Online diagnosis method for uniformity of common-rail oil injectors

A technology of common rail injectors and diagnostic methods, which is applied in the testing of machines/structural components, instruments, fuel injection devices, etc., and can solve the problems of inconspicuous combustion effects, many influencing factors, and insufficient accuracy of injector injection volume, etc. problems, to achieve the effects of improved diagnostic reliability, accurate diagnosis, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific drawings and embodiments.

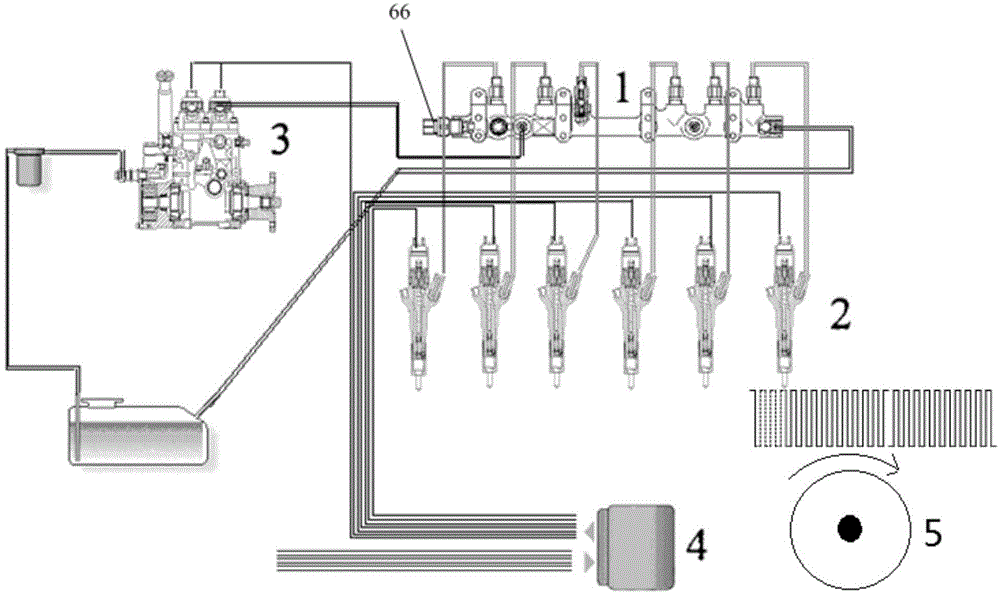

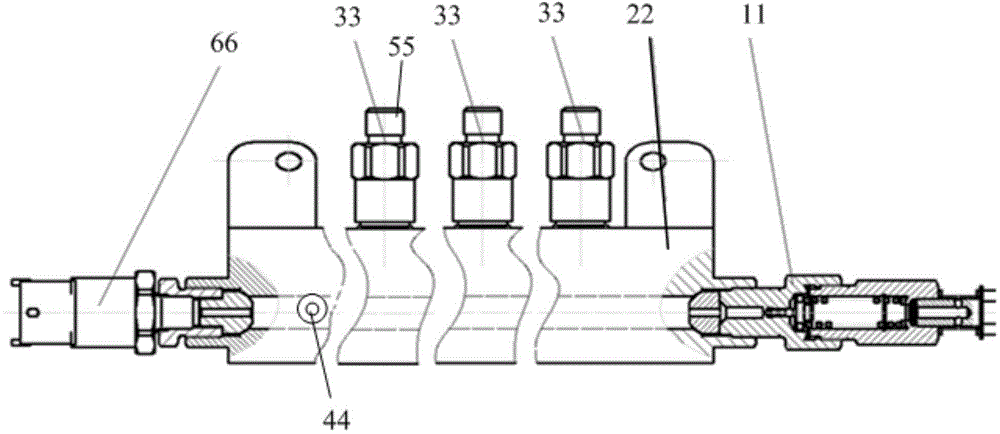

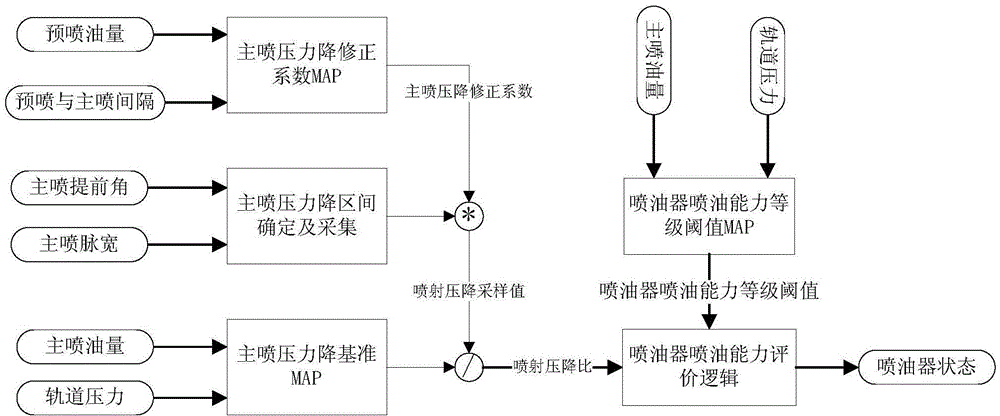

[0031] Such as figure 1 As shown, the electronically controlled diesel common rail fuel system includes a high-pressure common rail pipe 1, multiple fuel injectors 2, a high-pressure fuel supply pump 3, and an electronic control unit 4. The high-pressure common rail pipe 1 is a pressure vessel for storing fuel, and distributes the high-pressure fuel to each injector 2 through the high-pressure fuel pipe. The fuel injector 2 injects the pressurized fuel in the high-pressure common rail pipe 1 into the combustion chamber of the engine with the best injection timing, injection quantity, injection rate and injection method according to the signal sent by the electronic control unit 4 . A flywheel disc 5 is installed at the end of the power output shaft of the engine, and the flywheel disc is marked with spaced teeth similar to gears. With the rotation of the engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com