Super-high power ultrasonic sump oil emulsion breaking dehydration method

A super-high-power, ultrasonic technology, applied in separation methods, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of aggravating the difficulty of environmental protection treatment, increasing the cost of sewage discharge, poor dehydration effect, etc., and achieve continuous uninterrupted demulsification and dehydration , to achieve the effect of recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

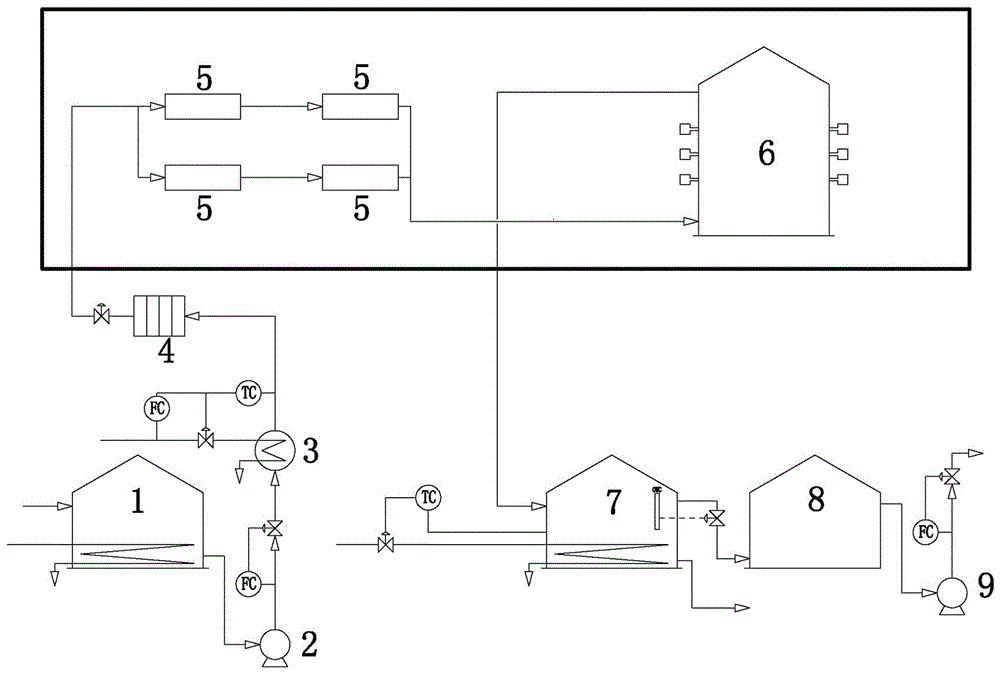

Embodiment 1

[0029]When the ultra-high-power ultrasonic demulsification and dehydration method for dirty oil provided by the present invention is used, a, firstly, the watery dirty oil in the dirty oil raw material tank 1 is preheated to 20° C. by inputting saturated steam of 1.1 MPa, and then the watery dirty oil is added by the watery dirty oil pump 2 After pressing, it is sent to the waste oil heater 3 to heat to 75°C, and the waste oil heater 3 uses 1.1MPa saturated steam to heat the pressurized water-containing waste oil; b. The heated water-containing waste oil is sent to two sets of series series The set of ultrasonic effectors 5 (two in series into one group and two groups in parallel) carry out continuous ultrasonic primary demulsification, and the heated water-containing dirty oil needs to be filtered by the impurity filter 4 before being sent to the ultrasonic effector 5; c, primary demulsification The emulsified dirty oil is sent through the pipeline to the pulse type ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com