when the cage works, an injector for injection can be placed in the cage, then the cage is started, the cage can attract laboratory mice by means of food, the laboratory mice are trapped in the container with the size fixed, then a needle sinks by 45 degrees to inject one mouse, a needle carrier is moved to the next position, the needle is replaced in the process, then the next mouse is injected, and therefore, the cage has the beneficial effects of being convenient, fast and effective.

Owner:佛山市千顺科技有限公司

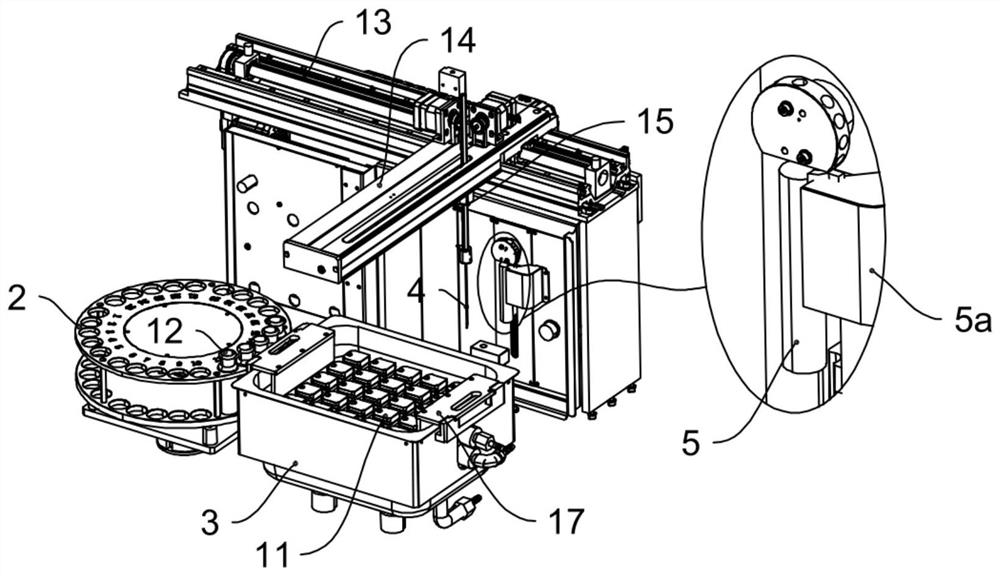

Full-automatic oil fume tester

The invention provides a full-automatic oil fume tester which comprises a machine body platform, an ultrasonic extractor, a constant-volume sample disc, a XYZ three-dimensional mechanical arm. Reagentbottles are distributed on the machine body platform and used for containing extraction reagents; a sleeve provided with a sampling filter cartridge is distributed in the ultrasonic extractor, and asampling hole is formed in the top of the sleeve; the constant-volume sample disc is used for placing a colorimetric tube and is matched with a visual constant-volume system to achieve the purpose that a set amount of reagent is filled into the colorimetric tube; a main frame is fixed to one side of the machine body platform, a multi-way injection pump is installed on the main frame, and the multi-way injection pump is connected with a steel needle through a hose to achieve extraction and injection actions. And the steel needle is driven by the XYZ three-dimensional mechanical arm to move among the containers, so that the actions of extraction and injection are completed. According to the full-automatic oil fume tester provided by the invention, an experimenter only needs to put a sample into the full-automatic oil fume tester, and the full-automatic oil fume tester can complete all processes in a full-automatic manner; and the working efficiency of experimenters is improved, and the contact of the experimenters with toxic and harmful reagents is reduced.

Owner:宁波然诺科学仪器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com