System for drying and decomposing wet acetylene sludge and firing cement clinker by using wet acetylene sludge as calcium raw material

A calcareous raw material, wet carbide slag technology, applied in cement production, clinker production and other directions, can solve problems such as increasing the decomposition heat consumption of the decomposition furnace system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

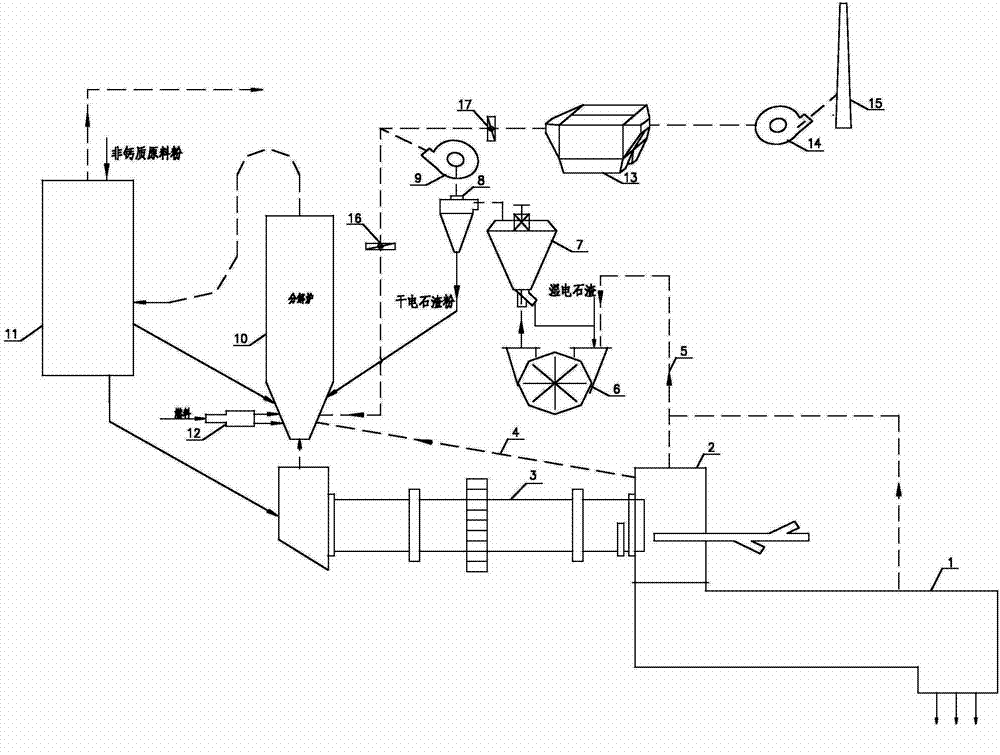

[0021] like figure 1 , a system for drying and decomposing wet calcium carbide slag and firing cement clinker as a calcareous raw material, including a clinker cooler 1, a rotary kiln 2, a kiln head cover 3, a tertiary air duct 4, a manifold 5, a drying Crusher 6, powder separator 7, cyclone dust collector 8, exhaust gas fan 9, calciner 10, preheater system 11, calciner fuel injection system 12, dust collector 13, fan 14, chimney 15, regulating valve 16. Regulating valve 17, the hot gas extracted from the clinker cooler 1 and or the kiln head cover 3 is mixed in the air manifold 5 and then enters the drying crusher 6, and is exchanged with the wet electricity slag fed to the drying crusher 6 After heating, it enters the bottom of the calciner 10 after passing through the powder separator 7, the cyclone dust collector 8 and the waste gas blower 9, and is used for fuel combustion in the calciner 10; It is directly fed into the calciner 10 alone, and the calcium hydroxide is dec...

Embodiment 2

[0026] If the calcareous raw material is calcium carbide slag, the wet calcium carbide slag is dried by hot air at the kiln head, and after powder selection, it is directly fed into the calciner 10 separately, and the non-carbide carbide raw material powder is preheated by the preheater system 11 and then enters the calciner. Mix and decompose with dry calcium carbide slag powder in the calciner and then enter the rotary kiln 2 to burn into cement clinker. In order to ensure that calcium hydroxide and other calcium raw materials (such as limestone) in the calcium carbide slag are completely decomposed , The outlet gas temperature of the decomposition furnace 10 is controlled above 850° C., and other implementation processes are the same as in Example 1.

Embodiment 3

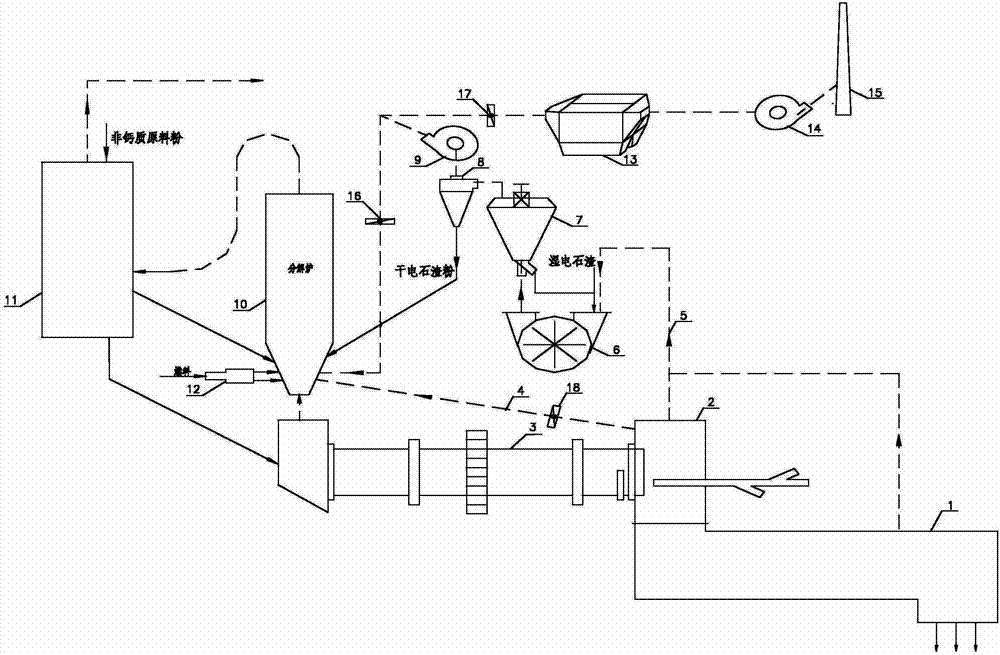

[0028] Tertiary air pipe 4 is provided with control valve 18, see figure 2 , according to the moisture content of calcium carbide slag and the amount of mixing in ingredients, the amount of hot air for drying calcium carbide slag and the fuel combustion of the calciner are controlled by adjusting the control valve 18. The opening of the control valve 18 is adjusted to 0-100%. Easy to burn, the control valve 18 of the tertiary air pipe 4 can be completely closed, and the tertiary air extracted from the kiln head cover 3 is all improved into the drying crusher 6, and other implementation processes are the same as in embodiment 1.

[0029]If the wet calcium carbide slag has a large amount of moisture after press filtration and there is a large amount of mixing in the ingredients, the amount of hot air drawn by the clinker cooler 1 and or the kiln hood 3 is not enough for drying the wet carbide slag, and other preheated air can be added to enter the drying process. The dry crushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com