Modified asphalt waterproof roll sizing material composition, modified asphalt waterproof roll sizing material as well as preparation method and application of modified asphalt waterproof roll sizing material

A waterproof membrane and modified asphalt technology, which is applied in the direction of asphalt material adhesives, adhesives, adhesive types, etc., can solve the problems of easy generation of a large number of pores, low temperature cracking resistance and poor bonding performance, and achieve excellent Effect of heat aging low temperature performance, short modification time and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

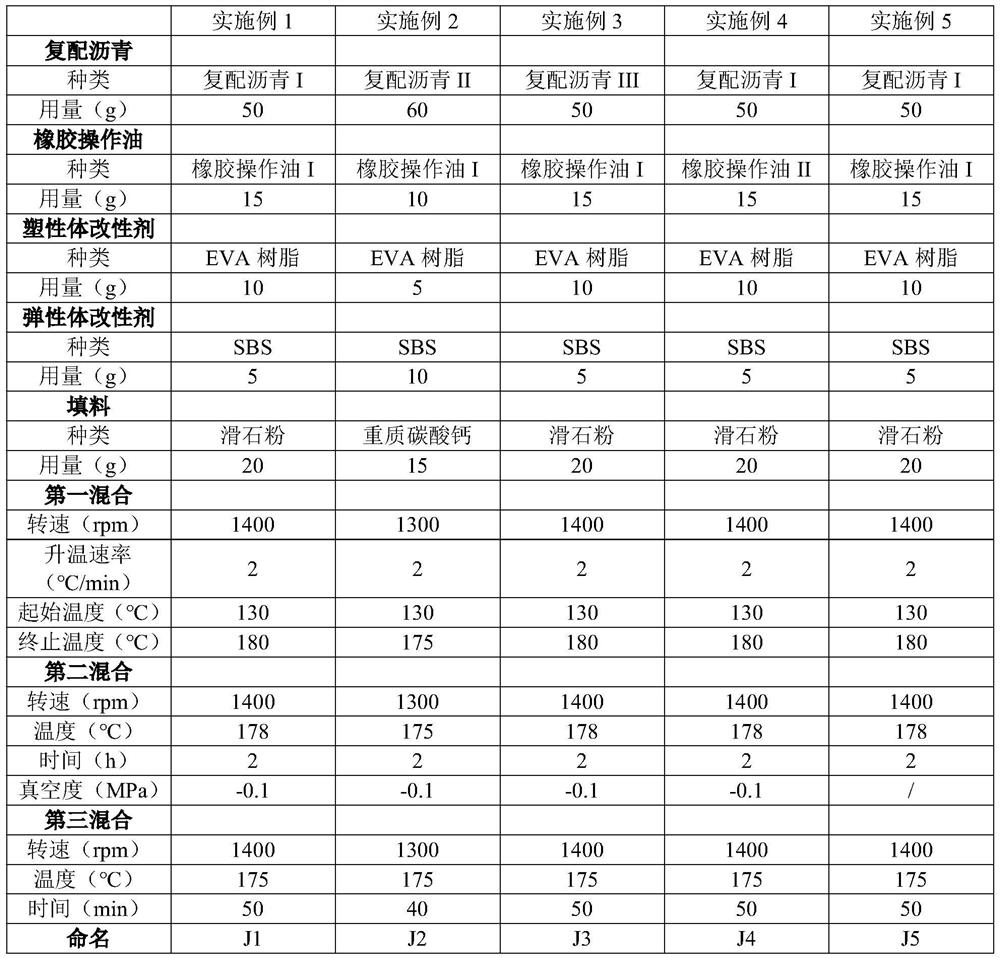

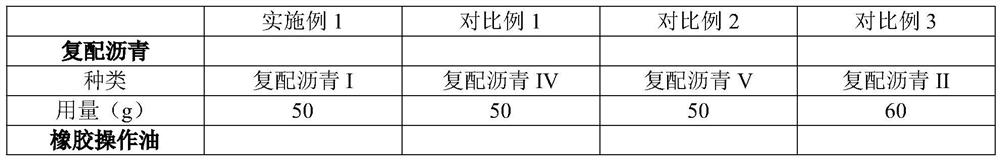

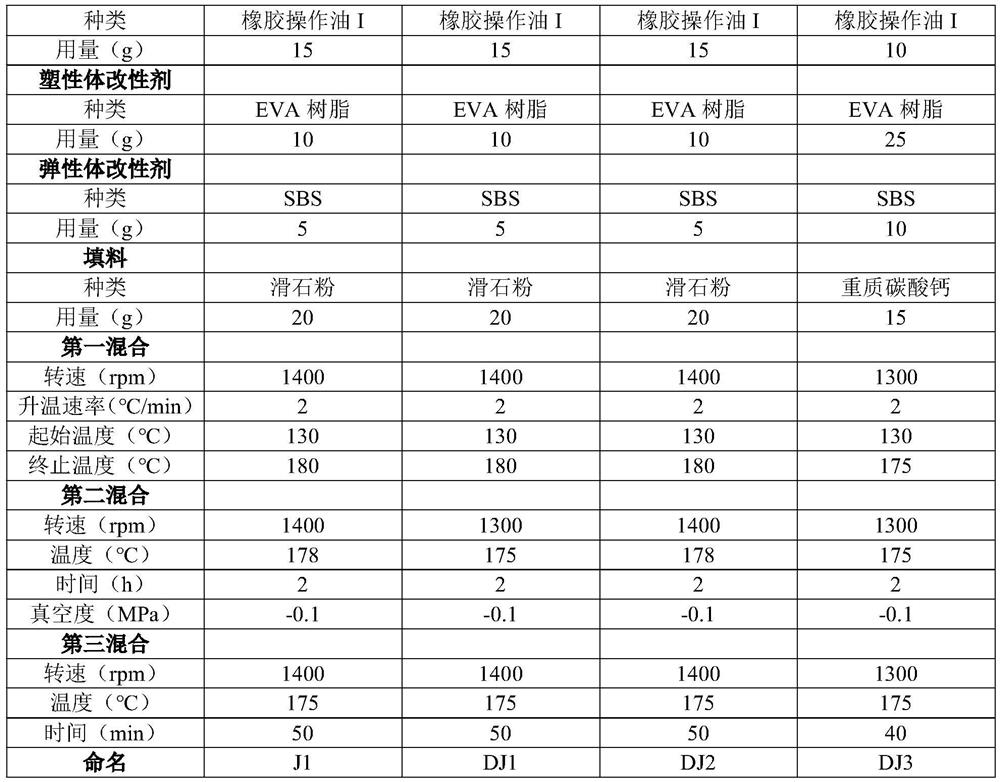

Method used

Image

Examples

preparation example 1

[0064] Preparation 1: Preparation of Comparative Asphalt I

[0065] (1) Removal of 50 # asphalt in the component treatment, resulting in a deprotected asphalt;

[0066] The removal component treatment is: the stirring speed is 1400 rpm, the starting temperature is 130 ° C, the temperature rise rate is 2 ° C / min, and the end temperature is 160 ° C;

[0067] (2) In the presence of oxygen, control the conditions of deprinted asphalt for dewaxing treatment, resulting in a wax content of 1.2% by weight;

[0068] The conditions of the dewaxing treatment are: the stirred speed is 1400 rpm, the temperature is 270 ° C, and the time is 2.5 h;

[0069] (3) Mix the dewaxing asphalt with the 10 # asphalt to obtain a compound asphalt I;

[0070] The mixed condition is: the stirring speed is 1400 rpm, the temperature is 175 ° C, and the time is 50 min;

[0071] The weight ratio of 10 # asphalt and 50 # asphalt in the batch asphalt I is 1: 7, a flash point 255 ° C, and the asphalt content is 24...

preparation example 2

[0072] Preparation 2: Preparation of Comparative Asphalt II

[0073] (1) Removal of 50 # asphalt in the component treatment, resulting in a deprotected asphalt;

[0074] The removal component treatment is: the stirring speed is 1300 rpm, the starting temperature is 130 ° C, the temperature rise rate is 2 ° C / min, and the termination temperature is 240 ° C;

[0075] (2) In the presence of oxygen, control the conditions of deprinted asphalt to perform dewaxing treatment, resulting in a wax content of 0.9 wt%;

[0076] The conditions of the dewaxing treatment are: the stirring speed is 1300 rpm, the temperature is 260 ° C, and the time is 2 h;

[0077] (3) Mix the dewaxing asphalt with the 10 # asphalt to obtain a compounded asphalt II;

[0078] The mixed condition is: the stirred speed is 1300 rpm, the temperature is 175 ° C, and the time is 50 min;

[0079] The amount ratio of 10 # asphalt and 50 # asphalt in the batch asphalt II is 1: 7, a flash point 252 ° C, and the asphalt co...

preparation example 3

[0080] Preparation 3: Preparation of Comparative Asphalt III

[0081] The institutional preparation is performed with the same procedure as the preparation 1, and the difference is that this system preparation example:

[0082] The conditions in step (2) are different, specifically, the stirred speed is 1200 rpm, the temperature is 240 ° C, the time is 1.5 h; the wax content of 2.1 wt% is obtained. Asphalt.

[0083] Preparation of a compounded asphalt III, the amount ratio of 10 # asphalt and 50 # asphalt in the compound asphalt III was 1: 7, a flash point 245 ° C, and the asphalt content was 23.5% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com