Gas drying apparatus removing heat by utilizing compressor and method

A compressor exhaust, compressor technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc. Process requirements, the effect of improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

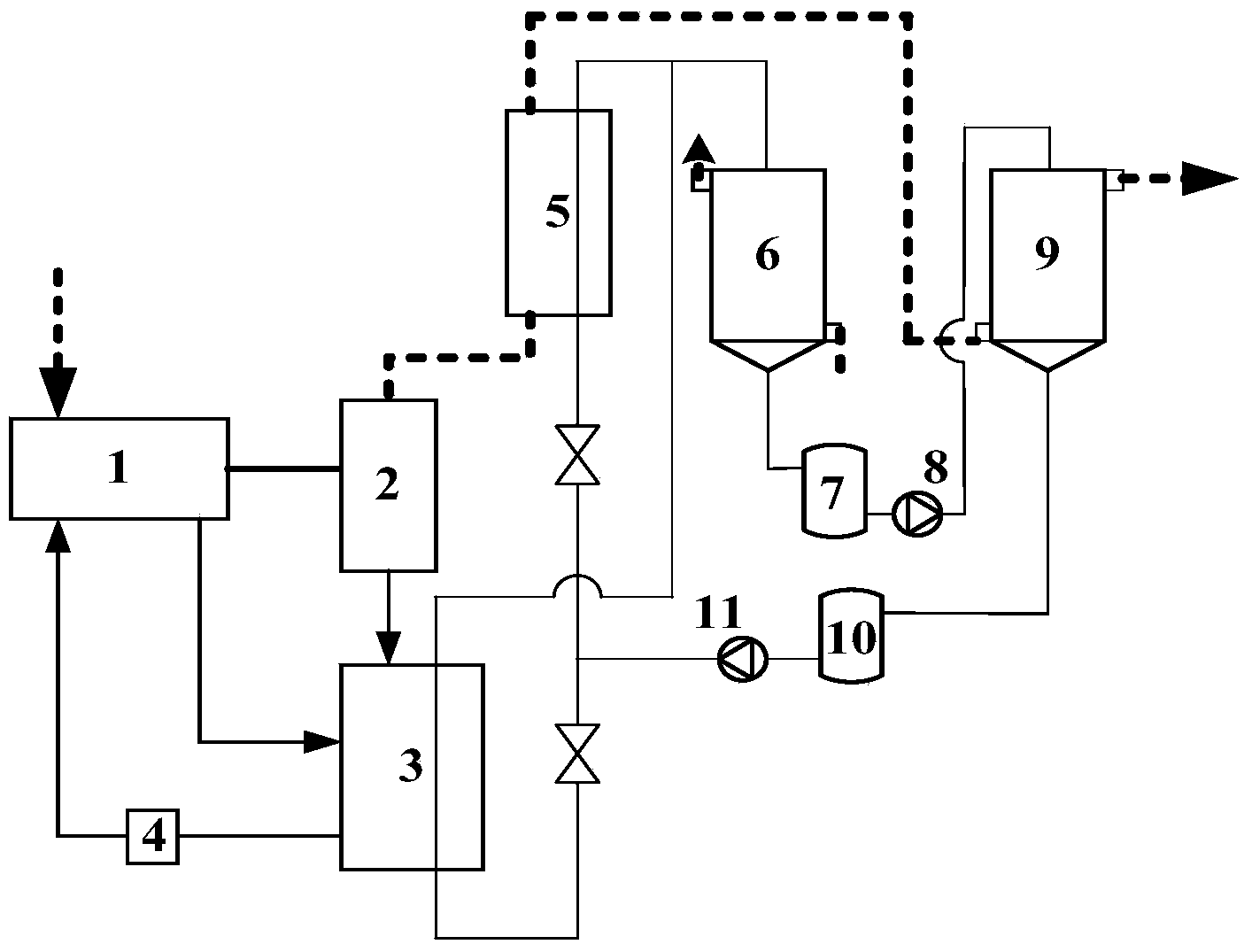

[0024] Embodiment 1: as figure 1 As shown, a gas drying method and device utilizing compressor exhaust heat mainly consists of a compressor host 1, an oil-gas separator 2, a lubricating oil heat recovery heat exchanger 3, an oil filter 4, and a compressor exhaust heat exchanger 5. It consists of a solution regenerator 6, a concentrated solution tank 7, a concentrated solution pump 8, a dehumidifier 9, a dilute solution tank 10, and a dilute solution pump 11. The lubricating oil heat recovery heat exchanger 3 and the inlet and outlet of the compressor exhaust heat exchanger 5 are respectively connected in parallel with the solution regenerator 6, the concentrated solution tank 7, the concentrated solution pump 8, the dehumidifier 9, the dilute solution tank 10, and the dilute solution tank 10. The solution pumps 11 are sequentially connected to form a cycle to form a solution loop. The dilute solution in the solution circuit is pumped to the lubricating oil heat recovery heat ...

Embodiment 2

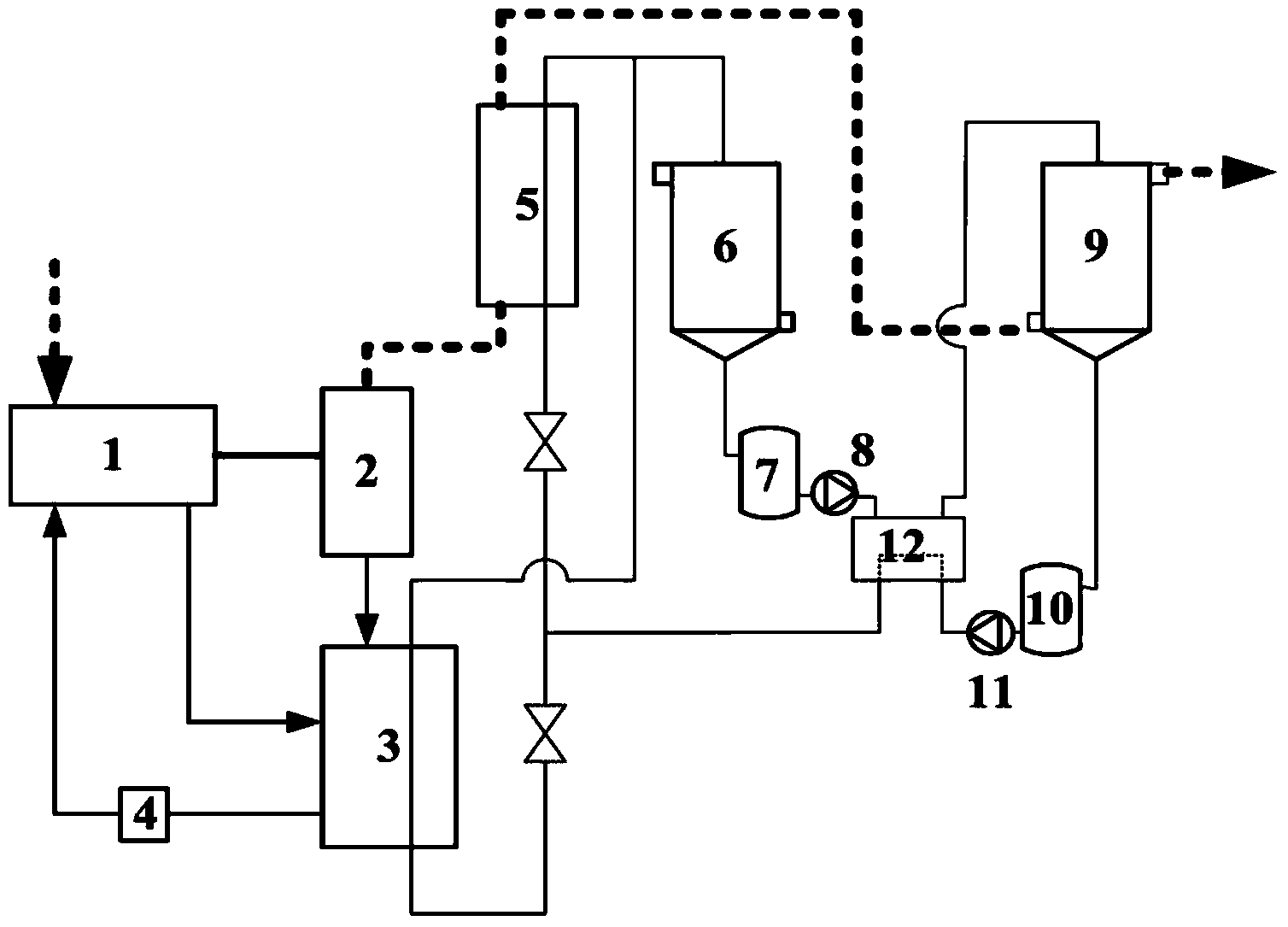

[0025] Embodiment 2: as figure 2As shown, a gas drying method and device utilizing compressor exhaust heat mainly consists of a compressor host 1, an oil-gas separator 2, a lubricating oil heat recovery heat exchanger 3, an oil filter 4, and a compressor exhaust heat exchanger 5. Solution regenerator 6, concentrated solution tank 7, concentrated solution pump 8, dehumidifier 9, dilute solution tank 10, dilute solution pump 11 and solution heat exchanger 12. After the lubricating oil heat recovery heat exchanger 3 and the compressor exhaust heat exchanger 5 are connected in parallel, they are connected with the solution regenerator 6, the concentrated solution tank 7, the concentrated solution pump 8, the solution heat exchanger 12, the dehumidifier 9, and the diluted solution. The solution tank 10 and the dilute solution pump 11 are sequentially connected to form a cycle to form a solution loop. In the solution loop, the dilute solution is first pumped to the solution heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com