Snail-like centrifugal ventilation device

A ventilation device and snail technology, which are applied in ventilation systems, space heating and ventilation, separation methods, etc., can solve the problems that the wind speed cannot be too high, restrict the wind speed, and affect the work efficiency of the system, so as to improve work efficiency and improve ventilation. Amount, easy to use effect

Inactive Publication Date: 2011-06-15

ZHUHAI FEIPENG PURIFICATION TECH

View PDF6 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, when the air purification system adjusts the air temperature, the condenser will produce water droplets, which will affect the working efficiency of the system. To improve the efficiency, ventilation needs to be designed. The ventilation speed of traditional air purification equipment cannot exceed 25 m / s, and the wind speed is too high The phenomenon of "flying water" will occur, that is, tiny water droplets fly to other components with the high-speed wind, affecting the work of other components, or in the high-voltage electrostatic precipitator system, it is necessary to use water spray to remove dust, and the wind speed cannot exceed High, the airflow passing through the dust removal channel is also easy to bring water droplets to other components. This "flying water" phenomenon seriously restricts the increase of wind speed, affects the working efficiency of the system and the air purification effect, and causes some inconvenience to users.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

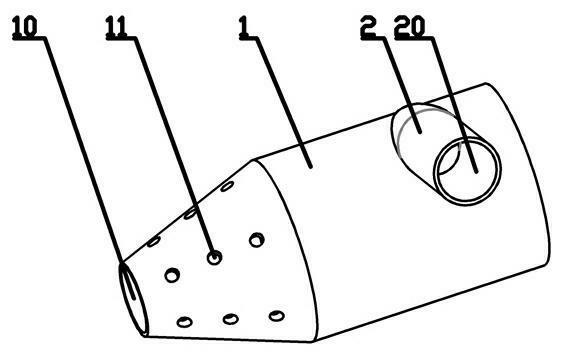

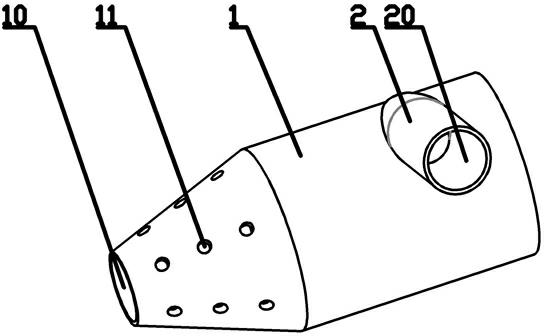

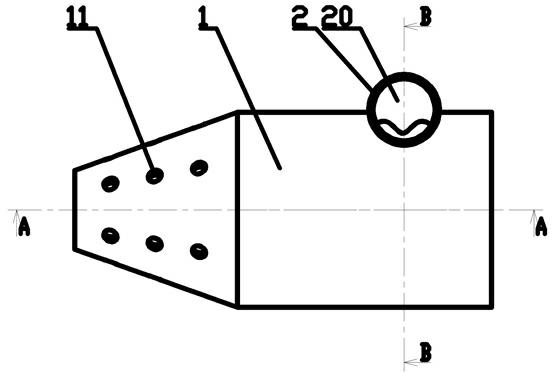

Login to View More Abstract

The invention discloses a snail-like centrifugal ventilation device, and aims to provide the snail-like centrifugal ventilation device which can improve the ventilation volume of an air purification system and the working efficiency of the system. The snail-like centrifugal ventilation device comprises a main ventilation pipe (1) and an air inducing pipe (2), wherein the front half part of the main ventilation pipe (1) is circular, and the rear half part of the main ventilation pipe (1) is a reducing conical part; a port of the front half part of the main ventilation pipe (1) is sealed, and the port of the rear half part of the main ventilation pipe (1) is an air outlet (10); the side wall of the rear half part of the main ventilation pipe (1) is provided with a plurality of small holes (11); and the air inducing pipe (2) is communicated with the front half part of the main ventilation pipe (1), is perpendicular to the main ventilation pipe (1) and is tangent to the main ventilation pipe (1). The ventilation device can be widely applied to purification systems.

Description

A spiral centrifugal ventilation device technical field The invention relates to a spiral centrifugal ventilation device. Background technique At present, when the air purification system adjusts the air temperature, the condenser will produce water droplets, which will affect the working efficiency of the system. To improve the efficiency, ventilation needs to be designed. The ventilation speed of traditional air purification equipment cannot exceed 25 m / s, and the wind speed is too high The phenomenon of "flying water" will occur, that is, tiny water droplets fly to other components with the high-speed wind, affecting the work of other components, or in the high-voltage electrostatic precipitator system, it is necessary to use water spray to remove dust, and the wind speed cannot exceed High, the airflow passing through the dust removal channel is also easy to bring water droplets to other components. This "flying water" phenomenon seriously restricts the increase of win...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D45/16F24F7/04B01D5/00

Inventor 王浦林

Owner ZHUHAI FEIPENG PURIFICATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com