Extrusion die head adjusting device

A technology of adjusting device and fine-tuning device, which is applied in the field of coating machine to achieve the effect of improving the accuracy of lateral position and timely adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

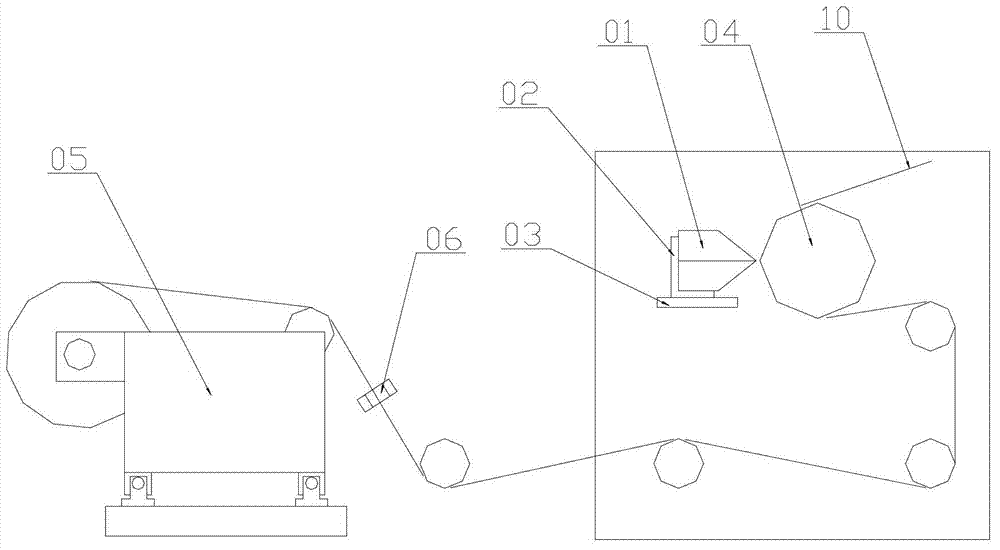

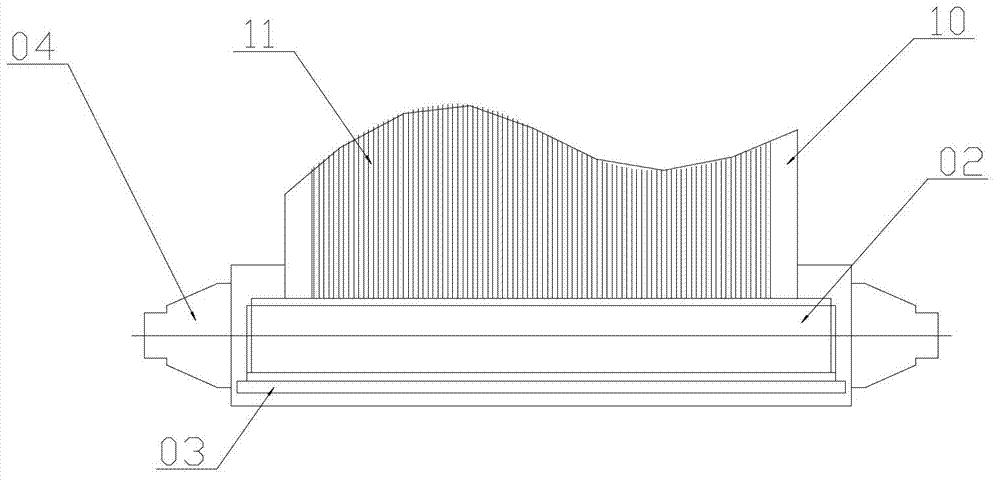

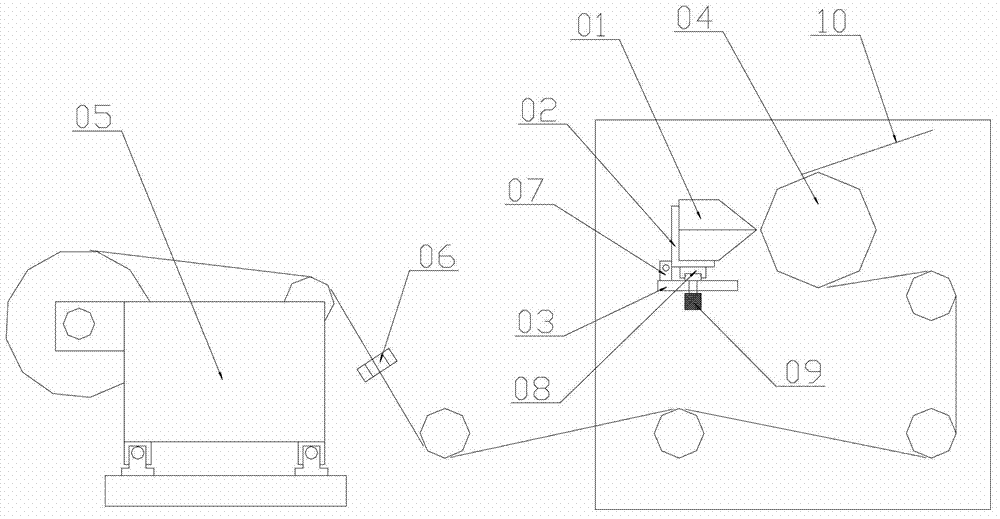

[0027] against attached Figure 1.a And attached Figure 1.b The coating device in can not completely and accurately carry out the defect that substrate 10 is sprayed, carry out such as Figure 2.a and Figure 2.b The improvement of the first embodiment of the present invention.

[0028] After the substrate 10 is sent out by the unwinding mechanism 05 and enters the correction device 06 of the unwinding mechanism for the first position correction, the position is corrected again when the extrusion die head 01 is spraying the substrate 10 . The main method is to install the guide device 08 at the bottom of the extrusion die support 02, and install the fixed end of the guide device 08 on the fixed bottom plate 03, so that the extrusion die 01 and the extrusion die support 02 can be relatively fixed The bottom plate 03 moves laterally (the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com