Steam fluid bed drying device and steam fluid bed drying method

A drying device and steam flow technology, applied in the directions of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of heat pump manufacturing difficulties and low energy consumption, and achieve high heat utilization efficiency, low equipment power consumption, simple effect design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

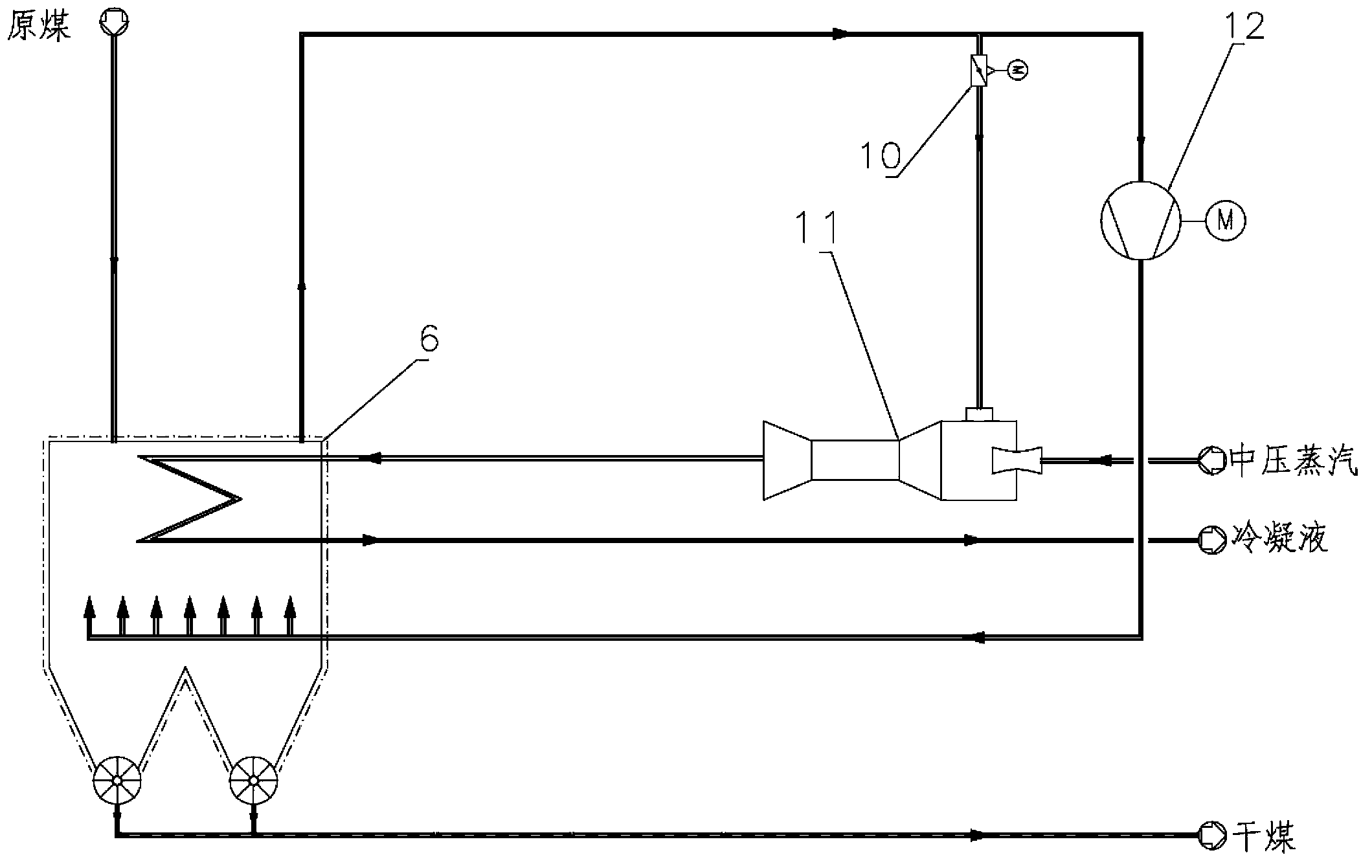

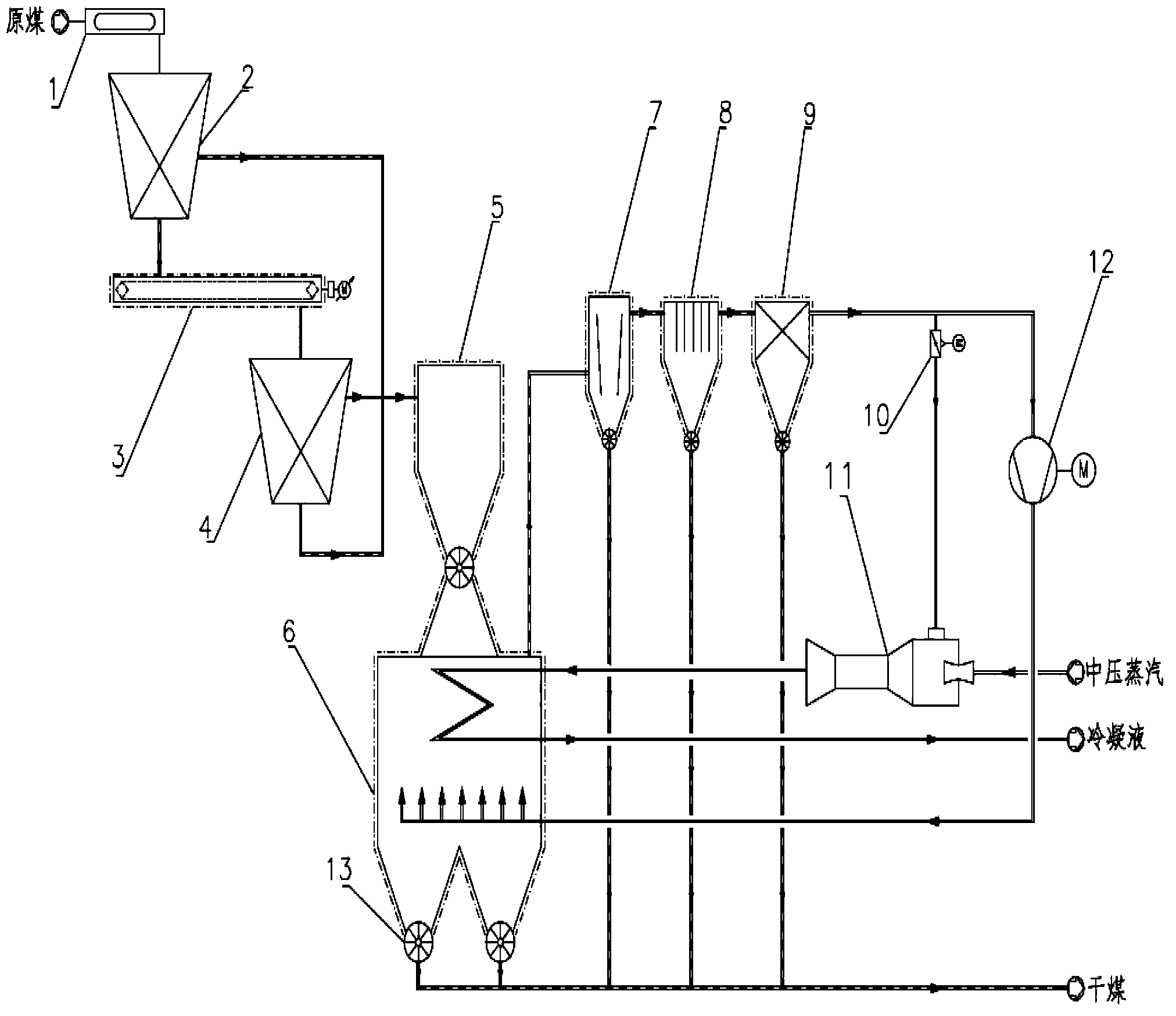

[0043] As a preferred technical solution of the present invention, such as figure 2 As shown, the steam injection fluidized bed lignite drying device includes a primary conveyor 1, a primary crushing and screening system 2, a secondary conveyor 3, a secondary crushing and screening system 4, a crushed coal bin 5, and a dryer 6. Cyclone separator 7, bag filter 8, electrostatic precipitator 9, regulating valve 10, ejector 11, fan 12, discharge valve 13.

[0044]Low-rank raw coal such as lignite is transported to the first-stage crushing and screening system 2 through the primary conveyor 1 for crushing and screening. In this system, the raw coal is first screened, and the raw coal with a particle size of less than 3mm is screened out and sent directly to the to the crushing coal bunker 5, and the particle size greater than 3mm is crushed to less than 10mm by the coal crusher, and transported to the secondary crushing and screening system 4 through the secondary conveyor 3, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com