Patents

Literature

45results about How to "Short modification time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface modification method of hollow glass beads

InactiveCN102604439AReduce consumptionImprove adhesionPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsEpoxyBound property

The invention discloses a surface modification method of hollow glass beads. The method comprises the following steps: firstly, removing surface impurities of the hollow glass beads with absolute ethanol or acetone, and then drying the hollow glass beads for 3 to 5 hours; secondly, adding the dried hollow glass beads into an agitator to be continuously heated after the agitator is preheated, and adding a coupling reagent 0.2-1.5% of the mass of the glass beads after the surface temperature of the hollow glass beads is increased to 95 to 135 DEG C; and thirdly, continuously stirring the hollow glass beads for 10-30min at 95 to 135 DEG C, and then discharging the hollow glass beads to obtain the hollow glass beads with modified surfaces. According to the method, the agitator is adopted to perform dry modification, the technology is simple, the operation is easy, the modification time is short, the cost is low, subsequent drying is not required, and the energy consumption is reduced. The hollow glass beads treated through the method can be better dispersed in epoxy resin, the binding property between the resin and fillers is improved, the material strength is improved, and the mechanical property of the composite material is obviously improved.

Owner:BENGBU HUAYANG POWDER TECH +2

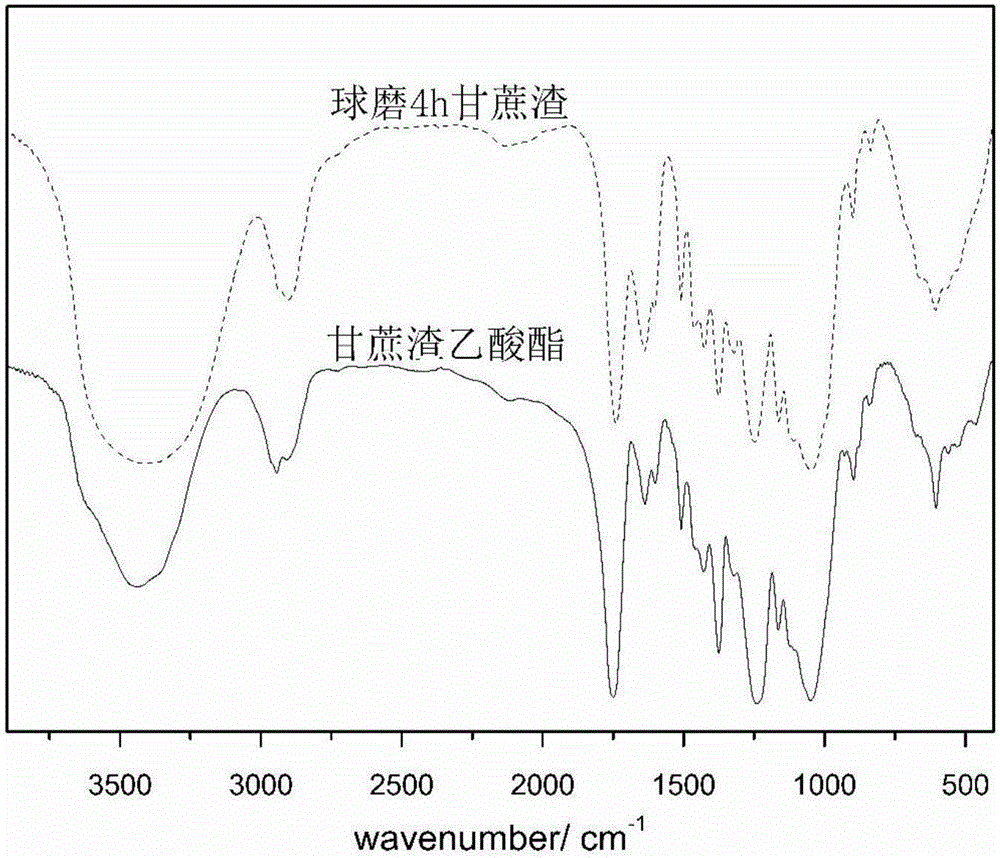

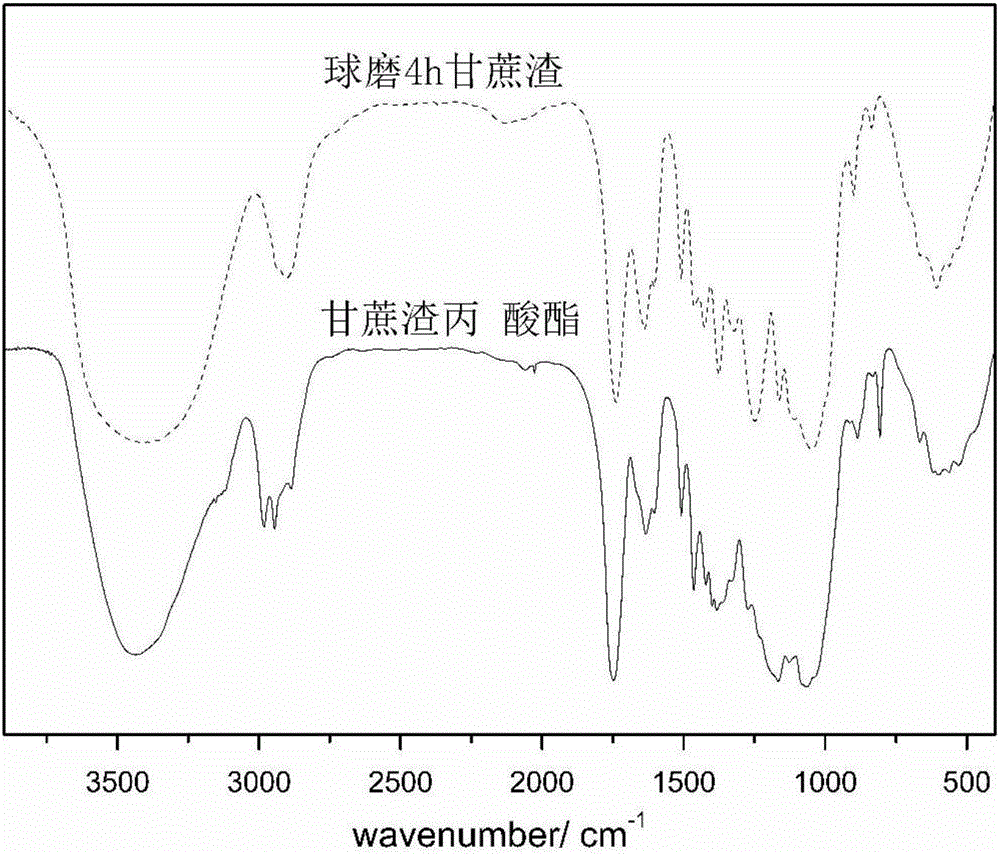

Homogeneous method for preparing wood fiber derivative under room temperature

The invention discloses a homogeneous method for preparing a wood fiber derivative under room temperature. The method comprises the following steps: drying ground wood fiber powder, suspending the dried wood fiber powder in a solvent, and stirring till the wood fiber is dissolved completely to obtain wood fiber solution; dissolving an acylation reagent in the same solvent, and stirring under the room temperature till the acylation reagent is dissolved completely to obtain acylation reagent solution; adding the acylation reagent solution into the wood fiber solution, and carrying out esterification reaction under the room temperature and a moisture isolated condition; and depositing the solution obtained after the esterification reaction, collecting, washing, freezing and drying deposits, and preparing to obtain the required wood fiber derivative. The invention has the advantages that homogeneous derivatization of wood fiber is realized under the room temperature; and not only can the homogeneity and the stability of the product be improved effectively, but also equipment requirements and energy requirements can be reduced. Therefore, the invention has a significant scientific value and practical significance on the development and the utilization of renewable resources such as wood fiber, biological substances and the like.

Owner:广西南宁绿园北林木业有限公司

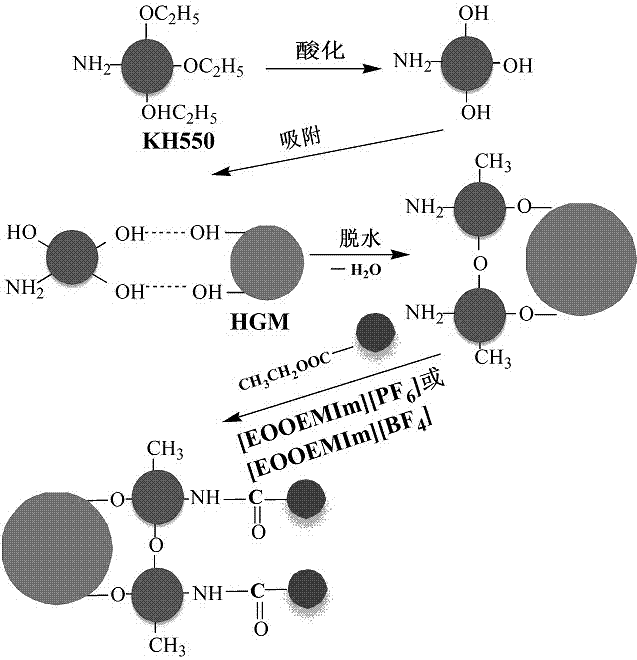

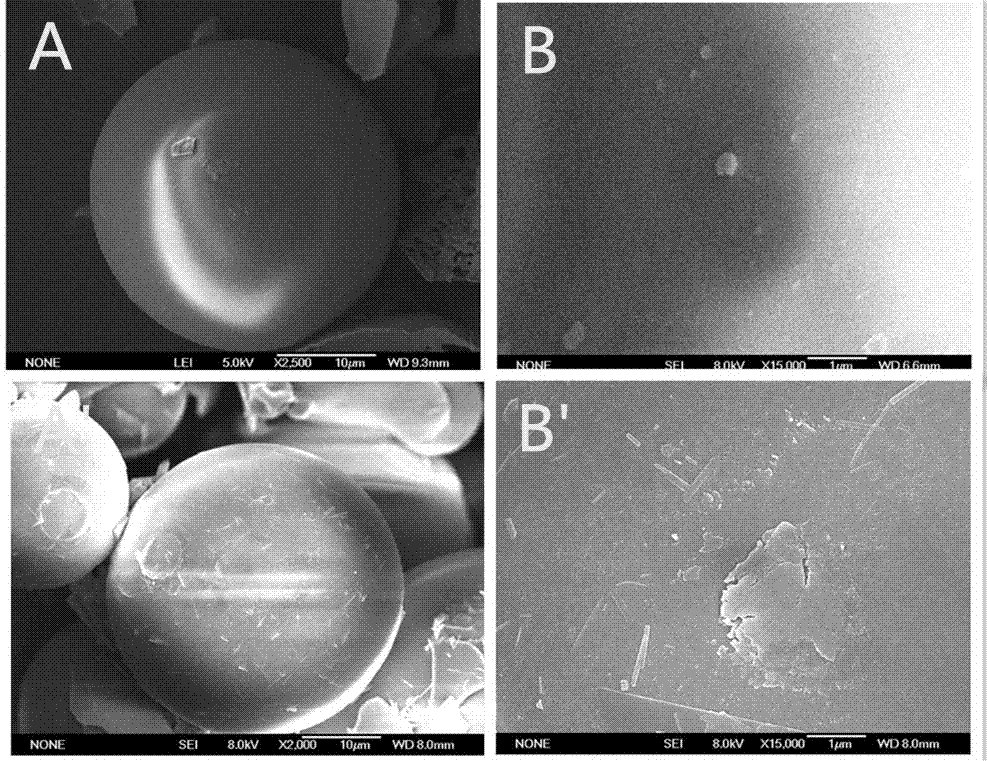

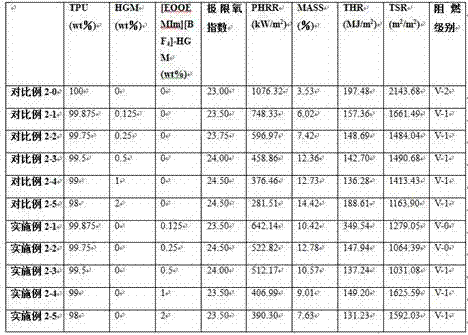

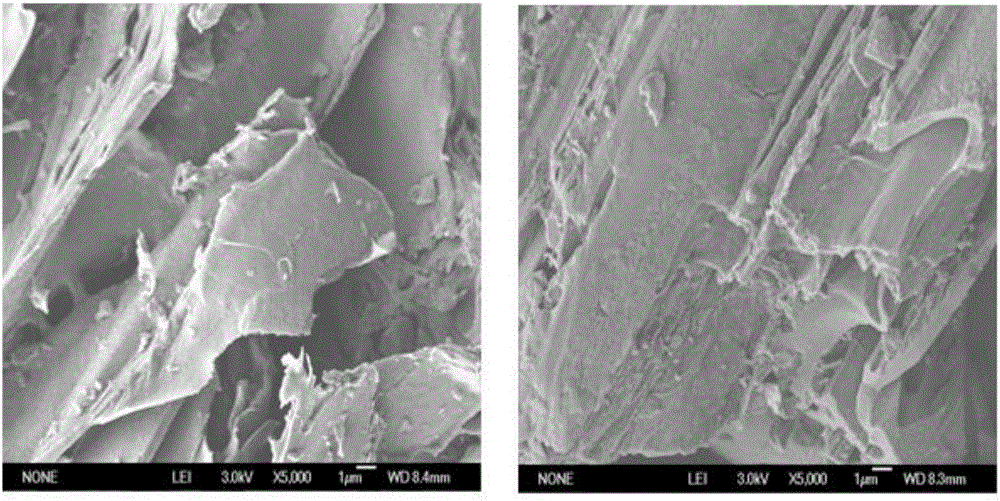

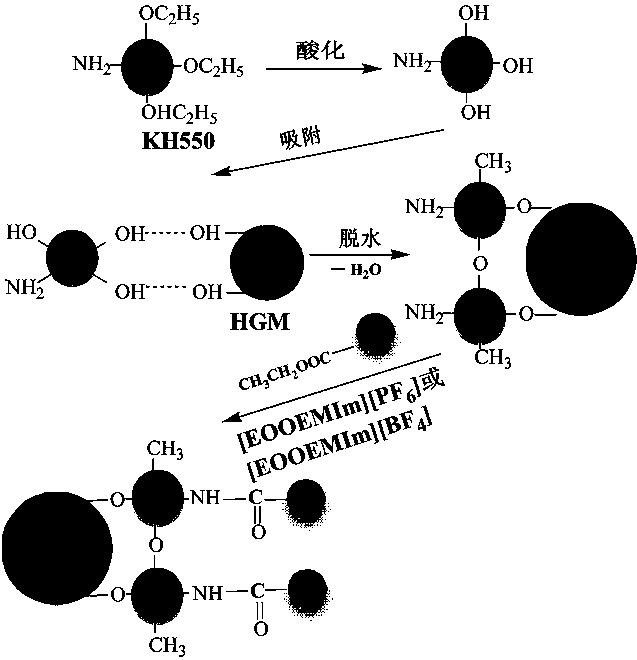

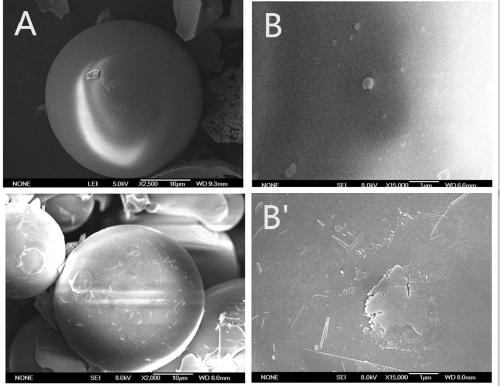

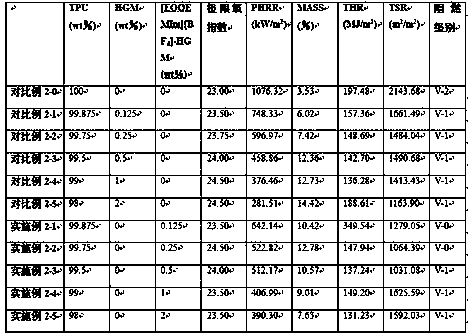

Method of modifying hollow glass microbeads with ionic liquid and flame-retarding thermoplastic polyurethane elastomer with the modified hollow glass microbeads as flame retardant

The invention discloses a method of modifying hollow glass microbeads with an ionic liquid and a flame-retarding thermoplastic polyurethane elastomer with the modified hollow glass microbeads as a flame retardant. The method includes the steps of: 1) treating the hollow glass microbeads with a hydrochloric acid solution; 2) after the acid treatment, repeatedly washing and drying the hollow glass microbeads; 3) activating the hollow glass microbeads, adding a silane coupling agent, and performing mechanical stirring reflux; 4) stopping the reaction and cooling the reaction product to room temperature, and performing suction filtration with acetonitrile, ethanol and deionized water and drying the reaction product; 5) adding the ionic liquid to the silanized hollow glass microbeads and performing mechanical stirring reflux; 6) stopping the reaction and cooling the reaction product to room temperature, performing suction filtration successively with ethanol, a mixed solution of ethanol and deionized water, and ethanol, and drying the reaction product. By means of the hollow glass microbeads modified with the ionic liquid as the flame retardant for preparing flame-retarding thermoplastic polyurethane (TPU) elastomer, not only is oxygen index of the composite material improved, but also the vertical combustion performance, which reflects melt-dripping resistance, is improved, so that heat release rate is reduced and smoke is significantly inhibited.

Owner:JIANGSU STERRIC CHEM IND

Homogeneous phase modifying method for cellulose in ion liquid

The invention discloses a method of cellulose homogeneous-phase modification in ionic liquid. The method comprises the following steps: firstly, the cellulose is dried to obtain dry cellulose; then the dry cellulose is added in the ionic liquid and is dissolved to obtain the ionic liquid solution of the cellulose under the conditions of moisture isolation and stirring; the dimethyl sulfoxide is added in the cellulose solution to reduce the solution viscosity, and the solid modification reagent dissolved in the dimethyl sulfoxide in advance is added in the cellulose solution for cellulose modification; and finally the modified cellulose ionic liquid solution is added with organic solvent or water for cellulose regeneration, the sediment is leached, and the sediment is cleaned and dried to obtain cellulose derivative. The adopted cellulose homogeneous-phase modification method is simple and convenient in operation, short in time and good in effect. The invention is suitable for cellulose homogeneous-phase modification of the solid modification reagent in the ionic liquid.

Owner:SOUTH CHINA UNIV OF TECH

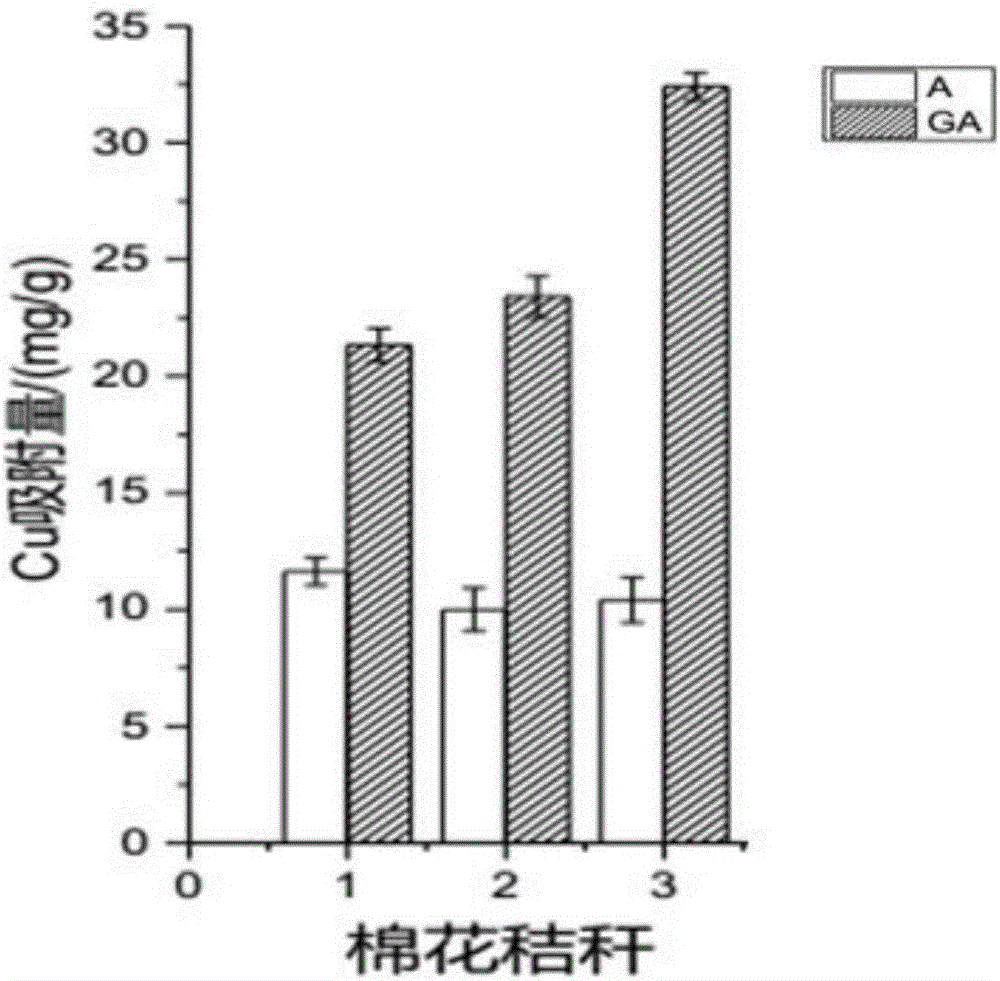

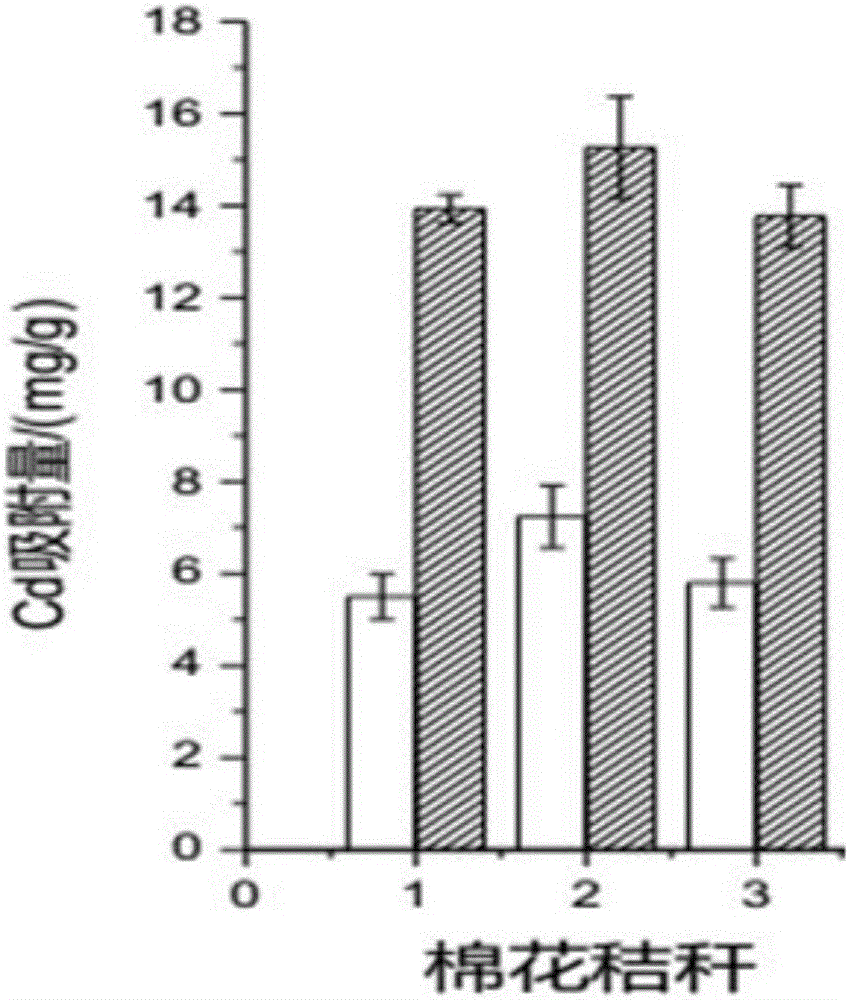

Method for preparing efficient heavy metal adsorbent from modified cotton stalk biomass charcoal

InactiveCN105879838ABiomass carbon pores increaseImprove adsorption capacityOther chemical processesBiomass carbonSorbent

The invention discloses a method for preparing a high-efficiency heavy metal adsorbent by modifying cotton stalk biomass charcoal. Carbonization at 300°C for 3‑6h; (2) Add 0.3mol / L KMnO to the cotton biochar prepared in step (1) 4 solution, and then add a mass fraction of 60% HNO 3 solution, heated at 85-95°C for 2.5-3.5h, filtered, washed, and dried to obtain a modified product, the biochar and KMnO 4 solution and HNO 3 The dosage ratio of the solution is 1g: (7-7.8)ml: (3.3-4.0)ml. The pore volume of the biomass charcoal obtained by carbonizing the cotton stalks prepared by the method of the invention is obviously increased, and can efficiently adsorb heavy metal copper and cadmium at the same time.

Owner:SHANDONG NORMAL UNIV

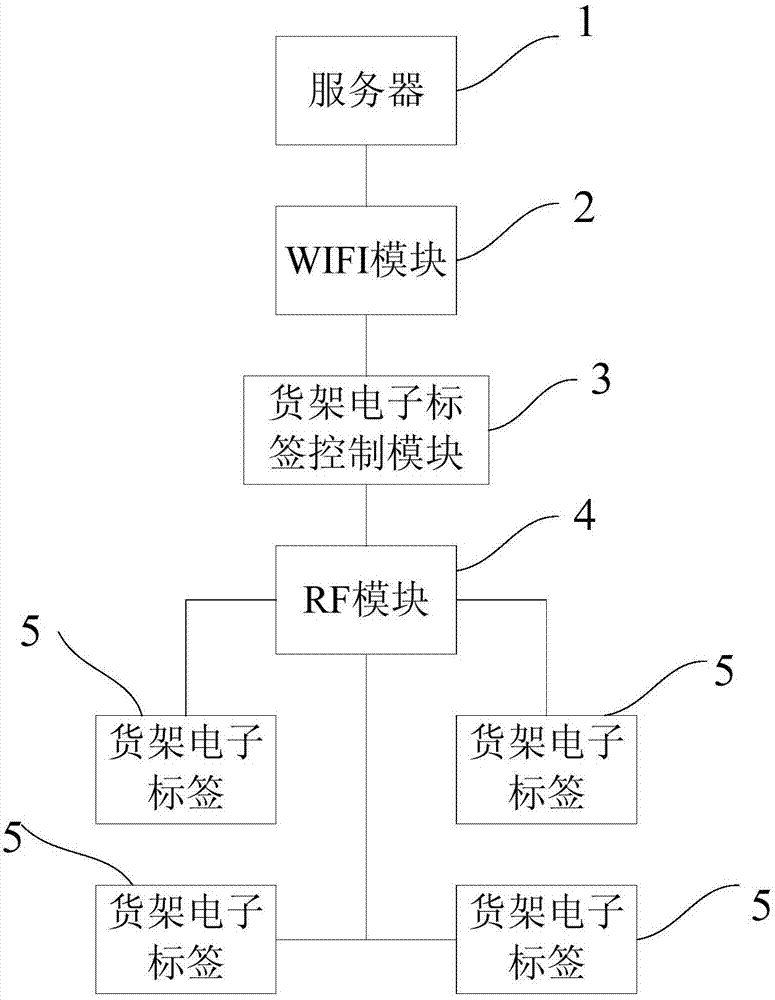

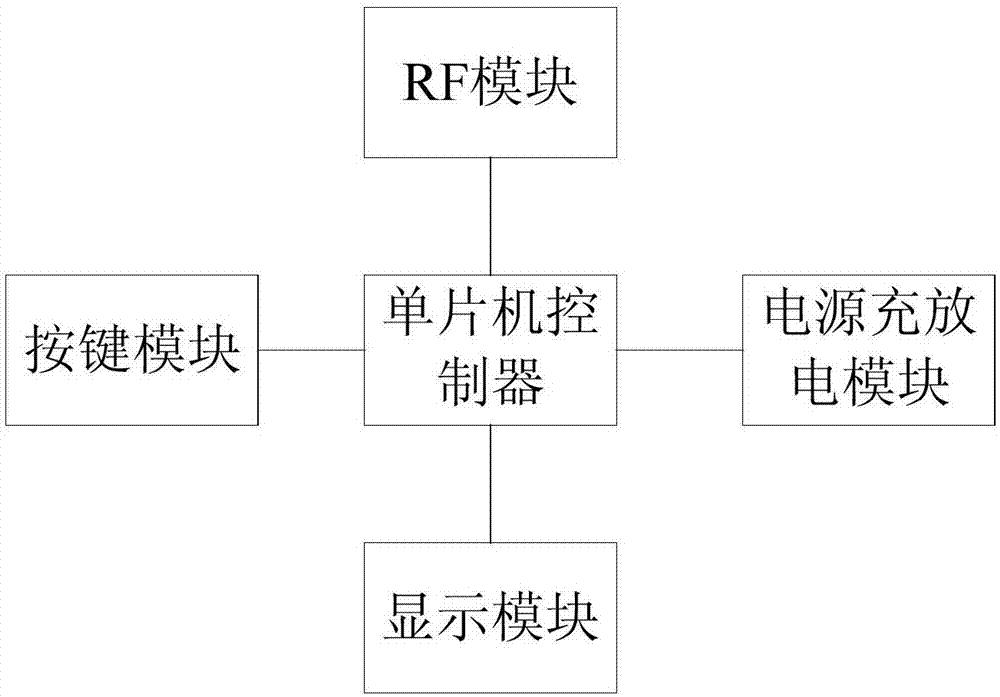

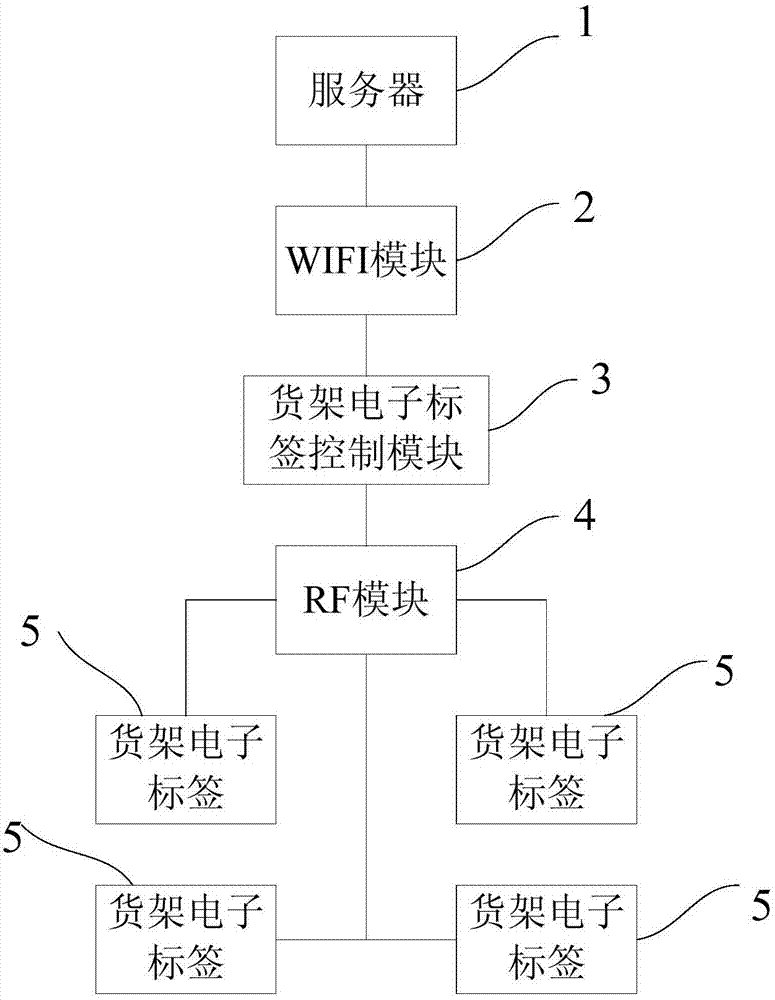

Smart shelf electronic tag system based on IOT (internet of things) RF (radio frequency) as well as information modification method

PendingCN107992921AImprove management efficiencyShort modification timeParticular environment based servicesCo-operative working arrangementsComputer moduleManagement efficiency

The invention applies to the technical field of electronic tags and discloses a shelf electronic tag system based on IOT (internet of things) RF (radio frequency) as well as an information modification method. The shelf electronic tag system based on IOT RF comprises a server, a WIFI module, a shelf electronic tag control module, an RF module and at least one shelf electronic tag for recording anddisplaying commodity information; during using, corresponding shelf electronic tag commodity information is modified by the server, the electronic tag control module receives the modified informationand a control instruction, performs analysis to determine a modified information delivery object and sends the modified information to a corresponding electronic tag for receiving, and the modified information is displayed by the corresponding shelf electronic tag. The price modification time of the electronic tag is short, so that timeliness is high, and management efficiency of shelf sales is improved; meanwhile, use cost and human cost are reduced.

Owner:NANJING HOWKING COMM TECH

Method for preparing cellulose succinate in ion liquid

InactiveCN101497667AHigh degree of substitutionSimple and fast operationIsopropyl alcoholIonic liquid

The invention discloses a method for preparing the cellulose succinate in ionic liquid. The method takes NBS as the catalyst and comprises the following steps: firstly, the dry cellulose is added in the ionic liquid, and then the cellulose is dissolved to obtain cellulose ionic liquid solution under the conditions of moisture isolation and stirring; the dimethyl sulfoxide is added in the cellulose solution to reduce the solution viscosity, and the modifying agent (butanedioic anhydride) dissolved in the dimethyl sulfoxide in advance and the catalyst (NBS) are added in the cellulose solution for cellulose modification; and finally, the isopropyl alcohol is added in the modified cellulose ionic liquid solution for cellulose regeneration, the sediment is leached, and then the sediment is cleaned and dried to obtain cellulose derivative. The adopted cellulose homogeneous-phase modification method is simple and convenient in operation, short in time, good in effect and high in degree of substitution of the cellulose. The invention has an important significance in the preparation of the novel industrial material and the novel derivative of the cellulose.

Owner:SOUTH CHINA UNIV OF TECH

Modification method for alcohol method modifying soybean concentrated protein

InactiveCN1802984AShort modification timeMaintain qualityVegetable proteins working-upChemistryEnzyme

The invention provides a modification method for alcohol method modifying soybean concentrated protein, which comprises the steps of soybean waste degreasing, ethanol extracting, soybean protein concentrating, protein slurry making, modifying, homogeneous processing and spray drying.

Owner:中粮工科(西安)国际工程有限公司

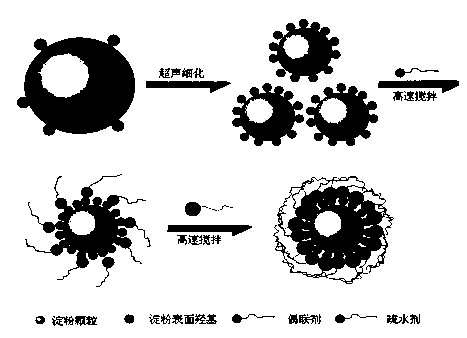

Microsphere-type high-hydrophoby starch, as well as preparation method and application thereof

The invention belongs to the technical field of modification of natural polymer materials, and particularly relates to microsphere-type high-hydrophoby starch, as well as a preparation method and the application thereof. The adopted technical scheme is that the preparation method of the microsphere-type high-hydrophoby starch comprises the following steps: dry starch is subjected to ultrasonic oscillation processing firstly, a coupling agent and a hydrophobic agent are added separately in sequence under the condition of stirring with high speed, and the microsphere-type high-hydrophoby starch is obtained after drying. The hydrophobic starch can remedy shortages of chemical modification, physical modification and coupling agent modification in the prior art, and is small in particle size, large in specific surface area, high in the efficiency of being packaged by the coupling agent and the hydrophobic agent, strong in hydrophobic nature, good in mutual solubility with polyolefin resin, and excellent in physical and biological degradability of modified starch-based plastic.

Owner:UNIV OF JINAN

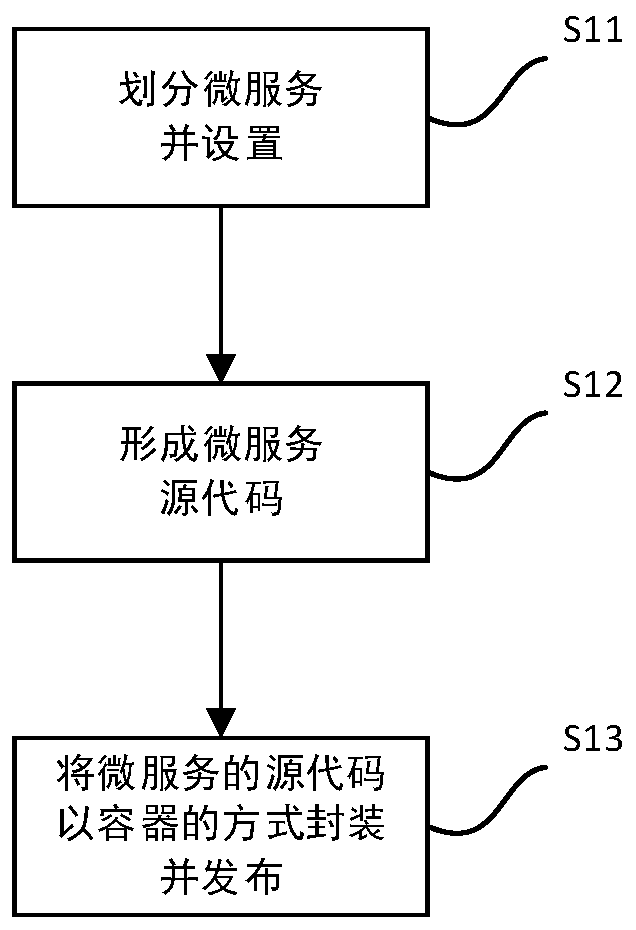

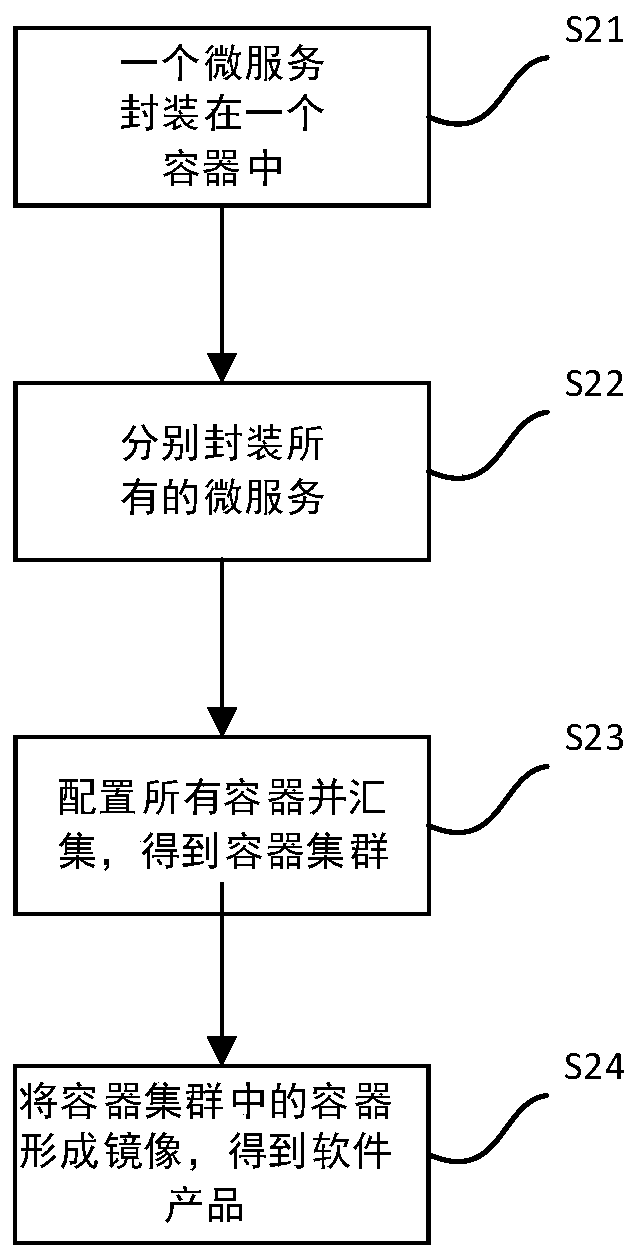

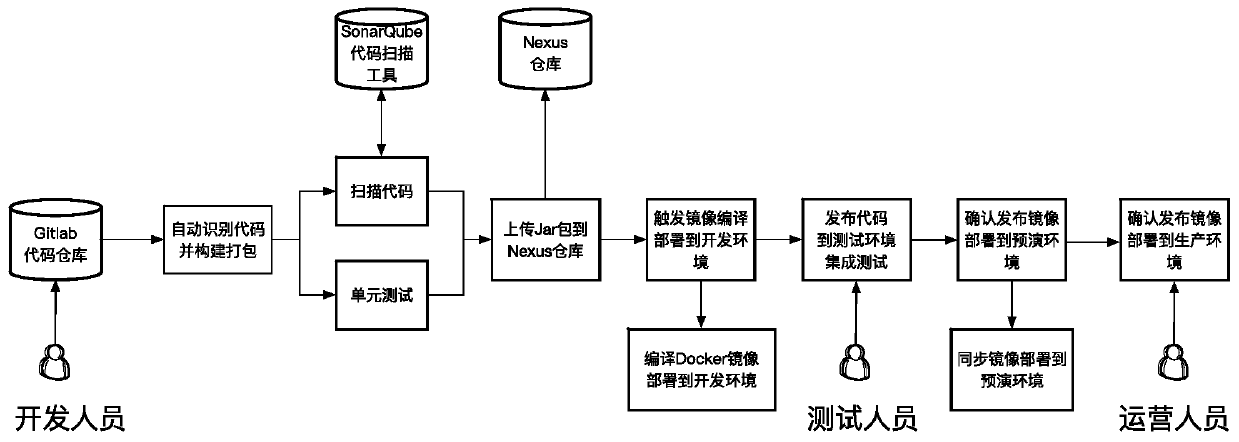

A method for intelligently deploying, operating and maintaining a software product through a cloud

PendingCN109933329ASmall modificationReduce workloadSoftware maintainance/managementTransmissionTime delaysWorkload

The invention relates to a method for intelligently deploying, operating and maintaining a software product through a cloud, which comprises the following steps of: dividing functions or services provided by software into a plurality of micro-services, and specifying data required to be transmitted and communication protocols and interfaces for data transmission among the micro-services; Taking the micro-service as a unit to obtain a source code for realizing the function of the micro-service; And arranging and debugging the obtained source codes of the plurality of units in a container form respectively, and forming product release. The method for intelligently deploying, operating and maintaining the software product through the cloud has the advantages that the modification time is short, the workload is small, and time delay is not prone to occurring.

Owner:深圳微品致远信息科技有限公司

Method for improving dissolubility of wheat gluten by ultrasonic treatment

InactiveCN102058013AEasy to operateLow temperature requirementVegetable proteins working-upFreeze-dryingMedicine

The invention relates to the technical field of processing of wheat gluten, in particular to a method for improving dissolubility of wheat gluten by ultrasonic treatment. The method comprises the following steps of: performing stirring hydration treatment on the wheat gluten for 1 to 30 minutes; adjusting the pH value to be between 3 and 5; performing intermittent ultrasonic treatment on the wheat gluten dispersion, and setting the pulse amplitude at 40 to 100 percent, wherein the on value of the continuous pulse working time is 1 to 60 seconds, the off value of the intermittent pulse time is 1 to 30 seconds and the ultrasonic time is 40 to 160 seconds; and spray-drying or freeze-drying the finally obtained product, and crushing and sieving the product to obtain a powdery modified wheat gluten product. The method has simple operation flow and low temperature requirement, and no other additives or impurities are added in the modification process; and compared with the wheat gluten without ultrasonic treatment, the dissolubility is obviously improved, the additional value of a wheat product is improved, and theoretical basis is provided for deep processing and high value generation of the wheat product.

Owner:SHANGHAI OCEAN UNIV

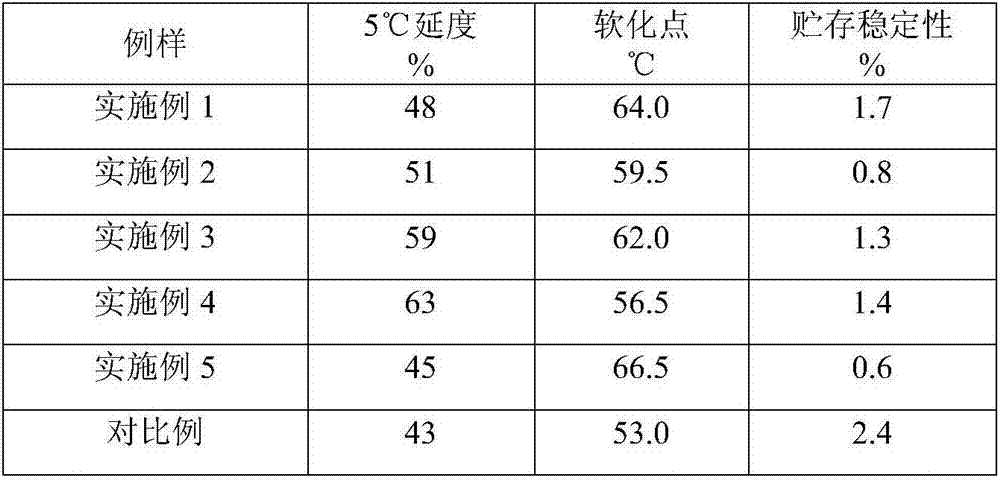

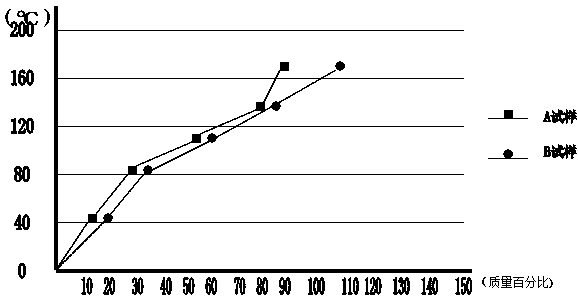

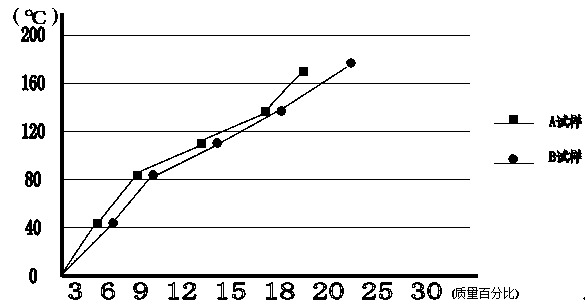

Preparation method of composite modified asphalt

ActiveCN107189462AHigh strengthReduce the temperatureBuilding insulationsPhosphoric acidButadiene-styrene rubber

The invention discloses a preparation method of composite modified asphalt. The preparation method comprises the steps of heating 1-3 parts by weight of polyphosphoric acid as an inorganic modifying agent to 105 DEG C and performing heat preservation, heating 2-4 parts by weight of styrene-butadiene segmented copolymer as an organic modifying agent to 65 DEG C, then adding the styrene-butadiene segmented copolymer into the heat-preserving polyphosphoric acid, heating to 120 DEG C, stirring at the speed of 120r / min until obvious styrene-butadiene segmented copolymer particles do not exist so as to prepare a composite modifying agent, heating 100 parts by weight of asphalt to 135 DEG C, then adding the prepared asphalt composite modifying agent, and stirring for 30min at the speed of 500r / min at 135 DEG C to obtain the composite modified asphalt. The composite modified asphalt prepared by the preparation method improves both high-temperature performance and low-temperature performance obviously compared with SBS (styrene butadiene styrene) modified asphalt prepared by a conventional method; the storage stability is obviously improved as well; in the preparation process, the stabilizer adding step is omitted, the heating temperature in the production process is reduced to 135 DEG C from 190 DEG C, and the production difficulty and production cost are reduced while the energy is saved.

Owner:HENAN NORMAL UNIV

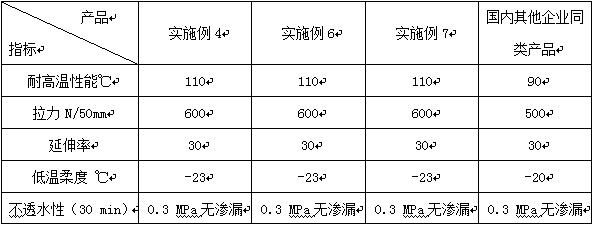

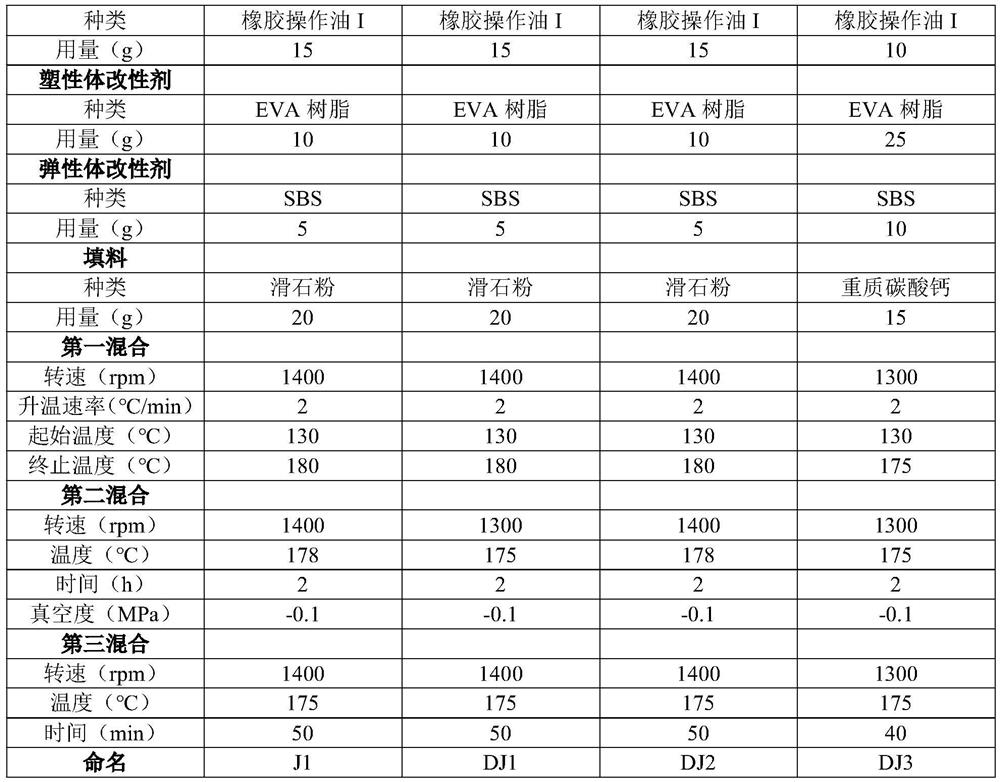

Elastic modified asphalt waterproof coil material and preparation method thereof

InactiveCN109762358AImprove aging resistanceReduce wax contentSynthetic resin layered productsBuilding insulationsPolyesterElastomer

The invention relates to a modified asphalt waterproof coil material and a preparation method thereof, and belongs to the technical field of chemical engineering. The modified asphalt waterproof coilmaterial is prepared from 90# asphalt, 10# asphalt, butadiene styrene rubber, activating glue powder, polyethylene membranes, polyester blanks, engine oil and filling materials. The 90# asphalt, 10# asphalt, YP03 activating glue powder, engine oil and other filling materials are added into the elastomer modified asphalt waterproof coil material; through the modification on the elastomer modified asphalt waterproof coil material by YP03 active rubber powder, the ingredient stirring process is studied; the process control parameters are changed; the proceeding of the ingredient stirring processin production at the lower temperature is realized; the high-temperature-resistant performance and the low-temperature softness performance are improved.

Owner:WEIFANG BOYUAN NEW WATERPROOF MATERIAL

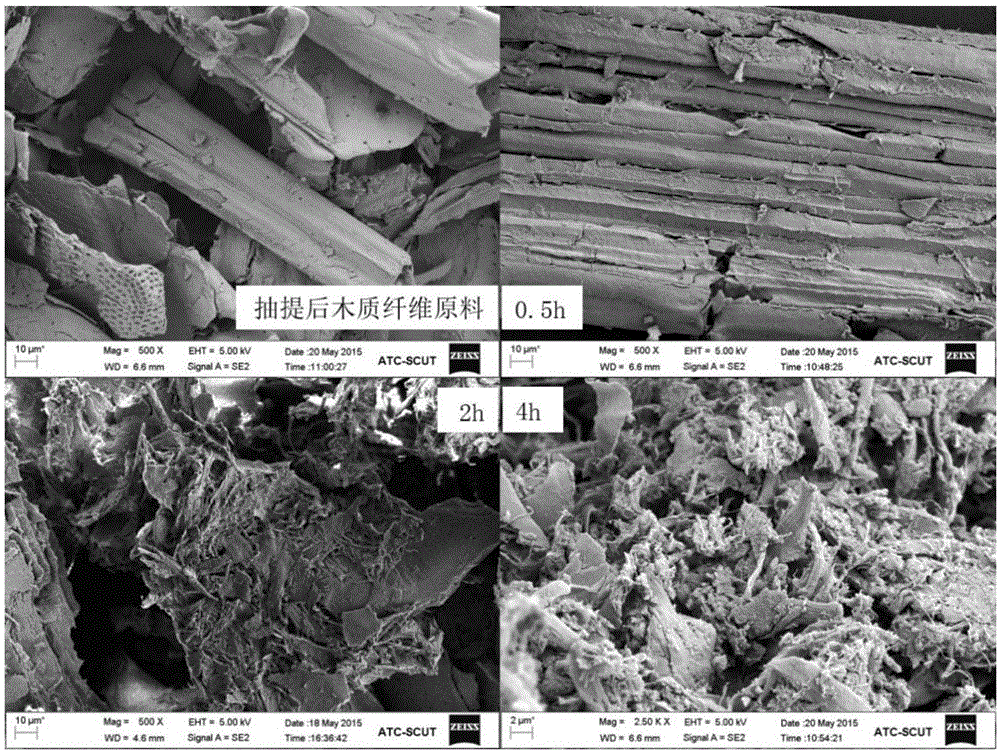

Preparation method of wood fiber oil-absorption material

InactiveCN106750368ASimple separation and purificationEasy to operateOther chemical processesFiberOrganic solvent

The invention provides a preparation method of a wood fiber oil-absorption material. An esterification reaction is carried out on wood fiber and an esterification reagent under the conditions of a pyridine catalysis effect and ball-milling, so that the wood fiber oil-absorption material is obtained, an organic solvent does not need to be used in the reaction process, the product separation and purification treatment is simple, and the preparation technology is convenient in operation, short in modification time, high in reaction degree and better in oil absorption effect; the absorption rate for diesel oil is 9.86 g / g, and the absorption rate for soybean oil is 10.21 g / g.

Owner:SOUTH CHINA UNIV OF TECH

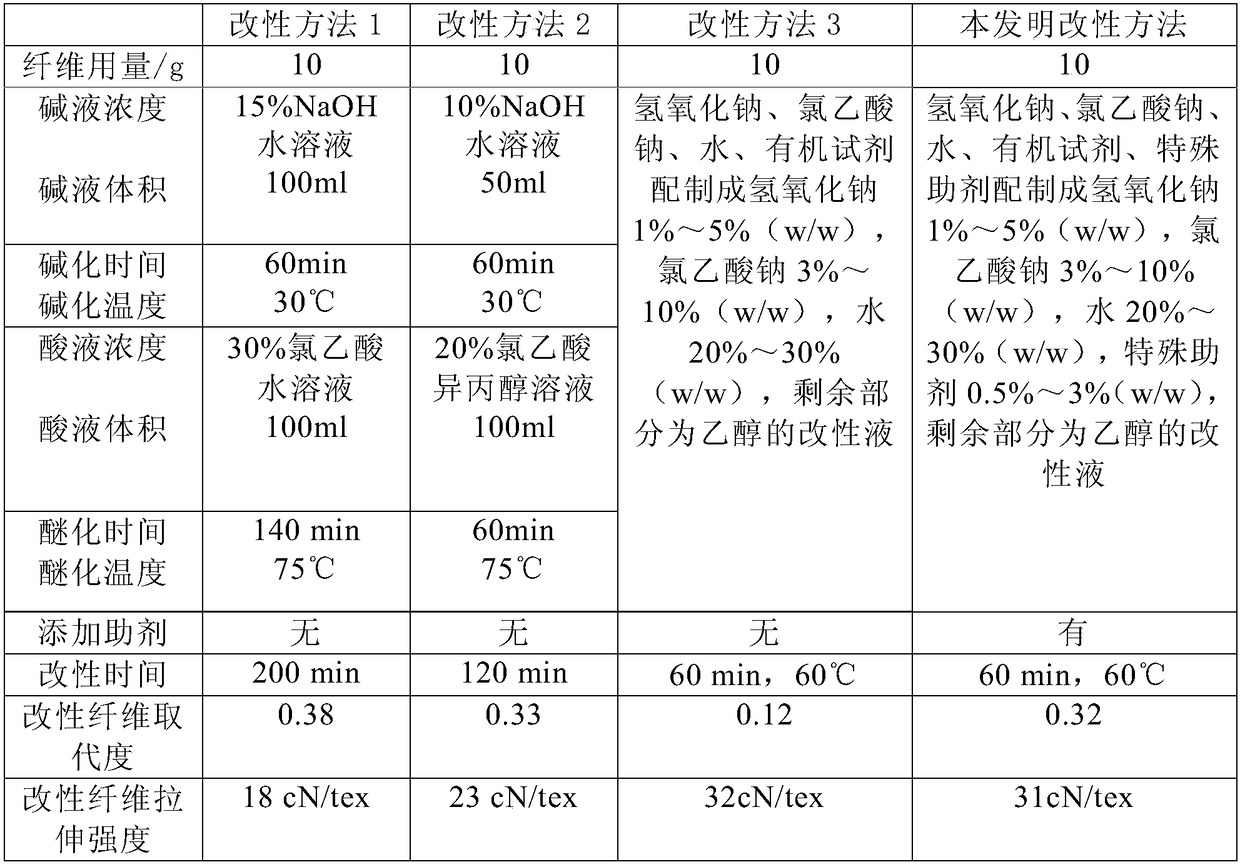

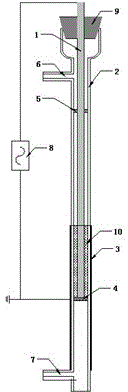

Medical hydrophilic fiber dressing

ActiveCN108774875AReduce concentrationLow degree of substitutionAbsorbent padsVegetal fibresCarboxymethyl celluloseCellulose fiber

The invention relates to a medical hydrophilic fiber dressing. Specifically, the invention discloses a cellulose fiber carboxymethylation treatment liquid which can effectively improve the performanceof the obtained sodium carboxymethyl cellulose fiber by adding a specific assistant to the treatment liquid, thereby facilitating preparation of dressing with excellent strength and liquid absorption.

Owner:SUZHOU HENRUI DISHENG MEDICAL CO LTD +1

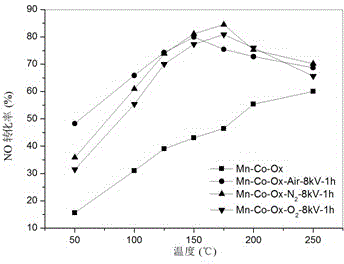

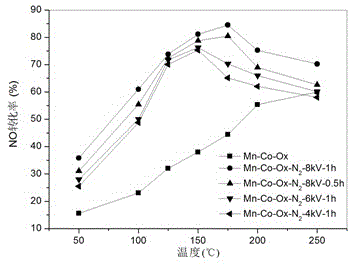

Method for catalytically oxidizing NO by dielectric barrier discharge plasma modified catalyst

InactiveCN102908896BEasy to observeGood catalytic activity at low temperatureDispersed particle separationCatalyst activation/preparationPtru catalystPhysical chemistry

The invention discloses a method for catalytically oxidizing NO by a dielectric barrier discharge plasma modified catalyst. The method comprises the steps of filling a catalyst into a dielectric barrier discharge plasma reactor to be modified; and placing the modified catalyst into a glass pipe type fixed bed reactor and introducing mixed gas to catalytically oxidize the NO into NO2. The modified catalyst has higher low-temperature catalytic activity and the NO catalytic oxidization efficiency can reach 75-85% at maximum; the cylindrical dielectric barrier discharge plasma reactor is adopted so as to be convenient for observing modification conditions of the catalyst; the actual operation is simple and the modification condition is easy to control; the energy consumption is lower; the modification time is shorter; the product NO2 can be absorbed by an alkali solution to obtain a byproduct and can be recycled; and the method is convenient for actual production and application and has a higher industrial application value.

Owner:KUNMING UNIV OF SCI & TECH

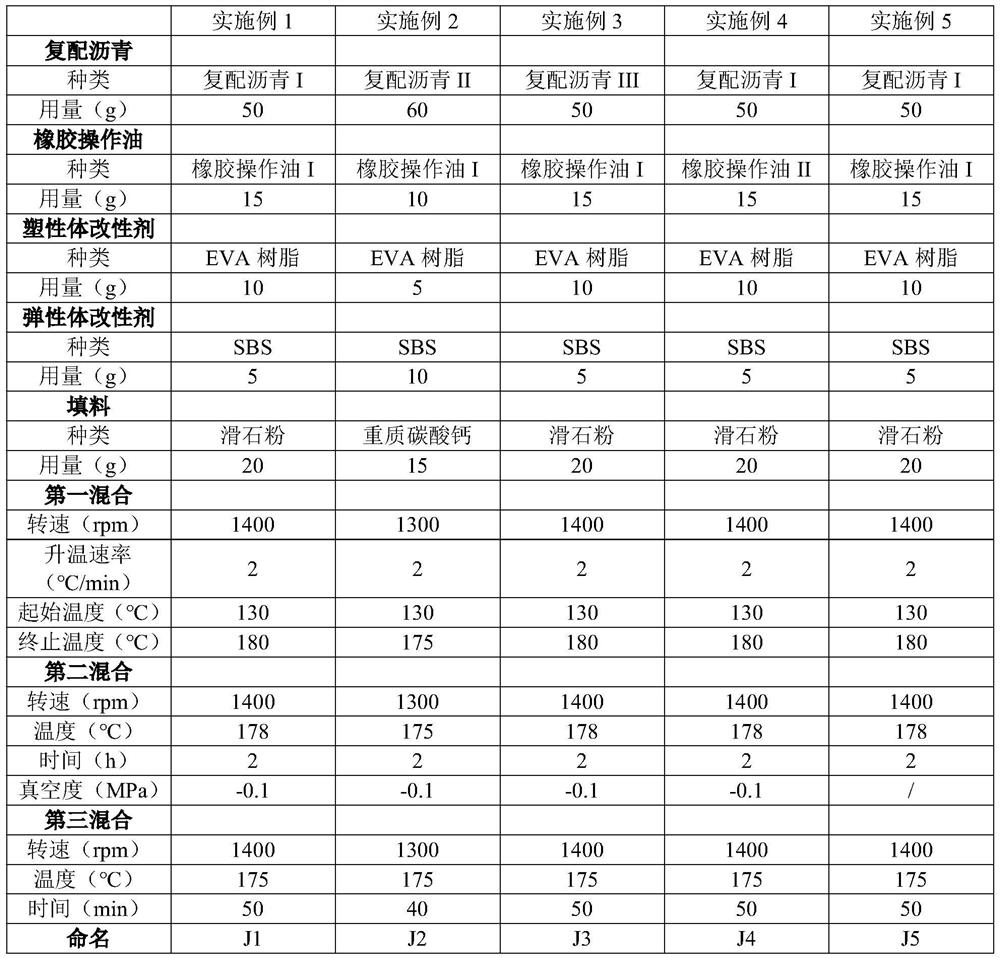

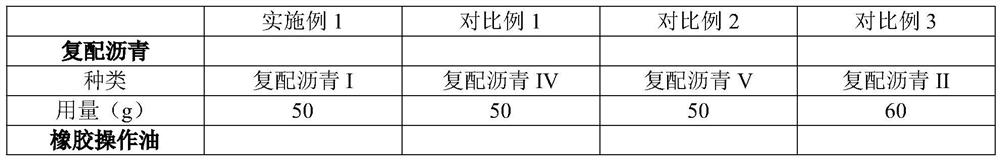

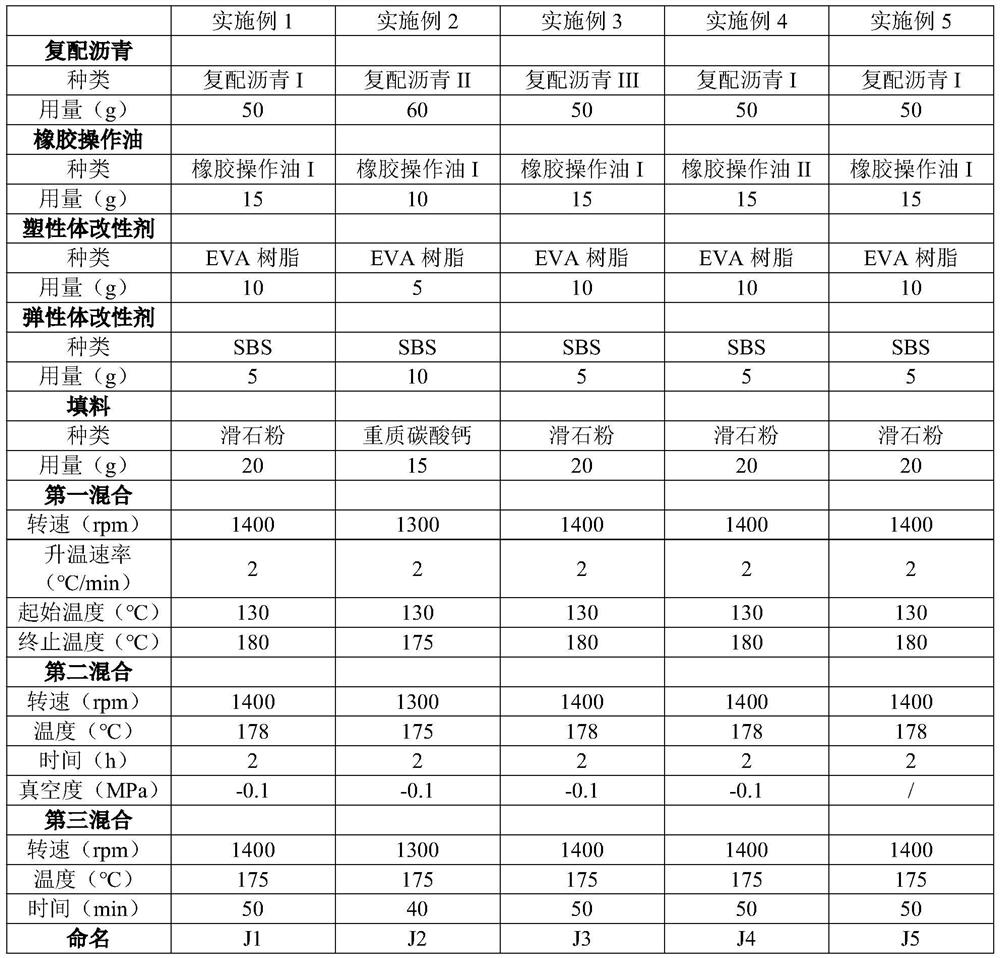

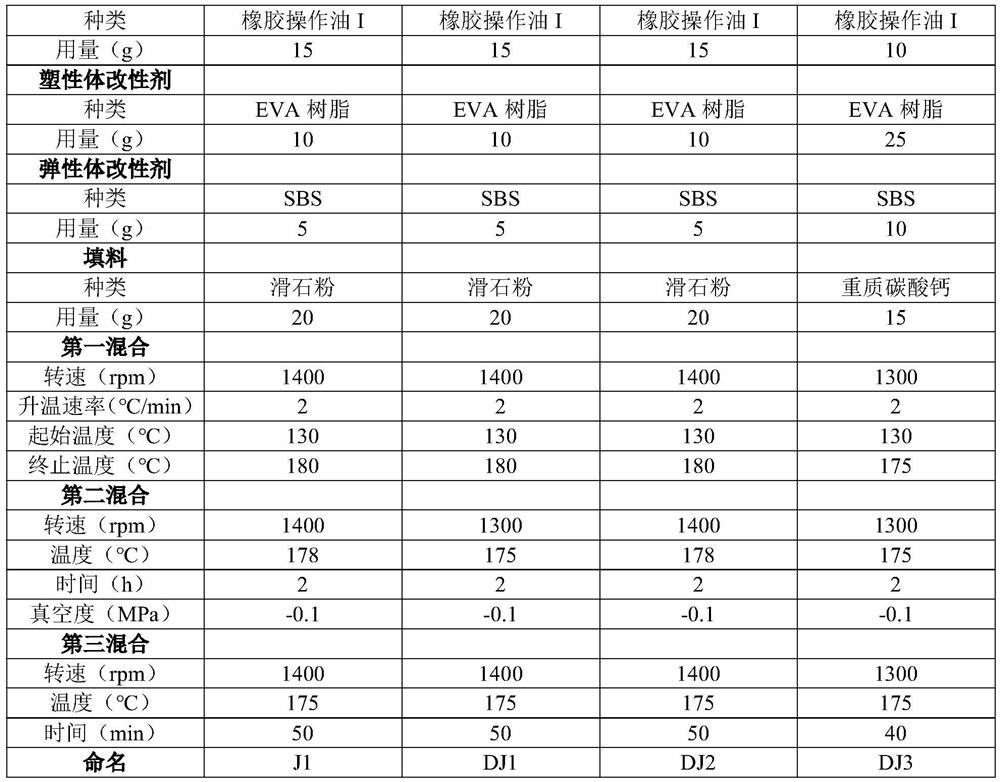

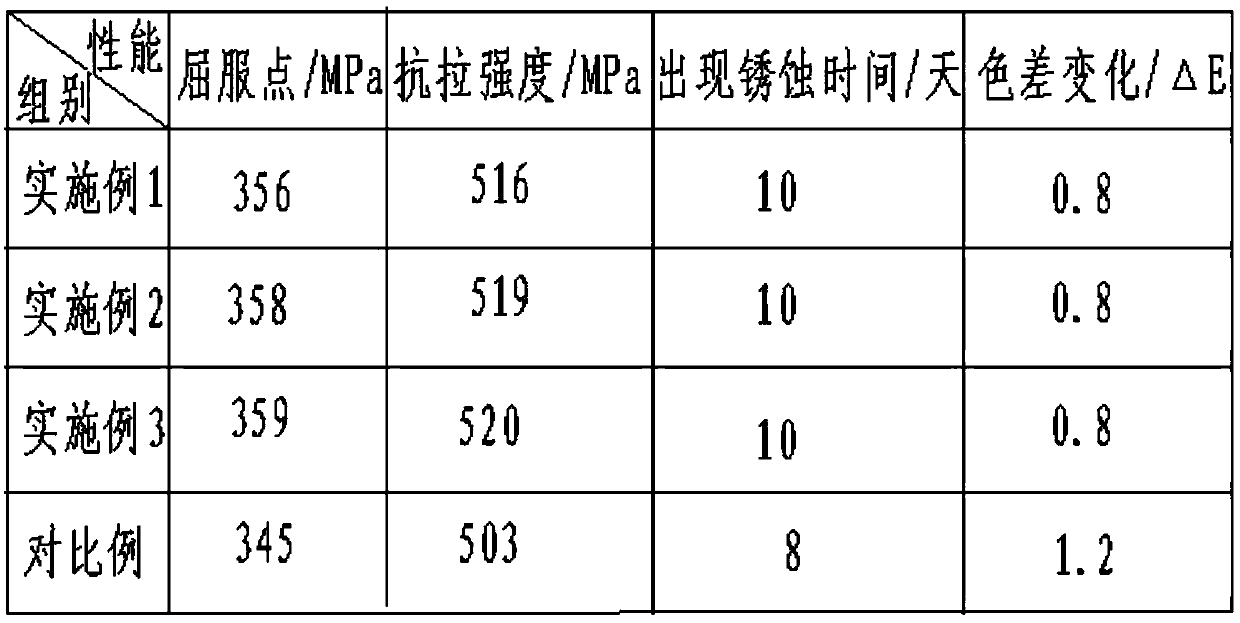

Modified asphalt waterproof roll sizing material composition, modified asphalt waterproof roll sizing material as well as preparation method and application of modified asphalt waterproof roll sizing material

ActiveCN113801629AEasy to processSolve unqualifiedNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolymer science

The invention relates to the field of asphalt waterproof rolls, and discloses a modified asphalt waterproof roll sizing material composition, a modified asphalt waterproof roll sizing material and a preparation method and application of the modified asphalt waterproof roll sizing material. The composition contains two or more of the following components which are stored in a mixed manner or independently stored: compound asphalt, rubber operating oil, a plastomer modifier, an elastomer modifier and a filler, wherein the compound asphalt is a combination of 10# asphalt and 50# asphalt in a weight ratio of 1:(4-9), the flash point of the compound asphalt is greater than or equal to 240 DEG C, and the asphaltene content is greater than or equal to 23wt%. A waterproof roll prepared from the modified asphalt waterproof roll sizing material prepared from the composition provided by the invention has stronger binding power with a concrete base surface and a roll lap joint, and meanwhile, the waterproof roll also has excellent thermal aging low-temperature performance.

Owner:德州科顺建筑材料有限公司

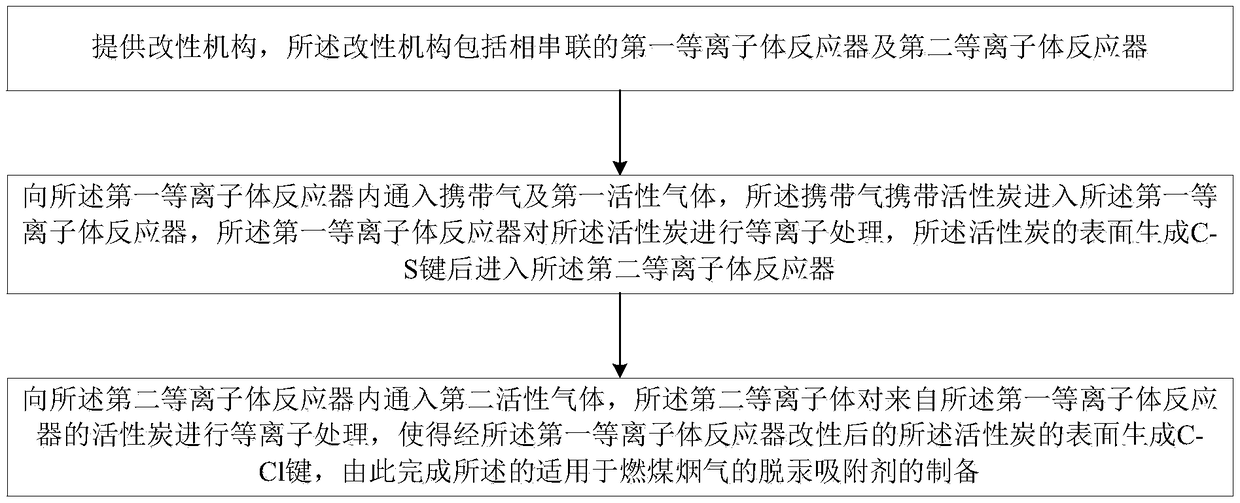

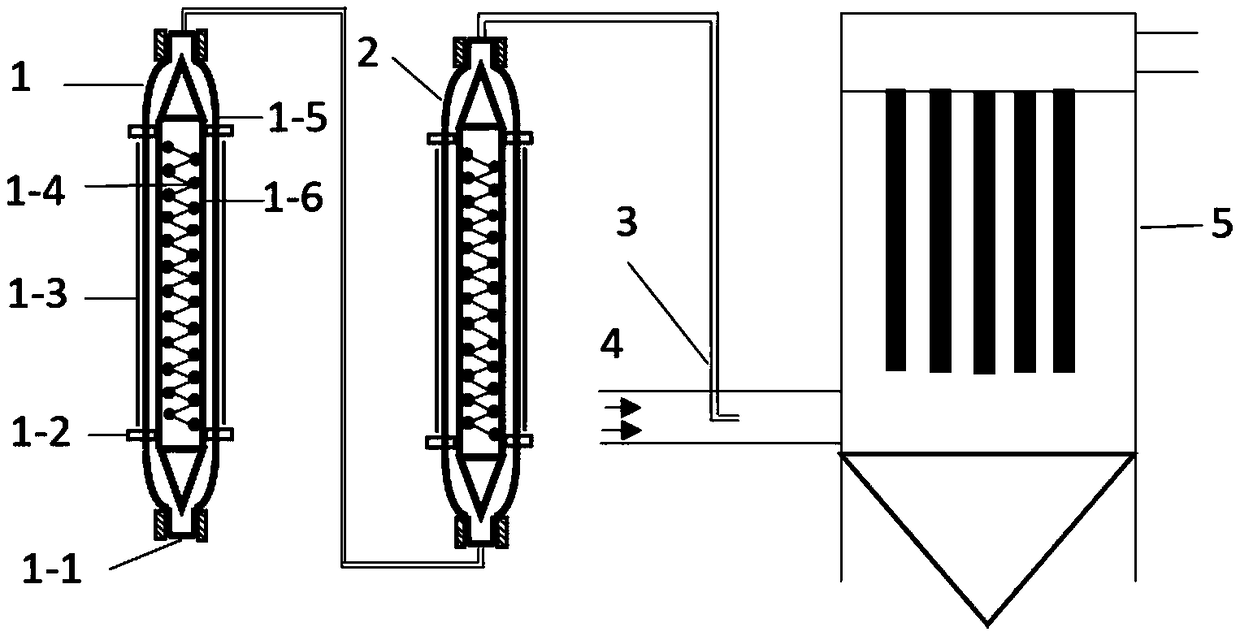

Mercury removal adsorbent suitable for coal-fired flue gas and preparation method thereof

ActiveCN108636350AImprove adsorption capacityReduce energy consumptionGas treatmentOther chemical processesActivated carbonSorbent

The invention belongs to the technical field related to mercury emission control of coal-fired flue gas, and discloses a mercury removal adsorbent suitable for coal-fired flue gas and a preparation method thereof, the method comprises the following steps: (1) a modification mechanism is provided, and the modification mechanism includes a first plasma reactor and a second plasma reactor connected in series; (2) a carrier gas and a first reactive gas are introduced into the first plasma reactor, the carrier gas carries activated carbon to enter the first plasma reactor, the first plasma reactorperforms plasma treatment on the activated carbon, and after C-S bonds generate on the surface of the activated carbon, the activated carbon enters the second plasma reactor; and (3) a second active gas is introduced into the second plasma reactor, and the second plasma reactor performs plasma treatment on the activated carbon to form C-Cl bonds on the surface of the activated carbon to complete the preparation of the mercury removal adsorbent. The preparation method has lower energy consumption, shorter cycle and higher flexibility.

Owner:HUAZHONG UNIV OF SCI & TECH

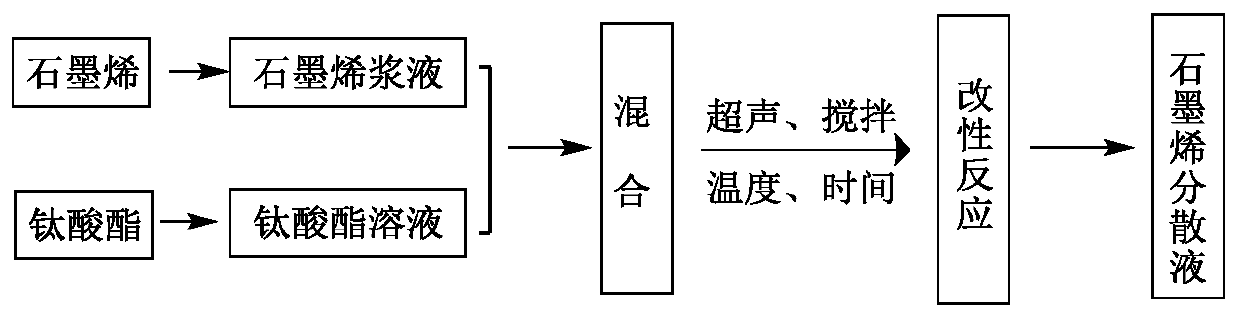

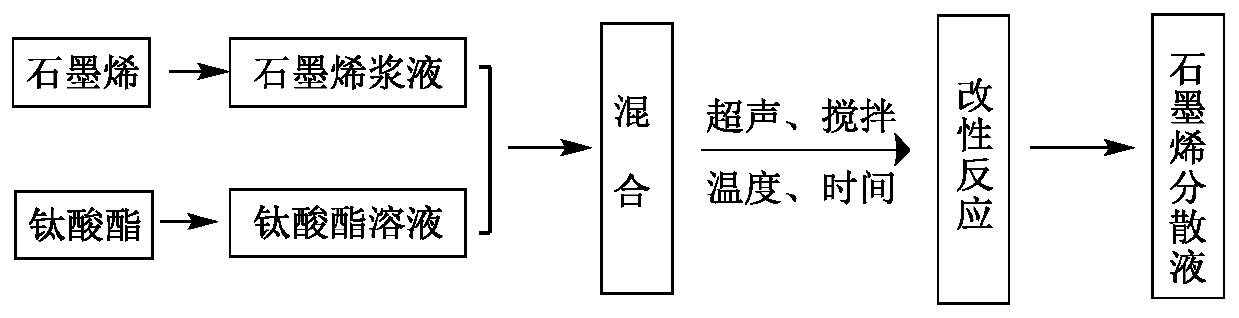

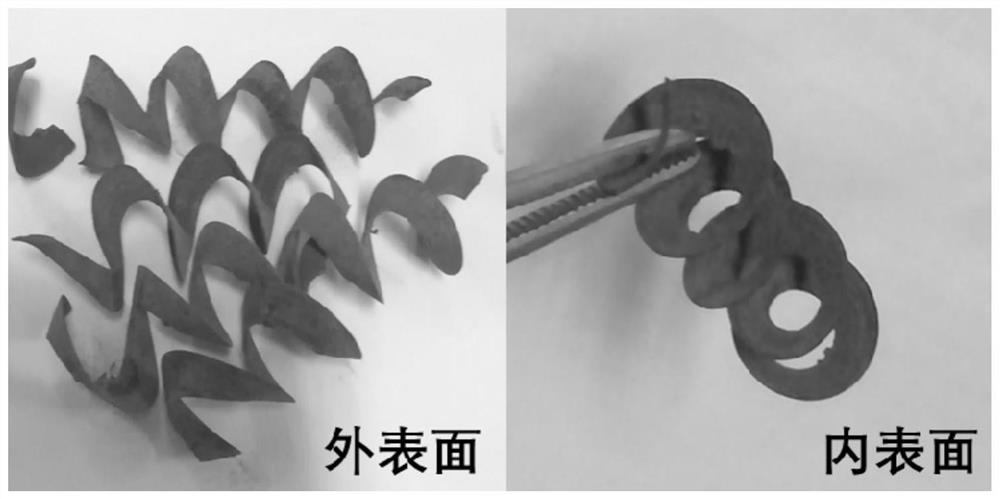

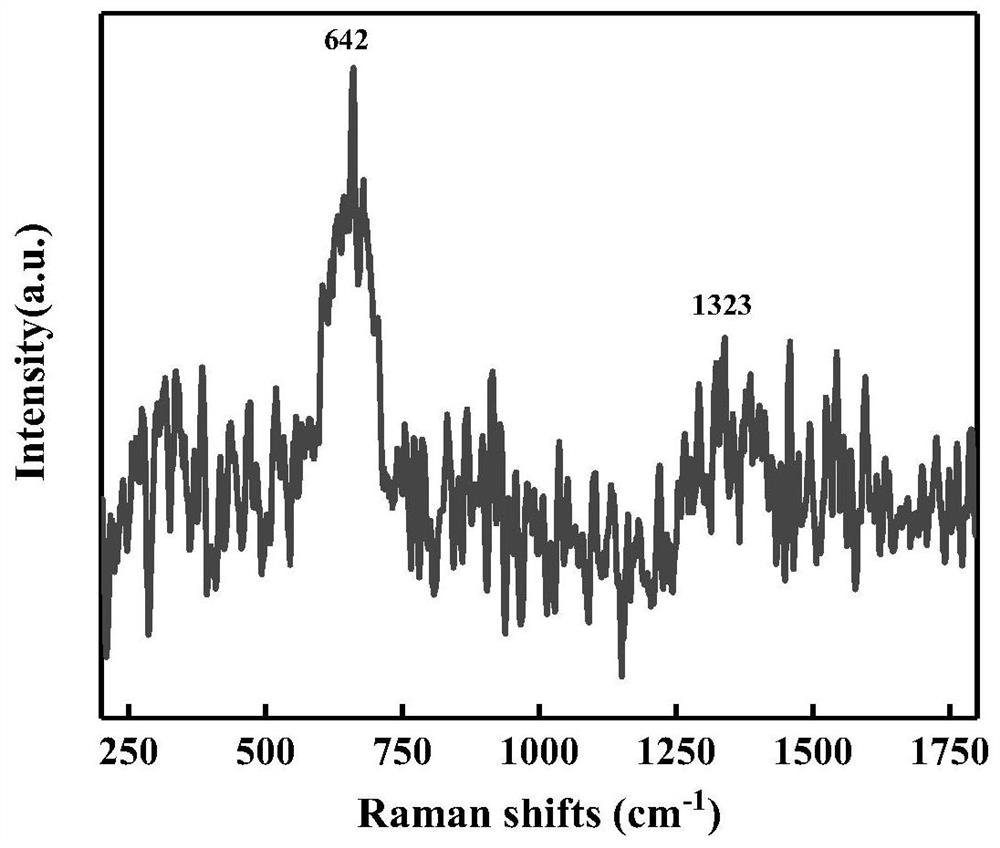

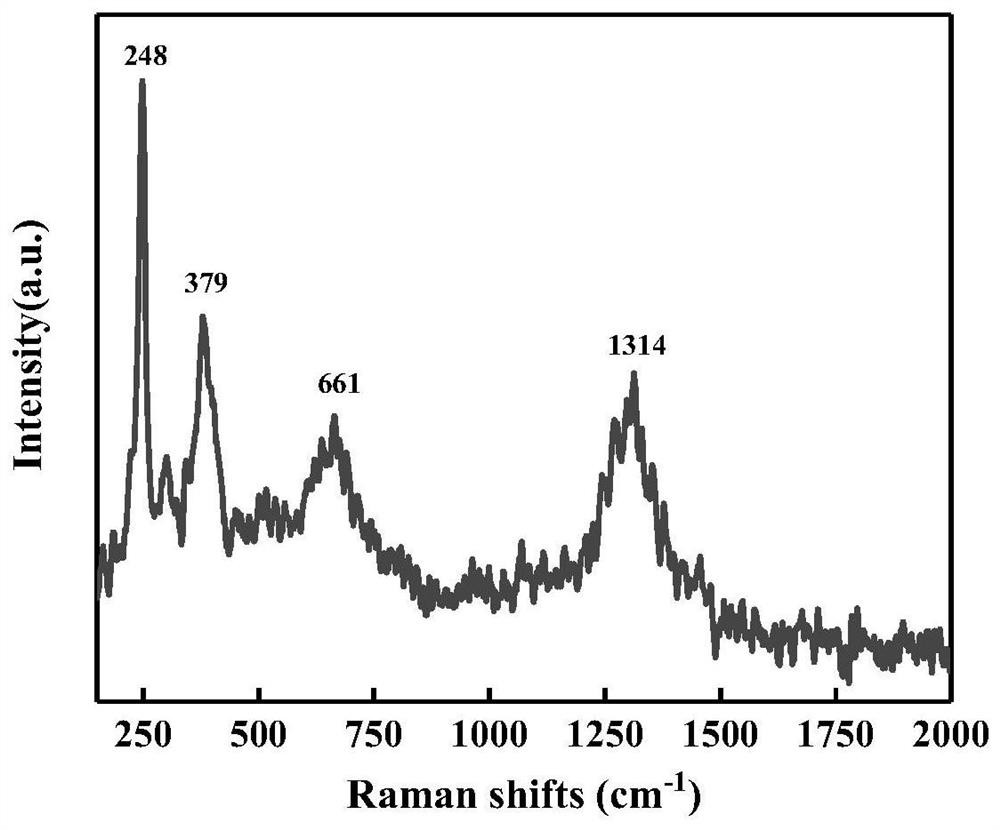

Water-based graphene dispersion liquid and preparation method thereof

The invention discloses a water-based graphene dispersion liquid and a preparation method thereof, and belongs to the technical field of graphene modification. The water-based graphene dispersion liquid is a durable stable dispersion liquid prepared by taking single-layer and / or double-layer and / or multi-layer nano graphene as a raw material to carry out a reaction with a chelating-type titanate under the action of ultrasonic waves and mechanical stirring. The water-based graphene dispersion liquid prepared by the preparation method is good in dispersion liquid stability, and no sedimentationphenomenon occurs when the dispersion liquid is placed for 30 days; the dispersion liquid is low in viscosity and good in liquidity, the dispersion medium is water, and no polymer is added or generated, so that the application field is wide; the preparation process of the dispersion liquid is simple, the reaction is mild, the modification time is short, and industrial application is easier; the dispersion liquid is an environment-friendly product, no harmful impurities are introduced in the preparation process, and a used coupling agent can be wound or bonded with a composite material to forma whole substance in subsequent processing.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

A kind of modification method that iron ions promote the rapid formation of γ-feooh layer on the surface of iron filings

ActiveCN113106433BSimplify the modification processModification conditions are easy to controlWater treatment parameter controlWater treatment compoundsPolyethylene glycolPhysical chemistry

The invention relates to a modification method for promoting the rapid formation of a γ-FeOOH layer on the surface of iron filings by iron ions, comprising the following steps: (1) selecting scrap iron filings of low carbon steel, medium carbon steel and low alloy structural steel, and carrying out pretreatment; (2) placing the iron filings obtained in step (1) in a mixed modification liquid containing an oxidant and a promoter for modification, and the modification liquid includes the following composition by mass percentage: 0.05% to 0.45% of the oxidant , accelerator 0.025~0.5%, polyvinyl butyral resin 0~2g / L, polyethylene glycol 0~1g / L, the balance is water, the pH of the modification solution is 2~4, and the temperature is 15-40℃ (3) After the modification in step (2) is completed, continue to add oxidant to the modification system to keep its mass concentration at 0.05% to 0.45%, and continue to modify for 20 to 60 min; (4) after the modification is completed, from The product is taken out from the above modification solution, air-dried naturally, and then the residual resin on the surface is cleaned. Compared with the prior art, the method of the invention can shorten the growth time of the γ-FeOOH layer, improve the modification efficiency, and the obtained product has stable catalytic performance and surface components.

Owner:TONGJI UNIV +1

Method for modifying hollow glass microspheres by ionic liquid and flame-retardant thermoplastic polyurethane elastomer using it as flame retardant

The invention discloses a method of modifying hollow glass microbeads with an ionic liquid and a flame-retarding thermoplastic polyurethane elastomer with the modified hollow glass microbeads as a flame retardant. The method includes the steps of: 1) treating the hollow glass microbeads with a hydrochloric acid solution; 2) after the acid treatment, repeatedly washing and drying the hollow glass microbeads; 3) activating the hollow glass microbeads, adding a silane coupling agent, and performing mechanical stirring reflux; 4) stopping the reaction and cooling the reaction product to room temperature, and performing suction filtration with acetonitrile, ethanol and deionized water and drying the reaction product; 5) adding the ionic liquid to the silanized hollow glass microbeads and performing mechanical stirring reflux; 6) stopping the reaction and cooling the reaction product to room temperature, performing suction filtration successively with ethanol, a mixed solution of ethanol and deionized water, and ethanol, and drying the reaction product. By means of the hollow glass microbeads modified with the ionic liquid as the flame retardant for preparing flame-retarding thermoplastic polyurethane (TPU) elastomer, not only is oxygen index of the composite material improved, but also the vertical combustion performance, which reflects melt-dripping resistance, is improved, so that heat release rate is reduced and smoke is significantly inhibited.

Owner:JIANGSU STERRIC CHEM IND

Hydrophilic modified PVDF (Polyvinylidene Fluoride) membrane and green in-situ covalent hydrophilic modification method thereof

ActiveCN114288878AImprove hydrophilicityImprove pollutionSemi-permeable membranesPolymer scienceBovine serum albumin

The invention provides a simple preparation method of a hydrophilic PVDF (Polyvinylidene Fluoride) membrane. The preparation method comprises the following steps: adding a polyamino compound into a PVDF membrane casting solution to activate PVDF in a membrane solution preparation process, carrying out phase separation to form a membrane, and soaking the membrane in a subsequent grafted compound aqueous solution to obtain the modified PVDF membrane. The PVDF membrane prepared by the method has excellent hydrophilicity. A BSA (Bovine Serum Albumin) pollution resistance test shows that the modified PVDF membrane has good pollution resistance. The method provided by the invention has the advantages of few steps, cheap and easily available materials, short modification time and industrial application potential.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

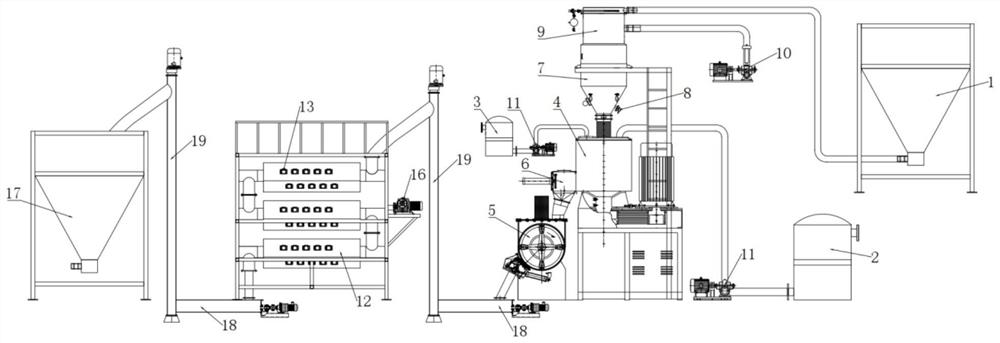

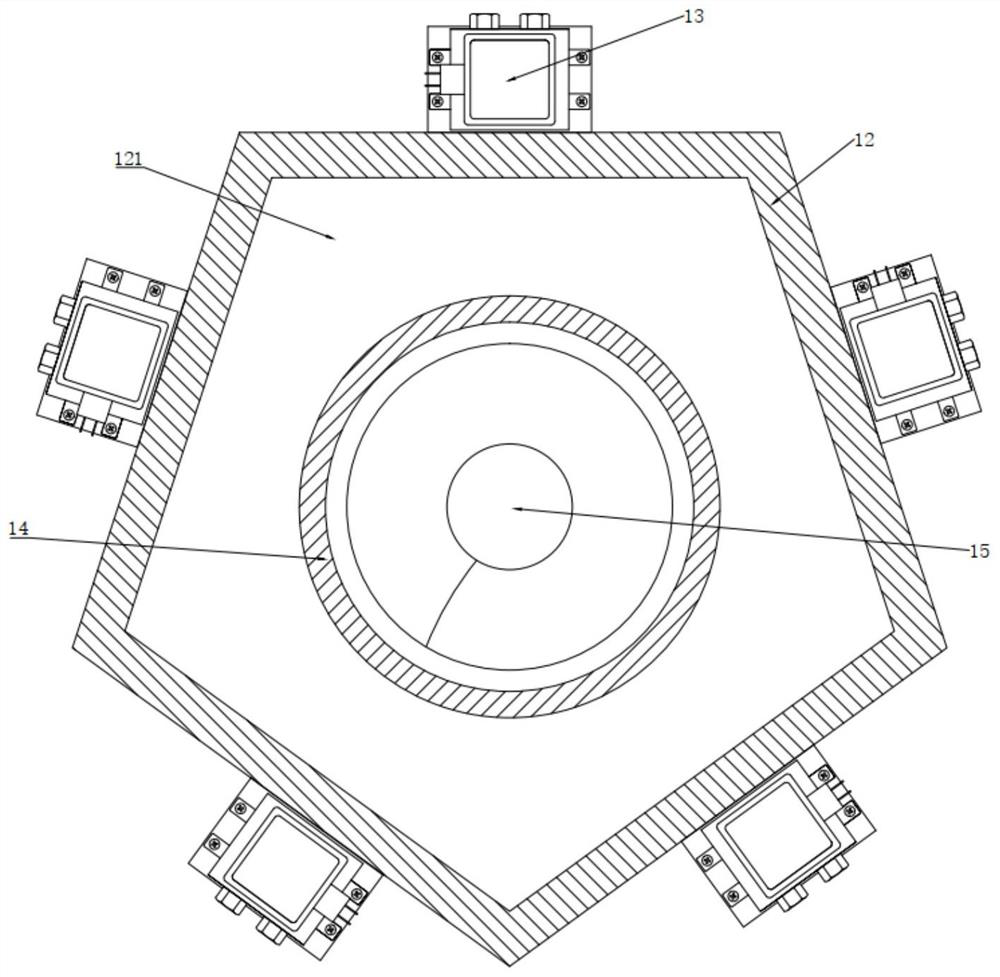

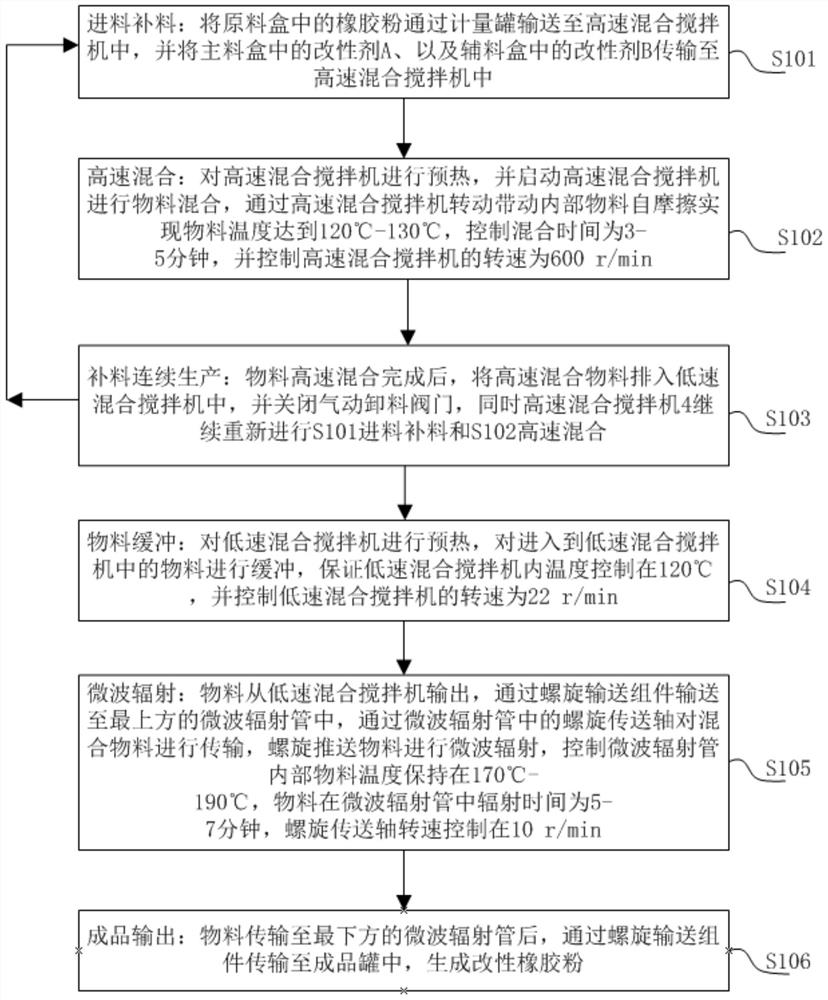

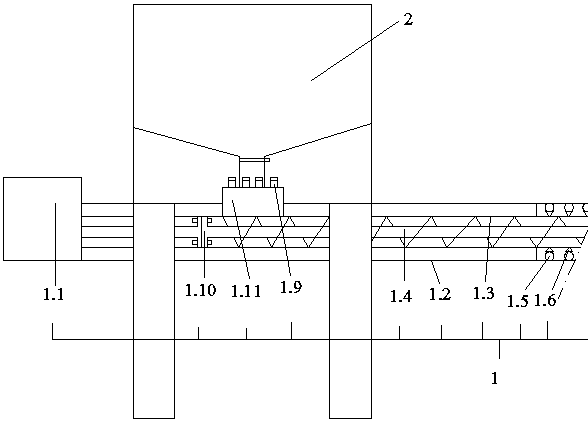

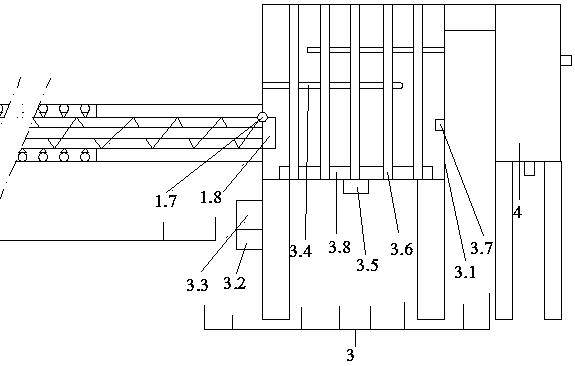

Microwave radiation rubber powder continuous production system and method

PendingCN111645217AHigh affinityImprove high temperature performancePlastic recyclingBuilding insulationsTemperature controlProcess engineering

The invention discloses a microwave radiation rubber powder continuous production system. The continuous production system comprises a raw material module, a mixing module, a microwave radiation heating module, a temperature control module, a metering module and a wind power conveying module, wherein the raw material module comprises a raw material box, a main material box and an auxiliary material box, the raw material box, the main material box and the auxiliary material box are all in conveying connection with the mixing module, the mixing module comprises a high-speed mixing stirrer and alow-speed mixing stirrer, and the microwave radiation heating module comprises a plurality of groups of microwave radiant tubes, a heating resonant cavity and a lining tetrafluoro spiral conveying system. The invention further discloses a microwave radiation rubber powder continuous production method. According to the continuous production system, the modified rubber powder has good compatibilitywith matrix asphalt, so that the modified asphalt containing the modified activated rubber powder has good high-temperature performance, aging resistance and storage stability.

Owner:安徽锐达橡胶科技有限公司

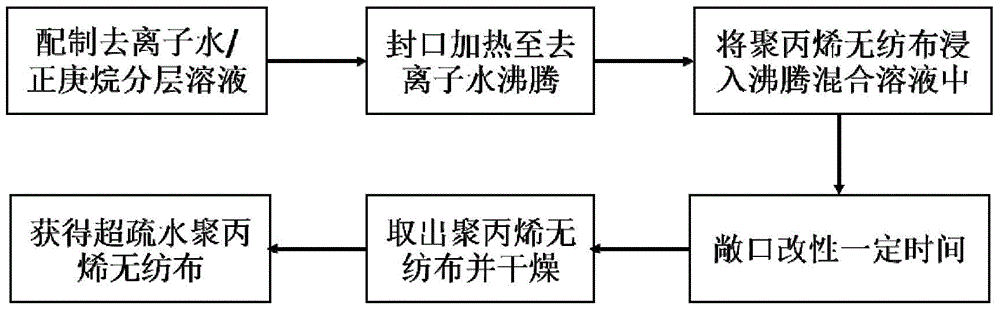

Production method and application of super-hydrophobic surface polypropylene nonwoven fabric

ActiveCN105133305ASimple preparation processEasy to operateDispersed particle filtrationFibre typesOrganic solventFlue gas

The invention discloses a production method and an application of a super-hydrophobic surface polypropylene nonwoven fabric. The method comprises the following steps: arranging a polypropylene nonwoven fabric in a boiling water / n-heptane solution system, immersing, taking out, and drying to obtain the super-hydrophobic surface polypropylene nonwoven fabric. The method has the advantages of simple operation, low cost, environmental protection, and industrial production requirement meeting; and the super-hydrophobic surface polypropylene nonwoven fabric produced in the invention has the advantages of good hydrophobicity and good permeability maintenance, and can be applied to the fields of separation of water and water-insoluble organic solvents, and water mist removal of flue gas.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD +1

A special heavy calcium carbonate modification method and device for wire and cable

ActiveCN105566951BShort modification timeThoroughly modifiedPigment treatment with macromolecular organic compoundsPigment physical treatmentPolyesterDispersity

The invention relates to a modification method for heavy calcium carbonate special for wires and cables. The modification method is characterized by including the following steps that heavy calcium carbonate is added into a grinding device and ground into fine powder with the average particle size being 1500-2000 meshes; water, stearic acid, an aluminate coupling agent and polyester type hyperdispersant are added into the powder through four feeding pipes respectively and are stirred to form a mixture, wherein the water, stearic acid, the aluminate coupling agent and the polyester type hyperdispersant account for 0.4-0.5%, 0.9-1.1%, 1-1.2% and 0.5-0.8% of the total weight of the mixture respectively. The modification method has the advantages that the time for modifying heavy calcium carbonate is shorter due to the function from inside to outside, modification is more sufficient, modified heavy calcium carbonate has heat resistance and dispersity, and can be compatible with a resin organic carrier and a high polymer material, so that toughness, brightness, plastic thermal hysteresis performance and bending strength of wires and cables are improved, and light resistance and ageing resistance are enhanced.

Owner:HUNAN LEIXIN NEW MATERIAL TECH

A kind of anti-caking agent for agricultural compound fertilizer and preparation method thereof

ActiveCN103804089BImprove bindingLow modification costFertilizer mixturesFoaming agentAnticaking agent

The invention discloses an anti-caking agent for agricultural compound fertilizers. The anti-caking agent comprises the following raw materials in parts by weight: 80-96 parts of biomass ash, 2-10 parts of a modifier, and 2-10 parts of a crystal phase control agent, wherein the modifier is at least one of hydrogenated tallow amine, sodium aliphatate, phosphate and paraffin, and the crystal phase control agent is at least one of sodium dodecylbenzene sulfonate and lauryl sodium sulfate. In the process of preparation, the biomass ash and the modifier are added into a screw extruder in required proportion to carry out modification so as to form a modified material, and then, the modified material and the crystal phase control agent are simultaneously poured into a cooling cylinder; in the process of cooling the modified material, the modified material and the crystal phase control agent are uniformly mixed. According to the invention, the anti-caking effect of the anti-caking agent is improved, and the production cost is reduced.

Owner:湖北海力环保科技股份有限公司

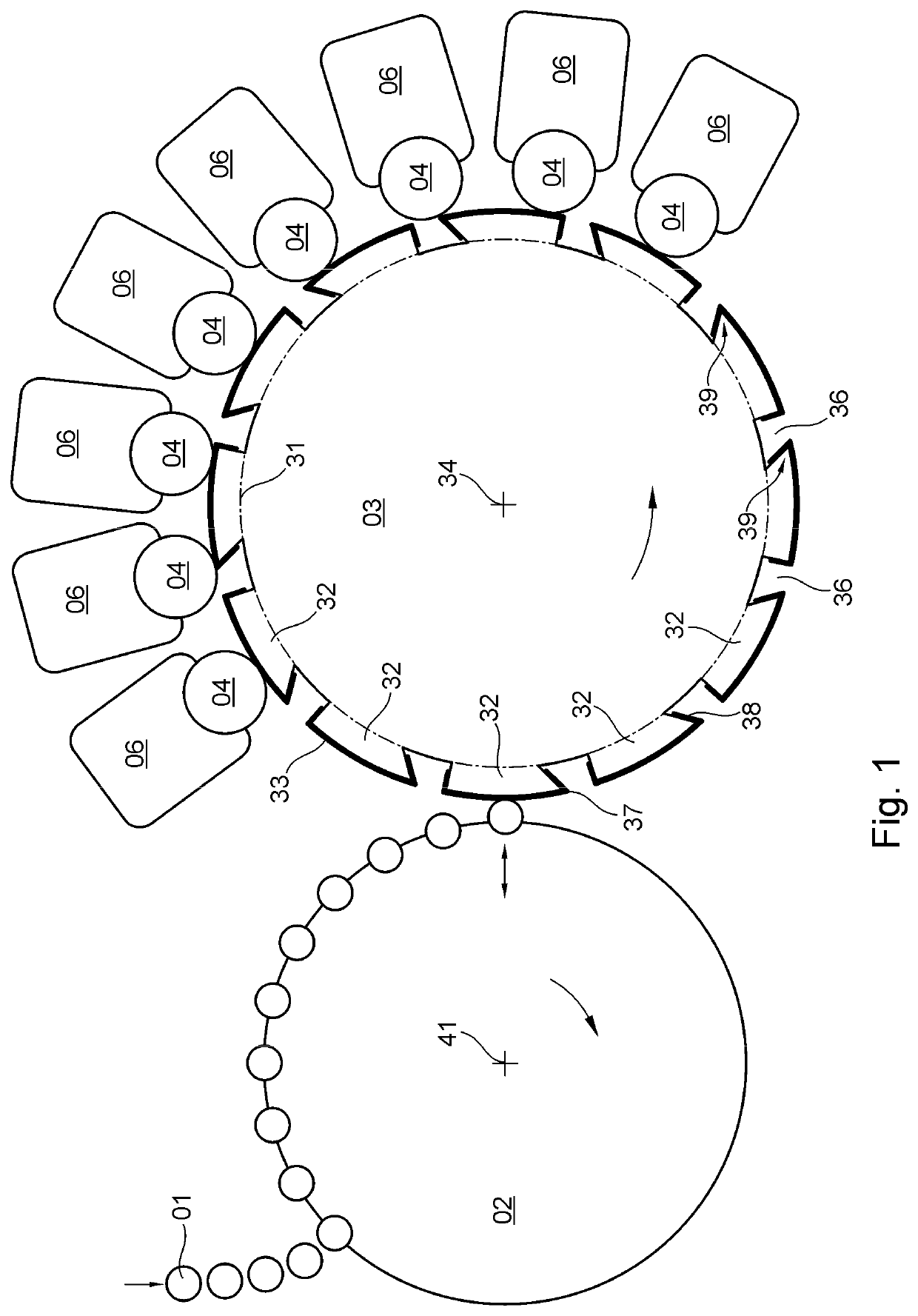

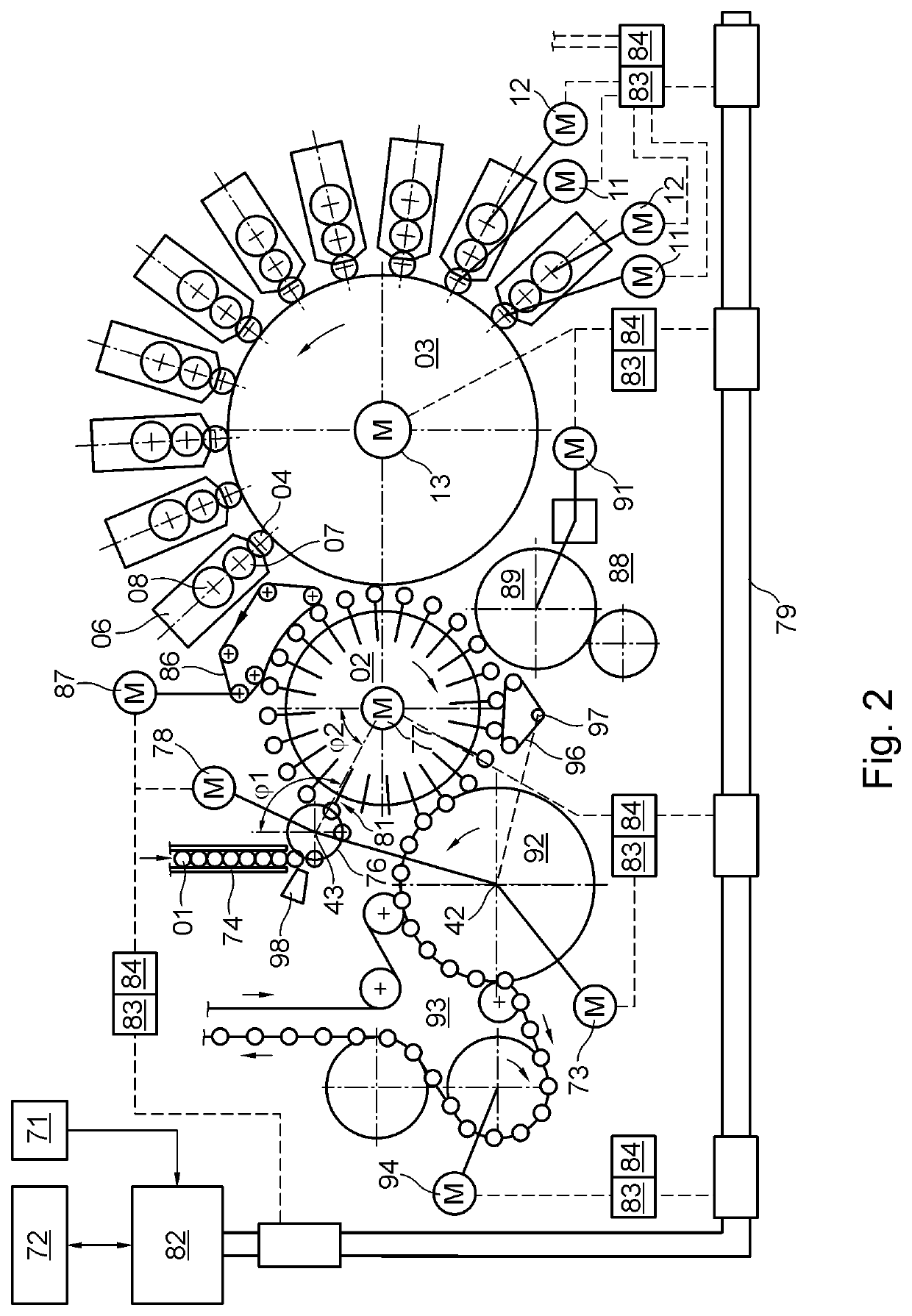

Method and device for printing the respective lateral surface of hollow objects

ActiveUS20220212463A1Short modification timeQuick conversionRotary pressesPrinting press partsEngineeringMechanical engineering

A method is provided for operating a device that is usable for printing the respective lateral surface of hollow objects. The device comprises at least one mandrel wheel for holding the hollow objects on projecting expanding mandrels, and a transfer wheel for transporting the hollow objects, which transfer wheel is arranged downstream of the mandrel wheel in a transport direction of the hollow objects. The mandrel wheel and the transfer wheel are each rotatably arranged in a laterally offset manner, with respect to one another, in two different planes that are parallel to one another. Hollow objects, which are printed during ongoing printing production, are transferred from the work arbors of the mandrel wheel to the transfer wheel. During a modification of the device, from a first production of hollow objects having a first height, to a second production of hollow objects having a second height, a lateral offset between the mandrel wheel and the transfer wheel is adapted to the height of the hollow objects to be printed in the second production by automatically changing the axial position of the transfer wheel relative to the position of the mandrel wheel.

Owner:KOENIG & BAUER AG

Modified bitumen waterproof membrane compound, modified bitumen waterproof membrane compound, preparation method and application thereof

ActiveCN113801629BEasy to processSolve unqualifiedNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolymer science

Owner:德州科顺建筑材料有限公司

Modifying method of quick lime for sintering

PendingCN109095490AShort modification timeLow costCalcium/strontium/barium oxides/hydroxidesAqueous solutionMechanical property

The invention relates to a modifying method of quick lime for sintering. The modifying method comprises the following steps of (1) crushing quick lime which is not treated; (2) adding water to the quick lime which is crushed in the step (1), performing sufficient stirring, and then performing standing for 30-40min; (3) adding sodium hydroxide solid to a solution prepared in the step (2), and performing uniform stirring; (4) heating the solution prepared in the step (3) to 60-70 DEG C, and continuing performing stirring; (5) mixing sodium sulfide with water in the mass ratio of the sodium sulfide to the water being 1 to 100 so as to obtain a sodium sulfide aqueous solution; (6) uniformly adding the sodium sulfide aqueous solution which is prepared in the step (5) to the solution prepared inthe step (4); (7) charging carbon dioxide to the solution prepared in the step (6), after the solution become turbid, continuing charging the carbon dioxide until a clarifying layer appears at the upper layer of the solution; and (8) filtering the solution prepared in the step (7). According to steel products prepared from the modified quick lime, the mechanical property is obviously improved, the life is prolonged, and the steel products are excellent in quality and high in stability.

Owner:SHANDONG TAISHAN STEEL GROUP

Method for rapidly depositing dopamine or derivative thereof on surfaces of natural fibers in non-aqueous medium environment

ActiveCN107287891AImprove adsorption rate and utilizationGood stabilityVegetal fibresAnimal fibresSurface modificationPre treatment

The invention relates to the field of surface modification of natural fibers and discloses a method for rapidly depositing dopamine or a derivative thereof on the surfaces of natural fibers in a non-aqueous medium environment. The method comprises the following steps: (1) soaking and preprocessing a natural fiber fabric in an alkali solution for later use; (2) adding dopamine or the derivative of dopamine into a non-aqueous medium, and adequately stirring so as to uniformly scatter dopamine or the derivative of dopamine in the medium; and (3) soaking the natural fiber fabric processed in the step (1) into the non-aqueous medium of the step (2), stirring, taking out the fabric, and flushing and drying the fabric. By utilizing the non-aqueous medium environment, a brand-new method for the modifying surfaces of the natural fibers by virtue of dopamine or the derivative of dopamine is provided. By utilizing the method, the uniform deposition of dopamine or the derivative of dopamine on the natural fibers can be realized in a short time, and the utilization rate of dopamine or the derivative of dopamine is high.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com