Composite mass flowmeter

A mass flowmeter and composite technology, applied in the direction of indirect mass flowmeter, mass flow measuring device, measuring device, etc., can solve the problems of unstable outflow coefficient, low accuracy, easy to accumulate pollution, etc., and achieve reasonable structure, Easy installation and construction, high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

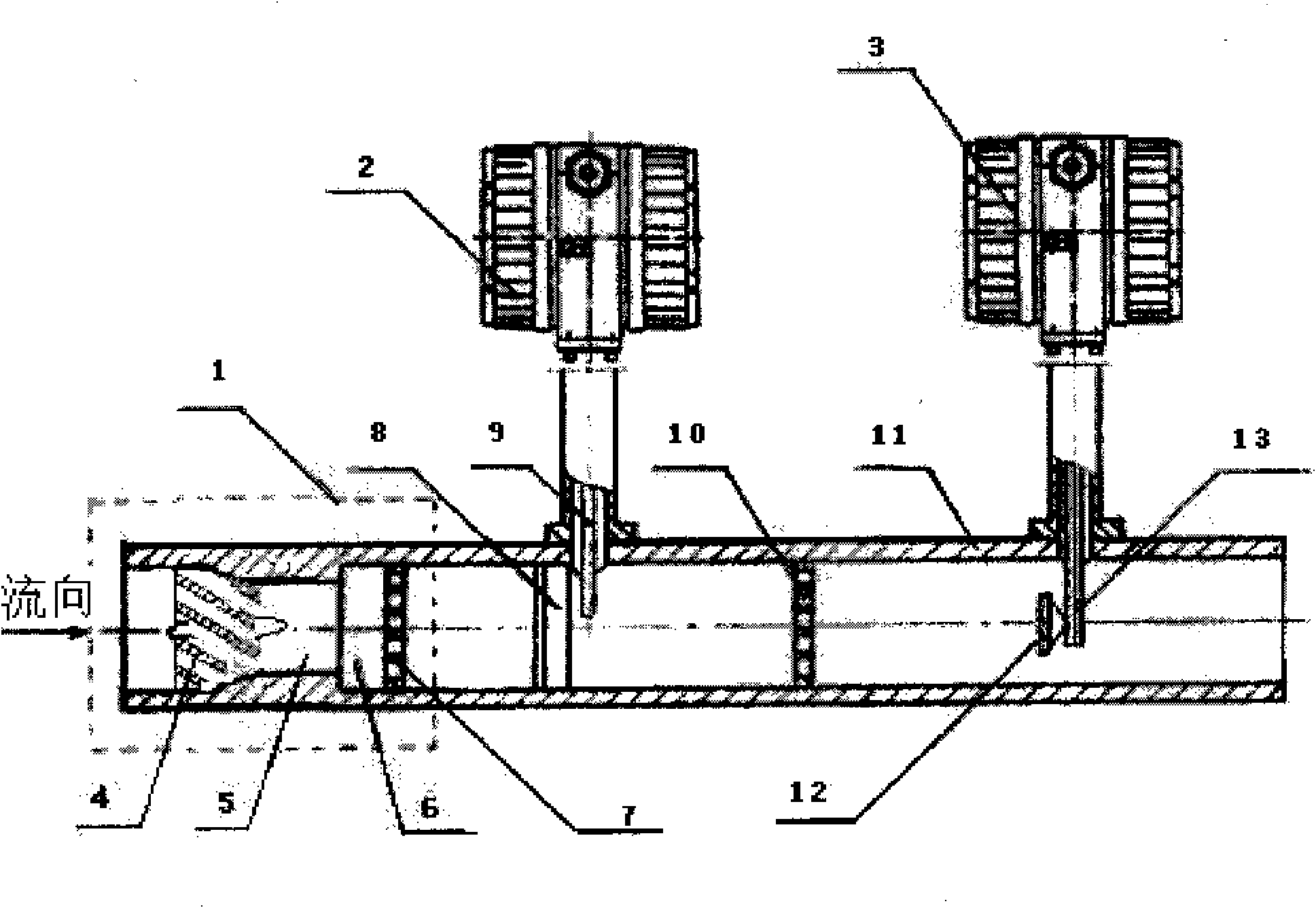

[0018] Example 1: from figure 1 It can be seen from the figure that a composite mass flowmeter includes a pipeline surface body 11, a vortex flow sensor 2, and a target flow sensor 3. On the meter body 11, the vortex generating body 8 and the vortex street detection probe 9 are installed in the pipeline meter body 11, the downstream of the pipeline meter body 11 is installed with a target flow sensor 3 for measuring flow velocity force, and the upstream end is equipped with a multiphase flow rectification device 1. The multi-phase flow rectification device 1 of the present invention is composed of a rotary vane wheel 4, a diameter-reducing area 5, a diffusion area 6, and a porous rectifier 7, and its shell and the pipe surface are integrally structured. That is to say, the shell of the multiphase flow rectification device 1 is a part of the pipeline surface body 11 .

[0019] The flow state of the two-phase flow or the multi-phase flow in the pipeline of the present inventio...

Embodiment 2

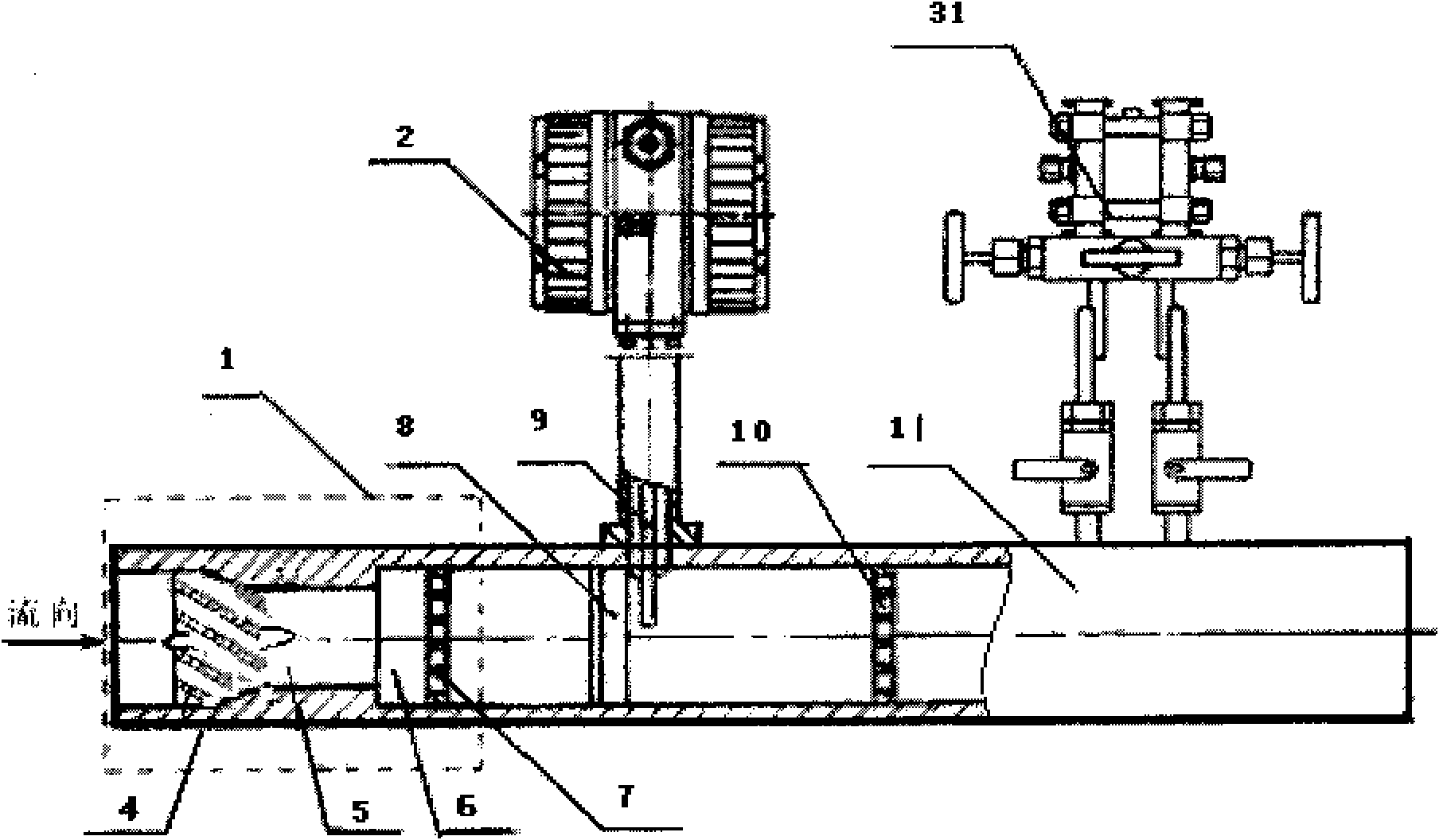

[0020] Example 2: from figure 2 It can be seen from the figure that a composite mass flowmeter includes a pipeline surface body 11, a vortex flow sensor 2, and a differential pressure flow sensor 31. On the pipeline surface body 11, the vortex generating body 8 and the vortex street detection probe 9 are installed in the pipeline surface body 11, a differential pressure flow sensor 31 for measuring flow differential pressure is installed downstream of the pipeline surface body, and a multiphase flow rectifier is installed at the upstream end device 1. Said multi-phase flow rectifying device 1 is the same as that of Embodiment 1. The invention uses a vortex street flow sensor to measure the flow velocity, a differential pressure flow sensor to measure the flow differential pressure, combines the sensing signals, collects, calculates, looks up the table through a microprocessor, and realizes the dryness, density, and flow measurement of the fluid.

Embodiment 3

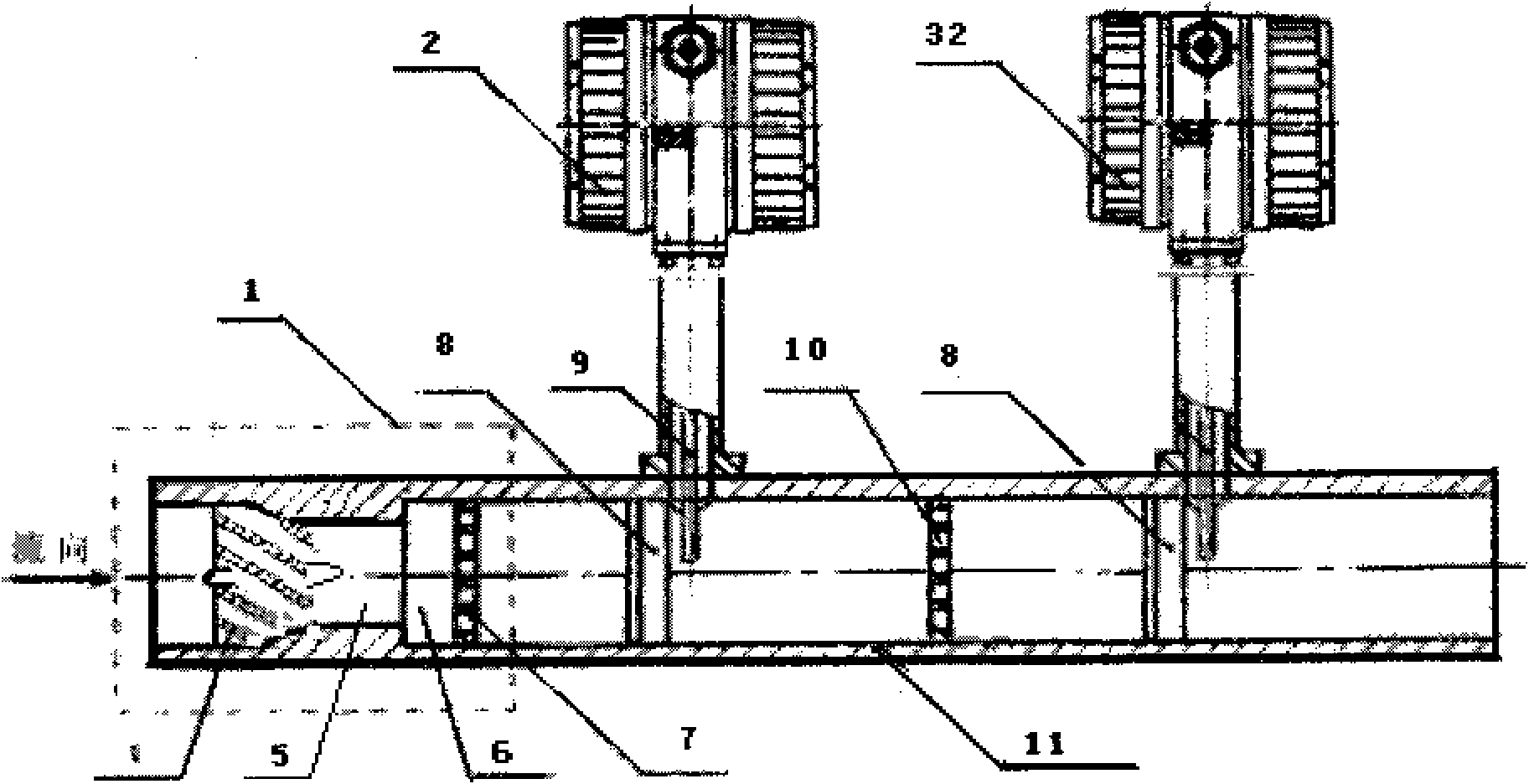

[0021] Example 3: from image 3 It can be seen from the figure that a composite mass flowmeter includes a pipeline surface body 11, a vortex flow sensor 2, and a vortex flow sensor 32. On the surface body 11, the vortex generating body 8 and the vortex detection probe 9 are installed in the pipeline surface body 11, a vortex flow sensor 32 for measuring the vortex lift force is installed downstream of the pipeline surface body, and a multiphase flow rectification device is installed at the upstream end 1. Said multi-phase flow rectifying device 1 is the same as that of Embodiment 1. The present invention utilizes the vortex flow sensor 2 to measure the flow velocity and the vortex flow sensor 32 to measure the vortex lift force, and combines these sensing signals to collect, calculate, and look up the table through the microprocessor to realize the dryness, density, and flow of the fluid. Measurement.

[0022] The invention has the advantages of reasonable structure, conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com