Patents

Literature

60results about How to "Solve unqualified" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

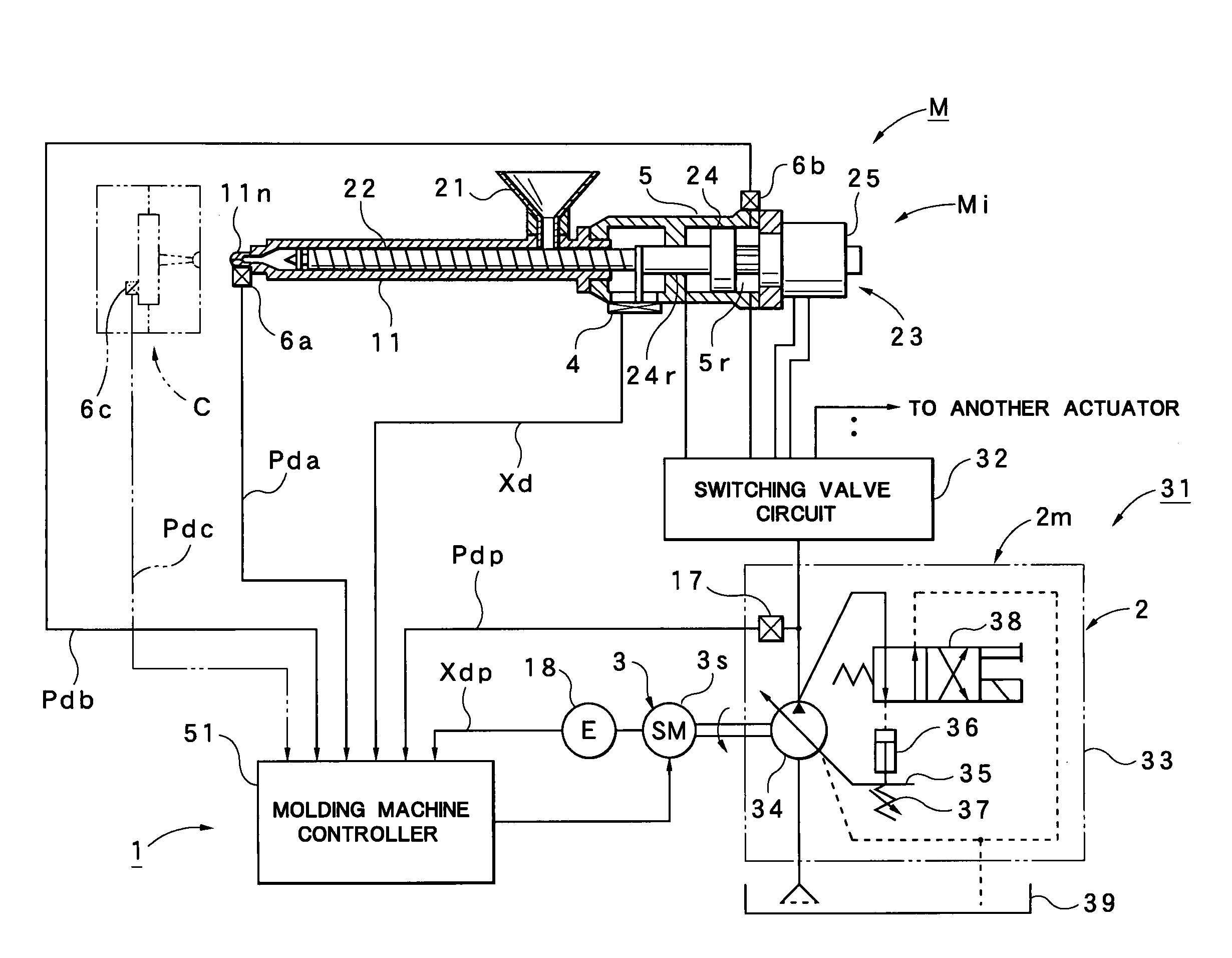

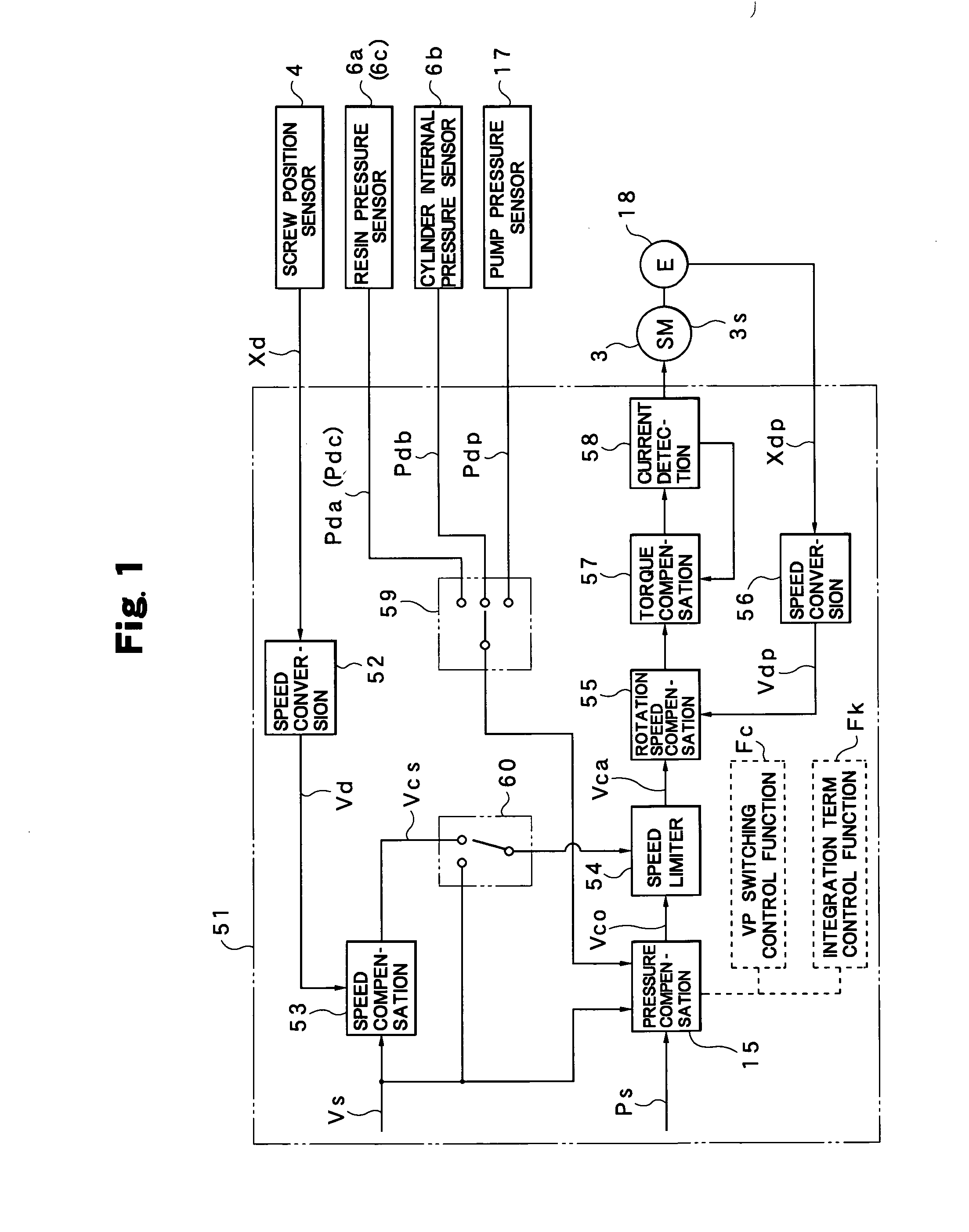

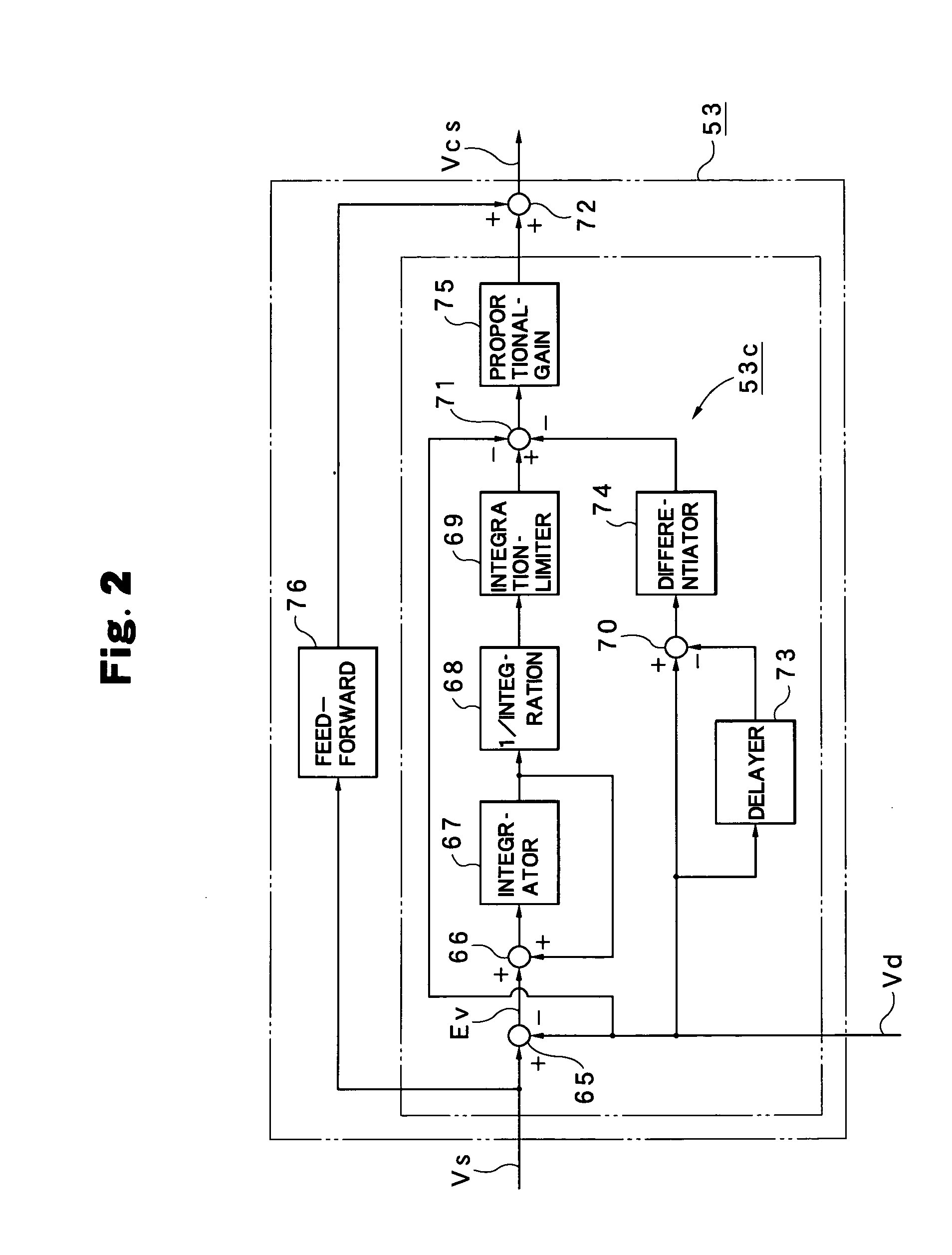

Controller of injection molding machine

ActiveUS20090087510A1Significant changeSolve unqualifiedAuxillary shaping apparatusInjection pressureScrew position

The present invention comprises a speed feedback control system for carrying out speed feedback control on the basis of a speed detected value Vd obtained by converting a position detected value Xd obtained from a screw position sensor 4, a pressure feedback control system for carrying out a pressure feedback control on the basis of a pressure detected value Pdb obtained from an injection pressure sensor 6b, and a VP switching control function portion Fc for carrying out switching from a speed control region to a pressure control region Zp when a pressure deviation Ep between a preset pressure set value Ps and the pressure detected value Pdb becomes a preset switching determination value Eps or less and carrying out the switching to the pressure control region Zp after control of a speed command value in the speed control region Zv by a predetermined control pattern Dp at this switching.

Owner:NISSEI PLASTIC IND CO LTD

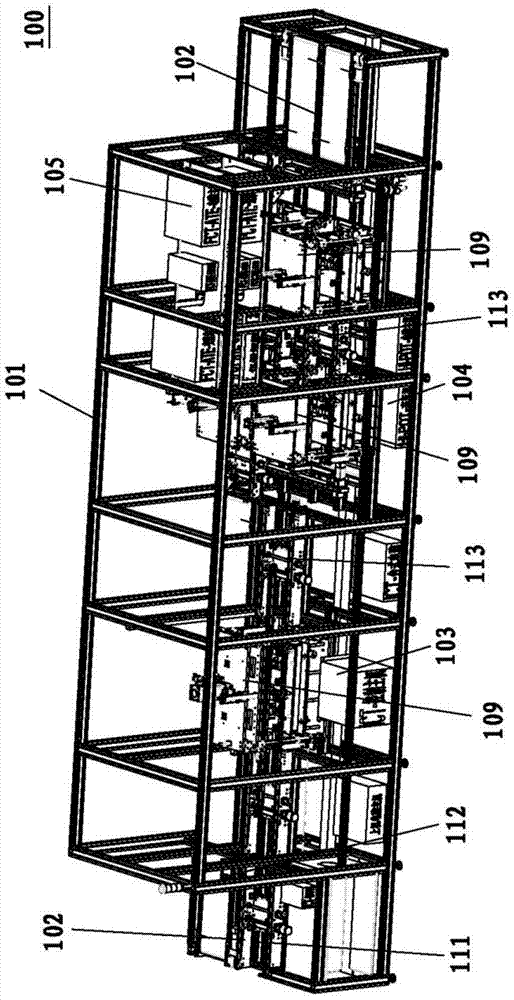

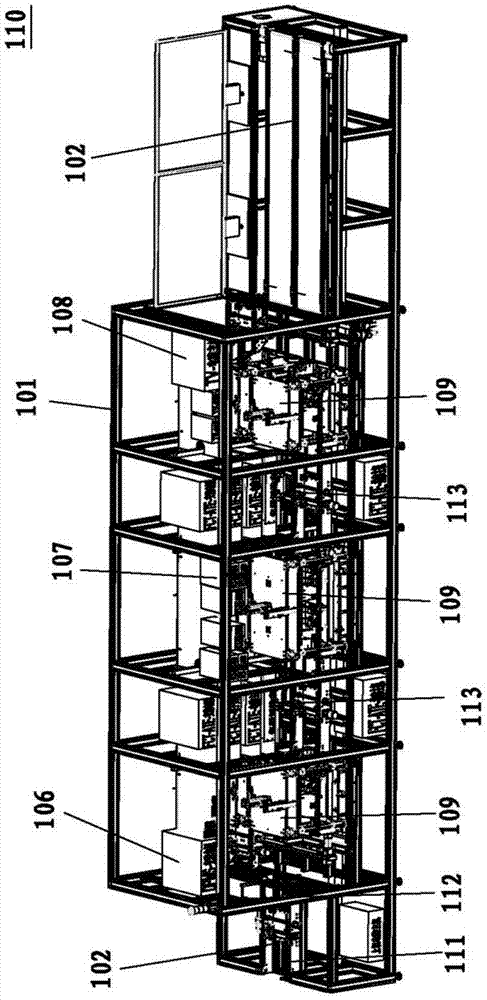

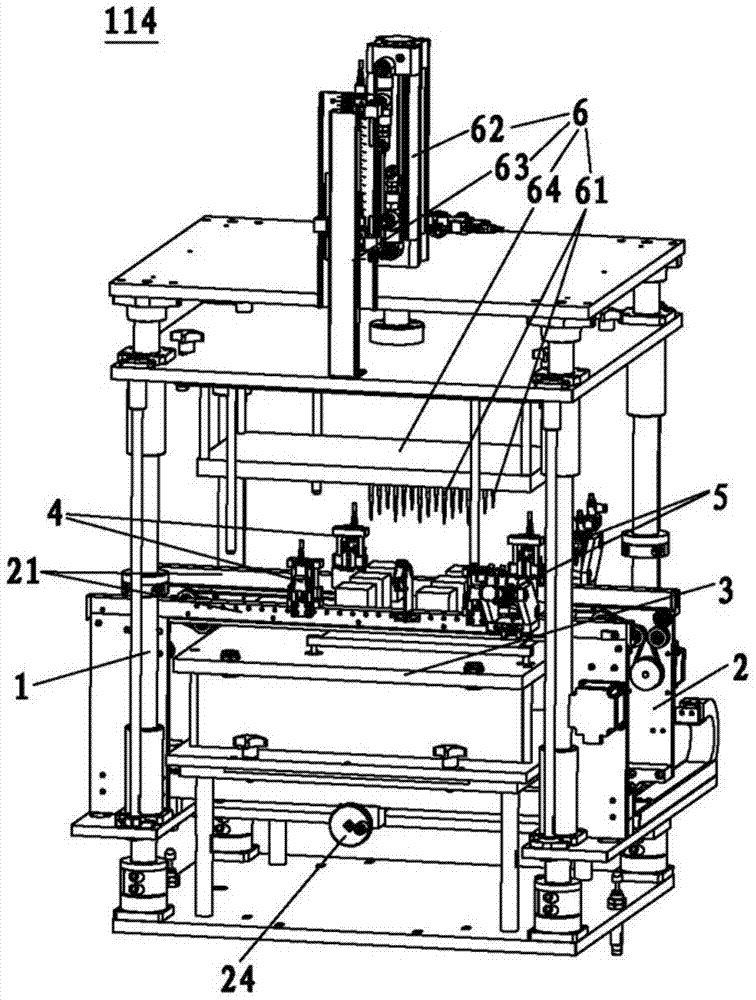

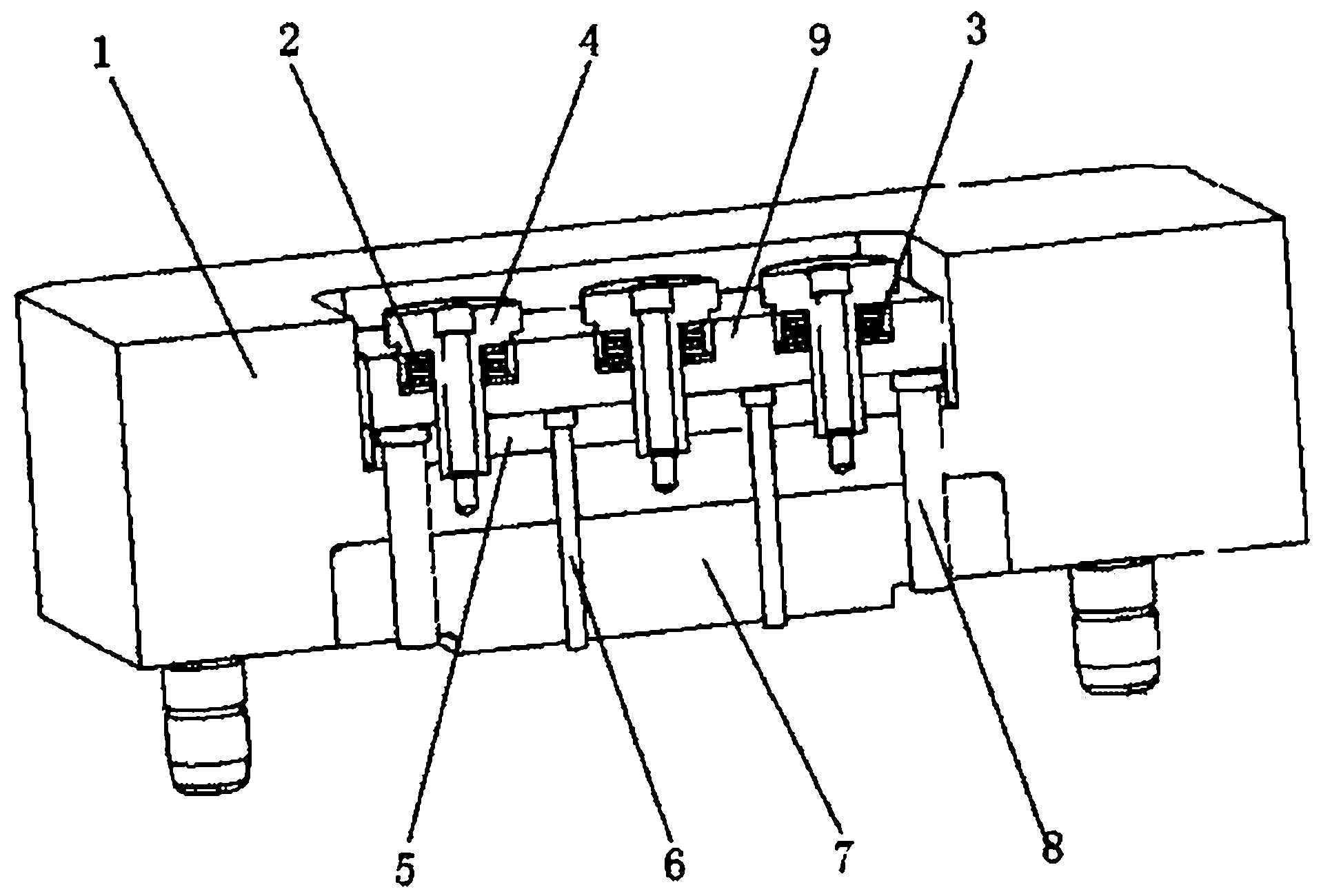

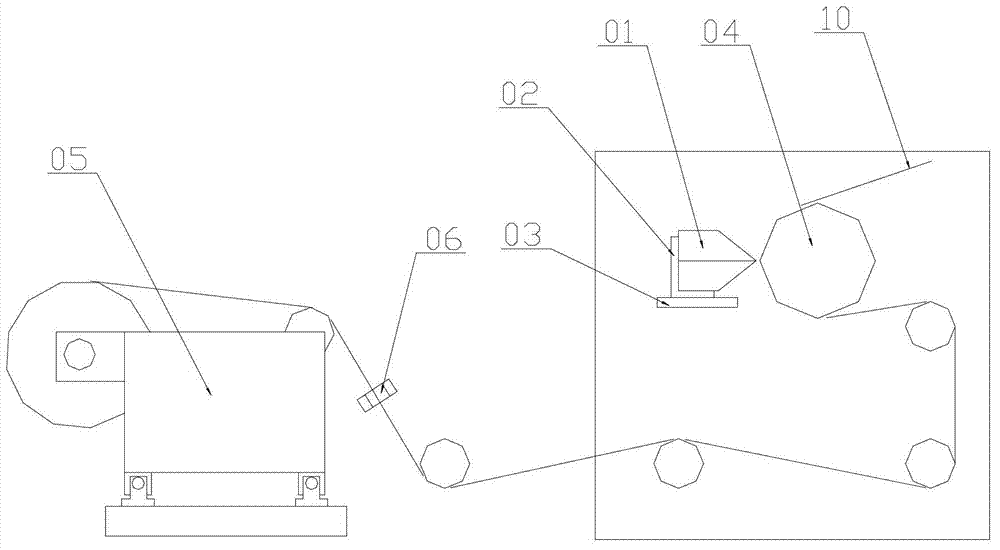

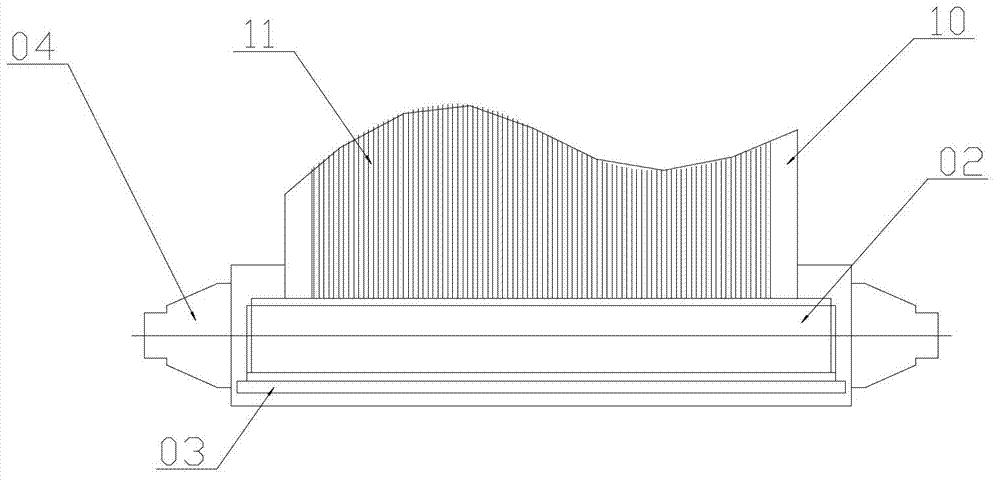

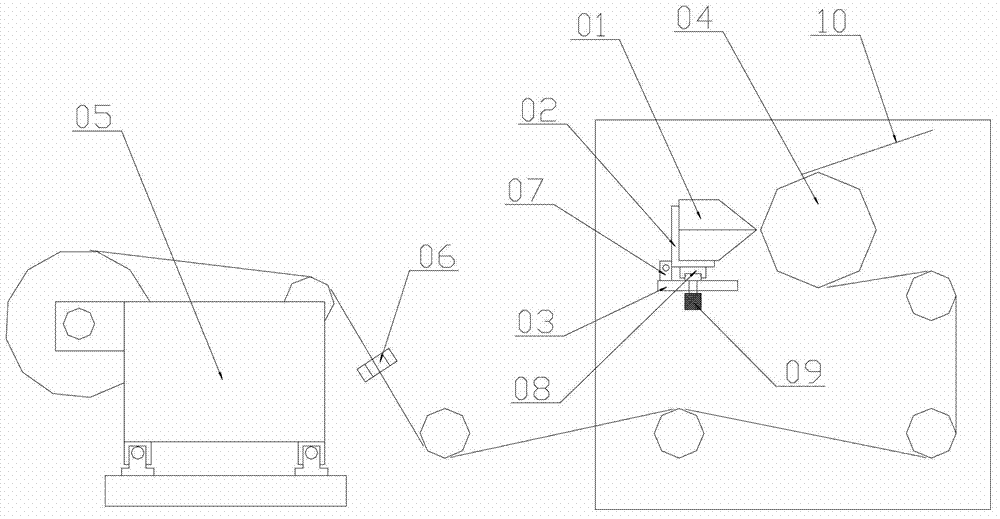

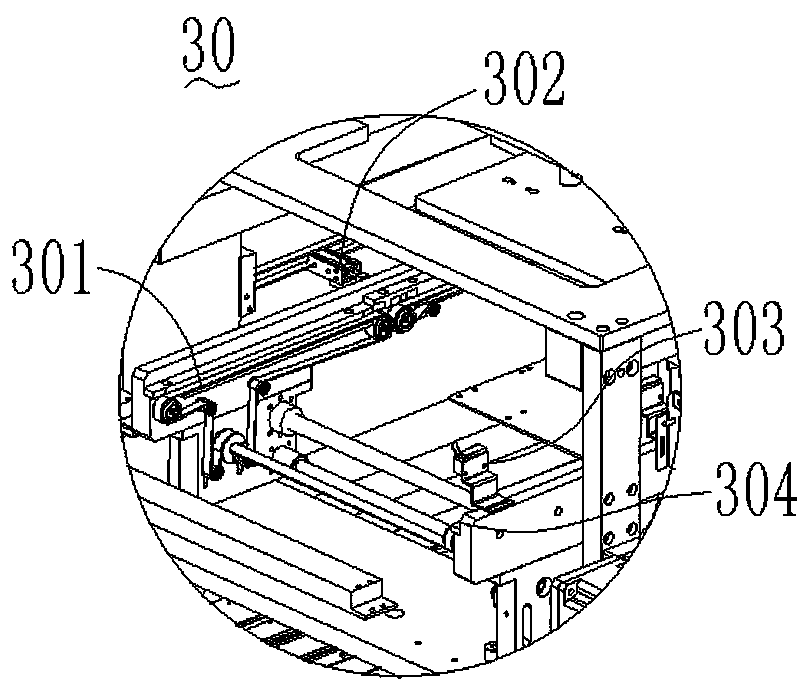

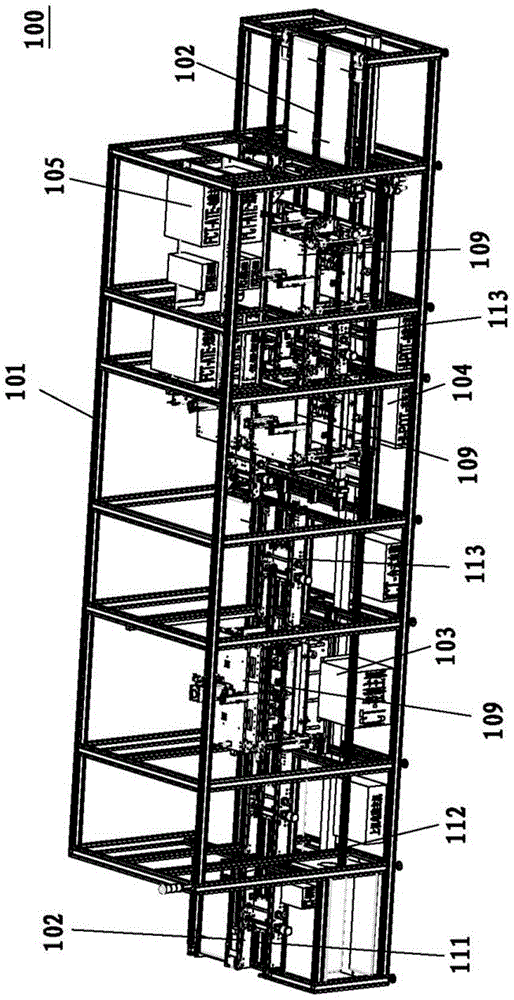

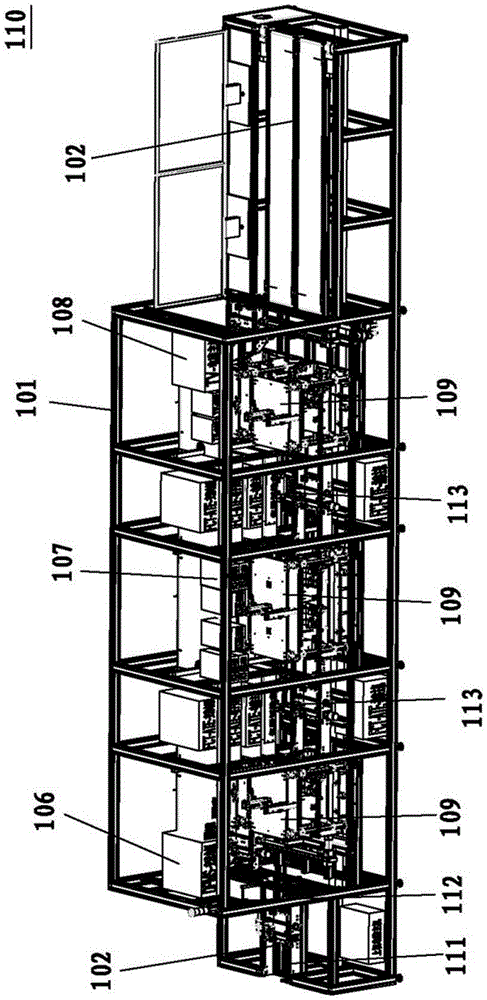

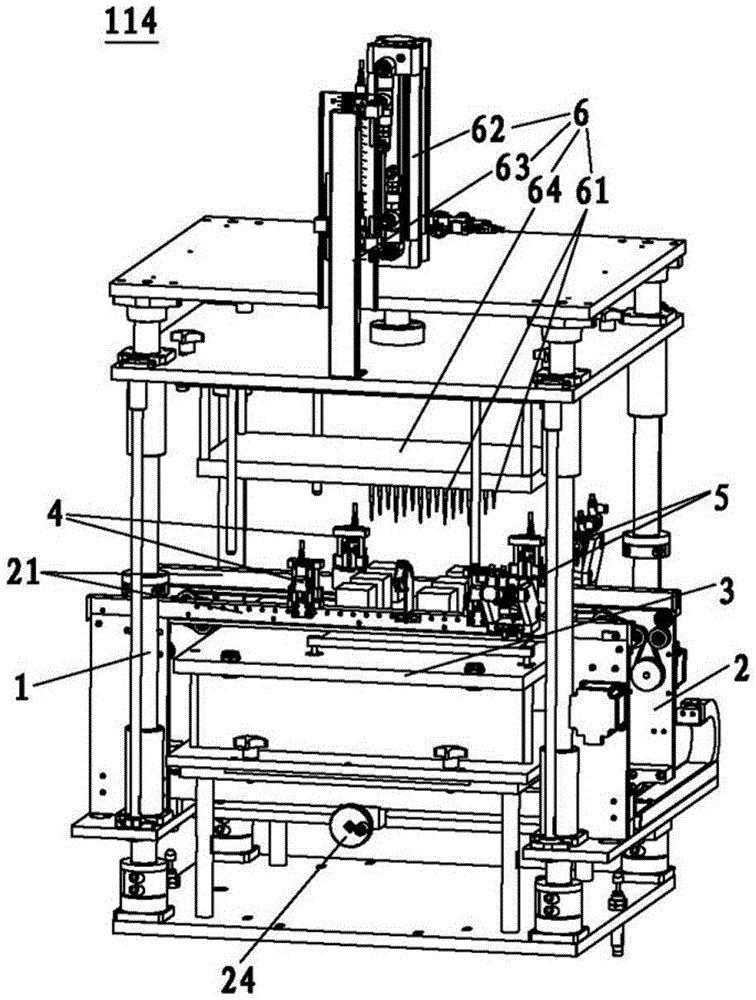

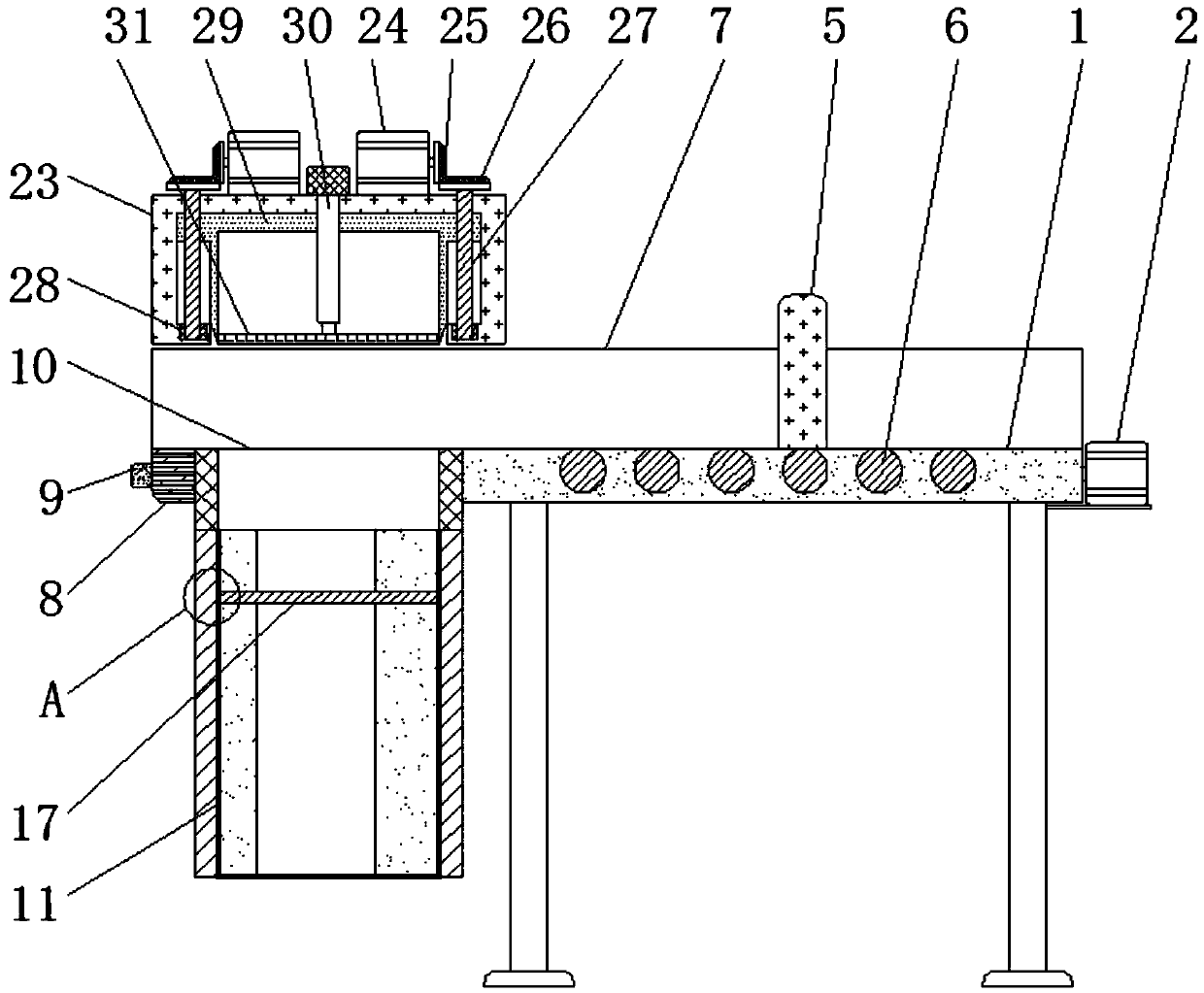

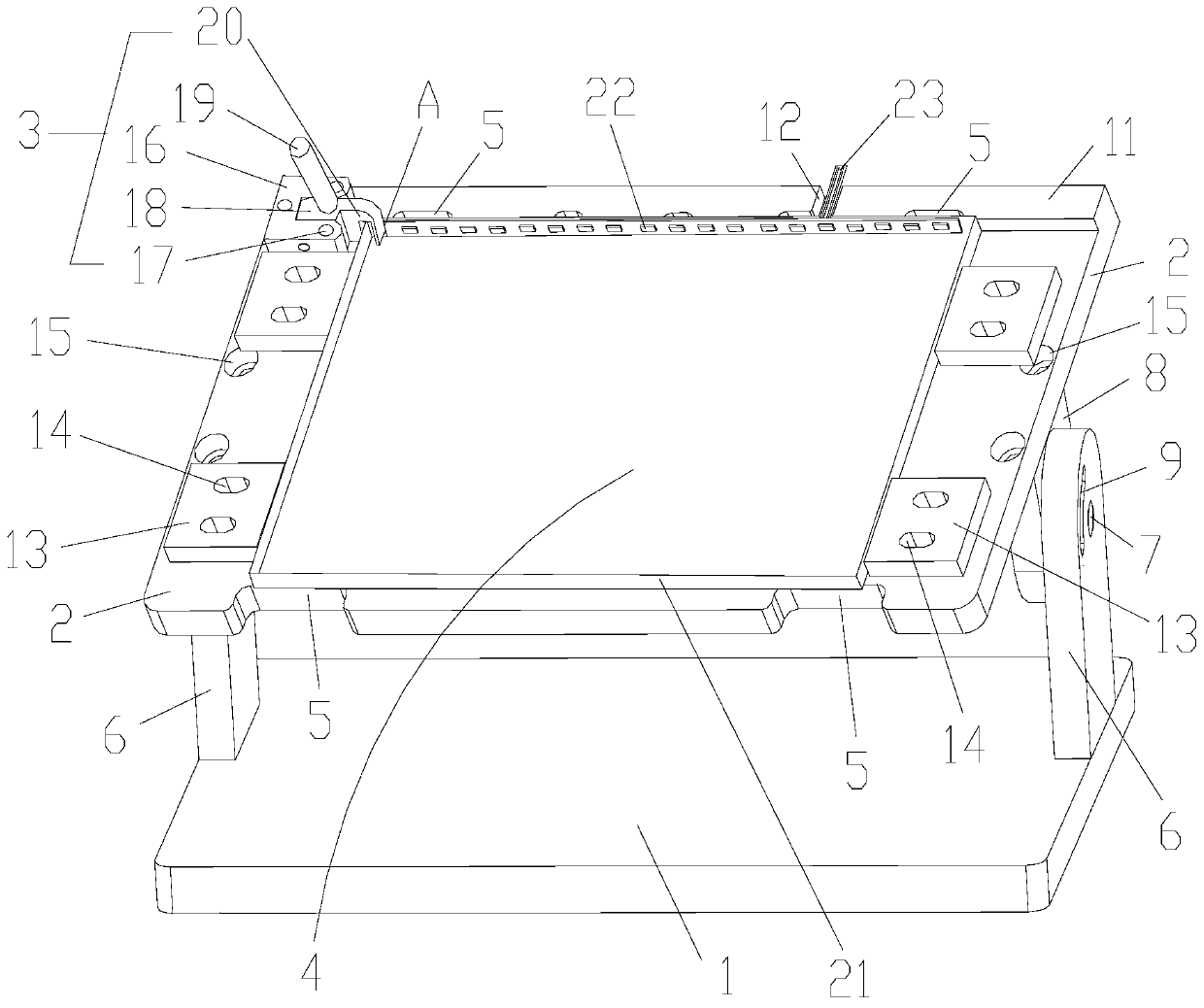

Multifunctional power panel testing production line

ActiveCN104267330ASolve unqualifiedImprove work efficiencyElectronic circuit testingMeasurement instrument housingProduction lineEngineering

The invention discloses a multifunctional power panel testing production line. The multifunctional power panel testing production line comprises a first testing device and a second testing device. A power panel enters the second testing device after passing through the first testing device. The first testing device and the second testing device each comprise a rack, a conveyer belt stretching across the rack and a testing fixture arranged on the rack. The first testing device further comprises an ICT testing mechanism, a Hi-pot testing mechanism and an FCT testing mechanism, and the ICT testing mechanism, the Hi-pot testing mechanism and the FCT testing mechanism are sequentially arranged on the rack of the first testing device. The second testing device further comprises a DPMS testing mechanism, an ATE testing mechanism and a TV testing mechanism, and the DPMS testing mechanism, the ATE testing mechanism and the TV testing mechanism are sequentially arranged on the rack of the second testing device. The multifunctional power panel testing production line improves the working efficiency and automation of PCBA tests and makes the quality of the PCBA tests more stable.

Owner:DONGGUAN GUANJIA ELECTRONICS EQUIP

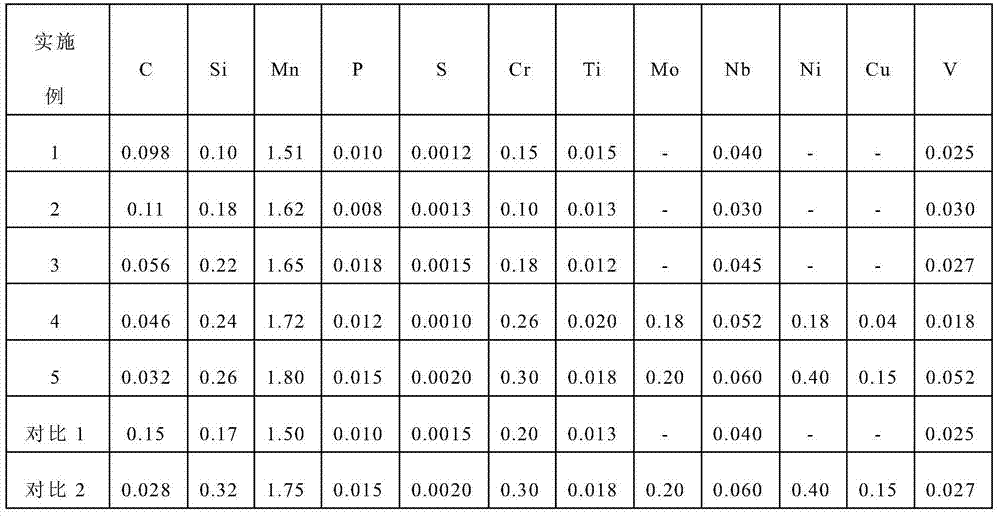

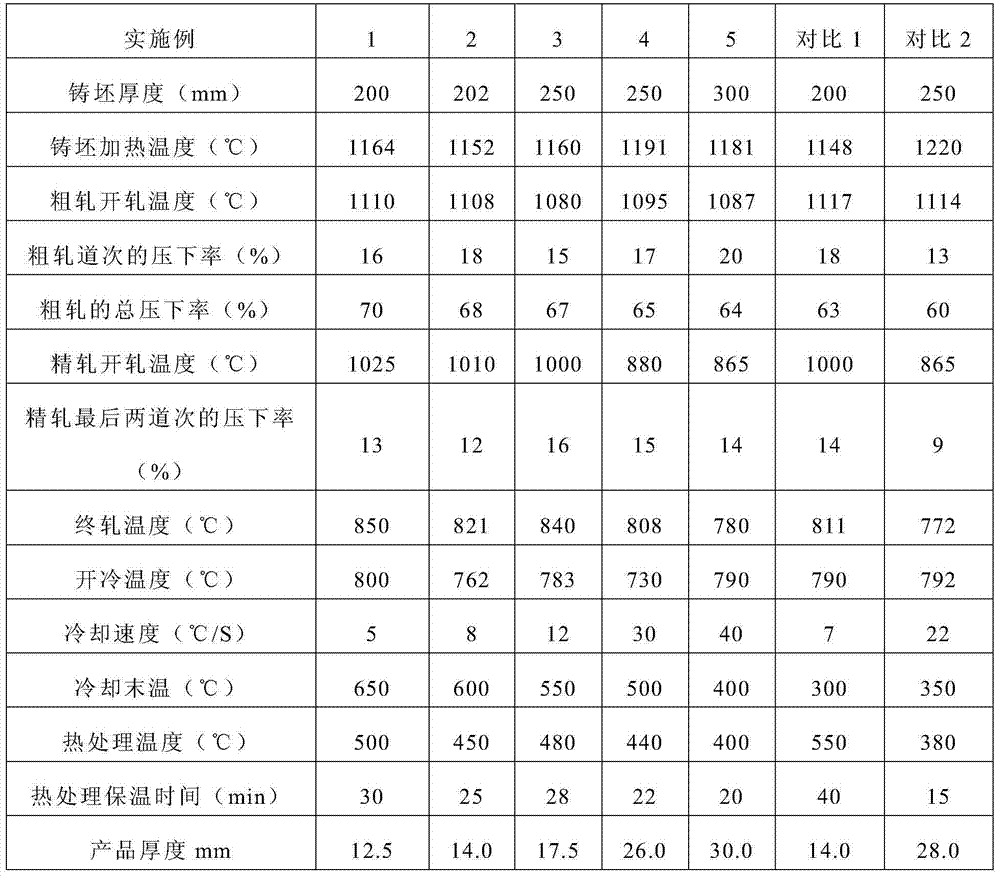

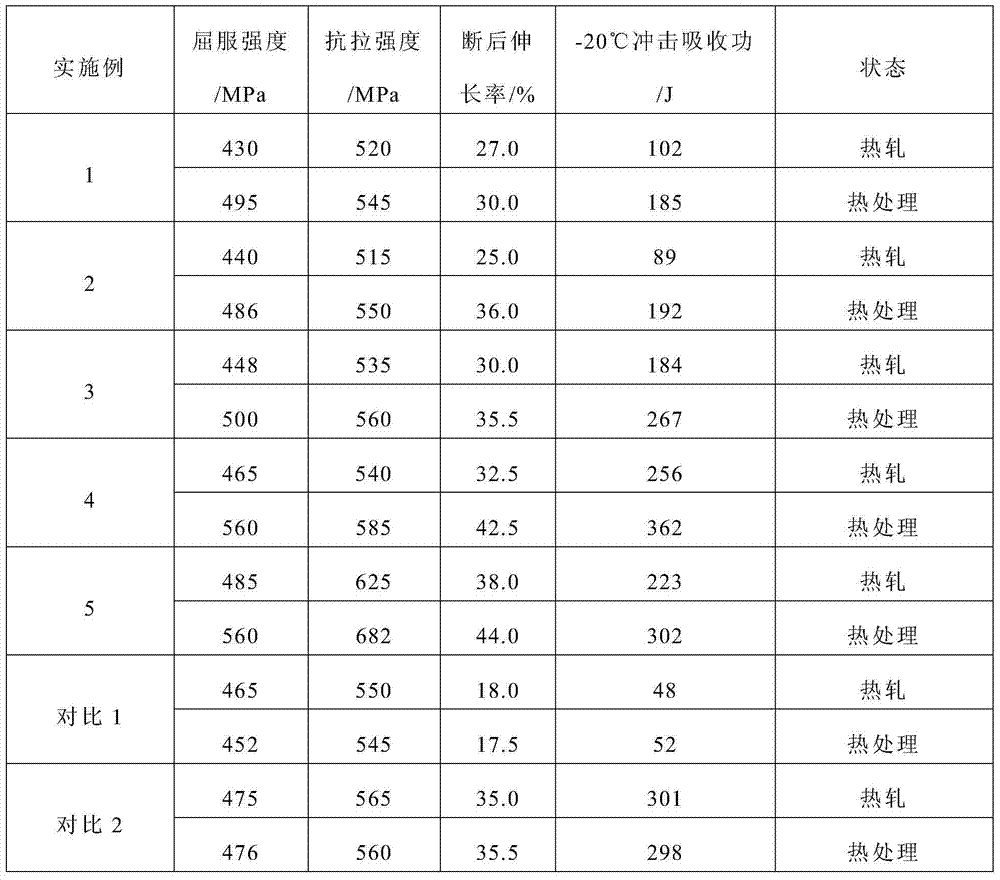

High-strength high-toughness steel plate and preparation method thereof

The invention discloses a high-strength high-toughness steel plate. The steel comprises the following chemical components in percentage by weight: 0.032-0.11% of C, 0.10-0.26% of Si, 1.51-1.80% of Mn, 0.03-0.06% of Nb, 0.012-0.020% of Ti, at most 0.052% of V, at most 0.20% of Mo, at most 0.40% of Ni, at most 0.30% of Cr, at most 0.15% of Cu, at most 0.018% of P, at most 0.0020% of S, and the balance of Fe and inevitable impurities. The invention also discloses a preparation method of the high-strength high-toughness steel plate, which comprises the following steps: 1) blank casting; 2) heating; 3) rolling; 4) cooling; 5) heat treatment; and 6) air cooling. The method has the advantages of simple hot rolling technique, low heat treatment temperature, short holding time, low energy consumption and lower production cost, obtains the product with higher quality, and enhances the yield.

Owner:武钢集团有限公司

Preparation method for flucloxacillin sodium

The invention relates to a preparation method for flucloxacillin sodium. The method comprises the following steps of: (1) weighing 6-aminopenicillanic acid, 3-(2-chloro-6-fluorophenyl)-5-methyl isoxazole-4-phosgene and sodium iso-octoate; (2) adding water into 6-aminopenicillanic acid, cooling in an ice bath, and adding acetone to obtain a solution A; (3) preparing 3-(2-chloro-6-fluorophenyl)-5-methyl isoxazole-4-carbonyl chloride and an organic solvent into a solution B; (4) adding the solution B into the solution A, and performing an acylation reaction; (5) after reacting, acidifying, and adding an organic solvent for extracting; (6) slowly adding a part of organic solution of sodium iso-octoate into the an extracting solution obtained in the step (5), performing a salt-forming reaction, and growing a crystal after the crystal is precipitated out; and (7) after growing the crystal, continually adding the residual sodium iso-octoate solution, preserving heat, stirring, leaching, soaking, washing and drying in vacuum. The method has the advantages of short process route, high process operability and capability of effectively increasing product quality and yield.

Owner:河北华日药业有限公司

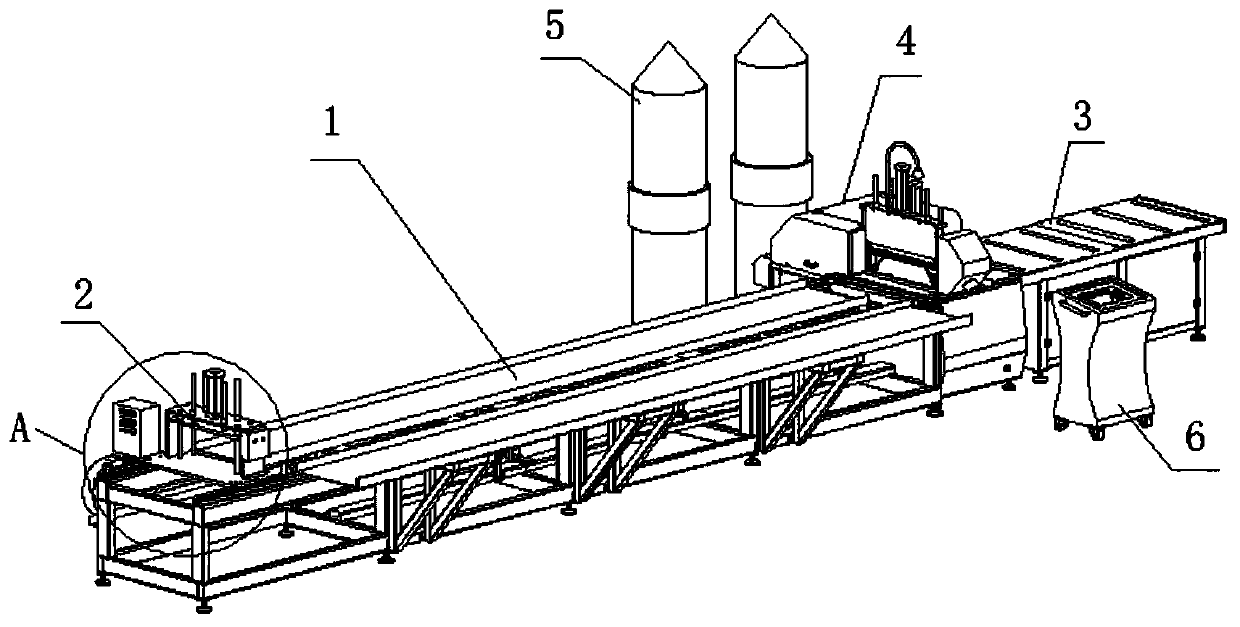

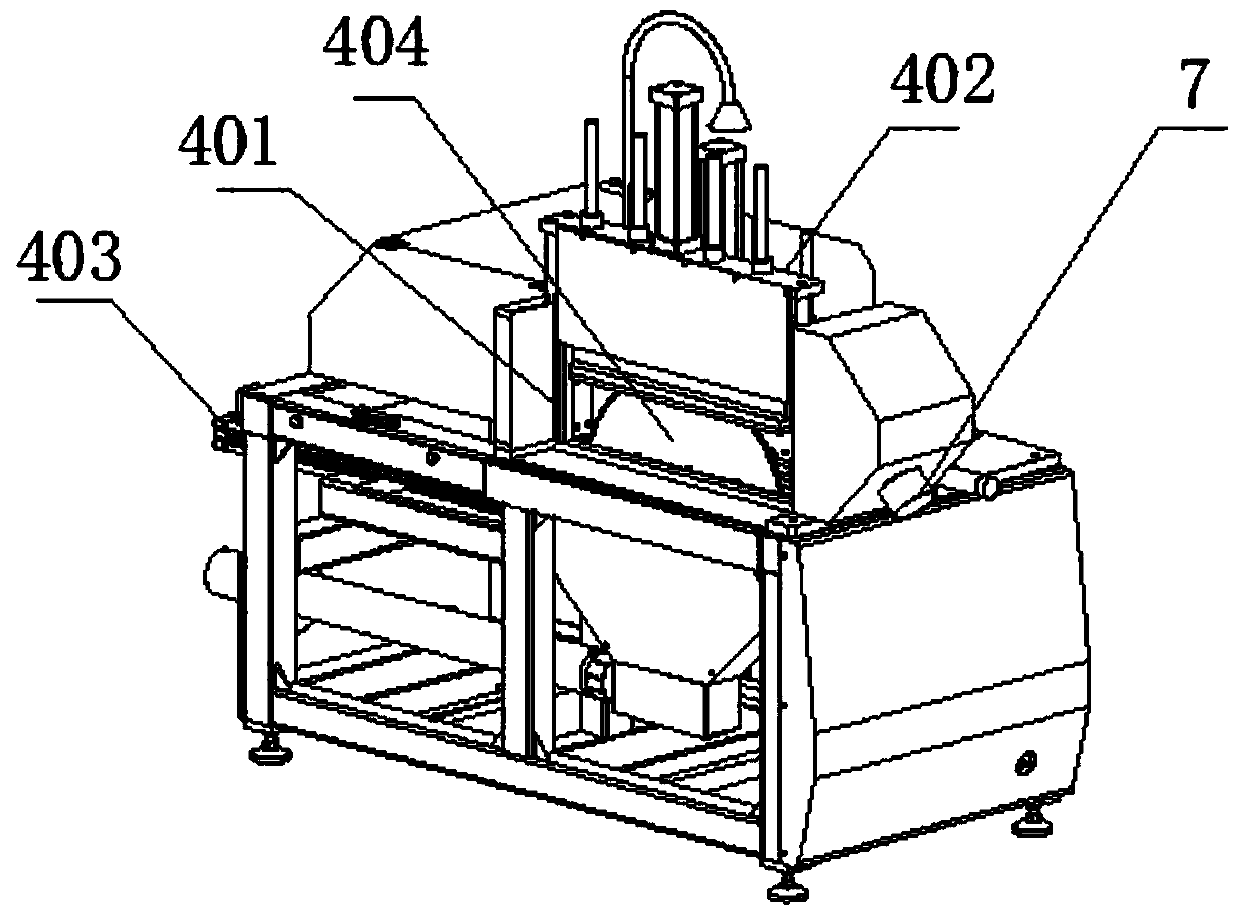

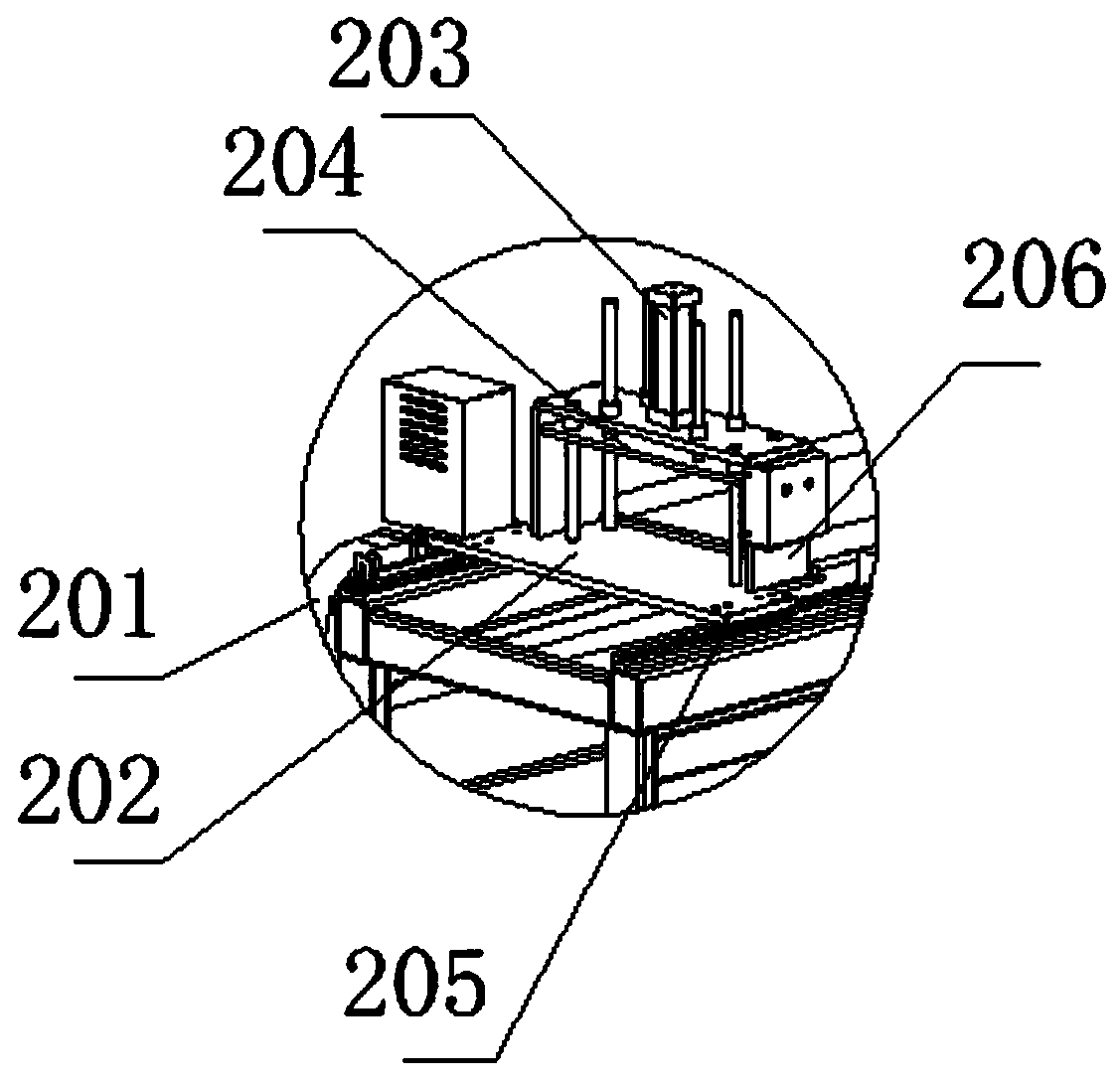

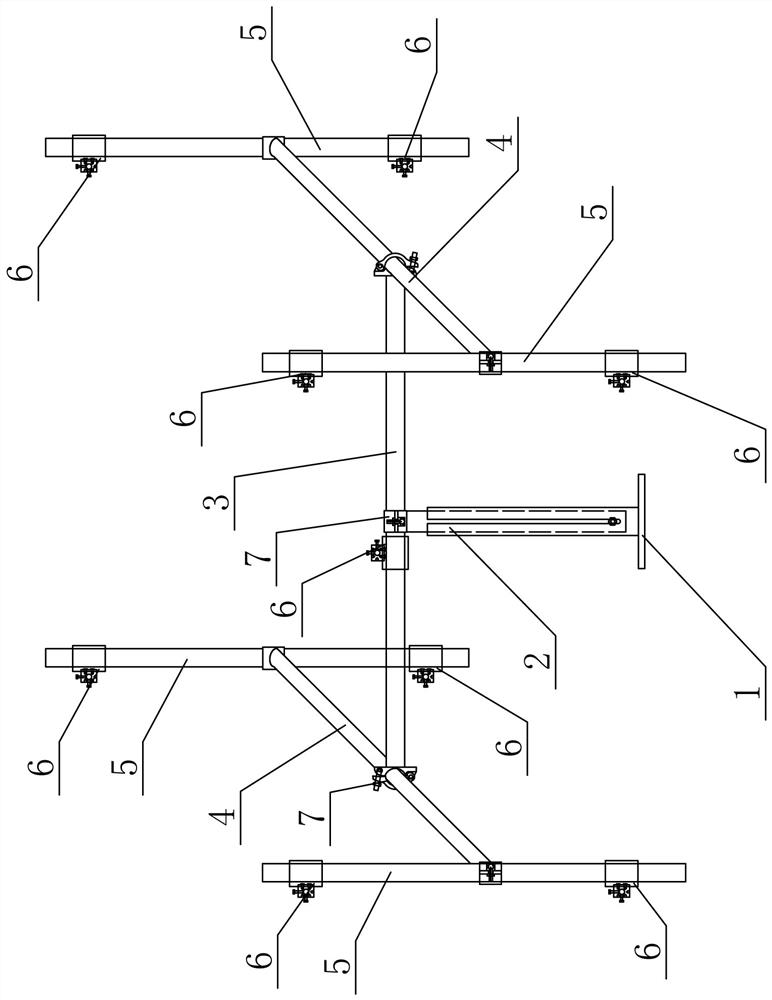

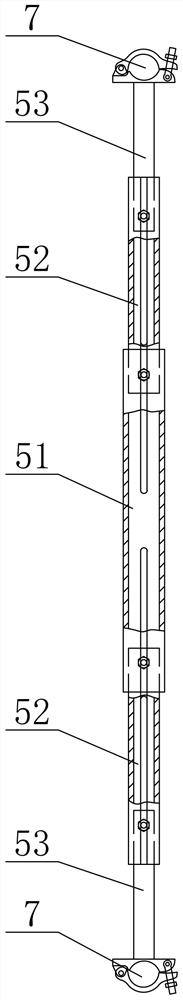

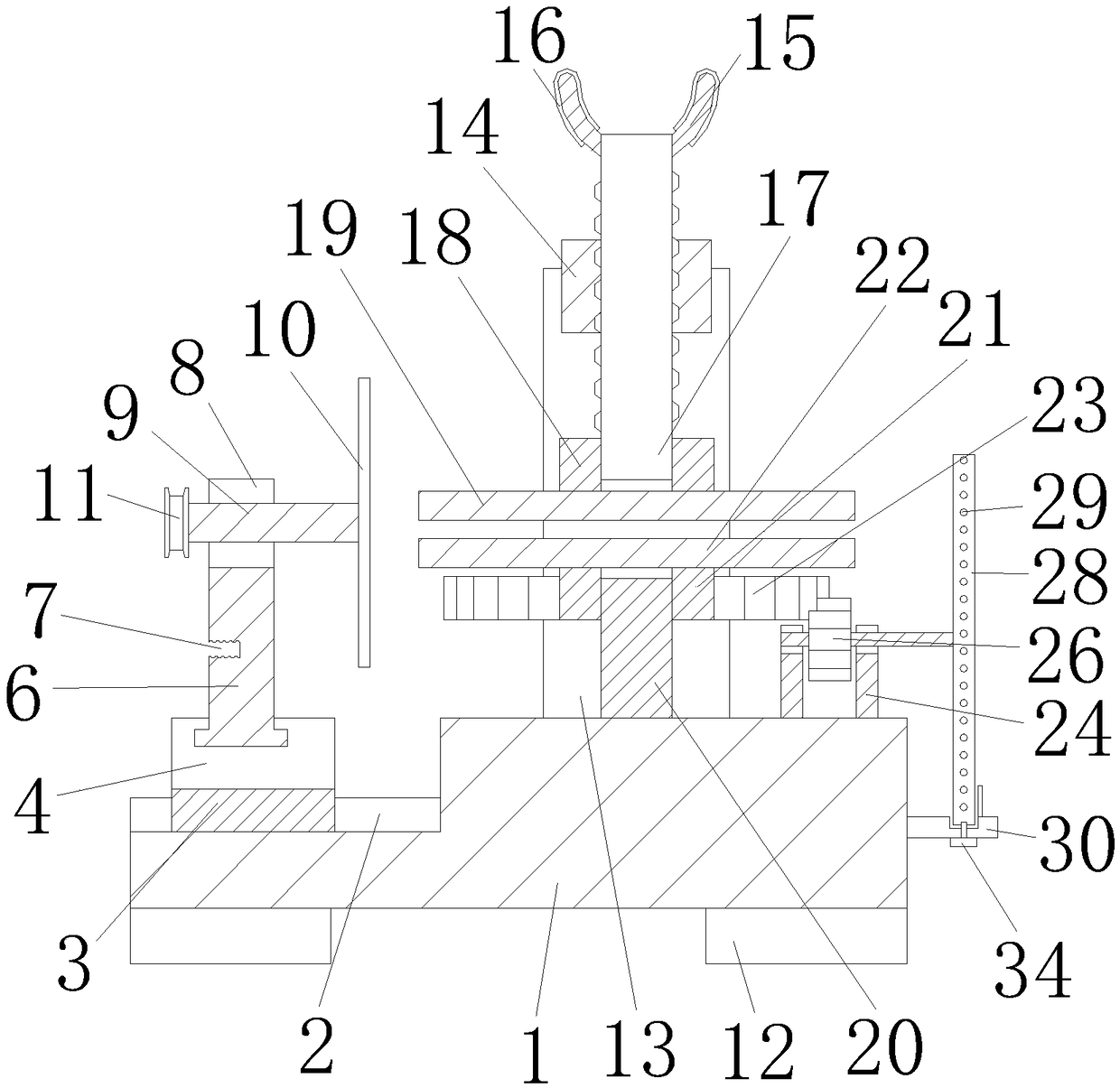

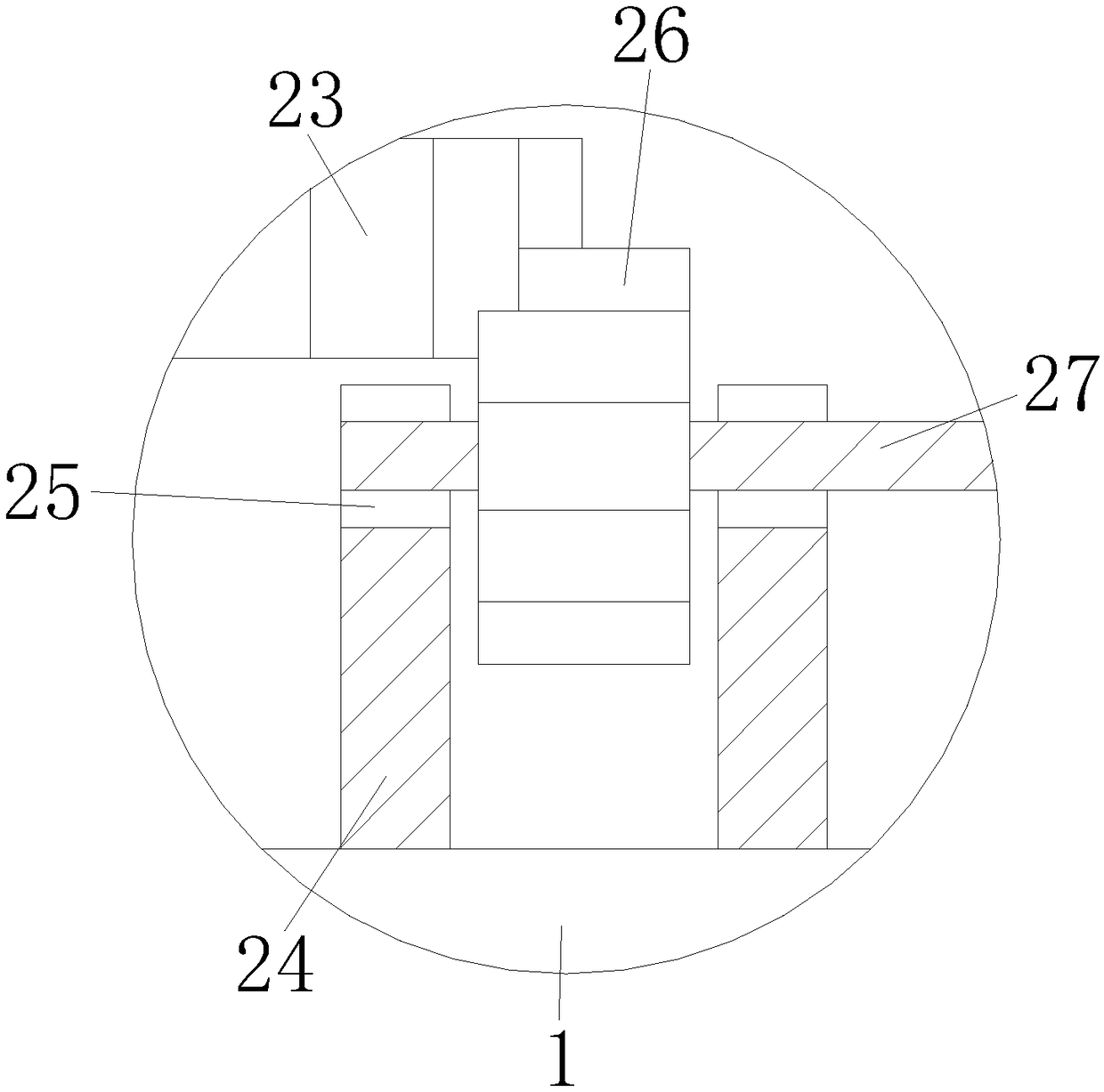

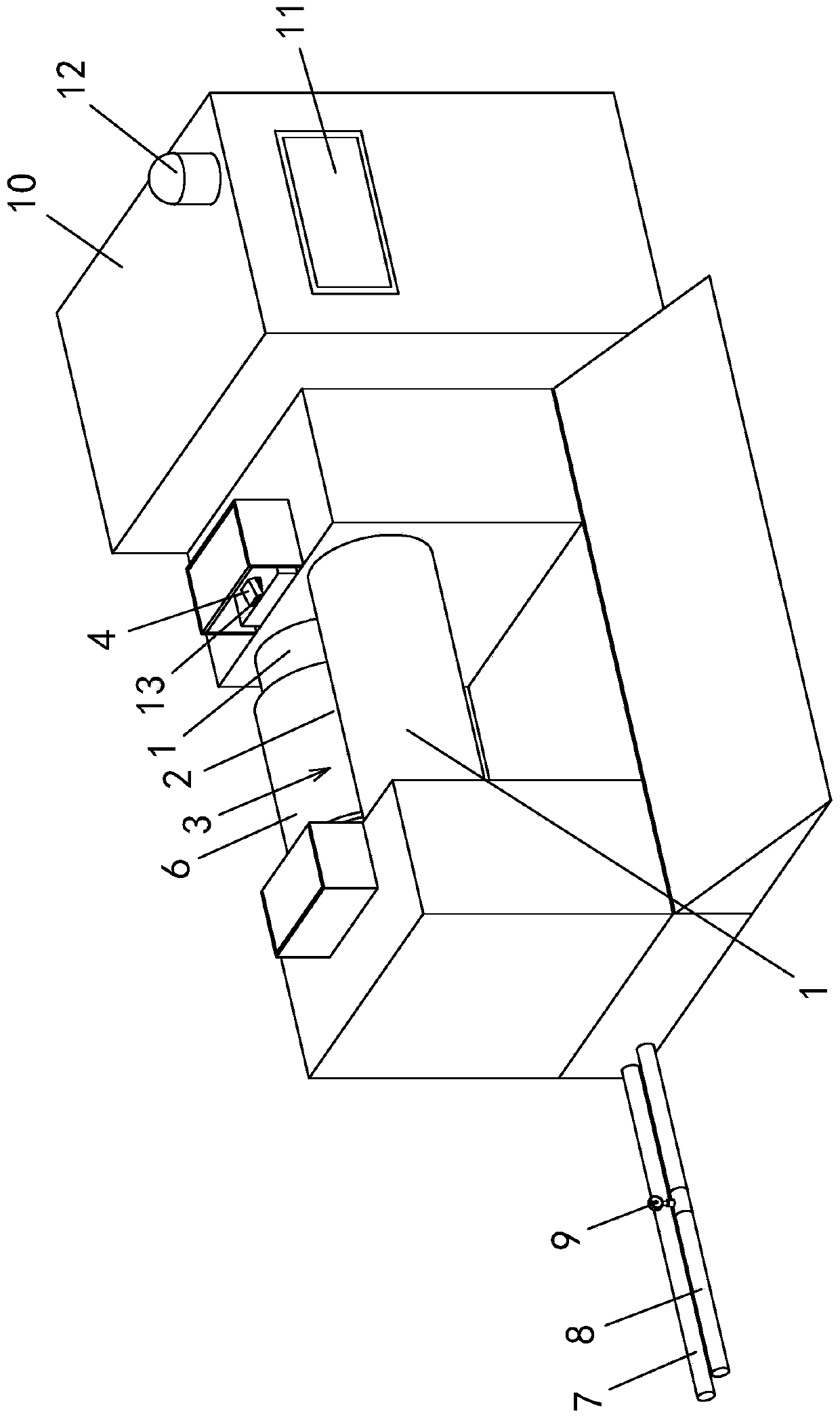

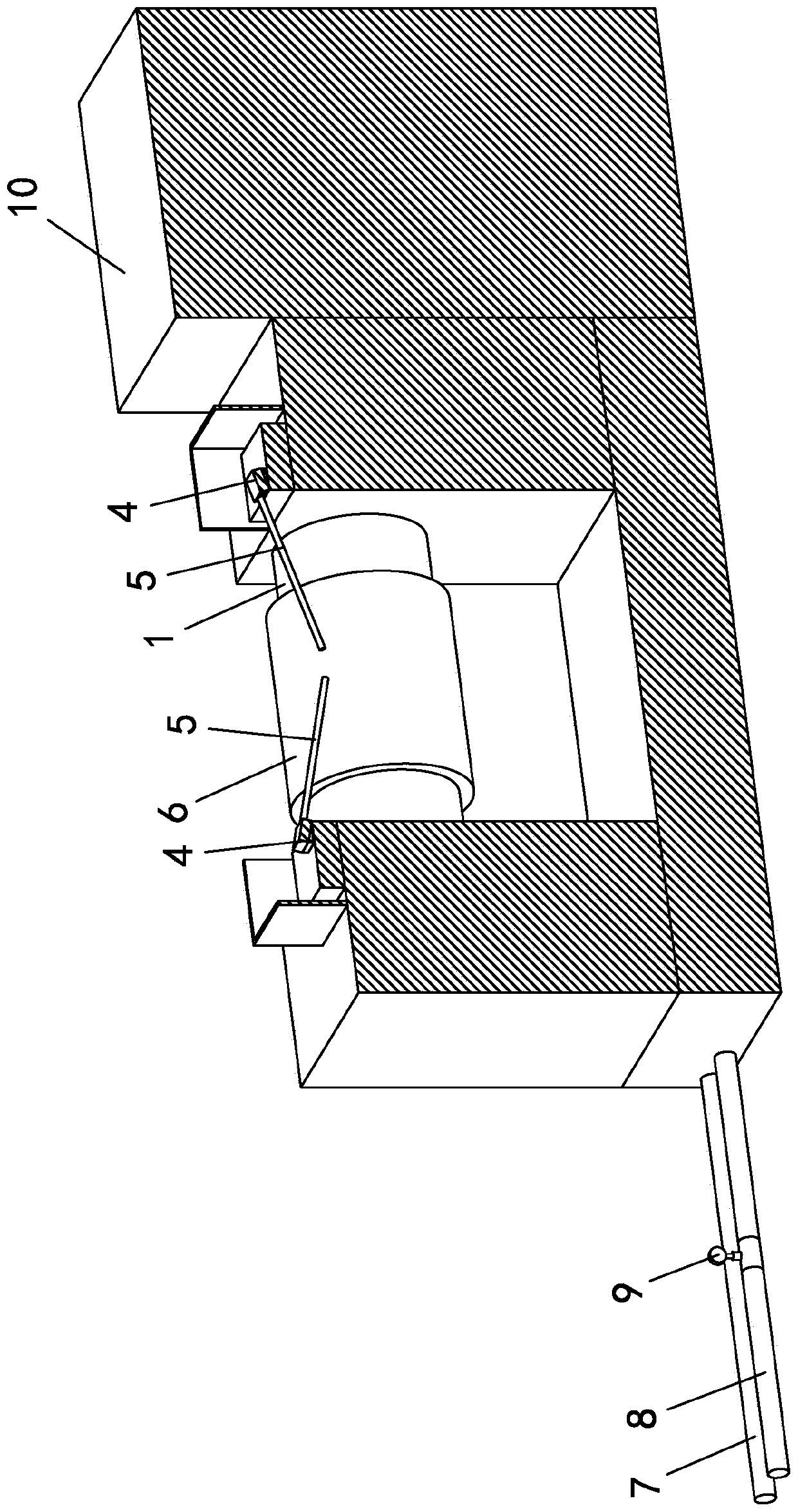

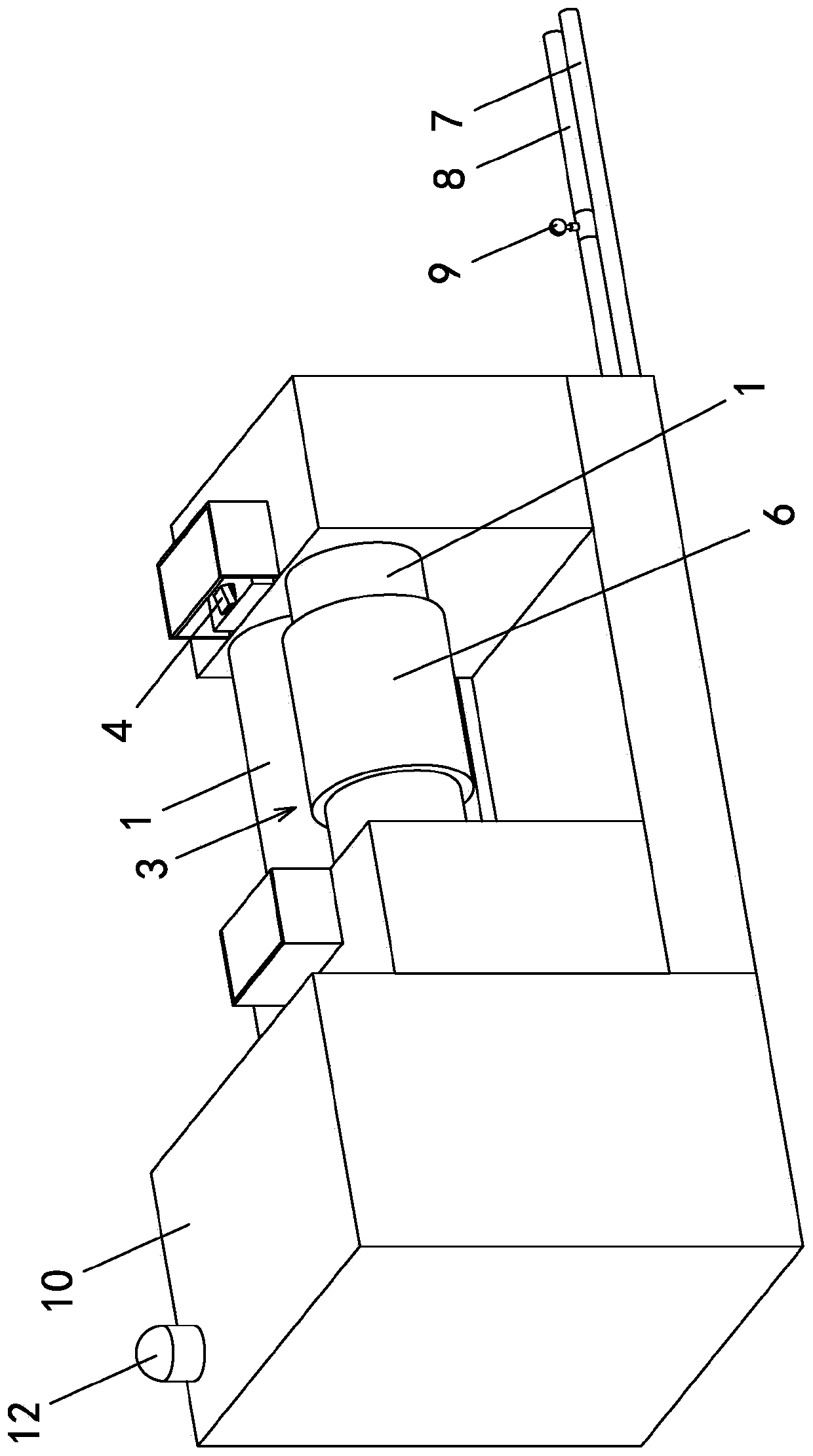

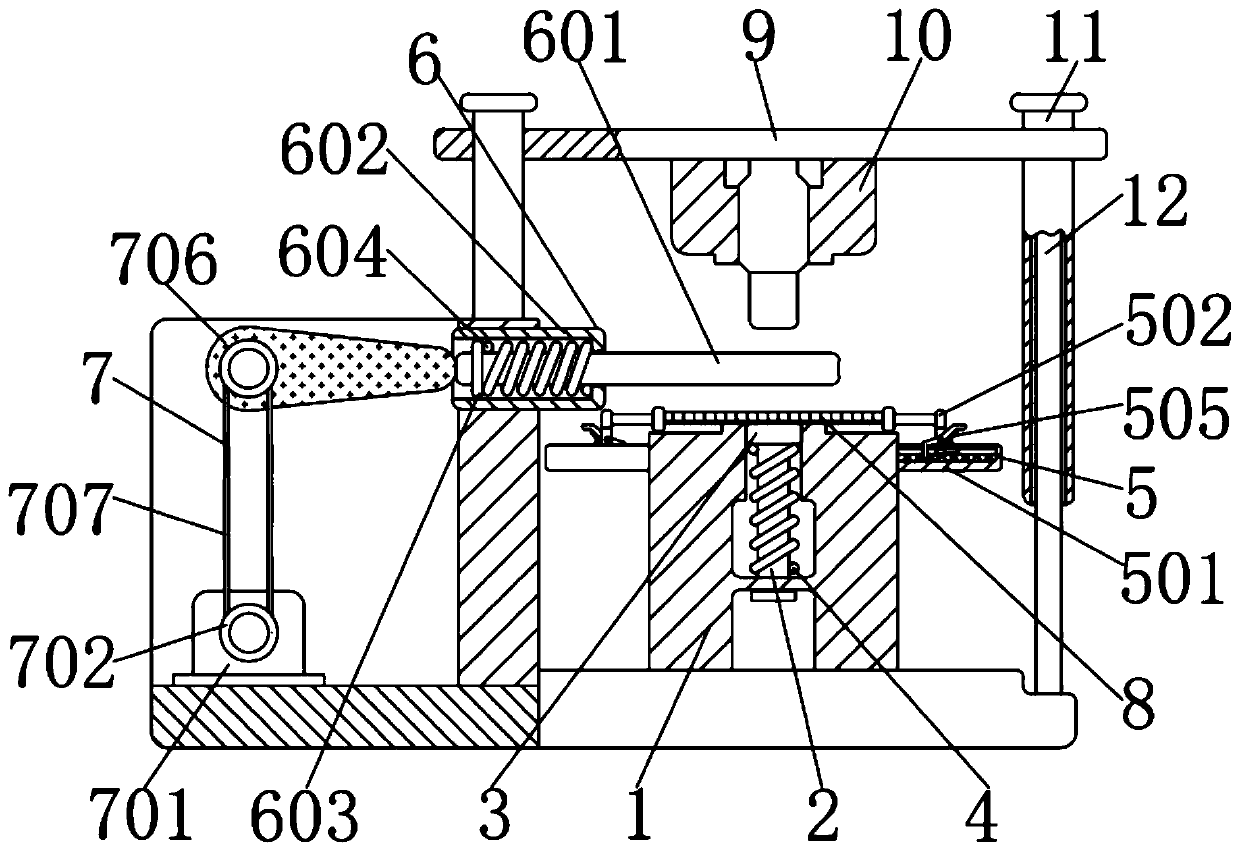

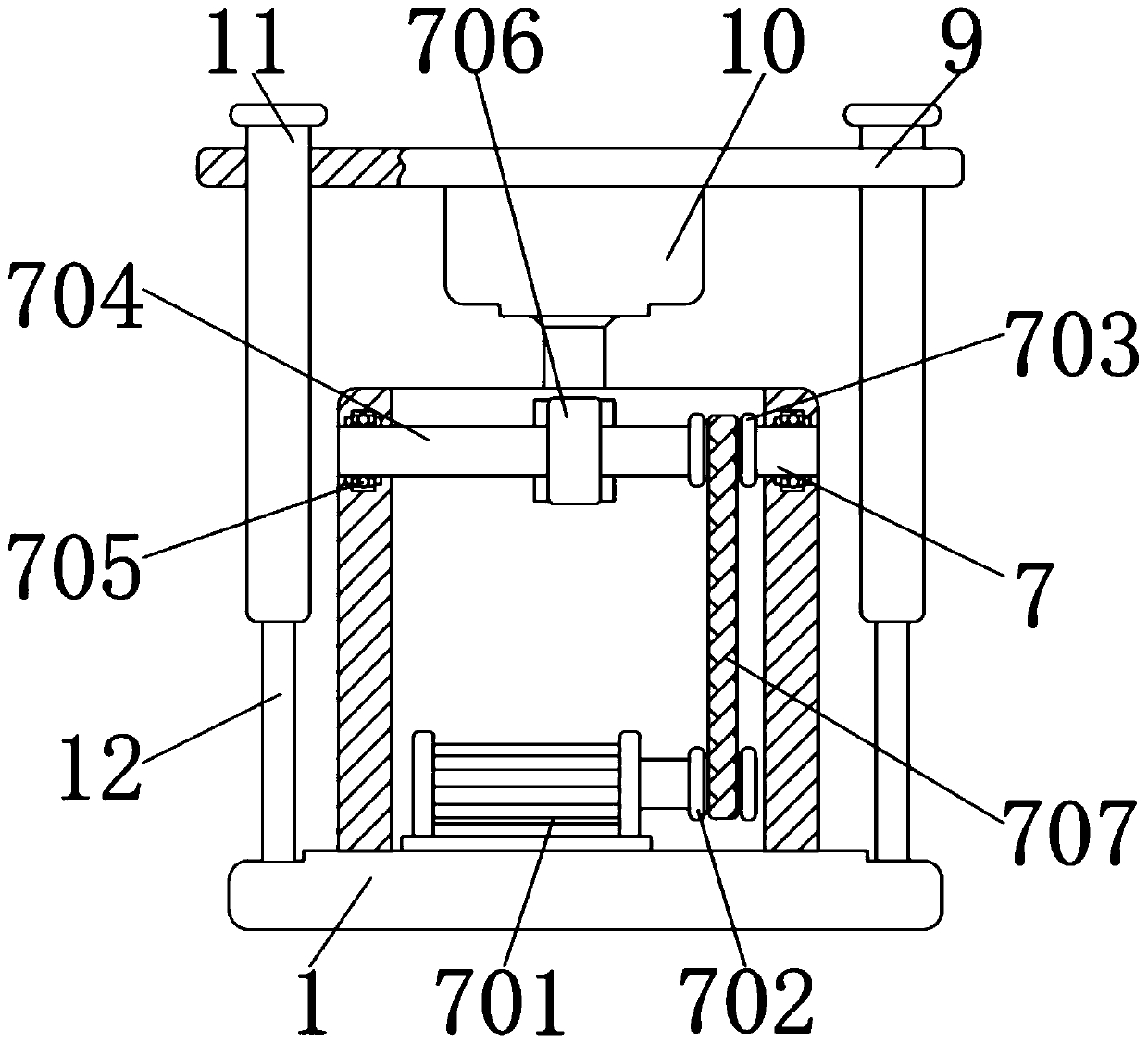

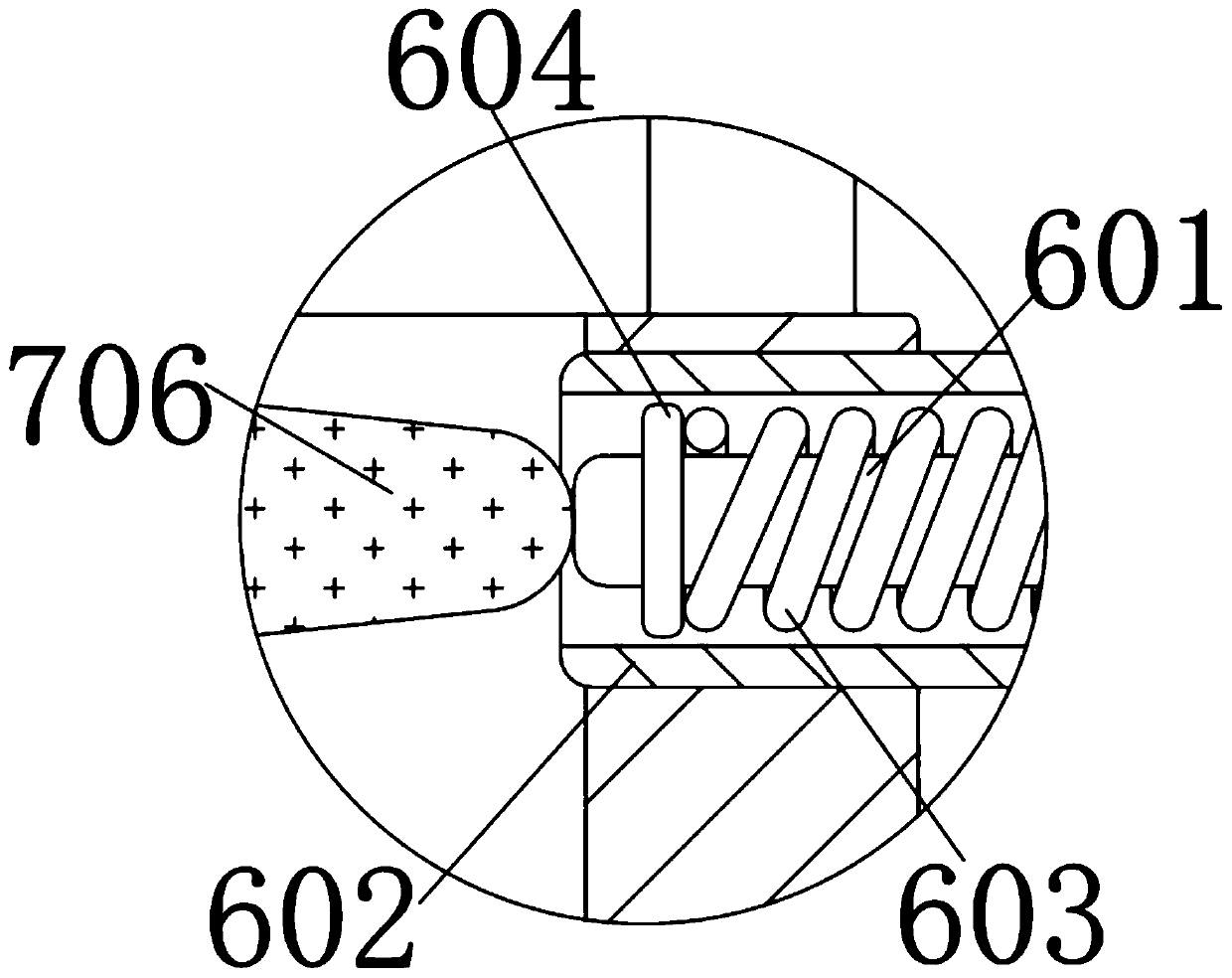

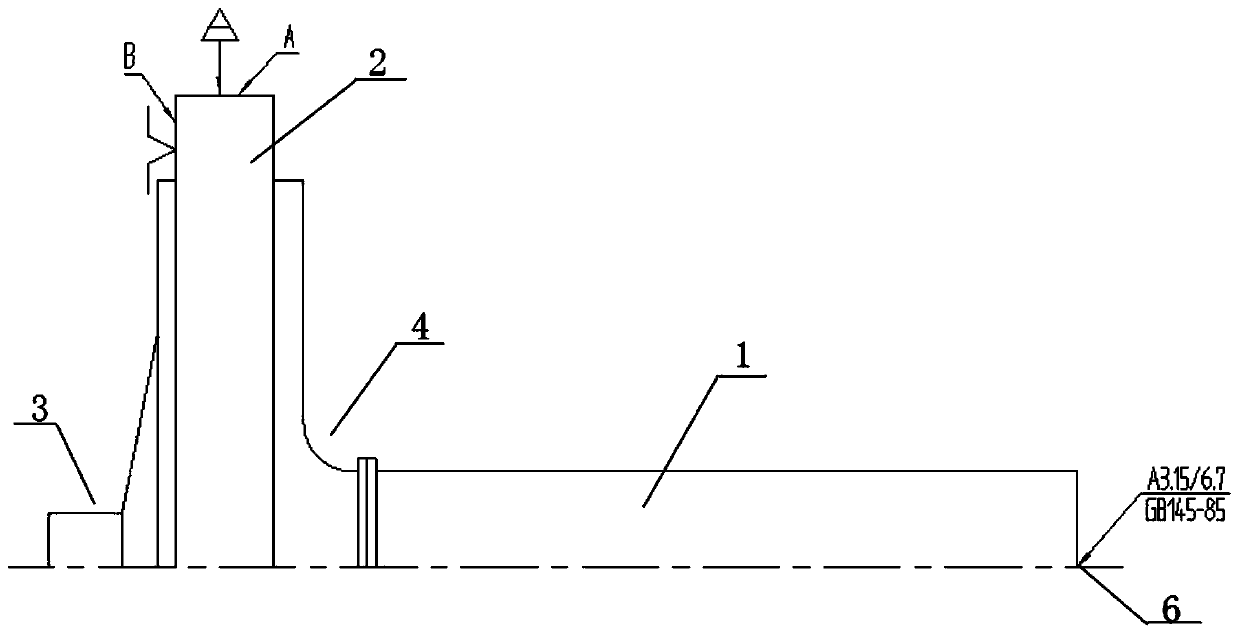

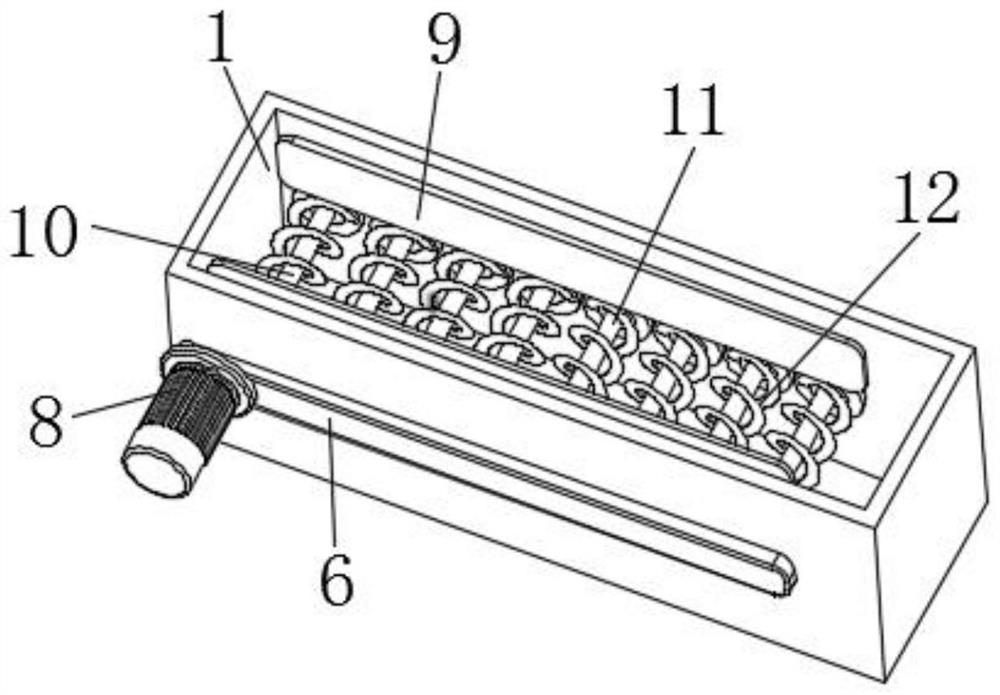

Automatic feeding saw for building aluminum formwork

InactiveCN109773266ASolve unqualifiedPlay a role in material breakingMetal sawing devicesMetal working apparatusLoop controlClosed loop

The invention discloses an automatic feeding saw for a building aluminum formwork. The automatic feeding saw comprises a feeding mechanism and a sawing mechanism. The feeding mechanism comprises a feeding frame mounted at the bottom, and a feeding machine head is mounted on the upper side of one end of the feeding frame. The feeding machine head is driven by a servo motor and subjected to closed-loop control through a magnetic railing ruler. The sawing mechanism is mounted at the other end of the feeding frame, and a dust collector is mounted beside the sawing mechanism. A discharging frame ismounted at the discharging end of the sawing mechanism, and an electric control cabinet is mounted beside the discharging frame. The feeding mechanism, the sawing mechanism and the dust collector areelectrically connected with the electric control cabinet. The automatic feeding saw for the building aluminum formwork is sawing equipment for the building aluminum formwork, a cut-off function is achieved, the automatic feeding mechanism is arranged, and the automatic feeding size is precise. The problem that original workpieces sawn by manual operation are unqualified is solved, the feeding speed is high, and the machining efficiency is high.

Owner:广东斯丹诺智能装备有限公司

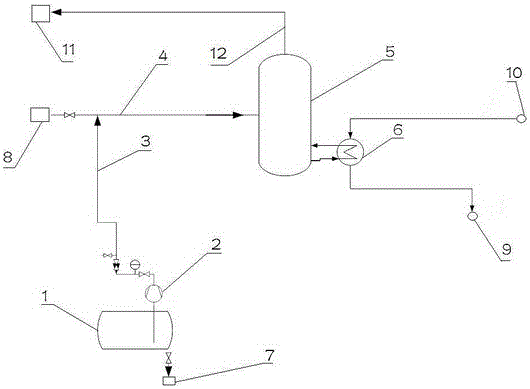

Method for processing delay coking liquid hydrocarbons with gas fractional distillation apparatus

InactiveCN101319149ASolve unqualifiedHydrocarbon distillationTreatment with plural serial refining stagesThiolLiquid state

The present invention discloses a method for producing propylene, propane and C4 fraction by pre-processing a liquid state hydrocarbon generated by a delayed coker and processing the liquid state hydrocarbon as a raw material of a gas fractionation plant. The method is comprises the following steps that: the coked liquid state hydrocarbon in which hydrogen sulfide is removed by an amine solution is subjected to sodafining and water washing to remove thiol and a small amount of water before entering a gas separation device; and then the liquid state hydrocarbon enters a COS hydrolyzer to desulfurate; afterward, hydrogen sulfide generated from the hydrolization is removed; and then the liquid state hydrocarbon enters the gas fractionation plant as a material to be processed.

Owner:孙海兵 +1

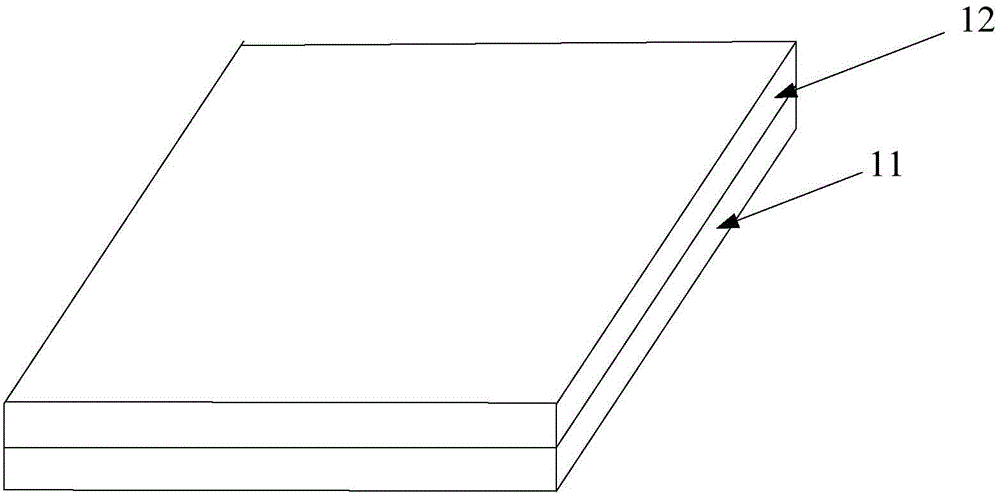

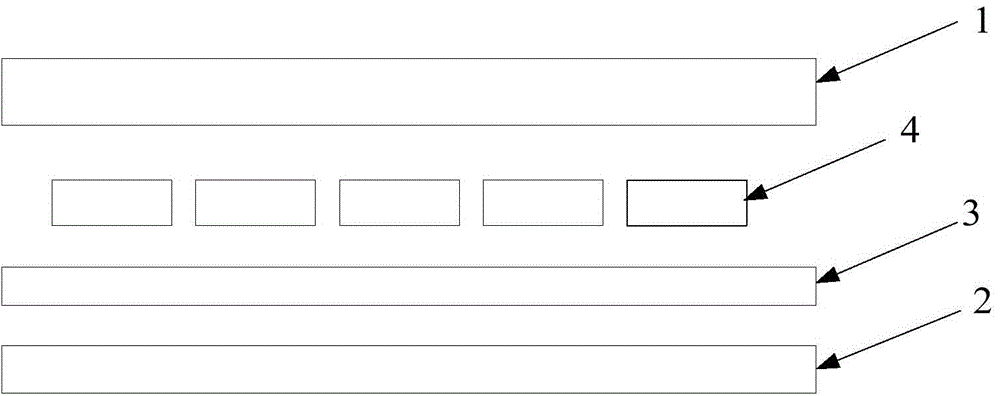

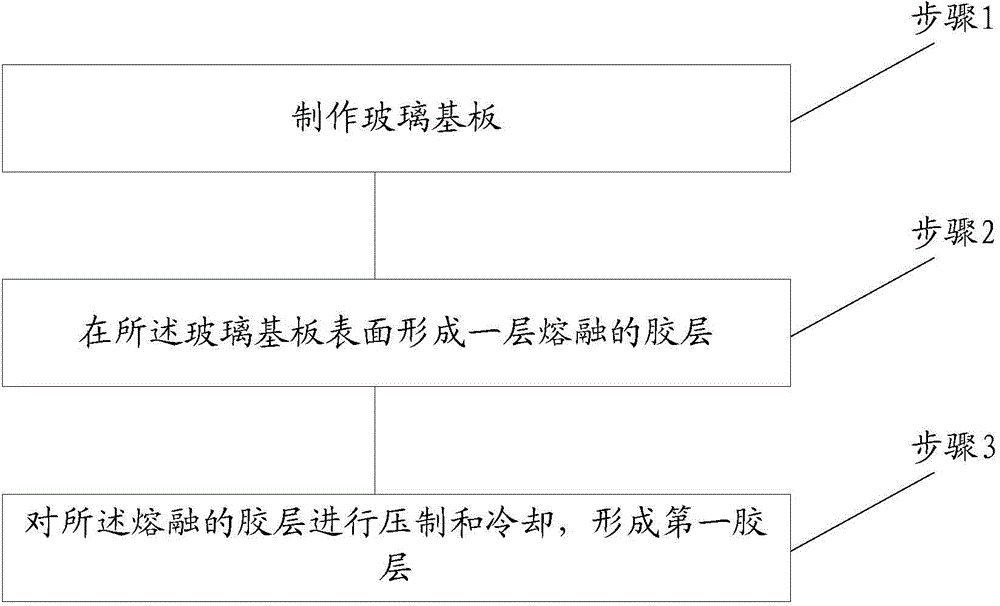

Photovoltaic glass and manufacturing method thereof, as well as photovoltaic module

InactiveCN104810421AImprove pass rateAvoids the problem of introducing foreign objectsFinal product manufacturePhotovoltaic energy generationEngineeringForeign matter

The embodiment of the invention discloses photovoltaic glass and a manufacturing method thereof, as well as a photovoltaic module comprising the photovoltaic glass. The photovoltaic glass is used for receiving sunlight irradiation in the photovoltaic module comprising the photovoltaic glass and comprises a glass substrate and a first adhesive layer positioned on the surface of the glass substrate, wherein the glass substrate and the first adhesive layer are of an integrated structure; the first adhesive layer has thermoplasticity and viscousness. Therefore, the photovoltaic glass disclosed by the embodiment of the invention is of an integrated structure, namely, the photovoltaic glass directly produced and manufactured in the same workshop in the same factory, and thus the problem that foreign matters are introduced in a laying process of the glass substrate and an EVA (Ethylene Vinyl Acetate) adhesive layer in the prior art is avoided, the problem that the photovoltaic module is unqualified when the foreign matters are introduced between the glass substrate and the EVA adhesive layer is solved, and the qualified rate of the photovoltaic assembly comprising the photovoltaic glass is increased.

Owner:BAODING YITONG PV SCI & TECH

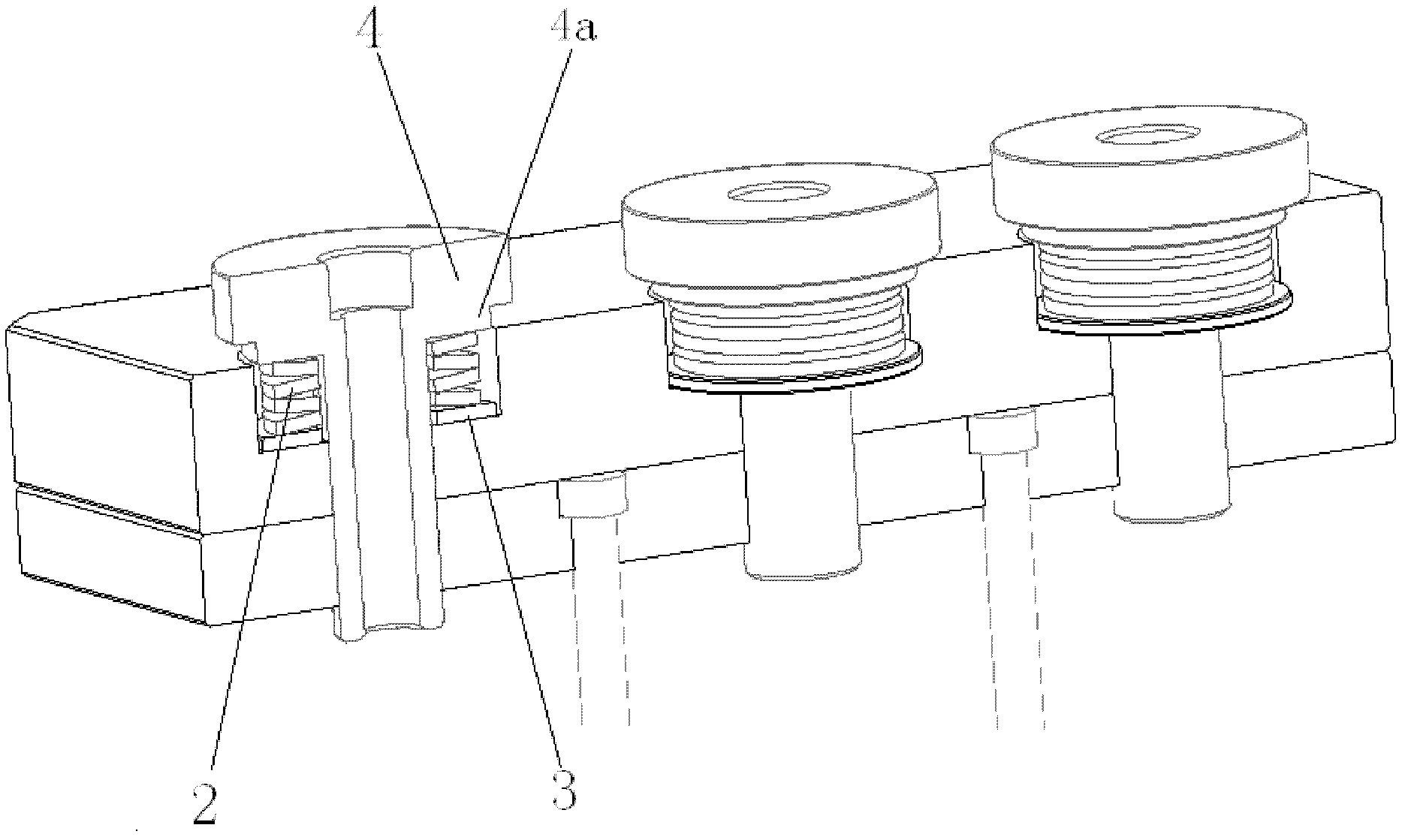

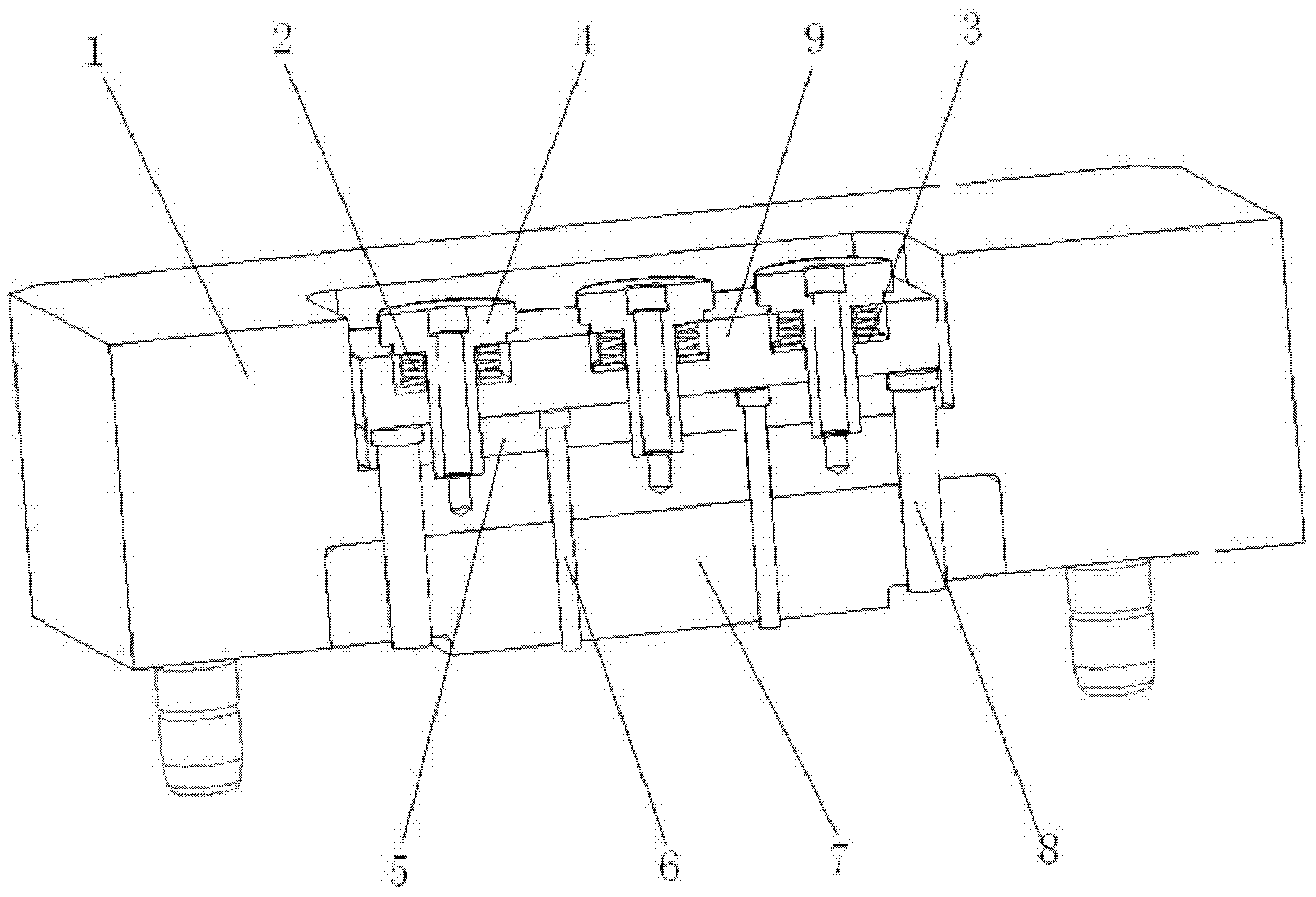

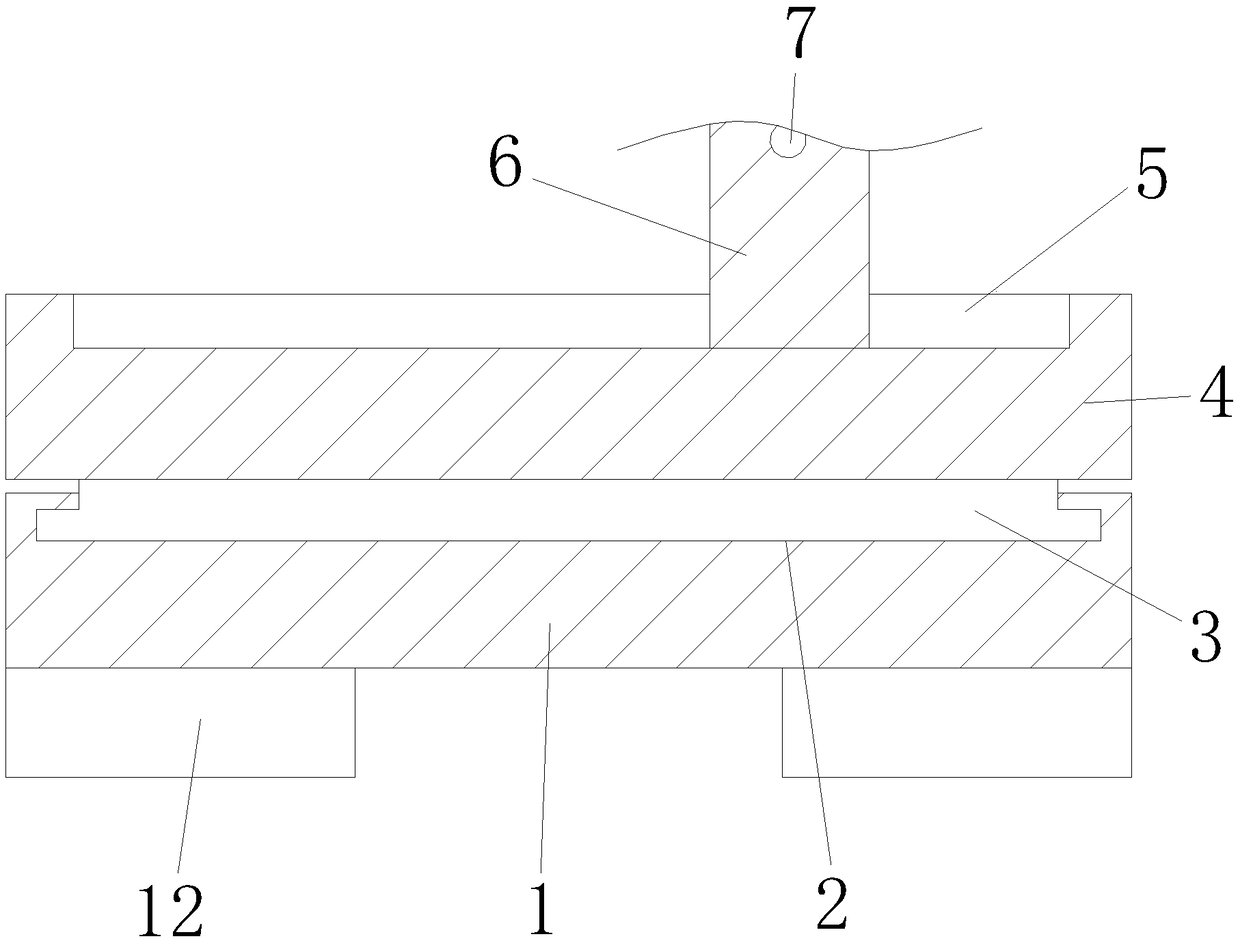

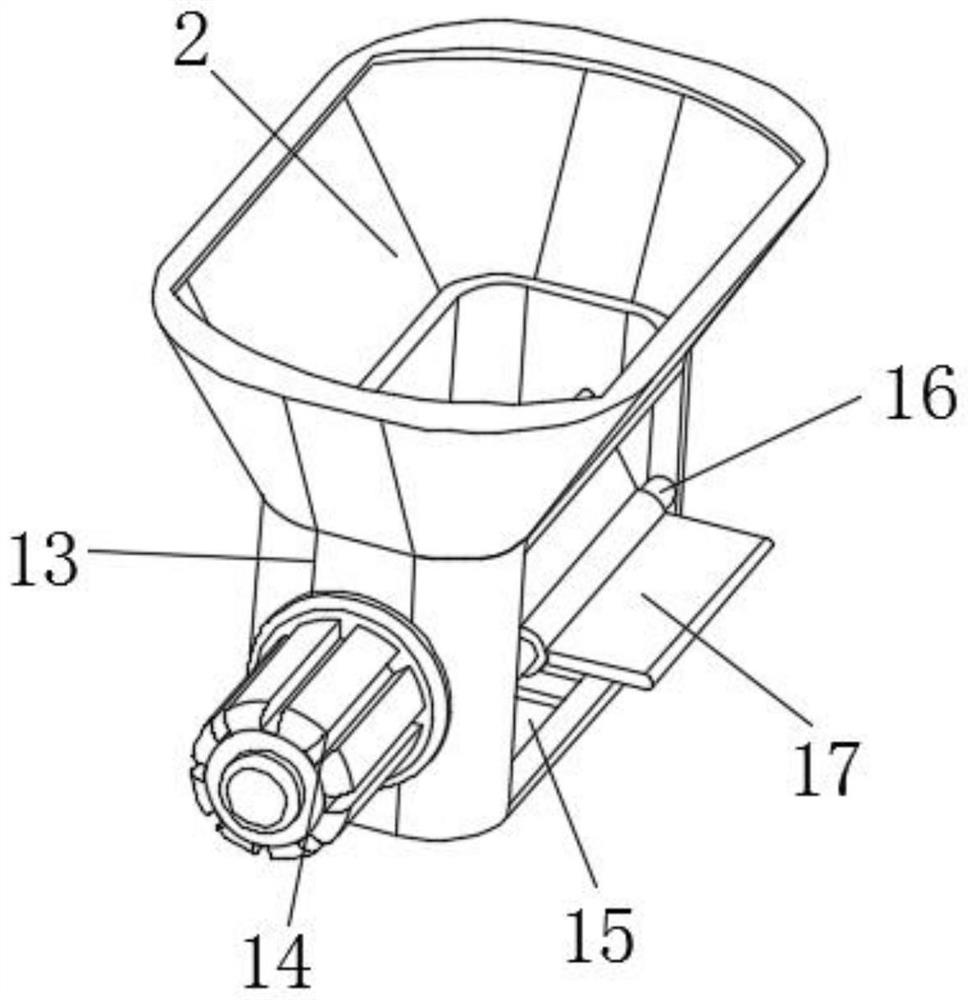

Ejection mechanism of fixed die push plate

The invention relates to an ejection mechanism of a fixed die push plate, which comprises a fixed die plate. Two corresponding installation grooves are arranged on the upper face and the lower face of the fixed die plate, an ejector pin retaining plate and a push plate are installed in the installation groove on the upper face of the fixed die plate from bottom to top, and three T-shaped installation holes are installed on the upper face of the push plate at equal intervals. A gasket and a plurality of belleville springs are padded on T-shaped shoulders of the installation holes from bottom to top, T-shaped guide bars are sleeved on the gasket and the belleville springs, and the lower portions of the heads of the guide bars protrude out to form small circular truncated cones which are in clearance fit with the T-shaped shoulders of the installation holes. The lower face of the push plate between every two installation holes abuts against an ejector pin. A fixed inner die is arranged in the installation groove on the lower face of the fixed die plate, release rods are installed on the left side and the right side of the fixed inner die, and the heads of the release rods abut against two sides of the lower face of the push plate. The ejection mechanism adopts the belleville springs to serve as pushing power producers, achieves fixed die auxiliary pushing functions during die sinking, and is ingenious in structure, even in pushing force distribution, and capable of improving force distribution quality of products.

Owner:宁波市优美屹科技有限公司

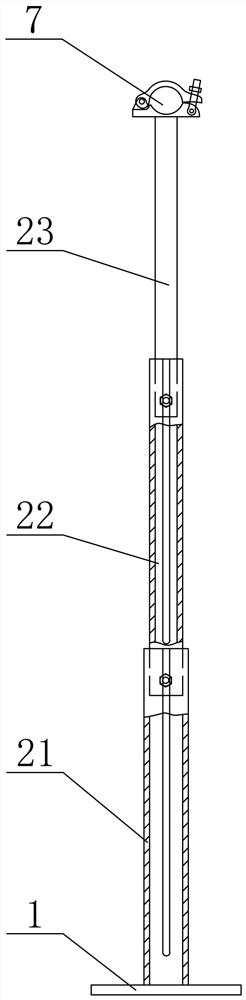

High-temperature heating furnace temperature sensor distribution device and metering calibration method thereof

PendingCN111649834AAvoid damageImprove accuracyThermometer detailsThermometer testing/calibrationElectrically conductiveHeating furnace

The invention provides a high-temperature heating furnace temperature sensor distribution device and a metering calibration method thereof. The temperature sensor distribution device is arranged, thedistribution requirements of the number of sensors and temperature measurement positions are met through the distribution device, a post-positioned temperature measurement mode is used, and an electric lead of a temperature sensor penetrates out of a rear temperature measuring hole of a high-temperature heating furnace to be detected, so that damage to the electric lead of the temperature sensor when a furnace door is closed in a front temperature measuring mode is avoided, and before the high-temperature heating furnace is calibrated, a temperature control thermocouple and a temperature controller of the high-temperature heating furnace are calibrated to improve the accuracy of a calibration result.

Owner:HENAN PROVINCE INST OF METROLOGY

Extrusion die head adjusting device

ActiveCN102773200AAvoid panningTimely adjustment of lateral alignment accuracyLiquid surface applicatorsCoatingsSpray coatingFriction force

The invention relates to an extrusion die head adjusting device. The device comprises an extrusion die head, an extrusion die head supporting seat, and a fixed bottom plate, wherein the extrusion die head is used for spraying coating materials to a basal body; the extrusion die head is mounted on the extrusion die head supporting seat, and the extrusion die head supporting seat is mounted on the fixed bottom plate; the device further comprises a micro-adjusting device, which is used for adjusting the position of the extrusion die head, and a guiding device; the guiding device is mounted between the extrusion die head supporting seat and the fixed bottom plate and is used for reducing a friction force during a lateral movement; and a fixed end of the micro-adjusting device is mounted on the extrusion die head supporting seat or the fixed bottom plate and is used for adjusting a lateral position of the extrusion die head and the extrusion die head supporting seat. Due to adoption of the extrusion die head adjusting device provided by the invention, a problem that unqualified products are caused due to lag of a lateral contraposition adjustment and repeated adjustment of a coating area relative to the basal body is solved through controlling the position of the extrusion die head. Through adopting the micro-adjusting device to directly adjust the lateral position of the extrusion die head, the lateral contraposition accuracy of the coating area can be intuitively and properly adjusted.

Owner:SHENZHEN HAONENG TECH

Polygonal cutting tool

The invention discloses a polygonal cutting tool which comprises a bottom plate, wherein a first chute is formed in the left side of the top of the bottom plate; a slide block is slidably locked in the first chute; a top plate is fixedly connected to the top of the slide block; a nut is fixedly connected above the front surface of a second bracket; a threaded rod is in threaded connection in the nut; and a second bearing is fixedly connected to the bottom of the outer wall of the threaded rod. The polygonal cutting tool solves the problem that a workpiece is repeatedly fixed in a conventionalpolygonal cutting process, solves the problem that the polygonal workpieces which are cut are unqualified as the angles are inaccurate and improves the workpiece percent of pass of a plant. The polygonal cutting tool fully can meet the demand of people on the polygonal cutting tool which is convenient to use and adjust and accurate to adjust the cutting angles, avoids material waste, and is simpleto operate at present.

Owner:利辛县宝隆橡塑密封件有限责任公司

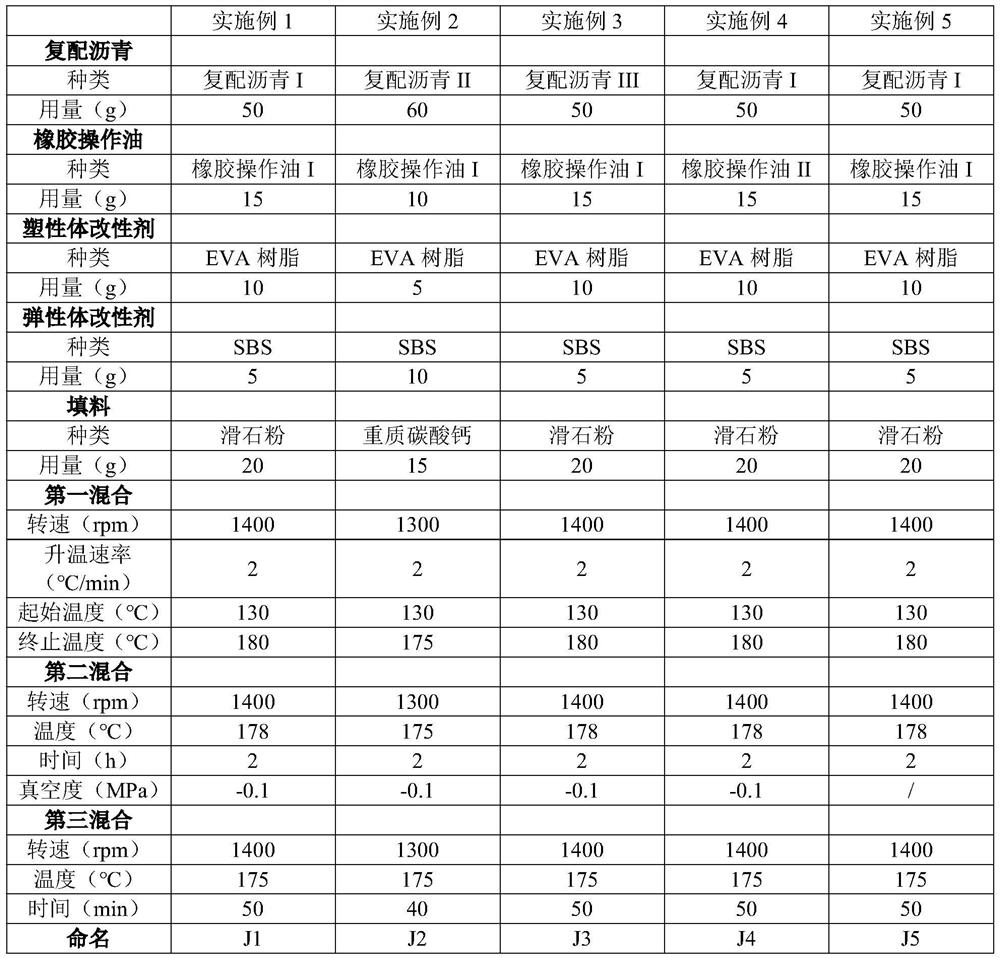

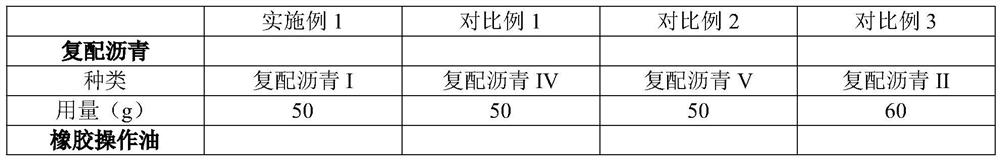

Modified asphalt waterproof roll sizing material composition, modified asphalt waterproof roll sizing material as well as preparation method and application of modified asphalt waterproof roll sizing material

ActiveCN113801629AEasy to processSolve unqualifiedNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolymer science

The invention relates to the field of asphalt waterproof rolls, and discloses a modified asphalt waterproof roll sizing material composition, a modified asphalt waterproof roll sizing material and a preparation method and application of the modified asphalt waterproof roll sizing material. The composition contains two or more of the following components which are stored in a mixed manner or independently stored: compound asphalt, rubber operating oil, a plastomer modifier, an elastomer modifier and a filler, wherein the compound asphalt is a combination of 10# asphalt and 50# asphalt in a weight ratio of 1:(4-9), the flash point of the compound asphalt is greater than or equal to 240 DEG C, and the asphaltene content is greater than or equal to 23wt%. A waterproof roll prepared from the modified asphalt waterproof roll sizing material prepared from the composition provided by the invention has stronger binding power with a concrete base surface and a roll lap joint, and meanwhile, the waterproof roll also has excellent thermal aging low-temperature performance.

Owner:德州科顺建筑材料有限公司

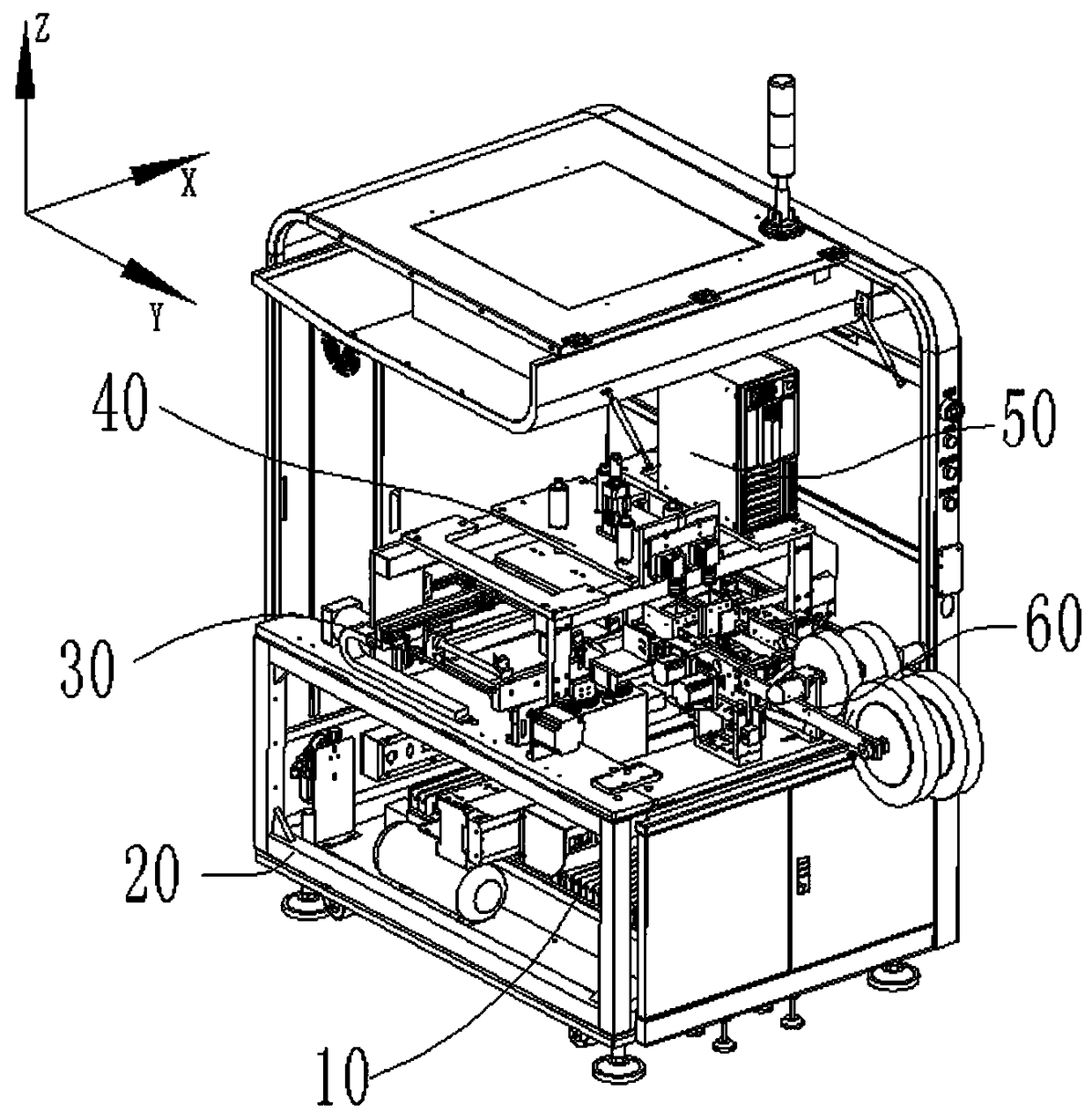

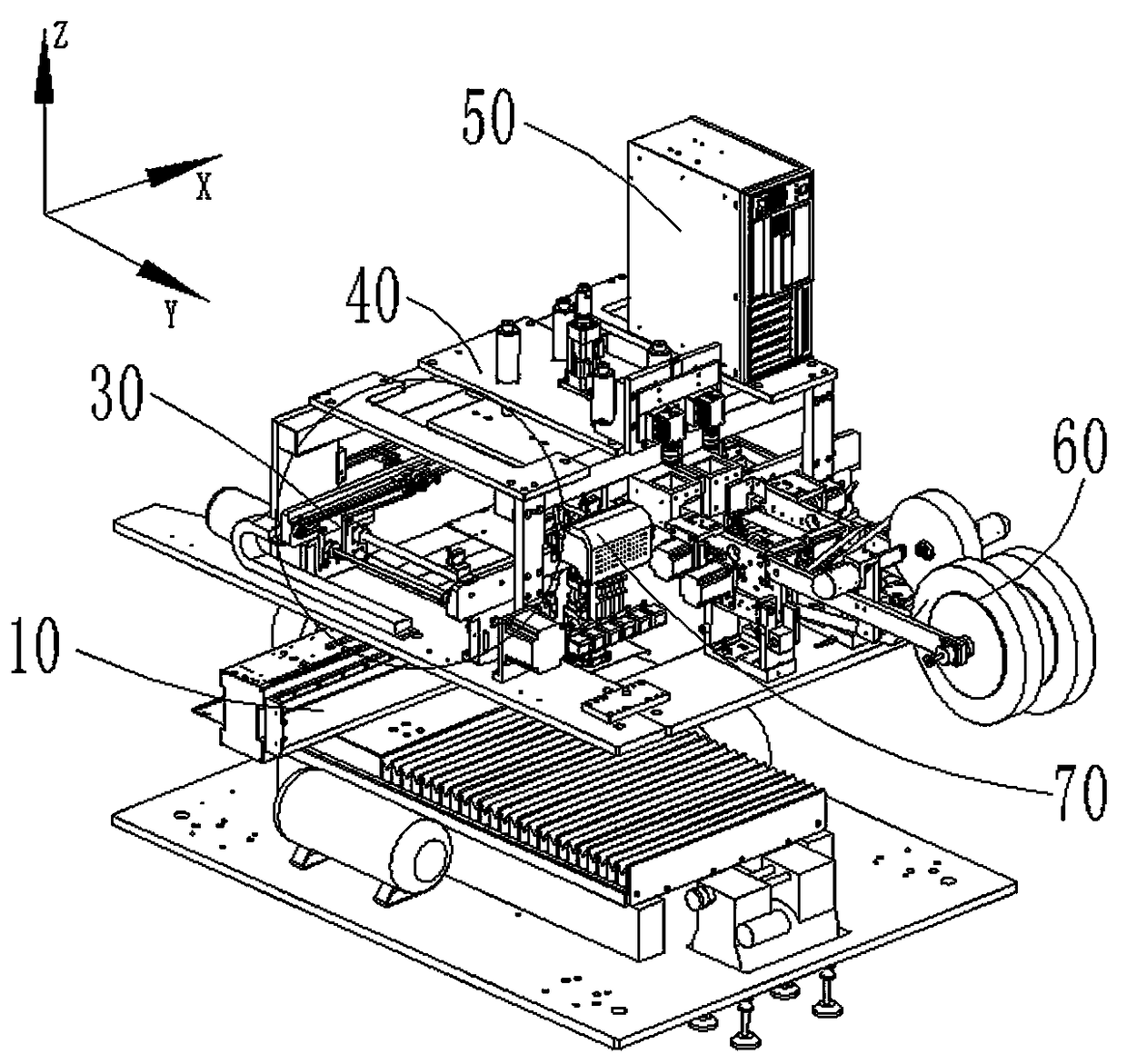

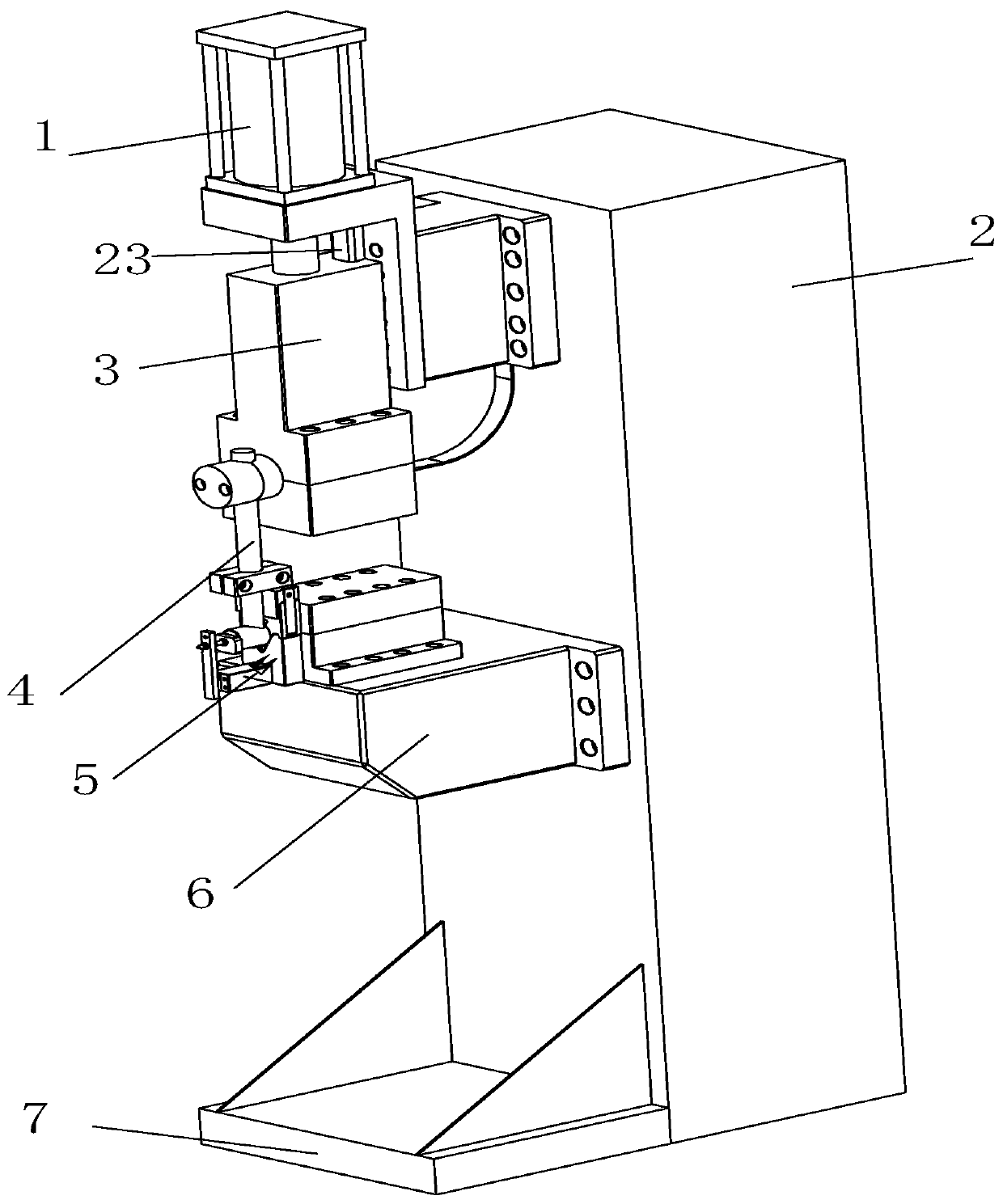

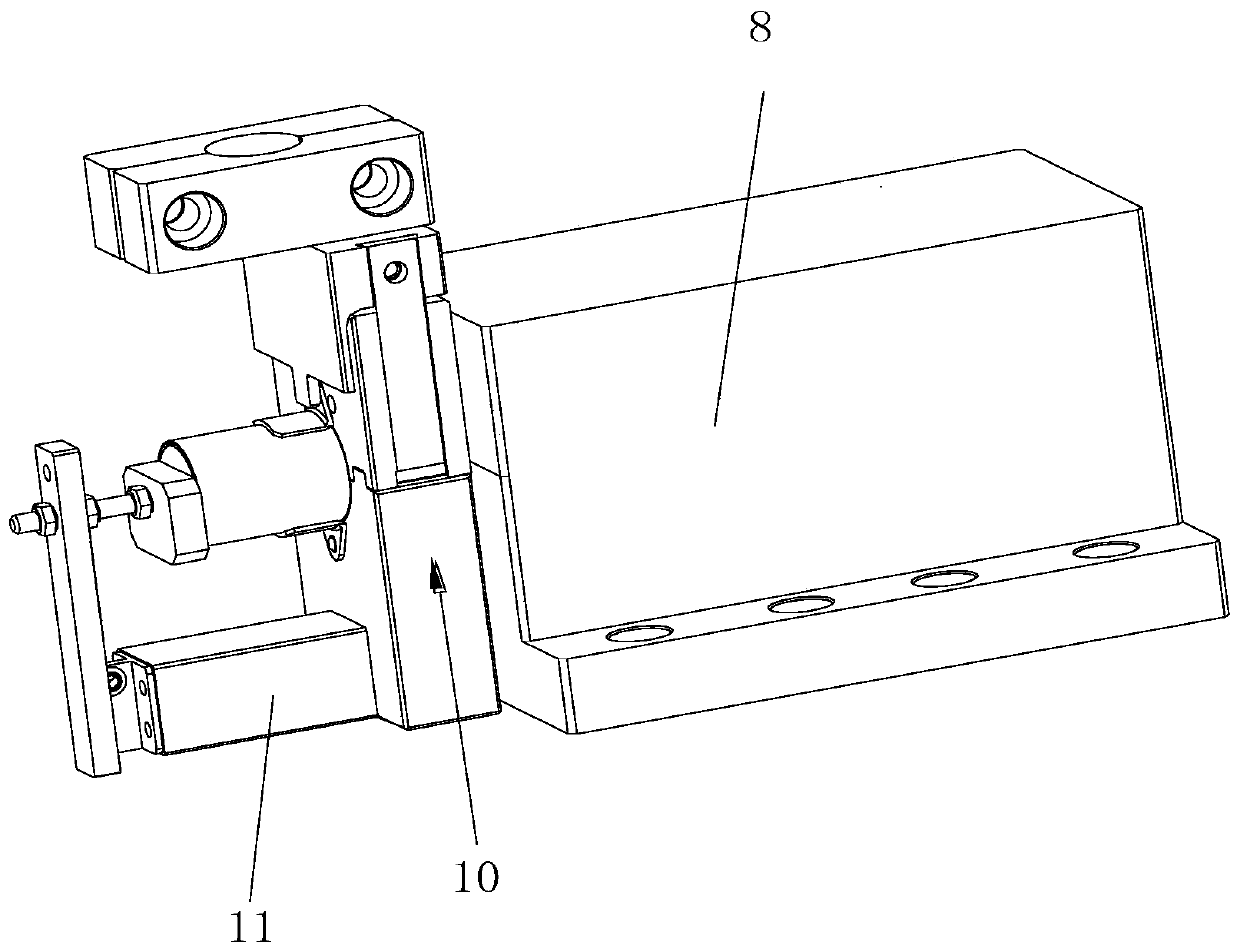

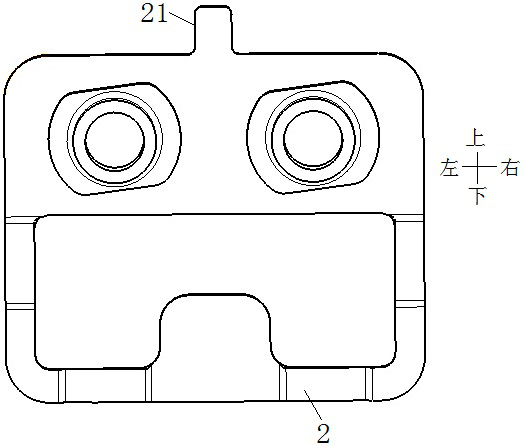

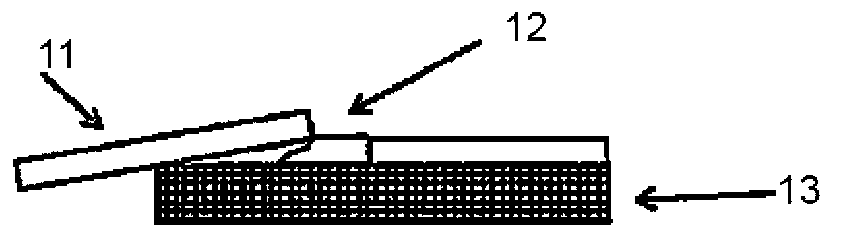

A tape device and a mounting device thereof

The invention relates to a tape device and a mounting device thereof. The tape device comprises a material stripping mechanism and a turnover bracket for mounting the material stripping mechanism, wherein the turnover bracket is rotatably connected with a shaft of the material stripping mechanism. By adding the turnover bracket, the stripping mechanism can realize 180-degree turning, that is, theconventional top-down mounting machine can be satisfied, and the purpose of mounting in different directions can also be satisfied, so that the application range of the stripping structure is wider; the mounting device comprises a mounting device, a feeding device, and the tape device, wherein the tape device, the mounting device and the feeding device are mounted and fixed on the mounting bracket. The method adopts a bottom-to-top mounting mechanism to carry out the mounting, and solves the problem that dust or impurities are easily dropped on the products required to be mounted by the conventional top-to-bottom mounting machine.

Owner:SHENZHEN BORWIN PRECISION MACHINERY

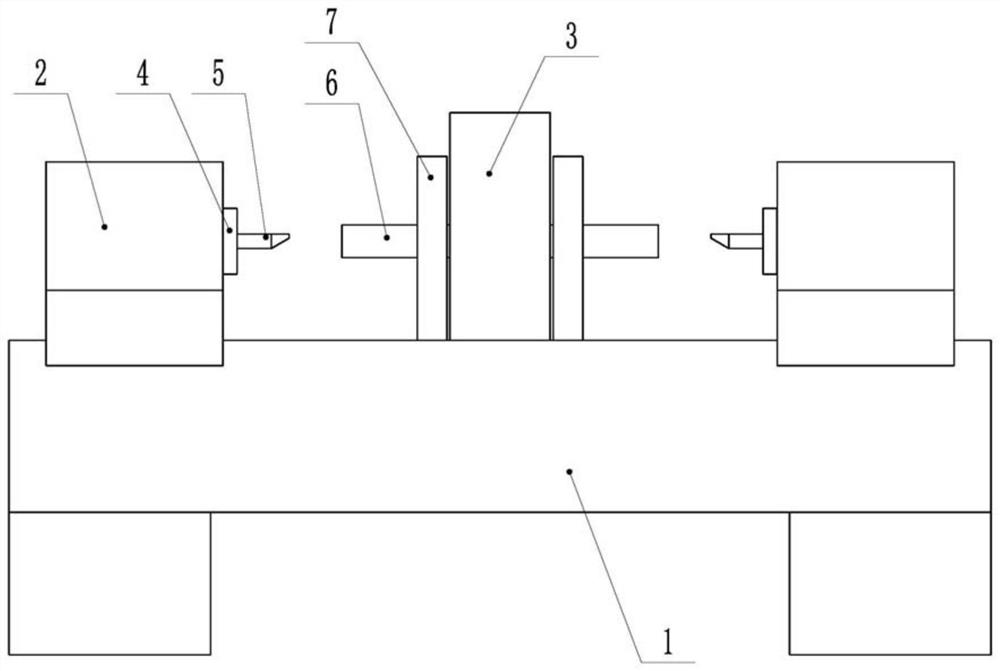

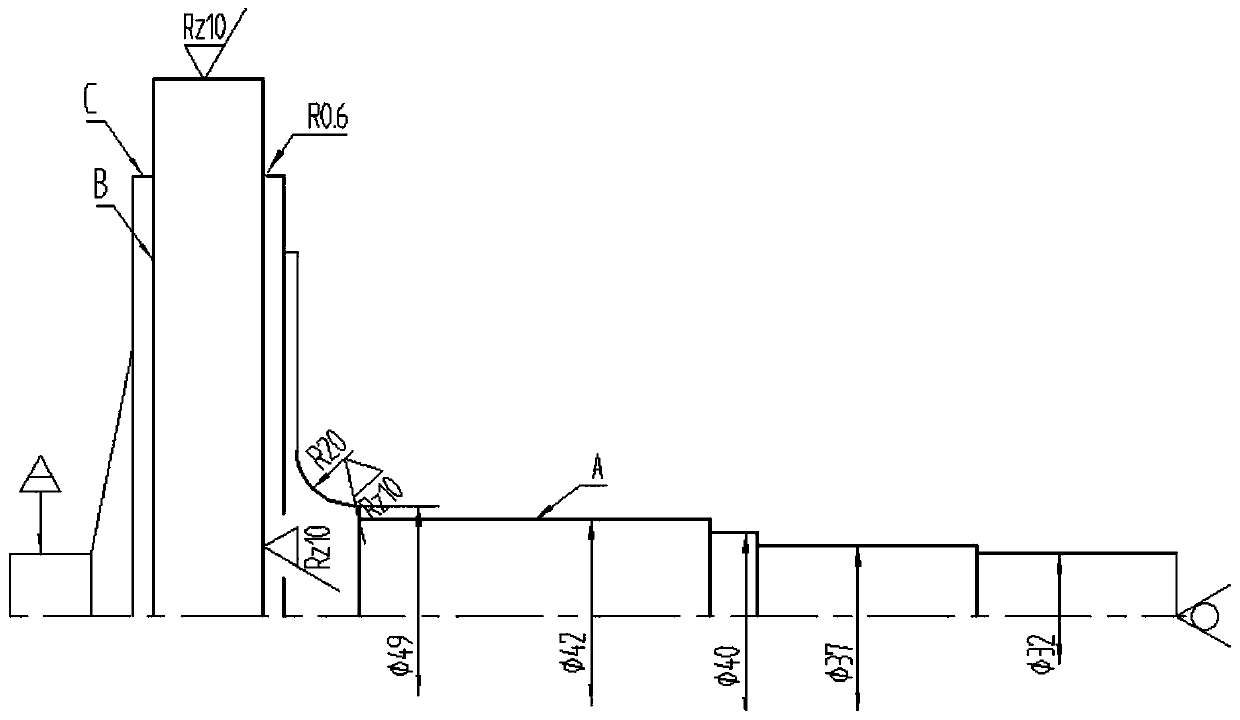

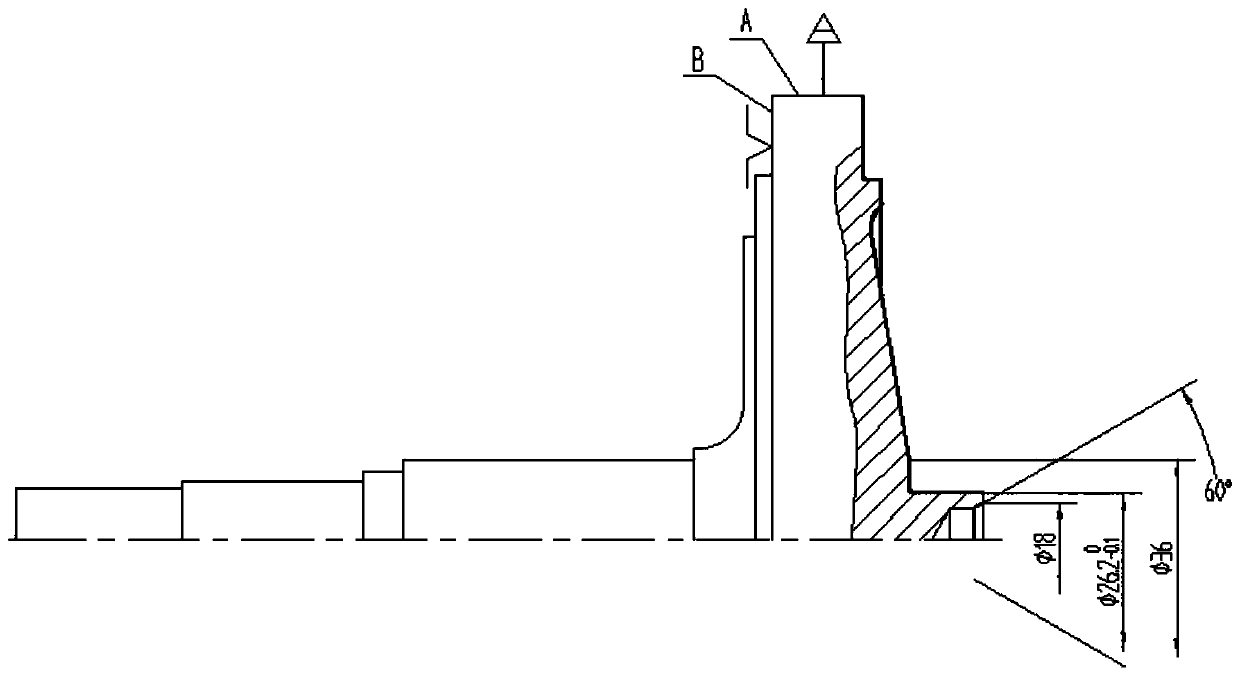

Finish-grinding treatment device and method for preventing hollow shaft center deformation

InactiveCN112405144ASolve unqualifiedRevolution surface grinding machinesGrinding drivesEngineeringMachine

The invention relates to the field of hollow shaft machining, and discloses a finish-grinding treatment method for preventing hollow shaft center deformation. The method comprises the following stepsof (1) heat treatment, wherein heat treatment is conducted on a hollow shaft formed by rough machining; (2), central hole correction, wherein the hollow shaft subjected to heat treatment in the step (1) is mounted on a finish-grinding treatment device, and finish-turning is conducted on central holes in the two ends of the hollow shaft to enable the central holes to be circular; and (3) outer circle finish-grinding, wherein the hollow shaft treated in the step (2) is mounted on a grinding machine, tips on the grinding machine are inserted into the two ends of the hollow shaft respectively, andthen a grinding wheel on the grinding machine is started to conduct finish-grinding on the outer circle of the hollow shaft. By means of the method, the problem that the cylindricity of the outer circle of the hollow shaft is poor due to deformation of the hollow shaft after heat treatment can be solved.

Owner:CHONGQING XINGJI GEAR

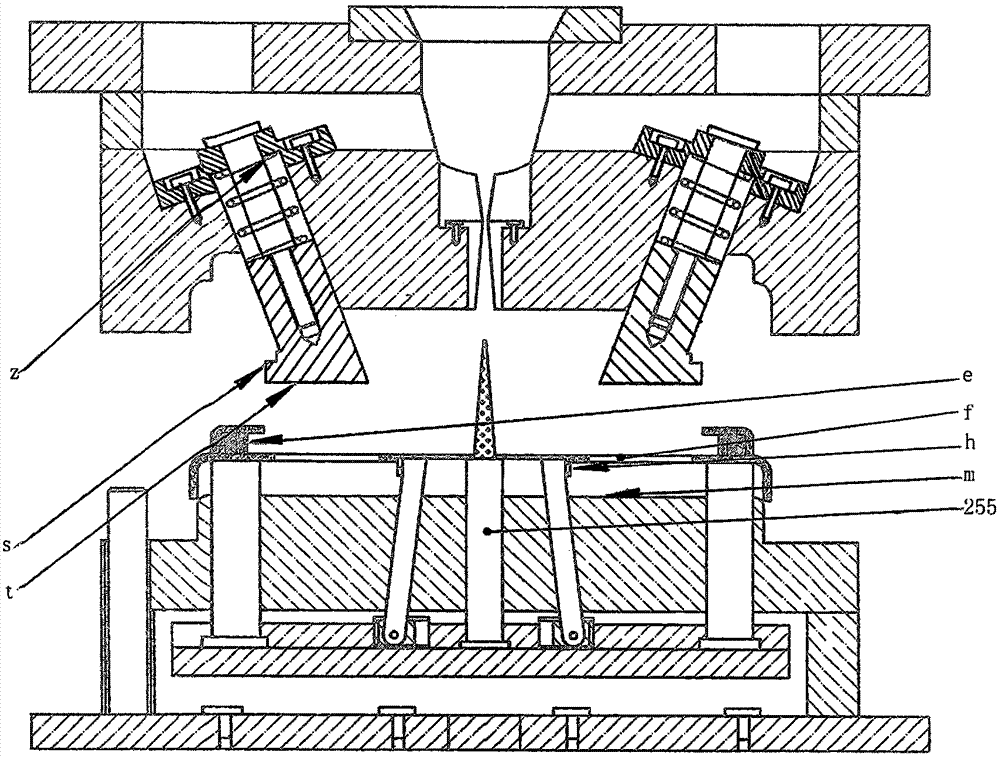

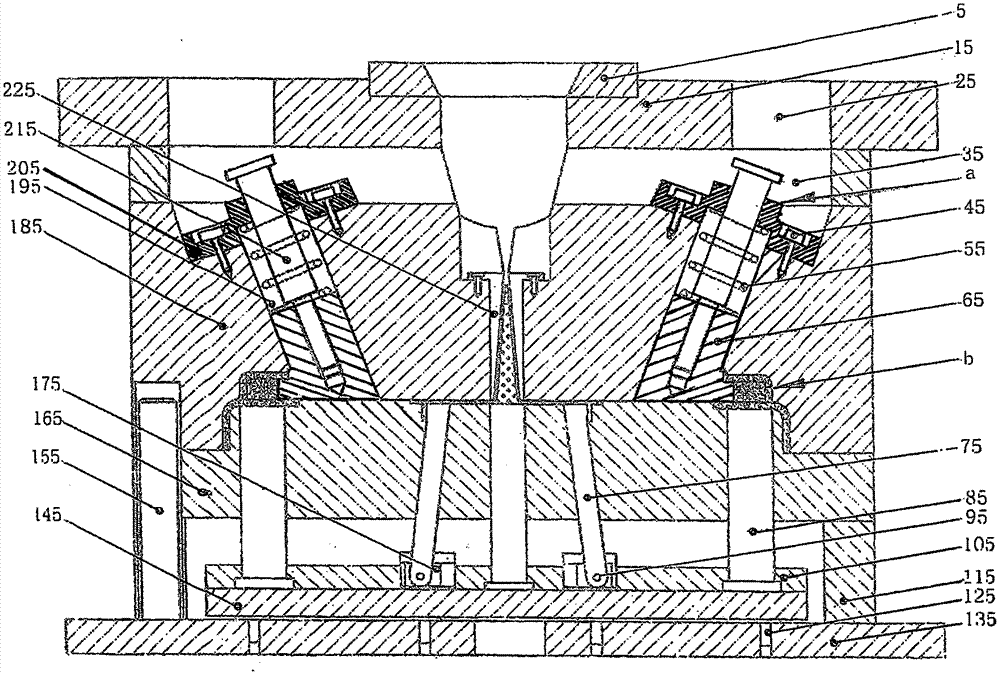

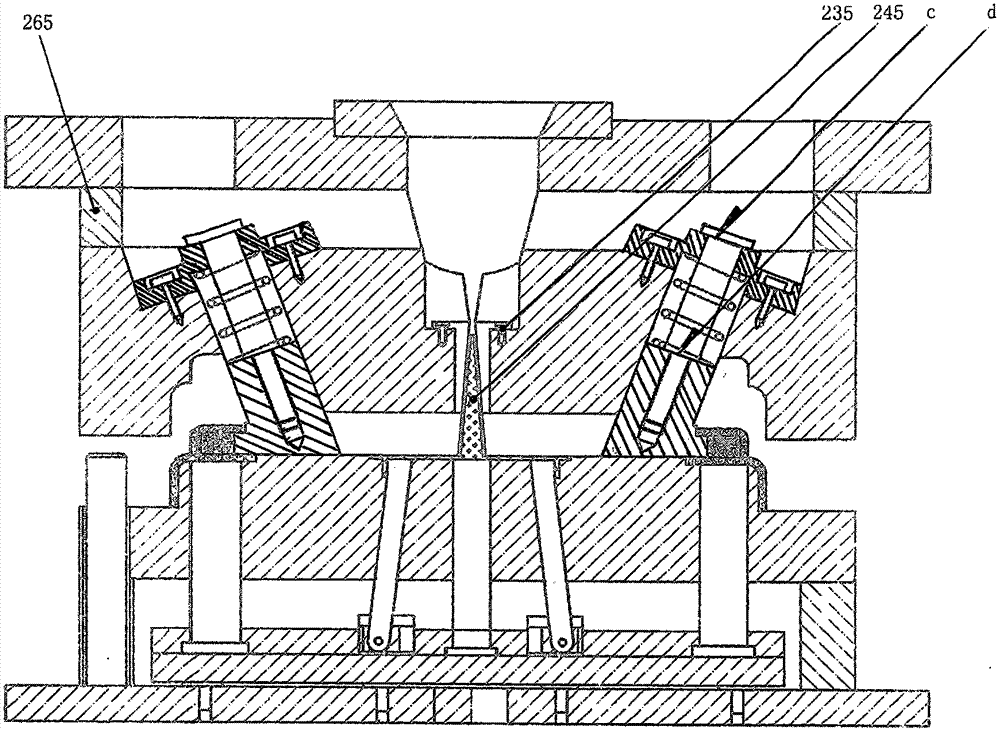

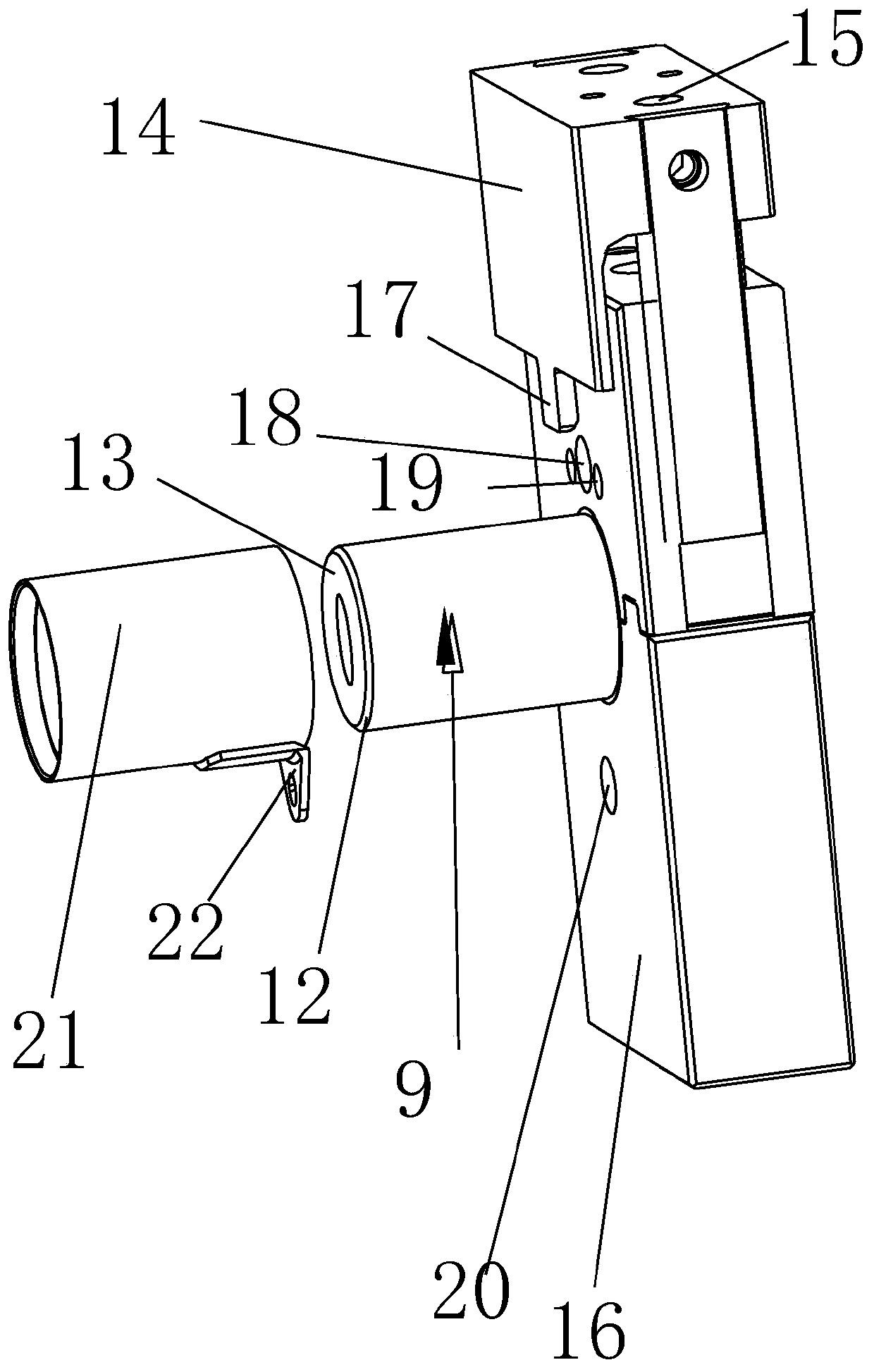

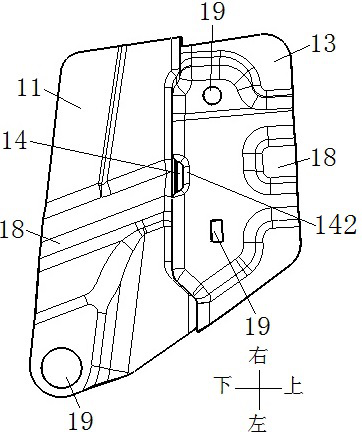

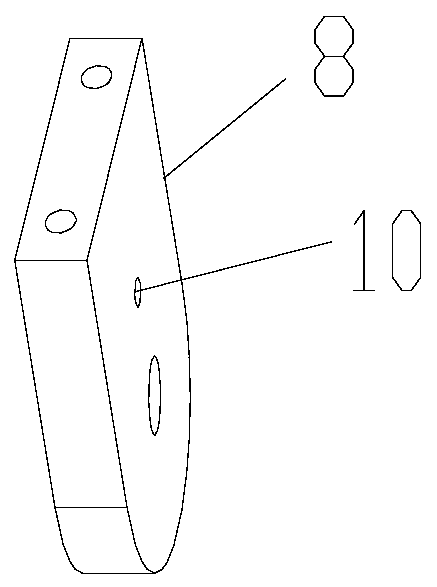

Die mechanism capable of realizing product formation by kiss-off through angle lifters and extraction of angle lifters from undercuts

The invention relates to a die mechanism capable of realizing product formation by kiss-off through angle lifters and extraction of the angle lifters from undercuts. The die mechanism comprises a fixed die and a moving die, wherein a fixed clamping plate (15), a support plate (265) and a fixed mold plate (185) are tightly connected by screws; guide sliding holes (195) are formed in the fixed mold plate (185); the fixed die angle lifters (65) are mounted in the guide sliding holes (195); the t positions of the fixed die angle lifters (65) are in contact with the m positions of a moving mold plate (165) so as to form penetration holes of the product b at f positions; the s positions of the fixed die angle lifters (65) are matched with the undercuts e in the product b; a limiting screw (215) is connected to the rear end of each of the fixed die angle lifters (65); the limiting screws (215) and springs (55) are mounted in and sleeved with the guide sliding holes (195); one end of each of the springs (55) is propped against a pressing plate (205), and the other ends of the springs are propped against the tail parts of the fixed die angle lifters (65).

Owner:牟维军

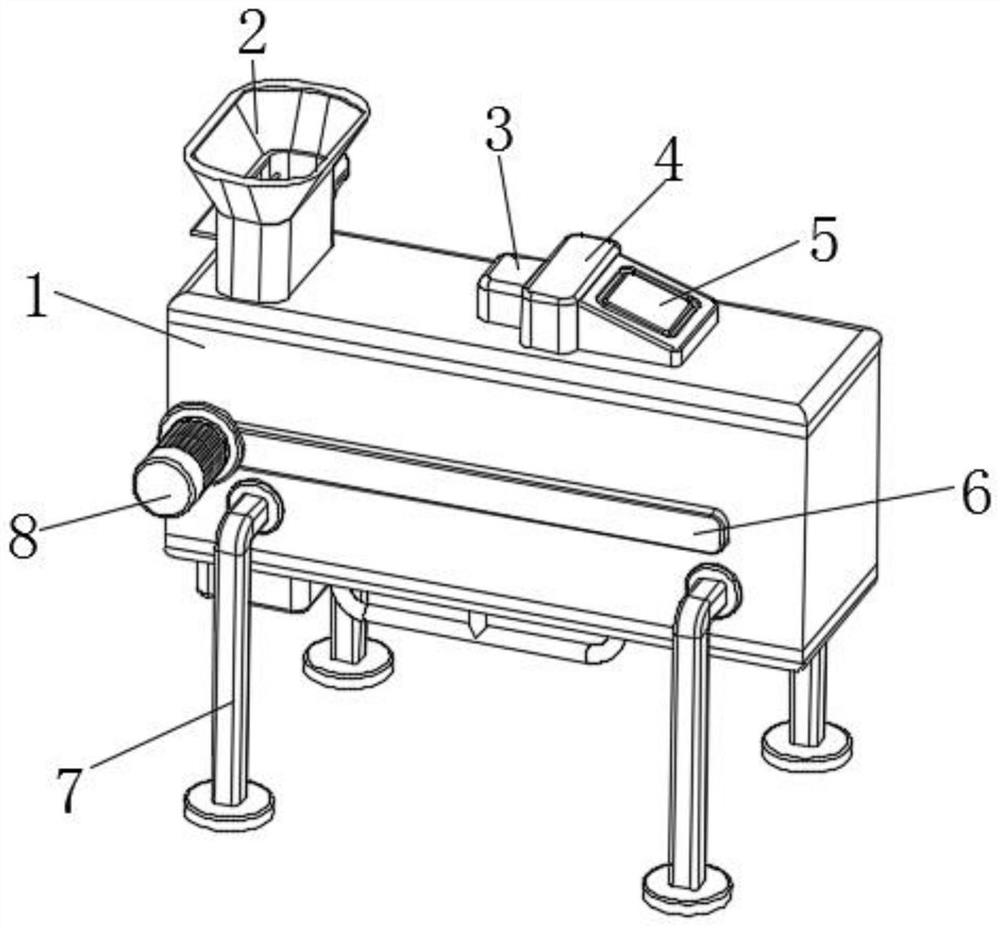

Novel silicon rubber mixing process control device

The invention discloses a novel silicon rubber mixing process control device. The device comprises a rubber mixing frequency monitoring unit, a cooling water temperature monitoring unit and a controlunit, wherein the rubber mixing frequency monitoring unit is arranged corresponding to rubber mixing rollers; a gap between the rubber mixing rollers is a rubber mixing extrusion channel; a rubber inlet is formed above the rubber mixing extrusion channel; a monitoring end of at least one position sensor device faces the rubber inlet; the position sensor device is electrically connected with the control unit; the cooling water temperature monitoring unit comprises a cooling water inlet pipe and a cooling water outlet pipe; a temperature sensor device is arranged in the cooling water outlet pipeand electrically connected with the control unit; and the control unit comprises a display device. According to the device, the position sensor device is arranged to monitor the rubber inlet so as tomonitor the rubber mixing frequency; and meanwhile, the temperature of the rubber mixing rollers is monitored through monitoring the temperature of the cooling water outlet pipe, so that the problemof unqualified silica gel products caused by different rubber mixing frequencies and excessive temperature of the rubber mixing rollers in the prior art is effectively solved.

Owner:JIANGSU HENGTONG ELECTRONICS CABLE TECH CO LTD

Punching die having function of fast positioning workpiece

InactiveCN110834053ASolve unqualifiedImprove practicalityShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a punching die having a function of fast positioning a workpiece. The punching die comprises a lower die seat, a vertical rod, a die demounting plate and a first compression spring. The vertical rod is connected in the lower die seat in a sleeved manner. The die demounting plate is fixedly connected to the top end of the vertical rod. The first compression spring is connected to the outer wall of the vertical rod in a sleeving manner. The upper end and the lower end of the first compression spring are attached to the die demounting plate and the lower die seat correspondingly. Positioning mechanisms are fixedly connected to the left end and the right end of the lower die seat. By means of the punching die having the function of fast positioning the workpiece, due tothe cooperative use of a torsion spring, a top seat, a rack groove plate and the like, the problem that when an existing punching is used, the workpiece is not accurately installed, and a punched product is not qualified is solved; and due to the cooperative use of a transverse rod, a second compression spring, a baffle and the like, the material change time is saved, and therefore the productionefficiency is improved, and operation is easy.

Owner:长兴鲁易模具有限公司

Method for machining turbine rotor with special-shaped center hole

InactiveCN110640405AStrong reliabilityImprove the size and shape tolerance of each fileBlade accessoriesMachines/enginesStructural engineeringTurbine rotor

The invention discloses a method for machining a turbine rotor with a special-shaped center hole. The method for machining the turbine rotor with the special-shaped center hole comprises the followingsteps that a turbine disk and a turbine shaft are welded; heat treatment is conducted; a center hole is drilled, and the turbine disk outer circle and end face margin are removed; semi-finish turningis conducted on end faces of the turbine end of the turbine disk and the special-shaped center hole; turning is conducted on a technological choke plug; semi-finish turning is conducted on end facesof the air-compressing end the turbine disk and the outer circle and end faces of the turbine shaft and the outer circle; a turbine shaft inner hole is drilled; turning is conducted on a turbine shafttool withdrawal groove, chamfering and a shaft stair inner hole; heat treatment is conducted; the technological choke plug and the turbine disk are welded and fixed; the center hole is turned in thetechnological choke plug, and two end faces of the big outer circle of the turbine disk are turned; the big outer circle of the turbine disk and the outer circle M of the turbine shaft are ground; a turbine shaft threaded hole, a stair inner hole and taper are turned, and tapping is conducted; the big outer circle of the turbine disk and end faces, the outer circle of the turbine shaft and end faces, the small outer circle of the turbine disk and the turbine disk D face are ground; an air-sealing groove is turned; and the technological choke plug is removed.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

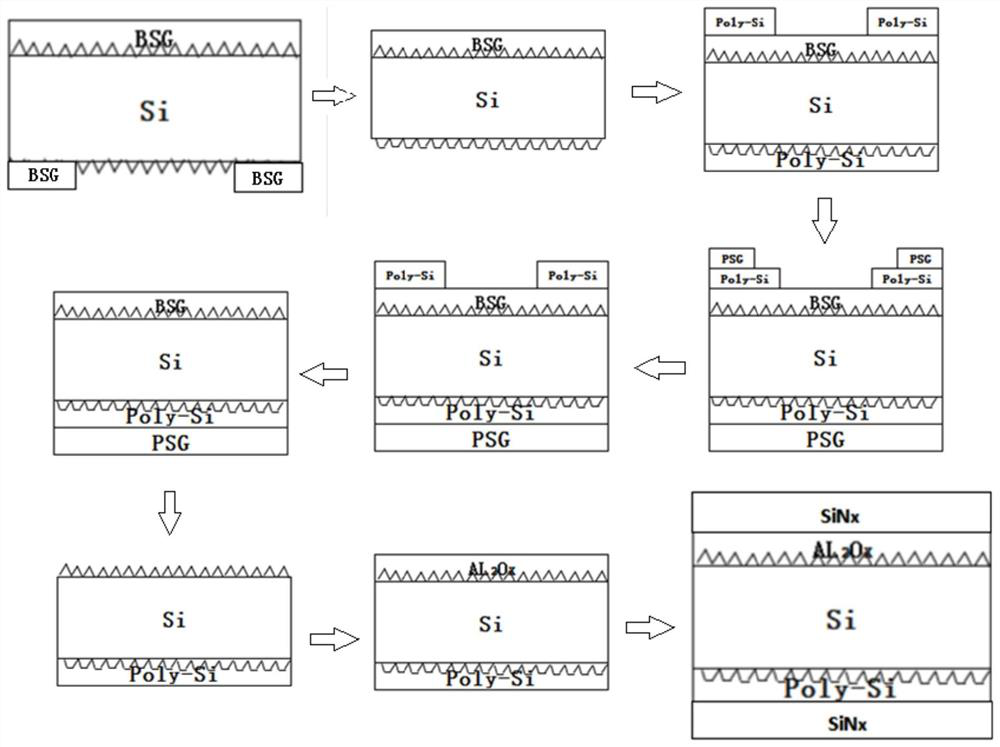

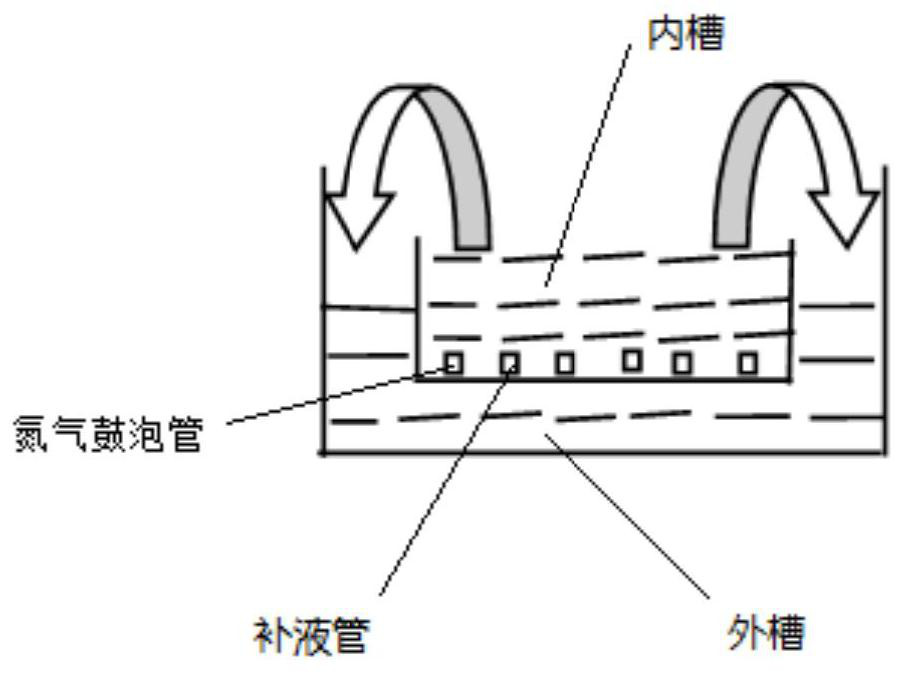

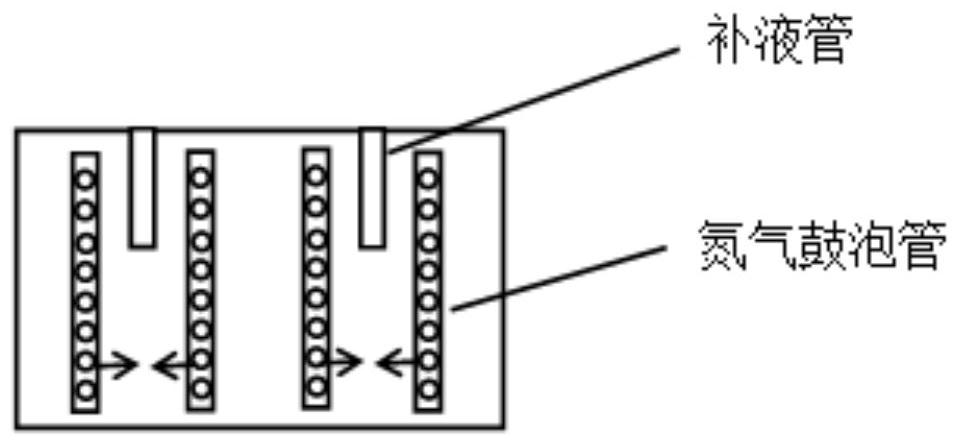

De-winding plating method for TOPCon battery and preparation method of TOPCon battery

ActiveCN112349584AGood removal effectNot volatileFinal product manufactureSemiconductor/solid-state device manufacturingHydrofluoric acidPhysical chemistry

The invention relates to the technical field of solar cells, and particularly discloses a winding and plating removing method for a TOPCon cell and a preparation method of the TOPCon cell. The methodcomprises the following steps: manufacturing a water film on the back surface of a phosphorus-doped silicon wafer, and removing phosphorus-doped layers wound and plated on the front surface and the side surface by using a hydrofluoric acid solution; soaking the obtained silicon wafer in a KOH solution or NaOH solution containing an additive, removing polycrystalline silicon on the front surface ofthe silicon wafer, taking out the silicon wafer, and washing with water; placing the obtained silicon wafer in a KOH or NaOH and H2O2 mixed solution to be soaked and then placing the silicon wafer ina hydrochloric acid solution to be soaked after washing, taking out the silicon wafer to be washed, completing the soaking treatment in a corresponding reaction tank, and arranging two sets of circulating bubbling systems in the reaction tank. According to the winding-plating-removing method provided by the invention, the winding plating phenomenon of the TOPCon battery can be effectively solved,the excellent rate of products is ensured, the appearance problem and EL disqualification problem caused by winding plating are solved, and the battery conversion efficiency is improved.

Owner:YINGLI ENERGY CHINA +1

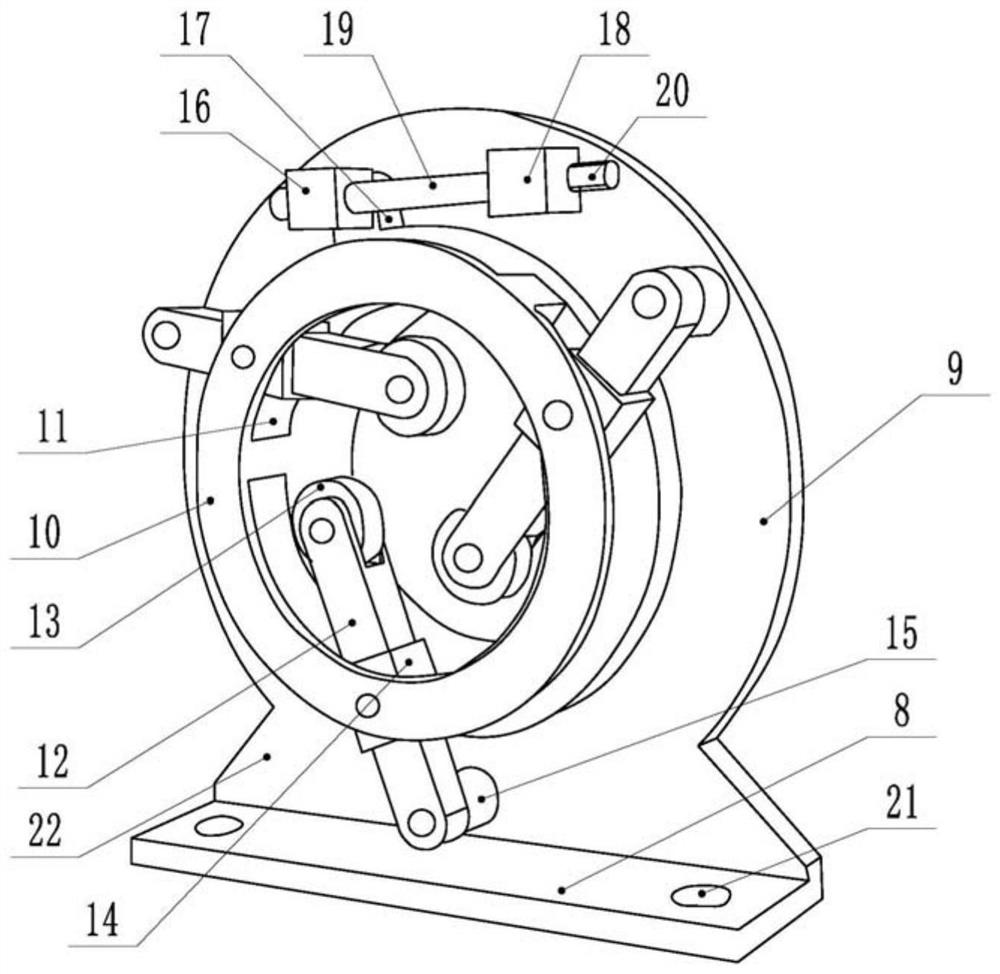

Circular shell welding device

PendingCN110328473AAppearance detectionIncrease production costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention relates to a circular shell welding device. The circular shell welding device comprises a cylinder, a welding machine, a sliding block, a welding joint, a rotary welding module, a workbench and a engine base, wherein the engine base is connected with the lower end of the welding machine; the workbench is connected with the middle of the side face of the welding machine; the rotary welding module is connected with the workbench; the cylinder is connected with the upper end of the welding machine; the cylinder is connected with the sliding block; the sliding block is connected withthe welding joint; the rotary welding module includes a servo motor, a mandrel, a guide block and a fixed cylinder; the servo motor passes through the guide block to be connected with the mandrel; and the fixed cylinder is arranged at the bottom of the guide block and connected with the guide block. The welding device achieves the automatic welding process of a circular shell, so that the production efficiency is greatly improved without manual operation in the whole process; and the welding effect is good, so that the product scrap rate is low, and the enterprise cost is reduced.

Owner:苏州神本精密机械有限公司

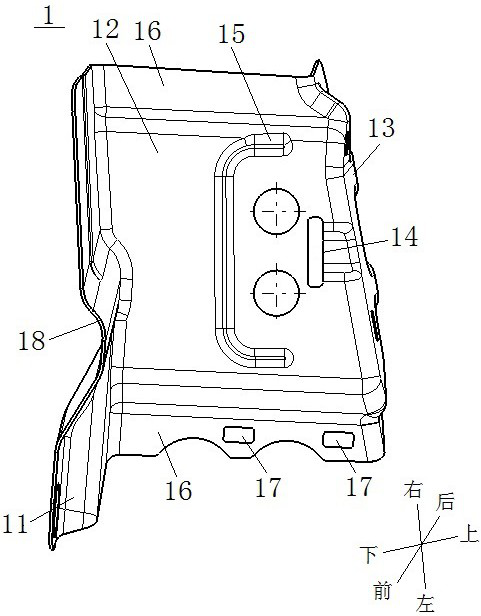

Vehicle door lock pin reinforcer, vehicle door assembly and vehicle

The invention discloses a vehicle door lock pin reinforcer, a vehicle door assembly and a vehicle. The vehicle door lock pin reinforcer comprises a reinforcer body with a Z-shaped cross section, wherein the reinforcer body comprises a lower transverse plate, a vertical plate and an upper transverse plate which are connected in sequence, the lower transverse plate and the upper transverse plate are in lap joint with a vehicle body, the front side of the vertical plate is fixedly connected with a lock catch nut plate; the front side of the vertical plate is provided with a limiting hole correspondingly matched with a limiting clamp on the edge of the upper end of the lock catch nut plate, and a movement allowance is reserved between the limiting clamp and the hole wall of the limiting hole. On the basis of ensuring rigidity and strength, poor attachment of the lock catch nut plate and the lock pin reinforcer can be avoided, so that the assembly quality of the lock catch nut plate is improved.

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES

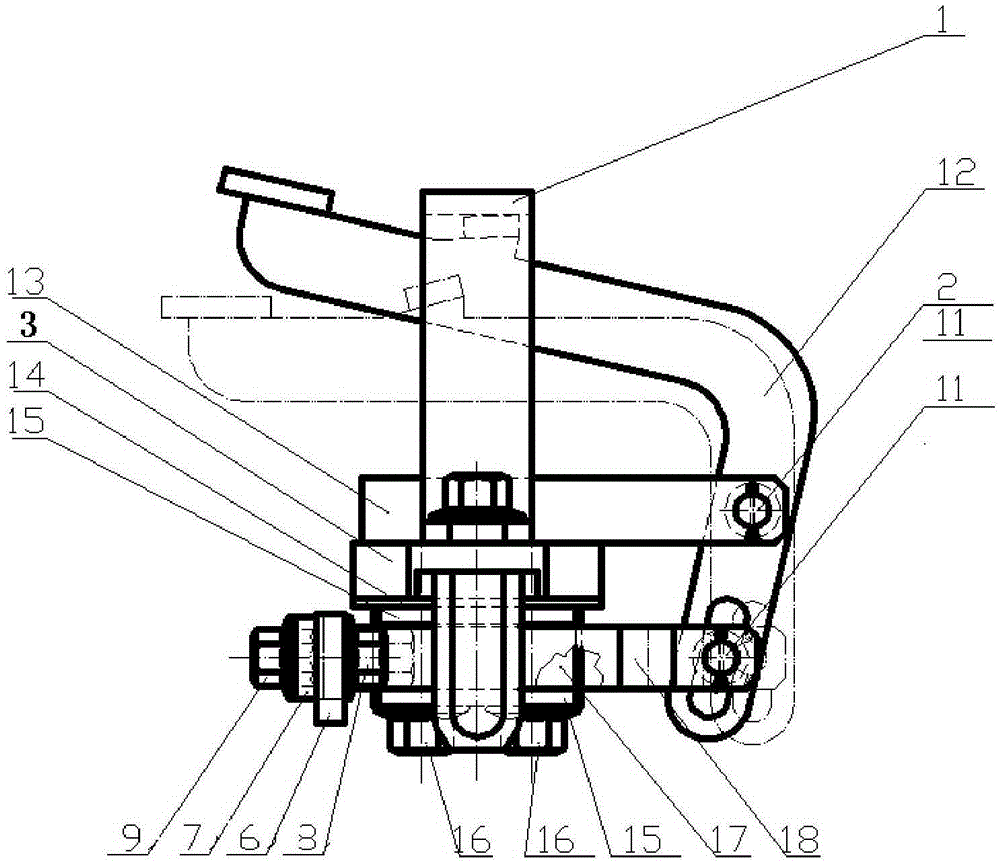

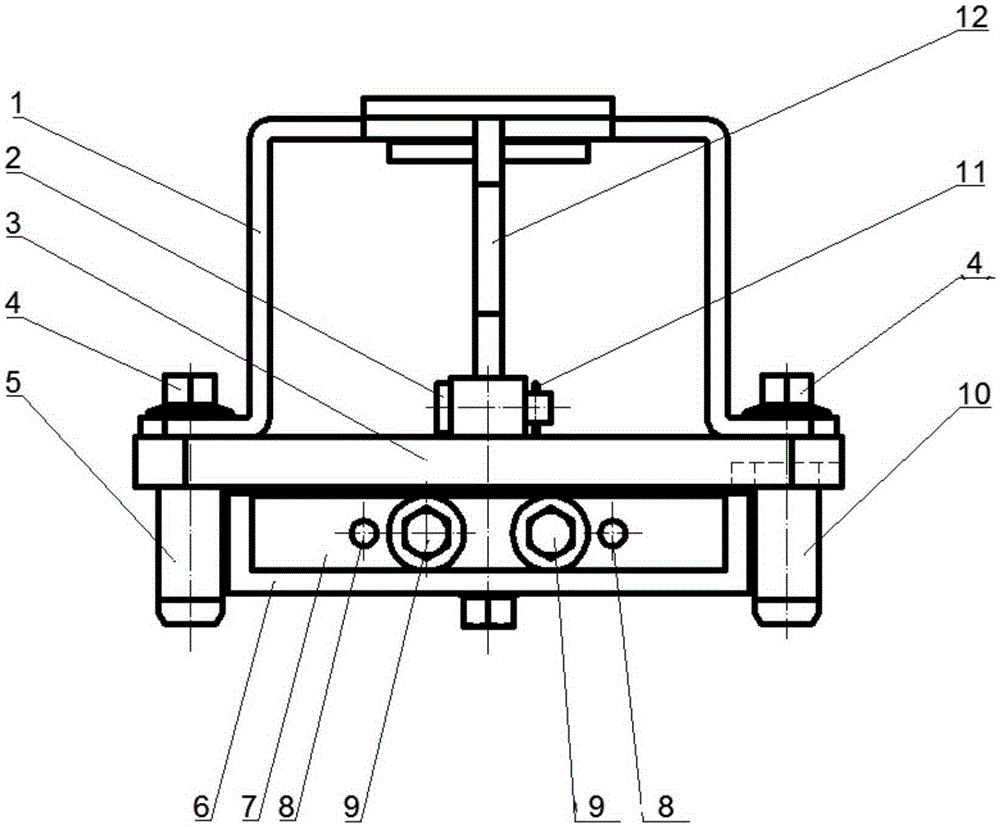

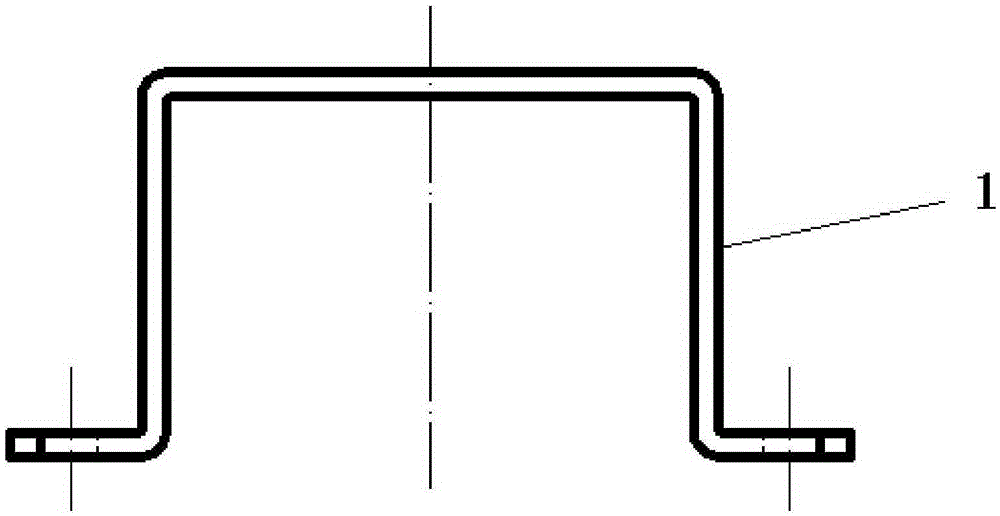

Pressing device of engine flange bearing bush

ActiveCN105252485AReduce the influence of human factorsImprove press fit quality and efficiencyMetal-working hand toolsEngineeringFlange

The invention discloses a pressing device of an engine flange bearing bush. The pressing device comprises a base, and a handle taking the shape of a Chinese character Ji, wherein the two sides of the handle are respectively fixed at the two sides of the top surface of the base through first bolts; extending ends, on the bottom surface of the base, of the first bolts are respectively fixed with a short pin and a long pin; a first opening groove is formed in one end of a bracket; the other end of the bracket is respectively fixed on the top surface and the bottom surface of the base through a second bolt and a guide block; a pressing rod is L-shaped; a middle fulcrum of the pressing rod is hinged with the bracket through a first pin shaft to form a lever structure; a second opening groove is formed in one end of a pull rod for connecting with the lower end of the pressing rod at one side of the middle fulcrum of the pressing rod through a second pin shaft; and a pressing plate and a pressing block are fixed at the other end of the pull rod through third bolts. The pressing device can reduce the influence of human factors, and improves the pressing quality and efficiency.

Owner:GUANGXI YUCHAI MASCH CO LTD

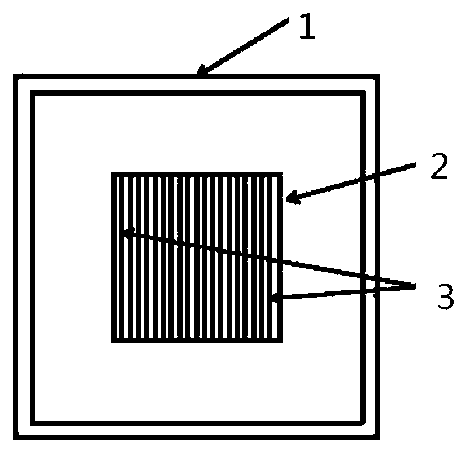

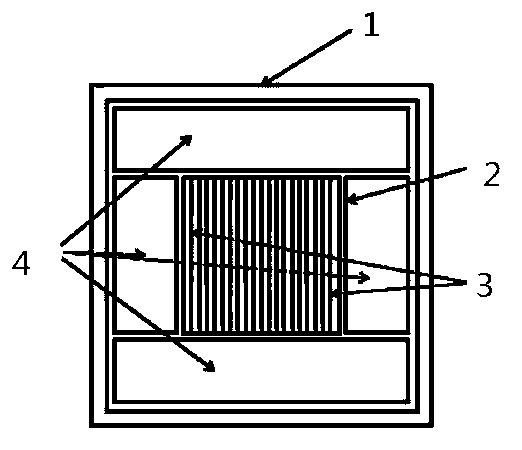

Method for eliminating screen printing edge bold lines and screen printing plate capable of eliminating edge bold lines

The invention discloses a method for eliminating screen printing edge bold lines and a screen printing plate capable of eliminating the edge bold lines. The method for eliminating the screen printing edge bold lines comprises the steps that a graphic area is set on a screen frame, and raised layers are arranged on the screen frame located on the periphery of the graphic area. The screen printing plate capable of eliminating the edge bold lines comprises the screen frame with the graphic area, and the raised layers are arranged on the screen frame located on the periphery of the graphic area. Through the raised layers, the screen printing plate is on the same plane basically, the problem that a product is unqualified due to the fact that a grid line on the utmost edge becomes thicker in the printing process is solved, the method is easy to implement, and hardly any cost is increased.

Owner:ALTUSVIA ENERGY TAICANG

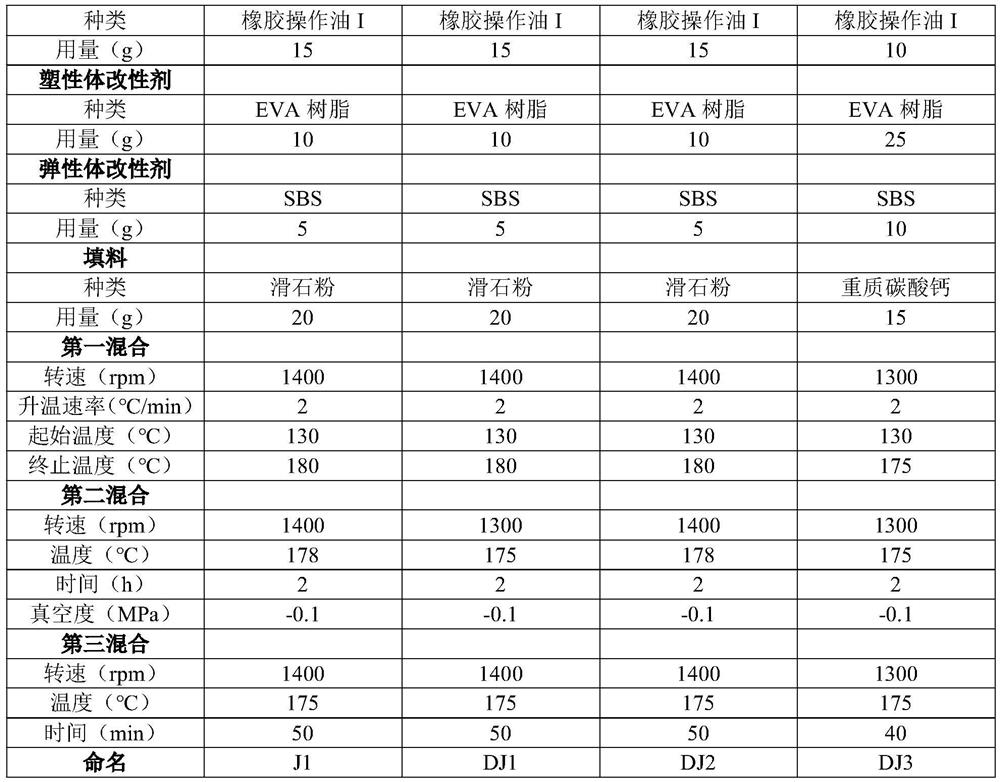

A multifunctional power board test production line

ActiveCN104267330BSolve unqualifiedImprove work efficiencyElectronic circuit testingMeasurement instrument housingProduction lineEngineering

The invention discloses a multifunctional power panel testing production line. The multifunctional power panel testing production line comprises a first testing device and a second testing device. A power panel enters the second testing device after passing through the first testing device. The first testing device and the second testing device each comprise a rack, a conveyer belt stretching across the rack and a testing fixture arranged on the rack. The first testing device further comprises an ICT testing mechanism, a Hi-pot testing mechanism and an FCT testing mechanism, and the ICT testing mechanism, the Hi-pot testing mechanism and the FCT testing mechanism are sequentially arranged on the rack of the first testing device. The second testing device further comprises a DPMS testing mechanism, an ATE testing mechanism and a TV testing mechanism, and the DPMS testing mechanism, the ATE testing mechanism and the TV testing mechanism are sequentially arranged on the rack of the second testing device. The multifunctional power panel testing production line improves the working efficiency and automation of PCBA tests and makes the quality of the PCBA tests more stable.

Owner:DONGGUAN GUANJIA ELECTRONICS EQUIP

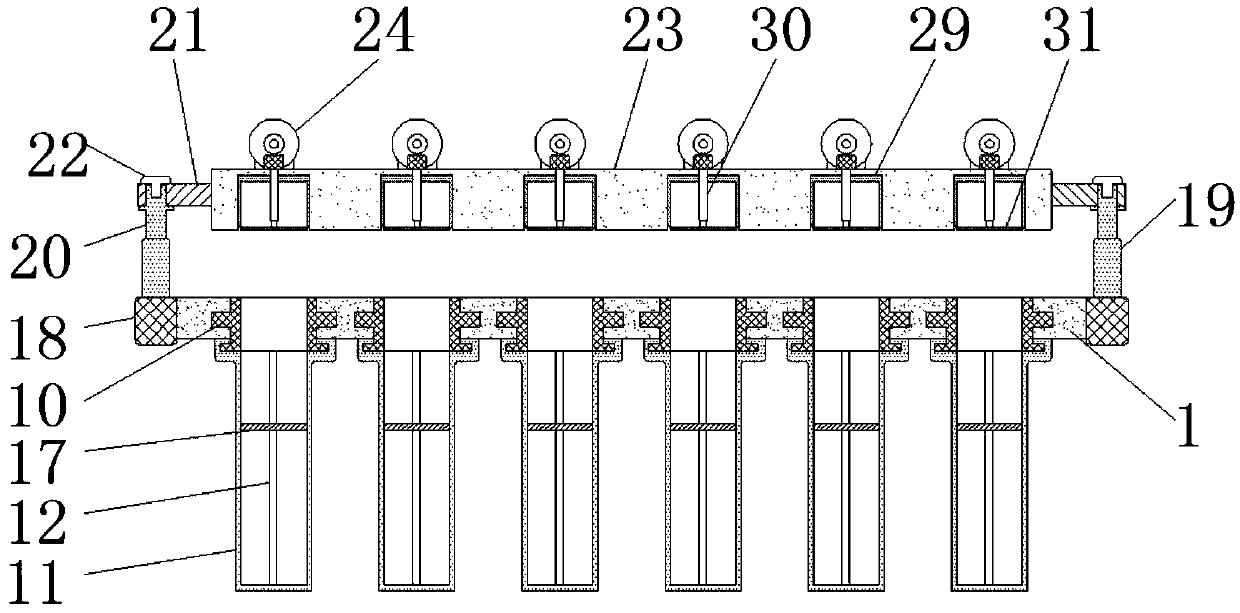

Preparation process of insole board for shoes

ActiveCN108669708ASolve unqualifiedSolve the problem of low production efficiency caused by inconvenient collectionShoemaking devicesDrive wheelEngineering

The invention provides a preparation process of an insole board for shoes. A working platform, a pressing plate and a cutter are included, wherein a first motor is arranged at the right end of the working platform, a fixing plate is arranged at the left end of the working platform, an insole board mold is mounted on the left side of the fixing plate, grooves are formed in the left and right ends of a collecting box, connecting plates are arranged on the left and right sides of the collecting box, springs are mounted on the inner sides of connecting blocks, support blocks are arranged on the left side of the working platform, lengthening rods are connected to the upper ends of telescopic rods, the pressing plate is located above the working platform, driving wheels are connected to the outer ends of second motors, driven rods are mounted at the lower ends of driven wheels, the cutter is located on the inner side of the pressing plate, and the lower end of a push rod is connected with apush plate. By means of the preparation process of the insole board for shoes, the problems that raw materials of the insole board for shoes easily wrinkle during cutting, the production efficiency islower and bending of the raw materials is easily caused in the pushing process in existing preparation processes of insole boards for shoes are solved.

Owner:浙江丽康鞋材有限公司

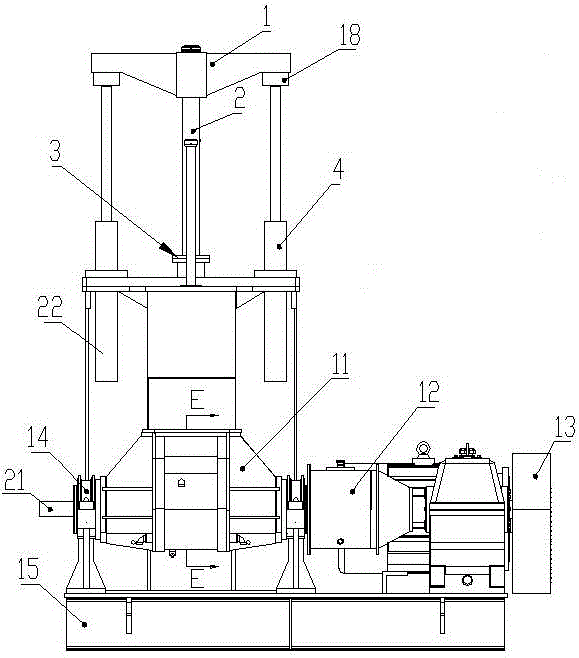

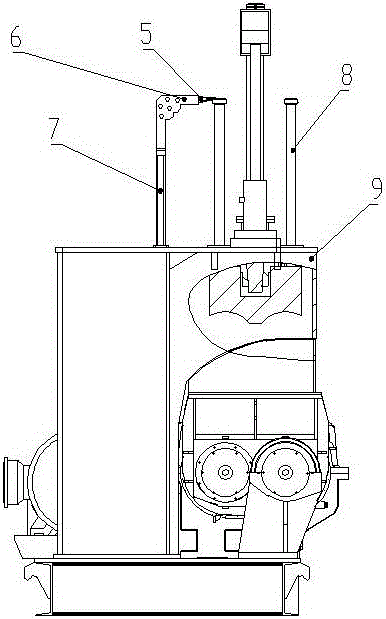

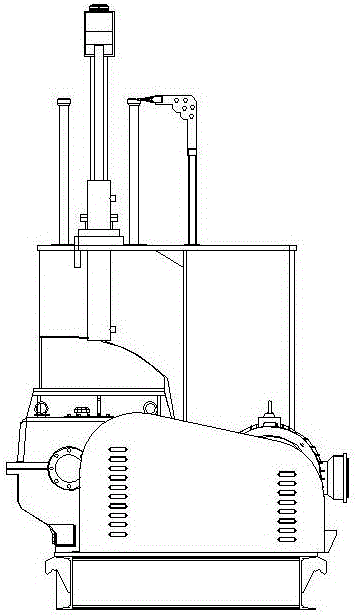

Double hydraulic internal mixer

The invention discloses a double hydraulic internal mixer. A rack is arranged on a rack base; a first hydraulic cylinder and a second hydraulic cylinder are arranged on the rack; position rods of the first hydraulic cylinder and the second hydraulic cylinder are connected with a top peg; a piston rod guiding device is arranged in the middle of the rack; the upper part of a piston rod is connected with the top peg; the lower part of the piston rod is connected with the piston rod guiding device; supporting seats are arranged on the rack base; a rotor is arranged on the supporting seats and is connected with a mixing mechanism; and the mixing mechanism is connected with a driving mechanism through a speed ratio mechanism. According to the double hydraulic internal mixer disclosed by the invention, the stability is good; the pressure acting on materials is uniform; due to the adoption of double hydraulic design, the problem of oil leakage in the prior art is solved; by adoption of a triangular design, the top peg has the stability; a rack guiding sleeve adopts a double sealing intermediate oil channel design, so that unnecessary wear of the piston rods when the piston rods vertically move due to dust leakage, and dust left on the piston rods and the like is avoided, and the service life of the piston rods is prolonged; and a top peg hydraulic mechanism separately adopts bolts for connecting and mounting.

Owner:大连嘉尔新橡塑机械有限公司

Pretreatment sterilization device for goose meat processing

InactiveCN113767959AEfficient sterilizationSolve the qualitative changePoultry cleaning/disinfectionPoultry transferring/conveying devicesAnimal scienceUltraviolet

The invention discloses a pretreatment sterilization device for goose meat processing, which comprises a box body, the top of the box body is provided with a feed chute, the top of the box body is provided with a feed channel located at the top of the feed chute, the bottom of the box body is provided with a discharge chute, the discharge chute and the feed chute are located at diagonal positions of the top and the bottom of the box body, a main rotating roller and driven rollers are assembled on the inner side of the box body, the distance between the main rotating roller and each driven roller is the same, and a chain box sleeved with the main rotating roller and each driven roller is fixedly installed on the outer wall of the box body. According to the pretreatment sterilization device for goose meat processing, due to the arrangement of an ultraviolet lamp panel on the inner side of the box body, a power source can be provided for the ultraviolet lamp panel through the power box to enable the ultraviolet lamp panel to emit light, and goose meat on the tops of the driven rollers and the main rotating roller can be efficiently sterilized in cooperation with different irradiation angles of the ultraviolet lamp panel, meanwhile, a steam generator is arranged at the bottom of the box body, and the goose meat can be efficiently sterilized in cooperation with a temperature detector and the ultraviolet lamp panel.

Owner:麻阳雁南飞食品有限责任公司

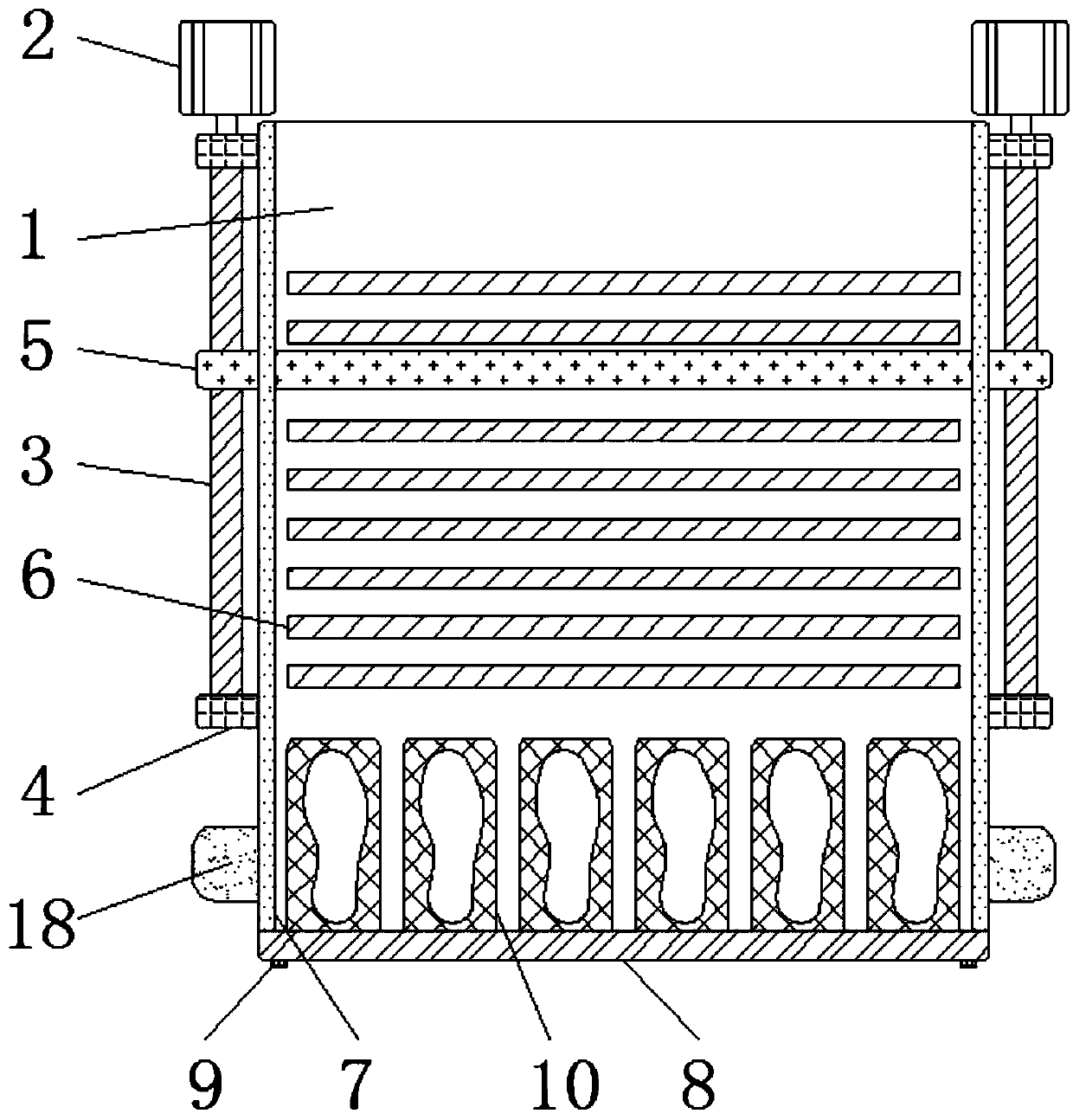

Device for assembling lamp plate to iron frame

The invention discloses a device for assembling a lamp plate to an iron frame. The device comprises a base, and further comprises a left support assembly, a right support assembly, a rotary platform and a lamp plate positioning mechanism, wherein the left support assembly and the right support assembly are located at the left end and the right end of the base respectively and can rotate, the rotary platform is fixed on the left support assembly and the right support assembly, and the lamp plate positioning mechanism is located at the upper left corner of the rotary platform; a longitudinal positioning area is arranged on the rear side of the rotary platform, a left positioning area is arranged on the left side of the rotary platform, a right positioning area is arranged on the right side of the rotary platform, the middle of the rotary platform is an iron frame placement area, and a plurality of strip-shaped grooves are formed in the lower side of the iron frame placement area; and theleft support assembly comprises a support, and a rotary block which is rotationally connected to the right side of the support through a rotary shaft, the upper end of the rotary block is fixedly connected with the middle of the left side of the rotary platform, and the bottom of the support is fixed at the left end of the base. According to the scheme, the structural design is simple and practical, the positioning effect is accurate, the operation is fast, and the efficiency of attaching the lamp plate is greatly improved.

Owner:惠州市福瑞尔光电有限公司

System for recycling condensate of extraction torch tank

ActiveCN106588541AAvoid quality impactIncrease non-aromatic contentDistillation purification/separationHydrocarbonsReboilerGas phase

A system for recycling condensate of an extraction torch tank comprises the extraction torch tank, a wet solvent tank, a torch tank condensate pump, a torch tank condensate pipeline, an extraction solvent circulating pipeline, a lean solvent pump, an extraction distilling tower, an extraction distilling tower reboiler, a non-aromatic steam pipeline and a non-aromatic distilling tower; the wet solvent tank is connected to the extraction torch tank, the extraction torch tank is connected to the torch tank condensate pump through a pipeline, the torch tank condensate pump is connected to the extraction solvent circulating pipeline through the torch tank condensate pipeline, one end of the extraction solvent circulating pipeline is connected to the lean solvent pump, the other end of the extraction solvent circulating pipeline is connected to the extraction distilling tower, the top of the extraction distilling tower is connected to the non-aromatic distilling tower through the non-aromatic gas pipeline, and the lower portion of the extraction distilling tower is connected to the extraction distilling tower reboiler. The problem is solved that mixed aromatic products are easily unqualified since condensate in the extraction torch tank is recycled by being discharged to an underground solvent tank, and the non-aromatic content of extraction mixed aromatic products is increased.

Owner:DALIAN FUJIA DAHUA GASOLINEEUM CHEM

Composition of gastric mucin capsule and preparation method for composition

ActiveCN102526696BSolve unqualifiedSolve market supply problemsPeptide/protein ingredientsDigestive systemAnatomyBiomedical engineering

The invention discloses a composition of a gastric mucin capsule and a preparation method for the composition. The gastric mucin capsule is mainly prepared from 50 to 96 weight percent of gastric mucin, 2 to 30 weight percent of filling agent and 2 to 20 weight percent of regulator by a wet granulation encapsulation method or a powder direct encapsulation method. By the composition of the gastric mucin capsule and the preparation method for the composition, the problem that the gastric mucin capsule is unqualified in disintegration is solved and the problem about market supply is solved.

Owner:HEFEI JINYUE PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com