Preparation and imidization method of polyimide hollow fiber membrane

A technology of polyimide and fiber membranes, applied in the field of polyimide hollow fiber membranes, can solve problems such as planarity and symmetry destruction, achieve a smooth and symmetrical segment structure, improve the degree of cyclization, and improve the degree of imidization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) PMDA and ODA are added in DMAc, stir, obtain the polyamic acid solution that solid content is 15%.

[0035] (2) The polyamic acid hollow fiber membrane was prepared from the polyamic acid solution by dry jet wet spinning, and then soaked in deionized water for 8 hours to make it completely solidified. After solidification, put it into a solvent with a small surface tension for solvent exchange, and soak for 20 hours.

[0036] (3) Put the prepared polyamic acid hollow fiber membrane into a system composed of dehydrating agent acetic anhydride, catalyst pyridine and triethylamine, and soak at a temperature of 30-100° C. for 20 h.

[0037] (4) Wrap the polyimide hollow fiber membrane after solvent exchange with aluminum foil and put it in an oven, raise the temperature from room temperature to 135-180°C, keep it warm for two hours to remove the solvent, and continue to heat up to 300-360°C to make it sub- Amination is complete.

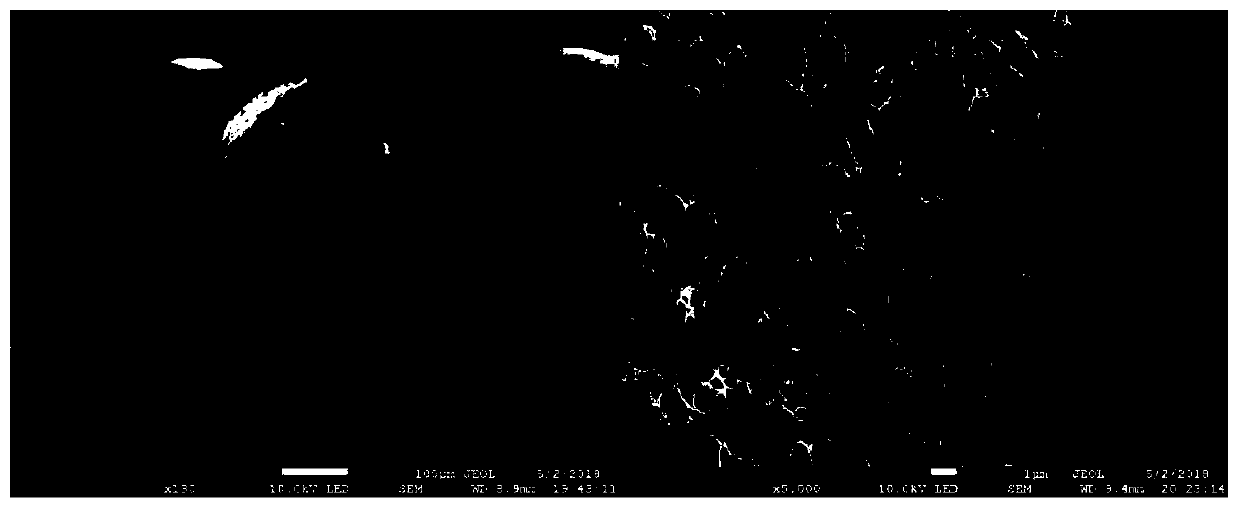

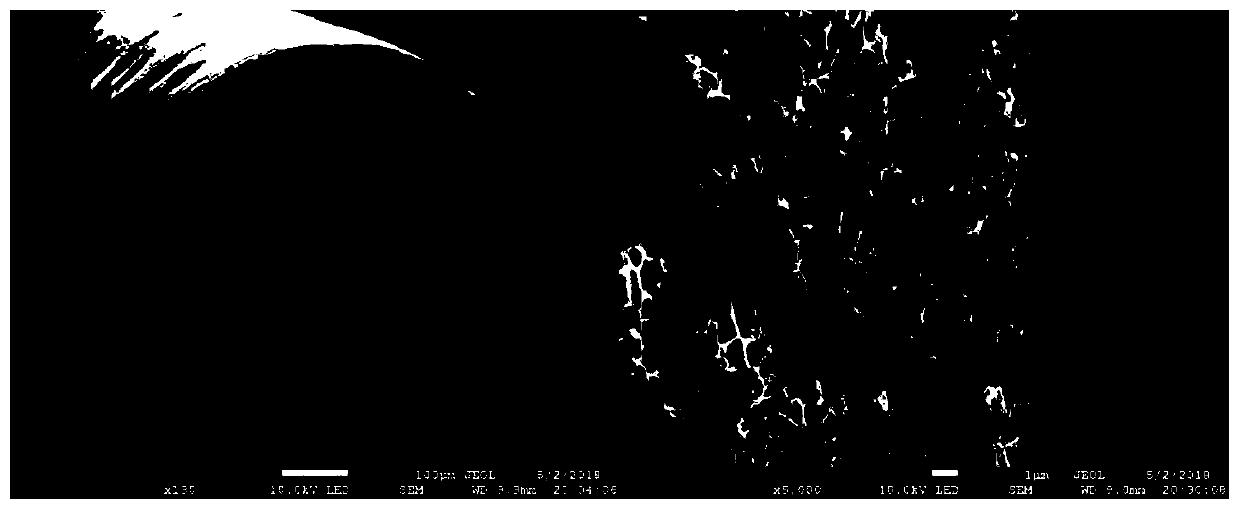

[0038] (5) The morphology of the poly...

Embodiment 2

[0043] (1) Add BPDA and ODA into DMAc, stir to obtain a polyamic acid solution with a solid content of 15%.

[0044] (2) The polyamic acid hollow fiber membrane was prepared from the polyamic acid solution by dry jet wet spinning, and then soaked in deionized water for 8 hours to make it completely solidified. After solidification, put it into a solvent with a small surface tension for solvent exchange, and soak for 20 hours.

[0045] (3) Put the prepared polyamic acid hollow fiber membrane into a system composed of dehydrating agent acetic anhydride, catalyst pyridine and triethylamine, and soak at a temperature of 30-100° C. for 20 h.

[0046] (4) Wrap the polyimide hollow fiber membrane after solvent exchange with aluminum foil and put it in an oven, raise the temperature from room temperature to 135-180°C, keep it warm for two hours to remove the solvent, and continue to heat up to 300-360°C to make it sub- Amination is complete.

[0047] (5) The polyimide hollow fiber m...

Embodiment 3

[0049] (1) Add 6FDA and ODA to DMAc and stir to obtain a polyamic acid solution with a solid content of 15%.

[0050](2) The polyamic acid hollow fiber membrane was prepared from the polyamic acid solution by dry jet wet spinning, and then soaked in deionized water for 8 hours to make it completely solidified. After solidification, put it into a solvent with a small surface tension for solvent exchange, and soak for 20 hours.

[0051] (3) Put the prepared polyamic acid hollow fiber membrane into a system composed of dehydrating agent acetic anhydride, catalyst pyridine and triethylamine, and soak at 30-100° C. for 20 h.

[0052] (4) Wrap the polyimide hollow fiber membrane after solvent exchange with aluminum foil and put it in an oven, raise the temperature from room temperature to 135-180°C, keep it warm for two hours to remove the solvent, and continue to heat up to 300-360°C to make it sub- Amination is complete.

[0053] (5) The polyimide hollow fiber membrane morpholog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com