Rear spiral-separation dewatering device for smoke water removal

A dehydration device and flue gas technology, applied in gas treatment, separation method, dispersed particle separation, etc., can solve problems such as secondary entrainment of droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

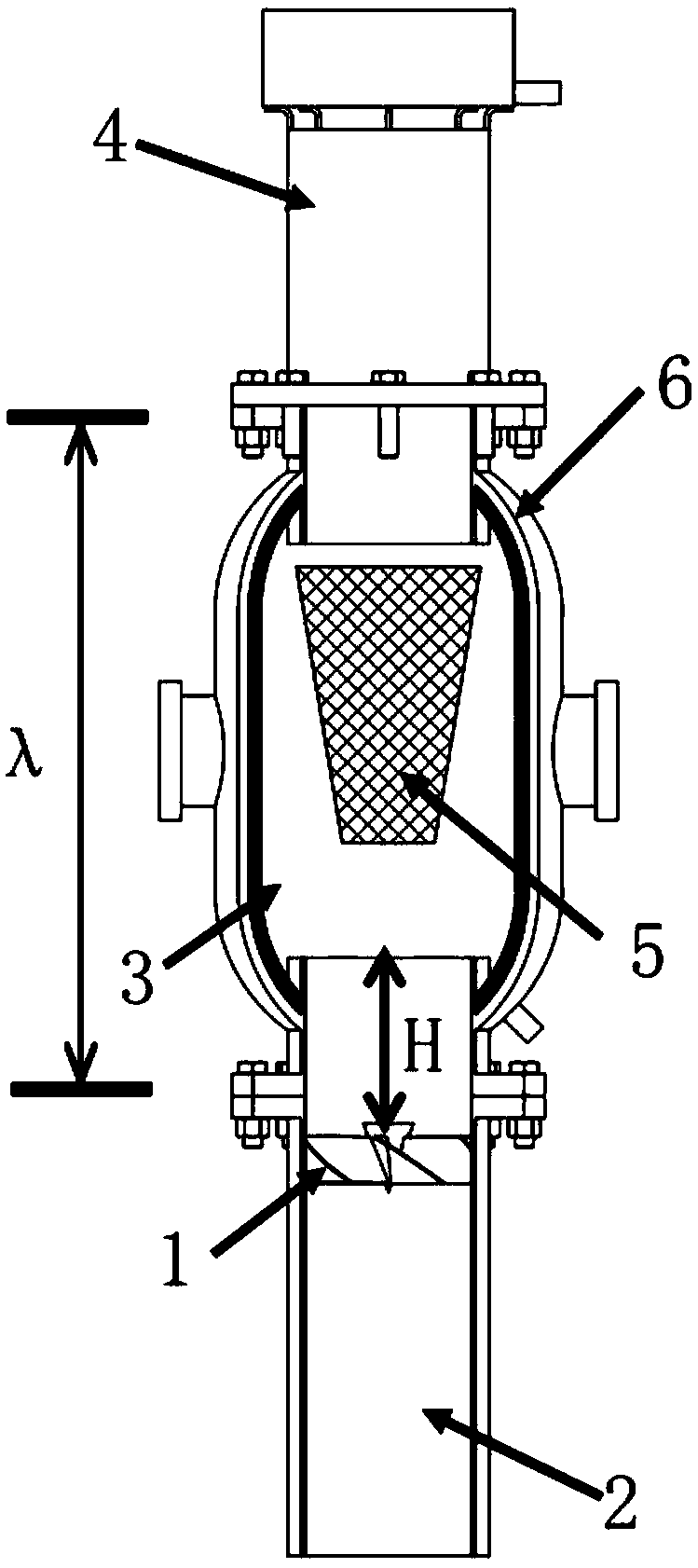

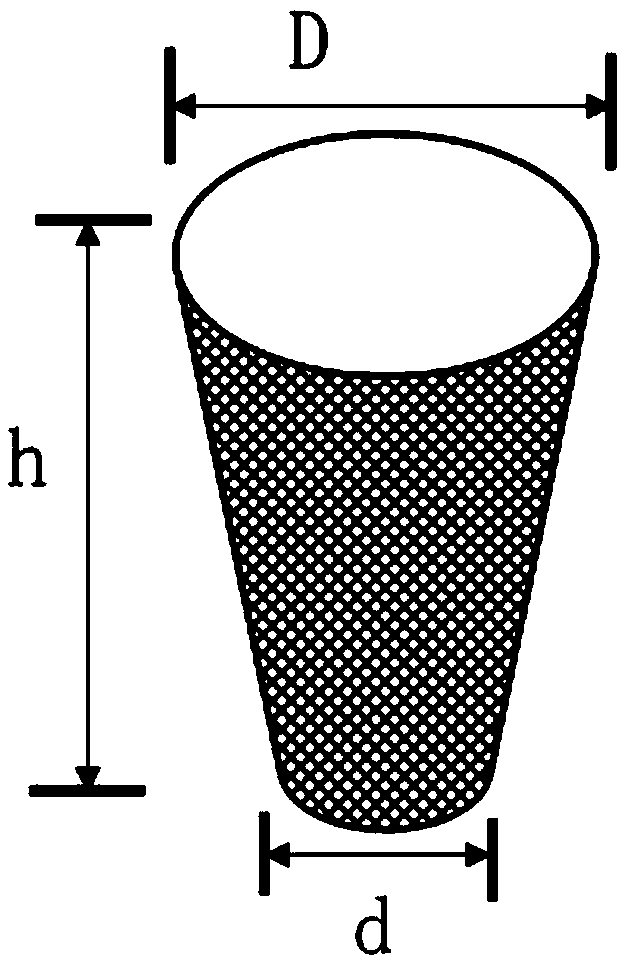

[0020] Such as figure 1 and figure 2 As shown, it is the equivalent ratio model of flue gas dehydration. The inner diameter of the flue gas channel is 209mm, and the overall height is 4000mm. The simulation of the pre-experimental environment provides 1000Nm with a simulated water content of 20%. 3 / h of flue gas, and ensure that the working temperature of the water removal pipeline is 60°C, and set up no special design pipeline for comparative tests.

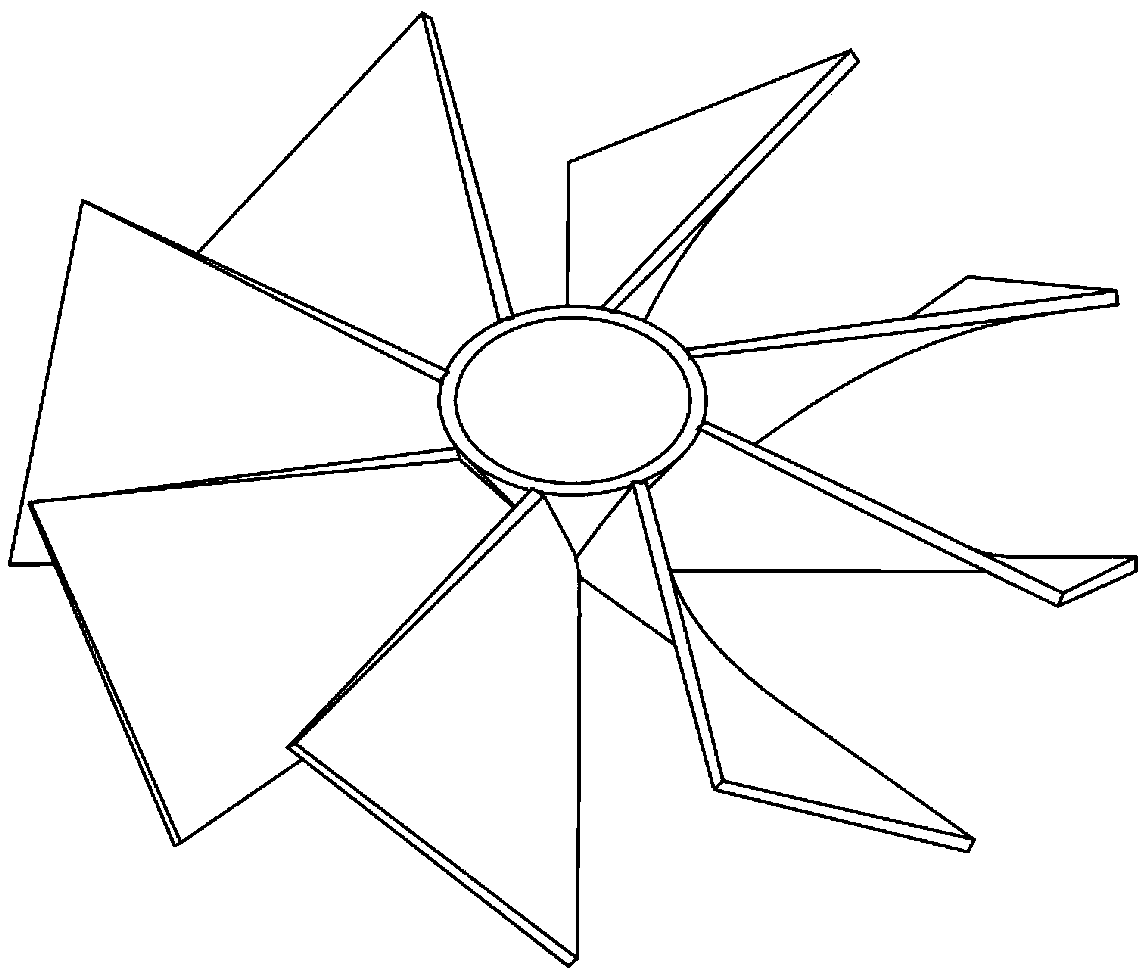

[0021] The installation method of the cyclone separator is determined by CFD software simulation according to the specific geometric dimensions of the flue and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com